Cycloidal gear tooth curve variable step size discretization method

A cycloid gear and variable step technology, which is applied to components with teeth, belts/chains/gears, portable lifting devices, etc., and can solve the problems of slow calculation speed, complex algorithm, large fitting error, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0071] The invention discloses a variable step size discrete method for a cycloidal gear tooth profile, which comprises the following steps:

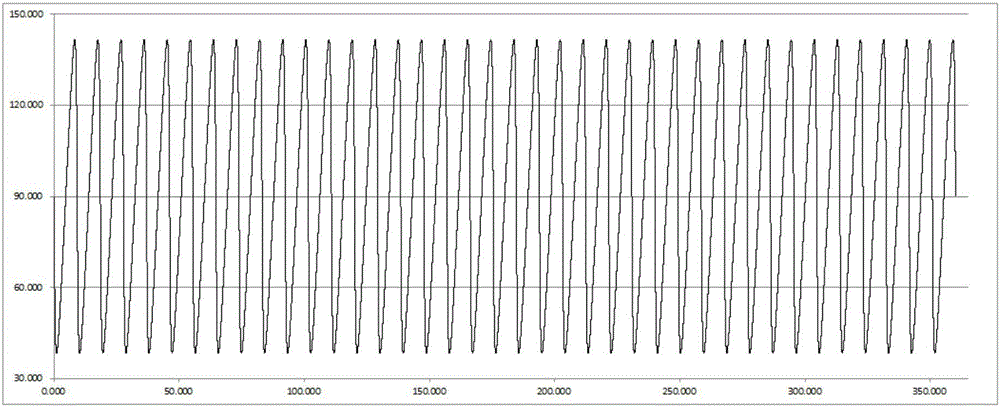

[0072] S1. Set the parameters of the cycloidal gear tooth profile curve: the radius of the needle tooth distribution circle R z =76.5mm, pin tooth radius r z =3mm, eccentric distance A=1.5mm, cycloid gear teeth number Z a =39, number of pins Z b =40, short amplitude coefficient K 1 = AZ b / R z =0.784;

[0073] S2. Deduce the cycloidal gear tooth profile curve equation

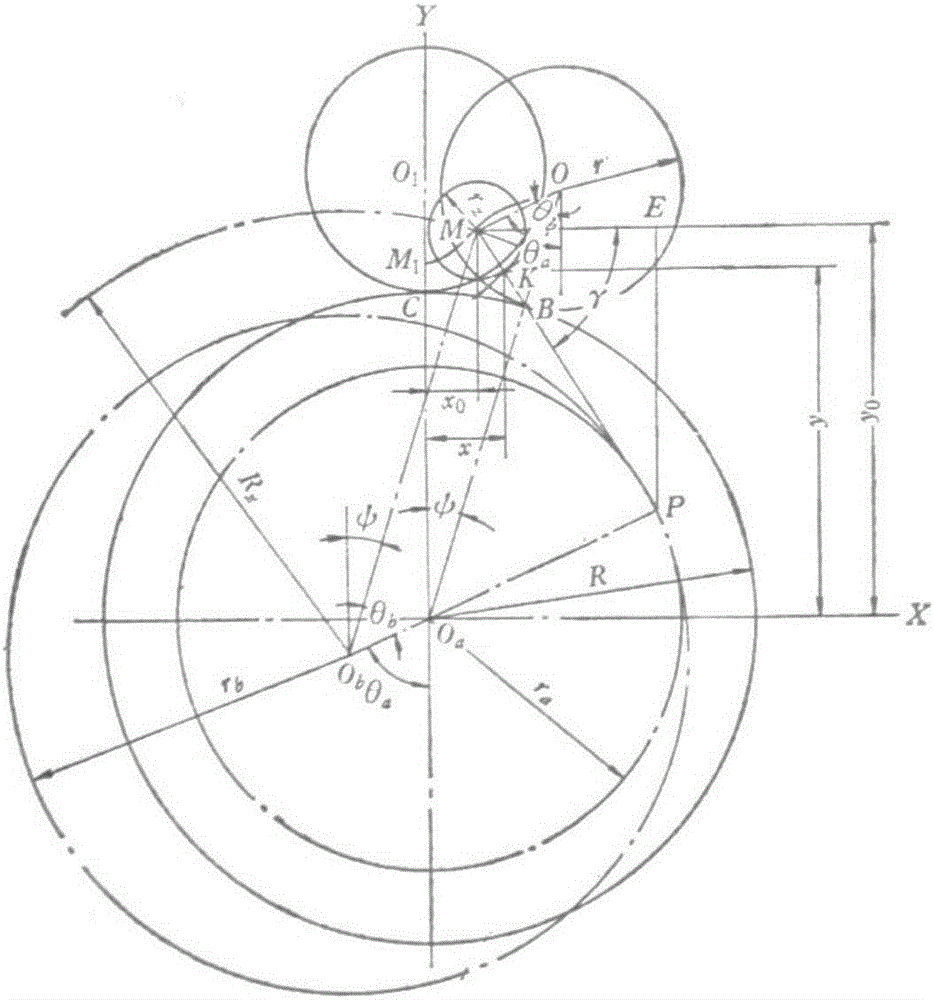

[0074] Such as figure 1 As shown, assuming that the base circle is fixed, take the center O of the base circle a is the origin of the X-Y rectangular coordinates, when the rolling circle r rolls from point C to point B on the base circle R, its center O revolves around the center O of the base circle a The angle of rotation is ψ, and the absolute rotation angle of rounding r is θ a , the relative rotation angle of the rolling circle r is θ b , then the coordin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com