Detection method for hardness of micron-size ultrahard grinding materials

A technology of super-hard abrasives and detection methods, applied in the direction of testing material hardness, measuring devices, analyzing materials, etc., can solve the problem that recycled sand and virgin sand cannot be applied at the same time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0038] First, extract the abrasive particle sample to test the roundness value R and the aspect ratio value A of the sample;

[0039] Wherein, aspect ratio (Aspect Ration) A refers to the length L of the width W / particle of particle; Obtain grain type coefficient S=AxR;

[0040] Then, after the destructive test is carried out on the abrasive particle sample, the degree of change in particle size is used to reflect the wear resistance of the abrasive.

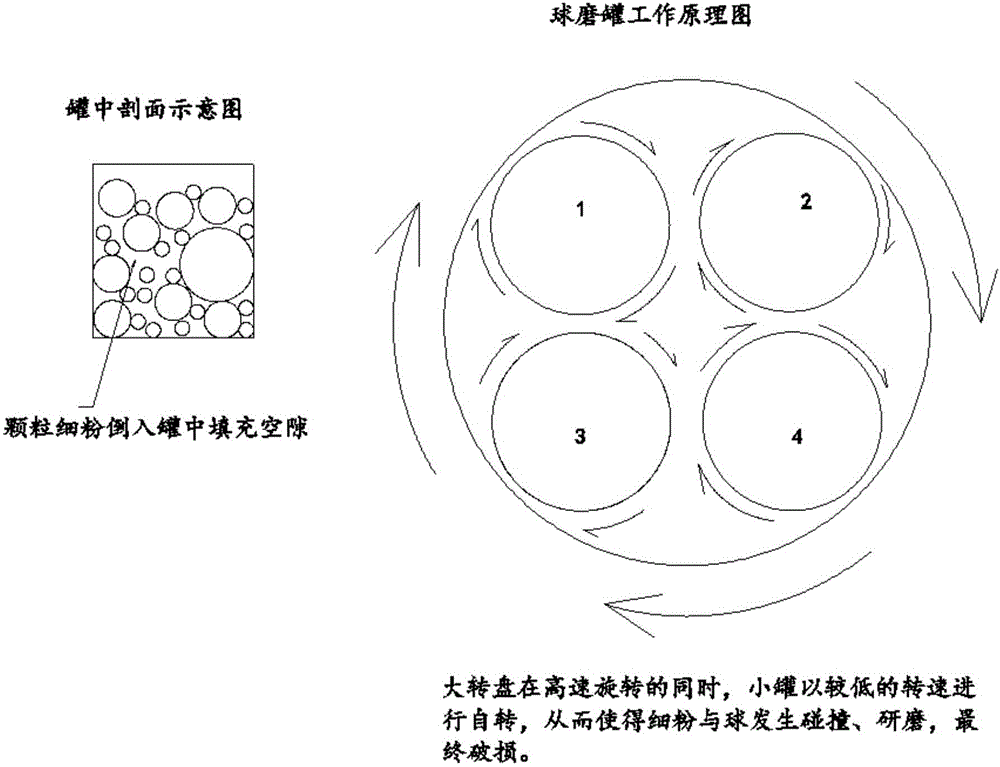

[0041] According to the size of the abrasive particles, zirconia balls of different sizes are used and combined in different ways to finally realize the test of the damage degree of the particles within a certain grinding frequency and time range. The method has the advantages of simple operation, less material consumption and strong feasibility.

[0042] For abrasive particles with a D50 of 10 μm, the present invention adopts the combination of small balls as shown in Table 1:

[0043] Table 1 Combination of grinding balls

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com