Silica gel composite heat insulation plate and cutting equipment thereof

A heat insulation board and cutting technology, applied in the direction of stone processing equipment, stone processing tools, work accessories, etc., can solve the problems of deformation and bending of the protective iron plate, failure to achieve the protective effect, damage to the bracket, etc., to ensure stable cutting The effect of improving the cutting adaptability and prolonging the replacement cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0057] like figure 1 As shown, the silicon condensate composite heat insulation board includes the following raw materials in weight percentage: 58% of aluminum oxide, 5% of silicon dioxide, 1% of calcium oxide, 6% of zirconia, 10% of high-alumina porcelain, 20% of high-alumina alum %.

[0058] The processing technology of silicon condensate composite heat insulation board, the specific steps are as follows:

[0059] Step 1, Al2O3, silicon dioxide, calcium oxide, zirconia, high-alumina porcelain and high-alumina alum are weighed according to the above ratio, and then added to a mixer with a mixer speed of 800r / min and a stirring time of 45min to obtain slurry;

[0060] Step 2. Pour the slurry into the forming mold, then put the filled mold on the vibrating table, shake out the air bubbles, place it on a drying rack to dry, and remove the mold after drying;

[0061] Step 3: After removing the formwork, use the size requirements according to the needs, and cut them by a cutting...

Embodiment 2

[0063] like figure 1 As shown, embodiment 2 is a further improvement to embodiment 1. The silicon condensate composite heat insulation board includes the following raw materials in weight percentage: 55% of aluminum oxide, 7% of silicon dioxide, 2% of calcium oxide, zirconia 8%, high alumina porcelain 13%, high alumina alum 20%.

[0064] The processing technology of silicon condensate composite heat insulation board, the specific steps are as follows:

[0065] Step 1, Al2O3, silicon dioxide, calcium oxide, zirconia, high-alumina porcelain and high-alumina alum are weighed according to the above ratio, and then added to a mixer with a mixer speed of 800r / min and a stirring time of 45min to obtain slurry;

[0066] Step 2. Pour the slurry into the forming mold, then put the filled mold on the vibrating table, shake out the air bubbles, place it on a drying rack to dry, and remove the mold after drying;

[0067] Step 3: After removing the formwork, use the size requirements acc...

Embodiment 3

[0070] Embodiment 3 is a further improvement to Embodiment 1.

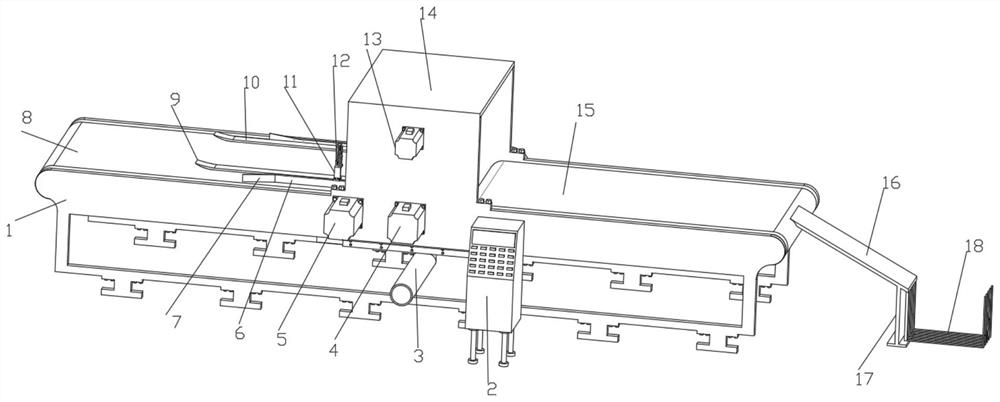

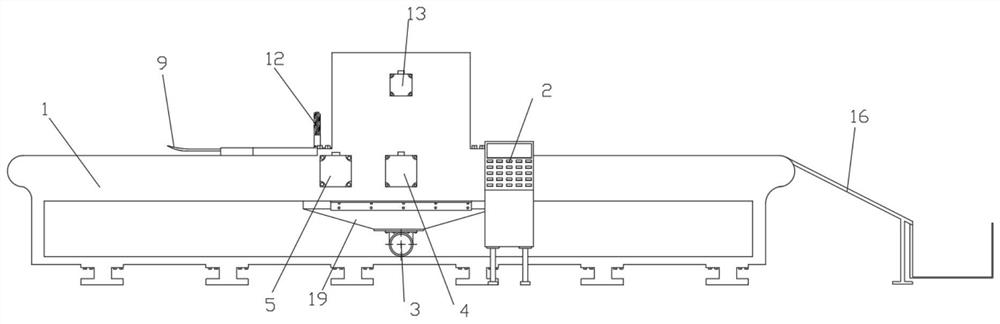

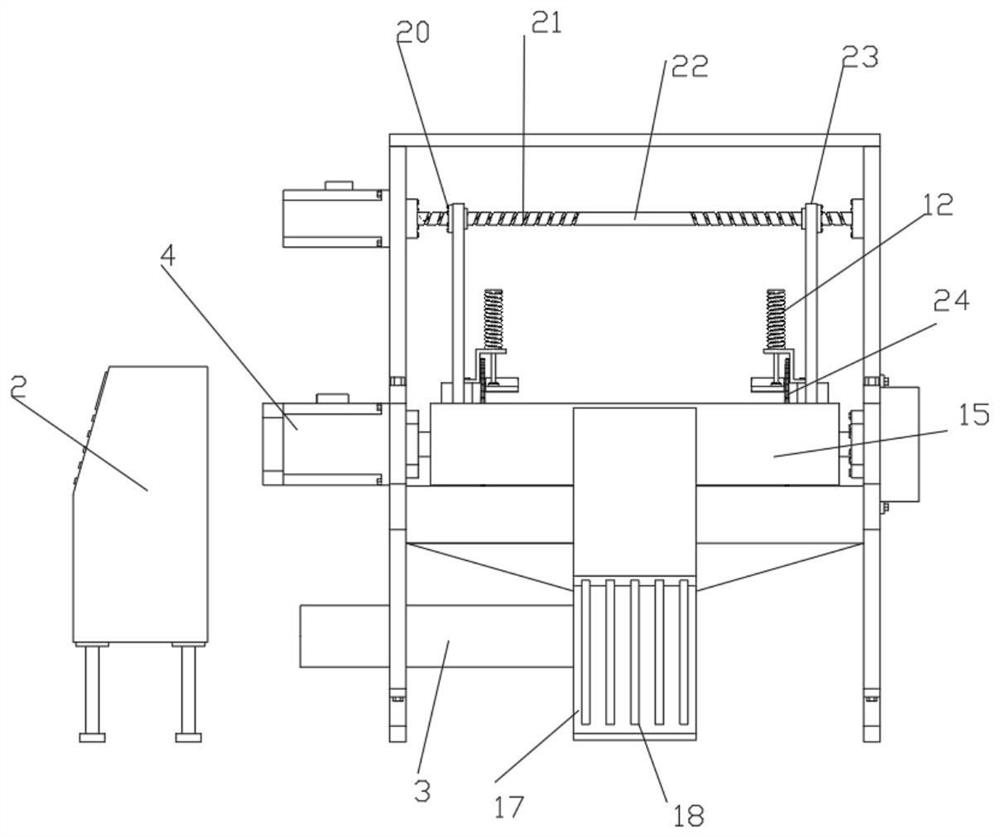

[0071] like Figure 1-8 As shown, the cutting equipment of the silicon condensate composite heat insulation board is the cutting machine in step 3, including the frame 1 and the control box 2;

[0072] Frame 1 is connected with a driving structure for moving the silicon solidified composite heat insulation board;

[0073] The driver structure includes:

[0074] The feeding component is installed on one end of the frame 1;

[0075] The feeding assembly includes a first conveyor belt 8 and a first driving roller 28 , the inner wall of the frame 1 is rotatably connected to the first driving roller 28 through a bearing, and the outer wall of the first driving roller 28 is movably connected to the first conveyor belt 8 .

[0076] The first driving assembly, the first driving assembly is installed on the side wall of the frame 1, and the feeding assembly is coaxially fixedly connected with the output end of the first...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com