Multi-path thick coating and one-step molded rubber-state waterproof coating and preparation method thereof

A waterproof coating and rubber-like technology, applied in asphalt coatings, chemical instruments and methods, coatings, etc., can solve problems such as high requirements for formula selection, damage to system stability, and easy demulsification of the system to achieve good physical and mechanical properties. Stability, improved solvency, no irritating odor effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

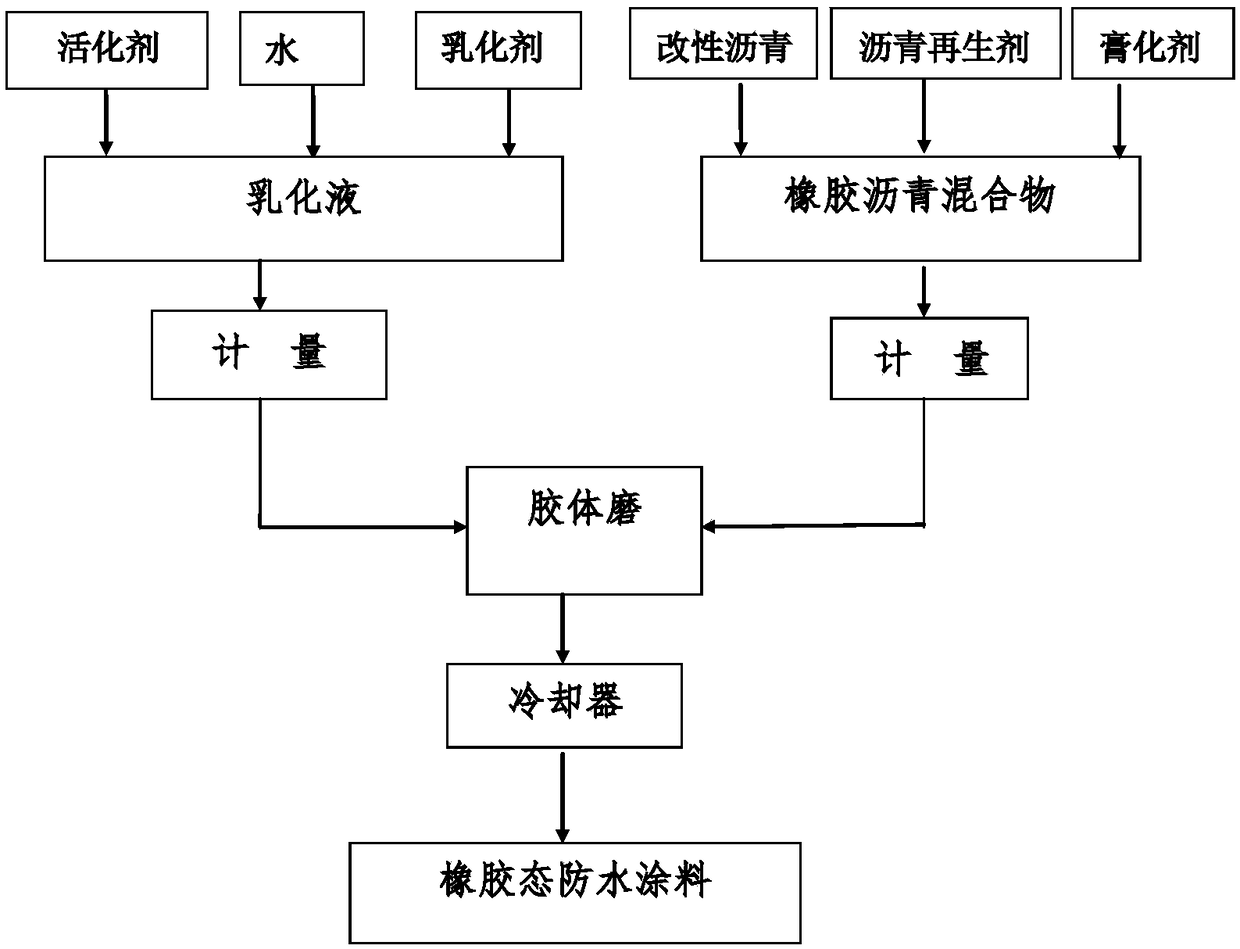

Method used

Image

Examples

Embodiment 1

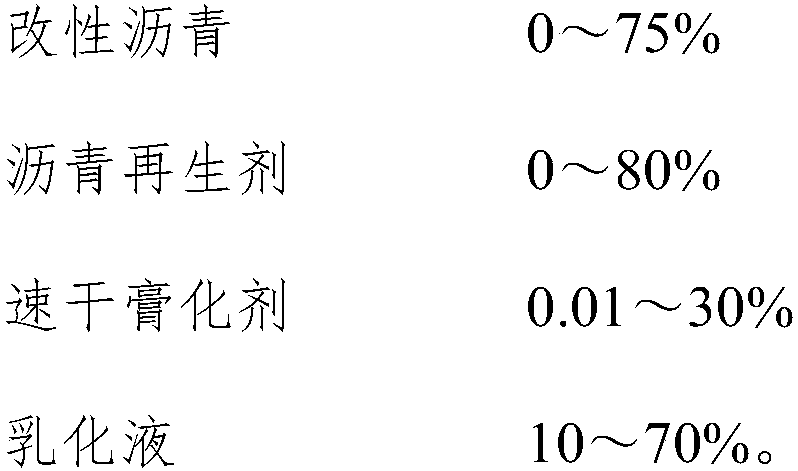

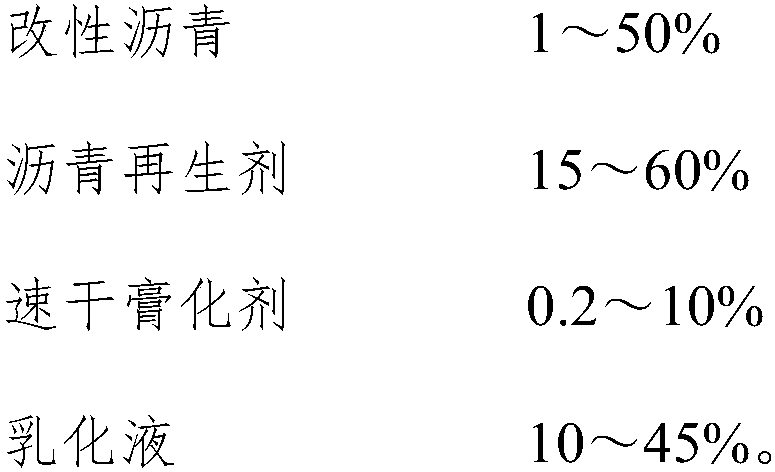

[0053]

[0054] Among them, the modified asphalt is composed of 90 # It is modified by petroleum asphalt and SBS modifier;

[0055] Wherein the quick-drying paste agent is lithium magnesium silicate;

[0056] Wherein the emulsion is an aqueous solution of emulsifier sodium butylnaphthalene sulfonate;

[0057] Among them, the asphalt rejuvenator is made of high-quality naphthenic heavy oil from Venezuela in South America, and is distilled under normal and reduced pressure.

[0058] The preparation method is as follows:

[0059] (1) Preparation of rubber asphalt mixture: Weigh the petroleum asphalt and modifier in mass percentage, put them into the reaction kettle, heat up to 160°C and stir evenly, add asphalt rejuvenator and quick-drying paste agent under stirring condition and mix for 10min , slowly raise the temperature to 200°C, and stir at constant temperature for 3 hours to obtain the rubber-asphalt mixture;

[0060] (2) Prepare the emulsion: add water to the soap t...

Embodiment 2

[0064]

[0065] Among them, the modified asphalt is composed of 90 # It is modified by petroleum asphalt and SBS modifier;

[0066] Wherein the quick-drying paste agent is magnesium aluminum silicate;

[0067] Wherein the emulsion is an aqueous solution of emulsifier sodium butylnaphthalene sulfonate;

[0068] Among them, the asphalt rejuvenator is made of high-quality naphthenic heavy oil from Venezuela in South America, and is distilled under normal and reduced pressure.

[0069] Preparation:

[0070] (1) Preparation of rubber asphalt mixture: weigh the petroleum asphalt and modifier in mass percentage, put them into the reaction kettle, heat up to 140°C and stir evenly, add asphalt rejuvenator and quick-drying paste agent under stirring condition and mix for 10min , slowly raise the temperature to 180°C, and stir at constant temperature for 2 hours to obtain the rubber-asphalt mixture;

[0071] (2) Preparation of emulsion: add water to the soap tank, add emulsifier, ...

Embodiment 3

[0075]

[0076] Among them, the modified asphalt is composed of 90 # It is modified by petroleum asphalt and SBS modifier;

[0077] Among them, the quick-drying paste agent is magnesium lithium silicate and magnesium aluminum silicate;

[0078] Wherein the emulsion is an aqueous solution of emulsifier sodium butyl naphthalene sulfonate.

[0079] Among them, the asphalt rejuvenator is made of high-quality naphthenic heavy oil from Venezuela in South America, and is distilled under normal and reduced pressure.

[0080] Preparation:

[0081] (1) Preparation of rubber asphalt mixture: Weigh petroleum asphalt and modifier in mass percentage, put them into the reaction kettle, heat up to 150°C and stir evenly, add asphalt rejuvenator and quick-drying paste agent under stirring condition, and mix for 15 minutes , slowly raise the temperature to 190°C, and stir at constant temperature for 3 hours to obtain the rubber-asphalt mixture;

[0082] (2) Prepare emulsion: add water to ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| penetration | aaaaa | aaaaa |

| flash point | aaaaa | aaaaa |

| thermal resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com