Method for recovering polytetrafluoroethylene dispersion resin

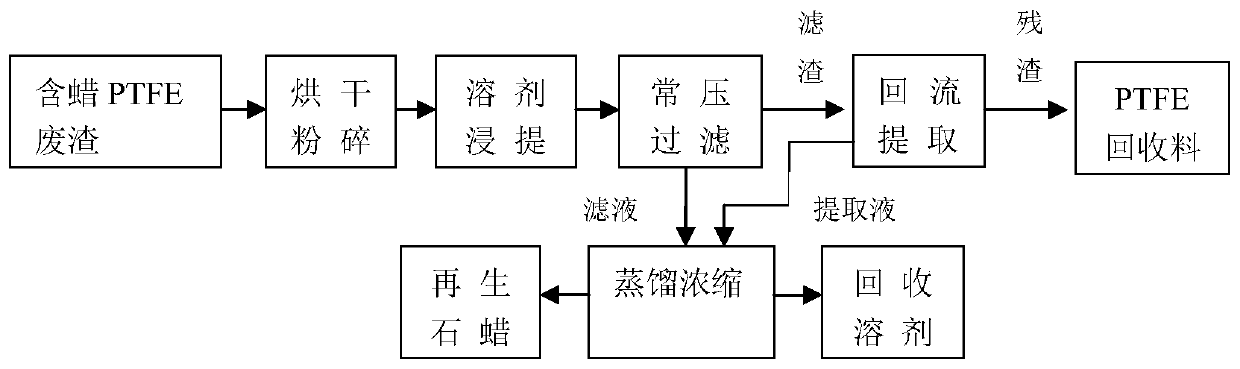

A polytetrafluoroethylene and dispersing resin technology, which is applied in the field of fine chemicals, can solve the problems of the paraffin content index not meeting the requirements, the large volume of organic solvents, and the unfavorable large-scale application, so as to avoid difficult immersion and stirring, and recovery costs Low, easy to promote the effect of implementation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] Present embodiment relates to a kind of method of reclaiming polytetrafluoroethylene dispersion resin, comprises the steps:

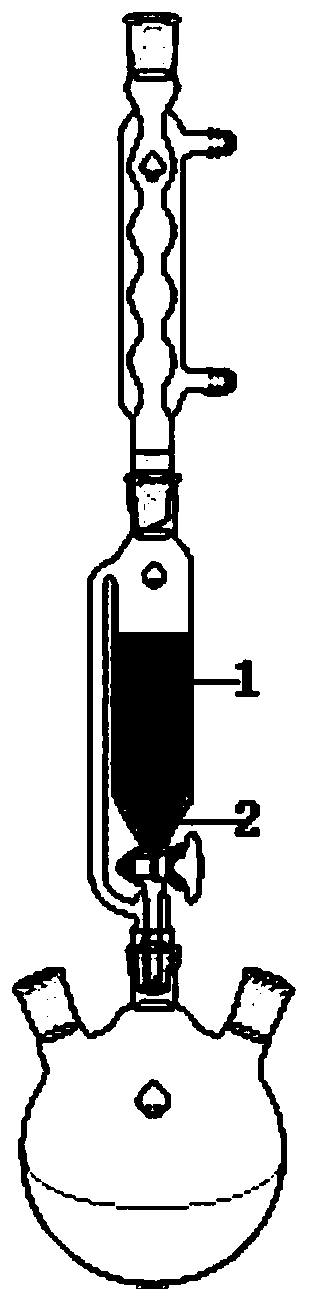

[0047] 1) Dry the waxy PTFE waste residue to a water content of 3.7%, crush it to a fineness of 100 mesh, use a thermogravimetric analyzer to carry out quantitative analysis of the wax content to 48.5%, accurately weigh 420.2g of the sample and add 3L of In the spherical three-port opening reactor, according to the solid-to-liquid ratio of paraffin and chloroform of 1:10g / mL, add 2040mL of corresponding extractant chloroform to it. Start the cantilever-type constant-speed powerful mixer to stir at a speed of 300r / min; at the same time, use the SXKW digital display temperature-controlled electric heating mantle to heat, the temperature is controlled at 50°C, and stir for 4 hours to complete the leaching. Quickly filter and separate the extract (extract phase) and residue (raffinate phase) on an all-copper double-layer hot filter funnel while hot t...

Embodiment 2

[0053] Present embodiment relates to a kind of method of reclaiming polytetrafluoroethylene dispersion resin, comprises the steps:

[0054] 1) Dry the waxy PTFE waste residue to a water content of 3.7%, crush it to a fineness of 100 mesh, use a thermogravimetric analyzer to carry out quantitative analysis of the wax content to 48.5%, accurately weigh 321.0g of the sample and add 3L of In the spherical three-port opening reactor, according to the solid-to-liquid ratio of paraffin and chloroform of 1:10g / mL, 1560mL of corresponding extractant chloroform was added thereto. Start the cantilever-type constant-speed powerful mixer to stir, the speed is 100r / min; at the same time, use the SXKW digital display temperature control electric heating mantle to heat, the temperature is controlled at 45°C, and stir for 4 hours to complete the leaching. Quickly filter and separate the extract (extract phase) and residue (raffinate phase) on an all-copper double-layer hot filter funnel while ...

Embodiment 3

[0060] Present embodiment relates to a kind of method of reclaiming polytetrafluoroethylene dispersion resin, comprises the steps:

[0061] Present embodiment relates to a kind of method of reclaiming polytetrafluoroethylene dispersion resin, comprises the steps:

[0062] 1) Dry the waxy PTFE waste residue to a water content of 3.7%, crush it to a fineness of 100 mesh, use a thermogravimetric analyzer to carry out quantitative analysis of the wax content to 48.5%, accurately weigh 402.1g of the sample and add 3L of In the spherical three-port open reactor, according to the solid-to-liquid ratio of paraffin and carbon tetrachloride 1:10g / mL, add 1950 mL of the corresponding extractant carbon tetrachloride to it. Start the cantilever-type constant-speed powerful mixer to stir at a speed of 300r / min; at the same time, use the SXKW digital display temperature-controlled electric heating mantle to heat, the temperature is controlled at 65°C, and stir for 4 hours to complete the lea...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com