Thin-specification cold-rolled low-alloy high-strength steel and production method thereof based on double-roller cast rolling

A thin-gauge, low-alloy technology, applied in the field of metallurgical industry, can solve the problems of long process flow, difficulty in producing thick hot-rolled plates, and high requirements for rolling mills, so as to reduce the number of cold-rolling passes, reduce costs and process time, and reduce Effect of rolling reduction and passes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

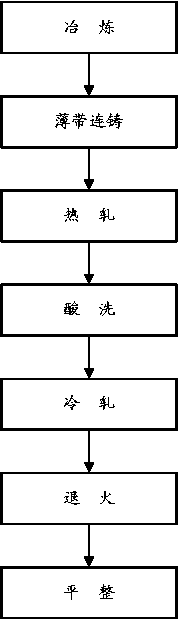

[0035] figure 1 It is a schematic flowchart of a method for producing thin-gauge cold-rolled low-alloy high-strength steel according to the present invention.

[0036] see figure 1 , the method according to the present invention includes the following steps.

[0037] (1) Molten steel smelting: electric furnace steelmaking, VD vacuum furnace degassing, and LF furnace refining, to obtain qualified molten steel, by weight percentage: C: 0.02%; Si: 0.26%; Mn: 1.44%; Nb: 0.054 %; Cr: 0.020; P: 0.01%; S: 0.002%; the balance is iron and unavoidable impurity elements.

[0038] (2) Thin strip continuous casting: The qualified molten steel is continuously cast by twin-roll casting and rolling process. Cast, the thickness of the cast strip is 1.78mm.

[0039] (3) Hot rolling: The cast strip is hot-rolled into a hot-rolled thin strip with a thickness of 1.20mm in one pass at a reduction of 33%. The hot-rolled exit temperature is 867°C. °C.

[0040] (4) Pickling: The hot-rolled thi...

Embodiment 2

[0047] figure 1 It is a schematic flowchart of a method for producing thin-gauge cold-rolled low-alloy high-strength steel according to the present invention.

[0048] see figure 1 , the method according to the present invention includes the following steps.

[0049](1) Molten steel smelting: electric furnace steelmaking, VD vacuum furnace degassing, and LF furnace refining, to obtain qualified molten steel, by weight percentage: C: 0.024%; Si: 0.42%; Mn: 1.32%; Nb: 0.050 %; Cr: 0.018; P: 0.01%; S: 0.003%; the balance is iron and unavoidable impurity elements.

[0050] (2) Thin strip continuous casting: The qualified molten steel is continuously cast by twin-roller casting and rolling process. Cast, the thickness of the cast strip is 1.74mm.

[0051] (3) Hot rolling: The cast strip is hot-rolled into a hot-rolled thin strip with a thickness of 1.0mm by one pass at a reduction of 43%. The exit temperature of the hot rolling is 860°C. °C.

[0052] (4) Pickling: The hot-r...

Embodiment 3

[0058] figure 1 It is a schematic flowchart of a method for producing thin-gauge cold-rolled low-alloy high-strength steel according to the present invention.

[0059] see figure 1 , the method according to the present invention includes the following steps.

[0060] (1) Molten steel smelting: electric furnace steelmaking, VD vacuum furnace degassing, and LF furnace refining, to obtain qualified molten steel, by weight percentage: C: 0.030%; Si: 0.36%; Mn: 1.21%; Nb: 0.046 %; Cr: 0.020; P: 0.01%; S: 0.002%; the balance is iron and unavoidable impurity elements.

[0061] (2) Thin strip continuous casting: The qualified molten steel is continuously cast by twin-roll casting and rolling process. Cast, the thickness of the cast strip is 1.71mm.

[0062] (3) Hot rolling: The cast strip is hot-rolled into a hot-rolled thin strip with a thickness of 0.9mm in one pass at a reduction of 47%. The hot-rolled exit temperature is 855°C. °C.

[0063] (4) Pickling: The hot-rolled thi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com