Machining center for automatically cutting single-branch door and window aluminum plastic profile at 45-degree angle

An automatic cutting and machining center technology, applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve the problems of great influence on cutting quality stability, unstable angle accuracy, and cutting accuracy cannot be guaranteed, etc., to achieve Improve cutting quality, reduce requirements, and ensure the effect of cutting stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0057] In order to clearly illustrate the technical features of the solution, the solution will be described below through specific implementation modes.

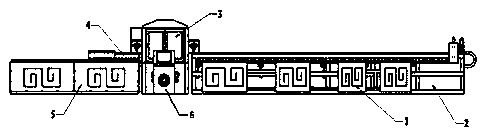

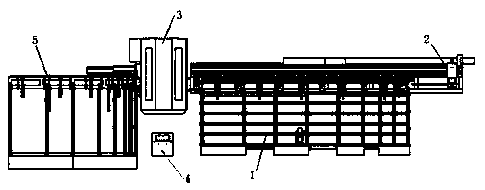

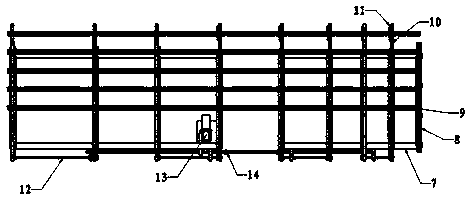

[0058] A processing center for automatically cutting single aluminum-plastic profiles for doors and windows at an angle of 45 degrees. The equipment can be controlled by the console 6 to realize functions such as automatic loading, automatic cutting, automatic unloading, and automatic collection of waste heads, including sequentially set storage. Material mechanism 1, feeding mechanism 2, cutting mechanism 3, retrieving mechanism 4 and unloading mechanism 5.

[0059] The storage mechanism 1 is used to place multiple profiles to be cut, usually 6-8 pieces; the feeding mechanism 2 is responsible for sending each profile to the cutting part in sequence according to the length listed in the form; the cutting mechanism 3 is used to cut at 45 degrees profiles; the retrieving mechanism 4 is to take out each cut profile and place i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com