RH vacuum refining bottom blowing powder injection device

A vacuum refining and powder spraying technology, applied in the field of iron and steel refining, can solve the problems of affecting operation stability, affecting the quality of molten steel, and low metallurgical efficiency of powder spraying, so as to improve operation safety, improve production quality, and facilitate continuous production Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

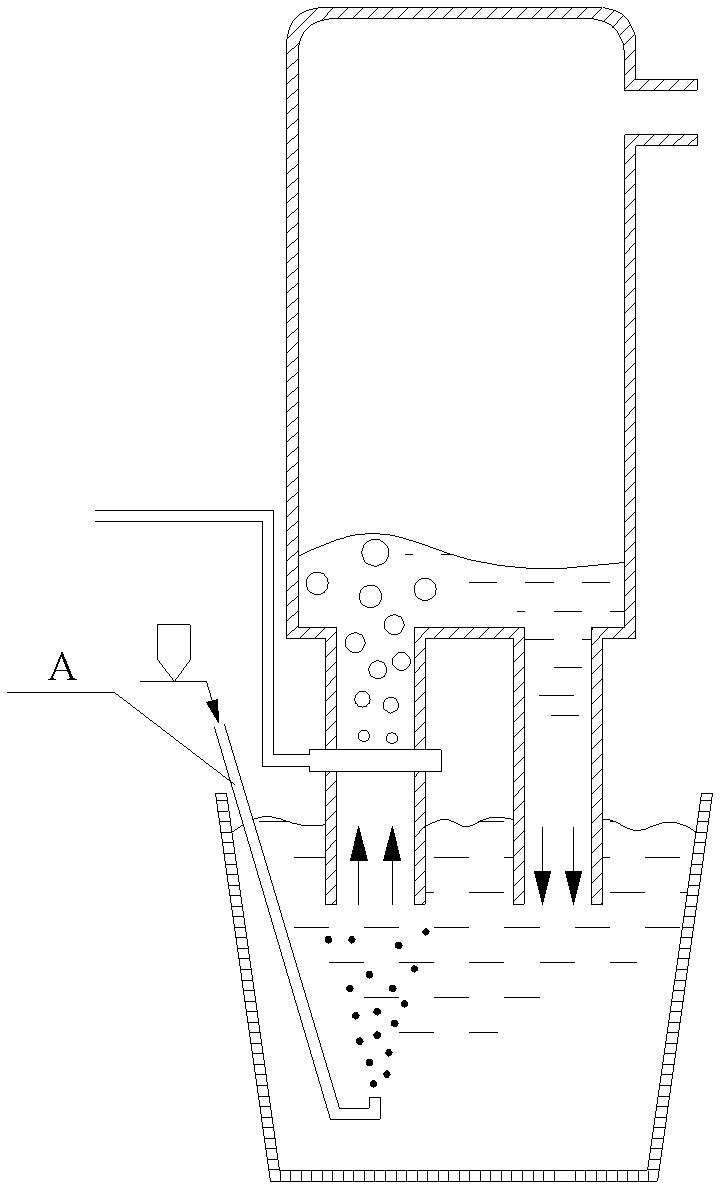

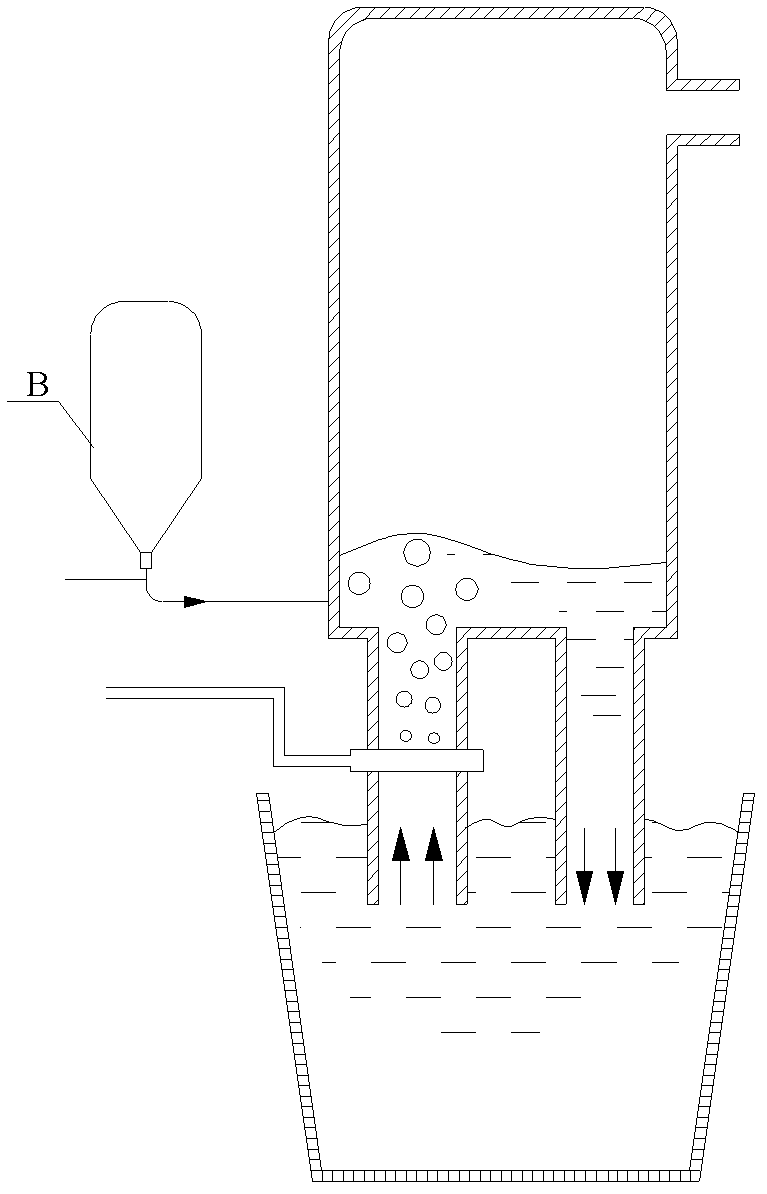

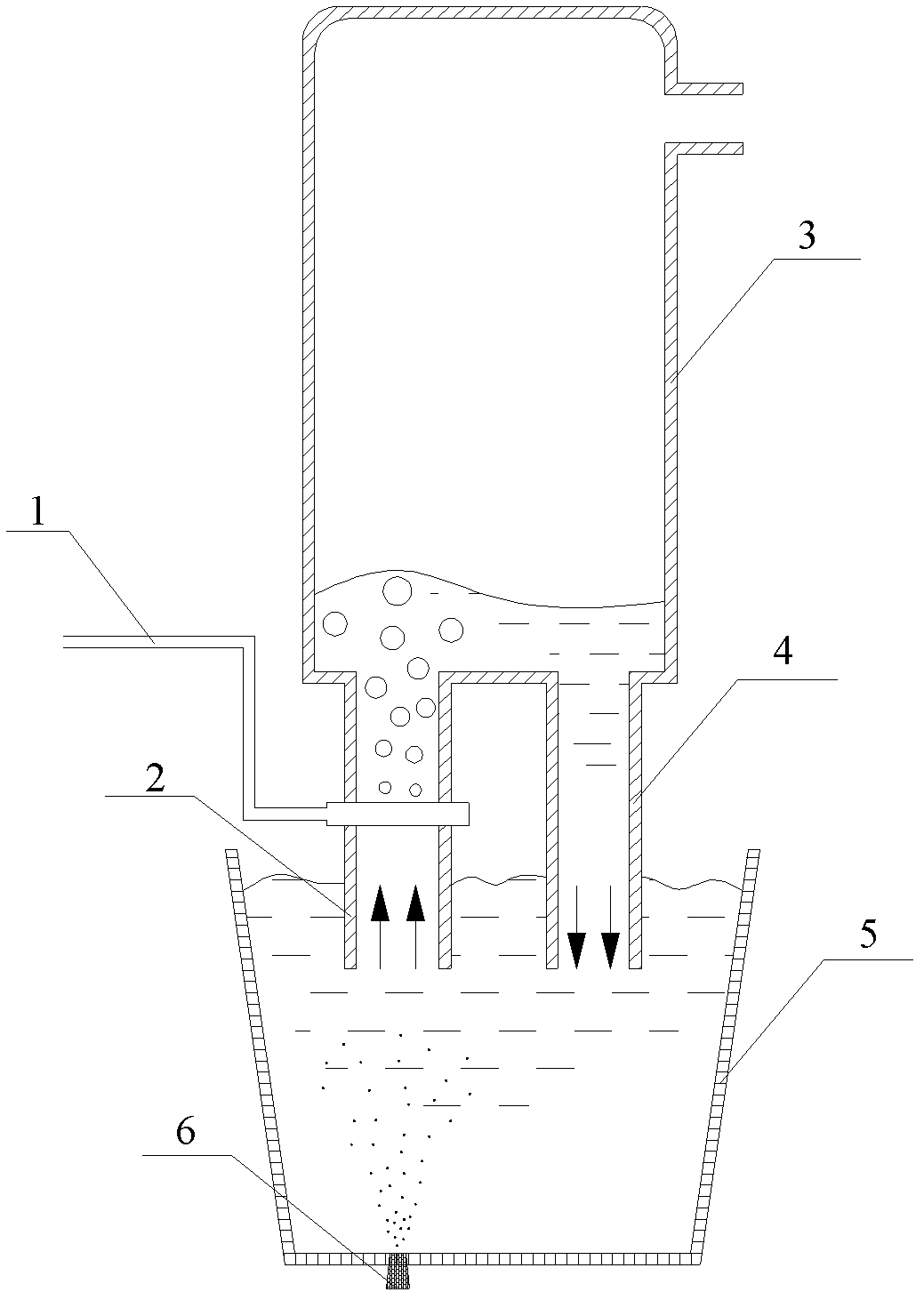

[0026] This embodiment designs a kind of RH vacuum refining bottom blowing powder spraying device, as image 3 As shown, it includes a driving gas system, a vacuum chamber 3, a ladle 5 and a bottom blowing powder member 6, the vacuum chamber 3 is arranged above the ladle 5, and the driving gas system includes a driving gas channel 1 and an air compressor connected to the driving gas channel 1 , the bottom of the vacuum chamber 3 is provided with an ascending pipe 2 and a descending pipe 4, the ascending pipe 2 and the descending pipe 4 extend into the molten steel in the ladle 5 and have an opening at the end, the driving gas channel 1 communicates with the ascending pipe 2, and the bottom blowing powder The component 6 includes a powder spraying element 7 and a gas storage chamber 11. The powder spraying element 7 is made of refractory material. The powder spraying element 7 is covered with a steel sleeve 9, and both sides of the steel sleeve 9 are provided with protruding con...

Embodiment 2

[0029]It is basically the same as Example 1, except that the number of bottom blowing powder spraying components 6 is 2, which are symmetrically arranged at the bottom of the ladle 5, that is, the double-hole bottom blowing powder spraying refining structure, that is, as Figure 7 As shown; the number of straight line slits 8a is 16.

[0030] The device is used for circulating degassing bottom blowing powder refining, the powder particle size is 200~400 mesh, the dry argon pressure is 0.6Mpa, the powder gas ratio is 8, and the smelting time is 20min, the stirring intensity of the ladle 5 is enhanced, and the temperature composition in the molten pool uniform, and the refining cycle is shortened, the penetration ratio of the powder measured after treatment is greater than 90%, and it can be achieved after treatment w [H]w [N]w [C]w [S]w [P]<0.002%, saving 1~10% of electric energy.

Embodiment 3

[0032] It is basically the same as Embodiment 1, except that the powder spraying element 7 of the bottom blowing powder spraying member 6 is provided with an annular gap 8b concentric with the center of the powder spraying component 7, and the number of annular gaps 8b is 2, such as Figure 8 , Figure 9 Shown; the gap width is 0.14mm.

[0033] The device is used for circulating degassing bottom blowing powder refining. The particle size of the powder is 200~400 mesh, the dry argon pressure is 0.6Mpa, the powder gas ratio is 6, and the smelting is 35min. After the treatment, the penetration ratio of the powder is 93%. After treatment, w[H]<0.00015%, w[N]<0.004%, w[C]<0.003%, w[S]<0.001%, w[P]<0.002%, saving 1~10% of electric energy .

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com