Anti-rutting agent, asphalt material and preparation method

A technology of anti-rutting agent and asphalt material, which is used in building thermal insulation materials, building components, buildings, etc., can solve the problems of low asphalt cohesion and low anti-rutting performance of mixtures, achieve strong cohesive performance and improve anti-rutting performance. , to ensure the effect of anti-skid performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

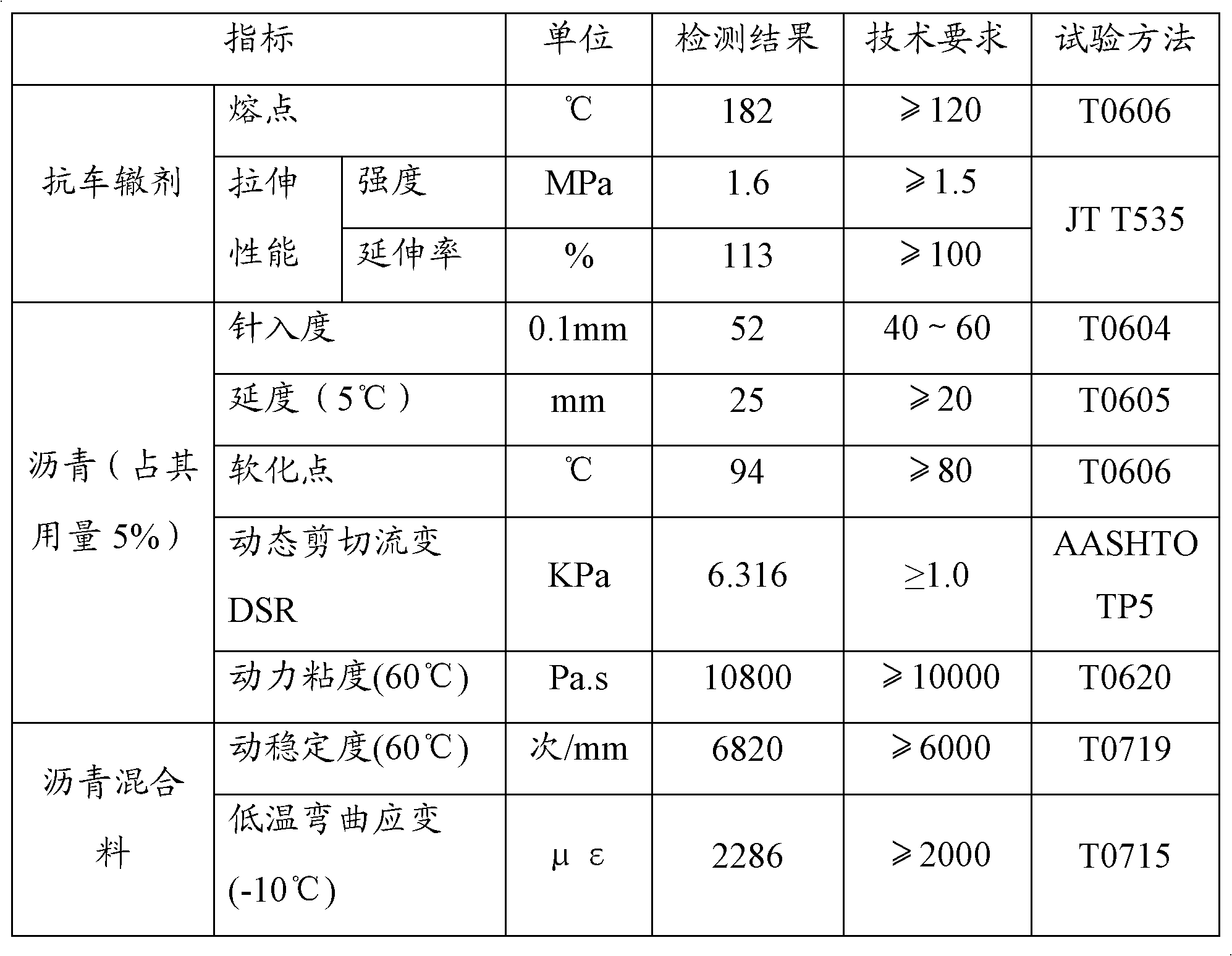

[0039] After determining a certain amount of anti-rutting agent raw materials, the anti-rutting agent is prepared according to the preparation method of the invention, and the anti-rutting agent is tested to measure the performance of the product itself. The test and detection indicators mainly include: melting point, viscosity (135°C) and tensile strength. Extensibility (strength, elongation).

[0040] Adopt the anti-rutting agent in the embodiment of the present invention to prepare the process of asphalt comprising:

[0041] Heat asphalt or modified asphalt to 135-150°C, add 5% to 15% anti-rutting agent, stir together and heat to 170-185°C to effectively mix asphalt and anti-rutting agent, mix the mixture evenly and then cool Get asphalt material.

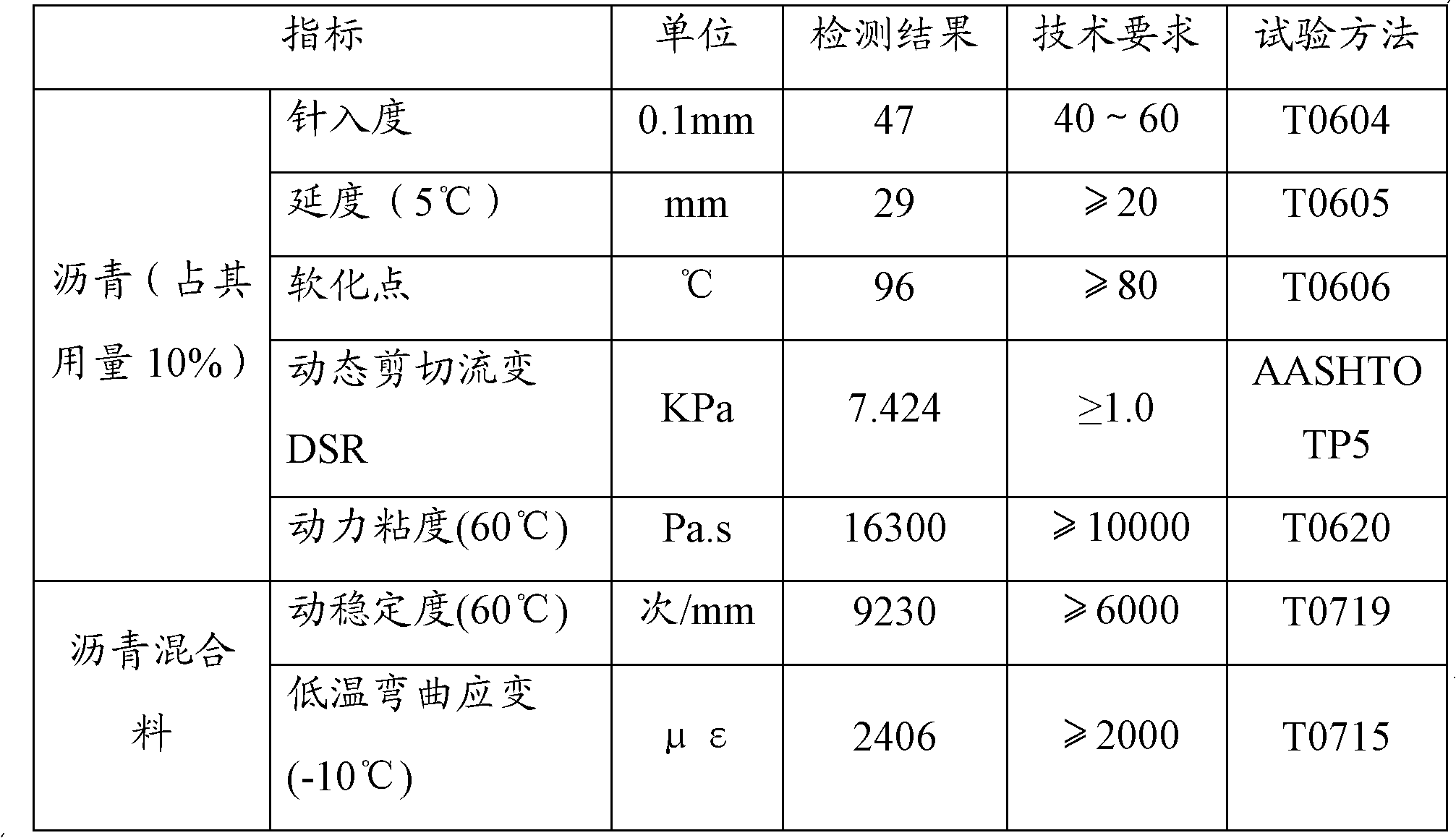

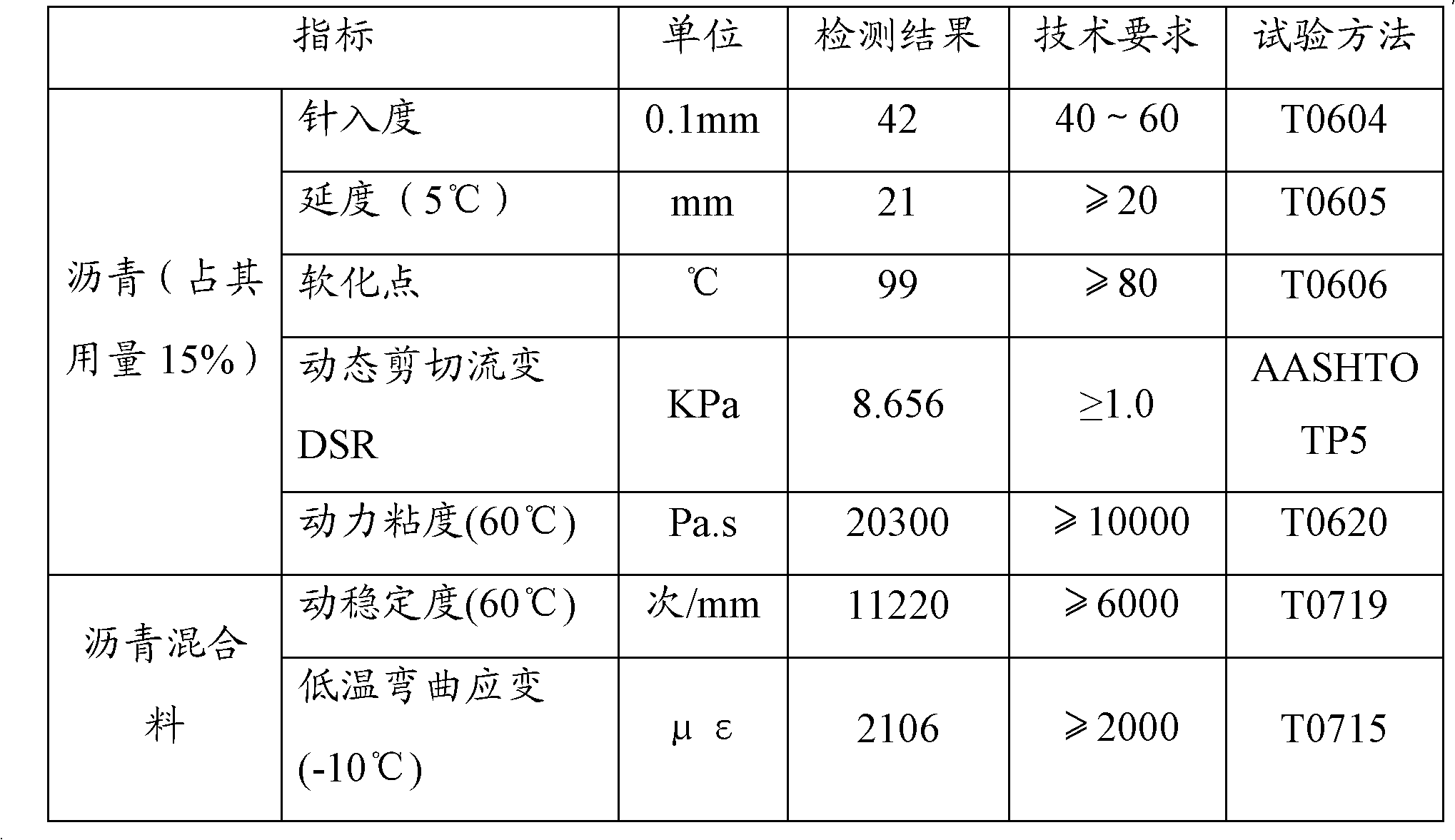

[0042] Penetration, ductility (5°C), softening point and dynamic viscosity (60°C) were tested for asphalt materials.

[0043] Carry out mixture gradation design, obtain the amount of coarse aggregate, fine aggregate, mineral p...

Embodiment 1

[0045] In this embodiment, taking the production of the anti-rutting agent 100kg of the present invention as an example, the raw materials used and the proportion thereof are:

[0046] Polyurethane: 30.0kg

[0047] Polyethylene terephthalate: 40.0kg

[0048] Polymethacrylonitrile: 15.0kg

[0049]Calcium carbonate: 15.0kg

[0050] Its preparation method is as follows:

[0051] 1. Add the diphenylmethane diisocyanate and propylene glycol into the tank reactor at a mass ratio of 1:1, fill the whole process with nitrogen protection, stir and heat to 145-155°C, preferably 150°C, and react 4 Hours to obtain polyurethane.

[0052] 2. Add 15.0kg of calcium carbonate powder into the reaction kettle for producing polyurethane, stir evenly, and discharge the material for storage.

[0053] 3. Add the polyurethane containing calcium carbonate powder, polymethacrylonitrile and polyethylene terephthalate into the twin-screw extruder according to the ratio, and the processing temperature...

Embodiment 2

[0066] In this embodiment, taking the production of the anti-rutting agent 100kg of the present invention as an example, the raw materials used and the proportion thereof are:

[0067] Polyurethane: 40.0kg

[0068] Polyethylene terephthalate: 50.0kg

[0069] Polymethacrylonitrile: 5.0kg

[0070] Calcium carbonate: 5.0kg

[0071] Its preparation method is as follows:

[0072] 1. Add the diphenylmethane diisocyanate and propylene glycol into the tank reactor at a mass ratio of 1:1, fill the whole process with nitrogen protection, stir and heat to 145-155°C, preferably 150°C, and react 4 Hours to obtain polyurethane.

[0073] 2. Add 5.0kg of calcium carbonate powder into the reaction kettle for generating polyurethane, stir evenly, and discharge the material for storage.

[0074] 3. Add polyurethane containing calcium carbonate powder, polymethacrylonitrile and polyethylene terephthalate into the twin-screw extruder according to the ratio, and the processing temperature is 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com