Line cutting device for sewing machine

A sewing machine and thread cutting technology, which is applied in the sewing machine to cut off the thread mechanism, sewing machine components, sewing equipment, etc., can solve the problems of interrupted production, blade passivation, difficult to cut sutures, etc., achieve high efficiency and simple operation process , Guarantee the effect of cutting quality and cutting stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

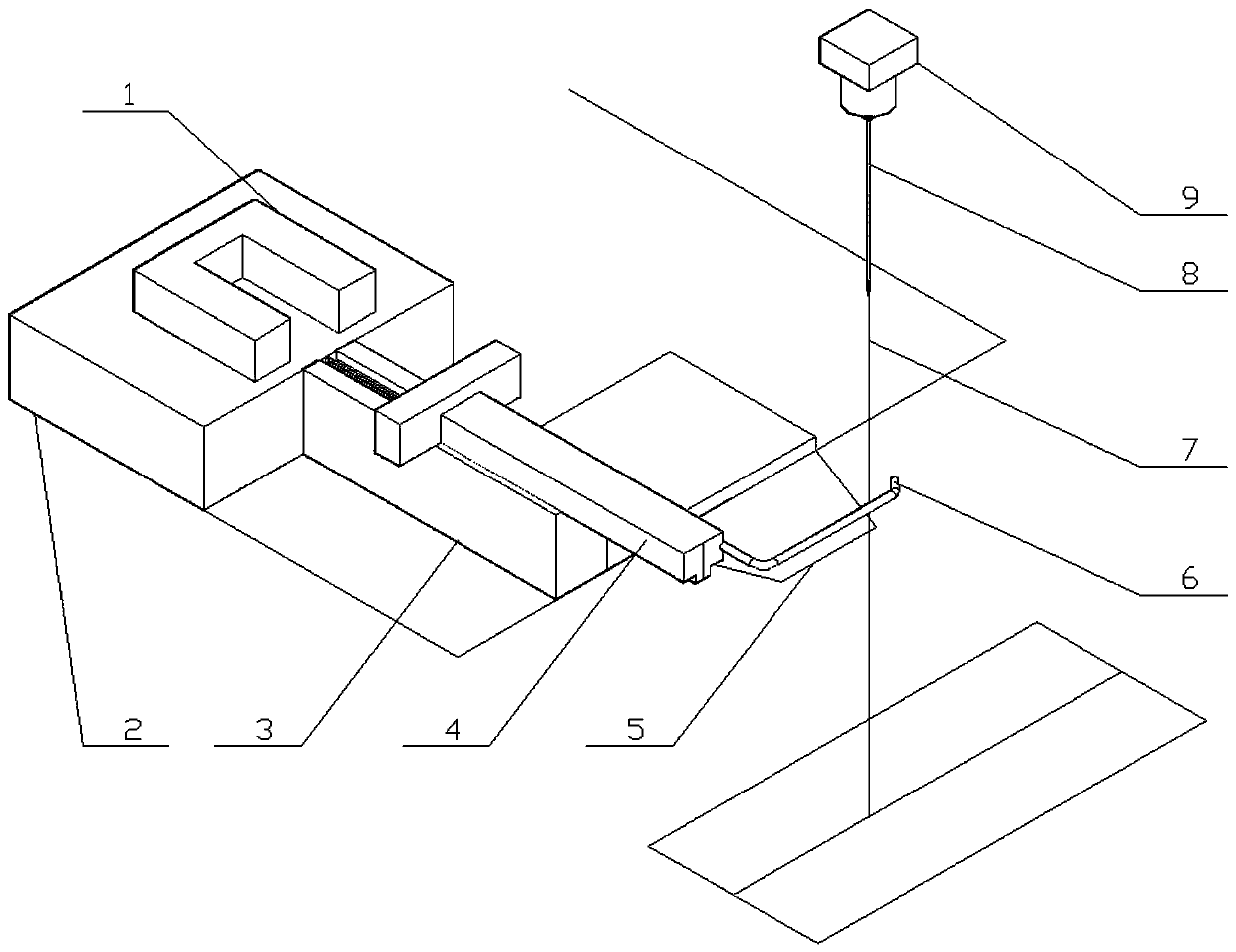

[0017] figure 1 The structure of an embodiment of the present invention is shown, and as shown in the figure, the present invention comprises a thread cutting assembly and a thread hook assembly; the thread cutting assembly includes a hot thread cutting blade 5 and an electric heater 12, and the electric heater 12 is installed on the hot thread cutting blade 5 backends.

[0018] The wire hook assembly includes a slide rail 4, a slideway 3, an electromagnet controller 2, an electromagnet 1, a return spring 10, a suction end 11, and a wire hook 6. Electromagnetic controller 2 is installed on the sewing machine platform, electromagnet 1 is installed on electromagnetic controller 2, the front end of electromagnetic controller 2 is installed and slides to 3, and a chute is opened on the upper surface of slid to 3, slide rail 4 is installed in the chute, and the slide rail 4, close to the end of the electromagnetic controller 2, the suction end 11 is installed, and the suction end ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com