Machine element clamping equipment with cutting function

A technology of mechanical parts and clamping equipment, which is applied in the field of mechanical processing, can solve problems such as steel pipe scratches, flattening, and affecting quality, and achieve the effects of easy cutting, reduced manual pressure, and strong adaptability of the device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

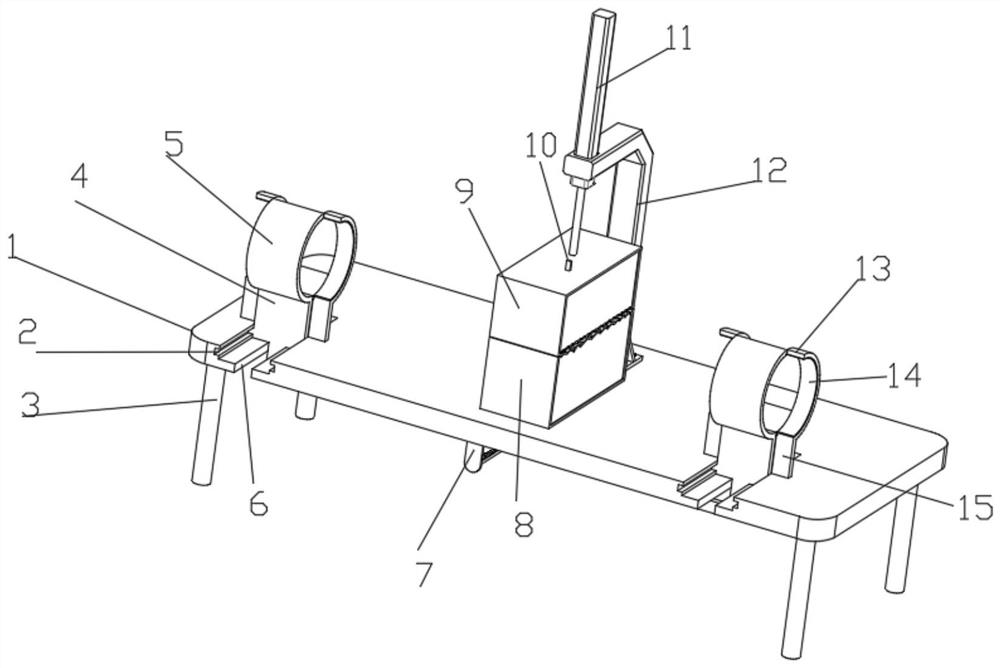

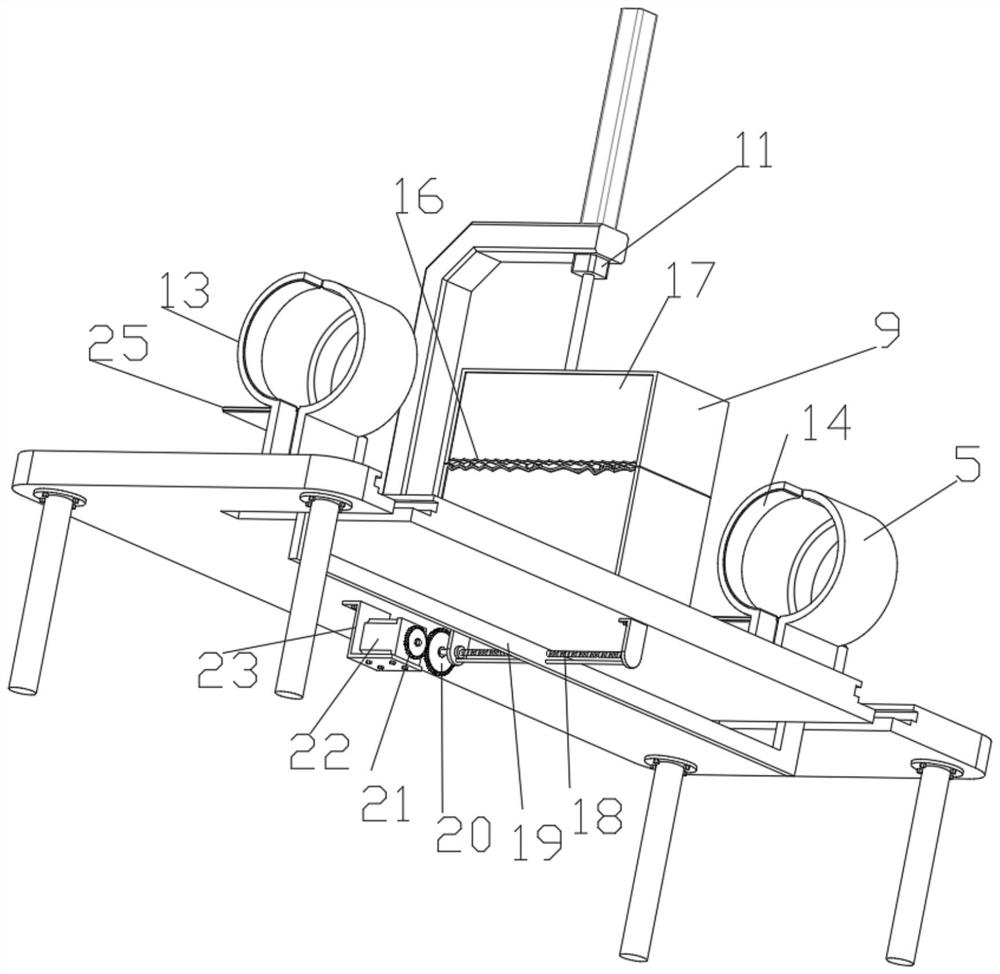

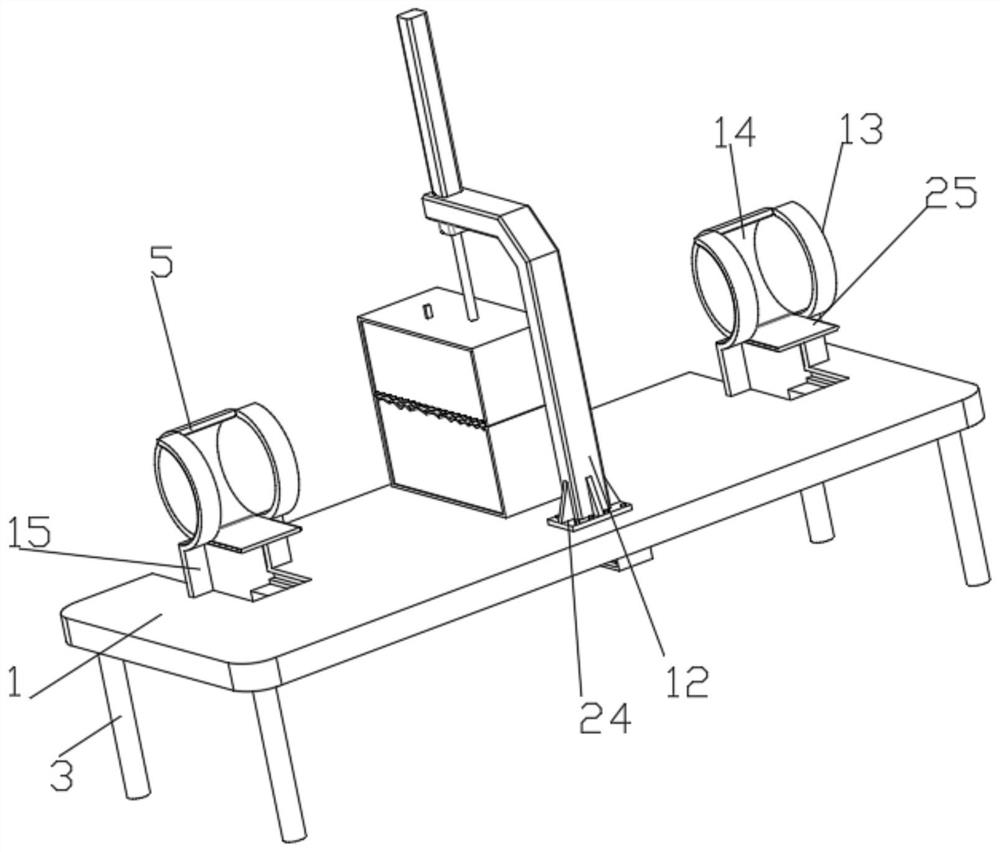

Embodiment 1

[0033] Such as Figure 1-5A clamping device for mechanical parts with a cutting function is shown, including a workbench 1 and a cylinder 11. The bottom of the workbench 1 is symmetrically fixedly connected with outriggers 3, and the workbench 1 is connected with a fixed structure for fixing parts. The fixed structure includes Cross chute 2, cross slide 4, middle arc splint 5, outer arc splint 13, connecting plate 15, threaded rod 18, driven ring gear 20, rotating motor 22 and Z-shaped support plate 23, Z-shaped support plate 23 The top of the top is fixedly connected with the bottom of the workbench 1, the Z-shaped support plate 23 is fixedly installed with a rotating motor 22, the output end of the rotating motor 22 is fixedly connected with a driving ring gear 21, and the driving ring gear 21 is meshed with a driven ring gear 20, The driven ring gear 20 is fixedly connected with a threaded rod 18, the threaded rod 18 is threadedly connected with a U-shaped plate 19, the top...

Embodiment 2

[0035] Such as Figure 1-5 A clamping device for mechanical parts with a cutting function is shown, including a workbench 1 and a cylinder 11. The bottom of the workbench 1 is symmetrically fixedly connected with outriggers 3, and the workbench 1 is connected with a fixed structure for fixing parts. The fixed structure Including cross chute 2, cross slide 4, middle arc splint 5, outer arc splint 13, connecting plate 15, threaded rod 18, driven ring gear 20, rotating motor 22 and Z-shaped support plate 23, Z-shaped support plate 23 is fixedly installed with a rotating motor 22, the output end of the rotating motor 22 is fixedly connected with a driving ring gear 21, and the driving ring gear 21 is meshed with a driven ring gear 20, and the driven ring gear 20 is fixedly connected with a threaded rod 18, and the threaded rod 18 A U-shaped plate 19 is threadedly connected, and cross slides 4 are fixedly connected to both ends of the top of the U-shaped plate 19. The top of the cr...

Embodiment 3

[0037] Embodiment 3 is a further improvement to Embodiment 1.

[0038] Such as Figure 1-5 A clamping device for mechanical parts with a cutting function is shown, including a workbench 1 and a cylinder 11. The bottom of the workbench 1 is symmetrically fixedly connected with outriggers 3, and the workbench 1 is connected with a fixed structure for fixing parts. The fixed structure Including cross chute 2, cross slide 4, middle arc splint 5, outer arc splint 13, connecting plate 15, threaded rod 18, driven ring gear 20, rotating motor 22 and Z-shaped support plate 23, Z-shaped support plate 23 is fixedly installed with a rotating motor 22, the output end of the rotating motor 22 is fixedly connected with a driving ring gear 21, and the driving ring gear 21 is meshed with a driven ring gear 20, and the driven ring gear 20 is fixedly connected with a threaded rod 18, and the threaded rod 18 A U-shaped plate 19 is threadedly connected, and cross slides 4 are fixedly connected to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com