1100-H16 aluminum alloy plate/strip and production method thereof

A technology for aluminum alloy strips and production methods, which is applied in the field of aluminum alloy manufacturing, can solve problems such as high requirements for annealing temperature uniformity, high requirements for annealing furnace temperature control, and unsatisfactory surface quality, and achieve the elimination of ingot structure irregularities. Uniformity, reduced yield strength instability, stable and qualified mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

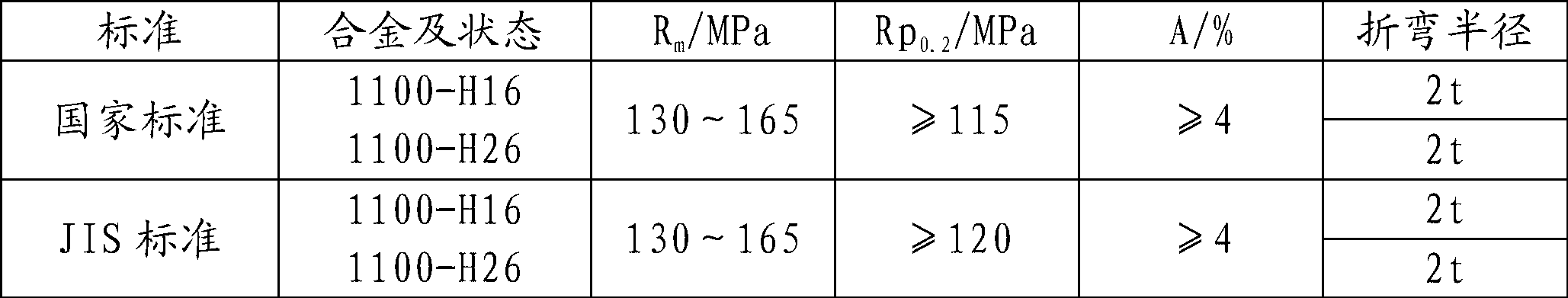

[0029] The production method of the 1100-H16 aluminum alloy plate and strip described in this embodiment includes: melting and casting→sawing→face milling→heating→hot rolling→cold rolling. The specific process parameters are as follows:

[0030] (1) Melting and casting: The mass percentage of the chemical composition of the ingot after melting and casting is: Si: 0.10%, Fe: 0.60%, Cu: 0.15%, Mn≤0.05%, Mg≤0.05%, Zn≤0.05%, Ti: 0.010% , Other impurities individually ≤0.02%, total ≤0.10%, the rest is Al; melting temperature is 750-760°C, refining temperature is 745°C, casting temperature is 705°C, casting speed is 55mm / min;

[0031] (2) Face milling: use a milling machine to mill the large and small faces of the ingot separately, and the milling amounts are 10mm and 8mm respectively;

[0032] (3) Heating: the heating temperature of the ingot is 570°C, the holding time is 2 hours, and the heating time is 500°C for 3 hours;

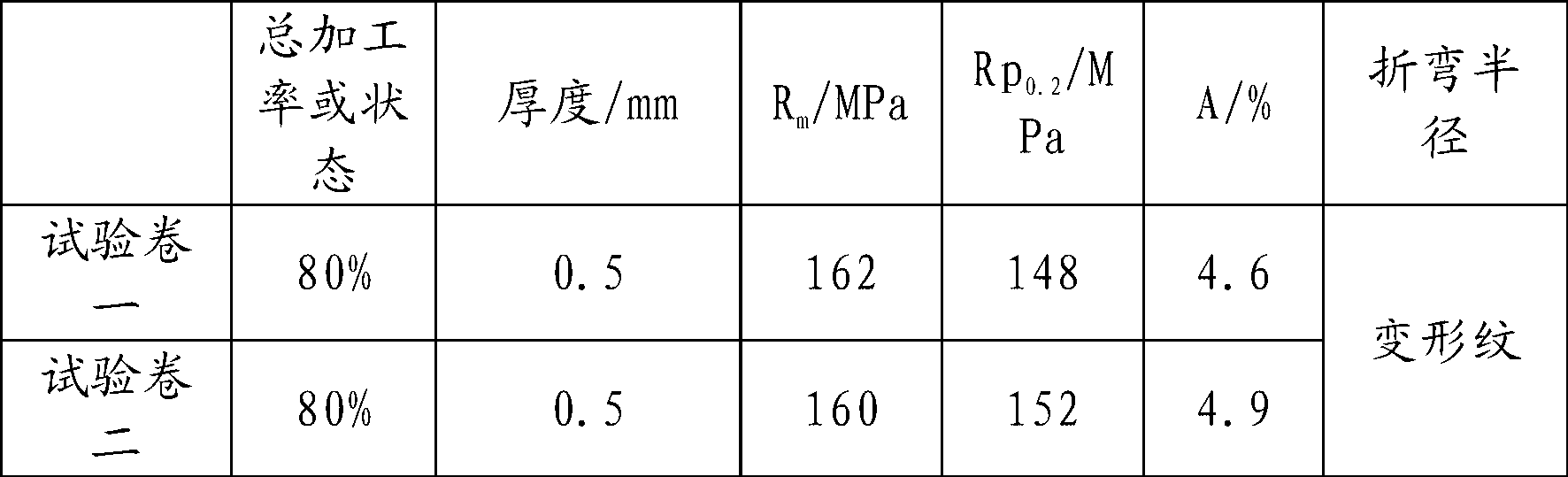

[0033] (4) Hot rolling: after hot rough rolling at 500°...

Embodiment 2

[0040] The production method of the 1100-H16 aluminum alloy plate and strip described in this embodiment includes: melting and casting→sawing→face milling→heating→hot rolling→cold rolling. The specific process parameters are as follows:

[0041] (1) Melting and casting: The mass percentage of the chemical composition of the ingot after melting and casting is: Si: 0.03%, Fe: 0.40%, Cu: 0.08%, Mn≤0.05%, Mg≤0.05%, Zn≤0.05%, Ti: 0.02% , Other impurities individually ≤0.02%, total ≤0.10%, the rest is Al; melting temperature is 745-760°C, refining temperature is 755°C, casting temperature is 685°C, casting speed is 65mm / min;

[0042] (2) Face milling: use a milling machine to mill the large and small faces of the ingot separately, and the milling amounts are 10mm and 6mm respectively;

[0043] (3) Heating: the ingot heating temperature is 550°C, the holding time is 3 hours, and the furnace is turned to 450°C for 3 hours;

[0044] (4) Hot rolling: after hot rough rolling at 450°C, ...

Embodiment 3

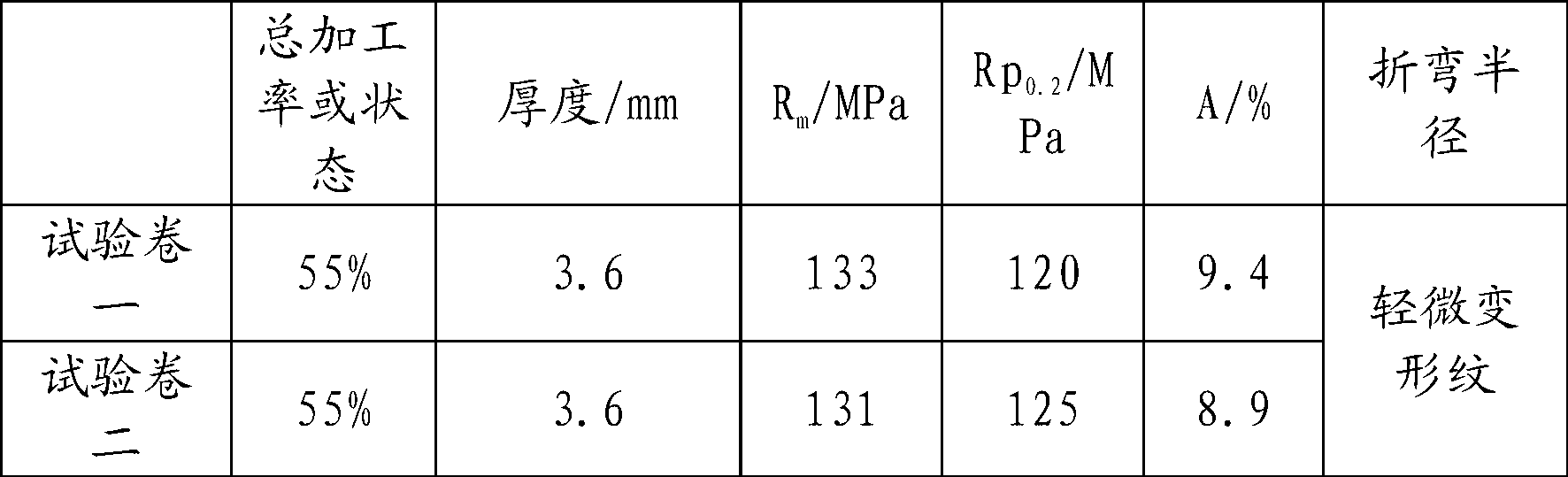

[0051] The production method of the 1100-H16 aluminum alloy plate and strip described in this embodiment includes: melting and casting→sawing→face milling→heating→hot rolling→cold rolling. The specific process parameters are as follows:

[0052] (1) Melting and casting: the alloy chemical composition (mass fraction) of the ingot is controlled at Si: 0.09%, Fe: 0.49%, Cu: 0.14%, Mn≤0.05%, Mg≤0.05%, Zn≤0.05%, Ti: 0.03 %, other impurities individually ≤0.02%, total ≤0.10%, the rest is Al; melting temperature is 745-760°C, refining temperature is 750°C, casting temperature is 690°C, casting speed is 60mm / min;

[0053] (2) Face milling: use a milling machine to mill the large and small faces of the ingot separately, and the milling amounts are 8mm and 8mm respectively;

[0054] (3) Heating: the heating temperature of the ingot is 560°C, the holding time is 3 hours, and the heating time is 480°C for 2 hours;

[0055] (4) Hot rolling: after hot rough rolling at 481°C, after 17 pass...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com