Nickel-saving stainless steel differential temperature drawing and forming device and method

A technology of temperature difference deep drawing and stainless steel, applied in the direction of forming tools, metal processing equipment, manufacturing tools, etc., can solve problems such as parts deformation, achieve high surface quality, easy maintenance, and save the effect of annealing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0033] Figure 4 It is a cylindrical part made by the existing deep drawing process. For details, refer to the background technology.

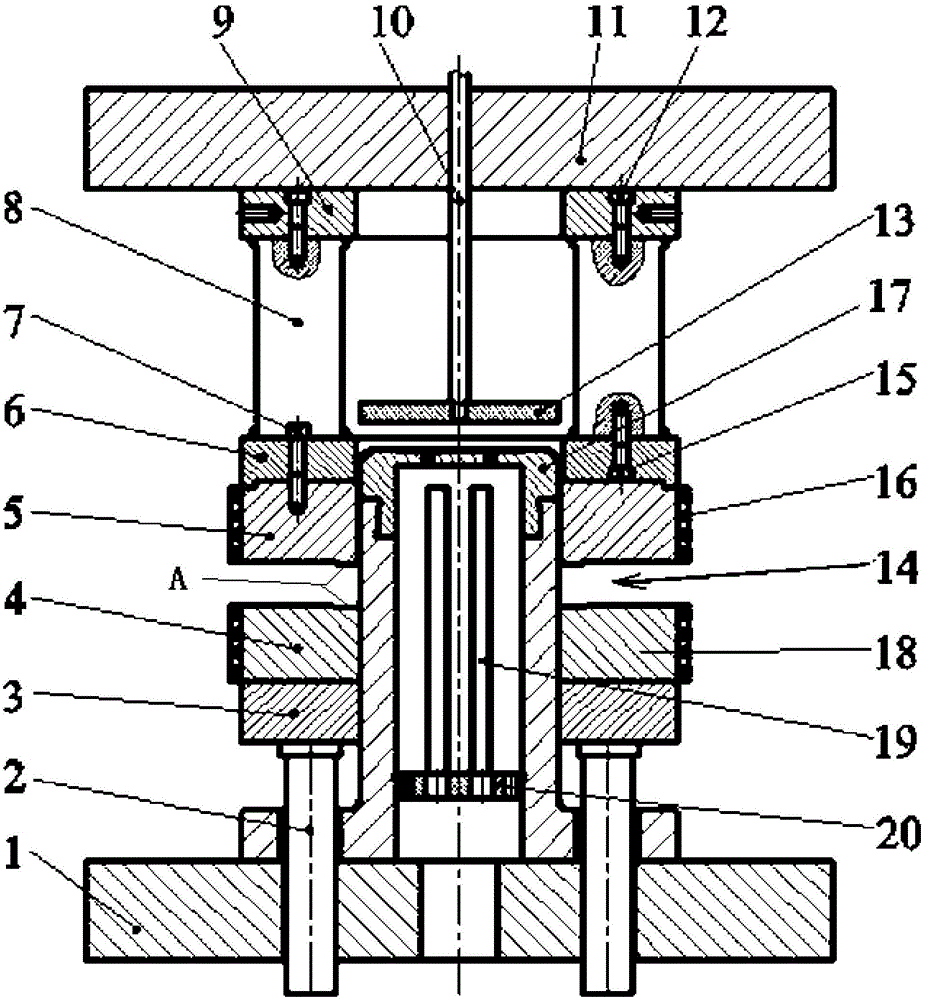

[0034] The present invention as Figures 1 to 3 As shown, a nickel-saving stainless steel temperature difference deep drawing forming device is disclosed, comprising a punch 14, a die 5, and a blank holder 4; the die 5 is driven by an upper die holder 11 to move up and down along the axial direction of the punch 14, The blank holder 4 is driven by the blank holder mandrel 4 to move up and down along the axial direction of the punch 14,

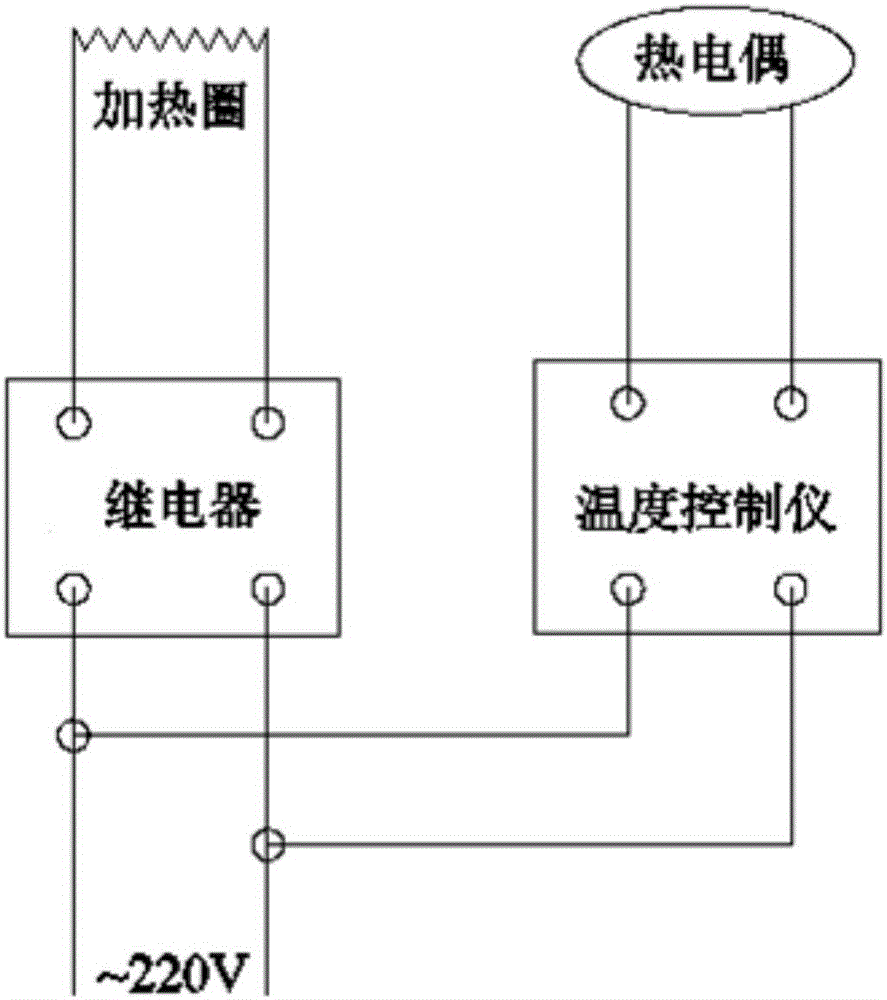

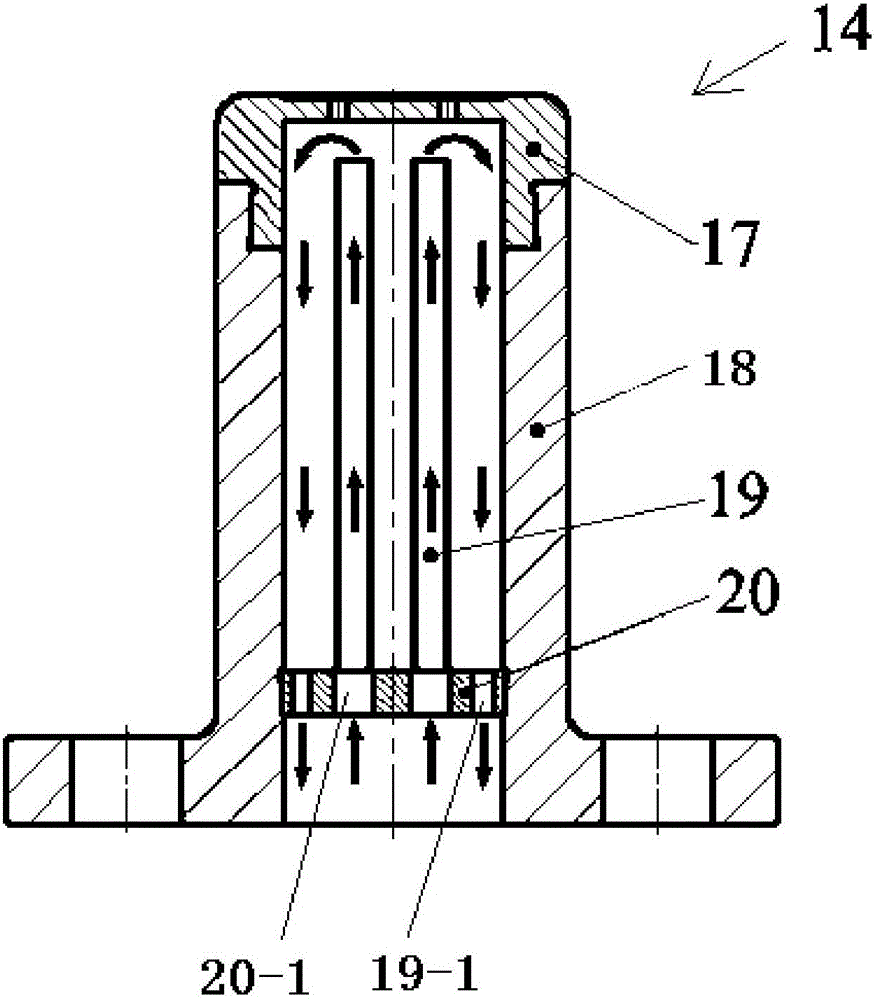

[0035] This section of nickel-type stainless steel temperature difference deep drawing forming device also includes a heating device for heating the die 5 and the blank holder 4; the inside of the punch 14 is a cavity, in which there is a Cooling air-cooled unit.

[0036] In order to make the sheet material flow more smoothly and prevent wrinkling during the drawing process, a drawing threshold is added at ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com