A Method for Aligning Longitudinal Seams Between Shells of Hot Blast Stoves

A technology for hot blast stoves and furnace shells, applied in the field of longitudinal seam alignment devices between hot blast stove shells, which can solve the problems of thick hot blast stove shells and inconvenient alignment welding of furnace shells, etc., so as to facilitate subsequent welding, improve construction quality, and manufacture simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

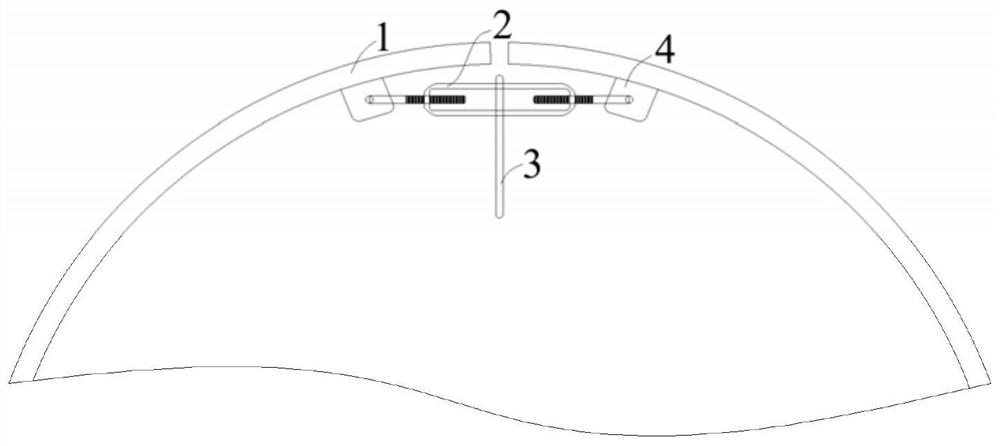

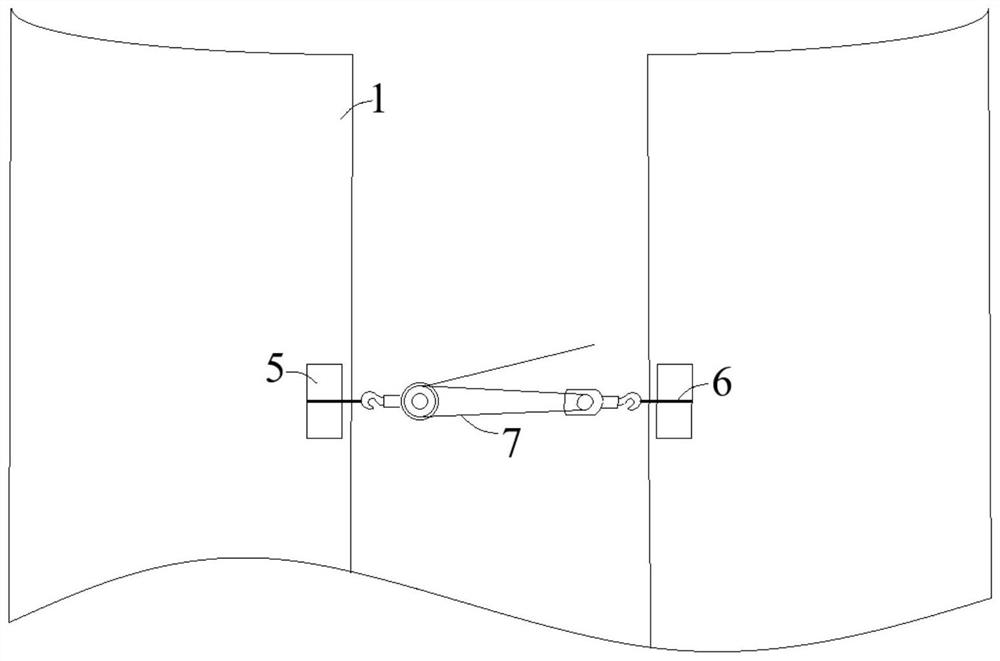

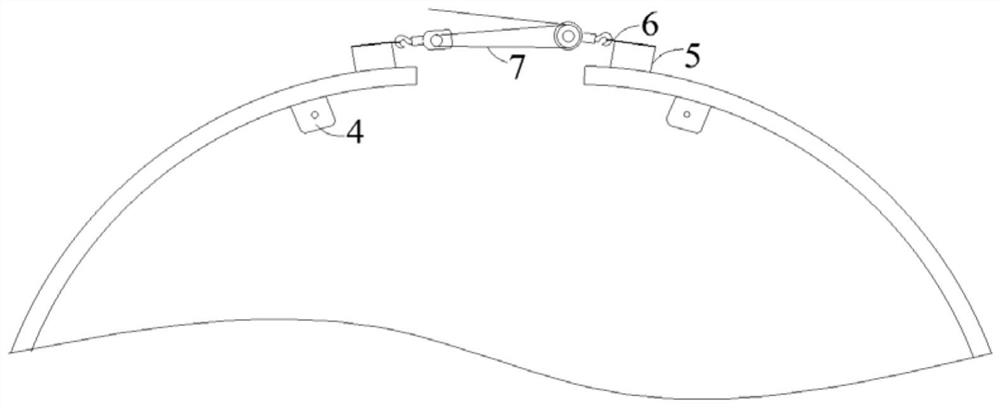

[0039] A device for aligning longitudinal seams between shells of a hot blast stove in this embodiment includes a main alignment mechanism and an auxiliary alignment mechanism. The main alignment mechanism is arranged inside the furnace shell 1 and includes turnbuckle bolts 2, holding rods 3 and positioning blocks 4; The alignment mechanism is arranged on the outside of the furnace shell 1 and includes a positioning block 5 , a lanyard 6 and a chain hoist 7 . Because the furnace shell 1 is large and heavy, it is laborious to move. In this embodiment, the furnace shell 1 longitudinal seam is equipped with two sets of main alignment mechanism and auxiliary alignment mechanism from top to bottom, which can be operated at the same time to align the longitudinal seam. The main alignment mechanism and the auxiliary alignment mechanism are taken as examples for specific description.

[0040] combine figure 1 , the positioning block 4 is made of a steel plate whose length*width*thick...

Embodiment 2

[0047] The steps for aligning using the longitudinal seam alignment device of embodiment 1 are:

[0048] Step 1, lifting the multi-piece furnace shell 1, and roughly assembling the furnace body, and welding the positioning block 4 and the positioning stopper 5;

[0049] Step 2. According to the distance between the two positioning blocks 4 that have been installed, screw the screw rods at both ends of the turnbuckle 2 until the hook whose length can meet the screw rod can be hooked into the hole set on the positioning block 4;

[0050] Using the fulcrum principle, the dynamic holding rod 3 is rotated from top to bottom to drive the elliptical frame of the turnbuckle bolt 2 to rotate, so that the screws at both ends tighten each other due to the rotation; the positioning block 4 is pulled by the screw hook of the turnbuckle bolt 2, Drive the furnace shell 1 to tighten and align to meet the welding distance;

[0051] It is worth noting that, at this time, the positioning stoppe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com