Easy-to-cut and easy-to-stick double-material hollow solar silicon wafer cutting lining plate and preparation method thereof

A dual-material, solar energy technology, applied in chemical instruments and methods, layered products, synthetic resin layered products, etc., can solve problems such as affecting the silicon crystal cutting process, and achieve easy adhesion, easy identification, and cost savings. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

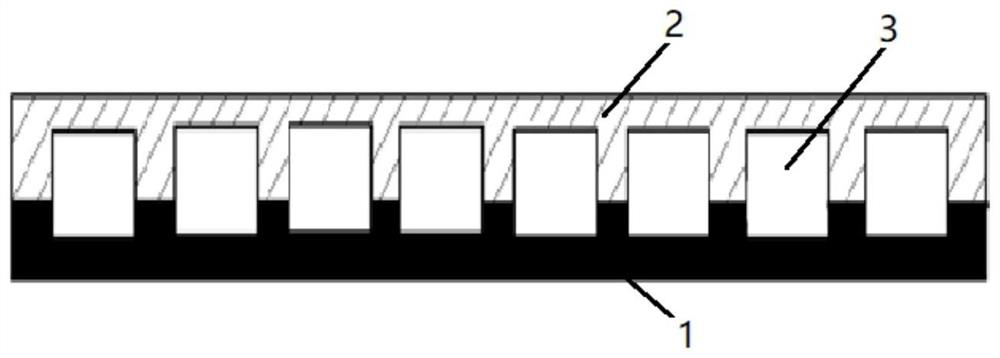

[0028] This embodiment provides an easy-to-cut and easy-to-adhesive double-material hollow solar silicon wafer cutting liner, comprising a B surface layer 1 and an A surface layer 2 arranged on the top of the B surface layer 1, and the B surface layer 1 is uniform along the length direction. A plurality of grooves B are distributed, and a plurality of grooves A corresponding to the grooves B are evenly distributed on the A surface layer 2 , and the grooves B and the grooves A are combined to form a sealed through hole 3 .

Embodiment 2

[0030] On the basis of adopting the technical solution of Example 1, the A surface layer includes the following components calculated by mass percentage: ABS resin 90wt%, cutting adjustment component 9wt%, antioxidant 0.6wt%, lubricant 0.4wt% %. The glue content of the ABS resin is 8wt%, and the preferred acrylocyanide is ABS with medium molecular weight. The cutting adjustment component includes any one or a combination of two or more of polytetrafluoroethylene powder, ultra-high molecular weight polyethylene powder, and polyvinylidene fluoride.

[0031] The surface layer B includes the following components calculated by mass percentage: ABS resin 80wt%, adhesion regulating component 19wt%, antioxidant 0.6wt%, lubricant 0.4wt%. The adhesion regulating component is mineral powder or metal powder, specifically selected from any one or a combination of two or more of calcium carbonate, talc powder, aluminum powder, iron powder and the like. The antioxidant is a compound of ant...

Embodiment 3

[0033] On the basis of adopting the technical solution of Example 1, the A surface layer includes the following components calculated by mass percentage: ABS resin 96wt%, cutting adjustment component 3wt%, antioxidant 0.6wt%, lubricant 0.4wt% %. The glue content of the ABS resin is 13 wt%, and the preferred acrylocyanide is ABS with medium molecular weight. The cutting adjustment component includes any one or a combination of two or more of polytetrafluoroethylene powder, ultra-high molecular weight polyethylene powder, and polyvinylidene fluoride.

[0034] The surface layer B includes the following components calculated by mass percentage: ABS resin 90wt%, adhesion regulating component 9wt%, antioxidant 0.6wt%, lubricant 0.4wt%. The adhesion regulating component is mineral powder or metal powder, specifically selected from any one or a combination of two or more of calcium carbonate, talc powder, aluminum powder, iron powder and the like. The antioxidant is a compound of an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com