Cutting head

A cutting head and lens technology, applied in welding equipment, laser welding equipment, metal processing equipment, etc., can solve the problems of difficult to accurately determine the initial point of cutting, cumbersome and complicated operation, and increase the actual load of the mechanical arm, so as to ensure the cutting quality and Stability, convenient and fast operation, and the effect of improving machining accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

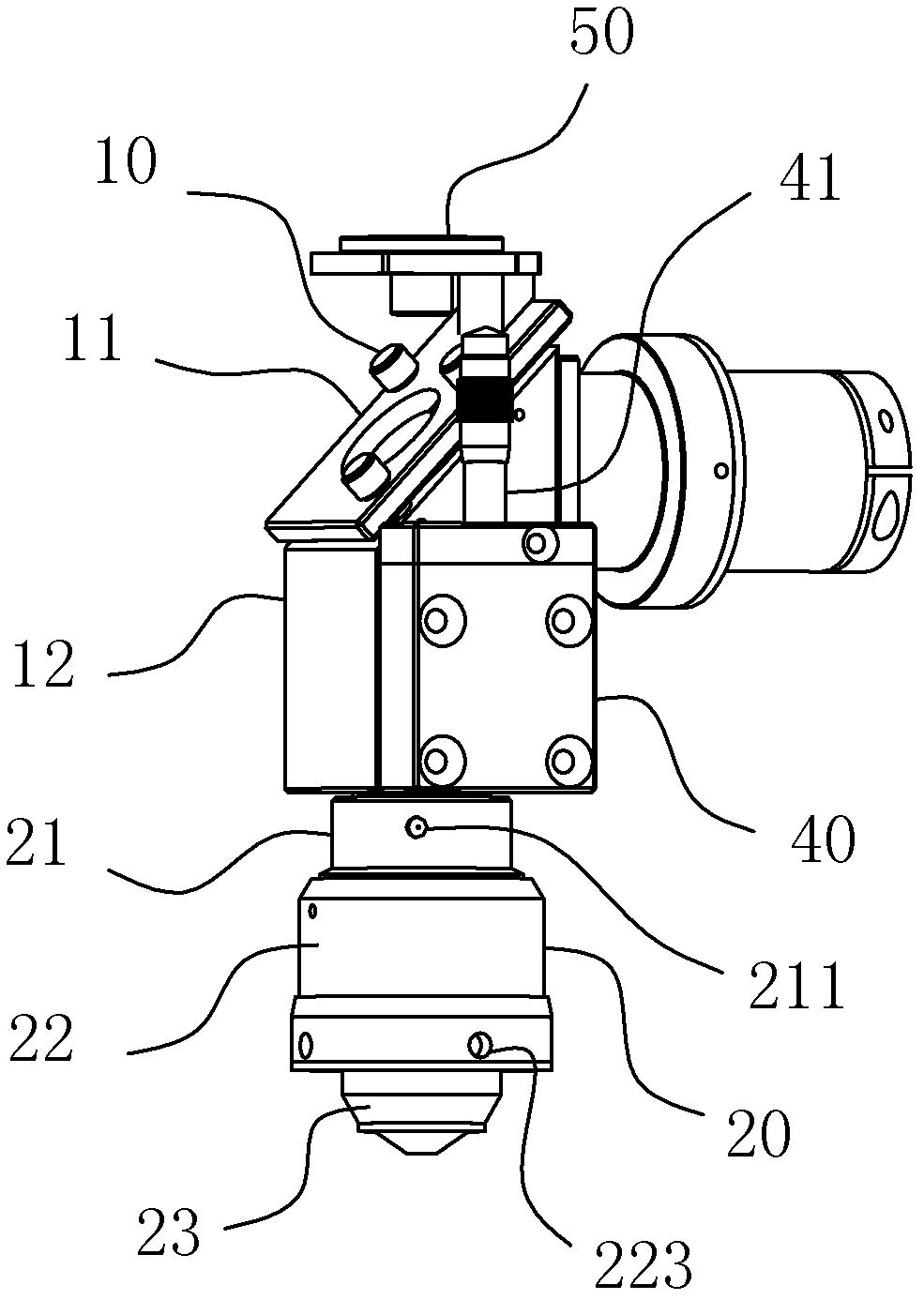

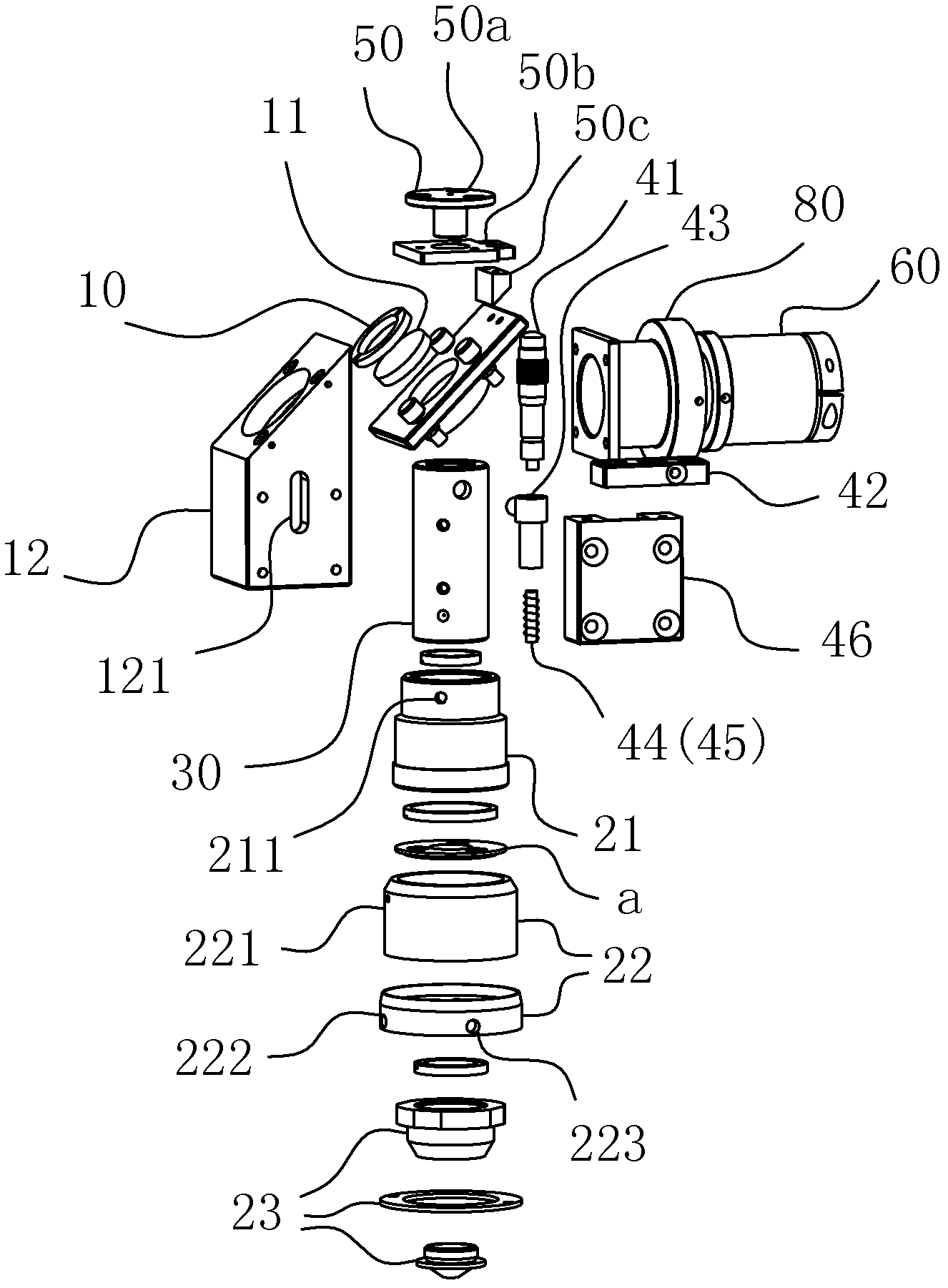

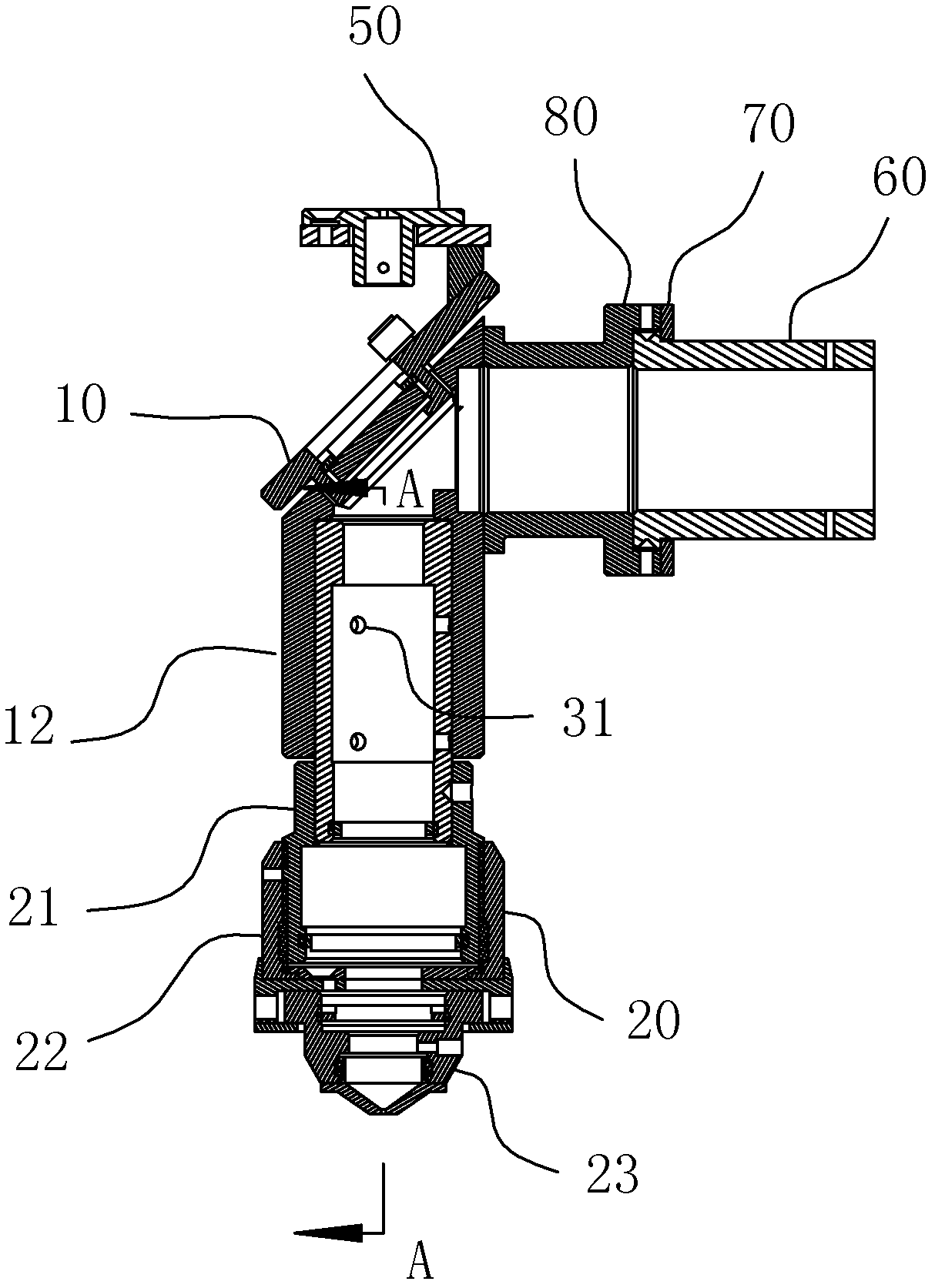

[0010] A cutting head, comprising an optical path entrance lens, an optical path exit lens, and a reflector assembly 10 for reflecting the light path. The main light beam enters the optical path entrance lens, is reflected by the reflector assembly 10, and then exits through the optical path exit lens. The optical path exit lens includes Focusing head assembly 20, the cutting head also includes an adjustment mechanism 40 that can be used to make the focusing head assembly move along the Z-axis direction, such as Figure 1-2 as well as Figure 4 shown.

[0011] In the actual processing of the laser cutting machine, the workpiece to be processed is laid horizontally on the processing plane of the laser cutting machine, and the output optical path of the cutting head is set perpendicular to the workpiece, which is the above-mentioned Z-axis setting. When it is necessary to adjust the distance between the cutting head and the battery plate, the Z-axis adjustment mechanism arrange...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com