Cutting device for building

A cutting device and construction technology, applied in the direction of stone processing tools, work accessories, manufacturing tools, etc., can solve the problems of separation from cutting equipment, low tile cutting efficiency, unfavorable batch cutting, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

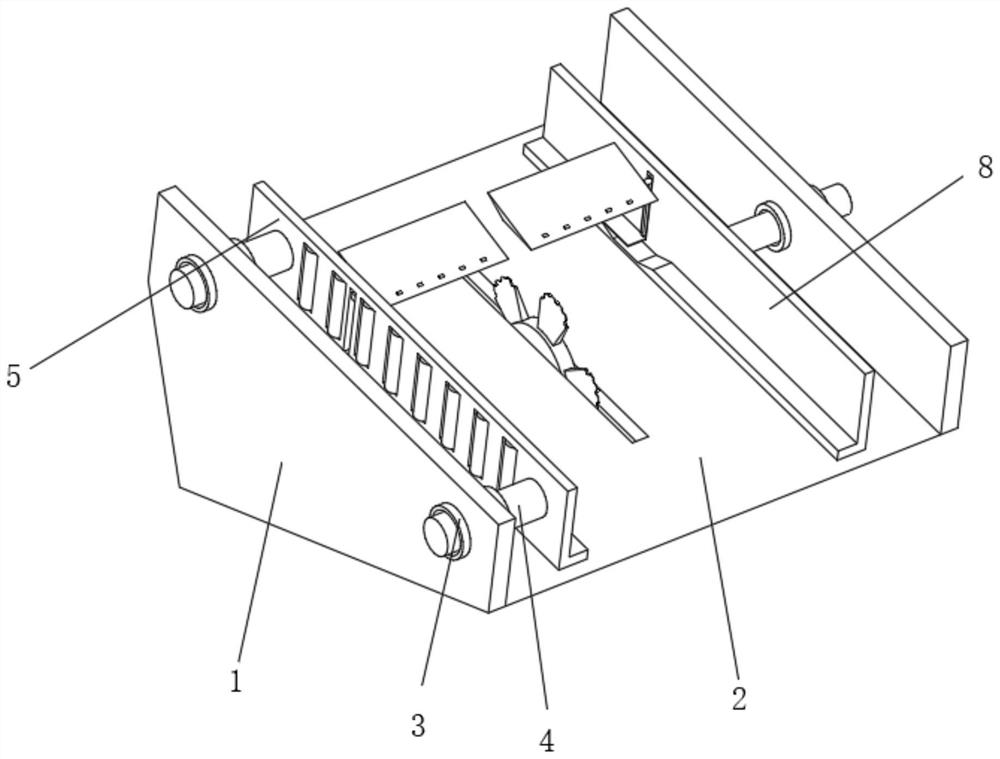

[0041] like Figure 1-3 As shown, the present invention provides a technical solution: a cutting device for construction, including an outer support frame 1, the middle position of the outer support frame 1 is fixedly connected with a guide inclined plate 2, and the front position of the guide inclined plate 2 is connected with the outer support frame. 1. The bottom of the front is on the same level. The front and rear ends on the left side of the outer support frame 1 are fixedly connected to the elastic sleeve rod 3 above the guide slant plate 2. The elastic sleeve rod 3 runs through and is slidably connected to the adjustment insert rod 4 One end of the adjustable plunger 4 located at the inner side of the outer support frame 1 is fixedly connected with a movable splint 5, the bottom of the movable splint 5 is arranged parallel to the top surface of the guide inclined plate 2, and the inside of the movable splint 5 is evenly and equidistantly rotated and connected with limit...

Embodiment 2

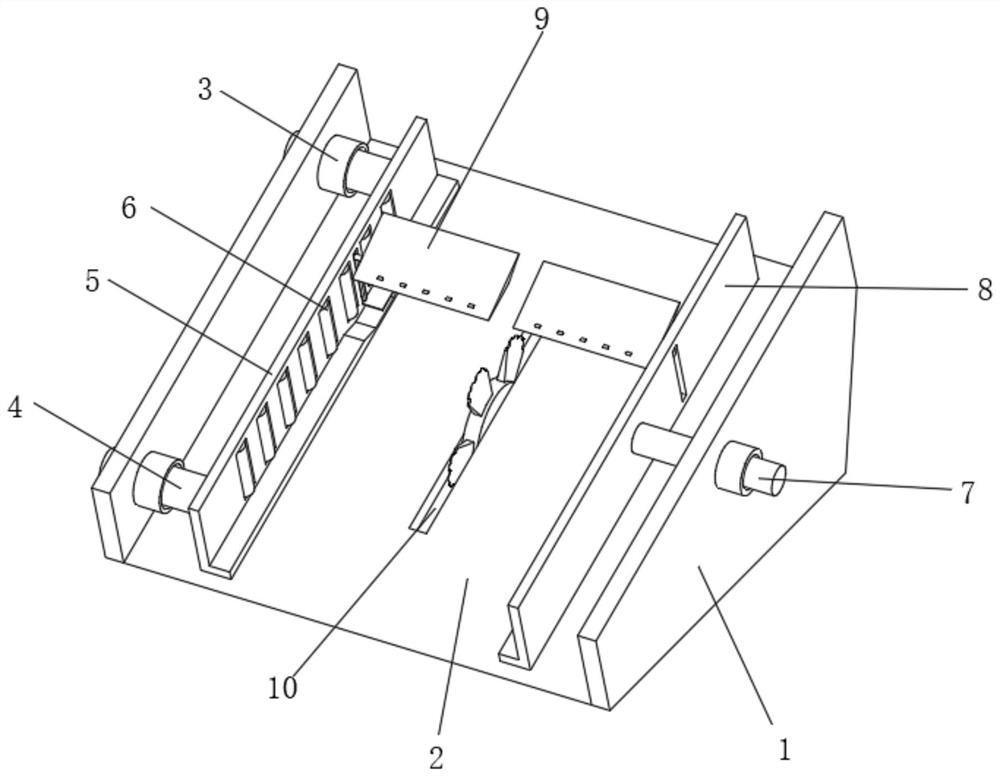

[0043] like Figure 4-6 As shown, on the basis of Embodiment 1, the present invention provides a technical solution: a cutting device for construction, the limiting pressing mechanism 9 includes a turning table groove 91, and the turning table groove 91 is arranged on the surface of the bottom of the movable splint 5, The position close to the back of the steering table groove 91 is rotatably connected with a pressure variable carrier plate 92 , and the pressure variable carrier plate 92 is arranged above the steering table groove 91 . Relieve the impact force during the initial cutting, realize the protection of the tile end when it is just cut, and avoid knocking damage when the end is just cut.

[0044] The turntable groove 91 adopts a large-up and down-small prism groove structure, and the turntable groove 91 and one end of the cutting drive mechanism 11 back are on the same level.

[0045] The inside of the movable splint 5 and the position between the limiting pulleys 6...

Embodiment 3

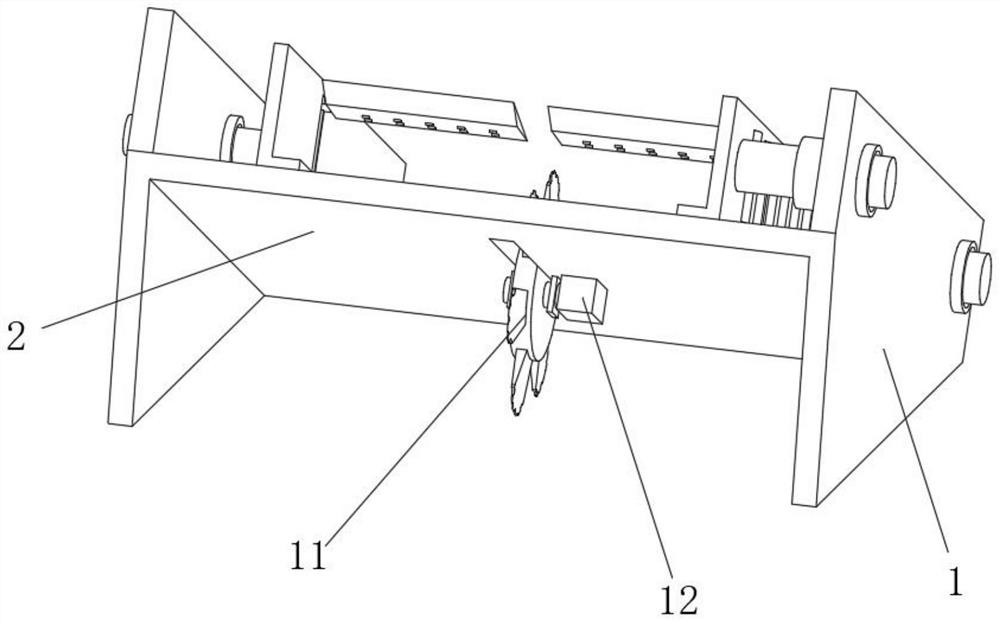

[0050] like Figure 7-9 As shown, on the basis of Embodiment 1 and Embodiment 2, the present invention provides a technical solution: a cutting device for construction, the end of the pressing cone plate 95 away from the adjustment slider 94 is fixedly connected with a magnet block 97, and the magnet The block 97 is arranged corresponding to the cutting drive mechanism 11 . The magnetic repulsion ensures the stability of the bricklaying in the vertical direction during the whole cutting process.

[0051] Cutting drive mechanism 11 comprises driving disk 111, and the circle center position outside driving disk 111 is fixedly connected with drive motor 12 output shafts, and the outer surface of driving disk 111 is evenly fixedly connected with cutting blade 112, and the outer surface of driving disk 111 and A contact cleaning assembly 113 is fixedly connected between the cutting blades 112 .

[0052] Both sides of the cutting blade 112 outside are fixedly connected with a push...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com