Patents

Literature

44results about How to "Guaranteed cutting stability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

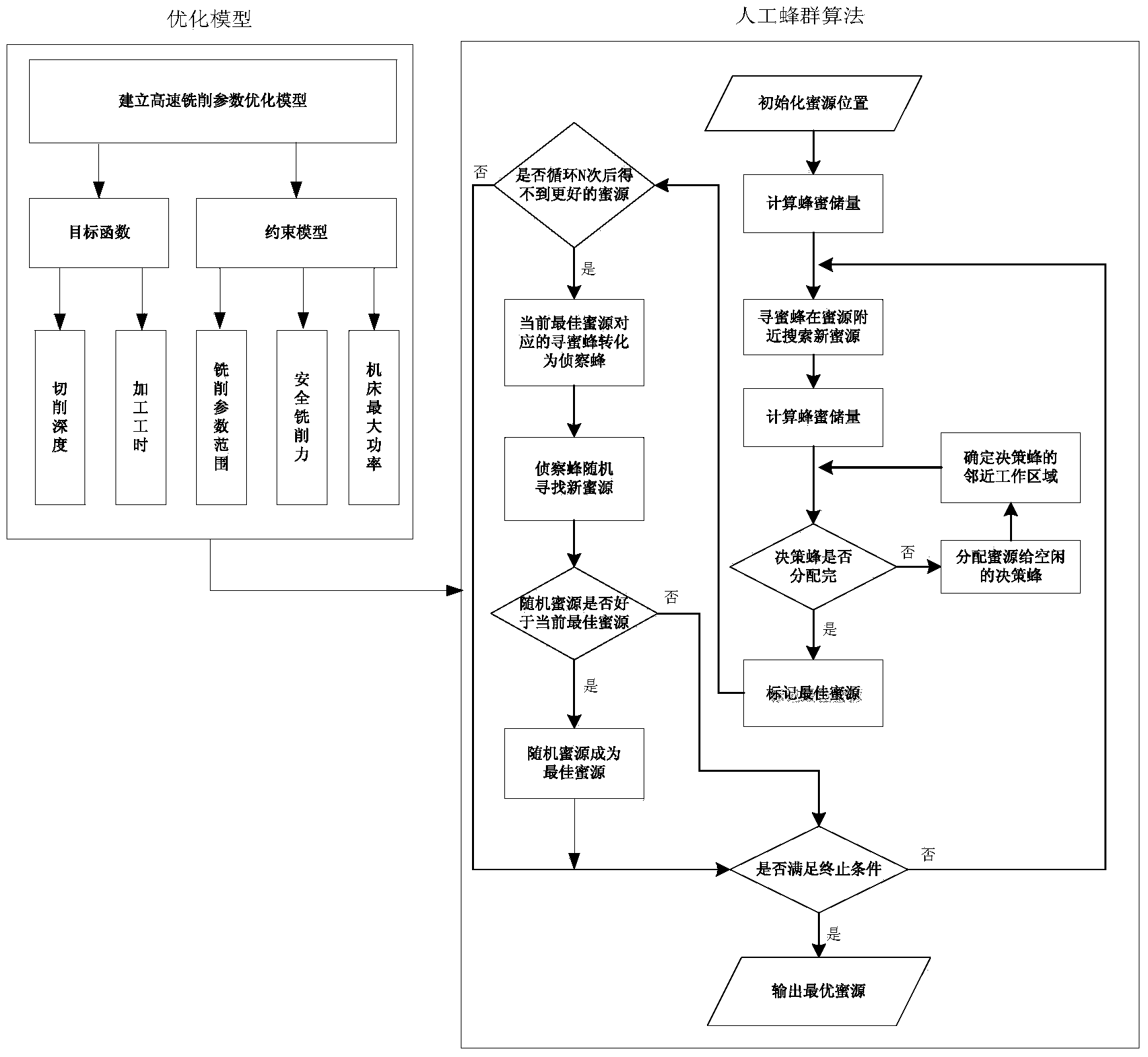

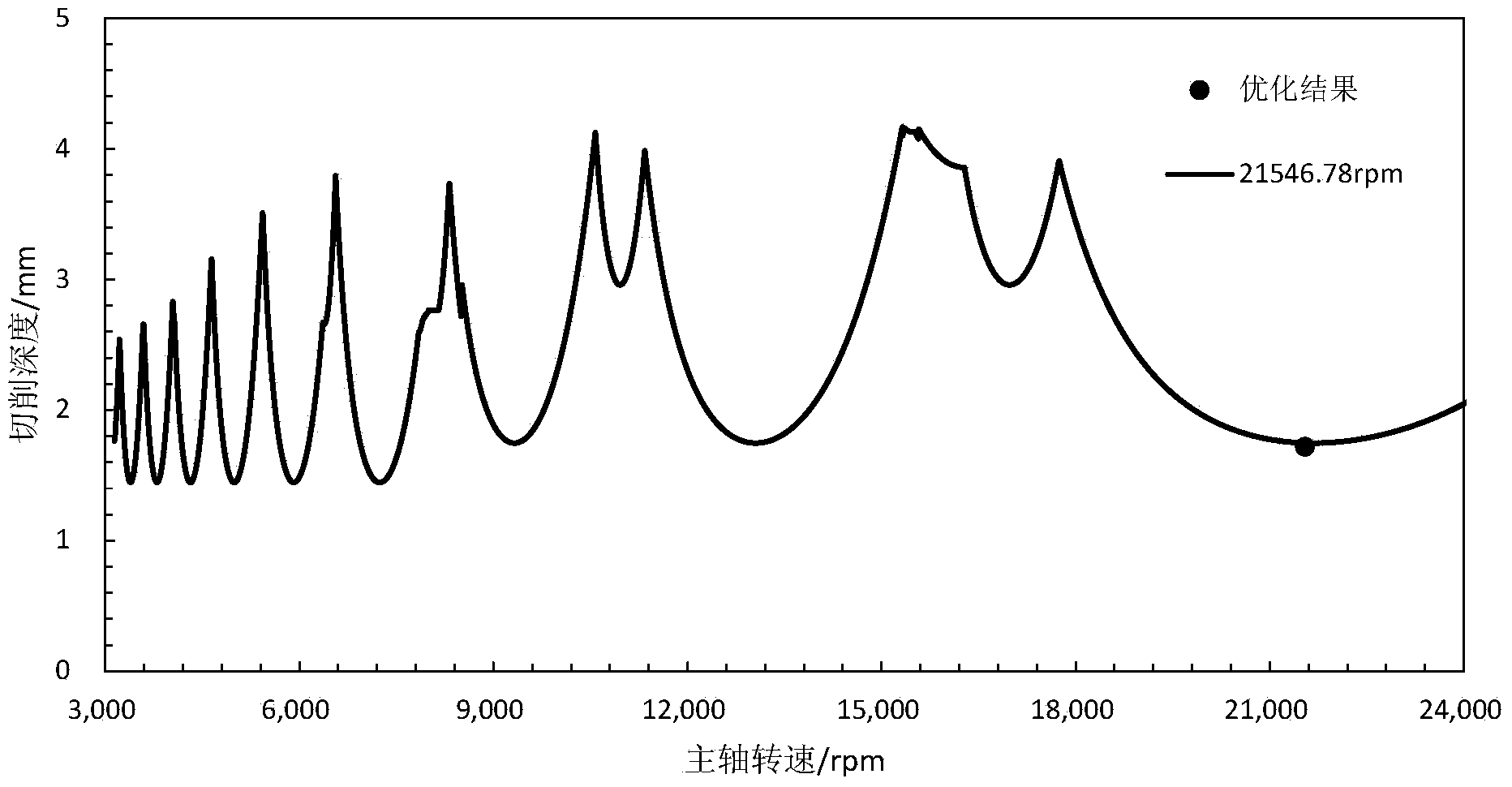

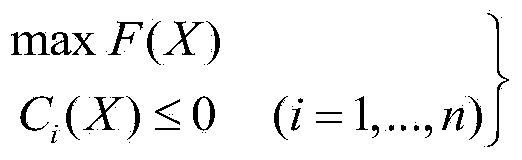

Milling process parameter optimization method

ActiveCN104076733AExcellent milling process parametersImprove productivityNumerical controlProduction rateProcess engineering

The invention provides a milling process parameter optimization method and belongs to the field of cutting machining processes. The coupling effect of a machining device dynamic behavior and the high-speed milling process is considered in the method, the maximum milling extreme cutting depth changing with the rotating speed of a machine tool spindle and shortest machining time of single part are regarded as optimization targets, a milling process parameter optimization model based on cutting stability and productivity is established, and optimal milling process parameters of a milling process parameter combining scheme under the condition that a cutting state is stable when the productivity is maximum are calculated. The milling process parameter optimization method can improve the cutting depth to the most extent during milling, decrease feed times, obtains maximum productivity, meanwhile ensures the cutting stability and avoids flutter. In addition, the milling process parameter optimization method can be applied to the high-speed milling process, the defect that the interactive effect of the machining device dynamic behavior and the milling process parameters is not considered in the high-speed milling process at present is overcome, and optimal high-speed milling process parameters can be obtained.

Owner:TONGJI UNIV

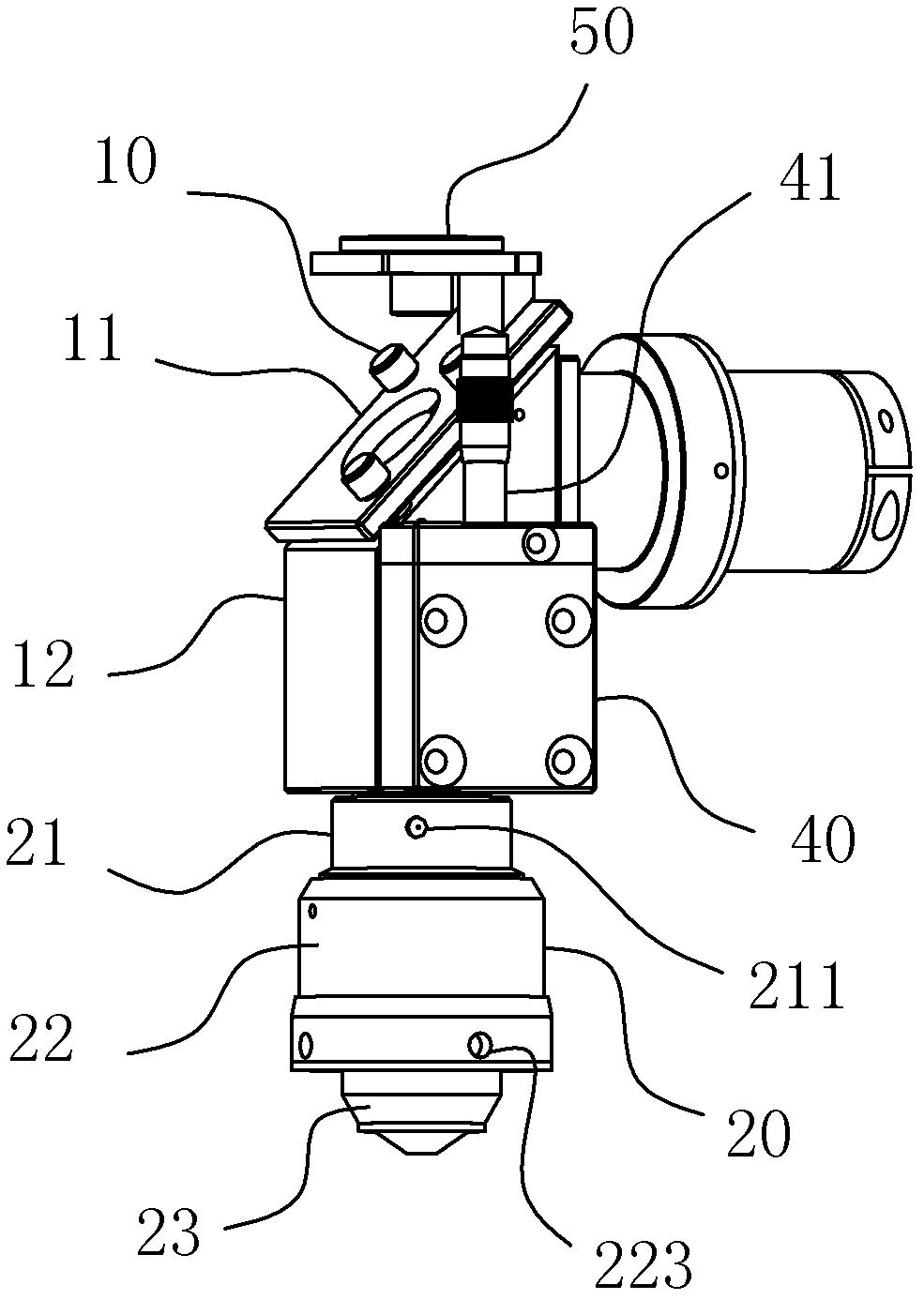

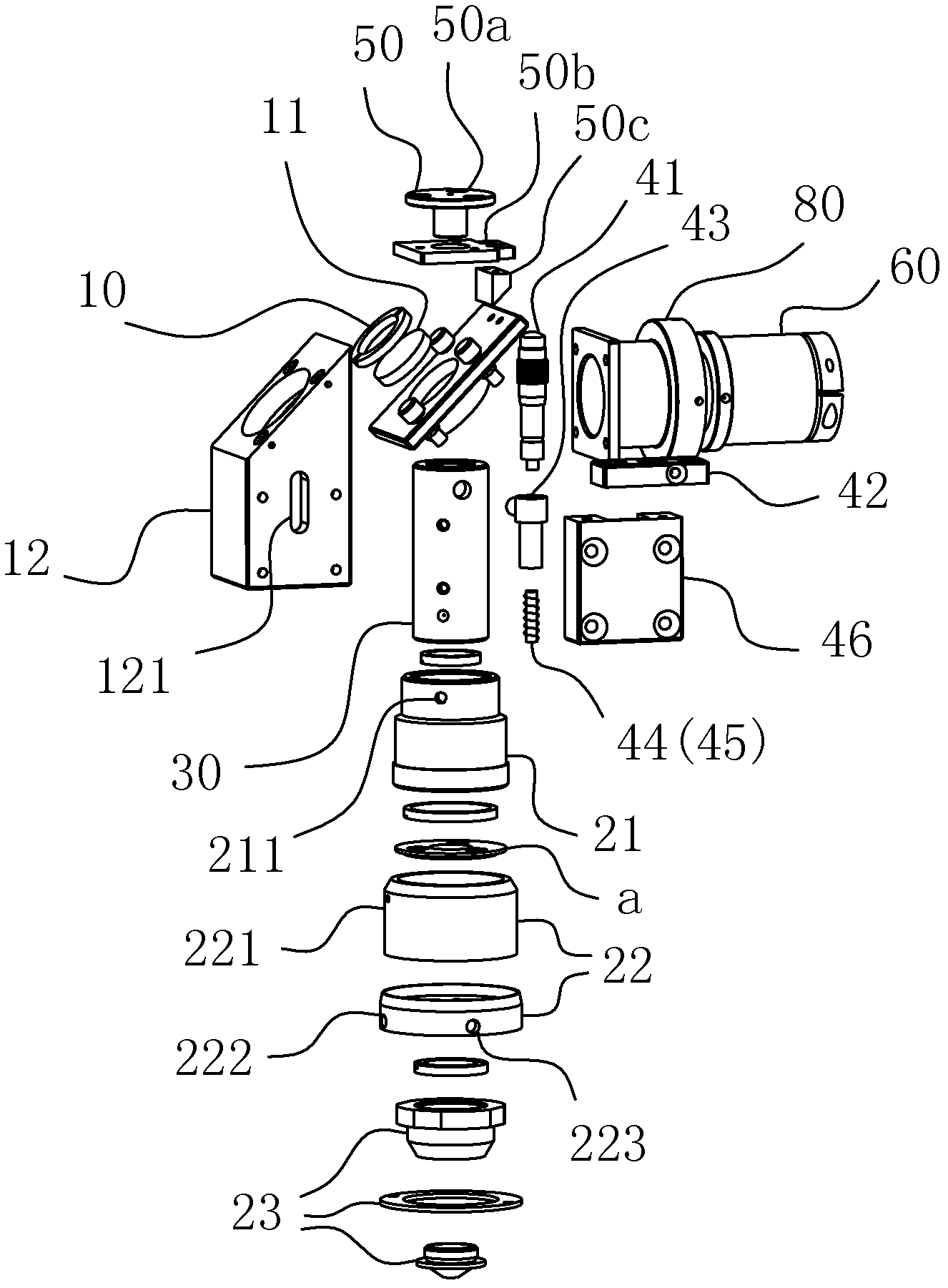

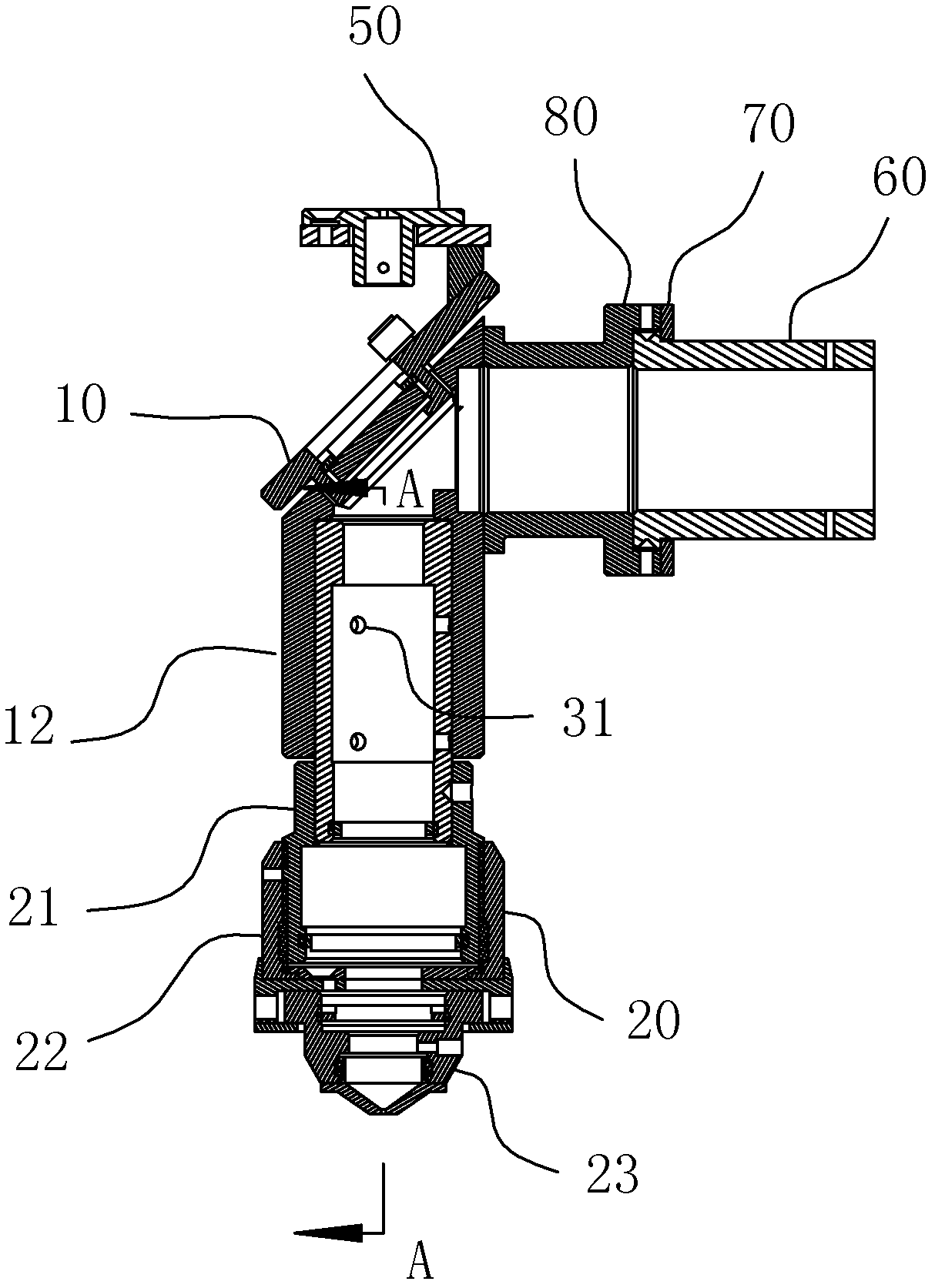

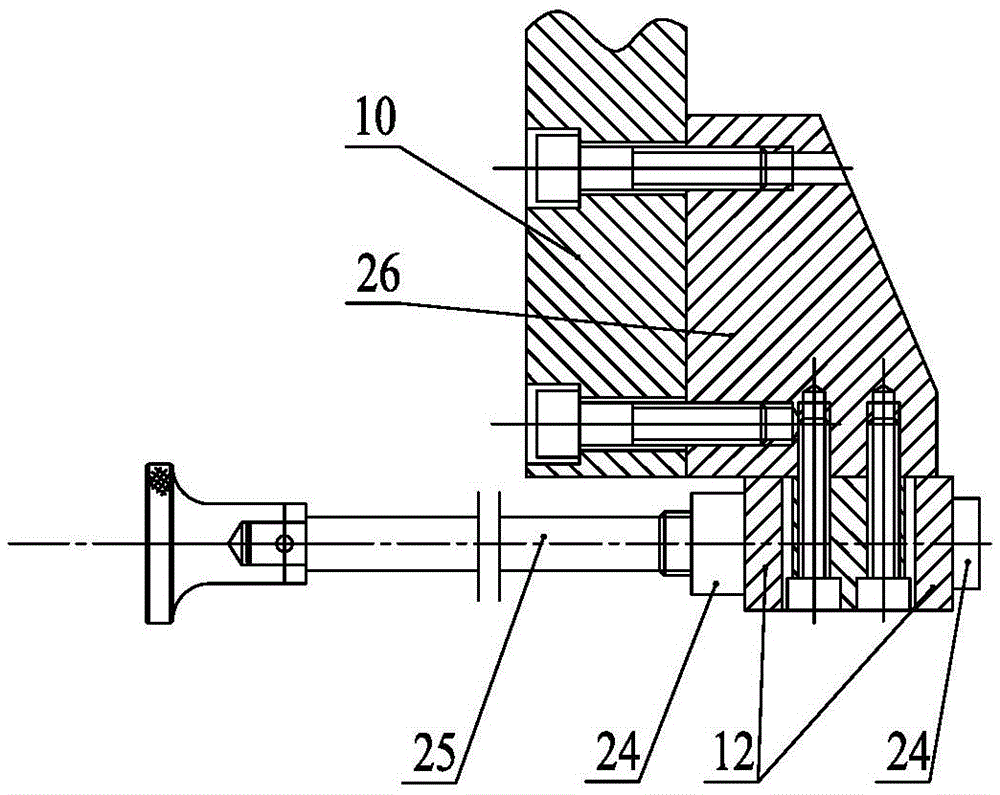

Cutting head

ActiveCN102500920AImprove adjustabilityPrecise control of focus point positionLaser beam welding apparatusLaser processingHigh energy

The invention belongs to the field of laser machining, and particularly relates to a cutting head, which is used for laser fine cutting and comprises a light path incident lens, a light path emergent lens, a reflector component and an adjusting mechanism. The reflector component is used for reflecting light paths, main light enters the cutting head via the light path incident lens and exits the cutting head via the light path emergent lens after being reflected by the reflector component, the light path emergent lens consists of a focusing head component, and the adjusting mechanism can be used for driving the focusing head component to move along a Z-axis direction. When the thickness of a machined workpiece is changed, the purpose of accurately controlling the position of a focal point of the focusing head component can be directly achieved by means of adjusting the Z-axis adjusting mechanism positioned in a cutting head body, high energy of laser within a focal depth range can be sufficiently utilized, machining precision is improved, and accordingly the quality and the stability of cutting of the workpiece are eventually guaranteed. In addition, the cutting head is more convenient and speedy in operation as compared with a traditional laser cutting head troublesome in operation due to the fact that the relative height of a mechanical arm connected with the traditional laser cutting head needs to be integrally adjusted.

Owner:CHERY AUTOMOBILE CO LTD

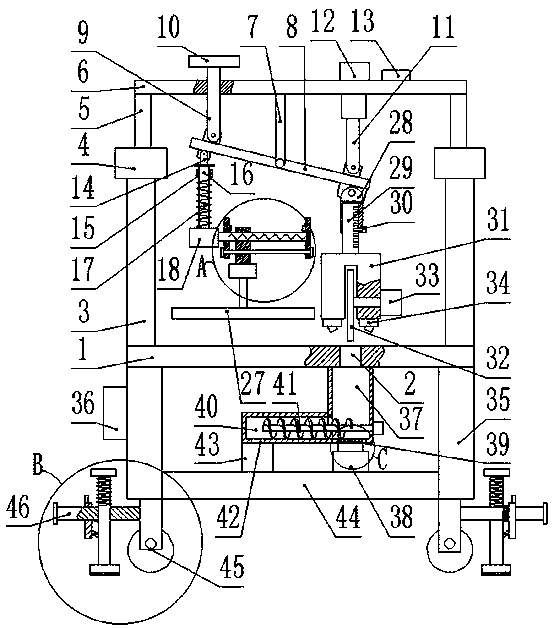

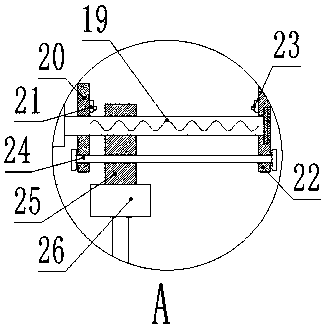

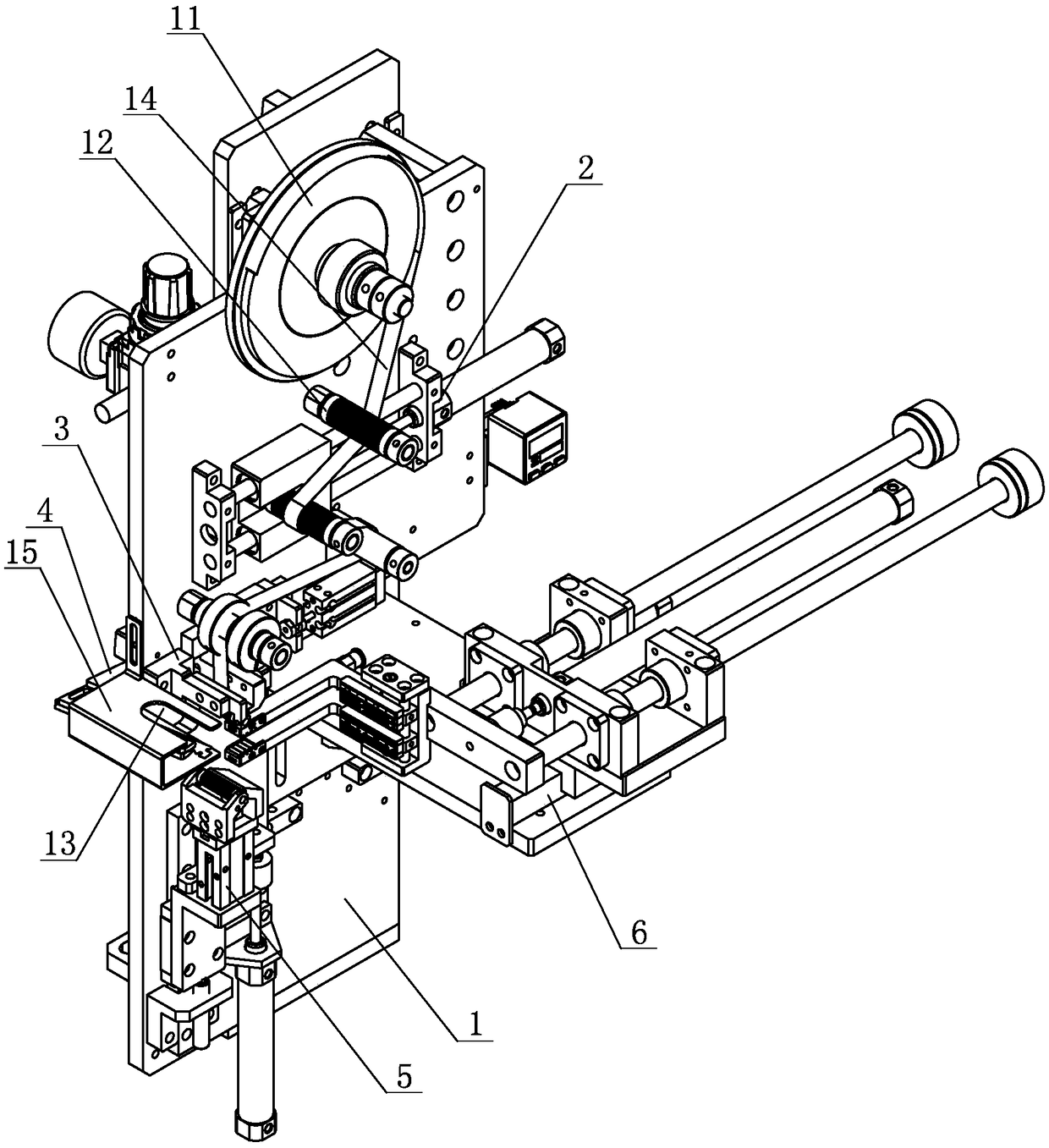

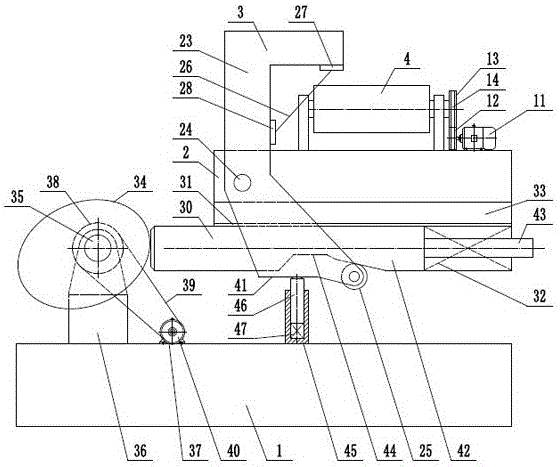

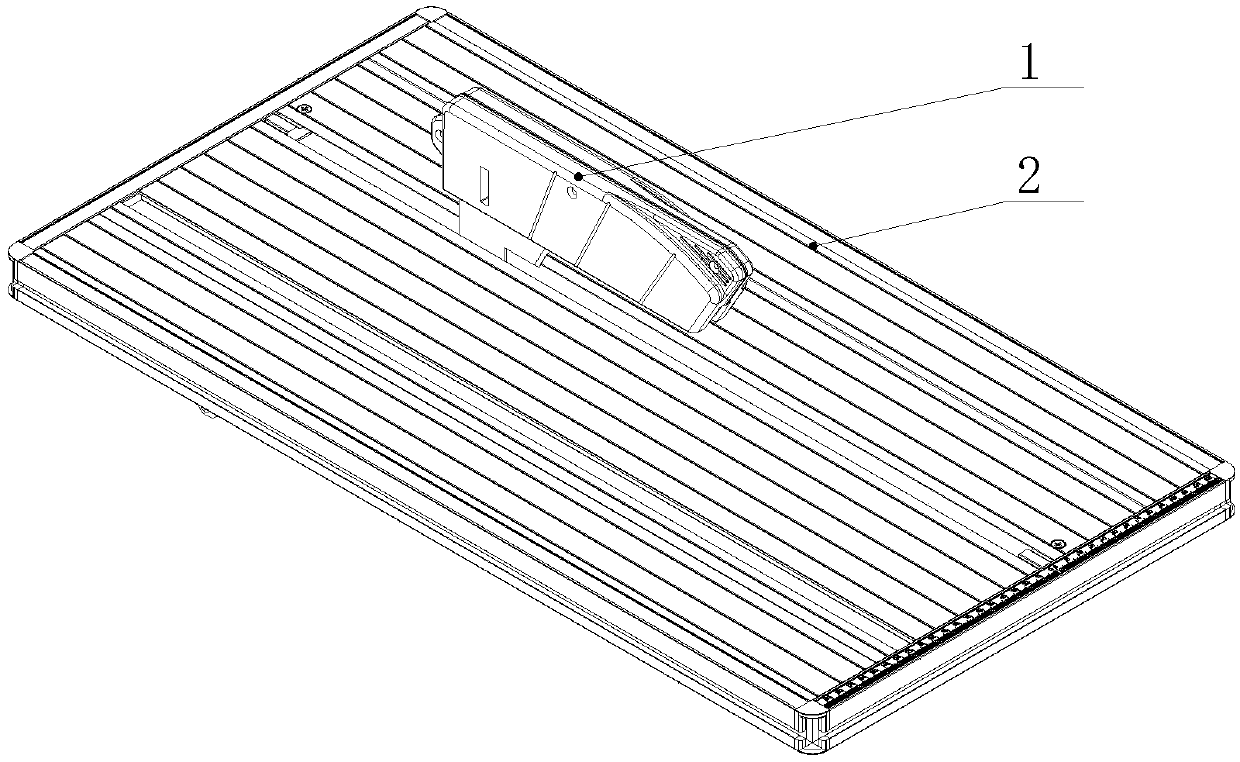

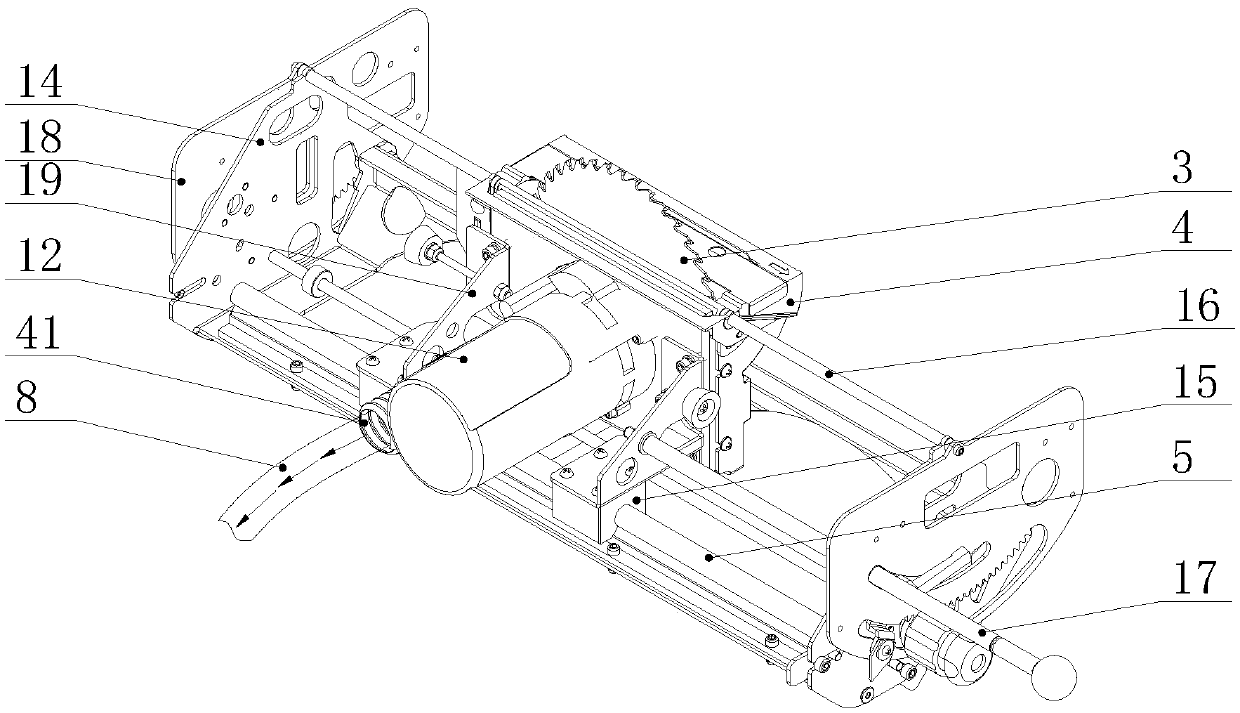

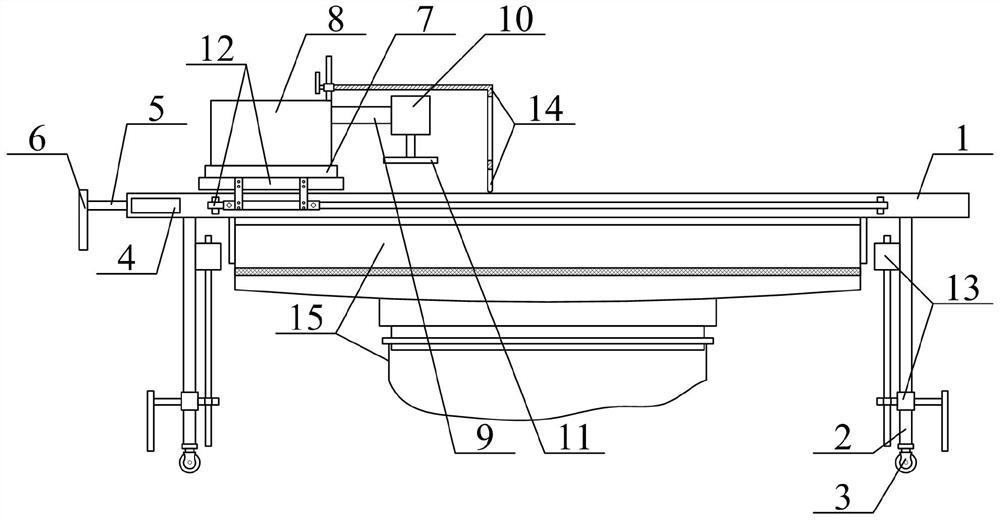

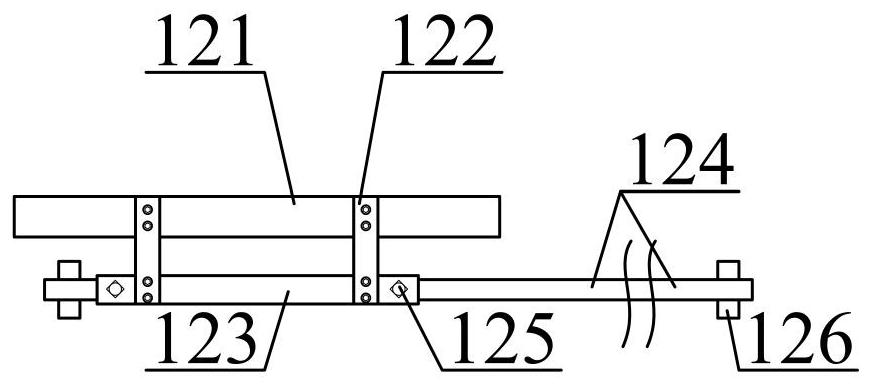

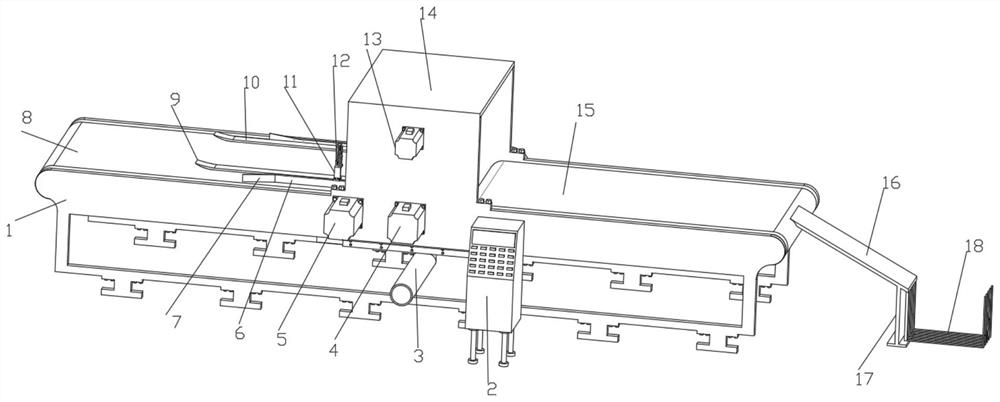

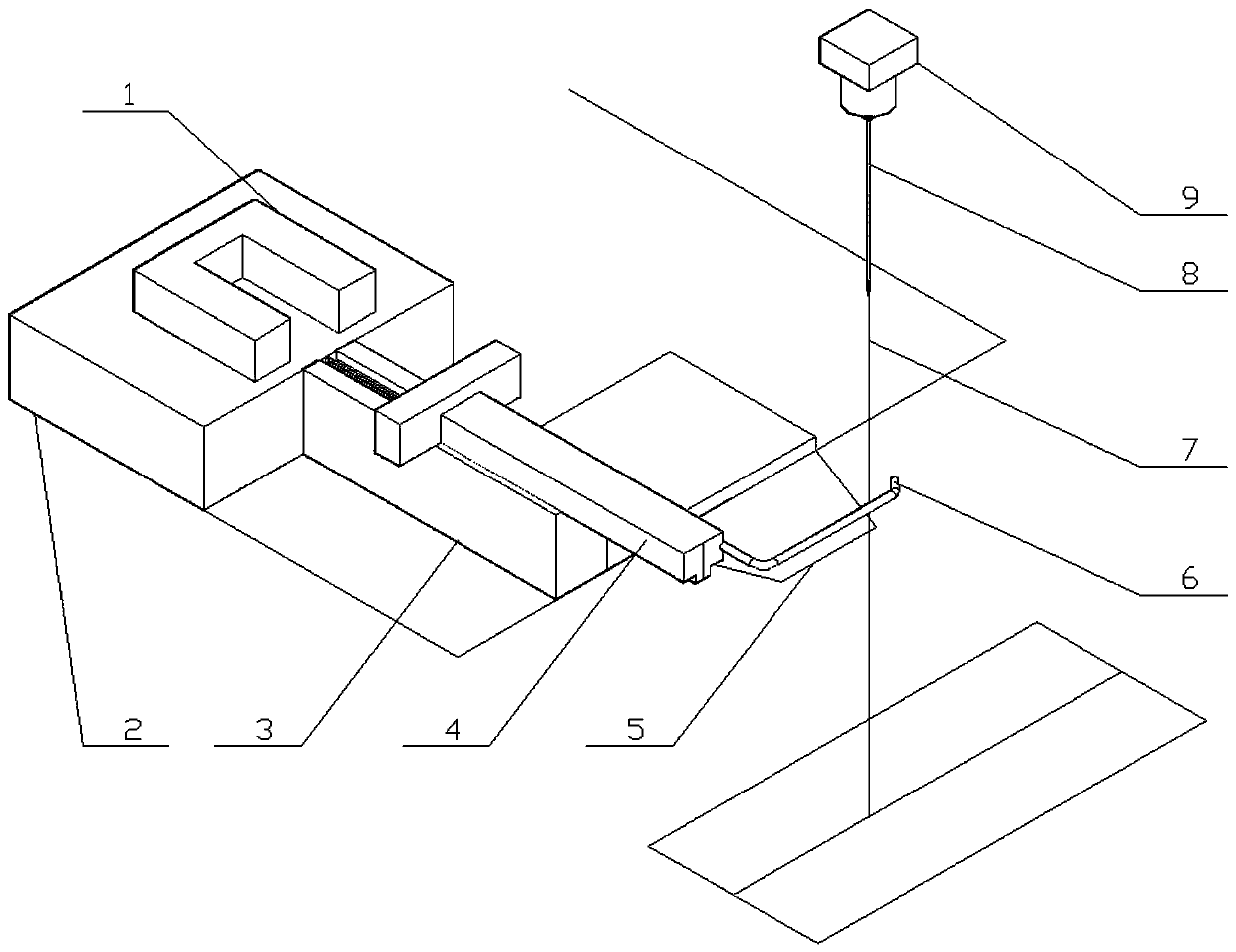

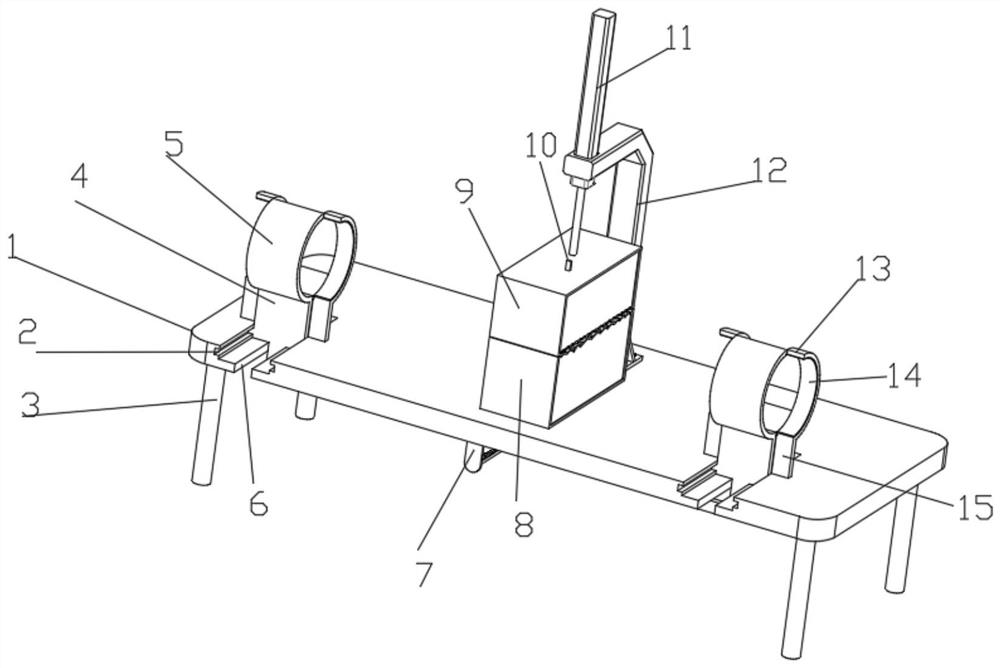

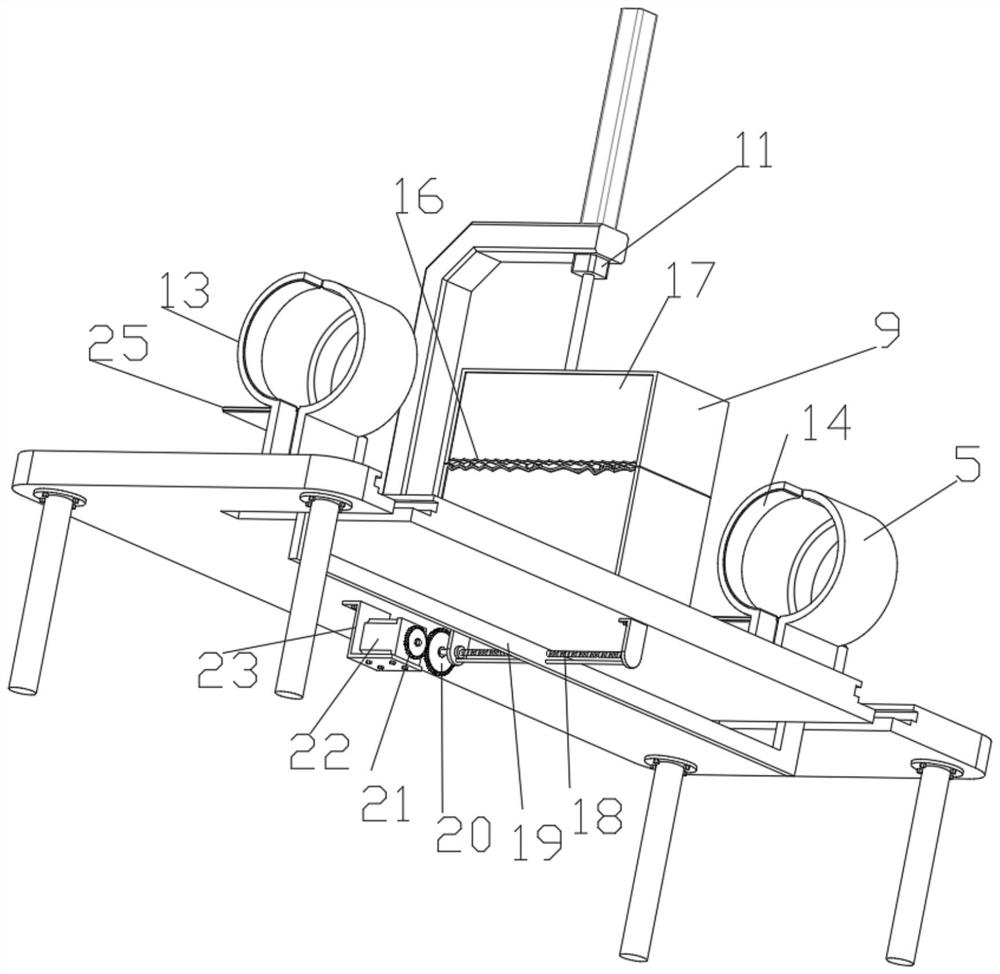

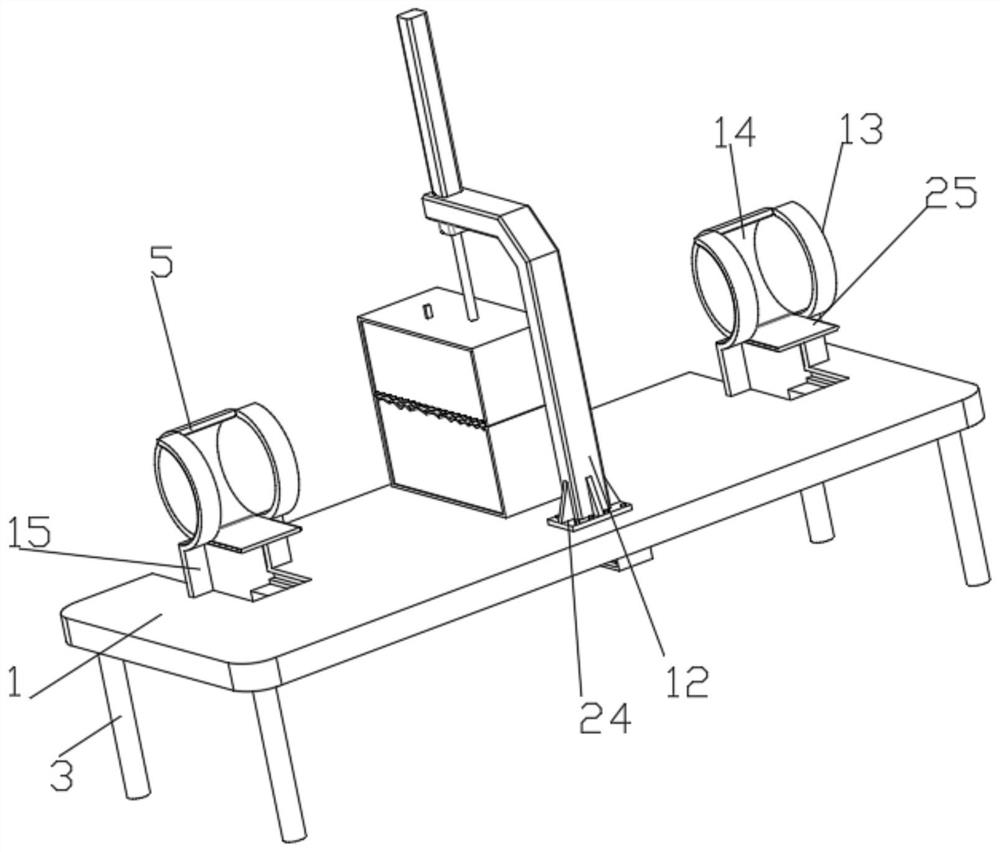

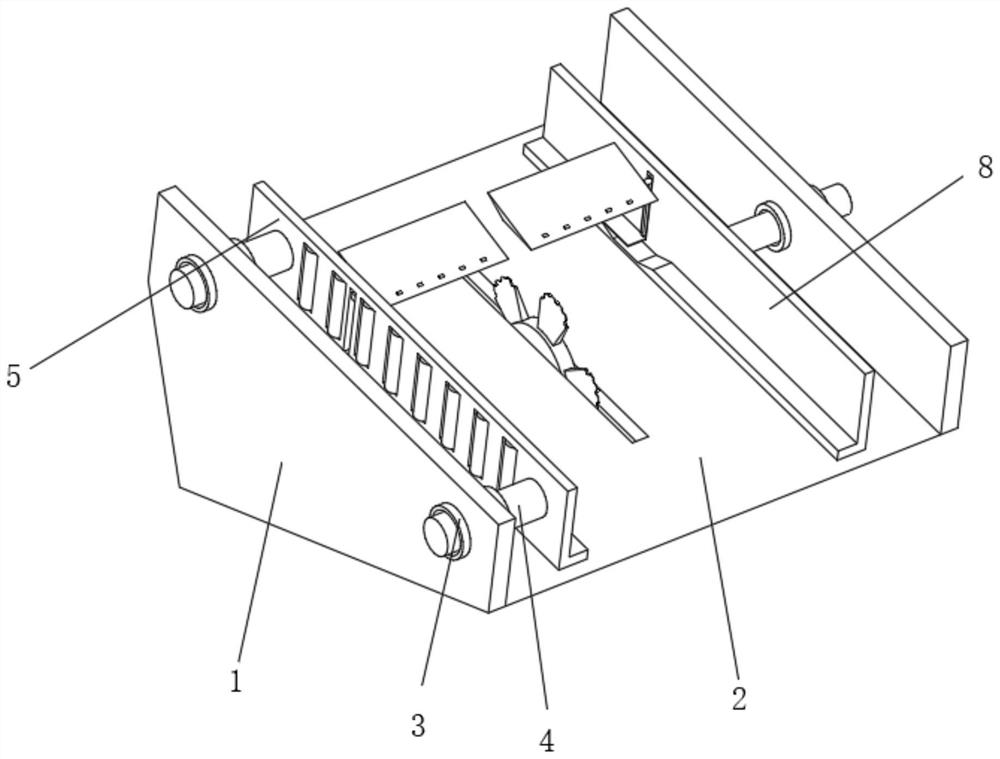

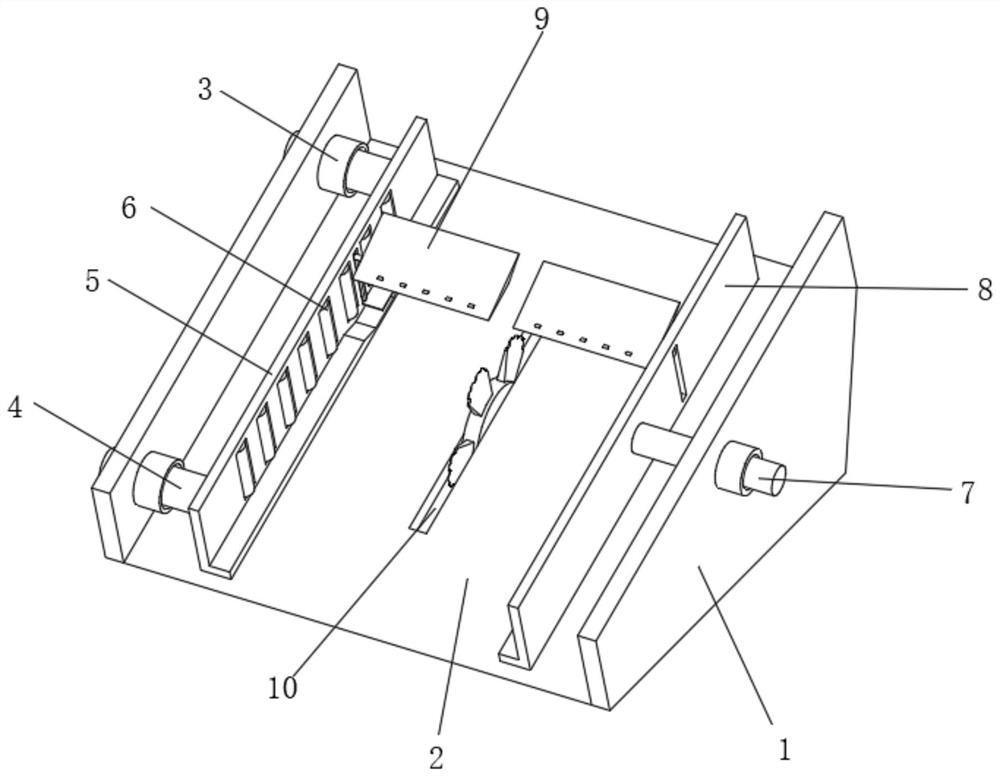

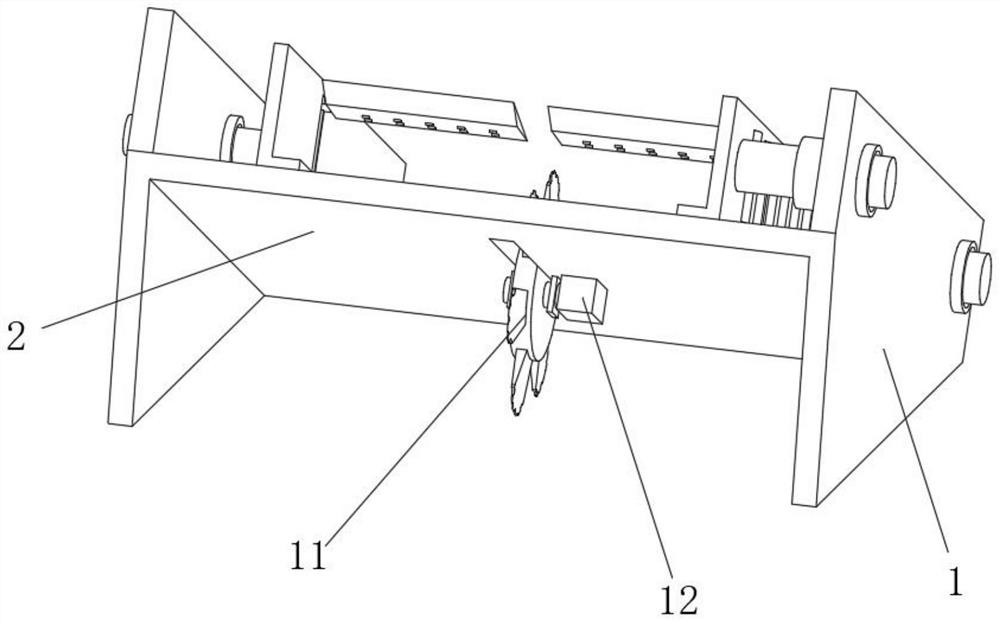

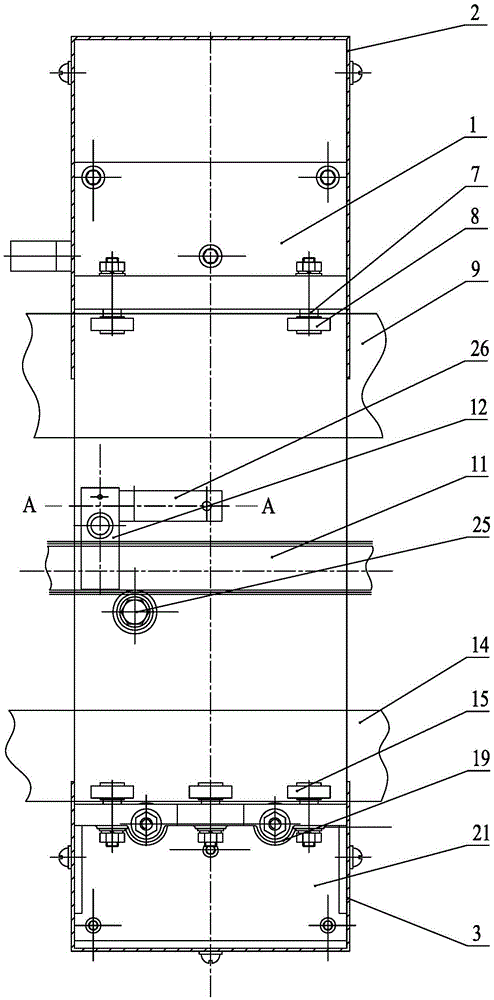

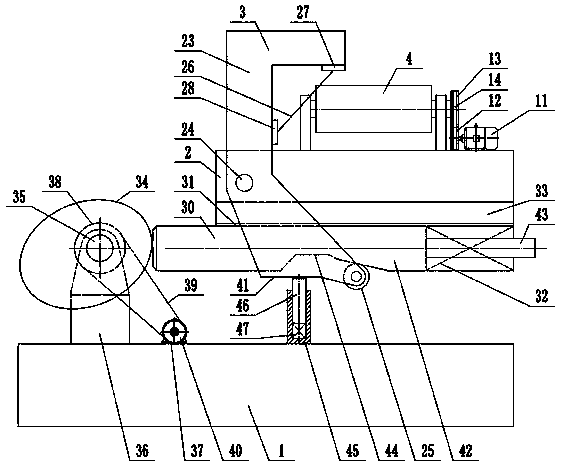

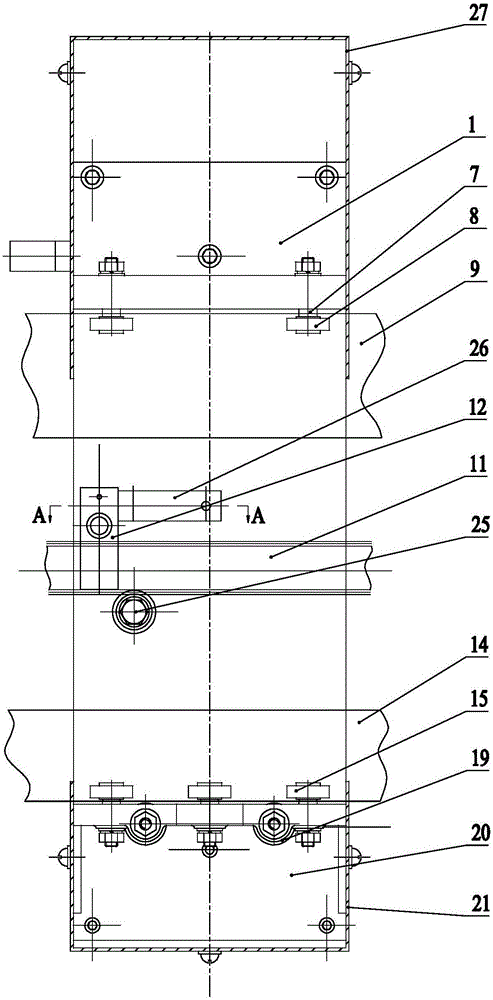

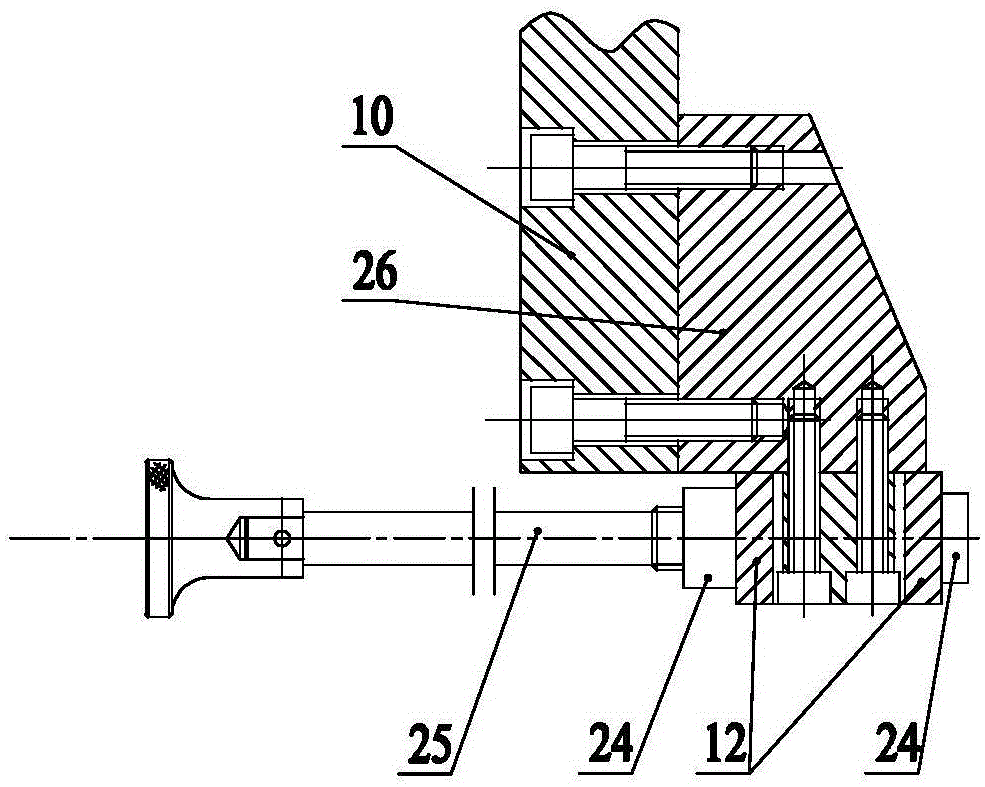

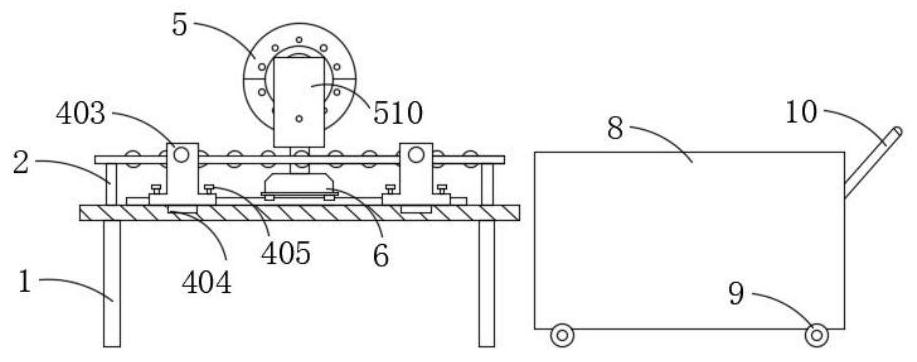

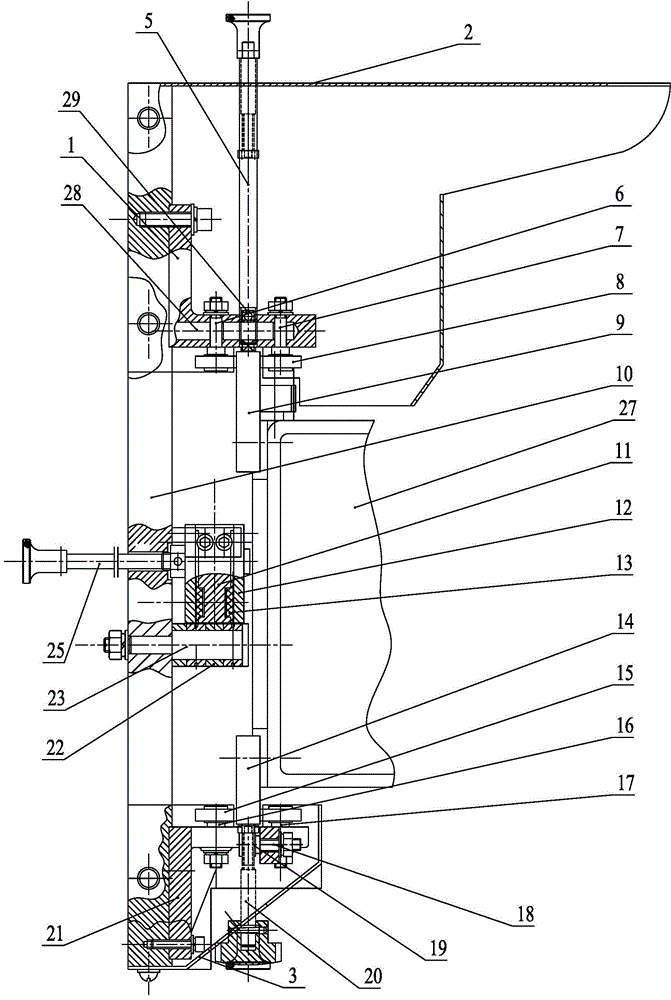

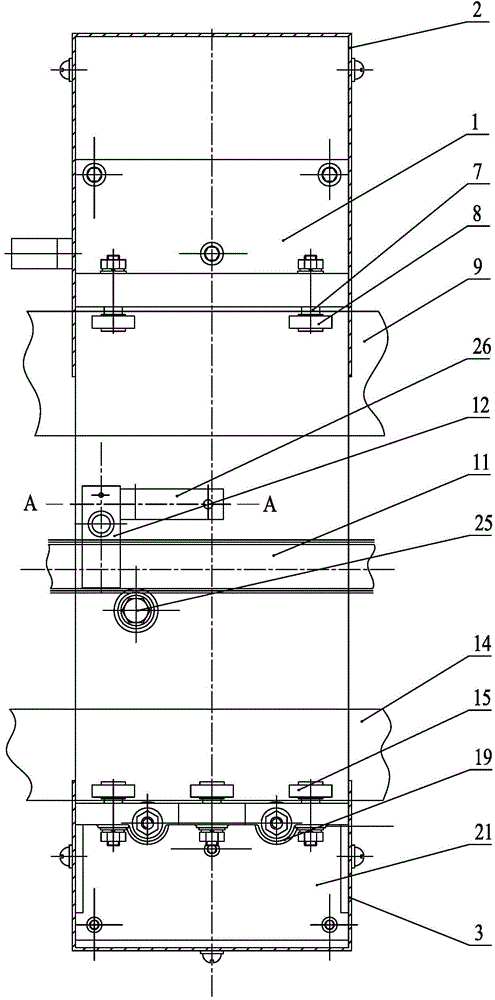

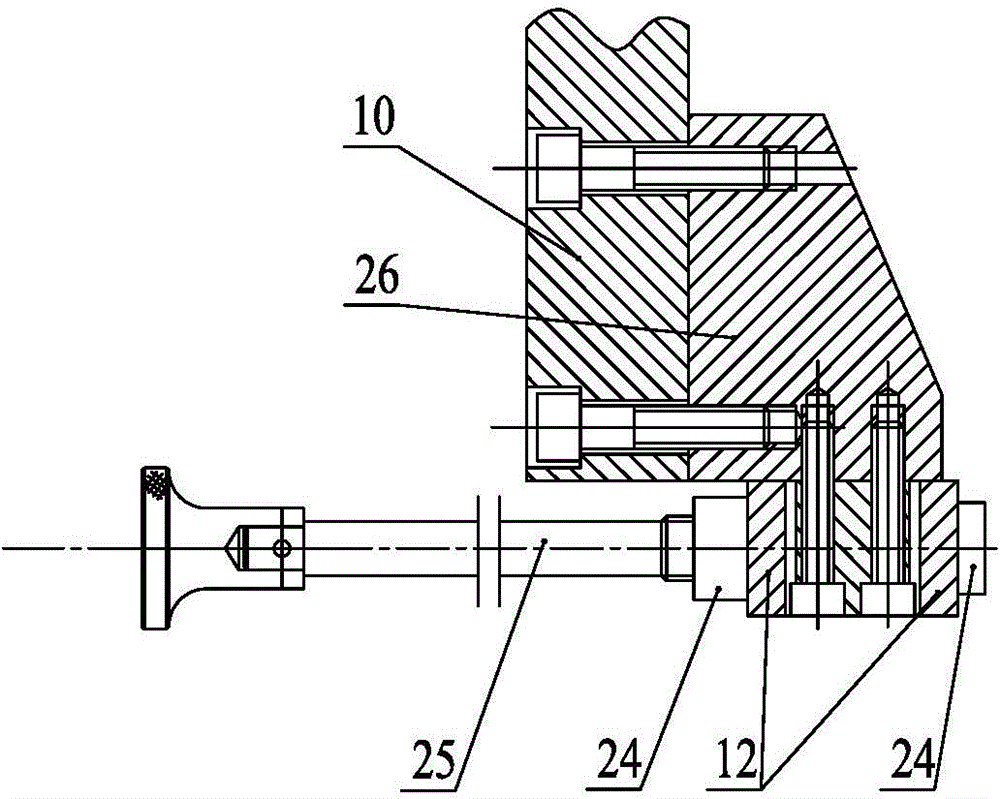

Machining center for automatically cutting single-branch door and window aluminum plastic profile at 45-degree angle

PendingCN110587023AReduce vibrationGuaranteed cutting stabilityMetal sawing devicesMetal working apparatusEngineeringMechanical engineering

The invention relates to a machining center for automatically cutting a single-branch door and window aluminum plastic profile at a 45-degree angle. The machining center comprises a console and a cutting mechanism; a cutting platform of the cutting mechanism is provided with two cutting openings which are arranged back and forth in the feeding direction and are perpendicular to the feeding direction; the cutting platform is provided with a first saw blade and a second saw blade, wherein the first saw blade and the second saw blade can perform reciprocating cutting movements in the cutting openings separately through cutting work-in assemblies; the cutting platform is provided with a tail material opening between the two cutting openings; a positioning plate used for limiting an aluminum plastic profile during cutting is vertically fixed on the cutting platform, and a pressing assembly guided through a guide rail and used for limiting the aluminum plastic profile during cutting is arranged between the positioning plate and the cutting platform; and the cutting platform is provided with a material-taking hand assembly for dragging a finished product after cutting out of the cutting mechanism in the discharging direction. The machining center is high in cutting precision, and functions of automatic feeding, automatic cutting, discharging, waste collecting and the like can be achieved.

Owner:JINAN SHITONG CNC MACHINERY CO LTD

Medium thickness stainless steel plate rapid perforating process

The invention provides a medium thickness stainless steel plate rapid perforating process. The process comprises following steps of firstly, deep blasting, wherein a cutting head with the laser powerbeing larger than or equal to 3000 watts is used for cutting, the height between the cutting head and the surface of a panel is set to range from 12 to 16 mm, the duty ratio ranges from 55 to 75%, theoxygen with the air pressure being 0.6 Bar to 1.2 Bar is adopted, the frequency ranges from 8 to 20 Hz, the focal position is below the surface of the board to be cut by 50 to 70%, and the laser radiation time ranges from 0.5 S to 1.5 S; secondly, slag purging, wherein the height of the cutting head is adjusted to the position away from the surface of the board by 10 mm, nitrogen with the pressure being 4 Bar is used, and the board is purged by 1S to 2S; and thirdly, perforating, wherein the cutting head with the power being larger than or equal to 3000 watts is used, the cutting head is adjusted to the position above the surface of the board by 16 mm, and cutting and perforating are carried out. The oxygen deep blasting is used, the material is carbonized, the nitrogen with the high pressure is used for blowing off carbonized slag, the too much surface slag stacking caused by long perforating time can be greatly reduced, after perforating, cutting connection is stable, and cutting stability is ensured.

Owner:WUXI ZHOUXIANG LASER MACHINERY

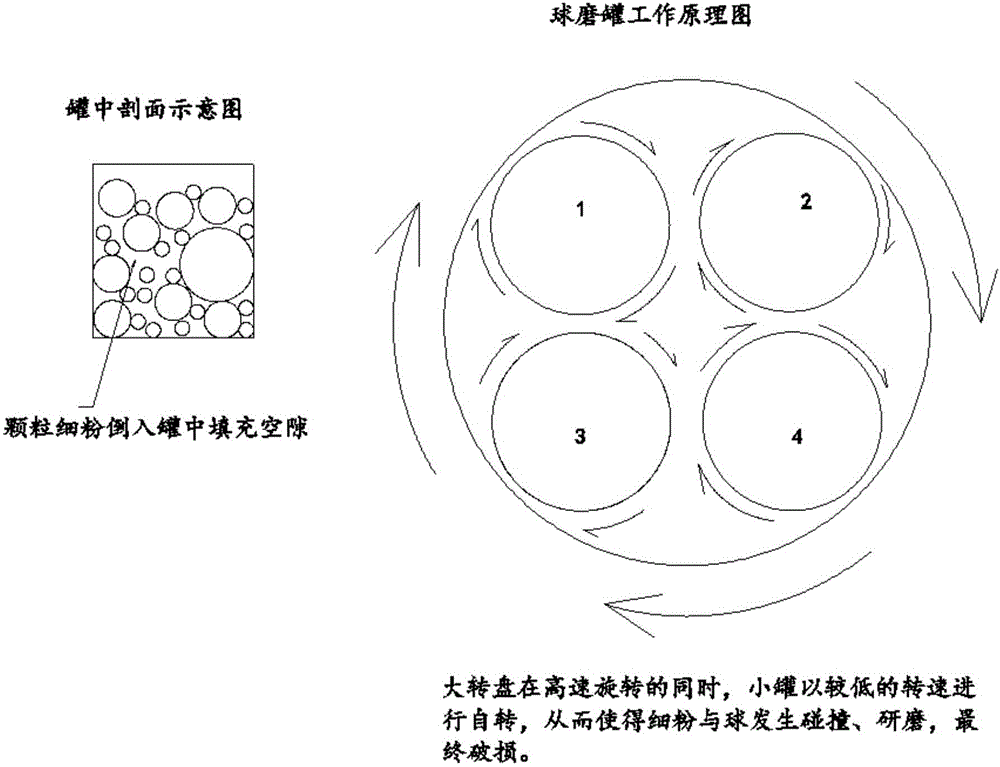

Detection method for hardness of micron-size ultrahard grinding materials

InactiveCN106404572AReflect fragilitySmall particle sizeInvestigating material hardnessFragilityHardness

The invention provides a detection method for the hardness of micron-size ultrahard grinding materials. The detection method comprises the following steps that 1, samples are extracted, a roundness value R and a length-width ratio value A of the samples are detected, and a grain shape coefficient is obtained according to S=A*R; 2, after the grinding grain materials are subjected to a destructive test, grain size distribution of the samples obtained after ball milling is obtained; 3, the grain size distribution, obtained in the step 2, of the samples obtained after ball milling is compared with grain size distribution of the samples before ball milling, and then the grain size decreasing degree of the grinding materials in the process can be obtained; 4, a wear degree coefficient B of the grinding materials is reflected through the grain size decreasing degree of the grinding materials, and the less the grain size is decreased, the lower the coefficient is, and the better the wear resisting capacity is; 5, by combining the grain shape coefficient with the wear degree coefficient, a hardness value (H=S*B) of the modulus can be comprehensively reflected. According to the novel detection method, whether the hardness of the grinding grains is qualified or not and how about the fragility is are mainly represented, and the quality of the materials is analyzed.

Owner:镇江荣德新能源科技有限公司

Robot for cutting wood plate

PendingCN108262812AEasy to cutEasy to collectProfiling/shaping machinesGrinding machinesWood plankMechanical engineering

The invention relates to a robot for cutting a wood plate. The robot comprises a working table, which is provided with a cutting hole, wherein positioning rods are fixedly arranged at four corners ofthe edge of the top end of the working table, the top end of the positioning rod is fixedly provided with a support horizontal rod A, the top surface of the support horizontal rod A is fixedly provided with a fixed vertical rod A, a support horizontal rod B is fixedly arranged between the two fixed vertical rods A, the center position of the bottom surface of the support horizontal rod B is fixedly provided with a swinging rod, and the edge positions on the top surface and the bottom surface of one side of the swinging rod are respectively hinged to a sliding rod A and a connection rod. According to the present invention, through the hydraulic stretching rod, the swinging rod is controlled to freely swing back and forth, the cutting wheel and the burnishing wheel are controlled to operate,and the positions of the cutting wheel and the burnishing wheel can be adjusted according to the thickness of the wood plate, such that the wood plates with different thicknesses can be convenientlycut or burnished; and through the opposite clamping device and hand-operated wire pulling wire, the manual operation on the wood plate by the worker is not required so as to effectively ensure the work safety and the cutting stability.

Owner:KUNMING UNIV OF SCI & TECH

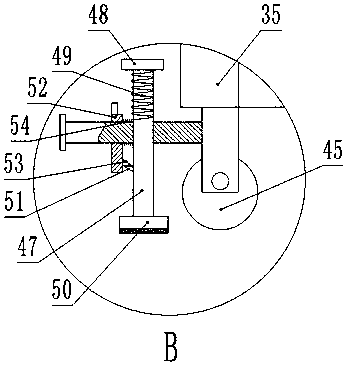

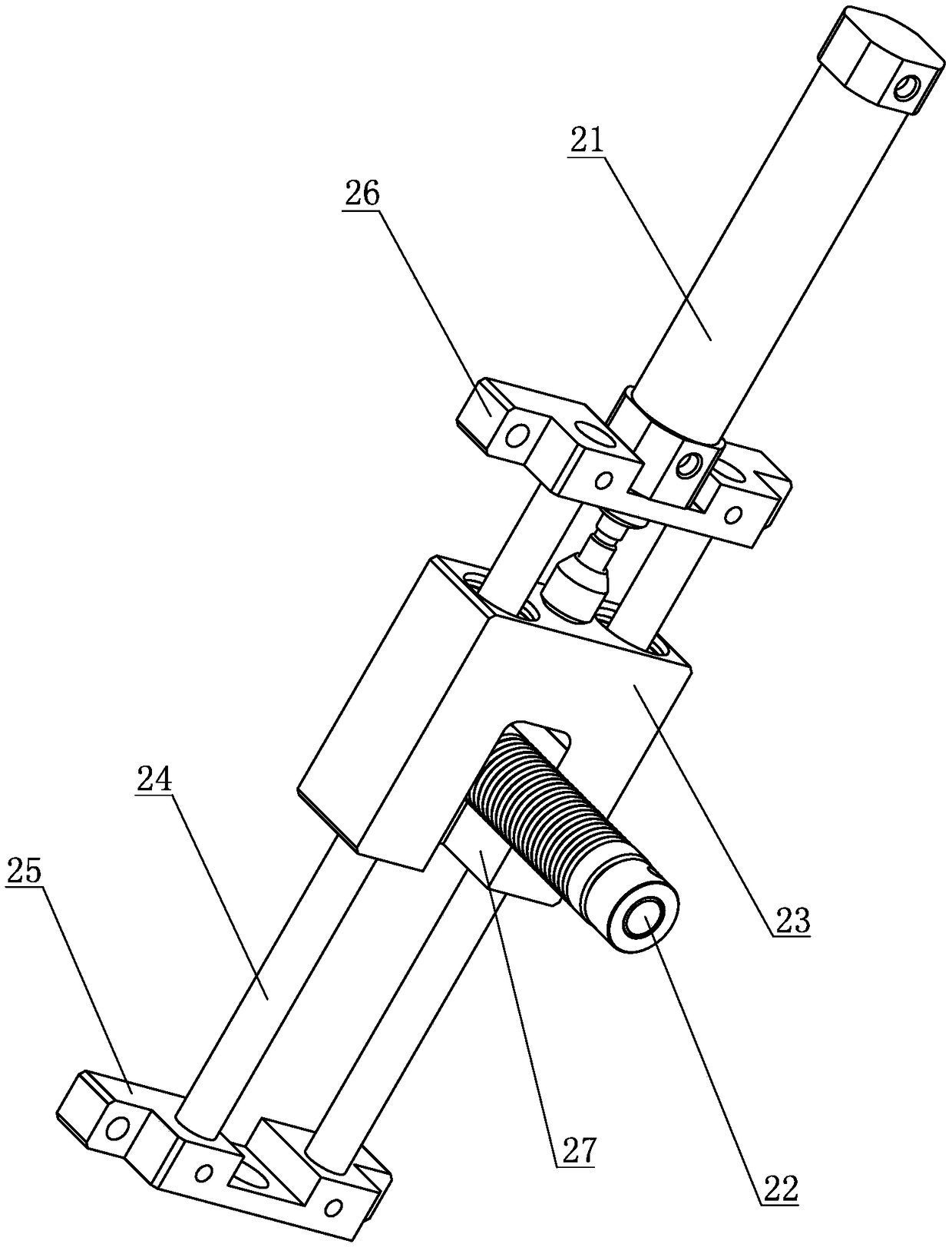

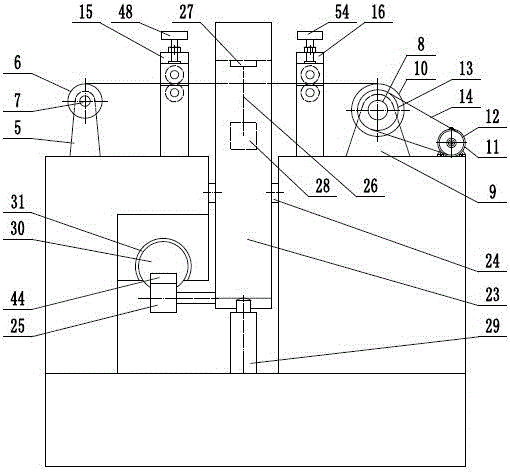

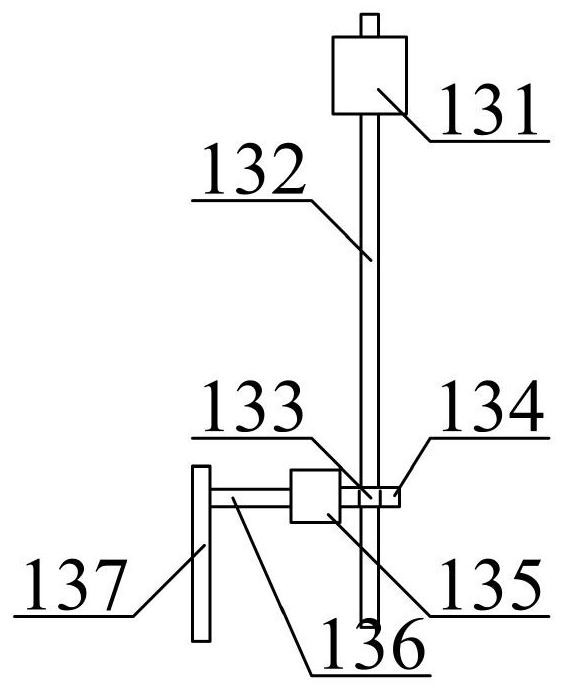

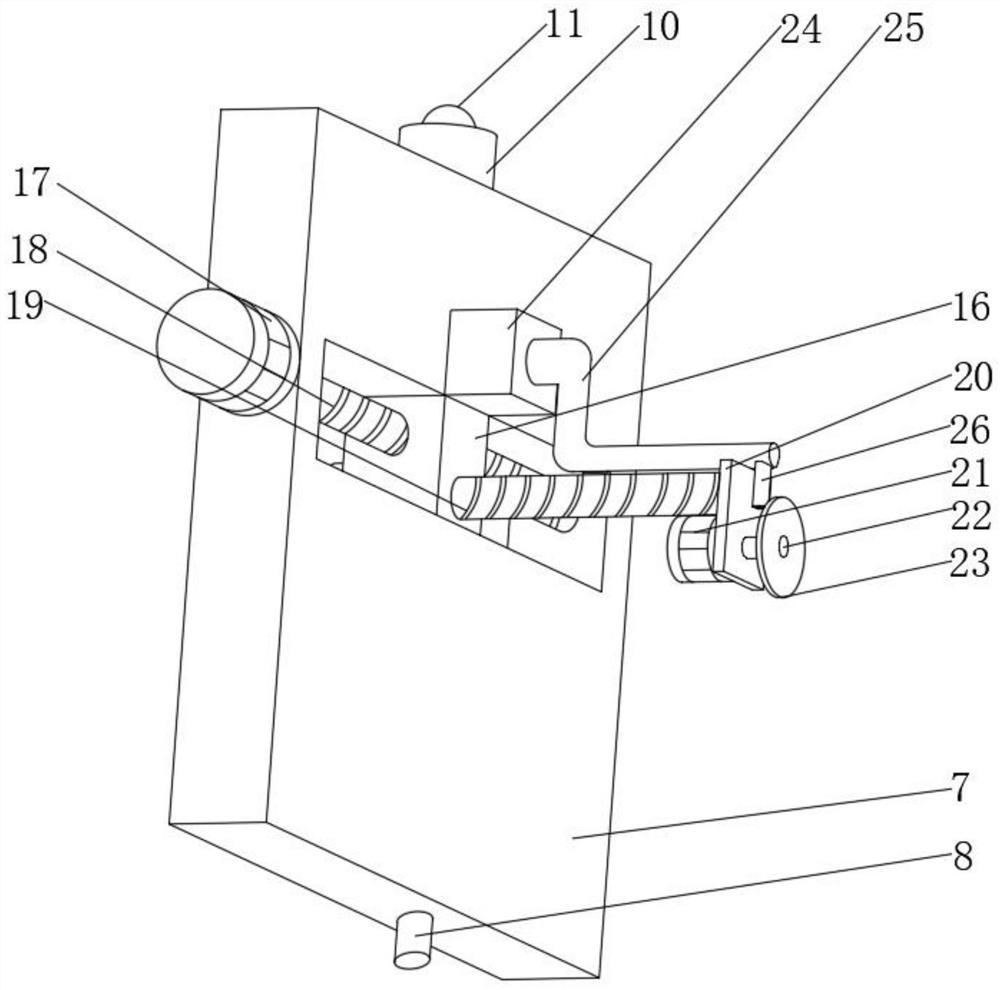

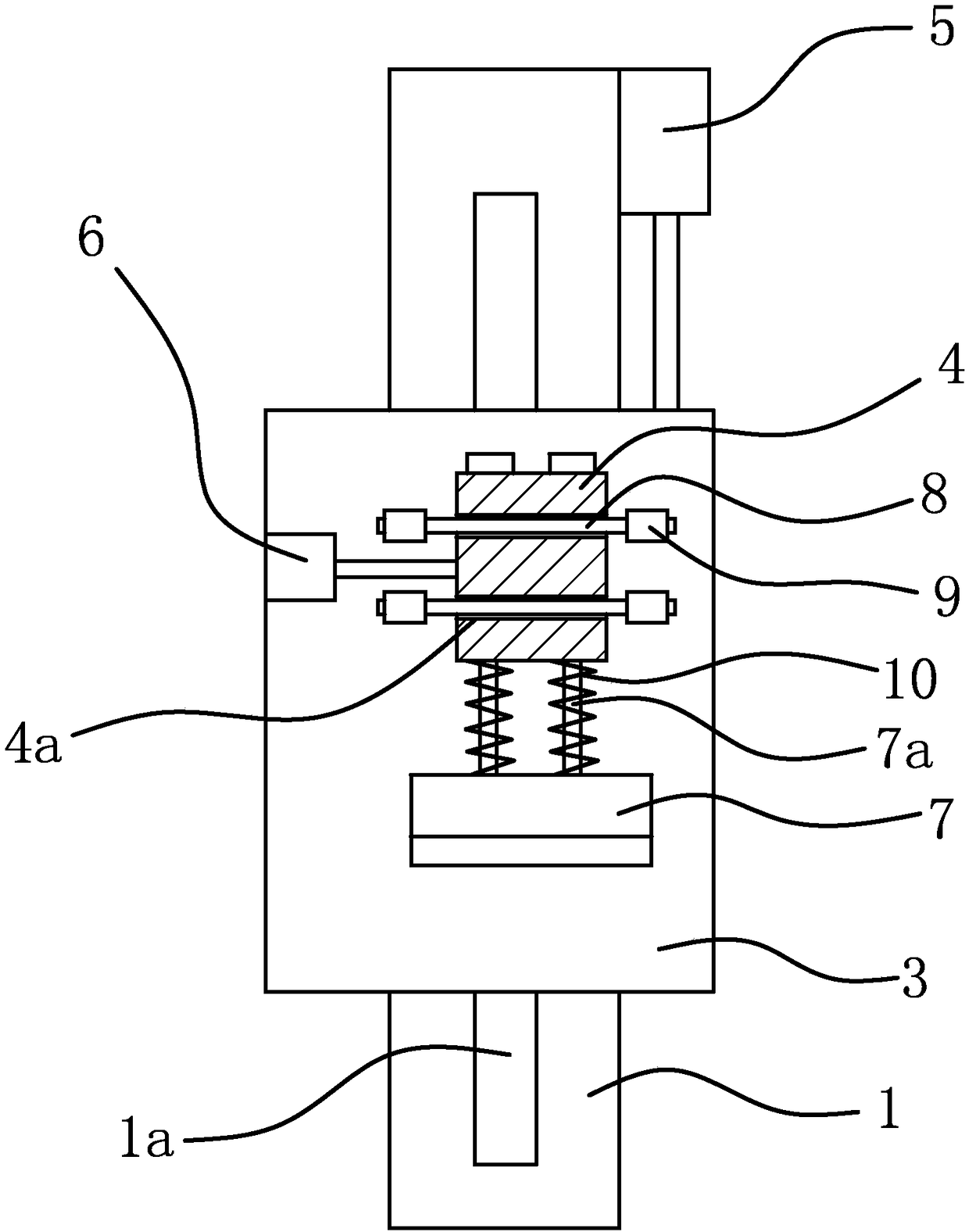

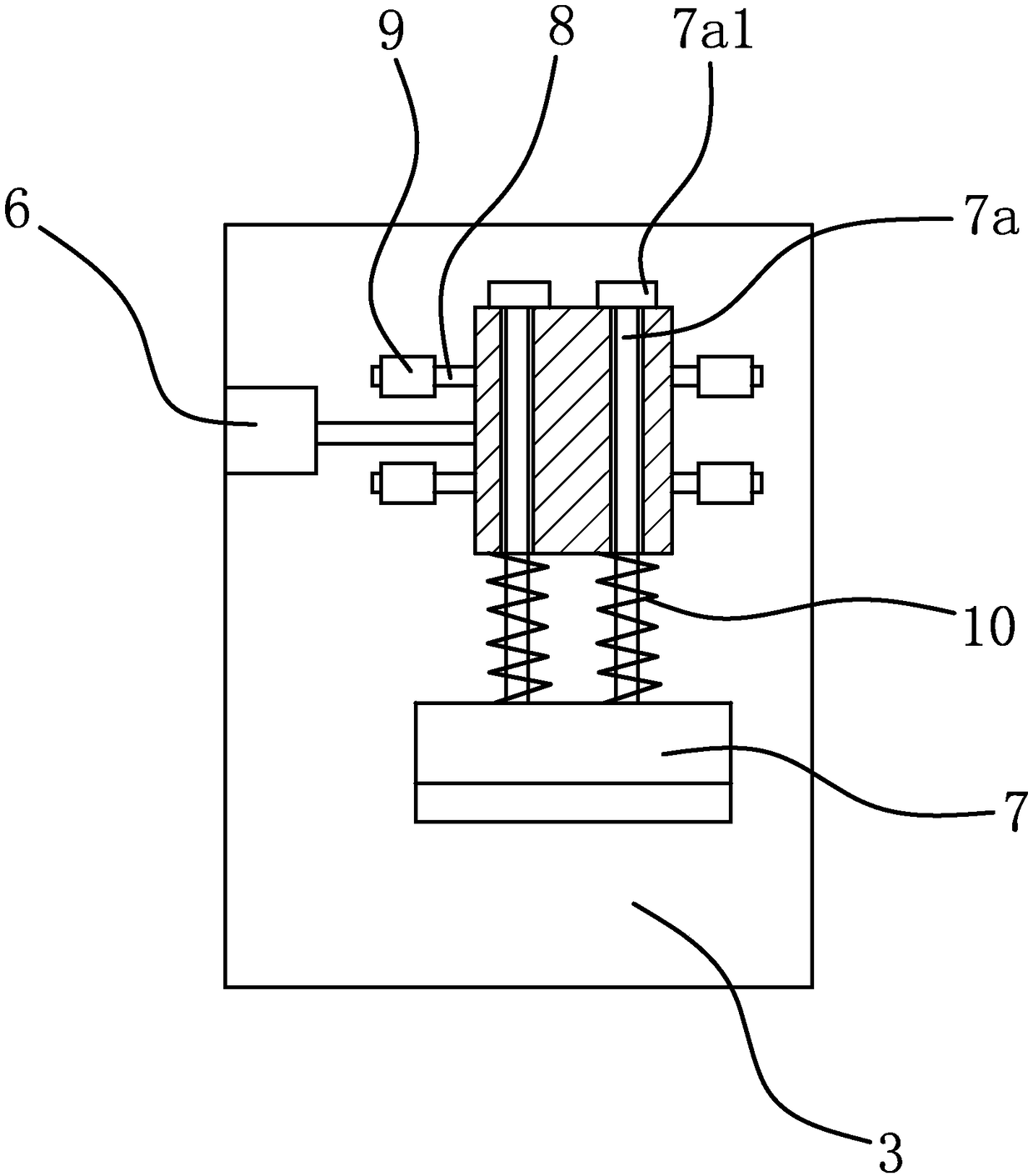

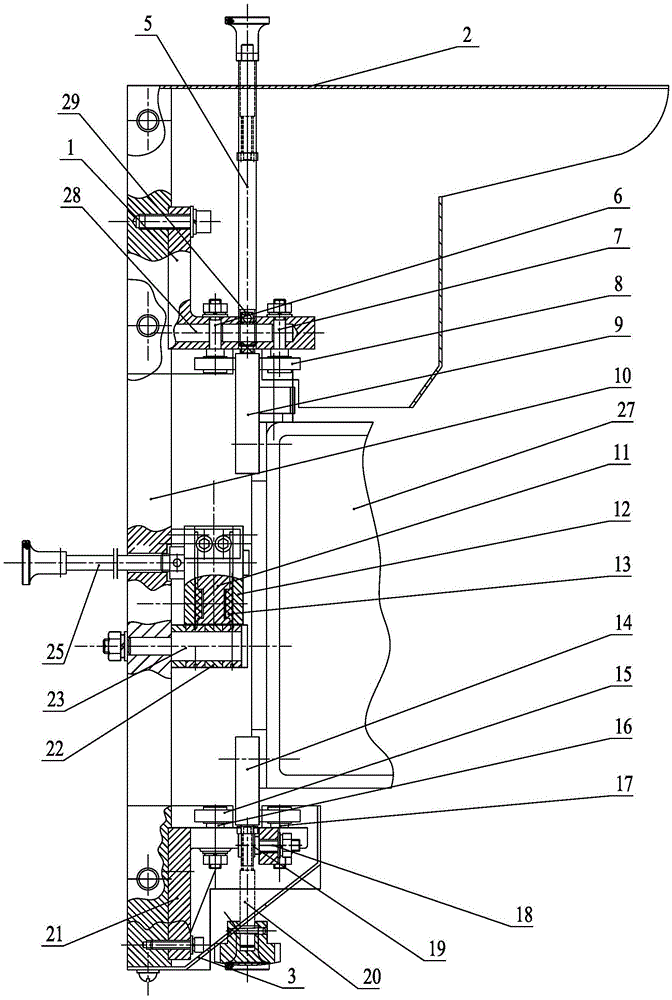

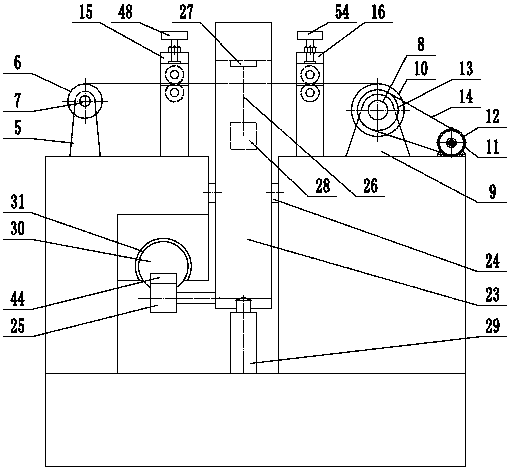

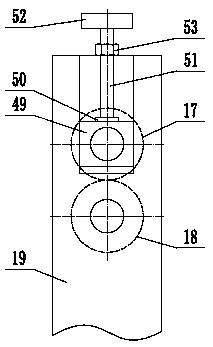

Tape applicator for battery cells

PendingCN109449498AImprove efficiencyQuality improvementFinal product manufactureElectrolyte accumulators manufactureEngineeringBattery cell

The present invention discloses a tape applicator for battery cells. The tape applicator comprises: a vertical plate, a tape tray, a tensioning mechanism, a tape clamping mechanism, a tape cutting mechanism, a tape stretching mechanism, a tape applying mechanism and a plurality of root drives. The tape disc is rotatably mounted on the top of the vertical plate; the tensioning mechanism is arrangedunder the tape tray; the tape clamping mechanism is arranged under the tensioning mechanism; the tape stretching mechanism is arranged directly under the left side of the tape clamping mechanism; theleft side of the vertical plate is provided with a cutting groove, and the cutting groove is arranged between the tape clamping mechanism and the tape stretching mechanism; the left side of the tapecutting mechanism is movably arranged in the cutting groove; the tape applying mechanism is installed under the tape clamping mechanism; and the left side of the tape applying mechanism is arranged between the tape clamping mechanism and the tape stretching mechanism. According to the technical scheme of the present invention, the efficiency and quality of applying the tape on the product can be improved.

Owner:KUNSHAN BOGUTE ELECTROMECHANICAL EQUIP

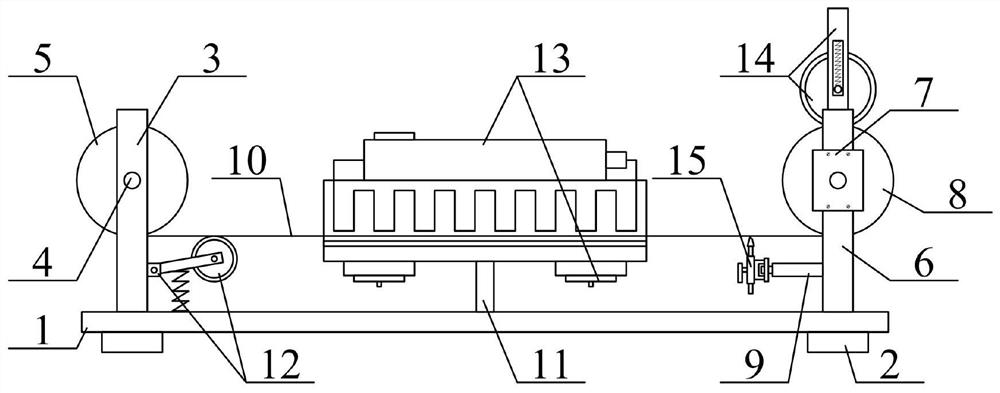

Swinging arm type advertisement paper cutting device

The invention provides a swinging arm type advertisement paper cutting device, and belongs to the technical field of cutting equipment. The swinging arm type advertisement paper cutting device comprises a cutting mechanism and a conveying mechanism, wherein an unrolling roller of the conveying mechanism is rotatablely arranged on an unrolling support frame; a coiling roller is rotatablely arranged on a coiling support frame; a swinging arm of the cutting mechanism is hinged onto the machine frame through a swinging arm pin shaft; the two ends of a cutting pulling wire are respectively arranged on a first wire pulling support seat and a second wire pulling support seat; a slide rod is arranged on a slide rod guide seat in a way capable of leftwards and rightwards sliding; a pressing jacking rod of the pressing assembly is always attached to a pressing platform arranged at the lower end of the swinging arm under the effect of a jacking rod press spring; a support rolling wheel arranged on the swinging arm is always attached to a wedge groove of the slide rod under the effect of the pressing jacking rod; the driving cam is rotatablely arranged on a cam support seat in an eccentric way through a cam shaft; the slide rod is always attached to a driving cam under the effect of a slide rod press spring. The swinging arm type advertisement paper cutting device has the advantages that the fast cutting on advertisement paper is realized; a cut edge is regular; the automation degree is high; the cutting efficiency is high; the reliability is high.

Owner:佛山市顺德区北滘镇千艺制版有限公司

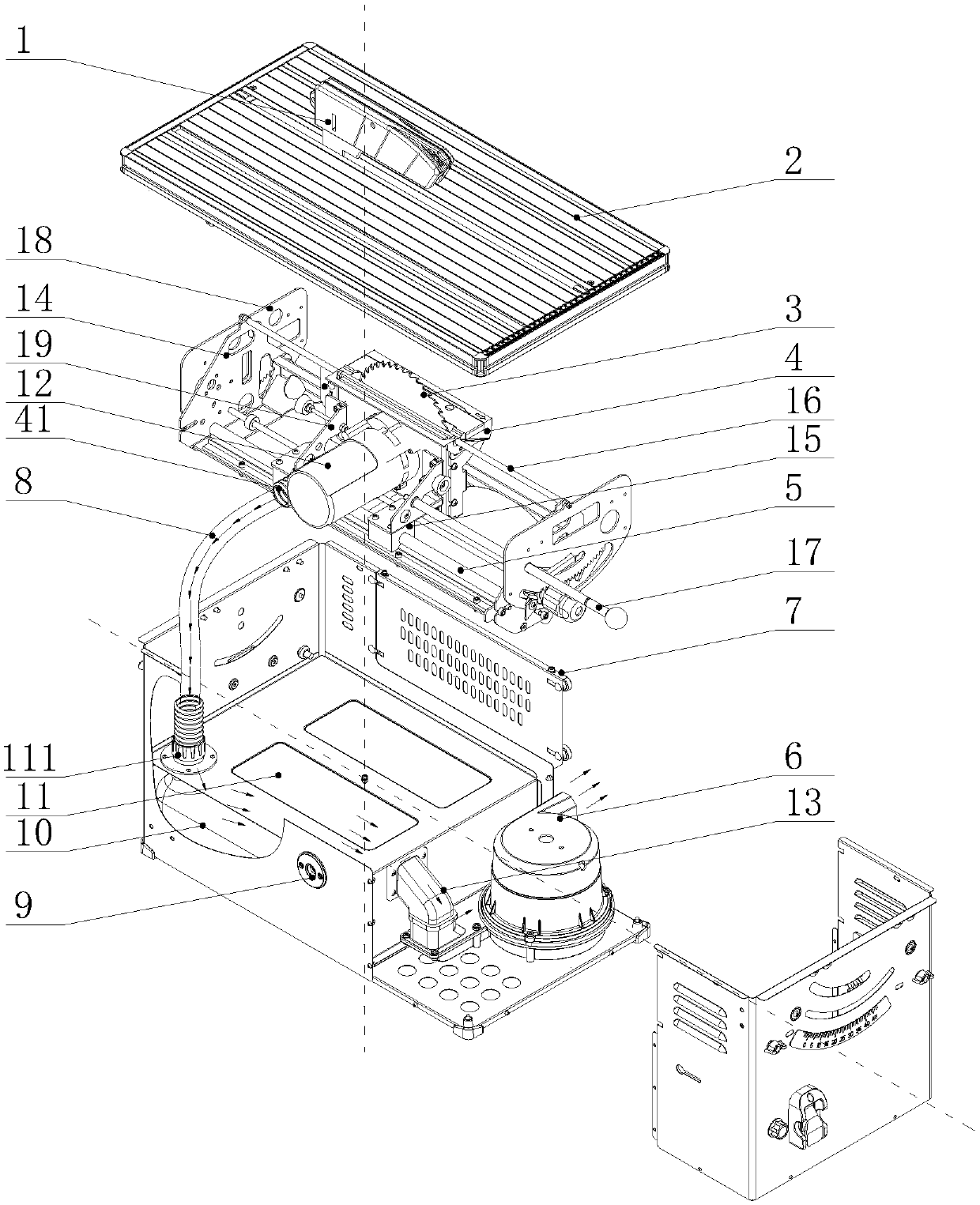

Pulling rod type bench saw with dust collection function

ActiveCN109605491AAdjustable tilt angle increasesMeet processing needsCircular sawsBark-zones/chip/dust/waste removalMechanical engineering

The invention discloses a pulling rod type bench saw with a dust collection function. The pulling rod type bench saw with the dust collection function comprises a workbench, a saw frame, a pulling rod, a saw blade and a motor used for driving the saw blade; the workbench is installed on the top of the saw frame and provided with a saw groove, and the upper portion of the saw blade penetrates through the saw groove and extends to the upper side of the workbench; a closed box is arranged on the portion, located at the saw groove, of the lower side of the workbench and arranged at the periphery of the lower portion of the saw blade, and a rotation shaft is arranged on the upper portion of the closed box and can rotate relative to the saw frame; a sliding mechanism is arranged on the closed box and drives the closed box to slide in the direction of being parallel to the rotation shaft through the pulling rod; the sliding mechanism, the closed box, the saw blade, the motor and the rotationshaft can synchronously rotate; and a dust collection mechanism is arranged on the saw frame and communicates with the closed box. According to the pulling rod type bench saw with the dust collectionfunction, the rotation shaft and the closed box are arranged, the closed box, the saw blade, the motor and the rotation shaft can synchronously rotate, therefore, the inclination angle of the adjustable saw blade is increased, and the dust collection effect is improved.

Owner:QINGDAO CHENBA IND & TRADE CO LTD

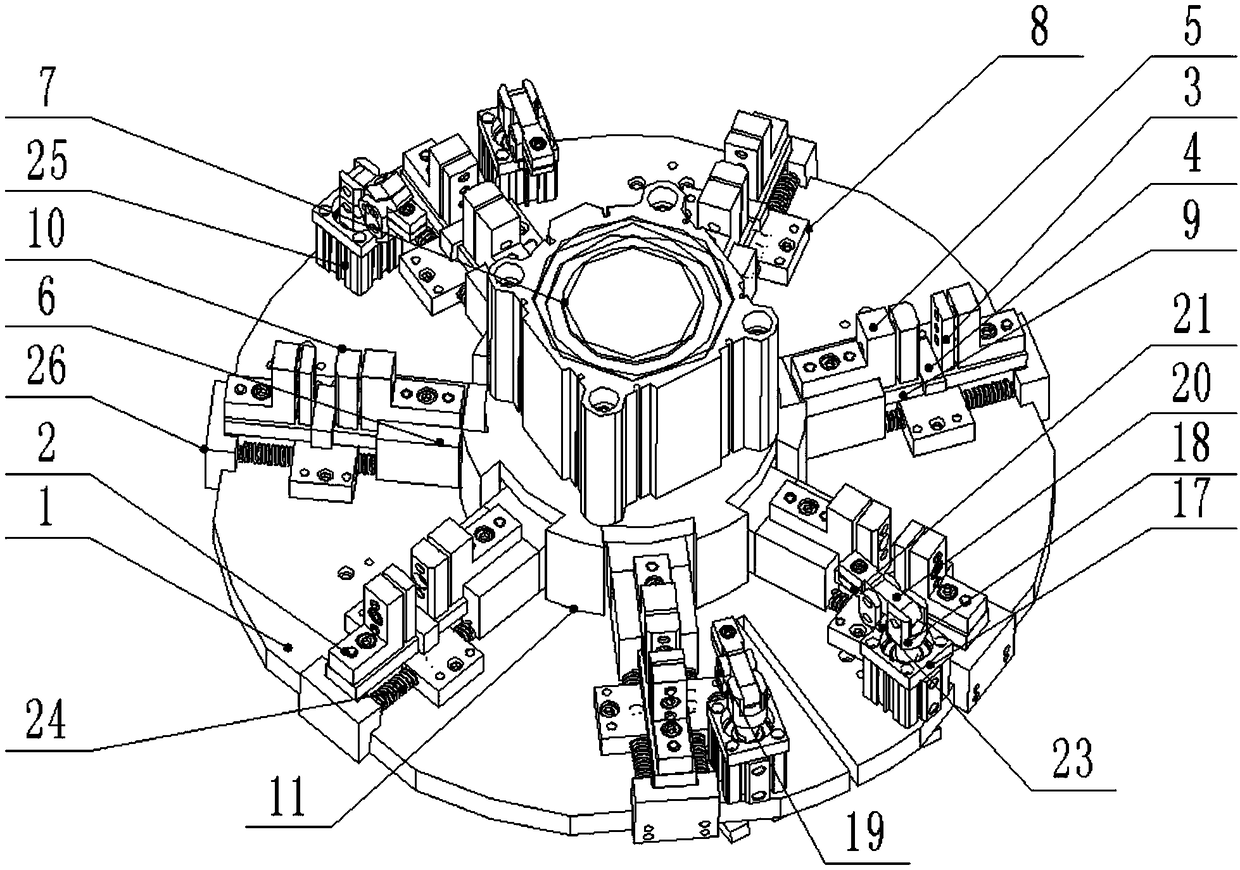

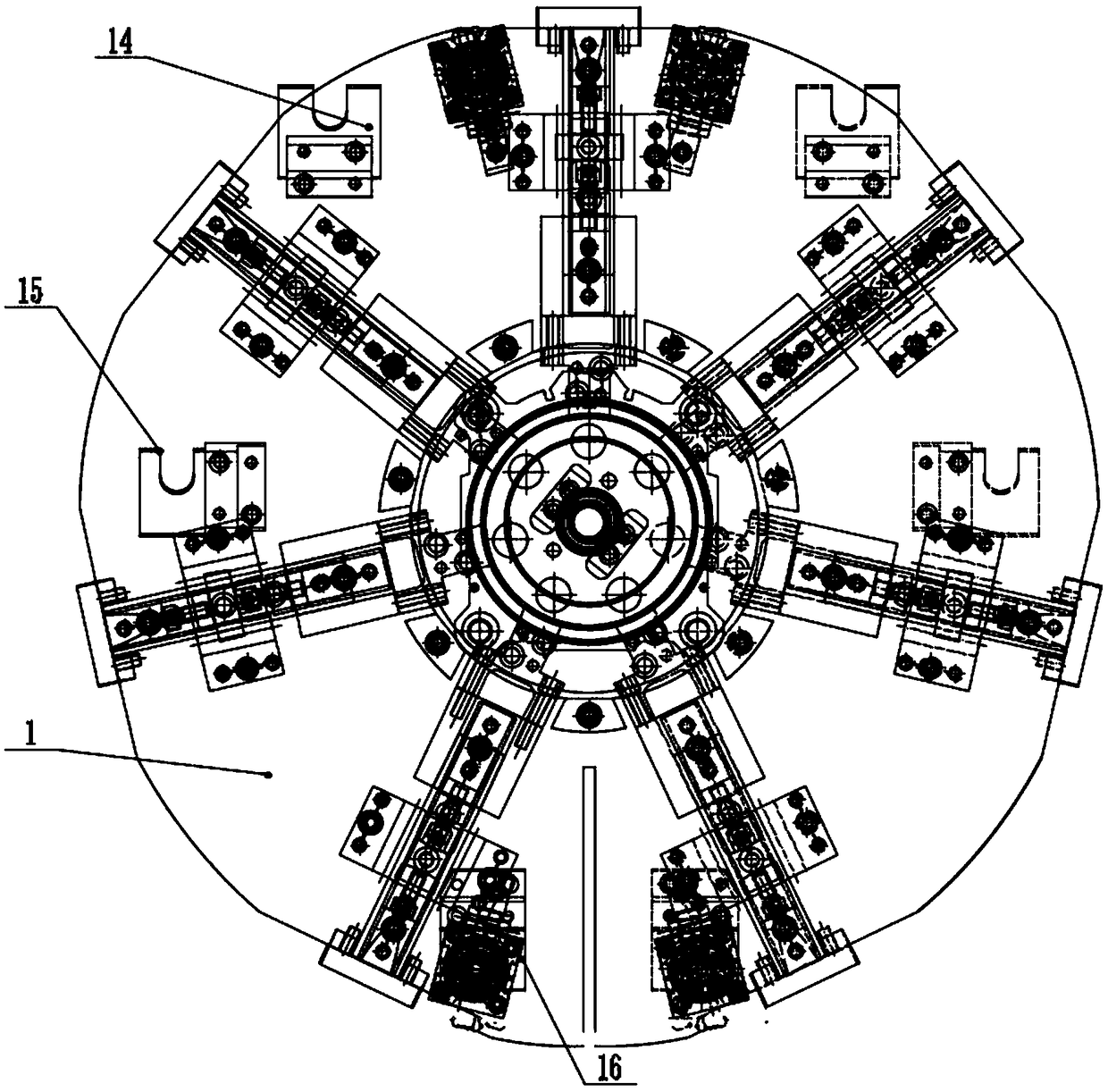

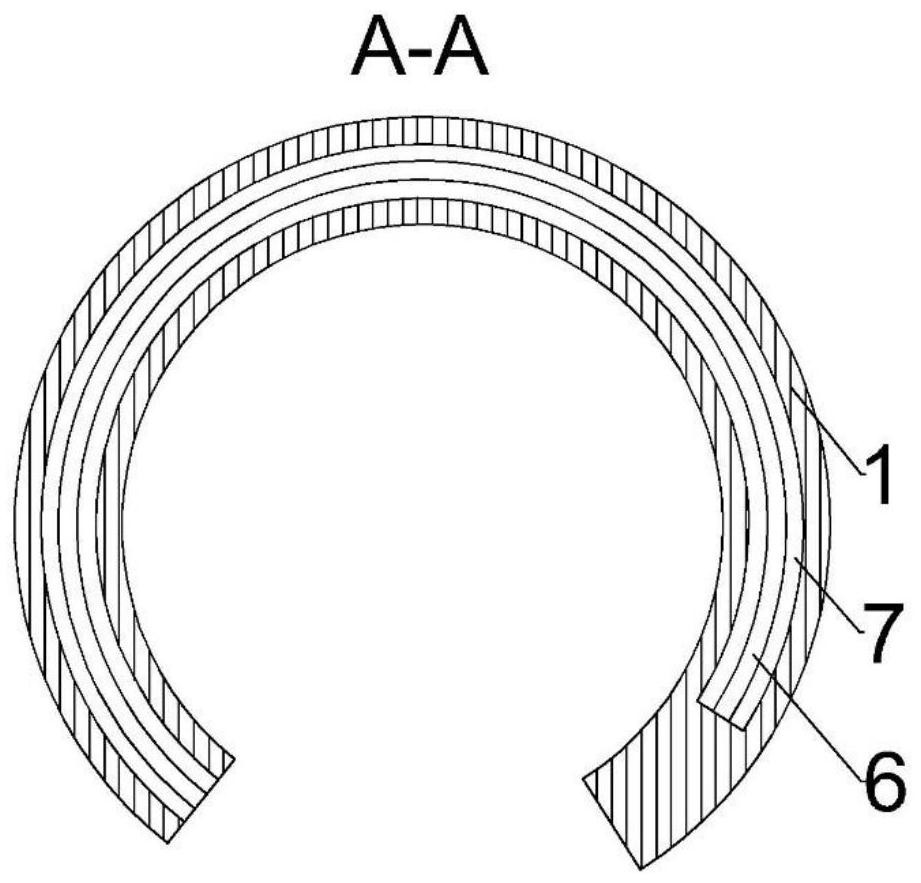

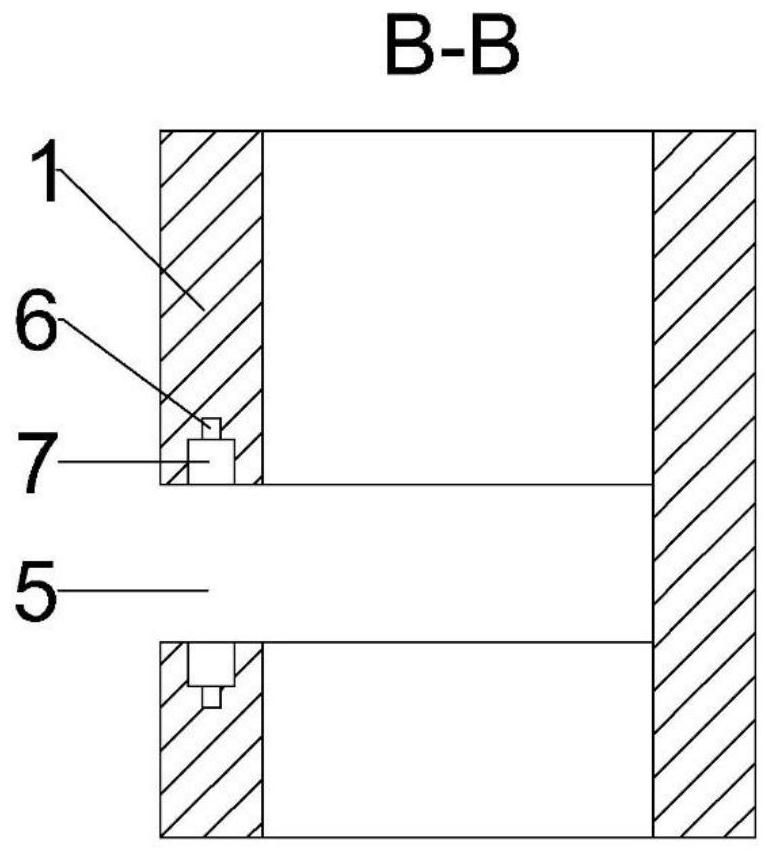

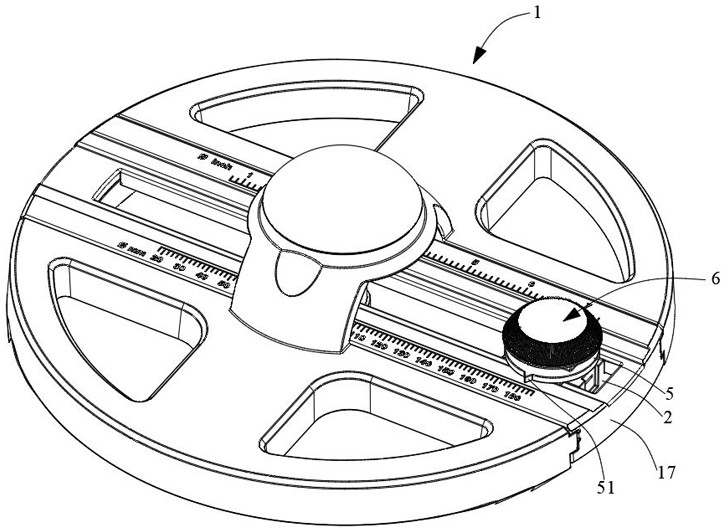

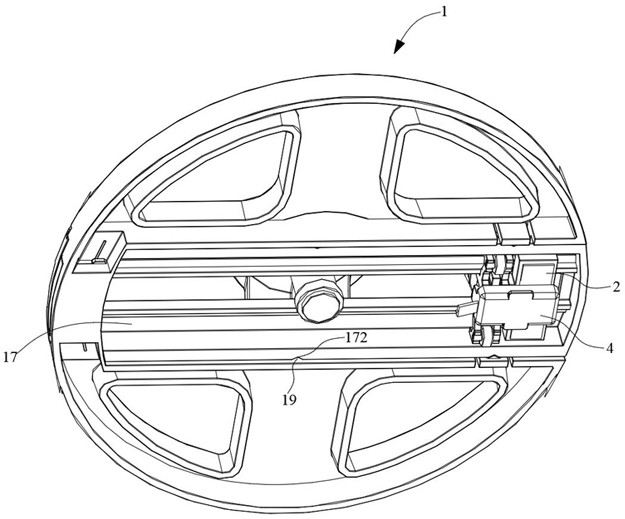

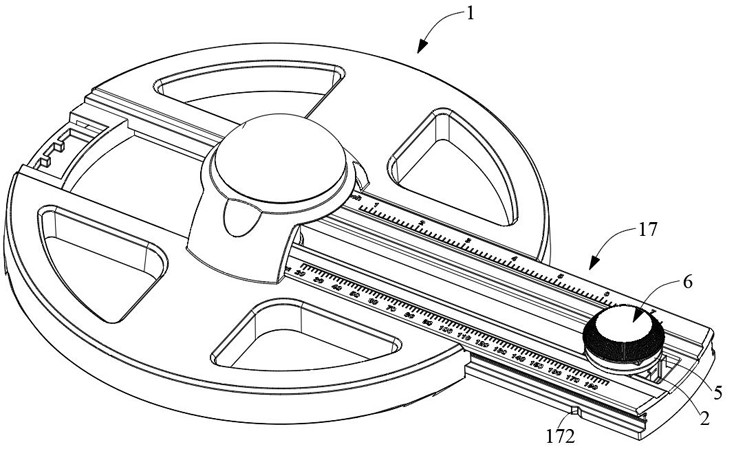

Cutting tool for steering wheel ring

InactiveCN108637753AEasy to operateEfficient productionWork clamping meansPositioning apparatusEngineeringEnergy consumption

The invention provides a cutting tool for a steering wheel ring. The cutting tool comprises a clamping cylinder and an end block; a bottom plate is of a disc structure and a step hole is formed in themiddle of the bottom plate; a first connection block is fixed to a sliding rail in a bolt connection mode, and a first limiting block is fixed to the inner side of the first connection block in a bolt connection mode; a second connection block is fixed to the top side of a sliding block in a bolt connection mode; a cylinder support is fixed to the top side of the bottom late in a bolt connectionmode; the clamping cylinder is connected to the top end of the cylinder support through bolts; and the sliding rail is arranged on the top side face of the end block, protrudes out towards the circlecenter of the bottom plate and is arranged on the bottom side of the sliding block. The cutting tool is convenient to operate, efficient in production and attractive in appearance, the dimension stability of the ring in the cutting process can be ensured, precision is improved to + / -0.5 mm, meanwhile, the phenomenon like a high degree of pollution in the cutting process of an abrasive wheel is avoided, the production work environment is greatly improved for workers in a workshop, the labor intensity of the workers is relieved, and energy consumption and cost are reduced.

Owner:十堰皓凡工贸有限公司

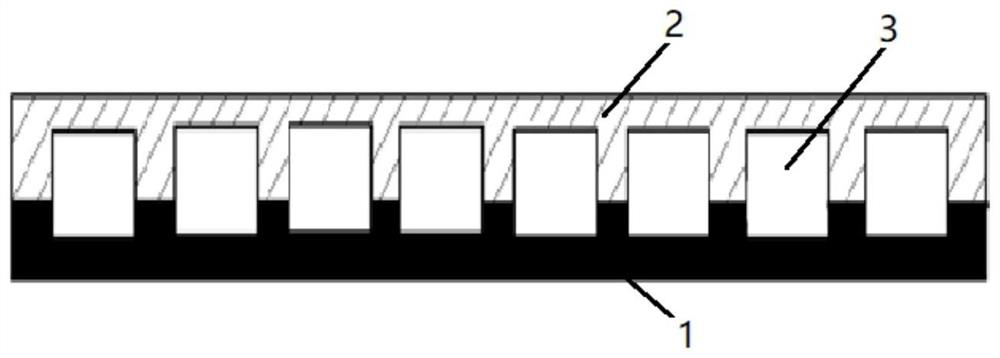

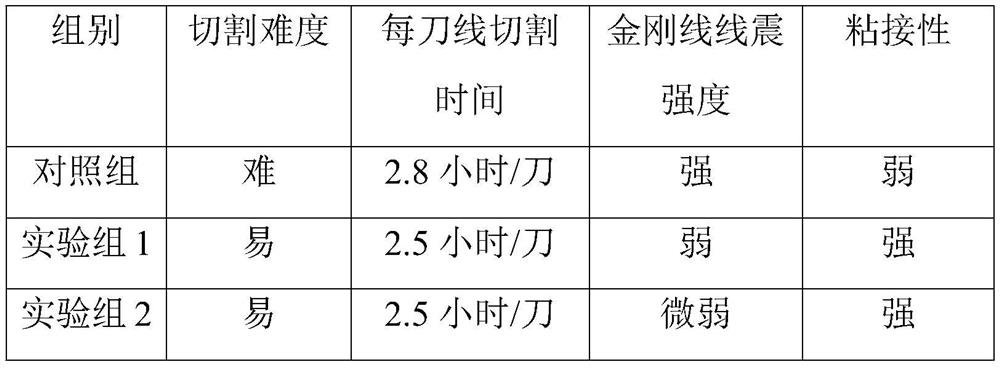

Easy-to-cut and easy-to-stick double-material hollow solar silicon wafer cutting lining plate and preparation method thereof

ActiveCN111746082AGuaranteed bonding performanceAdjust the formulaSynthetic resin layered productsWaferingWafer dicing

The embodiment of the invention discloses an easy-to-cut and easy-to-stick double-material hollow solar silicon wafer cutting lining plate and a preparation method thereof. The easy-to-cut and easy-to-adhere double-material hollow solar silicon wafer cutting lining plate comprises a surface layer B and a surface layer A arranged at the top of the surface layer B. A plurality of grooves B are evenly distributed in the surface layer B in the length direction, a plurality of grooves A corresponding to the grooves B are evenly distributed in the surface layer A, and the grooves B and the grooves Aare combined to form sealing through holes. In the easy-to-cut and easy-to-stick double-material hollow solar silicon wafer cutting lining plate provided by the invention, the surface layer A is madefrom self-lubricating cutting-resistant resin powder as a cutting regulator, so that the linear vibration is small, and the conditions of oblique cutting and wafer falling are not easy to occur. Thesurface layer B is made from mineral powder or metal powder as a bonding regulator, so that the bonding of the cutting lining plate and the crystal support can be effectively ensured, and rod fallingis avoided. According to the cutting lining plate, a double-material structure is innovatively adopted, the formula is easy to design and adjust, the surface layer A can better achieve the easy-to-cutperformance, and the cutting quality and stability are guaranteed.

Owner:江阴市嘉宇新材料有限公司

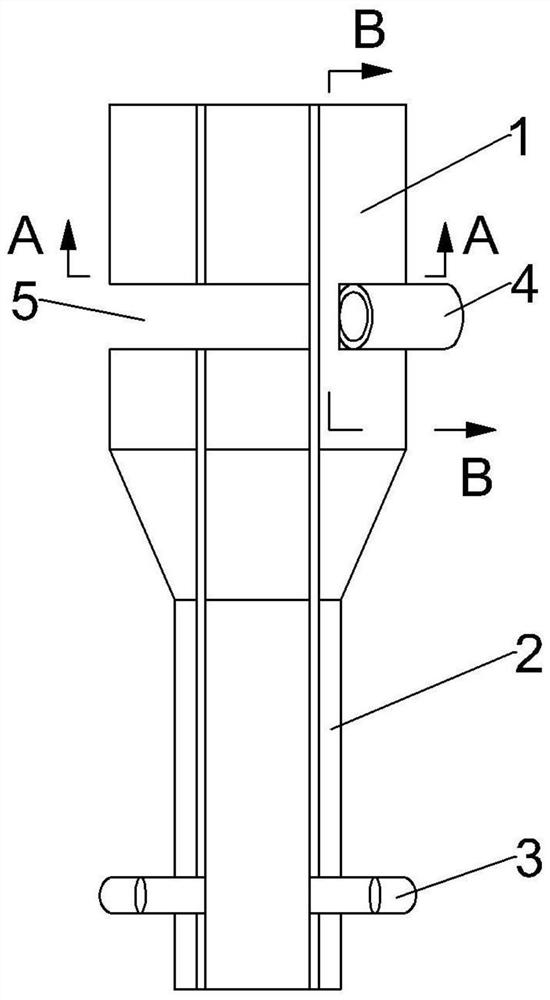

Intelligent electric spark cutting machine tool

PendingCN113020731AEasy to move aroundEasy to operateElectrical-based auxillary apparatusEngineeringElectric control

The invention provides an intelligent electric spark cutting machine tool. The intelligent electric spark cutting machine tool comprises a machine tool body, machine posts, moving caster wheels, an intelligent control screen, a draw bar, push-pull handles, a mounting base, an electric control box, a connecting rod, an electric spark cutting machine body and a cutting head, wherein the moving caster wheels are connected to the four corners of the bottom of the machine tool body; the intelligent control screen is connected to the left side of the front part of the machine tool body through screws; and the push-pull handles are mounted on the front part and the rear part of the left end of the machine tool body through the draw bar. According to the arrangement of a moving table, a support plate, a hollow-shaped sliding block, a linear sliding rail, a square head bolt and a fixed cushion block, a workpiece is arranged on the upper part of the machine tool body, the square head bolt is released according to cutting requirements, the hollow-shaped sliding block is movably adjusted to be located on the outer wall of the linear sliding rail, a cutting position is determined, and the square head bolt can be locked or unlocked, so that the cutting stability can be ensured, the cutting convenience is ensured, and the supporting stability is ensured through the moving table and the support plate.

Owner:济南新宇硬质合金股份有限公司

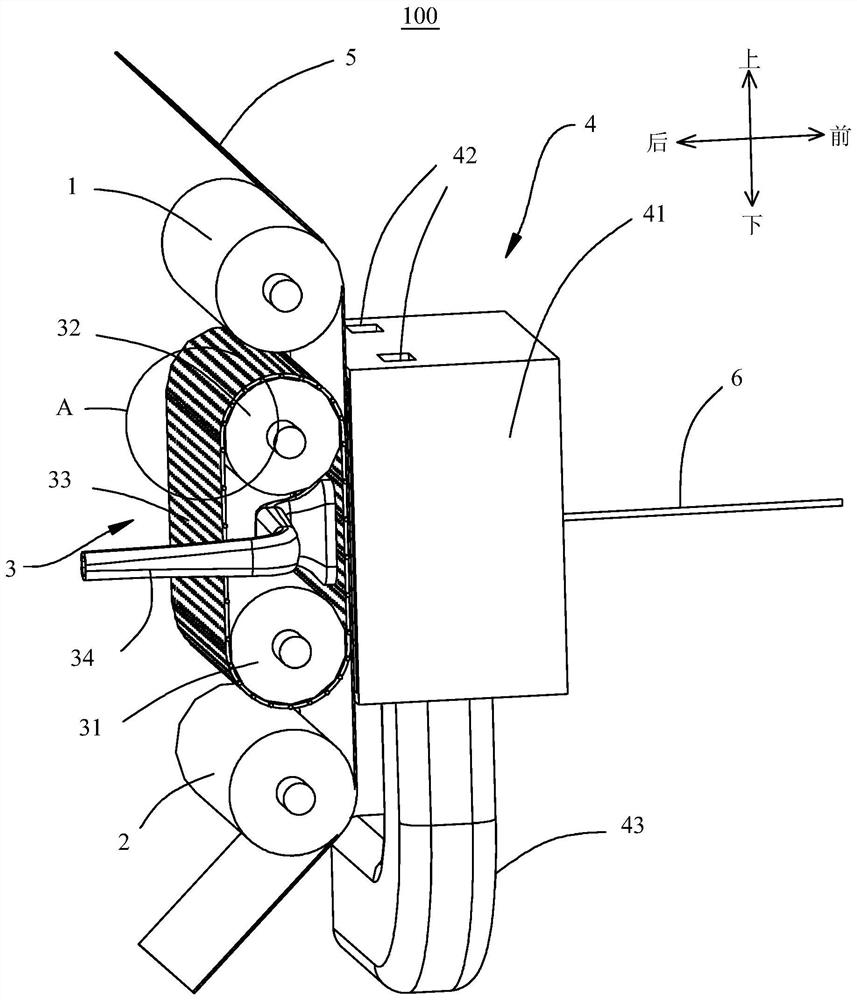

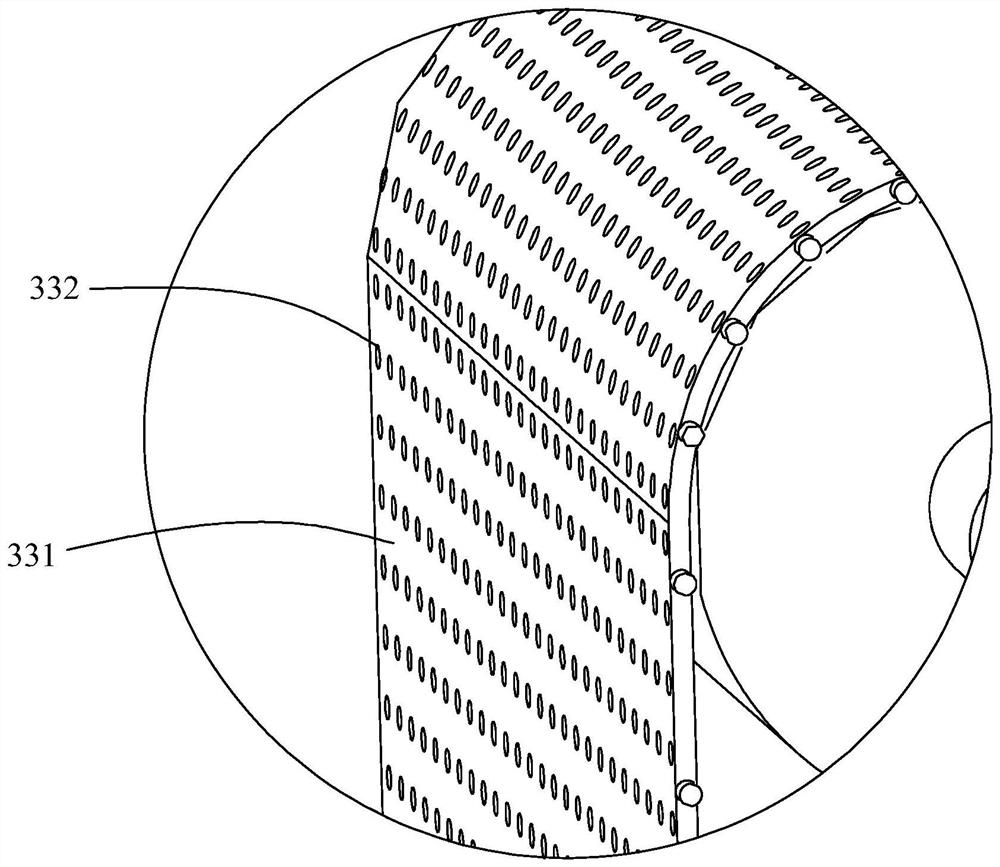

Laser cutting device

PendingCN111940920ATeleportation does not affectPlay a supporting roleMetal working apparatusLaser beam welding apparatusLaser cuttingMechanical engineering

The invention relates to a laser cutting device, and belongs to the technical field of laser cutting machinery. The laser cutting device comprises a first feeding roller and a second feeding roller which are used for conveying to-be-cut materials, and further comprises an anti-shaking mechanism which is arranged between the first feeding roller and the second feeding roller and comprises a drivingroller, a driven roller and a conveying belt, the driving roller, the driven roller, the first feeding roller and the second feeding roller are parallel to one another, the conveying belt is wound around the driving roller and the driven roller, and the conveying belt is used for synchronously moving with the to-be-cut materials and being attached to one side of the to-be-cut materials. Accordingto the laser cutting device, shaking of the to-be-cut materials during cutting can be overcome, and the cutting quality is improved.

Owner:GUANGDONG LYRIC ROBOT INTELLIGENT AUTOMATION CO LTD

Silica gel composite heat insulation plate and cutting equipment thereof

PendingCN113650131AEasy loading and unloadingImprove cutting adaptabilityCeramic shaping apparatusWorking accessoriesLaser cuttingSilicon oxide

The invention discloses a silica gel composite heat insulation plate and cutting equipment thereof, and relates to the technical field of laser cutting. The silica gel composite heat insulation plate comprises the following raw materials in percentage by weight: 55-60% of aluminum oxide, 5-7% of silicon dioxide, 1-2% of calcium oxide, 6-8% of zirconium oxide, 10-15% of high-alumina porcelain and 20-25% of high-alumina alum. According to the scheme, the prepared silica gel composite heat insulation plate is excellent in heat insulation performance, the silica gel composite heat insulation plate and laser cannot be directly broken down by the laser, and a support is prevented from being damaged; higher-strength sintering can be formed after high-temperature direct laser radiation, deformation and bending are avoided, and the protection effect is achieved; and after long-term use, a burning pit is formed on the surface, the pouring material can be normally used only by refilling the pouring material into the pit point, the replacement period is prolonged, the cost is reduced, and meanwhile, feeding and discharging are facilitated.

Owner:南通亿日自动设备有限公司

Laminating and cooling device for waterproof roll

PendingCN112659715AEasy to cleanEasy to operateLamination ancillary operationsLaminationElectric machineryEngineering

The invention provides a laminating and cooling device for a waterproof roll, which comprises a base, cushion blocks, an unwinding rack, a wheel shaft, an unwinding roller, a winding rack, a winding motor, a winding wheel, a support seat, a film material body and a support vertical seat, and the cushion blocks are in bolted connection with the four corners of the bottom of the base; the longitudinally-arranged unwinding rack is connected to the upper left side of the machine base through bolts. A wheel shaft is connected to a bearing on the middle upper side in the unwinding rack; the outer wall of the wheel shaft is in sliding key connection with an unwinding roller. Through the arrangement of the cleaning layer, the cleaning wheel body, the connecting shaft, the buffer frame, the mounting base and the supporting spring, dust on the surface of the film material body can be cleaned, operation is convenient, and when the film material body is released from the outer wall of the unwinding roller, dust can be cleaned through the cleaning layer on the surface of the cleaning wheel body; the buffer frame is driven by the supporting spring to act in the mounting base, the buffer cleaning stability can be guaranteed, and then the cleaning cleanliness is guaranteed.

Owner:朗行防水科技集团有限公司

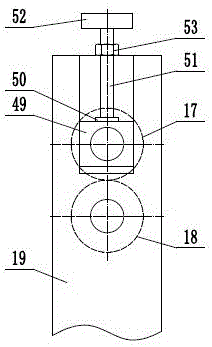

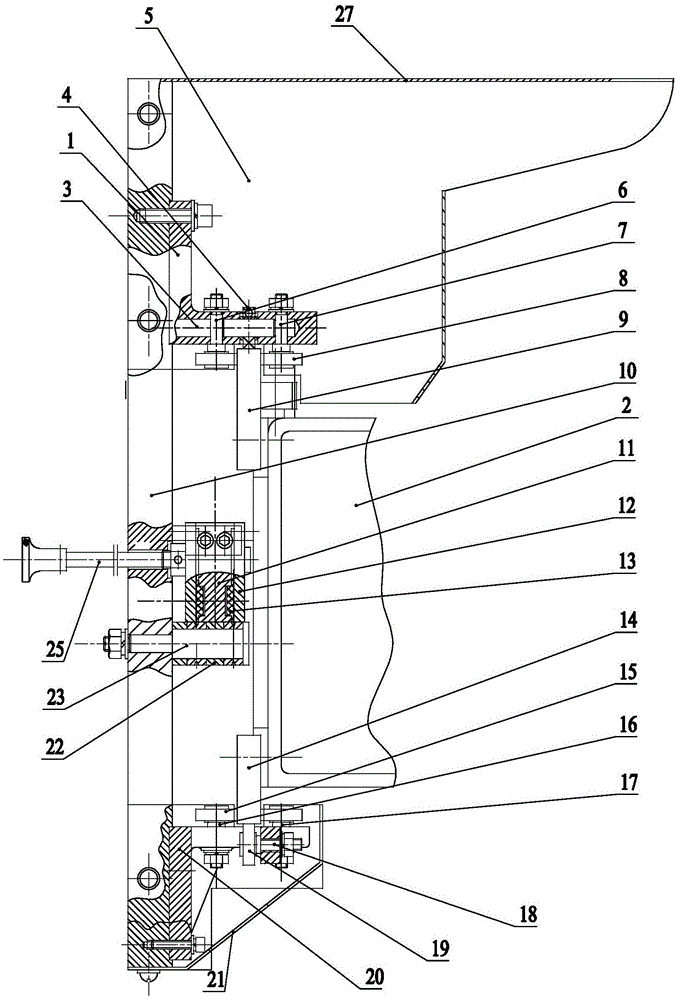

Line cutting device for sewing machine

InactiveCN107587277AAchieve closerEnsure quality stabilityNeedle severing devicesEngineeringElectromagnet

The invention provides a line cutting device for a sewing machine and capable of cutting sewing lines stably for a long time. The line cutting device comprises a line cutting assembly and a line hooking assembly; the line cutting assembly comprises a hot line cutting blade and an electric heater, the electric heater is arranged on the rear end of the hot line cutting blade; the line hooking assembly consists of a sliding rail, a sliding track, an electromagnet controller, an electromagnet, a reset spring, an actuation end and a line hooking hanger; the electromagnet controller is arranged on asewing machine platform, an electromagnet is arranged on the electromagnet controller, the sliding track is arranged on the front end of the electromagnet controller, a chute is formed in the upper surface of the sliding track, the sliding rail is arranged in the chute in a sliding manner, the actuation end is arranged on one end, close to the electromagnet controller, of the sliding rail, and isa magnet for attracting together with the electromagnet; and the reset spring is further arranged on the end of the actuation end; and a line hooking hanger is arranged on the front end of the sliding rail.

Owner:ZHAOQING CITY HI TECH ZONE XIAOJING TECH CO LTD

Rapid and practical cross pollination castration device and method

The invention provides a rapid and practical cross pollination castration device and method. The device comprises a first main body, one end of the first main body is fixedly connected with a second main body, the outer side wall of the first main body is provided with a cutting unit, and the outer side wall of the second main body is fixedly connected with an auxiliary support; the sections of the first main body and the second main body are of C-shaped structures correspondingly, and the first main body communicates with the second main body; and the cutting unit comprises a cutting channel formed in the outer side wall of the first main body, a cutting body is slidably connected into the cutting channel, and a sliding groove structure is formed in the end face of the cutting channel. According to the rapid and practical cross pollination castration device and method, stamens, pollen and petals can be accurately, cleanly and thoroughly removed, so that pistils are exposed without being damaged, and the working efficiency can be significantly improved.

Owner:广东和利农生物种业股份有限公司 +1

Video retrieval cognitive chip integrated electric plate cutting equipment

InactiveCN112476556AImprove yieldAvoid wastingMetal working apparatusVideo retrievalElectric machinery

The invention discloses video retrieval cognitive chip integrated electric plate cutting equipment. The equipment comprises a base; four supporting columns are fixedly installed at on the portions, close to the edges, on the upper surface of the base; the upper ends of the supporting columns are fixedly connected with a workbench; a first motor is fixedly installed between the middle positions ofthe base and the workbench; a first rotating shaft penetrating through the workbench is installed at the output end of the first motor; and a rotating rod is fixedly connected to the portion, close tothe top end, on the outer side surface of the first rotating shaft. According to the equipment, the material waste caused by the position deviation of an integrated electric plate in the cutting process can be avoided, the cutting stability of the cutting equipment is ensured, the yield of the integrated electric plate is improved, the automation degree is high, the convenient adjusting functionis realized, the working efficiency of the cutting equipment is improved, the blockage of chips on the reciprocating cutting process of a cutting wafer can be avoided, and meanwhile, large electric plates dropped by cutting can be collected so as to be recycled, so that good cleaning effect is achieved.

Owner:安徽速彩电子科技有限公司

Cutting device of leather

InactiveCN108517380ASteady againstGuaranteed cutting stabilityLeather clicking/perforating/clickingSkins/hides/leather/fur manufacturing apparatusMechanical engineering

The invention provides a cutting device of leather, belongs to the technical field of machinery, and solves the problem of low stability in the prior art. The cutting device of leather is fixedly connected to a rack and positioned at the upper part of a conveying channel and comprises a fixing plate, a sliding block, a driving part I, a driving part II and a cutter, wherein the driving part I is fixedly connected to the rack and is connected with the fixing plate; the driving part I can drive the fixing plate to horizontally move up and down; a guide structure capable of enabling the sliding block to horizontally move is arranged between the sliding block and the fixing plate; the driving part II is fixedly connected to the fixing plate and is connected with the sliding block; and the cutter is positioned between the sliding block and the conveying channel and is connected with the sliding block. The cutting device of leather is high in stability.

Owner:海宁金麒麟时装有限公司

Machine element clamping equipment with cutting function

InactiveCN112372067AEasy to fixEasy to cutMetal sawing devicesMetal sawing accessoriesPhysicsDrive motor

The invention relates to the field of machining, in particular to machine element clamping equipment with a cutting function. The clamping equipment comprises a workbench, wherein the workbench is provided with a fixing structure; the fixing structure comprises a cross-shaped sliding groove, a cross-shaped sliding plate, a middle arc-shaped clamping plate, an outer side arc-shaped clamping plate,a connecting plate, a threaded rod, a driven gear ring, a rotating motor and a Z-shaped supporting plate, wherein the Z-shaped supporting plate is provided with the rotating motor, the rotating motoris provided with a driving gear ring, the driving gear ring is provided with the driven gear ring, the driven gear ring is provided with the threaded rod, the threaded rod is provided with a U-shapedplate, the U-shaped plate is provided with the cross-shaped sliding plate, and the cross-shaped sliding plate is provided with the middle arc-shaped clamping plate; and the workbench is provided withthe connecting plate, the connecting plate is provided with the outer side arc-shaped clamping plate which is attached to the side wall of the middle arc-shaped clamping plate and is slidably connected with the same, the workbench is provided with the cross-shaped sliding groove, and the workbench is provided with a mounting bottom plate; and the mounting bottom plate is provided with a supportingframe, the supporting frame is provided with an air cylinder, the air cylinder is provided with a mounting frame, the mounting frame is provided with a driving motor, and the driving motor is provided with a cutting disc. According to the equipment, a pipe of a machine element can be conveniently fixed, and cutting is facilitated.

Owner:YANTAI ENG & TECH COLLEGE YANTAI TECHNICIAN INST

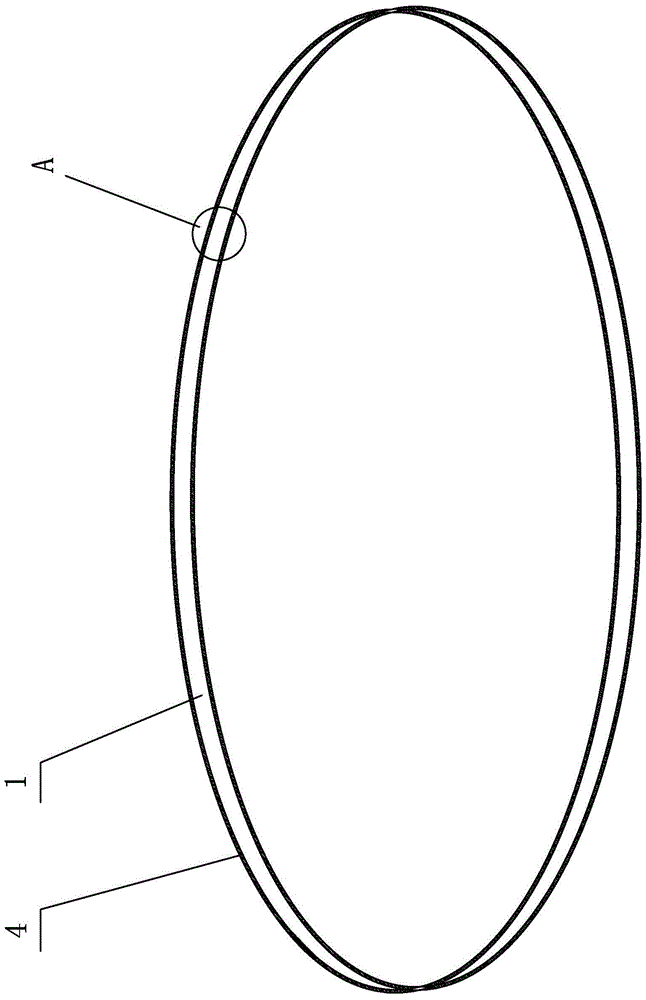

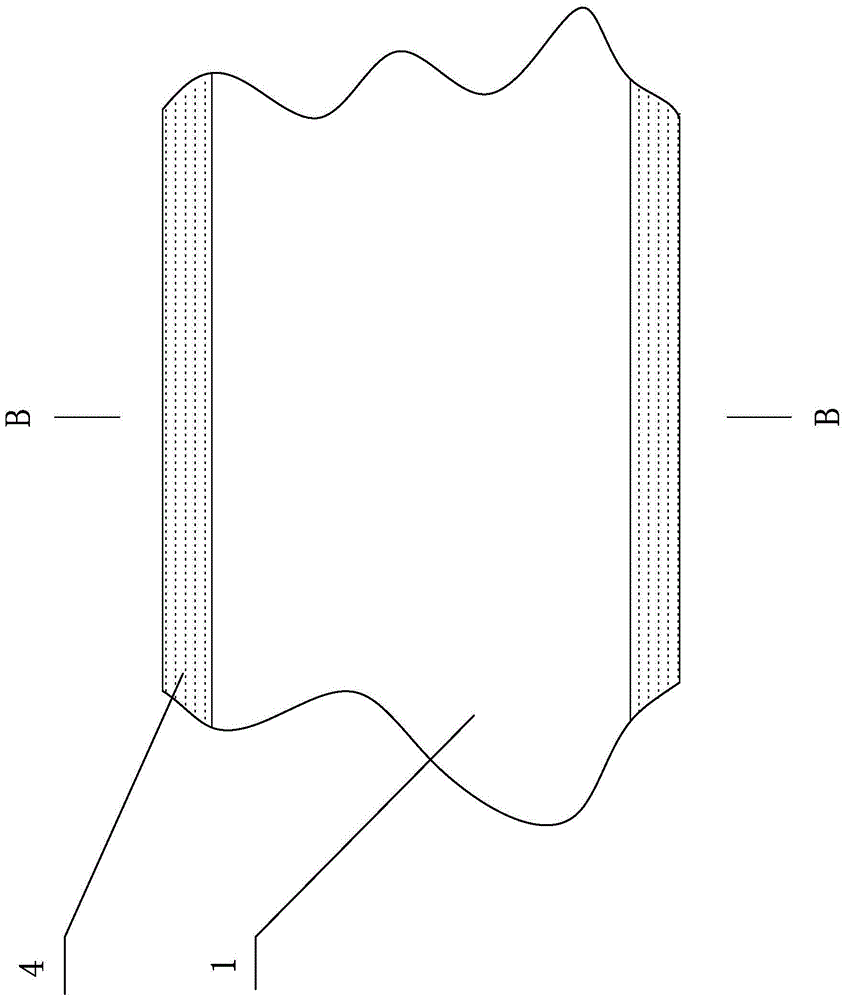

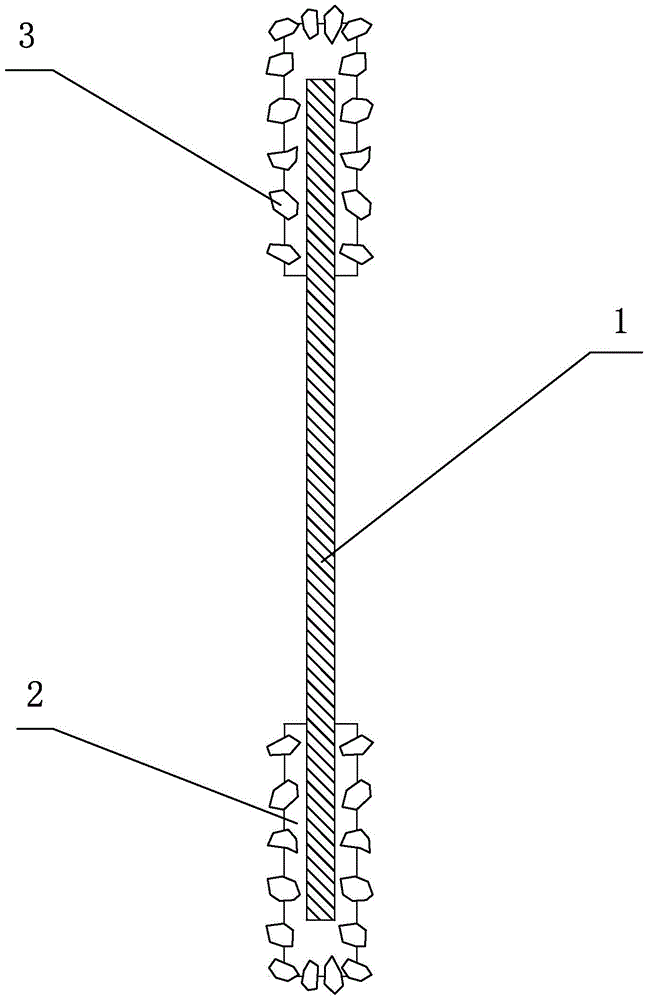

Circular diamond double-edged band saw and manufacturing method thereof

ActiveCN104210038BReduce mistakesGuaranteed stabilityElectrolytic coatingsMetal sawing tool makingWire cuttingCircular surface

Owner:CHINA NONFERROUS METAL (GUILIN) GEOLOGY & MINING CO LTD

Cutting device for building

InactiveCN112428454AAvoid shakingGuaranteed cutting stabilityWorking accessoriesStone-like material working toolsArchitectural engineeringCentrifugal force

The invention discloses a cutting device for a building. The cutting device comprises an outer supporting frame, a guide inclined plate is fixedly connected to the middle of the outer supporting frame, elastic sleeve rods are fixedly connected to the front end and the rear end of the left side of the outer supporting frame and located above the guide inclined plate, adjusting inserting rods are connected into the elastic sleeve rods in a penetrating and sliding mode, movable clamping plates are fixedly connected to the ends, located on the inner side of the outer supporting frame, of the adjusting inserting rods, limiting pulleys are evenly and rotationally connected into the movable clamping plates at equal intervals, adjusting clamping plates are rotationally connected to the ends, located on the inner side of the outer supporting frame, of adjusting threaded rods, limiting pressing mechanisms are symmetrically and fixedly connected to the positions close to the back faces of the movable clamping plates, and a cutting driving mechanism is rotatably connected to the interior of a cutting through groove. The invention relates to the technical field of buildings. According to the cutting device for the building, active feeding is achieved through the gravity of ceramic tiles, meanwhile, the cutting centrifugal force direction is perpendicular to the ceramic tile feeding moving direction, the ceramic tiles are prevented from shaking under the influence of multi-angle force, and cutting stability is guaranteed.

Owner:李良容

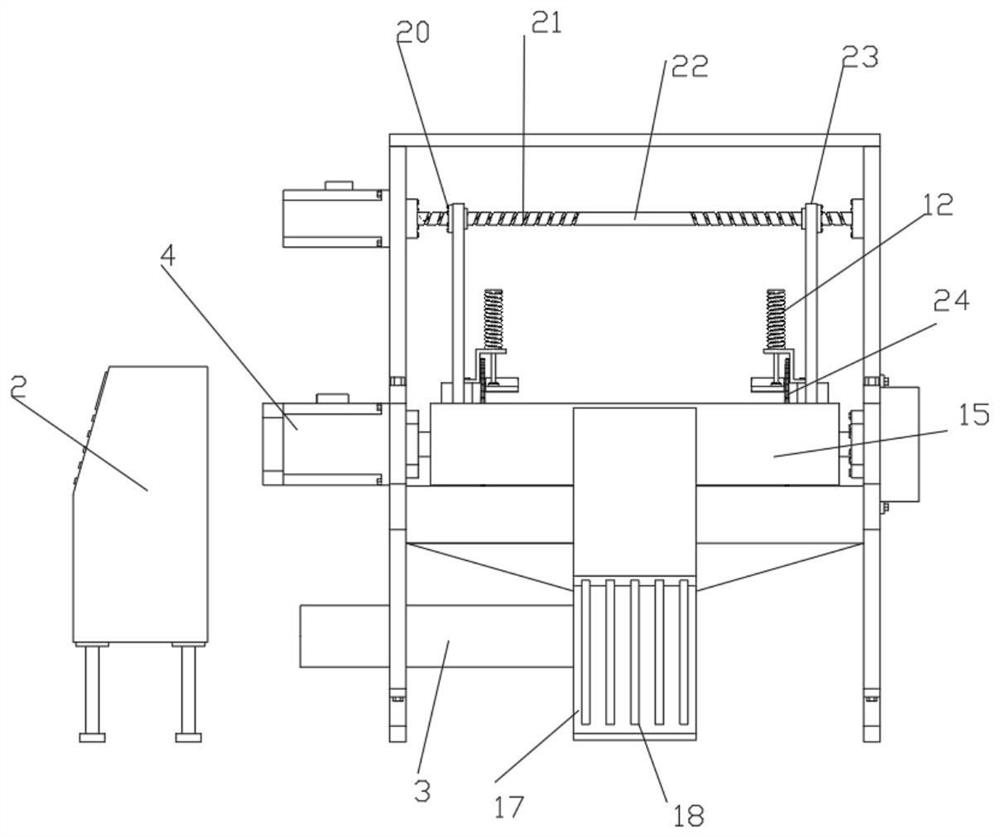

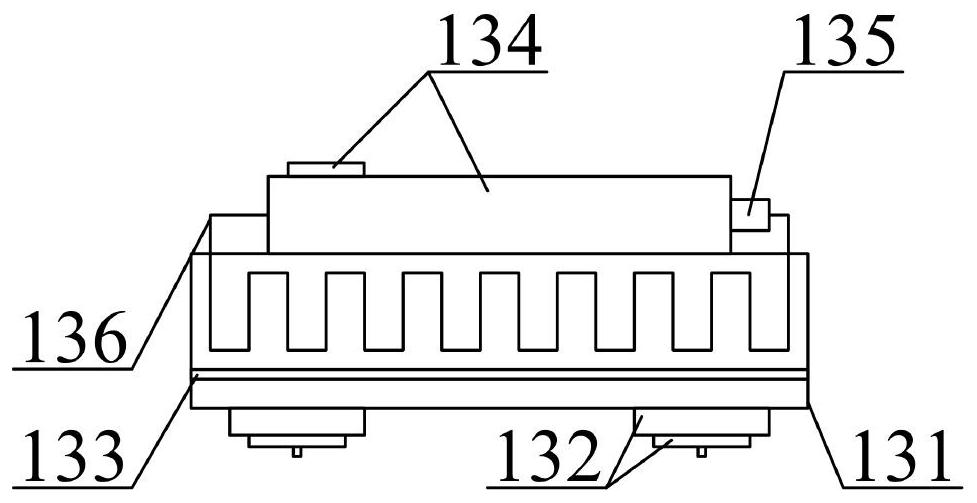

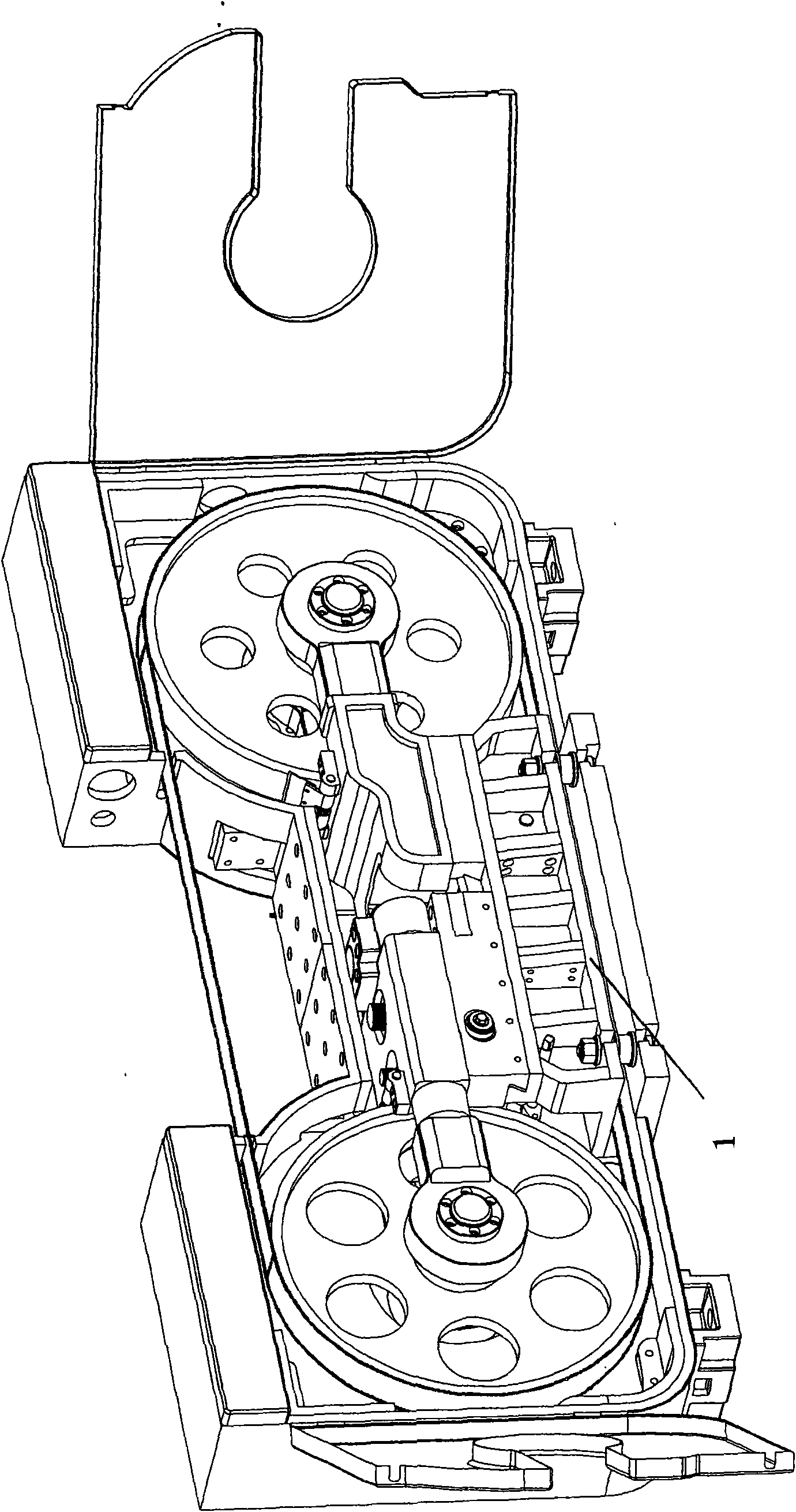

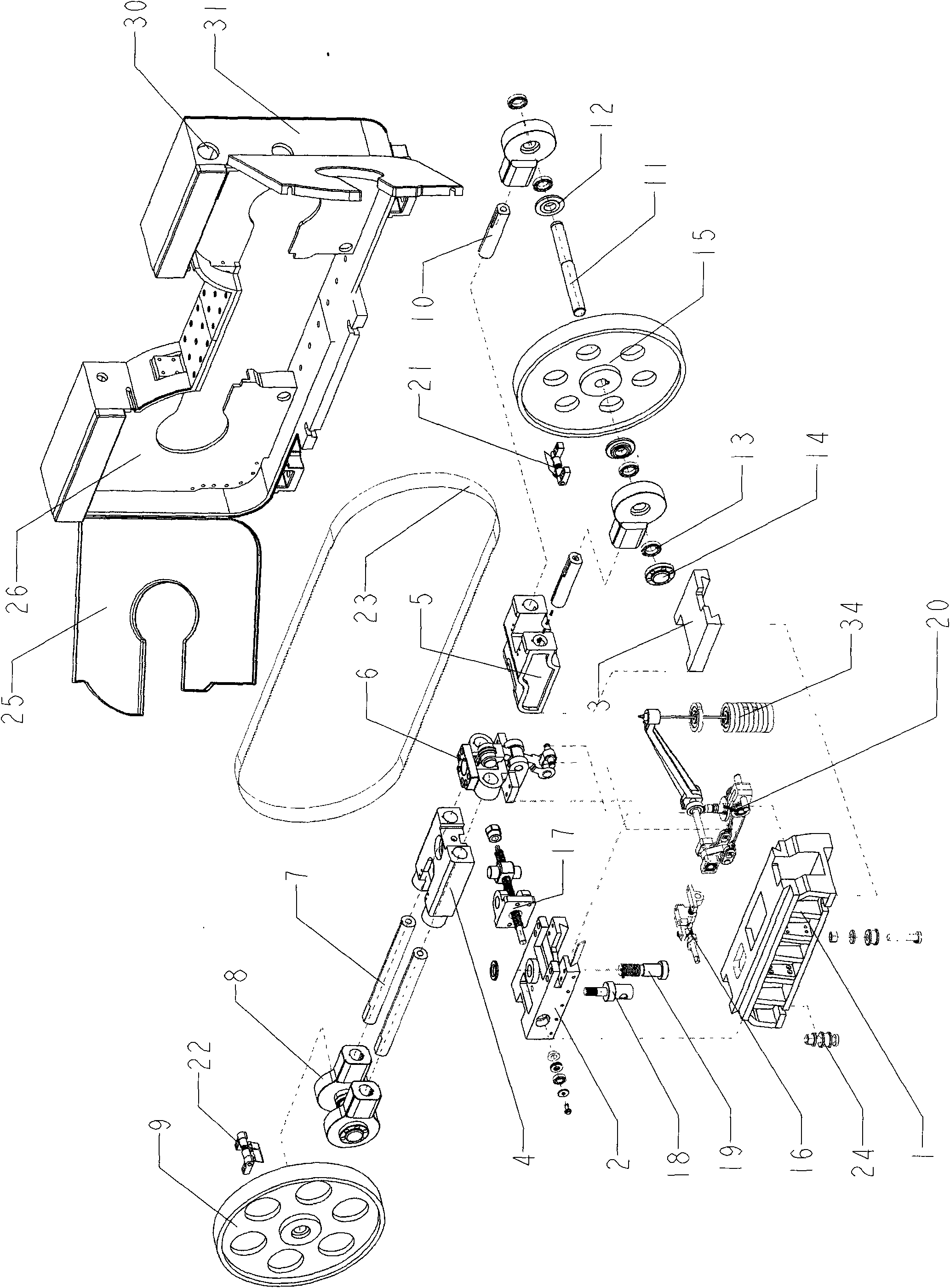

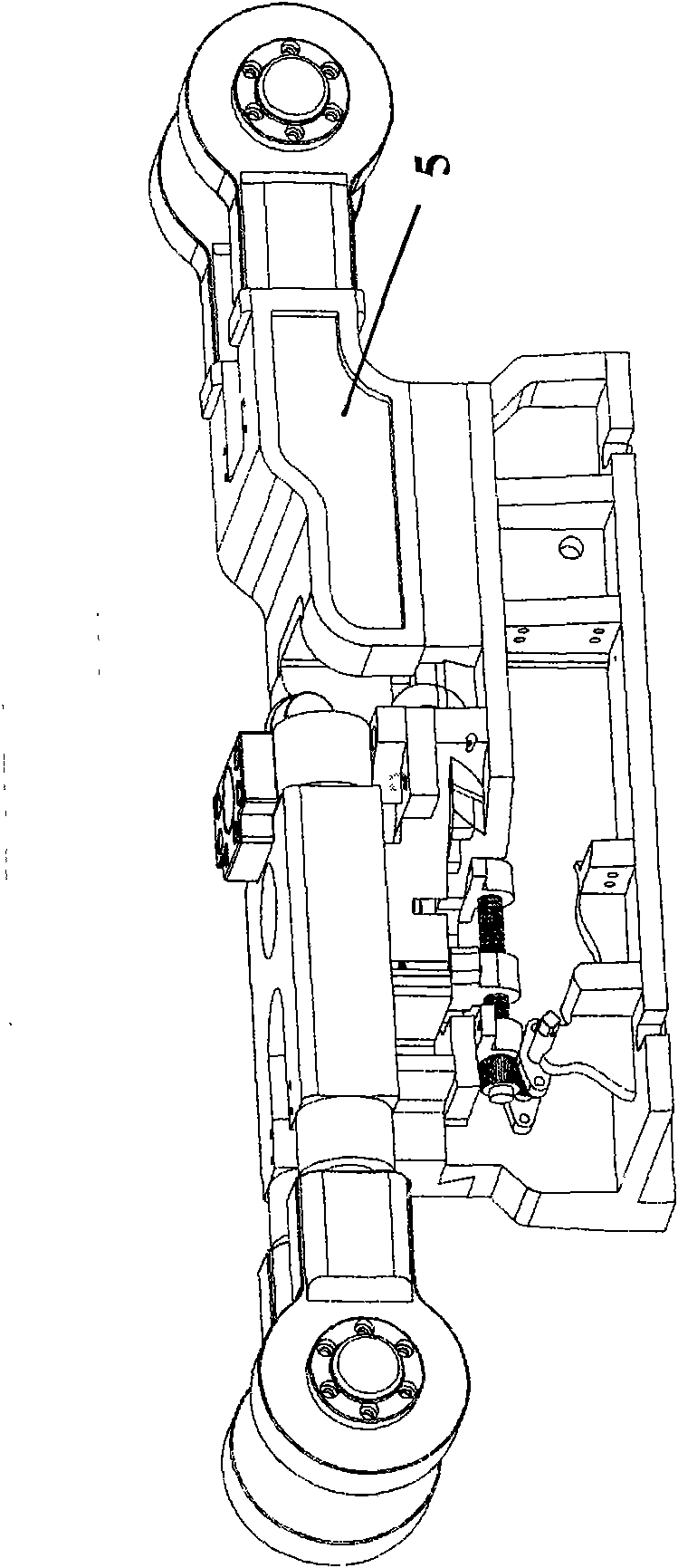

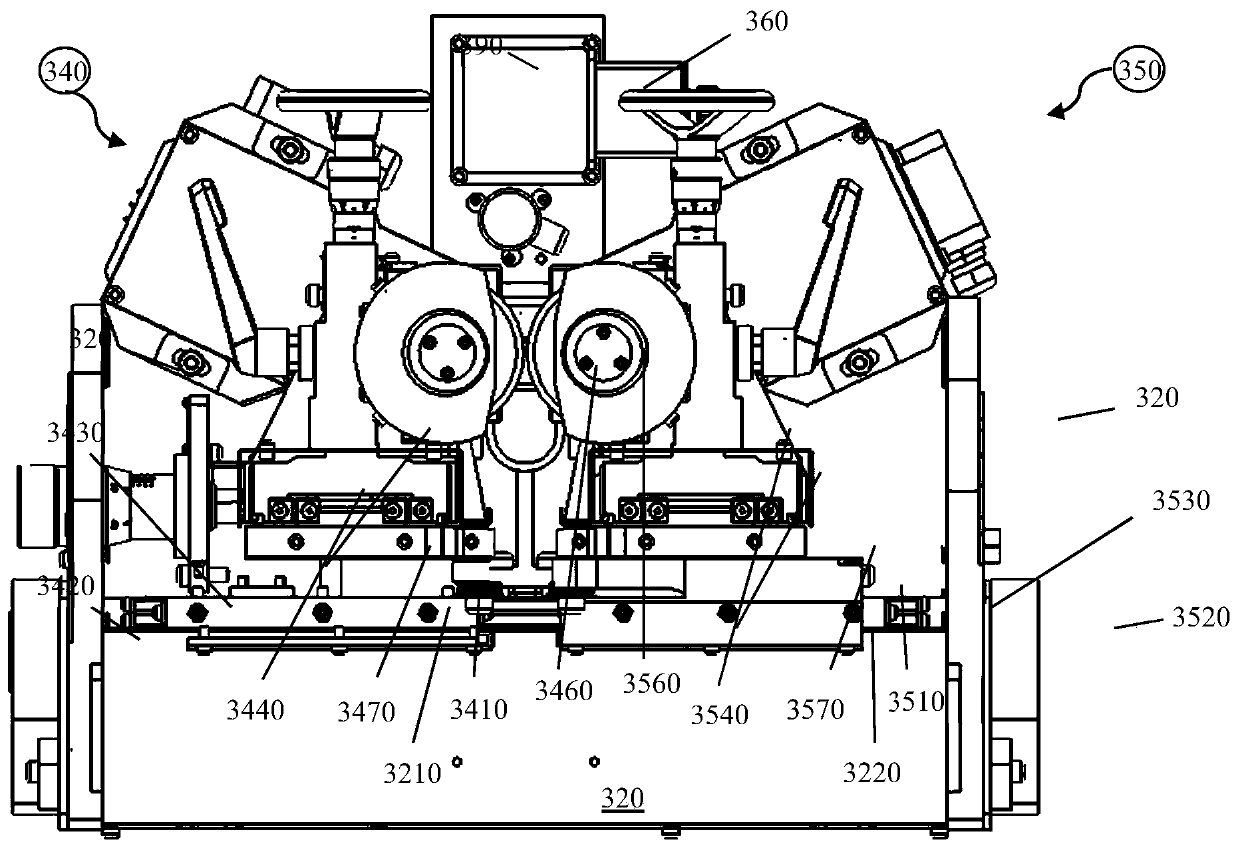

Sawing device for horizontal band sawing machine

InactiveCN102029629BGuaranteed cutting stabilityHigh precisionBand sawsBark-zones/chip/dust/waste removalFailure rateEngineering

The invention discloses a sawing device for a horizontal band sawing machine. The device is characterized in that a sawing base is arranged in a casing, and is provided with a first tension adjusting device; a drive saw wheel and a driven saw wheel are arranged at two ends of the first tension adjusting device respectively; the first tension adjusting device is connected with the drive saw wheel and the driven saw wheel through saw wheel attaching clamps; and the first tension adjusting device can adjust the distance between the driven saw wheel and the drive saw wheel, and ensures that the axis angle position of the driven saw wheel is deviated to adjust and position the central position of a band saw blade on the drive saw wheel and the driven saw wheel. The sawing device is arranged on a chassis of a machine tool; the machine tool is convenient for assembly and has low gravity center; the sawing device has the advantages of compact structure, reasonable design, impact resistance, firmness, elegance, durability,,high stability after long term use, low failure rate and high material processing accuracy, and is safe to operate and easy to regulate and maintain.

Owner:张家铭 +1

Driven slide plate for CNC cutting machine

InactiveCN104400539BGuaranteed cutting stabilityReasonable structural designWelding/cutting auxillary devicesAuxillary welding devicesNumerical controlSlide plate

The invention relates to a driven slide plate for a numerical control cutting machine, comprising a front plate, a lower support mechanism and an upper support mechanism installed on the front plate; in the upper support mechanism, the upper bracket is fixedly installed on the side wall of the front plate, and the upper bracket There is a row of upper support shafts arranged horizontally, and upper support bearings are installed on the upper support shafts; a row of upper fixed shafts is arranged on one side of the upper support bearings, and a row of upper eccentric shafts is arranged on the other side. The upper ends are respectively equipped with upper bearings; in the lower support mechanism, the lower bracket is fixedly installed on the side wall of the front plate, and a row of lower eccentric support shafts arranged horizontally is installed on the lower support shaft, and the lower support for supporting the slide plate is installed on the lower eccentric support shaft Bearing; One side of the lower support bearing is provided with a row of lower fixed shafts, and the other side is provided with a row of lower eccentric shafts, and the upper ends of the lower fixed shafts and the lower eccentric shafts are respectively equipped with lower bearings. The invention has reasonable structural design, safety and reliability, convenient installation and maintenance, and can ensure cutting stability.

Owner:WUXI HENGFU TECH

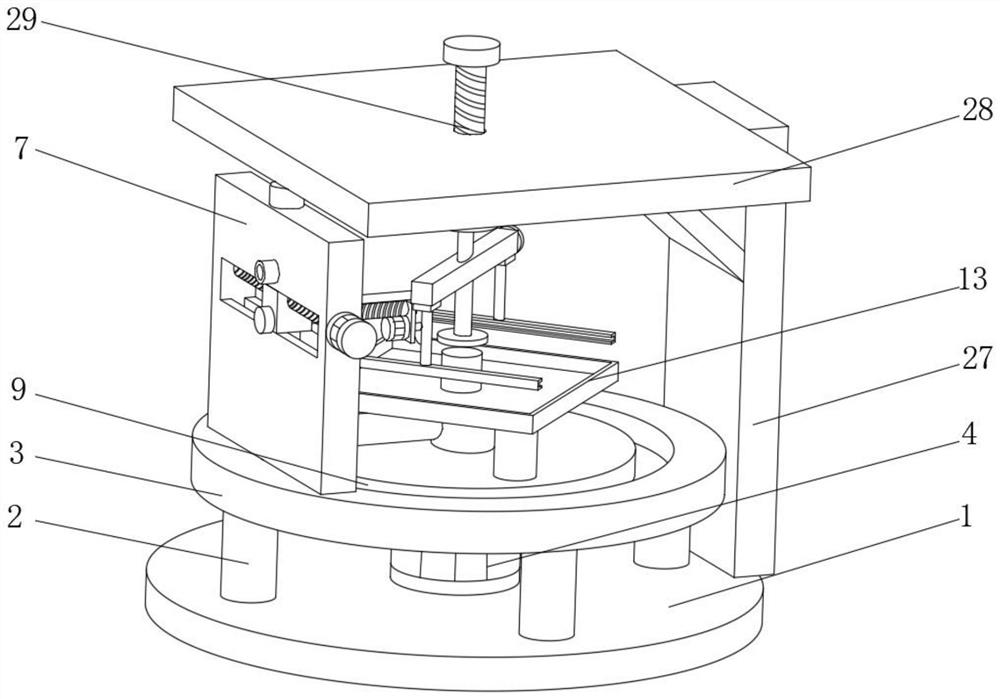

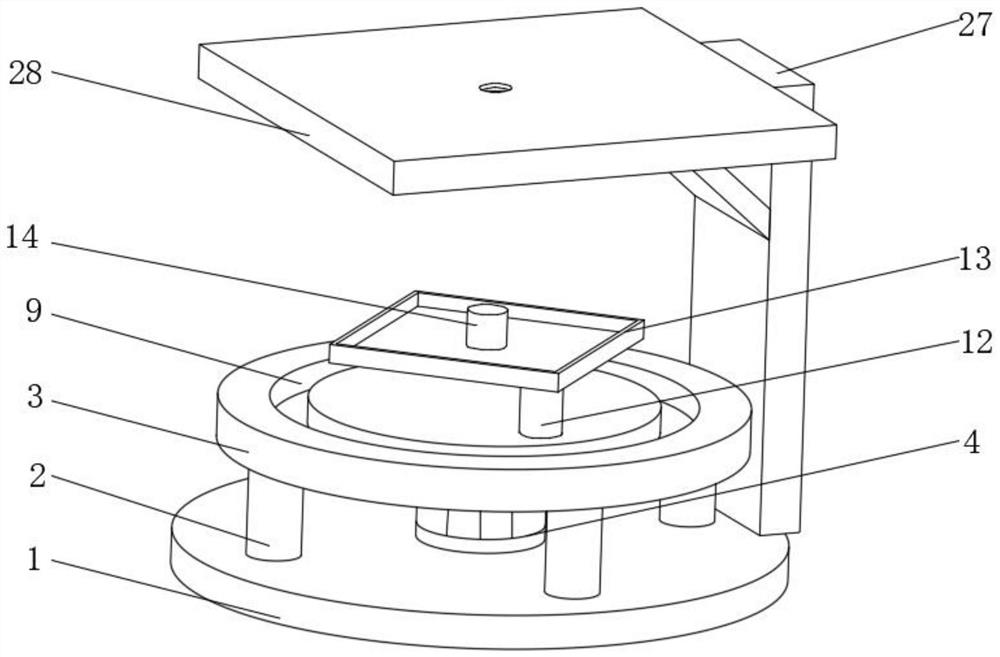

A stable circular cutting mechanism

ActiveCN112935924BSmooth dischargeGuaranteed cutting stabilityMaintainance and safety accessoriesStructural engineeringMachine tool

The present invention relates to the technical field of machine tool processing, in particular to a stable circular cutting mechanism, comprising: a base, a sliding seat radially sliding along the base, and a cutter fixed at the bottom of the sliding seat; and the sliding There is a liquid storage chamber inside the seat, and a liquid storage sleeve is rotatably connected to the liquid storage chamber, and the liquid storage sleeve is suitable for storing cutting fluid; a liquid outlet channel is provided in the sliding seat, and the liquid outlet One end of the channel communicates with the liquid storage chamber, and the other end of the liquid outlet channel faces the cutter; a locking assembly is also provided inside the sliding seat, and the locking assembly extends above the sliding seat ; where the liquid storage sleeve is rotated until the liquid outlet channel is connected, the locking assembly can lock the liquid storage sleeve. To ensure the stable discharge of cutting fluid, thereby ensuring cutting stability.

Owner:常州鑫琪机械制造有限公司

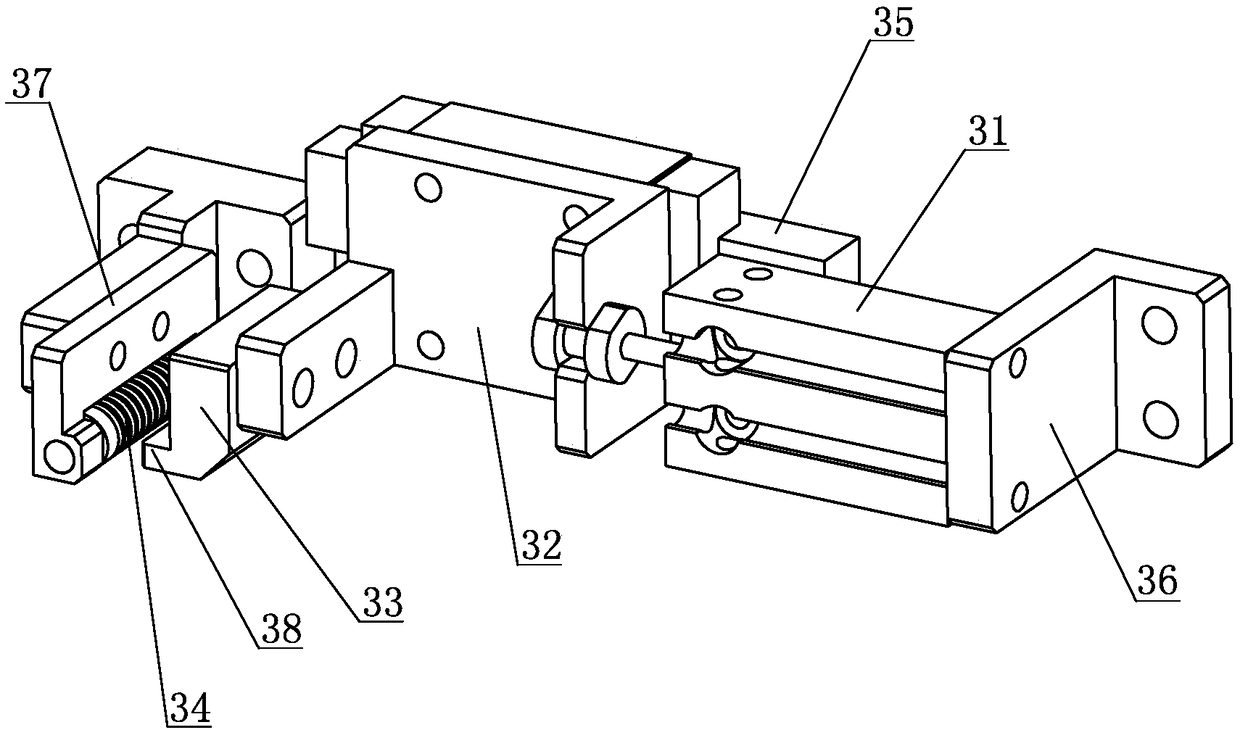

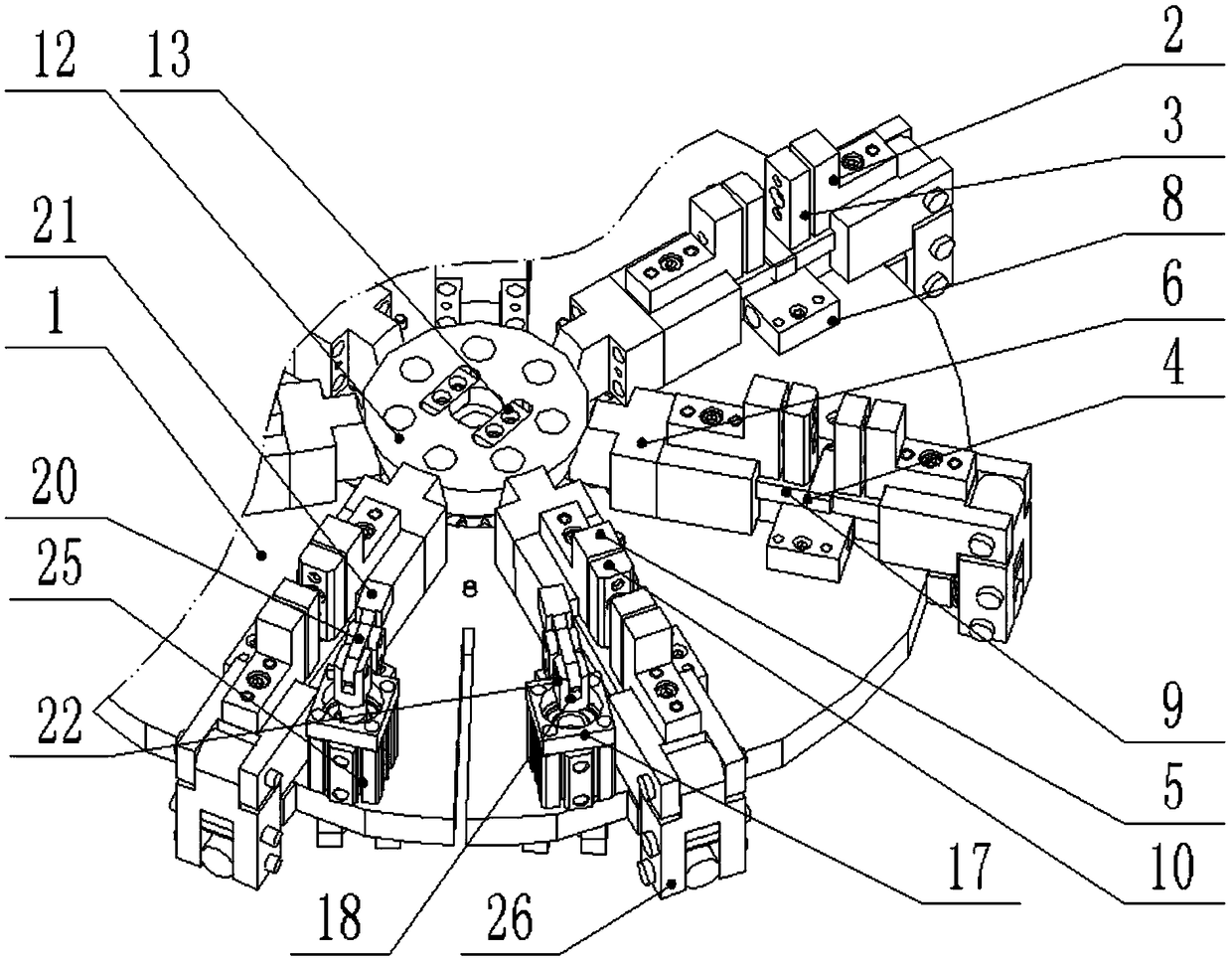

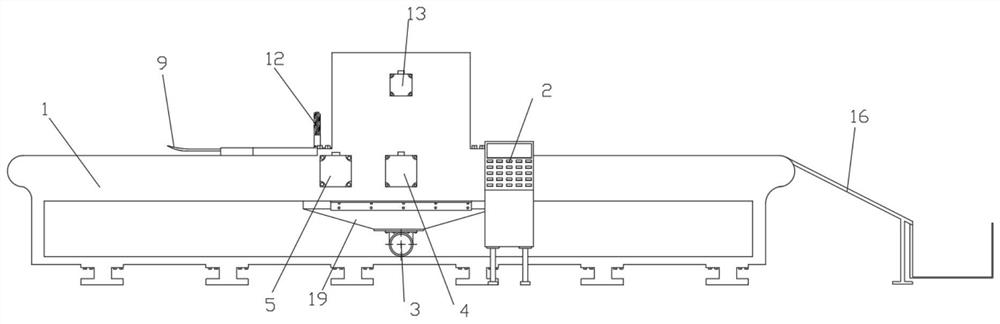

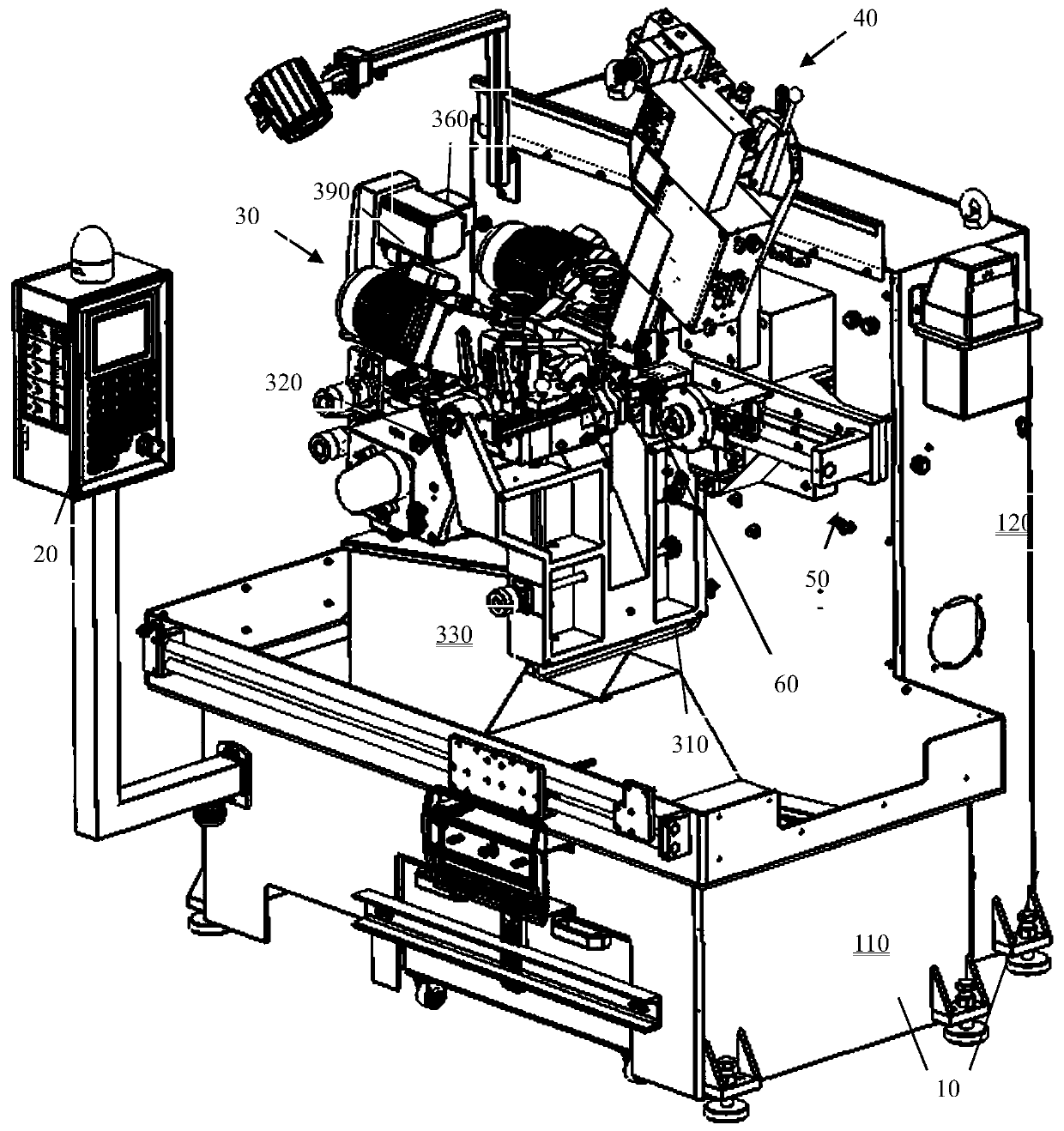

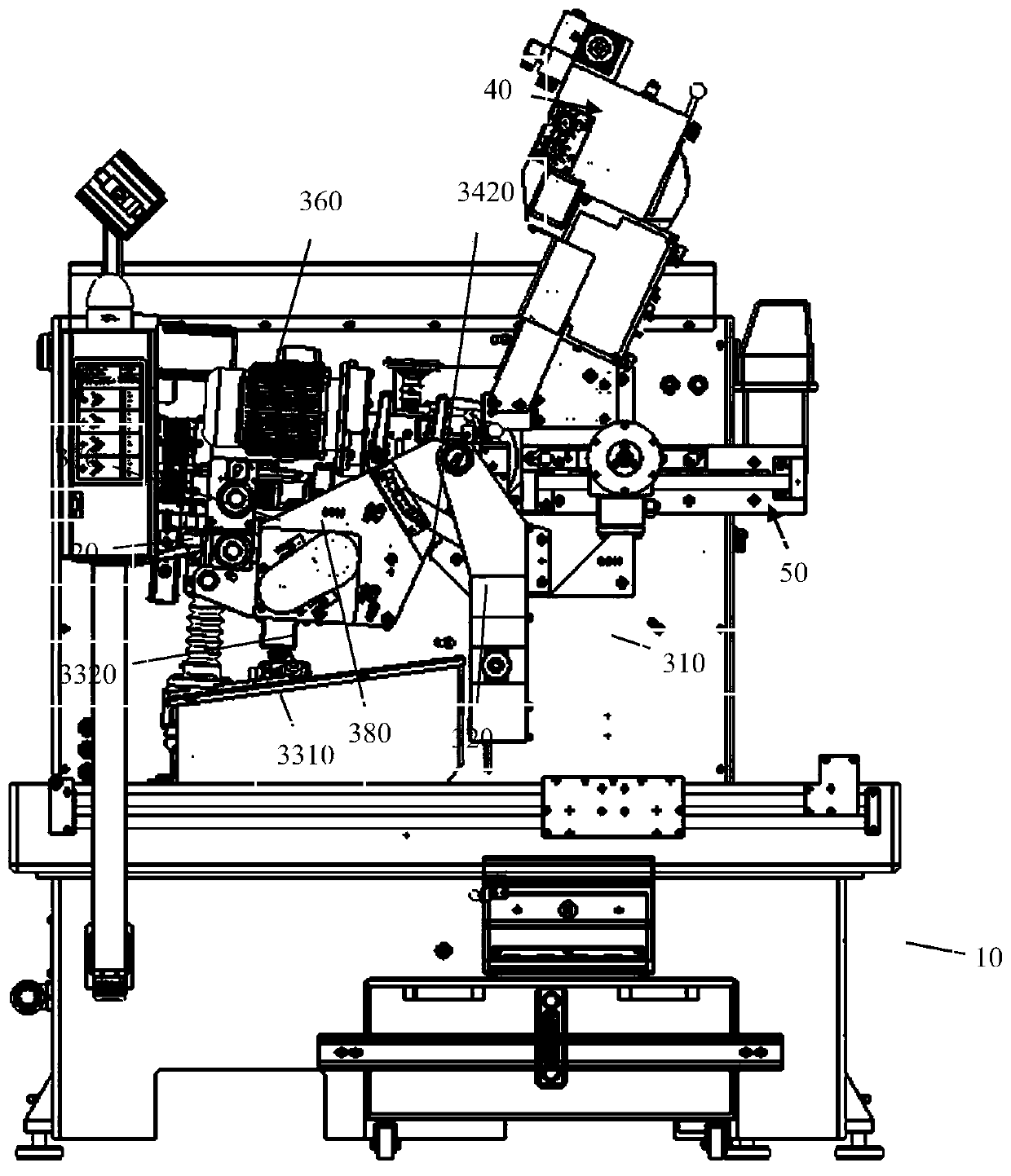

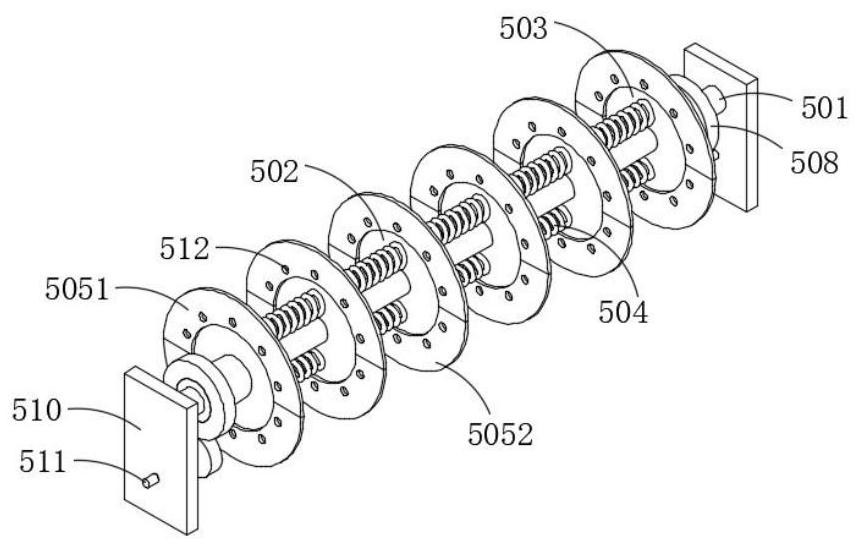

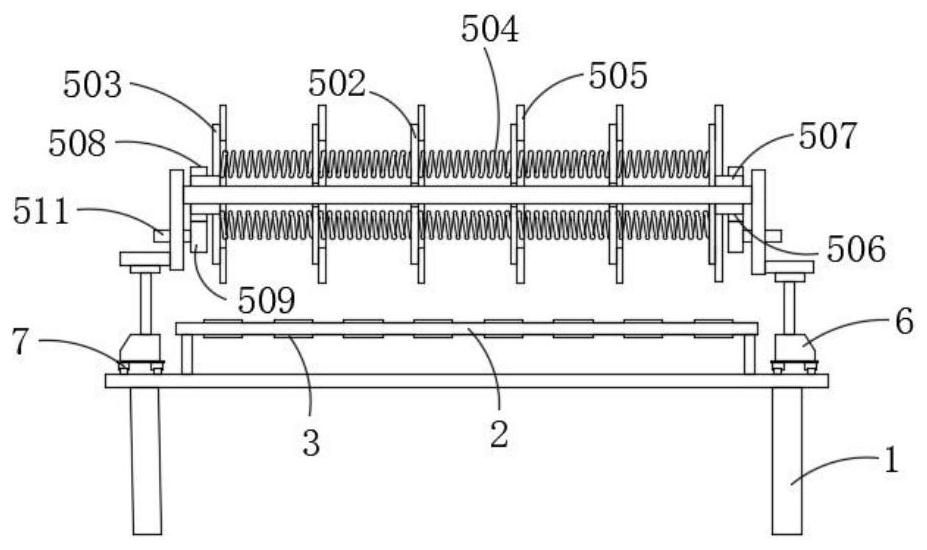

A fully automatic double side saw blade grinder

ActiveCN107081478BGuaranteed cutting stabilityExtended service lifeSawing tools dressing arrangementsElectric controlUltimate tensile strength

The invention belongs to the technical field of grinding of saw blades, and particularly discloses a full-automatic two-side-surface saw blade grinding machine. The full-automatic two-side-surface saw blade grinding machine comprises a machine tool seat and an electric control system, wherein a grinding device, a tooth dialing mechanism, a saw blade fixing mechanism and a saw blade clamping mechanism are arranged on the machine tool seat; the machine tool seat is used for mounting and bearing other assemblies or components; the saw blade fixing mechanism is used for fixing saw blades which need to be processed; the saw blade clamping mechanism is used for clamping the saw blade which need to be processed; the grinding device is used for completing the grinding of two side surfaces of each of the saw teeth; the tooth dialing mechanism is used for realizing the rotating tooth replacement of the saw blade; and the electric control system is used for providing a system control function. According to the full-automatic two-side-surface saw blade grinding machine provided by the invention, through the organic cooperation between the grinding device, the tooth dialing mechanism, the saw blade fixing mechanism, the saw blade clamping mechanism and the electric control system, the processing of two side surfaces of the saw blade can be completed at a time; and the full-automatic two-side-surface saw blade grinding machine is high in adaptability, good in accuracy and stability, high in automation degree, low in labor intensity and high in production efficiency.

Owner:东莞市领邦机械科技有限公司

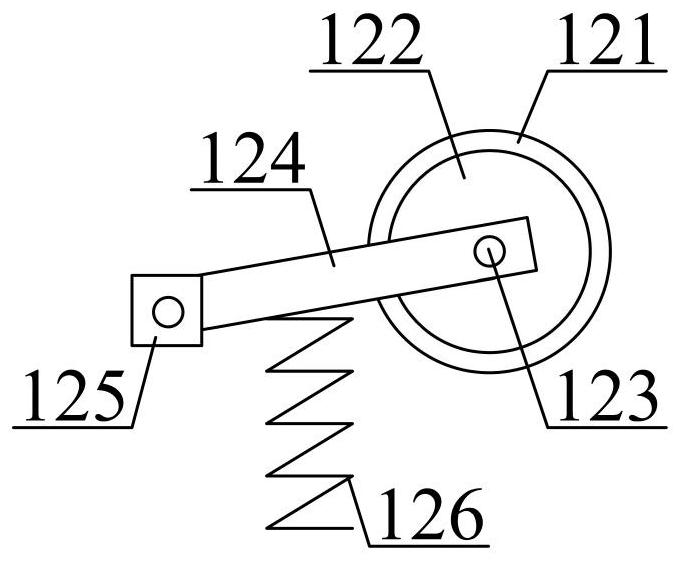

A swing arm type advertising paper cutting device

The invention provides a swinging arm type advertisement paper cutting device, and belongs to the technical field of cutting equipment. The swinging arm type advertisement paper cutting device comprises a cutting mechanism and a conveying mechanism, wherein an unrolling roller of the conveying mechanism is rotatablely arranged on an unrolling support frame; a coiling roller is rotatablely arranged on a coiling support frame; a swinging arm of the cutting mechanism is hinged onto the machine frame through a swinging arm pin shaft; the two ends of a cutting pulling wire are respectively arranged on a first wire pulling support seat and a second wire pulling support seat; a slide rod is arranged on a slide rod guide seat in a way capable of leftwards and rightwards sliding; a pressing jacking rod of the pressing assembly is always attached to a pressing platform arranged at the lower end of the swinging arm under the effect of a jacking rod press spring; a support rolling wheel arranged on the swinging arm is always attached to a wedge groove of the slide rod under the effect of the pressing jacking rod; the driving cam is rotatablely arranged on a cam support seat in an eccentric way through a cam shaft; the slide rod is always attached to a driving cam under the effect of a slide rod press spring. The swinging arm type advertisement paper cutting device has the advantages that the fast cutting on advertisement paper is realized; a cut edge is regular; the automation degree is high; the cutting efficiency is high; the reliability is high.

Owner:佛山市顺德区北滘镇千艺制版有限公司

The sliding plate locking mechanism on the driven sliding plate of CNC cutting machine

InactiveCN104384770BGuaranteed cutting stabilityReasonable structural designWelding/cutting auxillary devicesAuxillary welding devicesClassical mechanicsEngineering

The invention relates to a sliding plate locking mechanism on a driven sliding plate of a CNC cutting machine, comprising a front plate, a lower support mechanism and an upper support mechanism installed on the front plate; in the upper support mechanism, the upper bracket is fixedly installed on the side wall of the front plate On the upper support, a row of upper support shafts arranged horizontally is installed on the upper support shaft, and an upper support bearing is installed on the upper support shaft; a row of upper fixed shafts is arranged on one side of the upper support bearing, and a row of upper eccentric shafts is arranged on the other side. The upper ends of the shaft and the upper eccentric shaft are respectively equipped with upper bearings; in the lower support mechanism, the lower bracket is fixedly installed on the side wall of the front plate, and a row of lower eccentric support shafts arranged horizontally is installed on the lower support shaft. The lower support bearing for supporting the slide plate; one side of the lower support bearing is provided with a row of lower fixed shafts, and the other side is provided with a row of lower eccentric shafts, and the upper ends of the lower fixed shafts and the lower eccentric shafts are respectively equipped with lower bearings. The invention has reasonable structural design, safety and reliability, convenient installation and maintenance, and can ensure cutting stability.

Owner:WUXI HENGFU TECH

Slitting and sorting equipment for vertically adjustable partitions

ActiveCN110978239BGuaranteed cutting stabilityEasy to transportAuxillary shaping apparatusElectric machineryEngineering

The invention discloses slitting and sorting equipment for longitudinal adjustment diaphragms. The slitting and sorting equipment comprises a rack, wherein a diaphragm bracket is fixedly arranged at the top of the rack, carrier rollers are equidistantly arranged in the diaphragm bracket, four groups of positioning assemblies are symmetrically arranged at the two sides of the diaphragm bracket, a slitting assembly is fixedly arranged above the diaphragm bracket, two groups of lifting motors are symmetrically arranged at the two sides of the slitting assembly, electric sliding tables are fixedlyarranged at the bottoms of the lifting motors, a mobile collection frame is arranged at one side of the rack, each positioning assembly comprises an electric push rod, a positioning block is fixedlyarranged at an output shaft end of each electric push rod, a mobile support is fixedly arranged at the bottom of each electric push rod, the slitting assembly comprises a fixed shaft, four groups of first knife holders are slidably arranged on the surface of the fixed shaft, slitting knives are fixedly arranged at one sides of the first knife holders and second knife holders, the adjustment diaphragms with different widths are conveniently collected, and sorting of the diaphragms with different widths is achieved.

Owner:JIANGXI EQUIP INDAL GROUP GREAT INSURANCENT

Driven slide carriage for numerical-control cutting machine

InactiveCN104400539AGuaranteed cutting stabilityReasonable structural designWelding/cutting auxillary devicesAuxillary welding devicesSlide plateClassical mechanics

The invention relates to a driven slide carriage for a numerical-control cutting machine. The driven slide carriage comprises a front plate, as well as a lower supporting mechanism and an upper supporting mechanism which are arranged on the front plate; in the upper supporting mechanism, an upper bracket is fixedly arranged on the side wall of the front plate, the upper bracket is provided with a row of upper bearing shafts which are transversely arranged, and the upper supporting shafts are provided with upper supporting bearings; one side of each upper supporting bearing is provided with a row of upper fixed shafts, and the other side of each upper supporting bearing is provided with a row of upper eccentric shafts; the upper ends of the upper fixed shafts and the upper eccentric shafts are respectively provided with upper bearings; in the lower supporting mechanism, a lower bracket is fixedly arranged on the side wall of the front plate and is provided with a row of transversely-arranged lower eccentric supporting shafts; the lower eccentric supporting shafts are provided with lower supporting bearings used for supporting slide plates; one side of each lower supporting bearing is provided with a row of lower fixed shafts, and the other side of each lower supporting bearing is provided with a row of lower eccentric shafts; the upper ends of the lower fixed shafts and the lower eccentric shafts are respectively provided with lower bearings. The driven slide carriage is reasonable in structural design, safe and reliable, convenient in installation and maintenance and capable of ensuring the cutting stability.

Owner:WUXI HENGFU TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com