Patents

Literature

37results about How to "Teleportation does not affect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

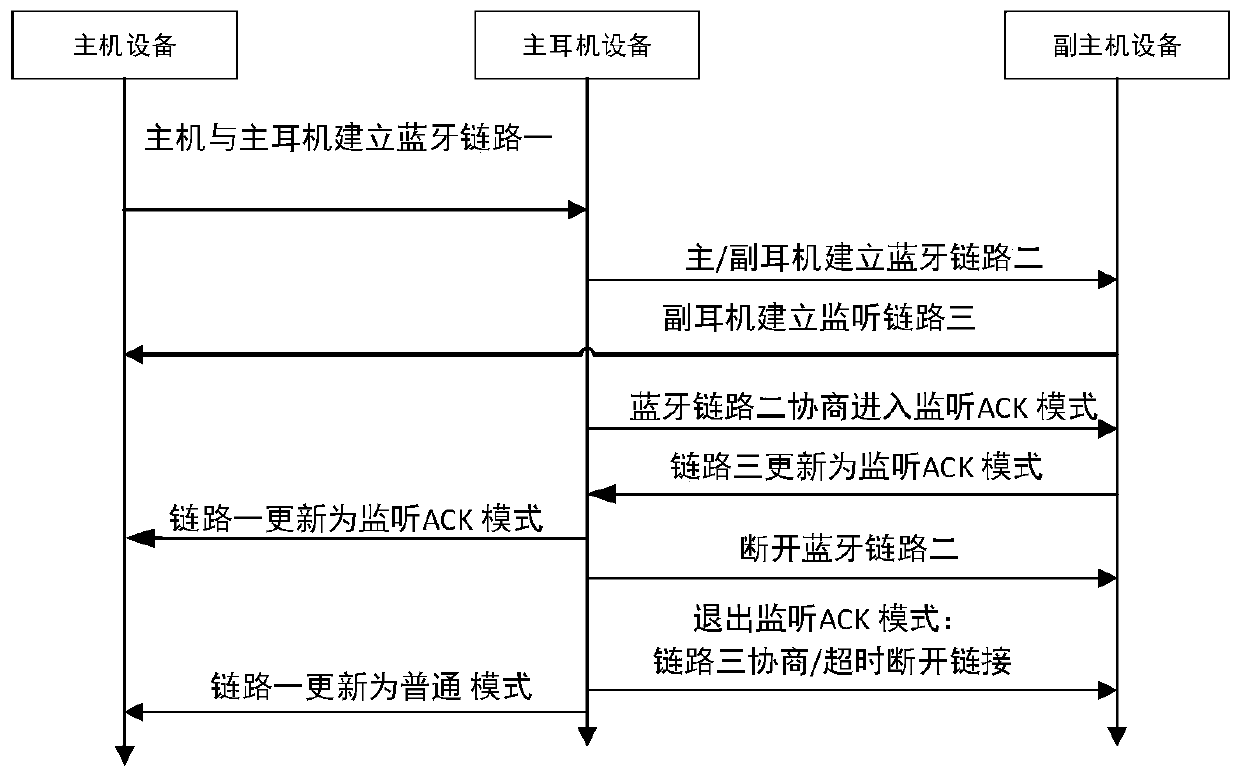

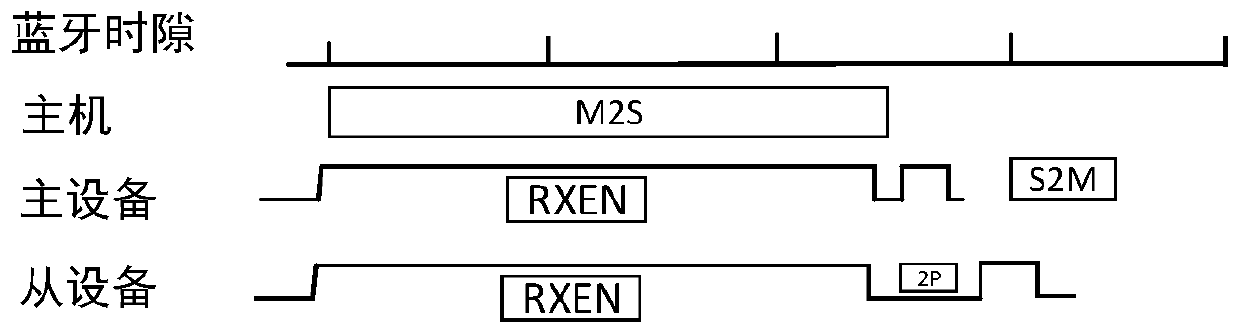

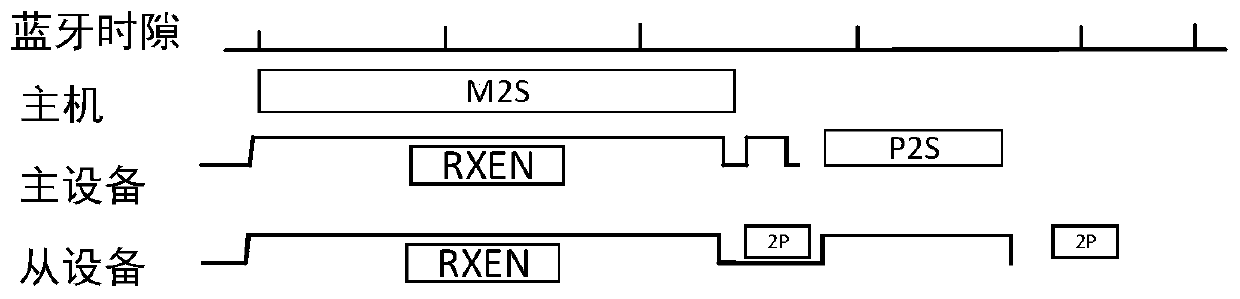

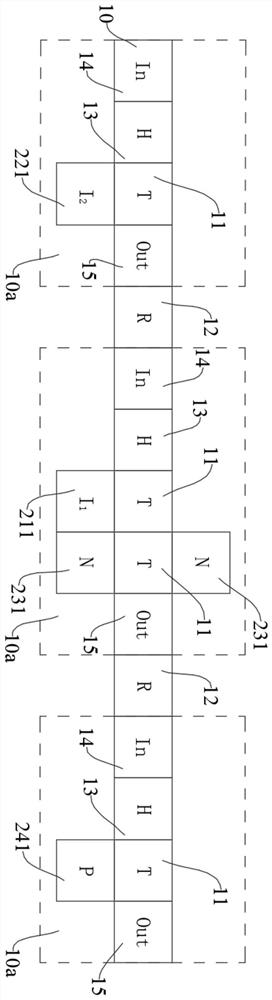

Device communication method and system for wireless communication system

PendingCN111163450ADoes not affect transmissionTeleportation does not affectPower managementNetwork topologiesCommunications systemTelecommunications link

The invention relates to a Bluetooth communication technology, and particularly relates to a device communication method and system for a wireless communication system. The method comprises the stepsthat S100 slave equipment establishes a monitoring link for communication between master equipment and host equipment; S200 the slave equipment negotiates with the master equipment to enter a monitoring confirmation mode; the monitoring link enters a monitoring confirmation mode; the master equipment and the host equipment enter the monitoring confirmation mode; and S300 the communication link between the slave equipment and the master equipment exits the monitoring confirmation mode after information interaction is completed. The system comprises the master equipment carrying a Bluetooth communication protocol, the slave equipment and the host equipment. According to the invention, the power consumption of the master equipment and the slave equipment can be reduced by reducing one link, which is helpful for reducing the burden overhead of the equipment and improving the user experience.

Owner:WU QI TECH INC

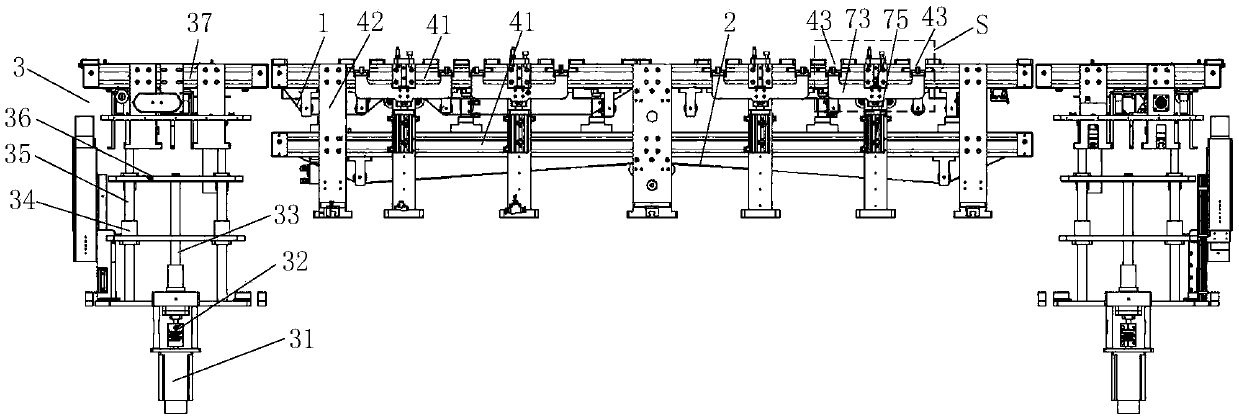

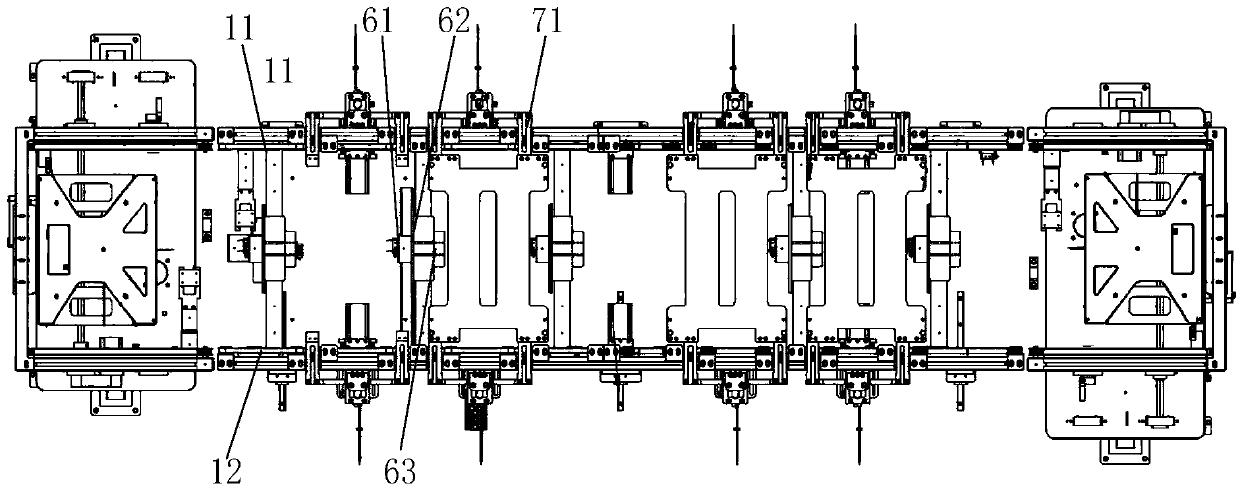

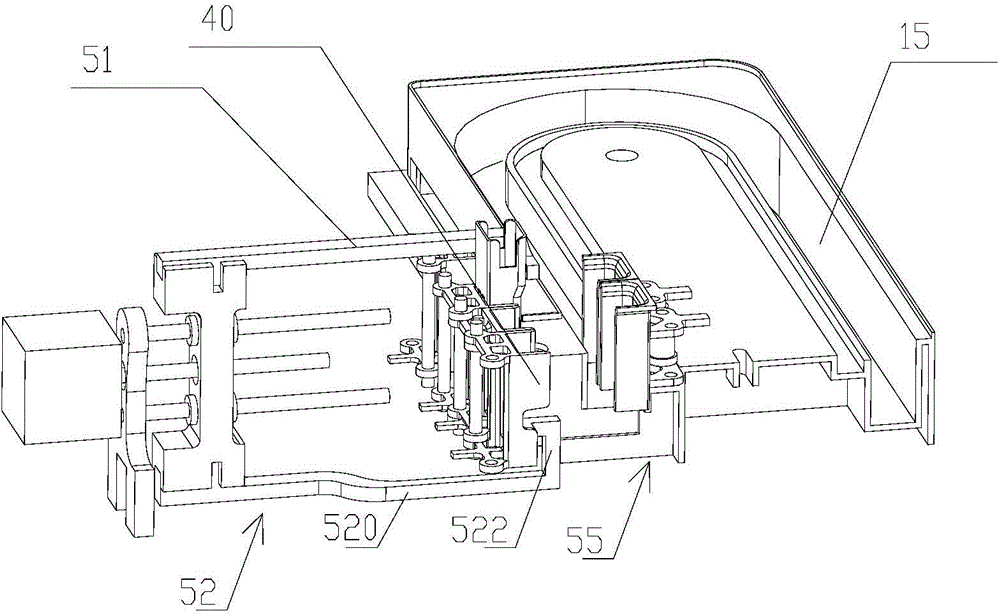

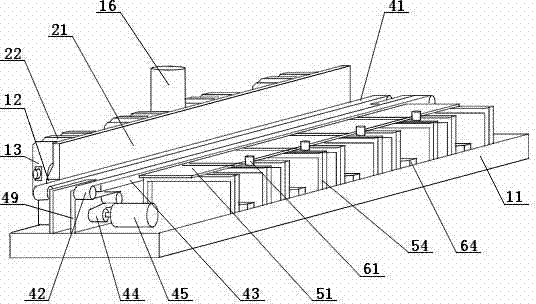

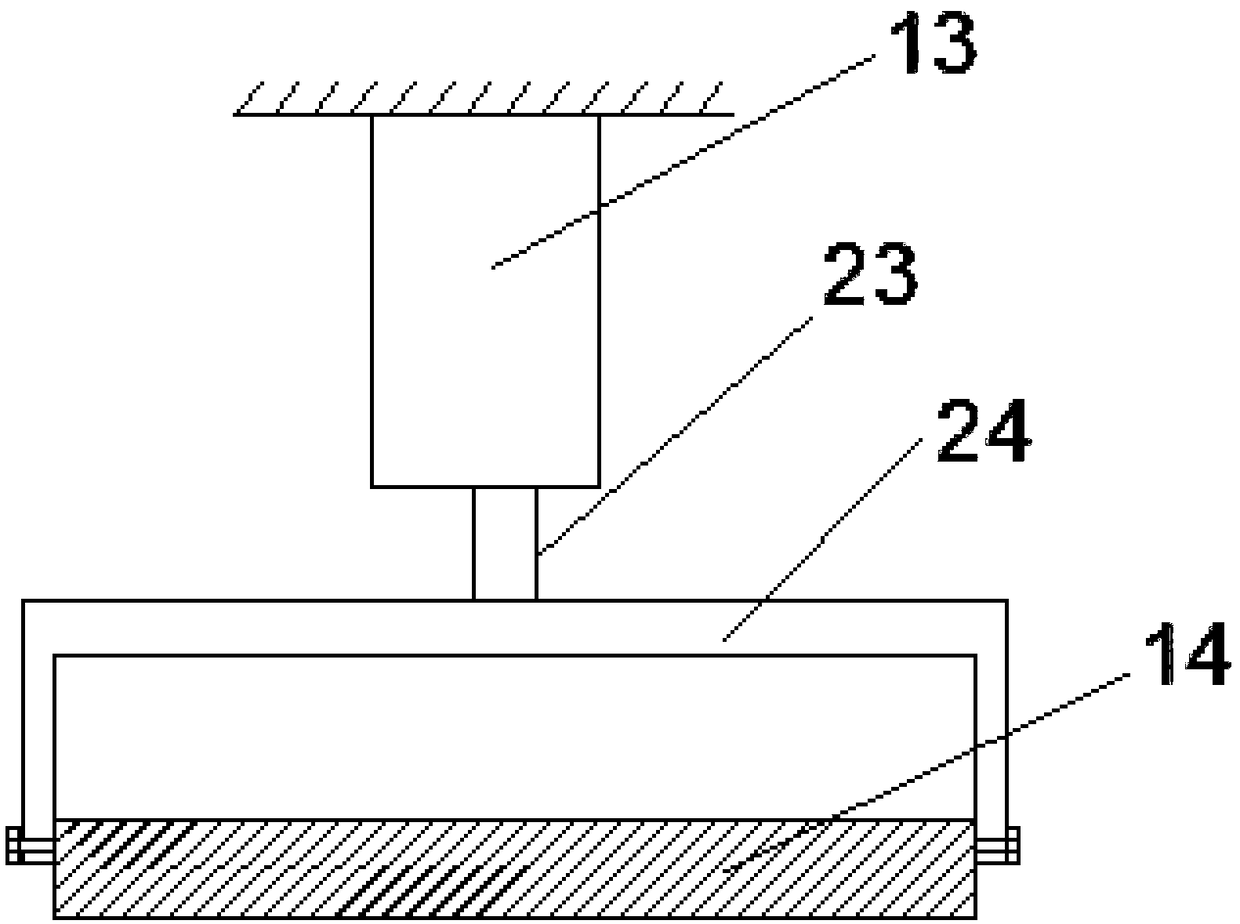

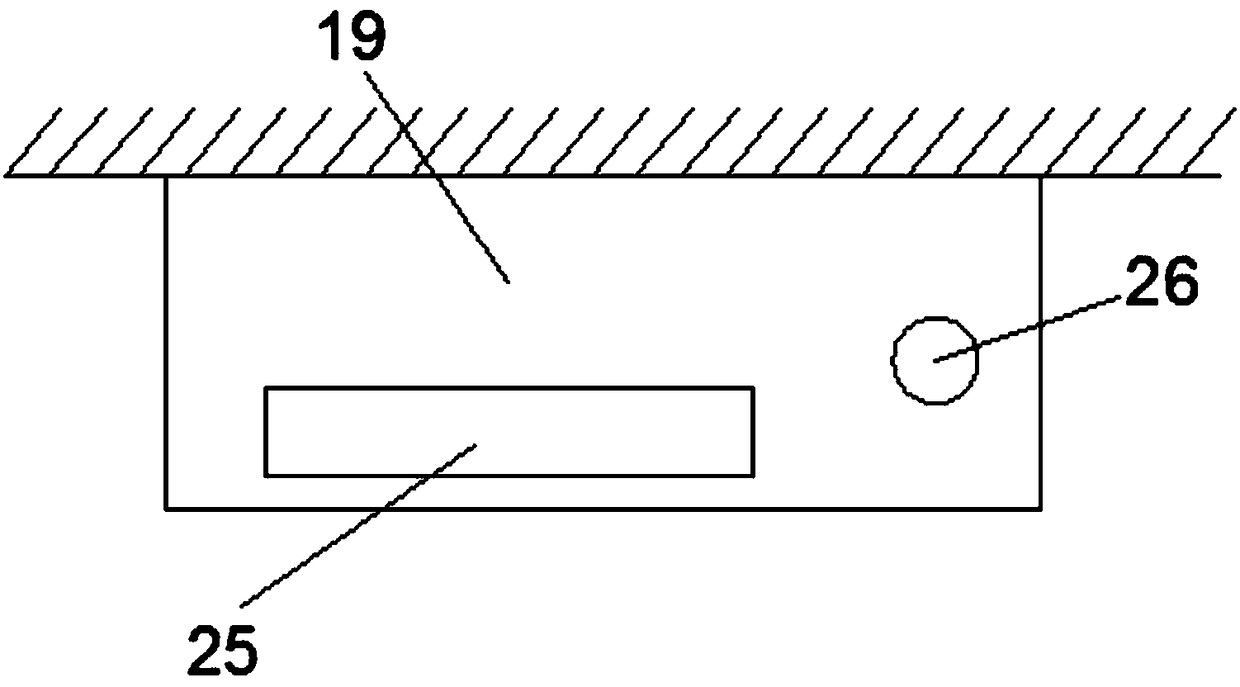

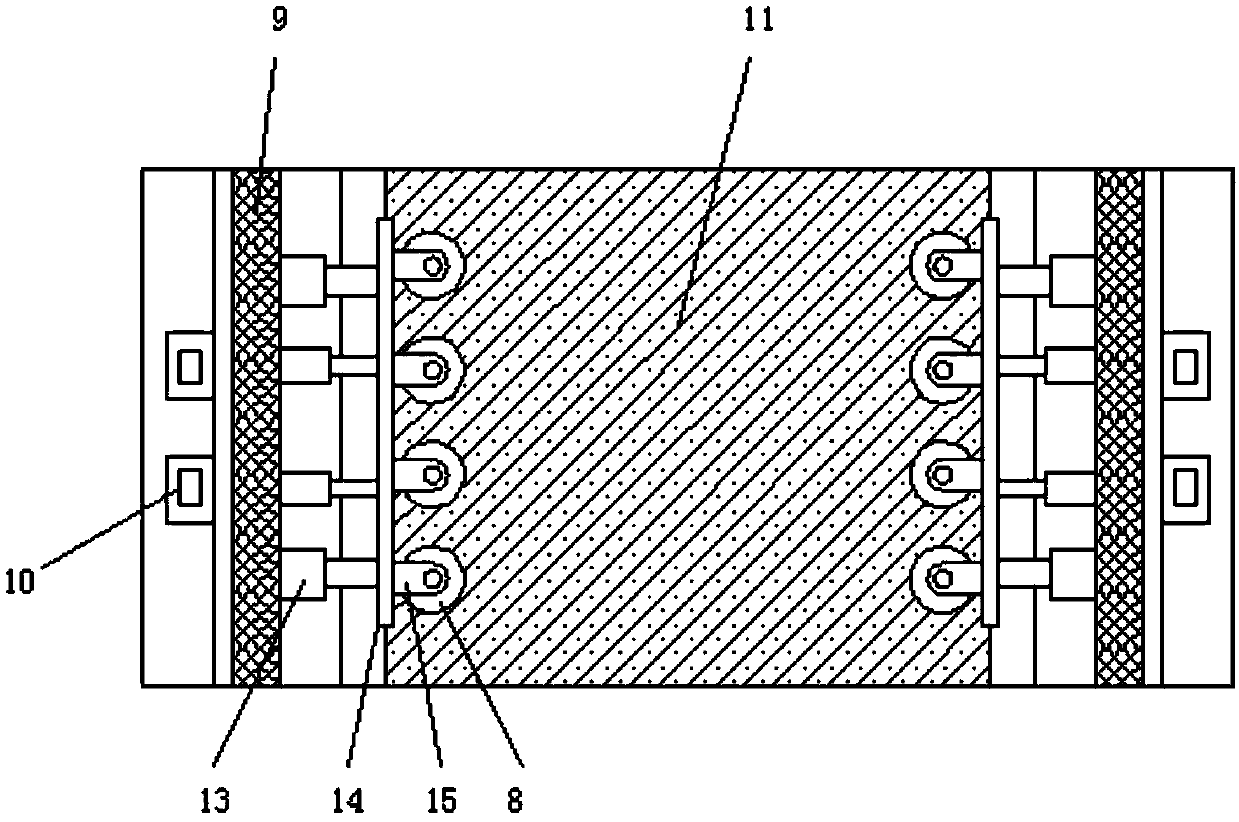

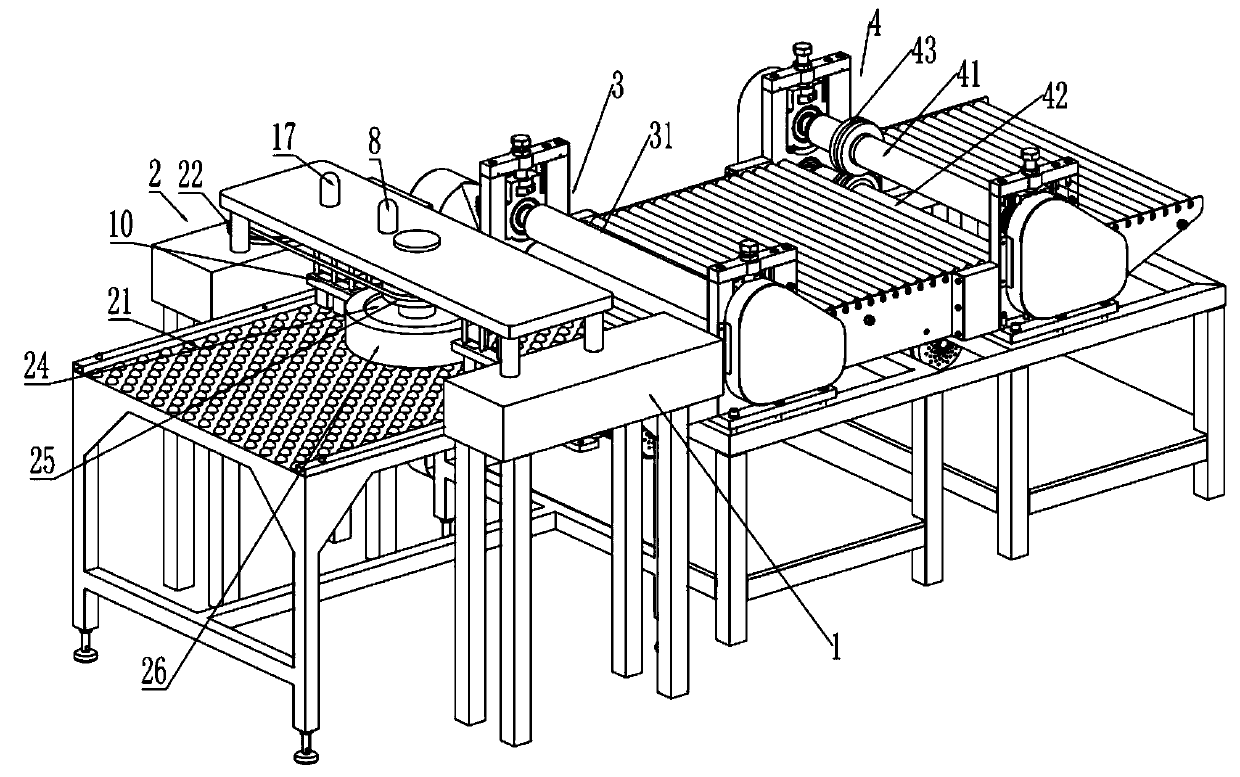

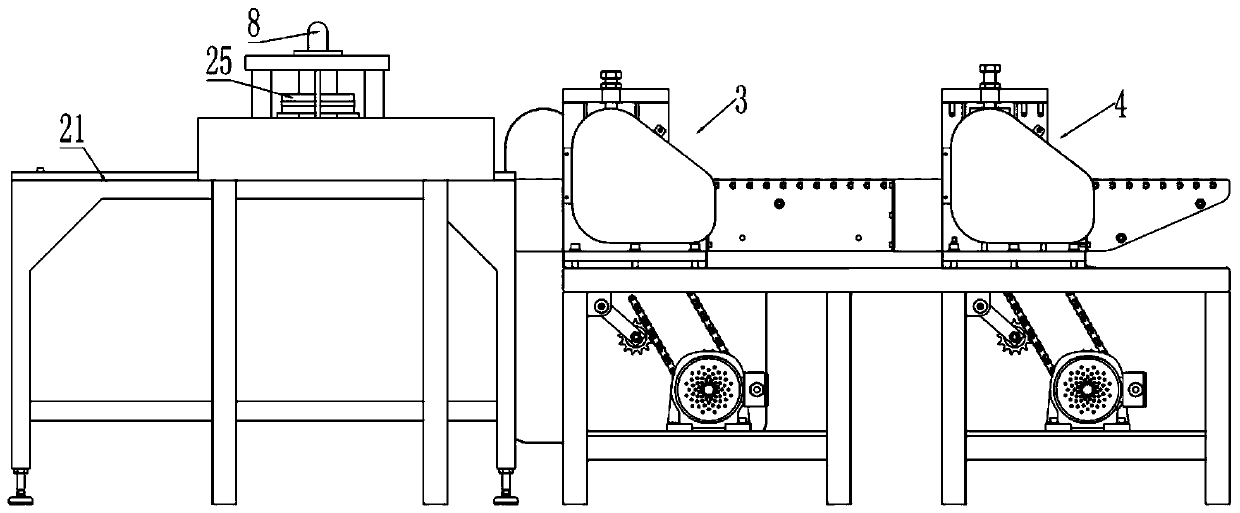

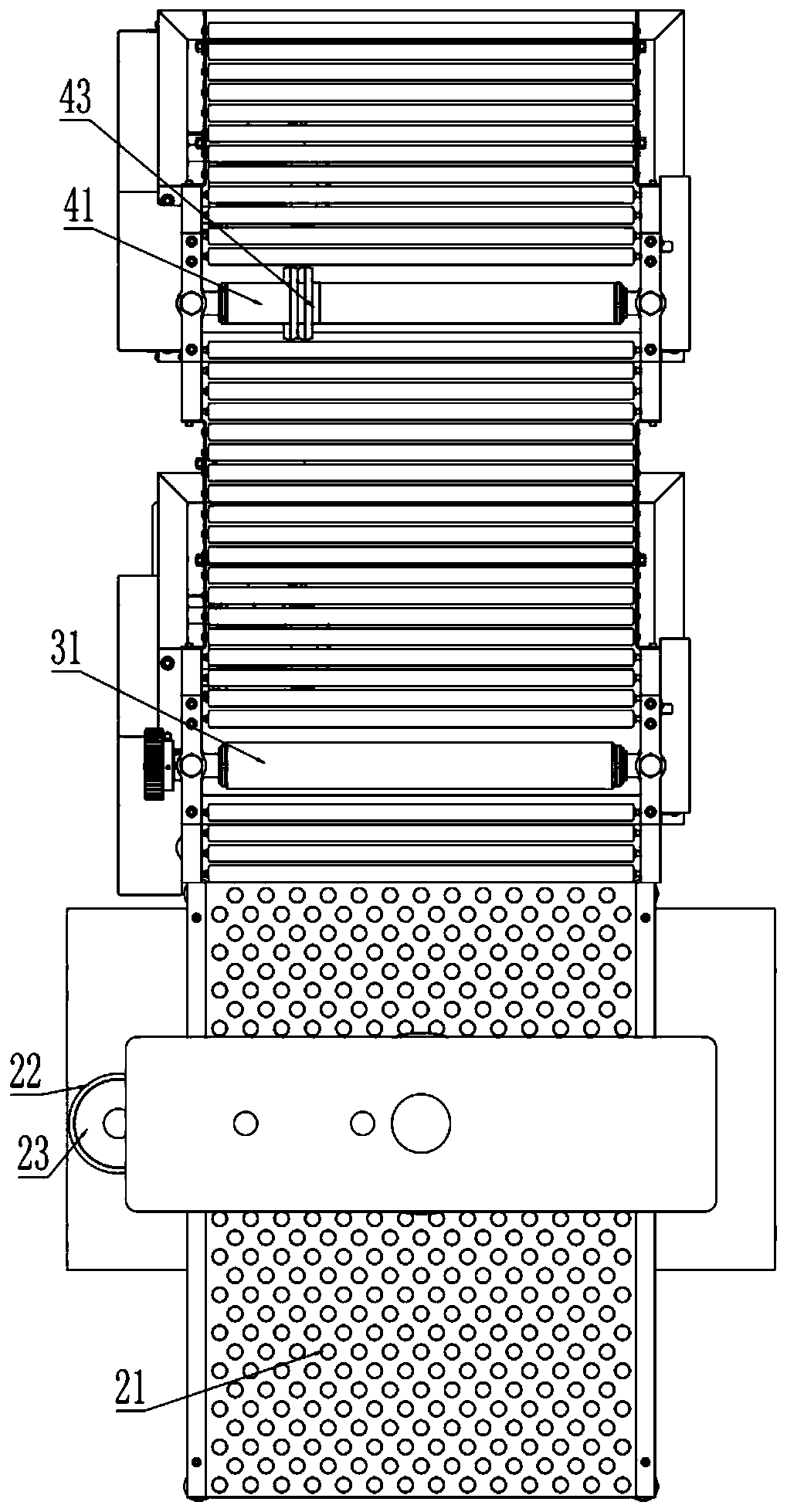

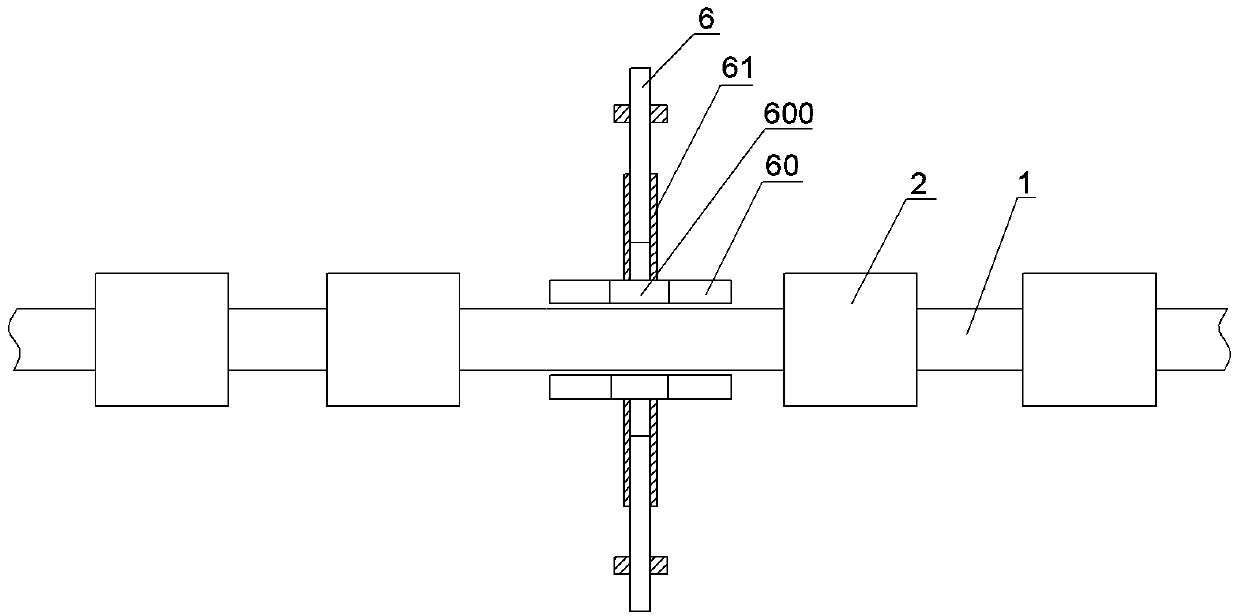

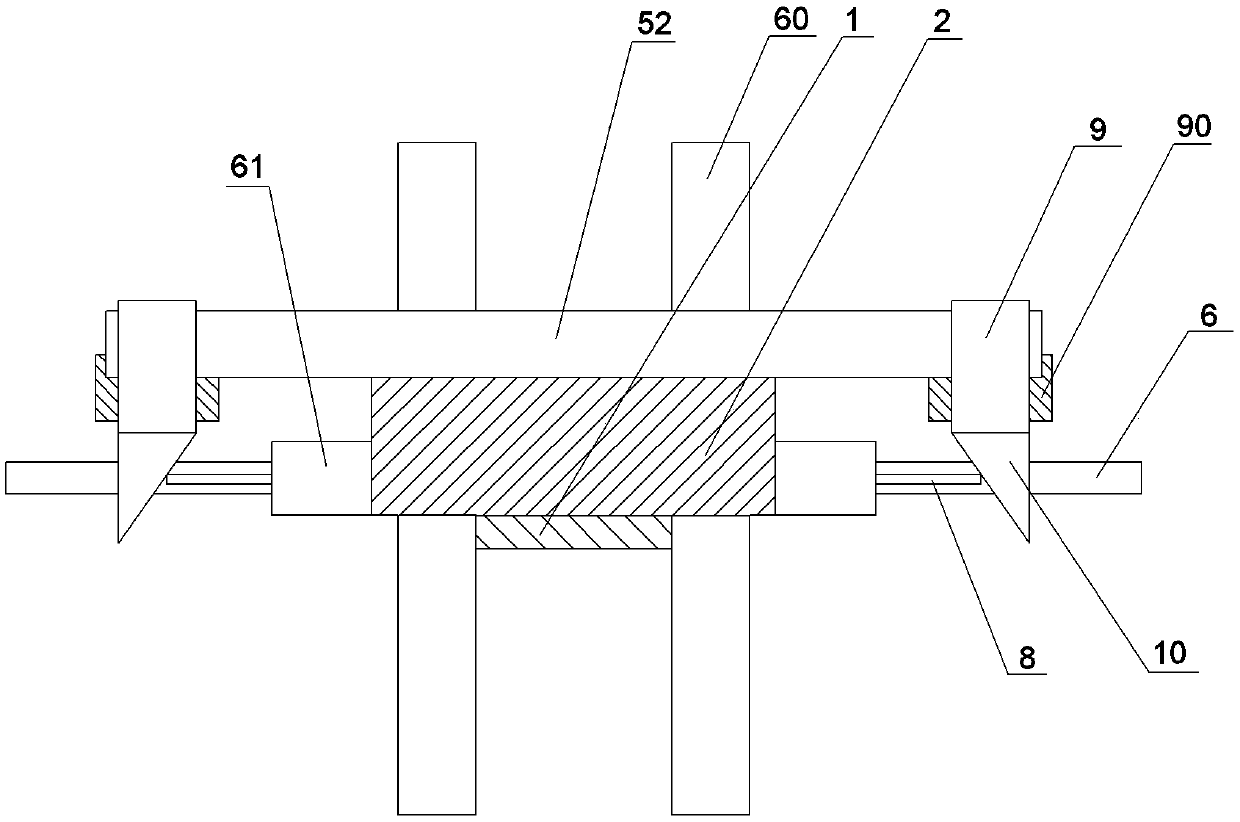

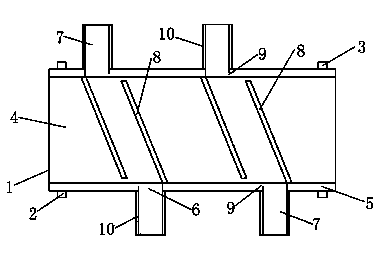

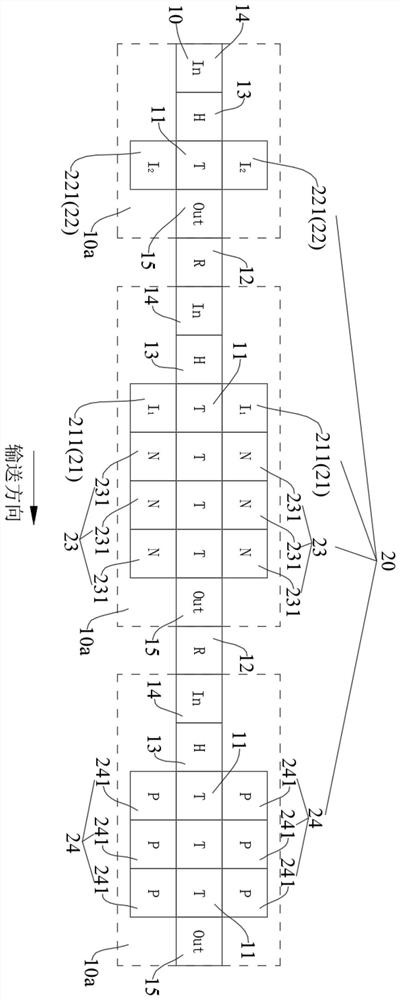

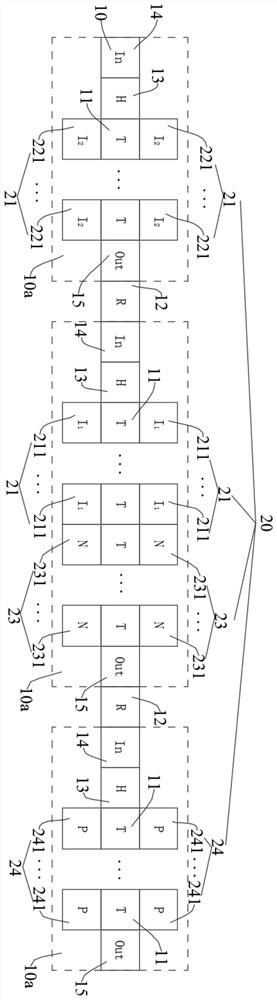

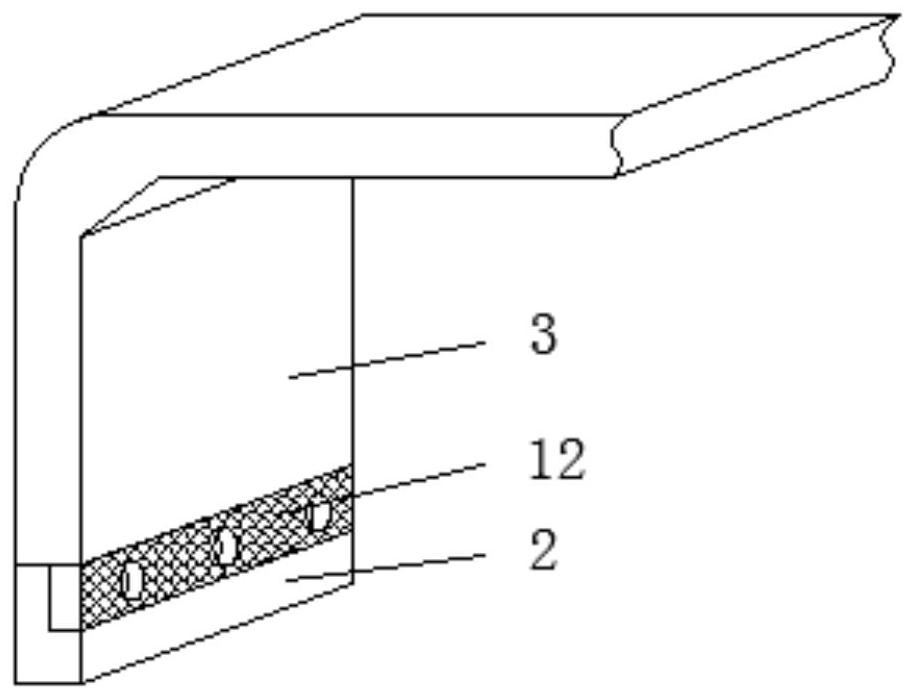

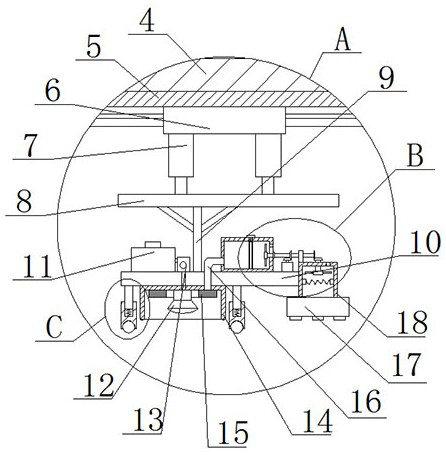

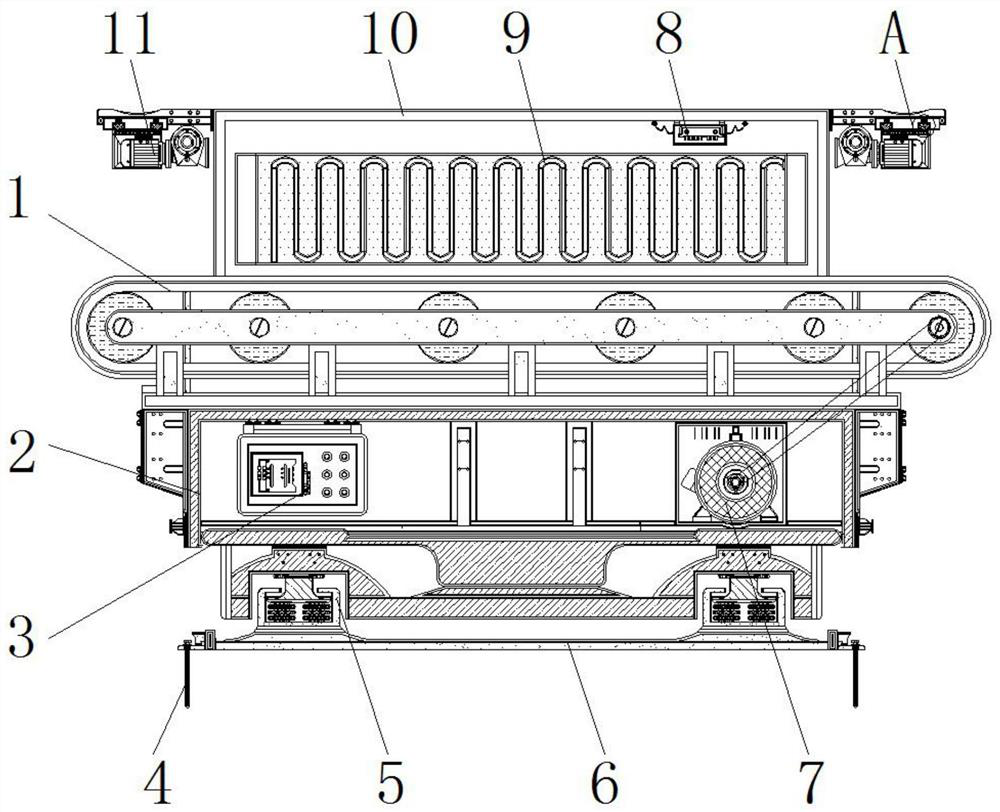

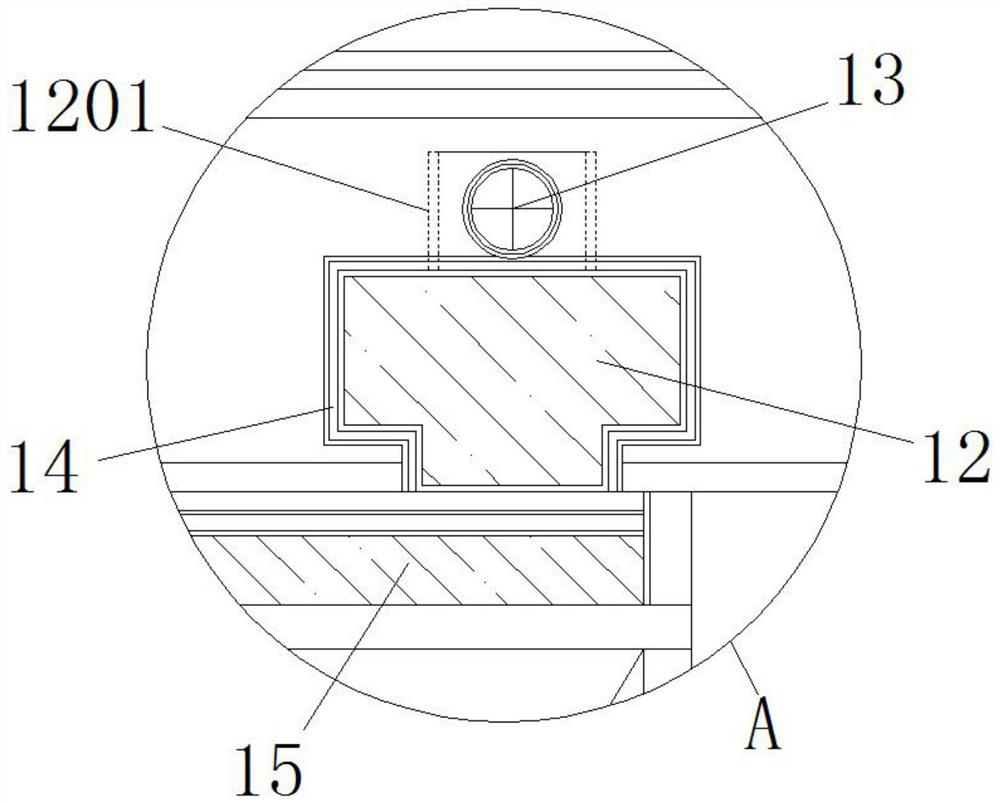

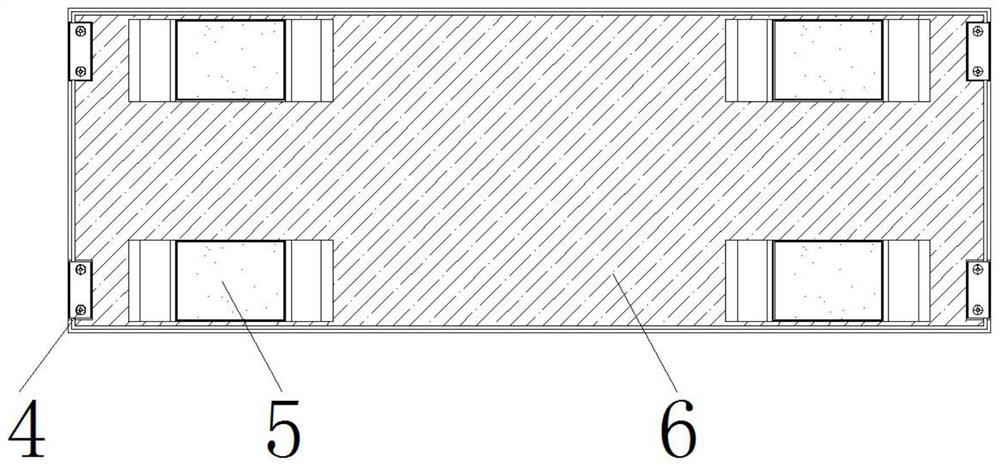

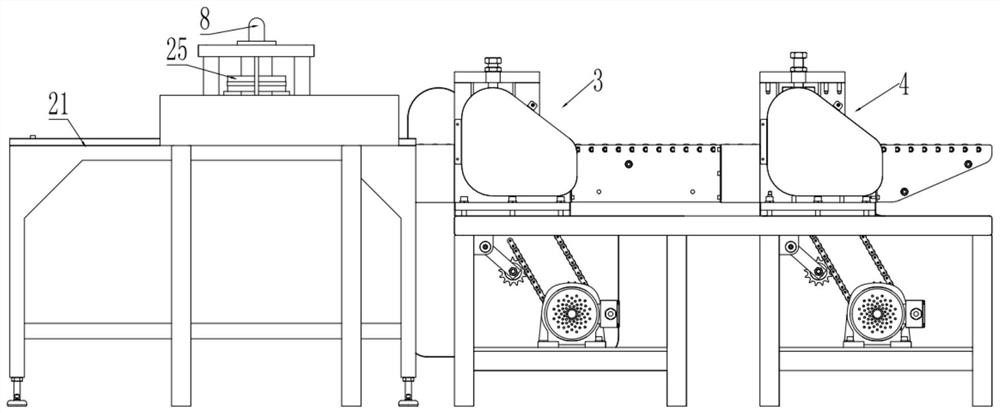

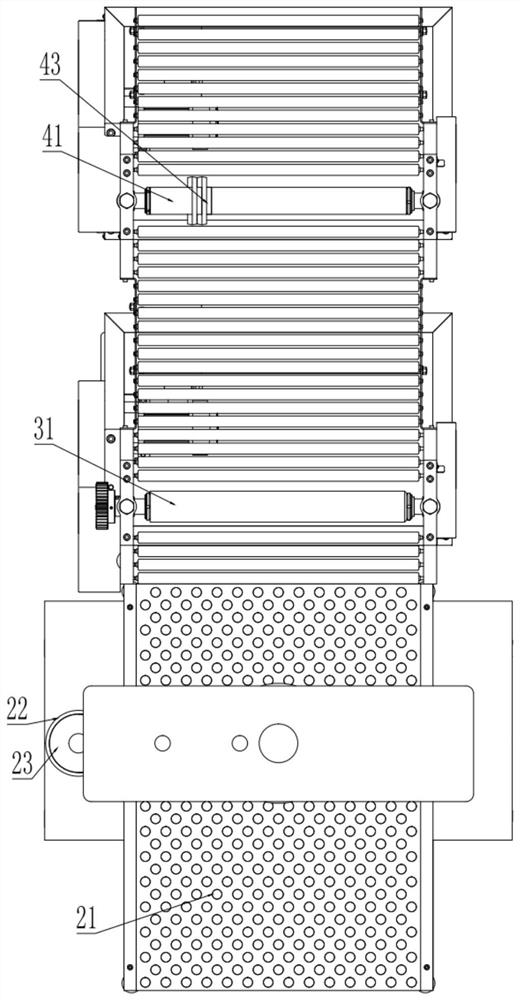

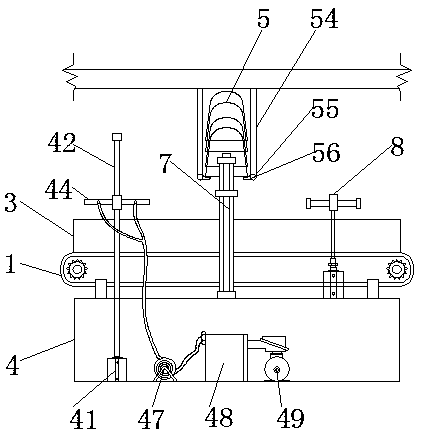

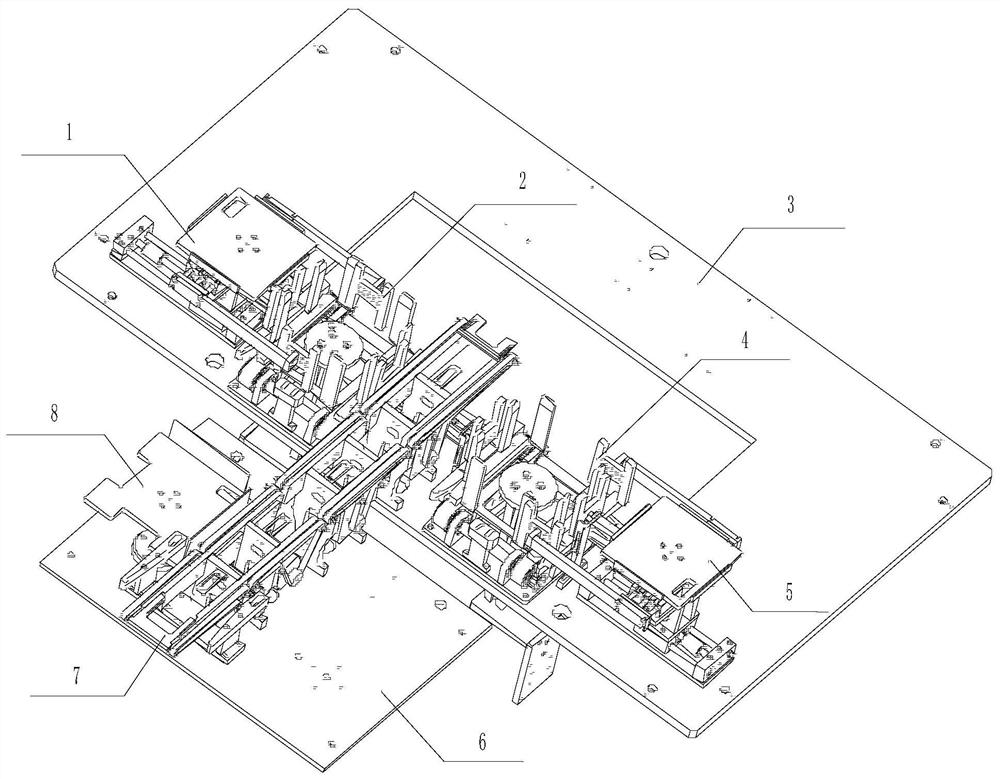

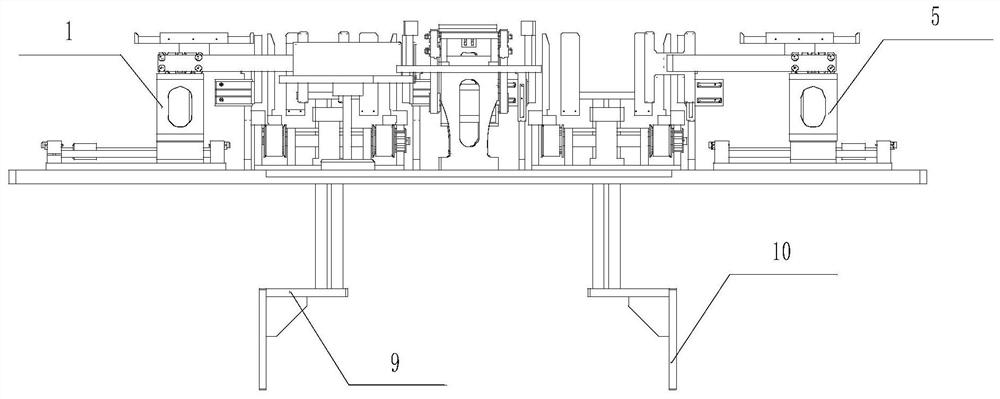

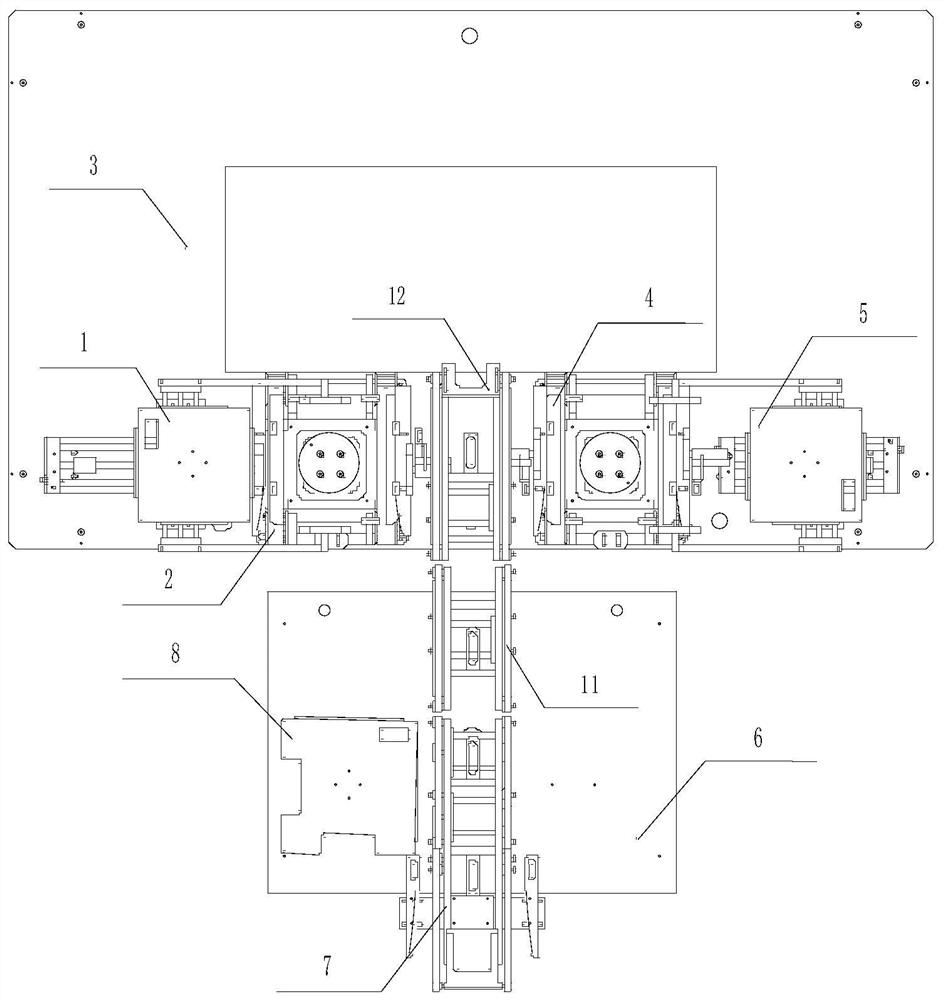

Assembly line for circulating carriers

PendingCN109573525AImplement automatic transferAchieve reflowControl devices for conveyorsMechanical conveyorsAssembly lineBackflow

The invention discloses an assembly line for circulating carriers. The assembly line comprises an upper layer assembly line and a lower layer assembly line which are arranged up and down, and transferdevices respectively arranged at two ends of the upper layer assembly line and the lower layer assembly line; the upper layer assembly line is used for successively transferring a plurality of carriers to all work stations at intervals in a first transfer direction; the lower layer assembly line is used for transferring all carriers in a second transfer direction, wherein the first transfer direction and the second transfer direction are opposite; the transfer device is used for transferring all carriers between the upper layer assembly line and the lower layer assembly line; a plurality of work stations are uniformly distributed on the upper layer assembly line, and each of the work stations comprises a barrier climbing mechanism; and the carrier climbing mechanism is used for blocking the carriers transferred to all work stations to the corresponding work stations, and climbing the carriers to a height of at least one carrier. With adoption of the assembly line, automatic transfer and backflow of the carriers can be realized, the transfer of other carriers is not influenced when one carrier is transferred to one work station.

Owner:SHENZHEN YANMADE TECH CO LTD

Full-automatic fecal occult blood detection analyzer

ActiveCN104569460AEasy to holdEasy to sendVaccination/ovulation diagnosticsMaterial analysisMedicineAnimal feces

Owner:W H P M BIORES & TECH

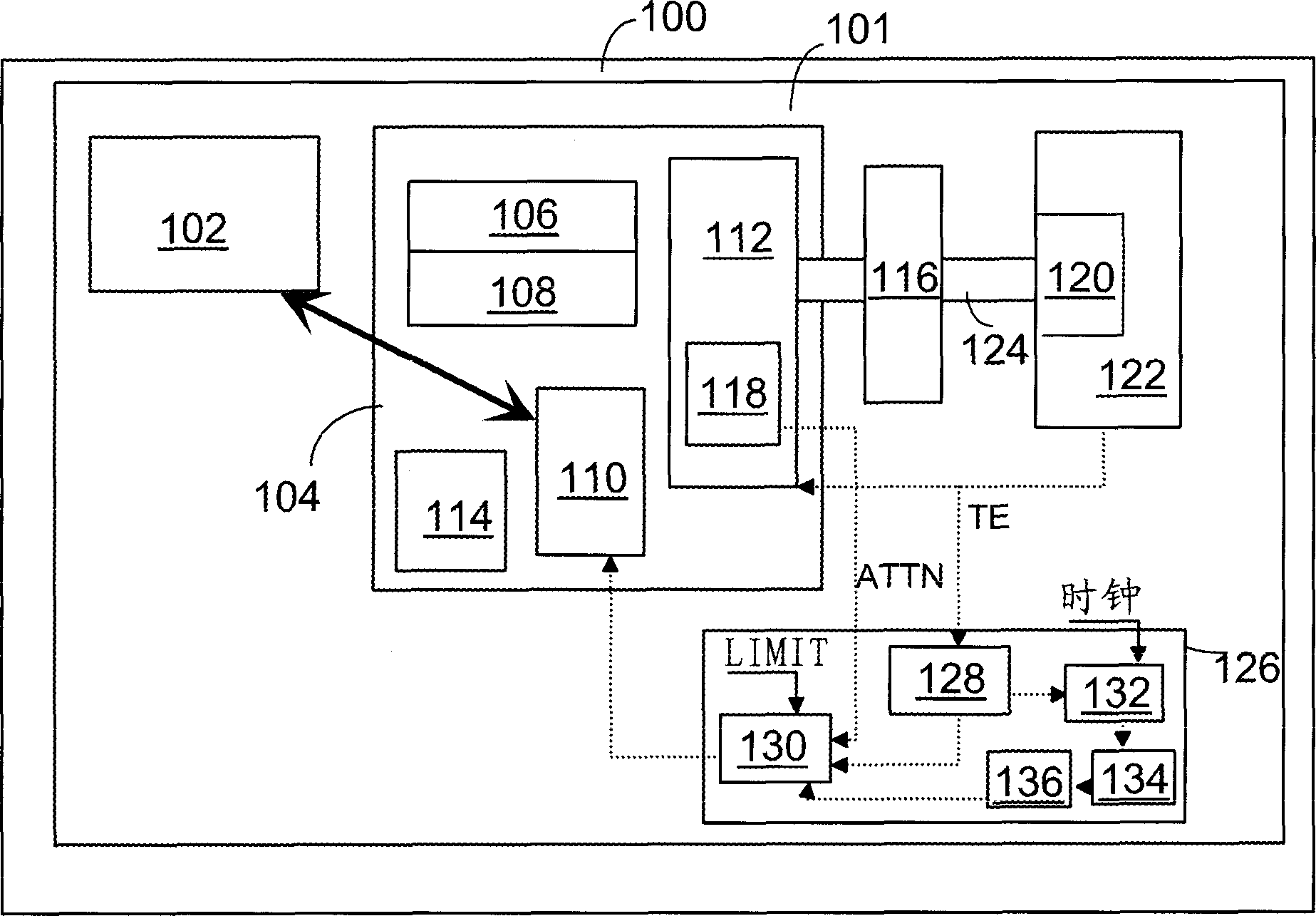

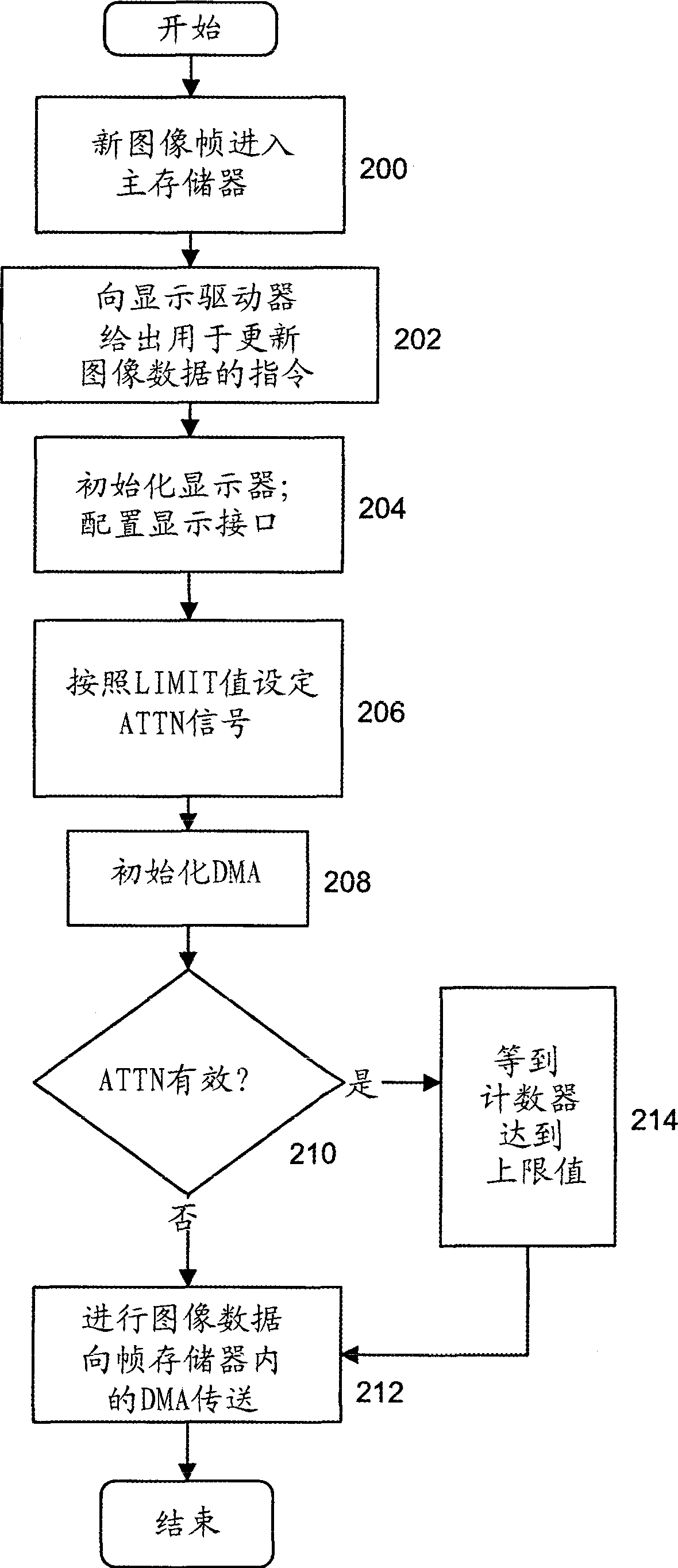

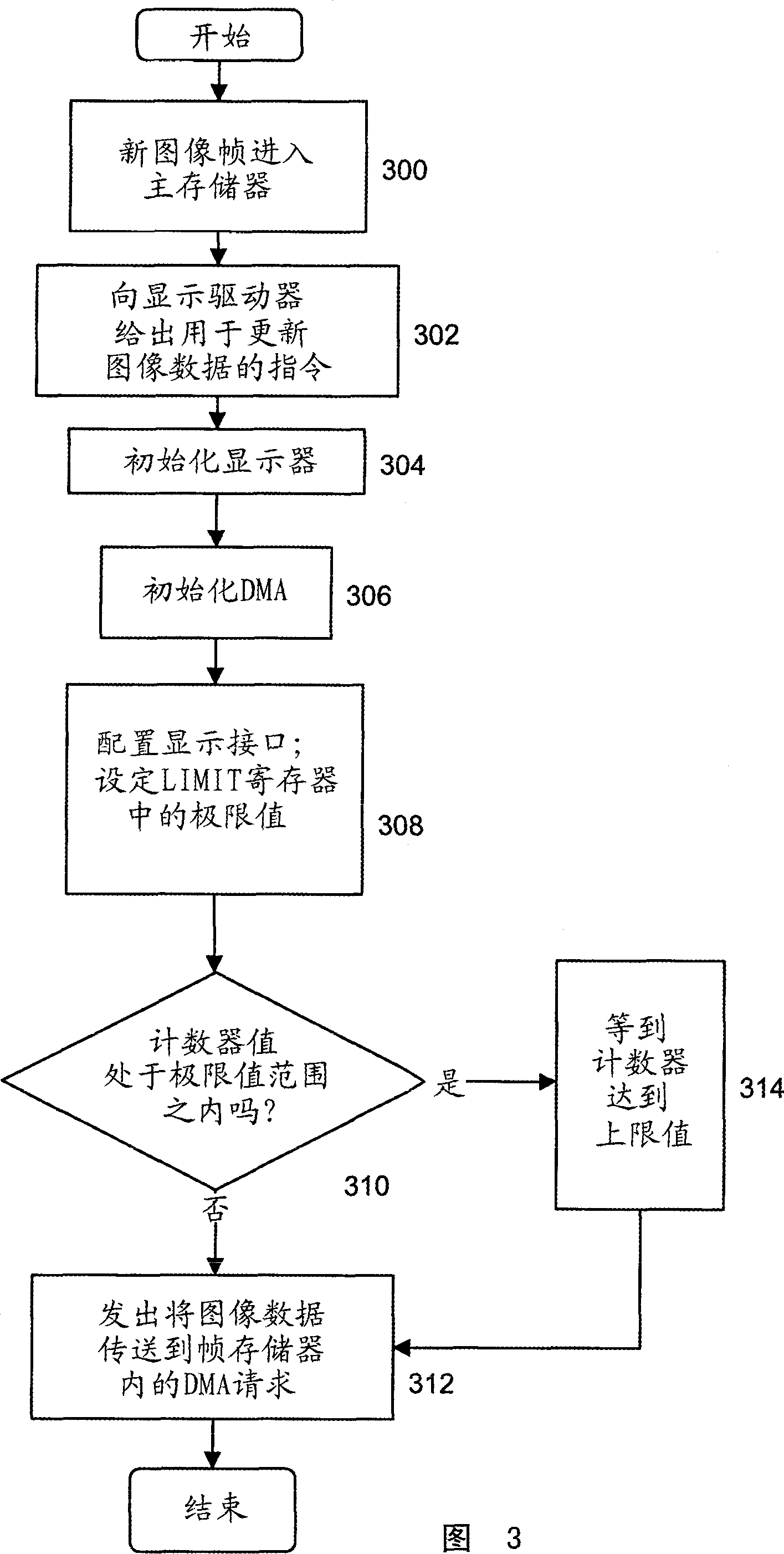

Synchronization of image frame update

InactiveCN1816844AMake sure to update regularlyDoes not cause synchronization issues with updatesCathode-ray tube indicatorsDigital output to display deviceComputer graphics (images)Limit value

A method of updating image frames to a display screen. A display system comprises a display screen, a frame memory for buffering the image frames prior to a transfer to the display screen, a display interface for receiving the image data into the frame memory, a separate controller for inputting the image data in the frame memory, and a display driver for controlling the display system. Image data are transferred by means of the separate controller to the display screen, after which a synchronization signal is fed back from the image frame updated to the display screen. A limiter register is used to specify a moment when image frame update in the frame memory is prevented. The separate controller is controlled to prevent image frame input in the frame memory as long as the counter value is within the limits of the limit value of the limiter register.

Owner:NOKIA CORP

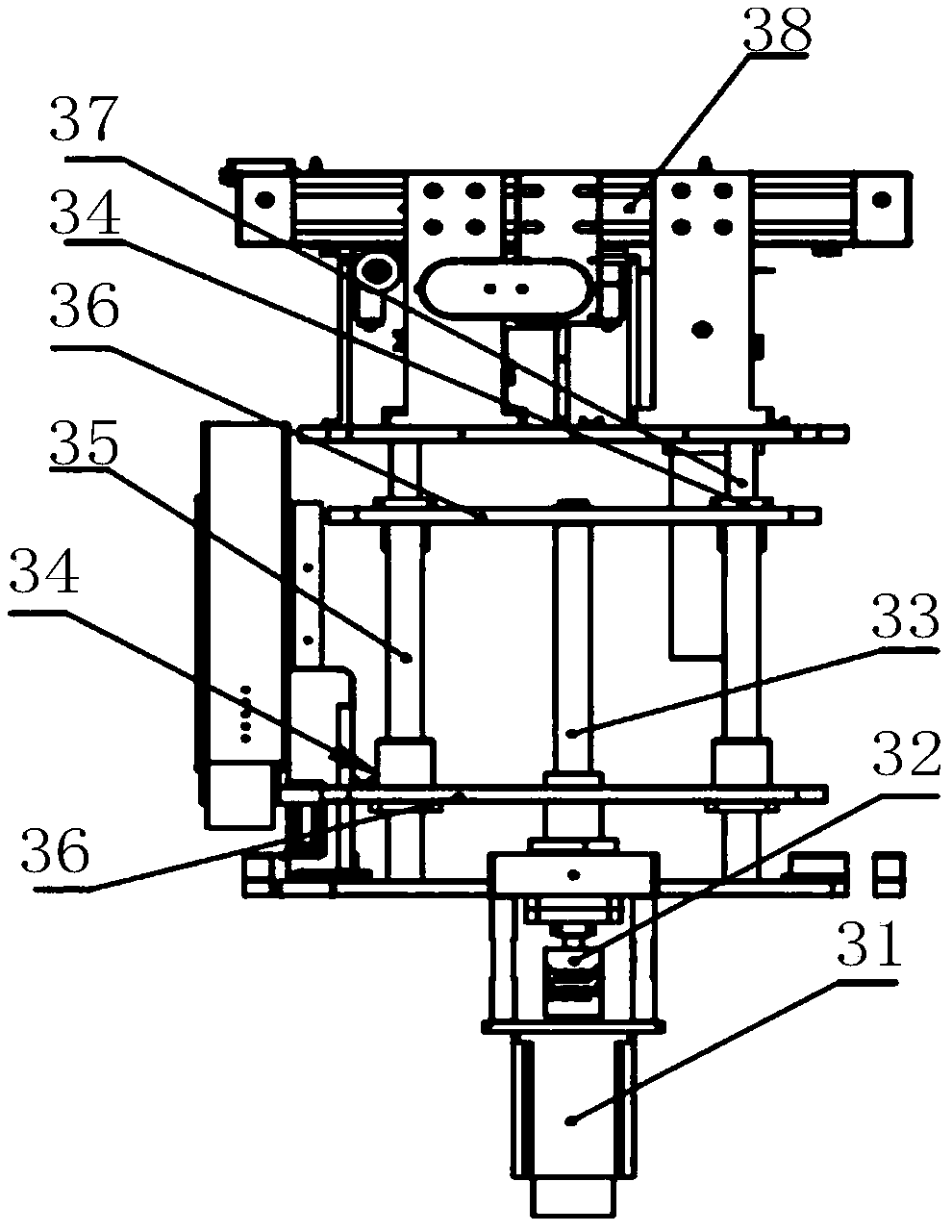

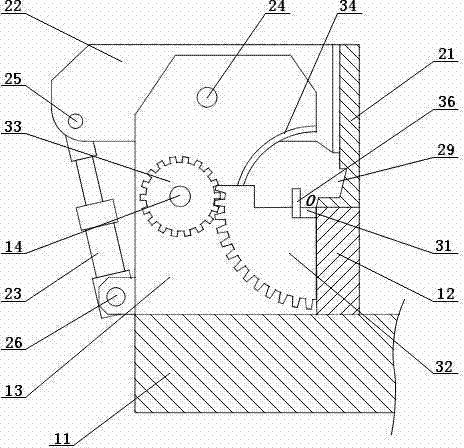

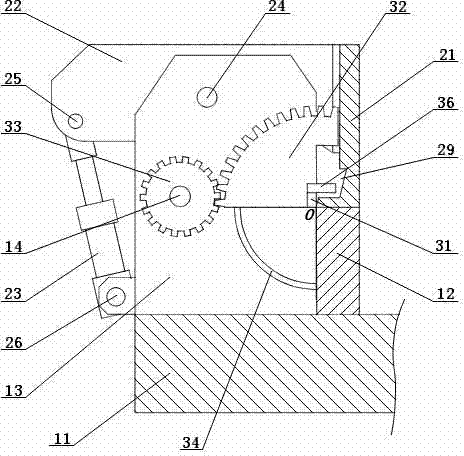

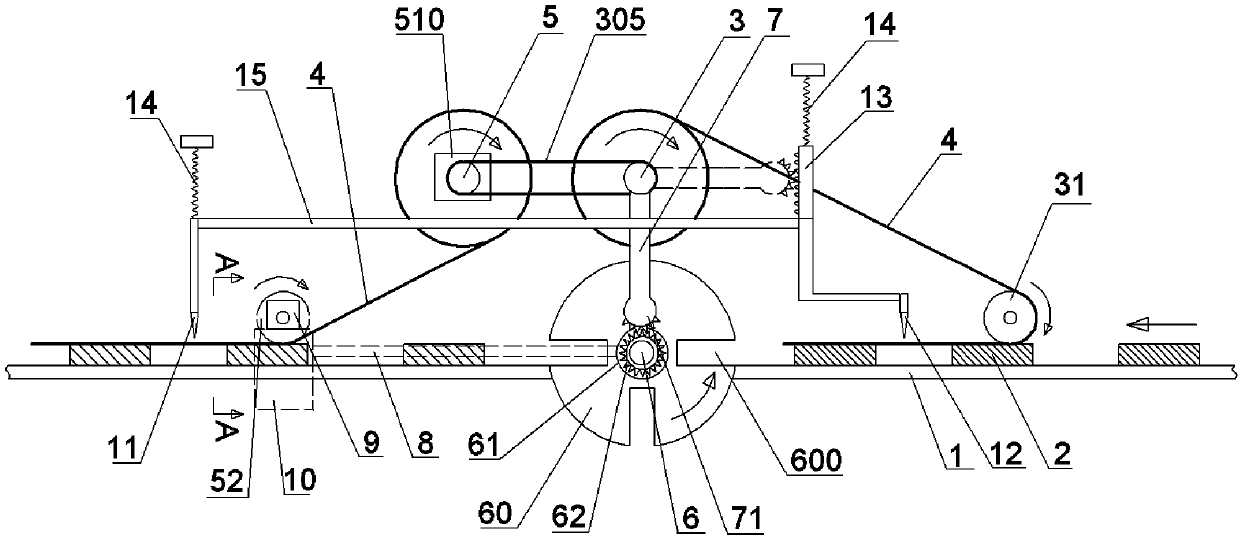

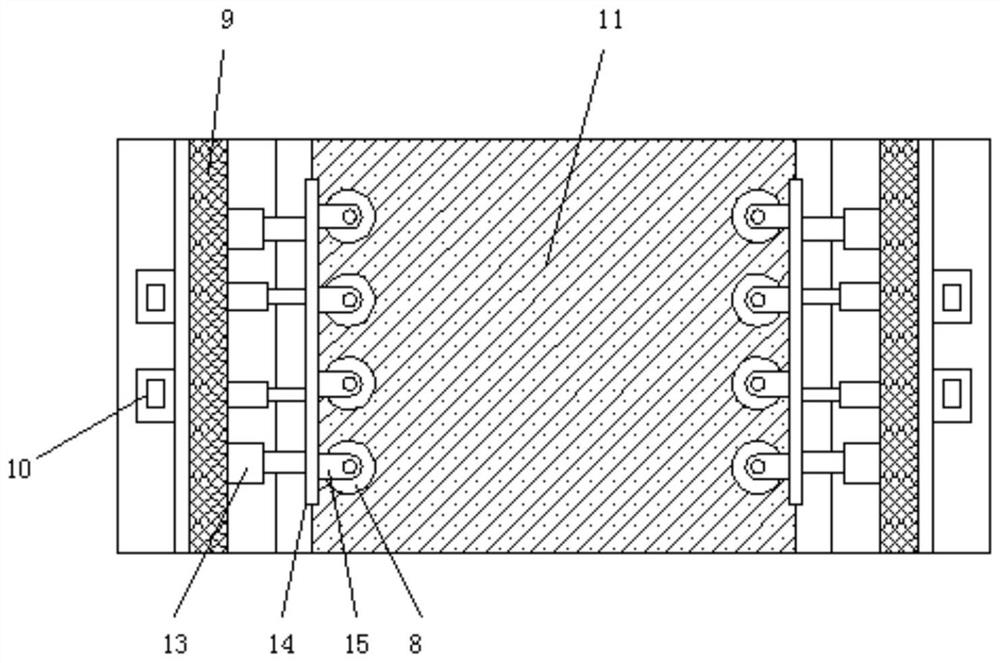

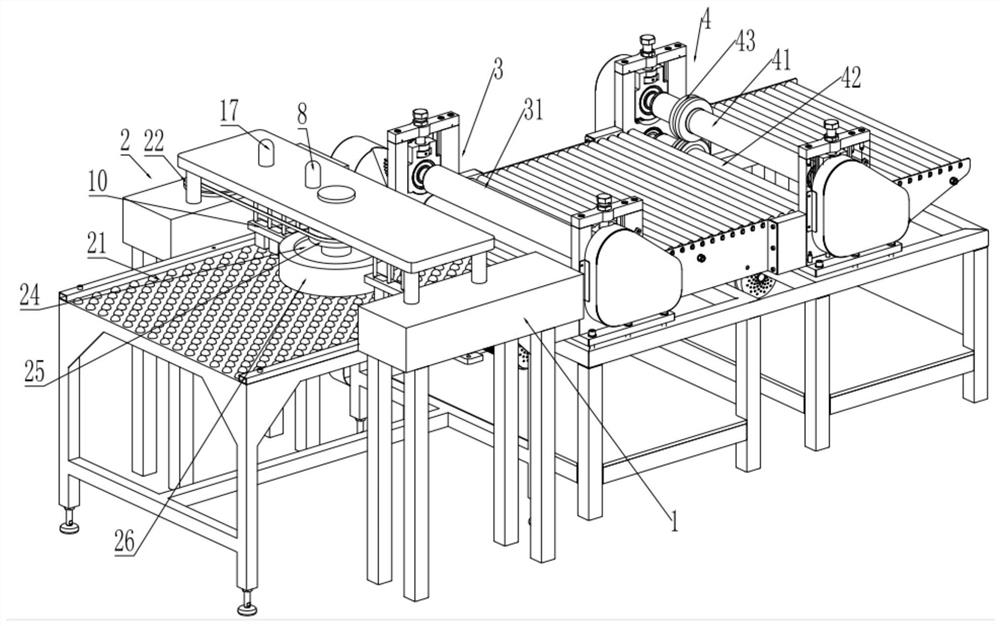

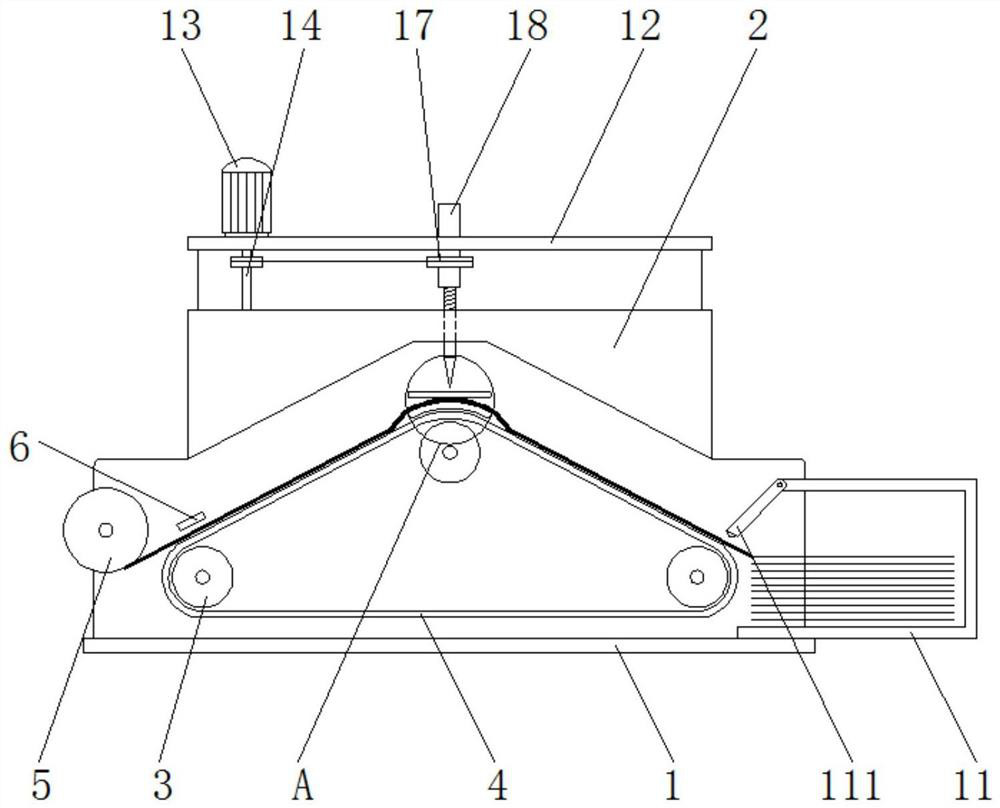

Extra-long plate flanging machine

ActiveCN104741425AEven by forceImprove yieldMetal-working feeding devicesPositioning devicesPower unitEngineering

The invention discloses an extra-long plate flanging machine, comprising a base, a plate-pressing platform, a plate-pressing mold bar, a flanging mold bar, a conveyor belt and a plurality of power units. The plate-pressing platform, the plate-pressing mold bar and the flanging mold bar are of long-strip shapes. The power units are arranged alternatively along the long-strip directions of the plate-pressing platform, the plate-pressing mold bar and the flanging mold bar. The power units comprise two support plates, a plate-pressing linkage frame, a plate-pressing hydraulic machine, a flanging mold bar frame and a flanging mold bar transmission gear. Semi-circular flanging mold bar frame rails are arranged on the support plates. The flanging mold bar frame is installed on a flanging mold bar frame rail and the external edge thereof is provided with a circular-arc-shaped gear meshed with the flanging transmission gear. The flanging mold bar is installed on a flanging mold bar frame; the flanging transmission gear is mounted on transmission rods which are installed on the support plates and connected with a flanging motor. The plate-pressing hydraulic machine is arranged between two support plates, and the piston rod thereof is connected with the plate-pressing linkage frame. The plate-pressing linkage frame is arranged on the rotating shaft between the support plates and connected with the plate-pressing mold bar.

Owner:ANHUI KINGPOWER EQUIP & MOLD MFR

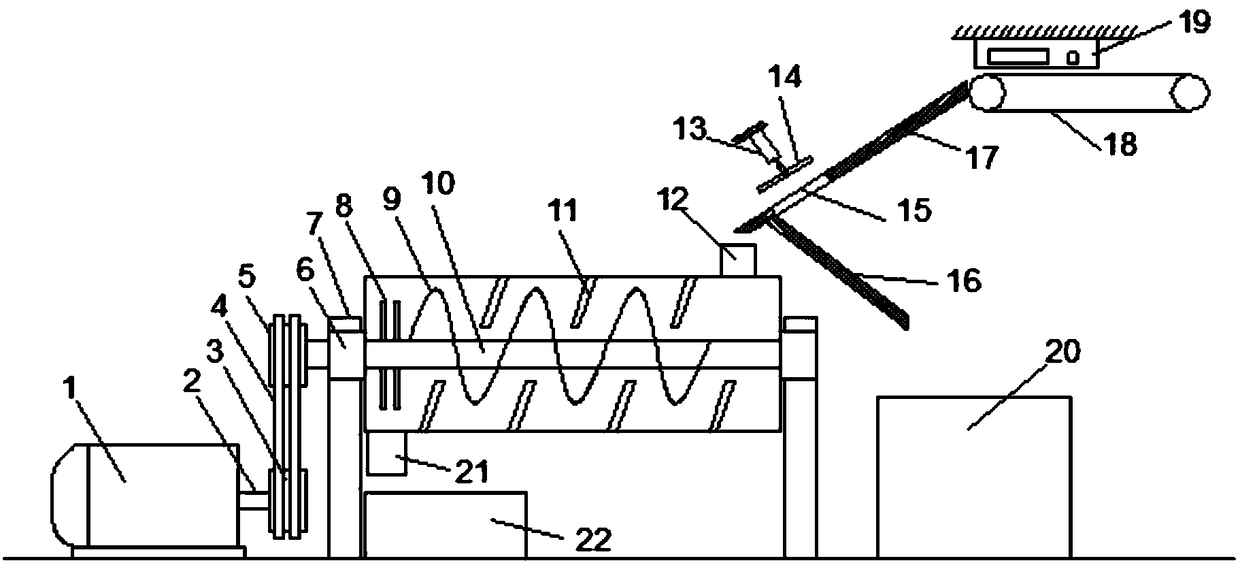

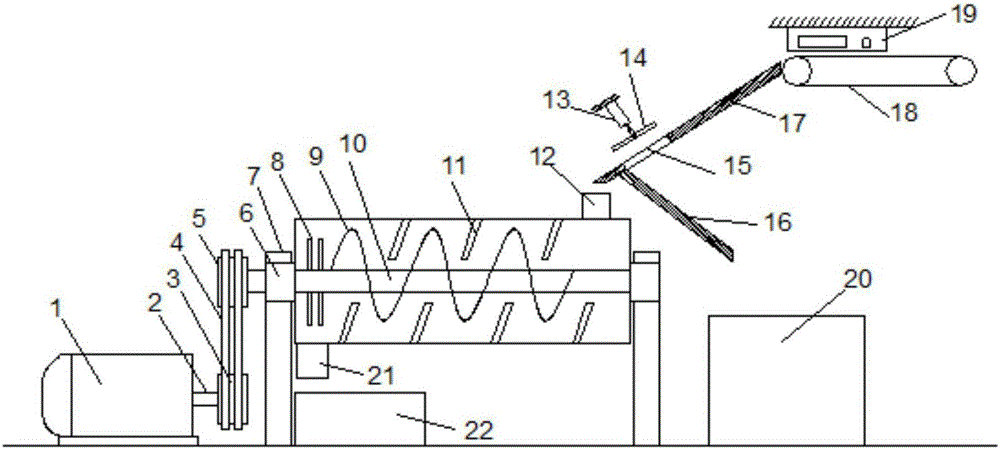

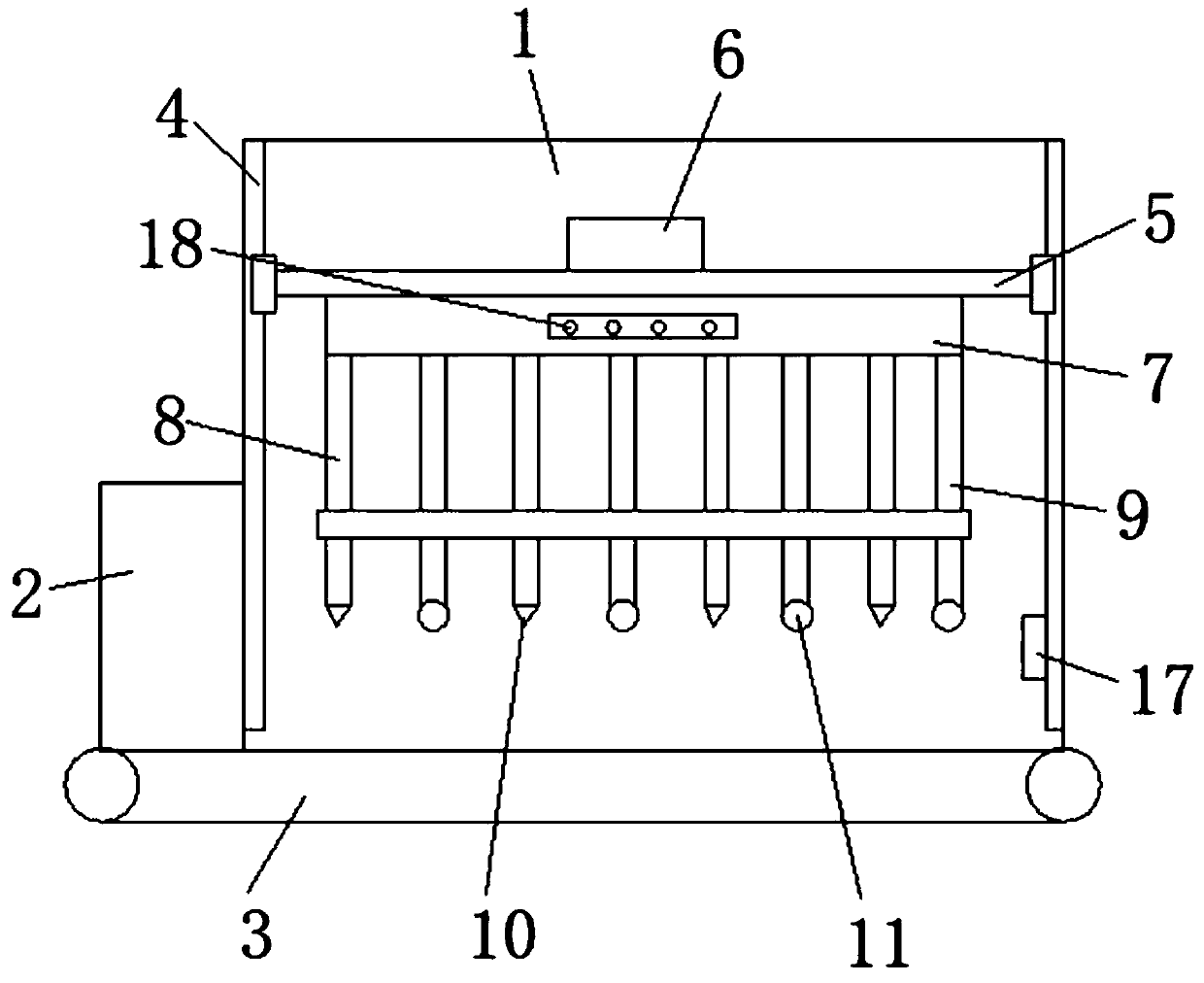

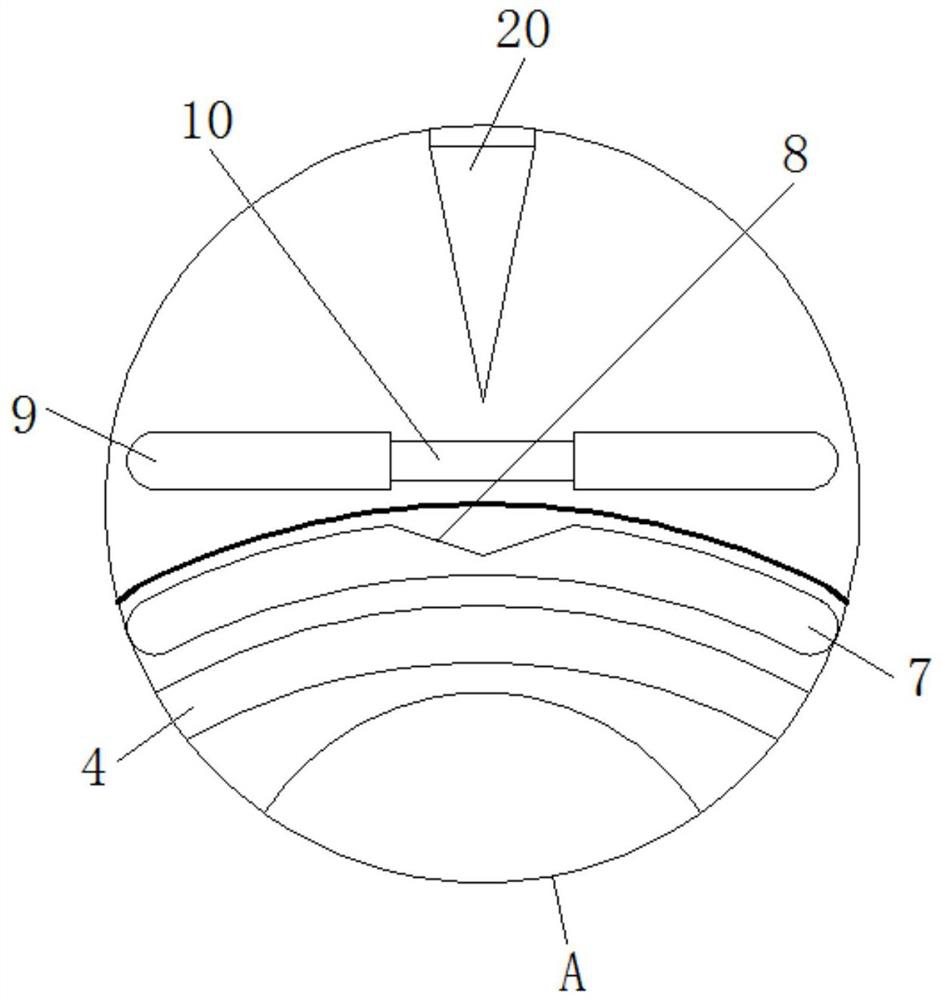

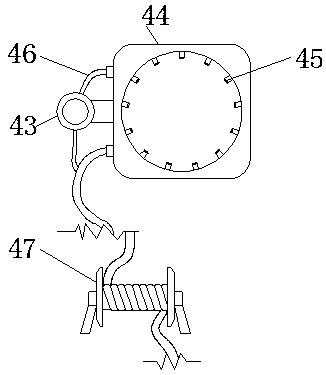

Automatic detecting and metal separating fertilizer crusher

The invention discloses an automatic detecting and metal separating fertilizer crusher. The automatic detecting and metal separating fertilizer crusher comprises a fertilizer crusher body and a metalimpurity removing device. The fertilizer crusher comprises two supporting frames. A smashing cylinder is arranged between the supporting frames. The smashing cylinder is internally provided with a horizontally arranged rotating shaft. The supporting frames are provided with bearings matched with the rotating shaft. The rotating shaft is sleeved with spiral smashing teeth, and the inner wall of thesmashing cylinder is fixedly provided with a plurality of helical teeth matched with the spiral smashing teeth. The rotating shaft extends out of the left side of the smashing cylinder to be connected with a belt wheel, the belt wheel is in transmission connection with a drive wheel through a belt, and the drive wheel is connected with a motor through a drive shaft. The automatic detecting and metal separating fertilizer crusher is reasonable in structural design and convenient to use, fertilizers containing metal impurities can be automatically detected and classified, the quality of the finished fertilizers can be guaranteed, the machine abrasion of the fertilizer crusher is reduced, and the service life is prolonged; and meanwhile, the smashing effect is good, blockage is not prone tobeing caused, and the automatic detecting and metal separating fertilizer crusher is suitable for automatic fertilizer production.

Owner:ZHENGZHOU SOUQU INFORMATION TECH CO LTD

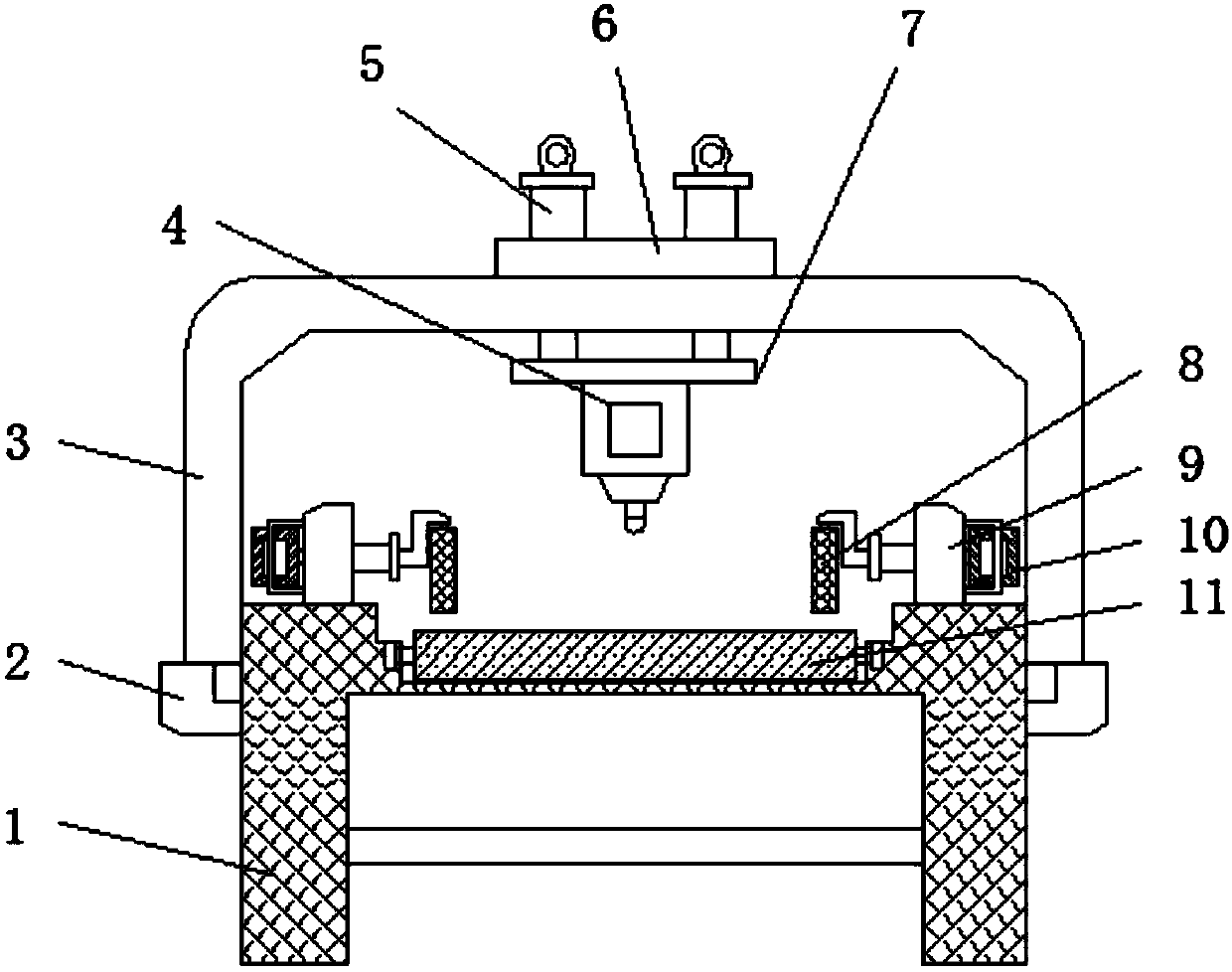

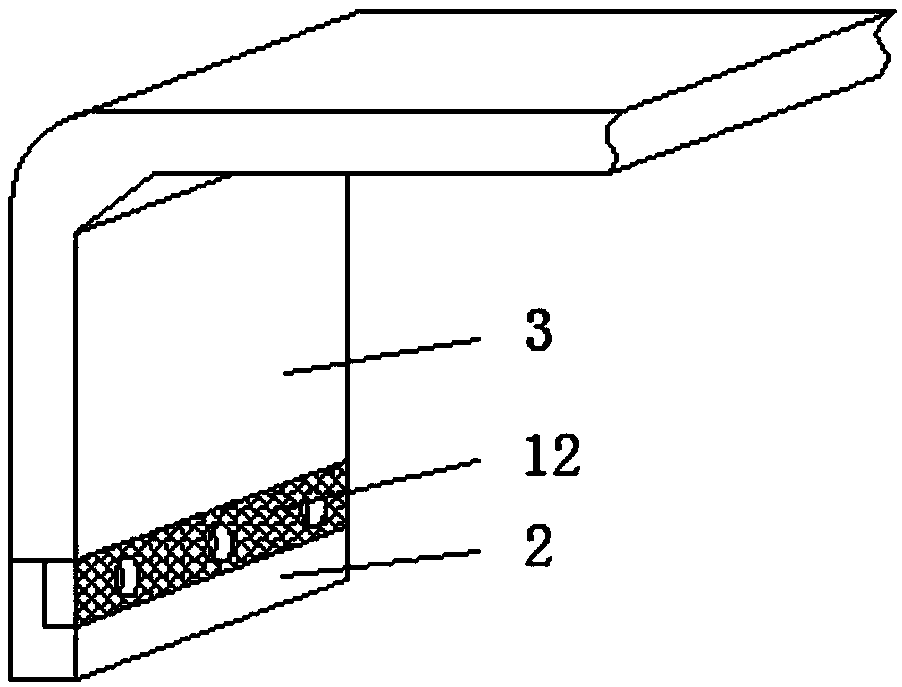

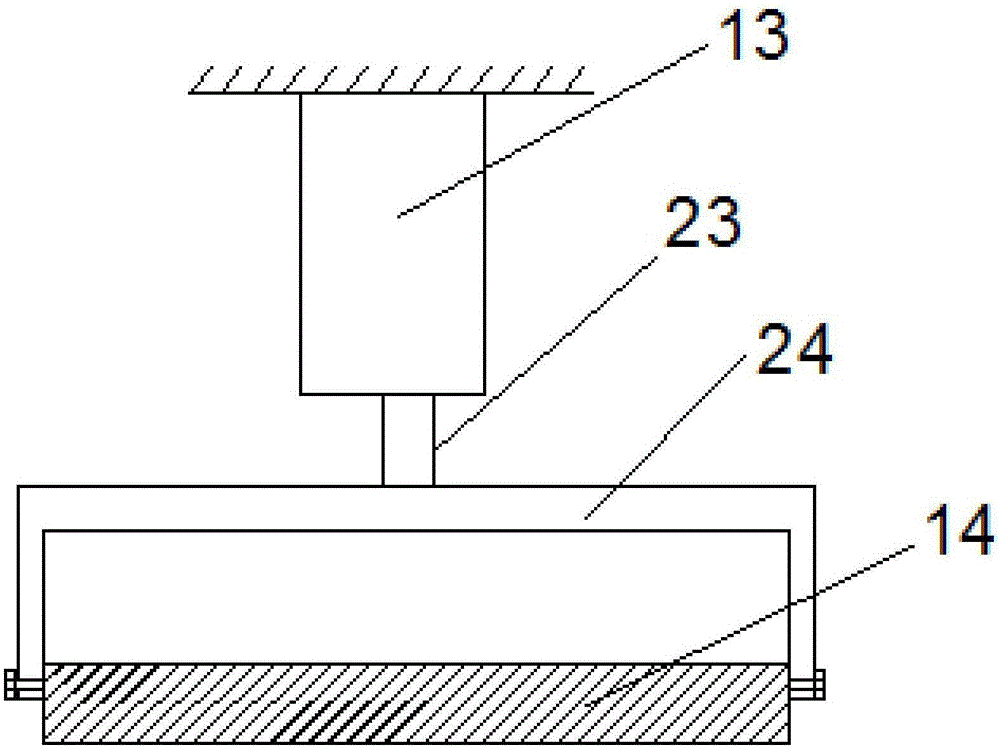

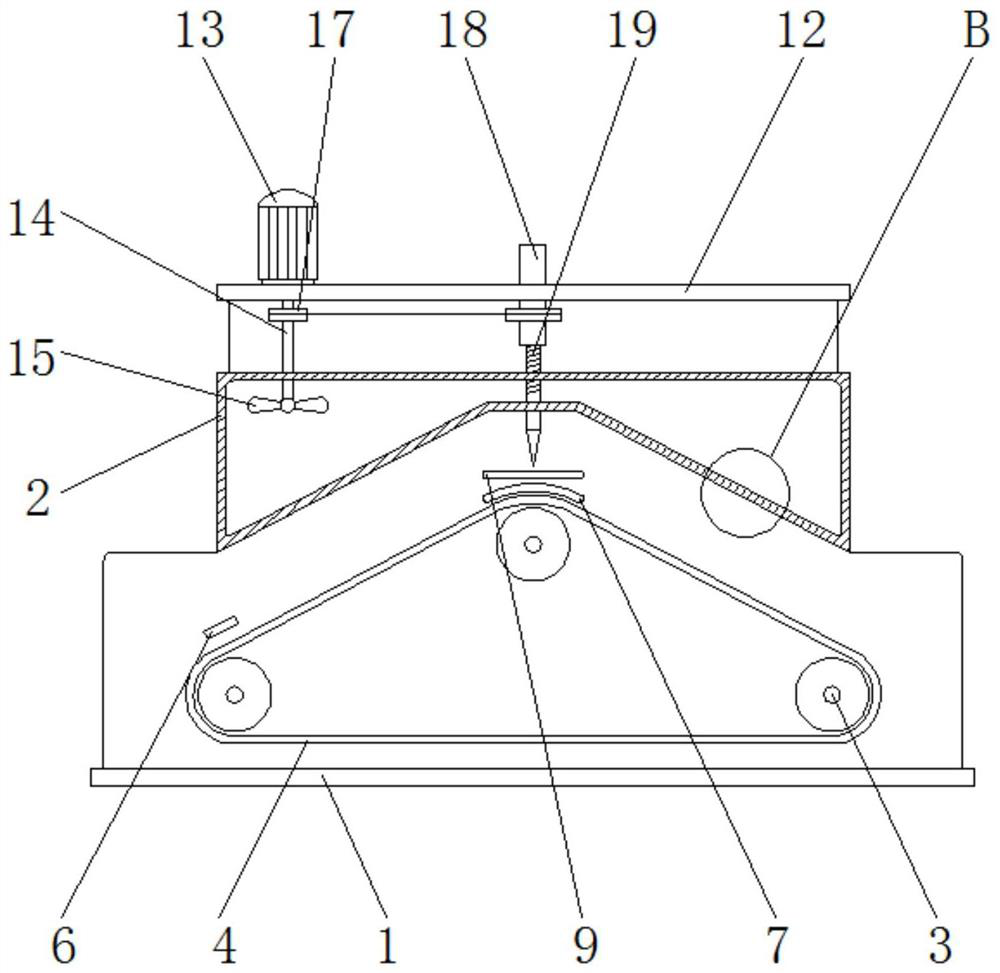

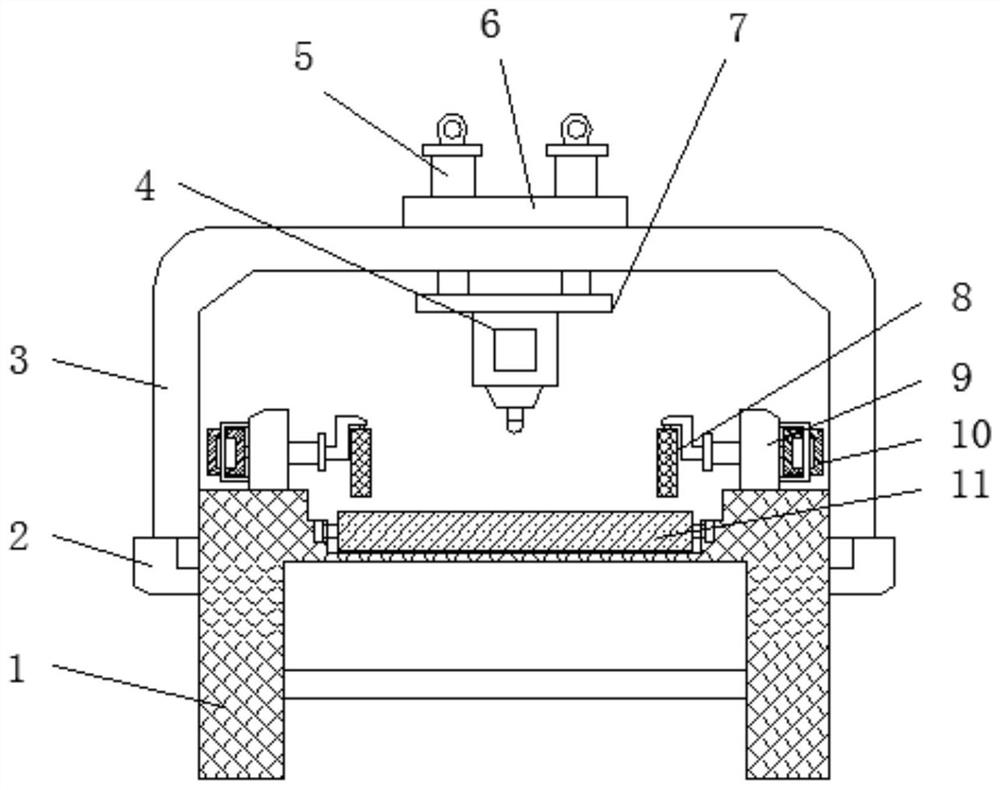

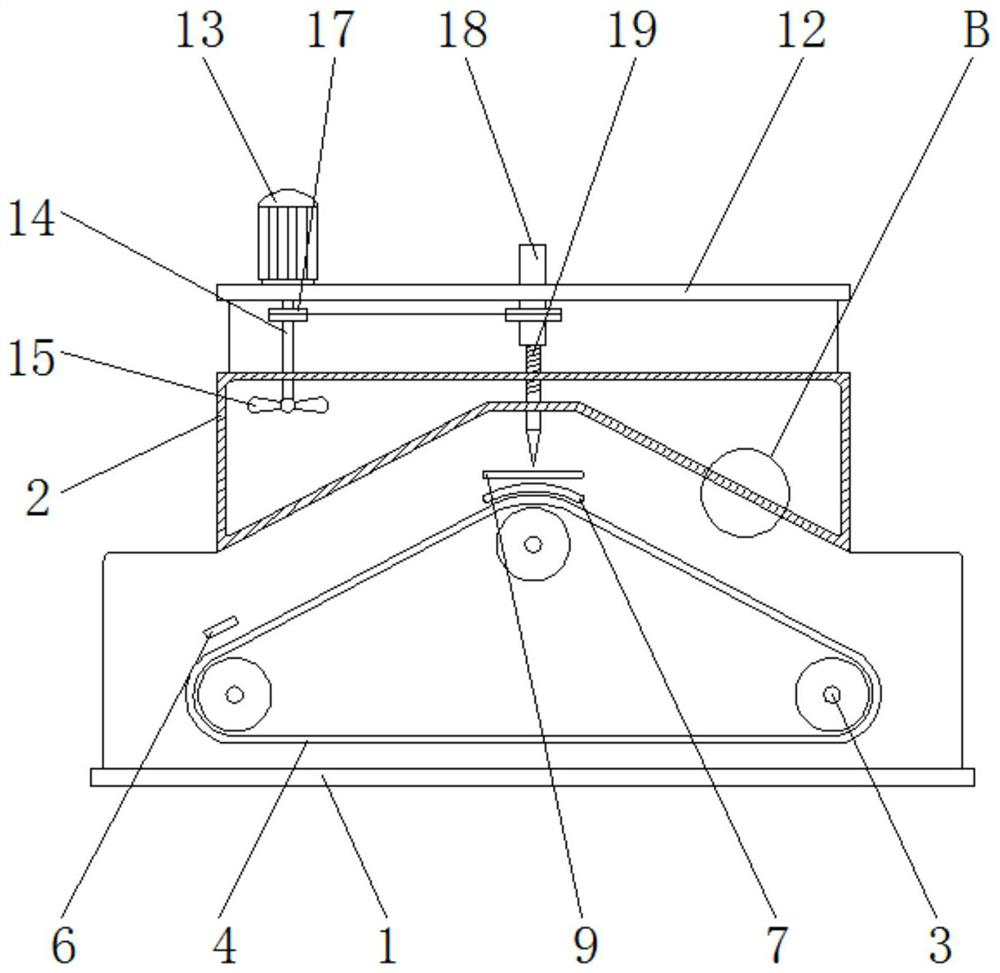

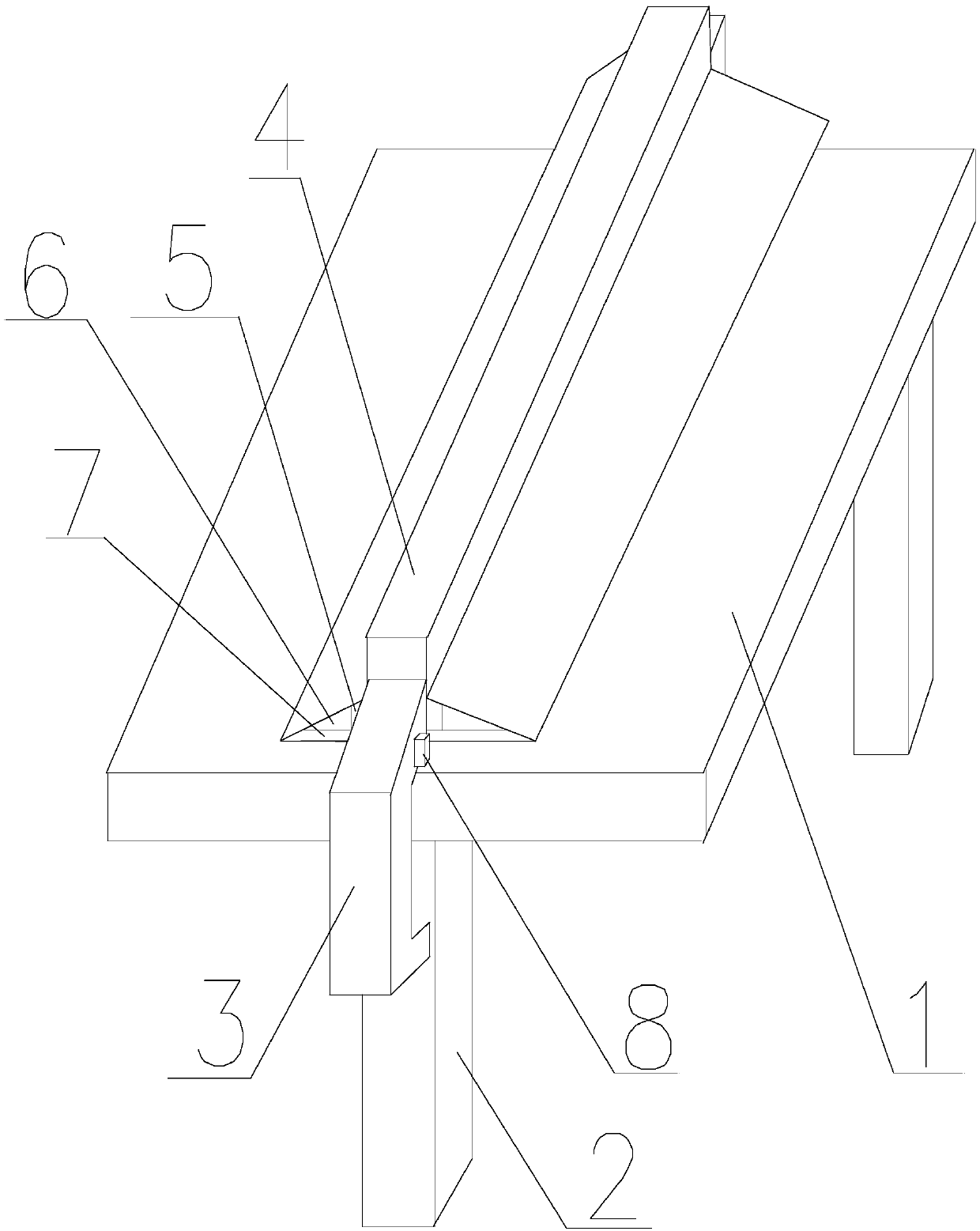

Wood carving device

ActiveCN109649056AEasy to moveEasy to transportOther artistic work equipmentsModel makingMortise and tenonEngineering

The invention discloses a wood carving device. The wood carving device comprises a main support, a main rack and a carving device. The main rack is located above the main support. Side mounting racksare welded to the upper portions of the two sides of the main support. The main rack is of a U-shaped structure. Pin plates are welded to the lower portions of the two vertical ends of the main rack.The main rack is in mortise and tenon connection with the side mounting racks through the pin plates. A mounting groove is formed in the center of the upper surface of the horizontal end of the main rack. A mounting plate is clamped to the mounting groove through alignment clamps. Electric push rods are welded to the mounting plate. The bottoms of the electric push rods penetrate through the mounting plate and the main rack to be provided with a lifting plate in a welded mode. The carving device is fixed below the lifting plate through bolts. The wood carving device is suitable for wood carving. The position of wood is not prone to skewing in the carving process. The wood carving device can be applicable to wood with different widths and is convenient to install, dismantle and move.

Owner:安徽天盛家具有限公司

Fertilizer crusher capable of automatically defecting and separating metal

ActiveCN106540789AImprove crushing effectExtended service lifeGrain treatmentsFertilizerElectric machinery

The invention discloses a fertilizer crusher capable of automatically defecting and separating metal, comprising a fertilizer crusher part and a metal impurity removal device, wherein the fertilizer crusher part comprises two support frames, a crushing cylinder is arranged between the support frames, a horizontally arranged rotating shaft is arranged in the crushing cylinder, and the support frames are respectively provided with bearings adaptive to the rotating shaft; spiral crushing teeth sleeve the rotating shaft, and the inner wall of the crushing cylinder is fixedly provided with multiple helical teeth adaptive to the spiral crushing teeth; the rotating shaft extends to the exterior of the left side of the crushing cylinder to be connected with a belt wheel, the belt wheel is in transmission connection with a driving wheel by a belt, and the driving wheel is connected with a motor by a driving shaft. The fertilizer crusher is reasonable in structure design and convenient to use, can be used to automatically defect fertilizer containing metal impurities and automatically classify, ensure the quality of finished fertilizer, reduce the machine wear of the fertilizer crusher, and prolong the service life, and also has the advantages of good crushing effect, low blocking possibility and suitability for automated fertilizer production.

Owner:NINGXIA RUISHENG MINGJIE INTPROP CONSULTING CO LTD

Steel plate cutting device

ActiveCN111250775ASimple structureLow costShearing machinesLarge fixed membersEngineeringMechanical engineering

The invention relates to the technical field of steel plate machining, and particularly discloses a steel plate cutting device. The device comprises a rack, an inclined pushing mechanism, a conveyingmechanism and a cutting mechanism, the inclined pushing mechanism comprises a universal ball platform and a rotary disc rotationally connected to the rack, the rotary disc is located above the universal ball platform, an electromagnet is slidably connected to the rotary disc, a first elastic piece is connected between the electromagnet and the rotary disc, and the electromagnet can move up and down along the rotary disc. The scheme is used for solving the problems that in the prior art, for trapezoidal steel plate cutting, the equipment structure is complex, and the cutting angle adjustment time is long.

Owner:重庆市荣昌区永世光电设备有限公司

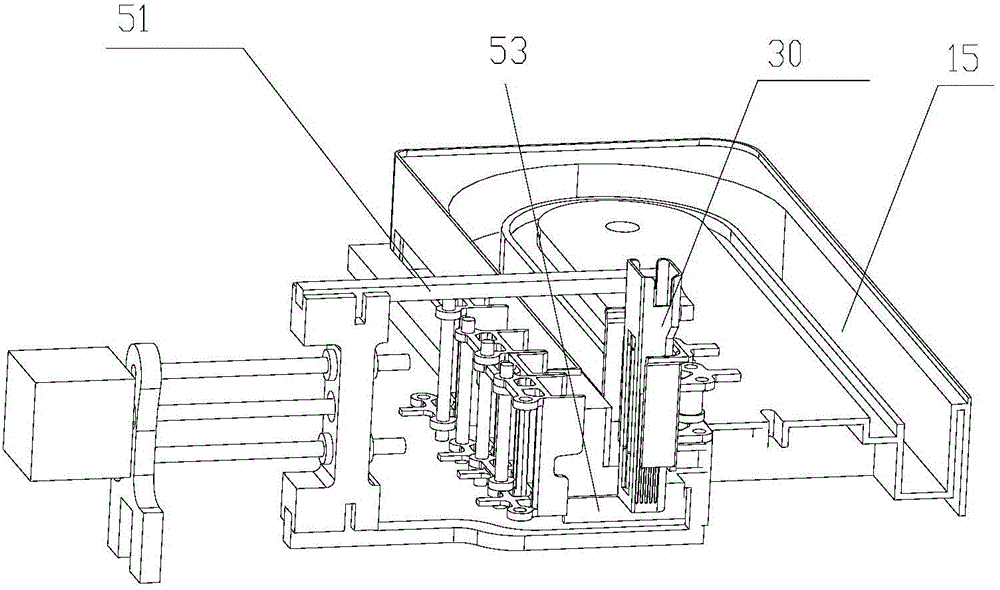

Package laminating machine

InactiveCN109677676AFlipTo achieve the effect of double-sided laminationPackagingEngineeringMechanical engineering

The invention belongs to the field of package printing, and particularly discloses a package laminating machine. A rack is included and provided with a conveying belt. A front face laminating mechanism, an overturning mechanism and a back face laminating mechanism are sequentially arranged in the conveying direction of the conveying belt. The front face laminating mechanism comprises a front facelaminating roller and a front face film cutter. The back face laminating mechanism comprises a sliding base, the sliding base is rotationally connected with a back face laminating roller, and a back face film cutter is arranged on the rack in a vertical sliding manner. The overturning mechanism comprises two overturning shafts rotationally connected to the rack and coaxially arranged, the two overturning shafts are located on the two sides of the conveying belt correspondingly and are in sliding connection with overturning discs, the overturning discs are provided with notches in which laminating workpieces are inserted, and the upper portions of the overturning shafts are rotationally connected with a front face film roll shaft and a back face film roll shaft. An overturning driving mechanism for driving the overturning shafts to intermittently rotate is connected between the front face film roll shaft and the overturning shafts. The package laminating machine can be universal for panel single-face laminating and double-face laminating.

Owner:重庆朝旭印务有限公司

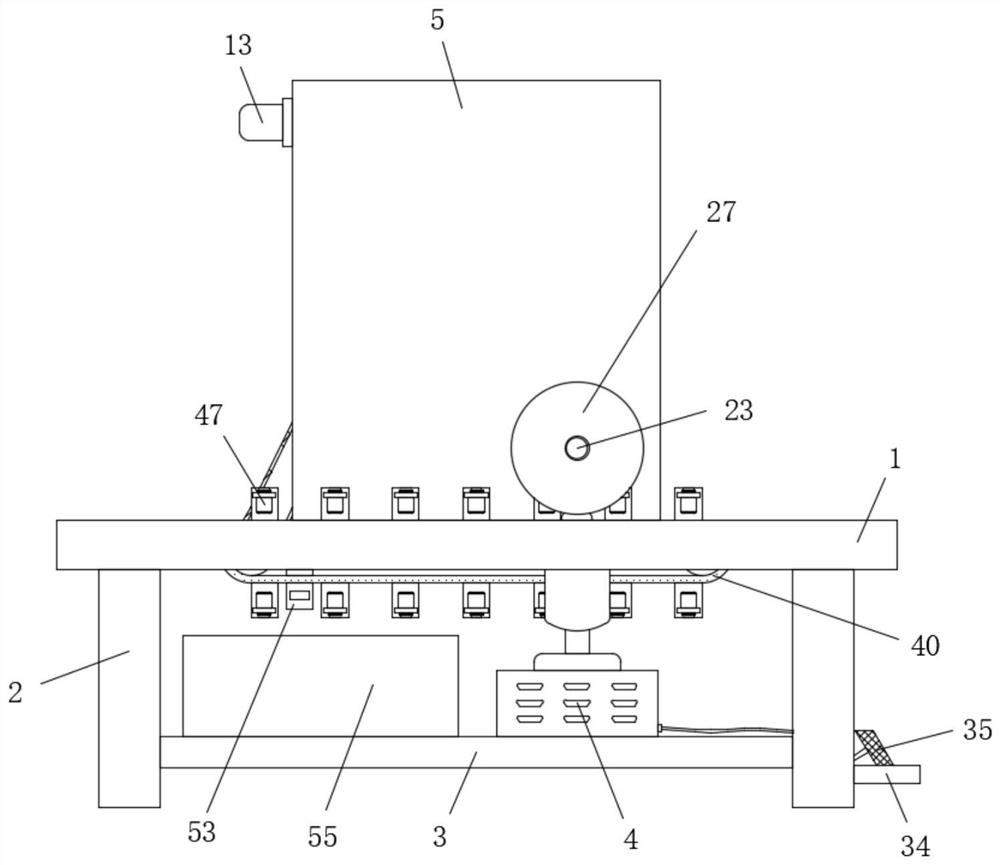

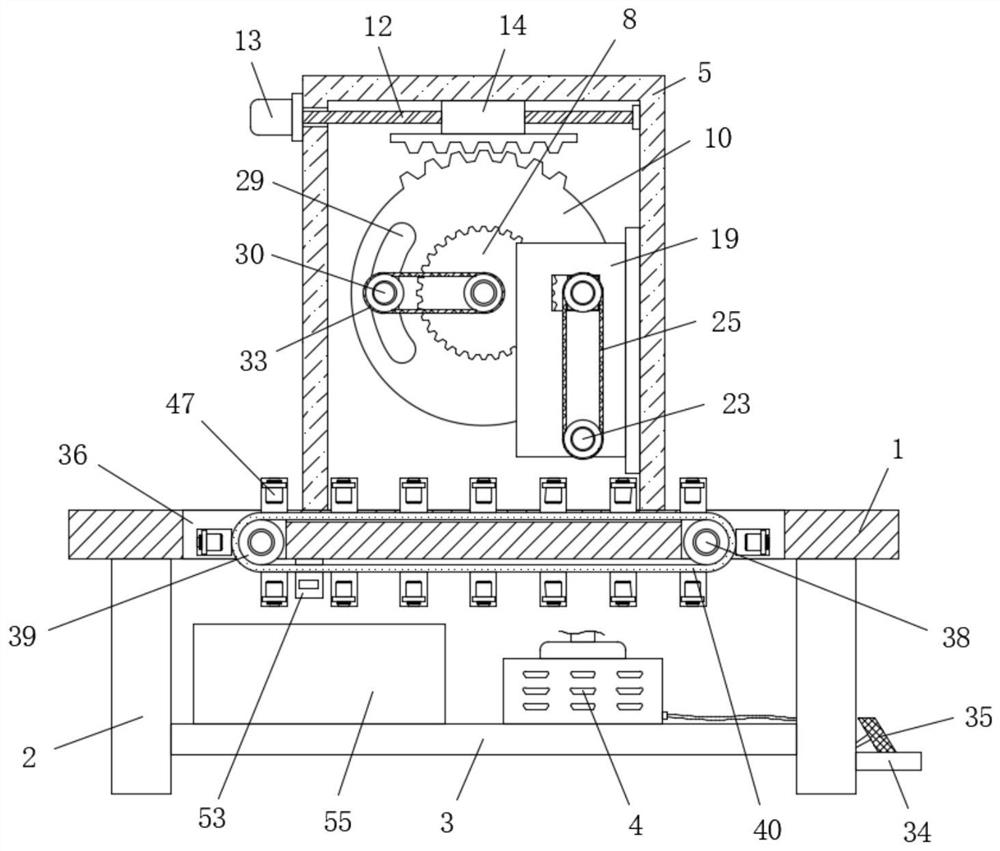

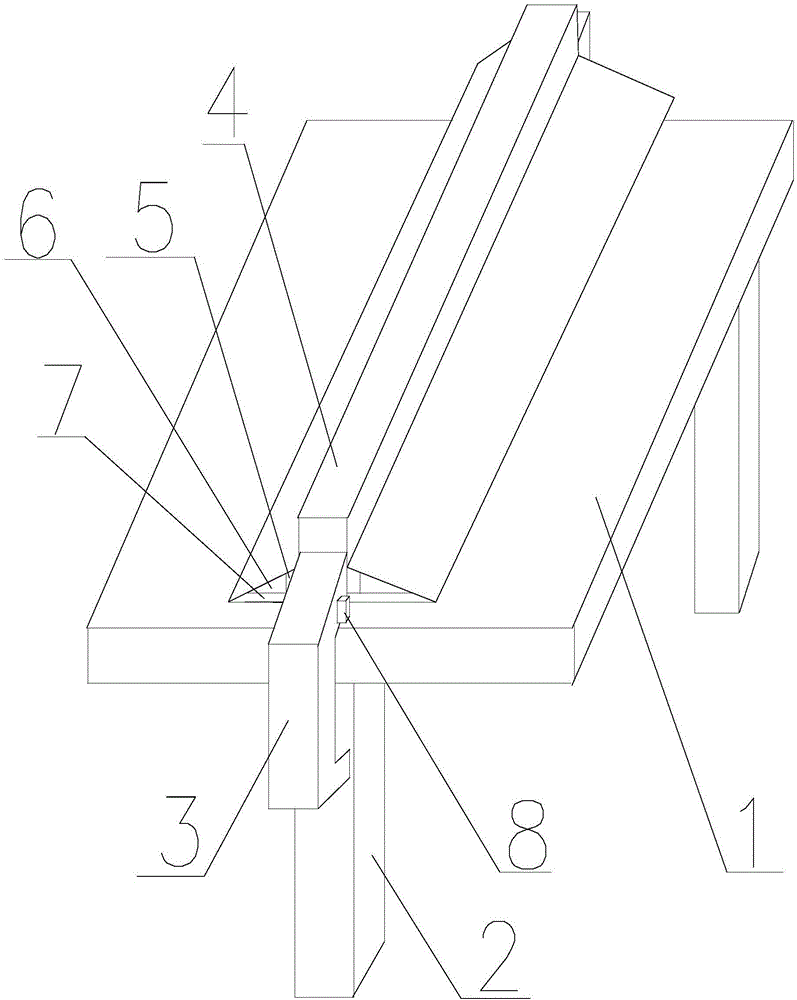

Medical surgical gown intelligent composite equipment and using method

PendingCN112519376ADoes not affect normal rotationEasy to operateLamination plant layoutLamination ancillary operationsSurgical GownsElectric machinery

The invention discloses medical surgical gown intelligent composite equipment which comprises an operation table, two supporting plates are symmetrically and fixedly connected to the bottom of the operation table, and the bottoms of the sides, close to each other, of the two supporting plates are fixedly connected with the same transverse plate; the invention also discloses a using method. The equipment has the advantages that the rotating motor is started to drive the pattern wheel to rotate and drive the conveying belt to conduct transmission, energy utilization is improved, meanwhile, clothes are conveyed conveniently, the height of the pattern wheel can be adjusted by starting the lead screw motor, rotation of the pattern wheel is not affected, operation is easy, use is convenient, bypressing a pressing block, the effect of clamping and conveying the clothing materials can be achieved, alignment and pulling of the clothing materials are facilitated so that the sewing flatness of the clothing materials is improved, the labor intensity is reduced, through cooperation of triangular blocks, the effect of automatically loosening waste materials can be achieved, automatic collectionof the waste materials is facilitated through a waste material collection box, and the practicability is improved.

Owner:彭满先

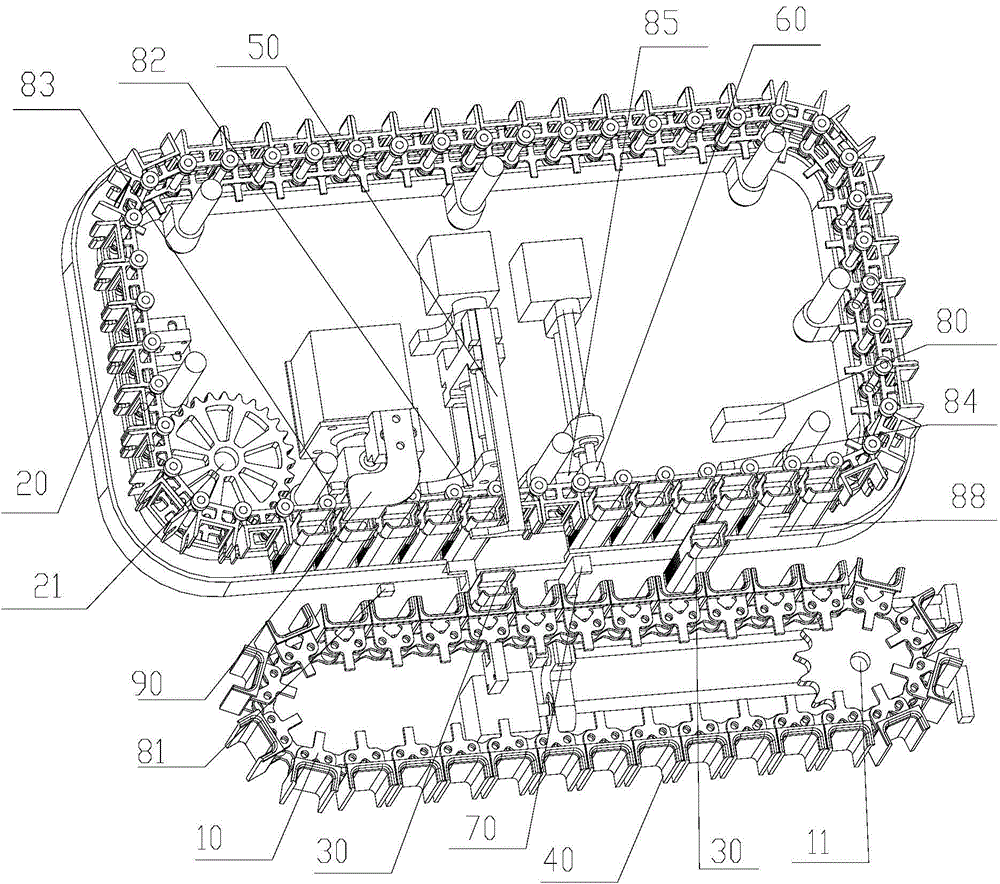

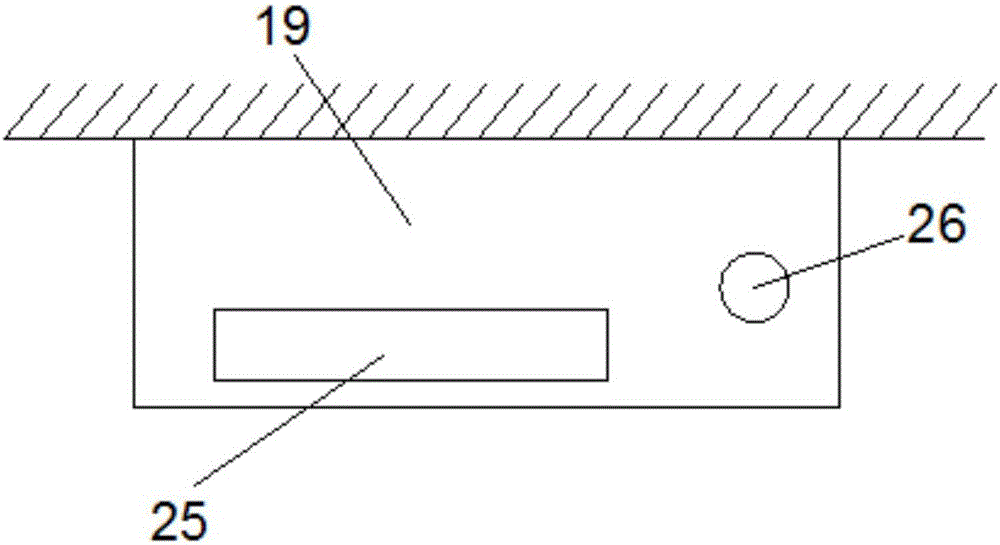

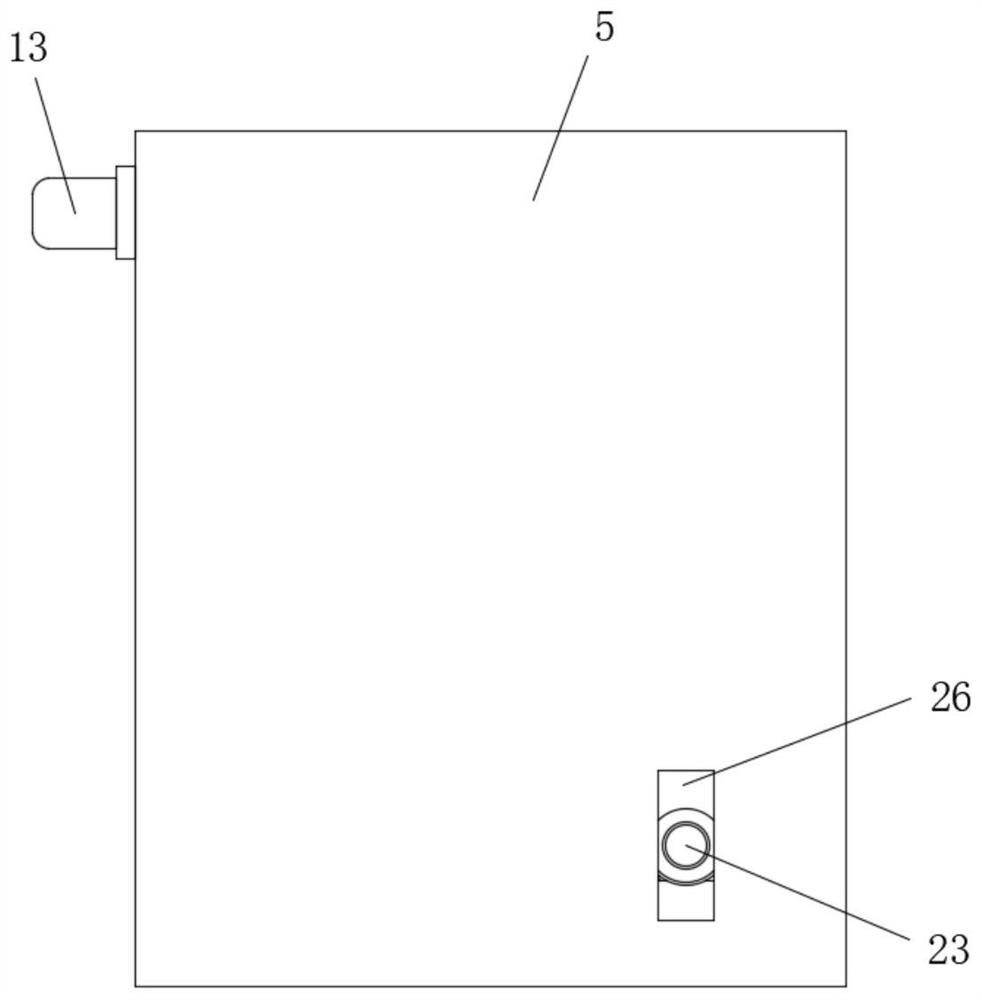

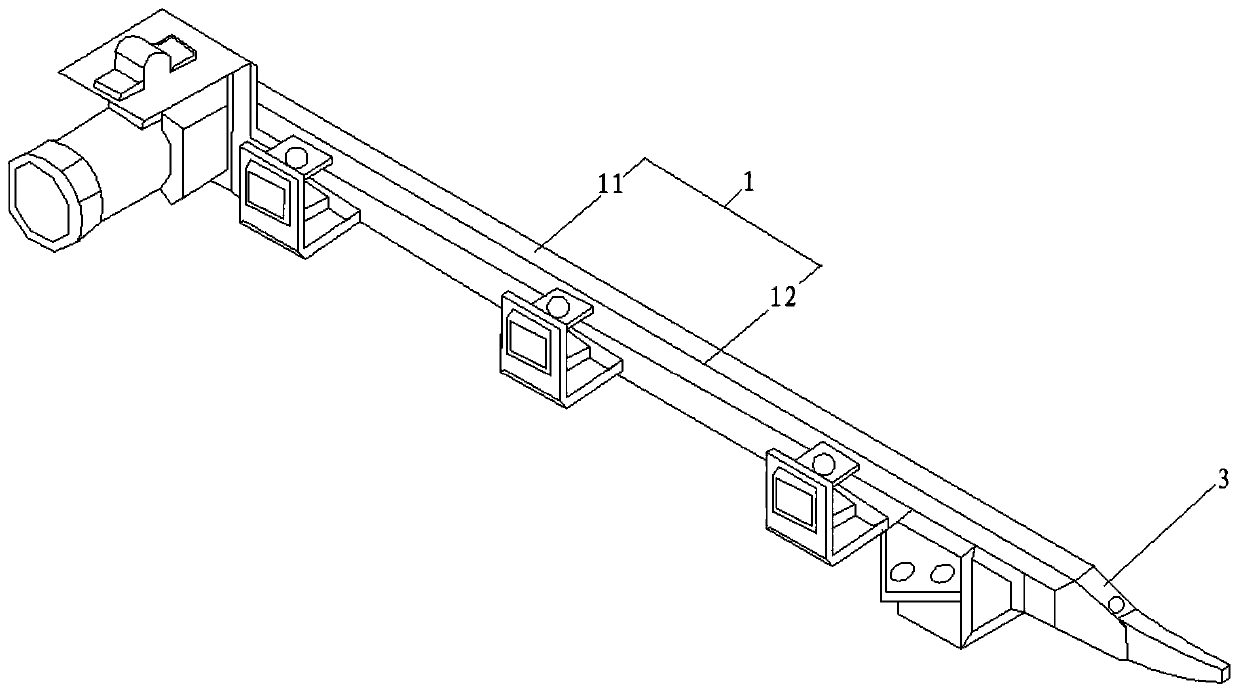

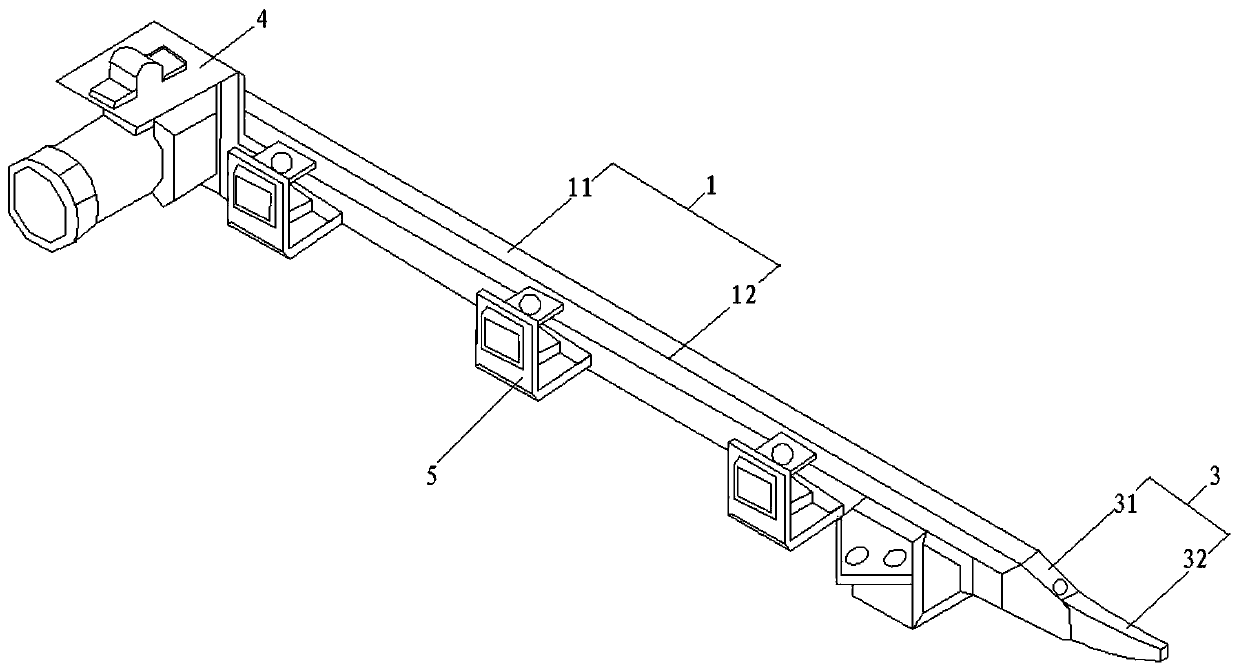

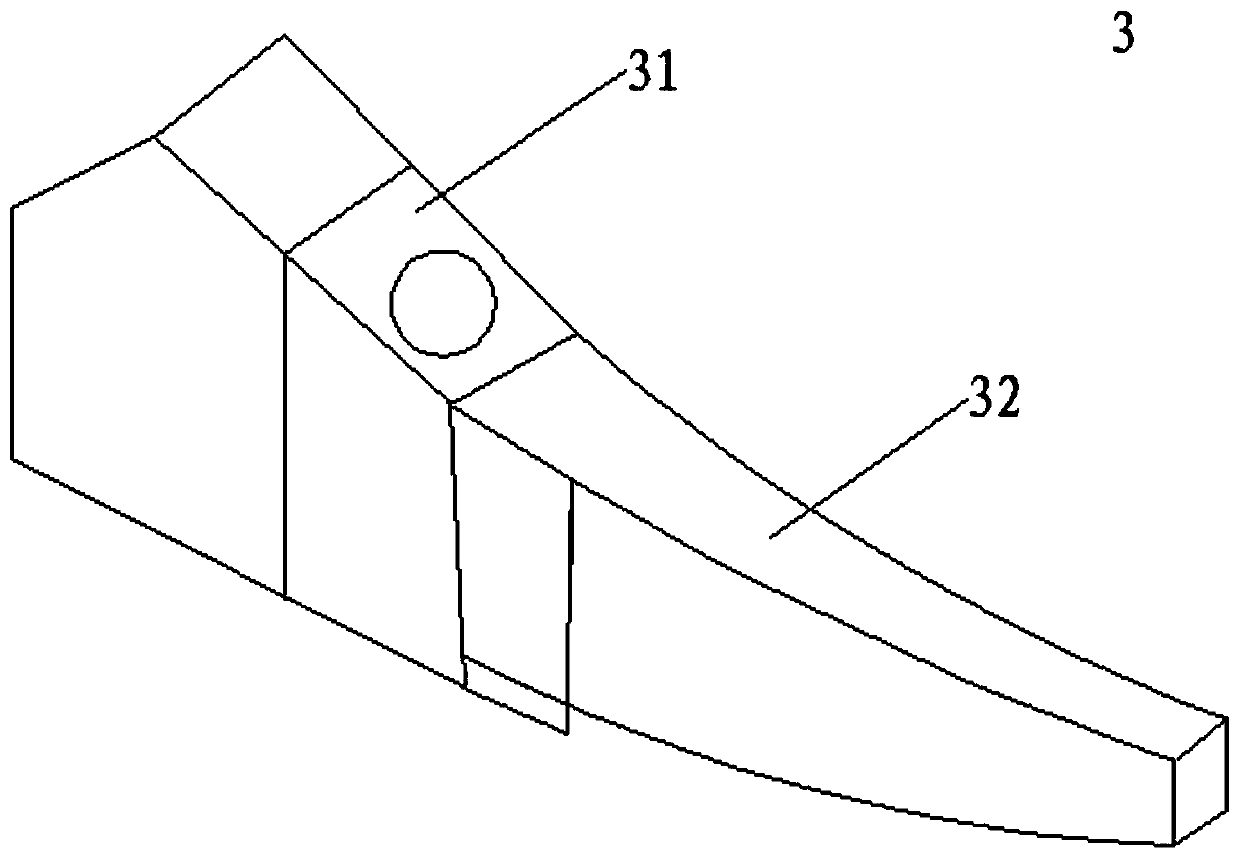

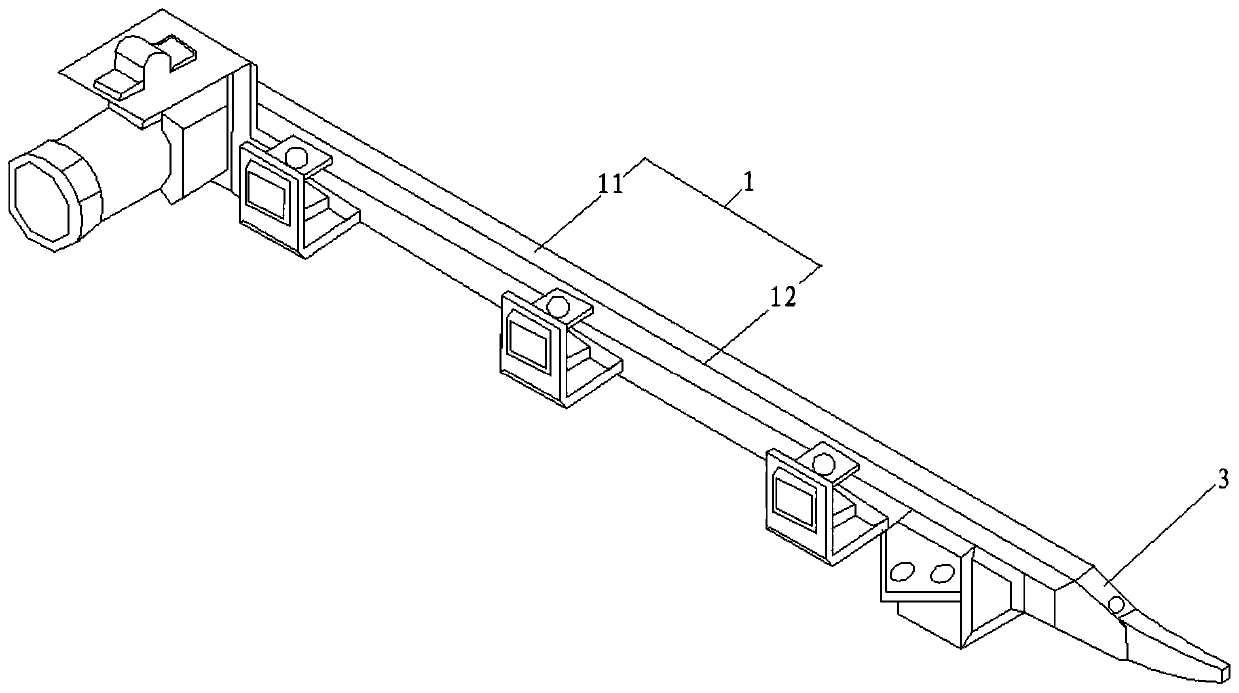

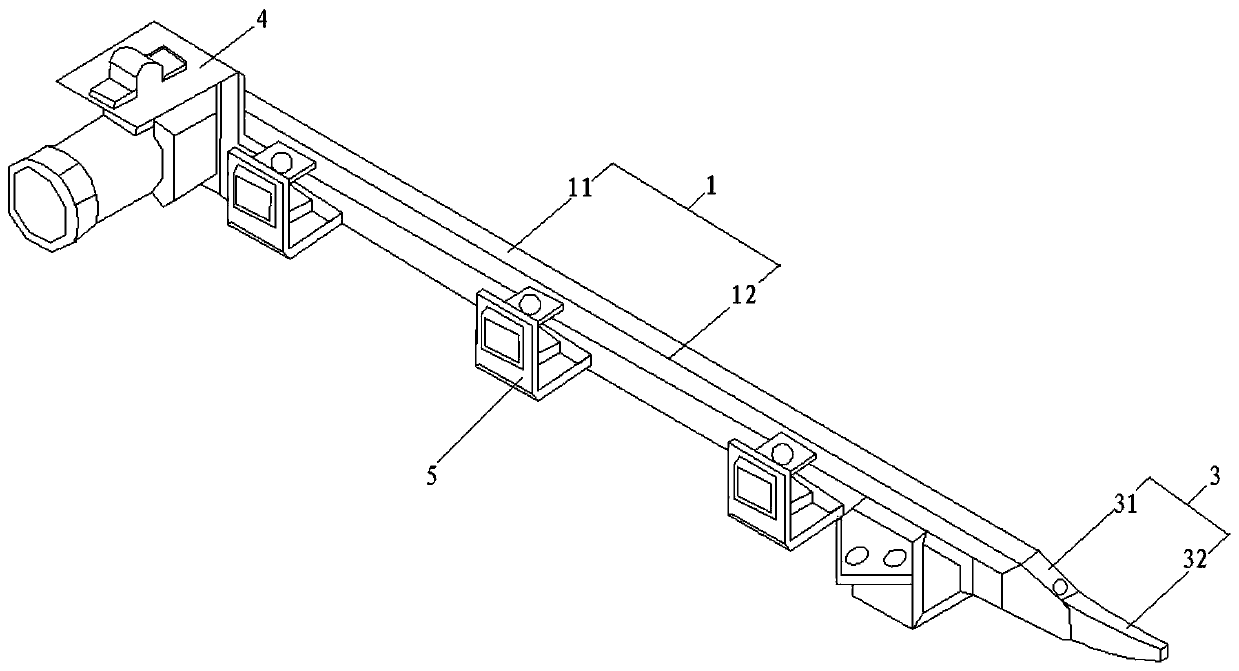

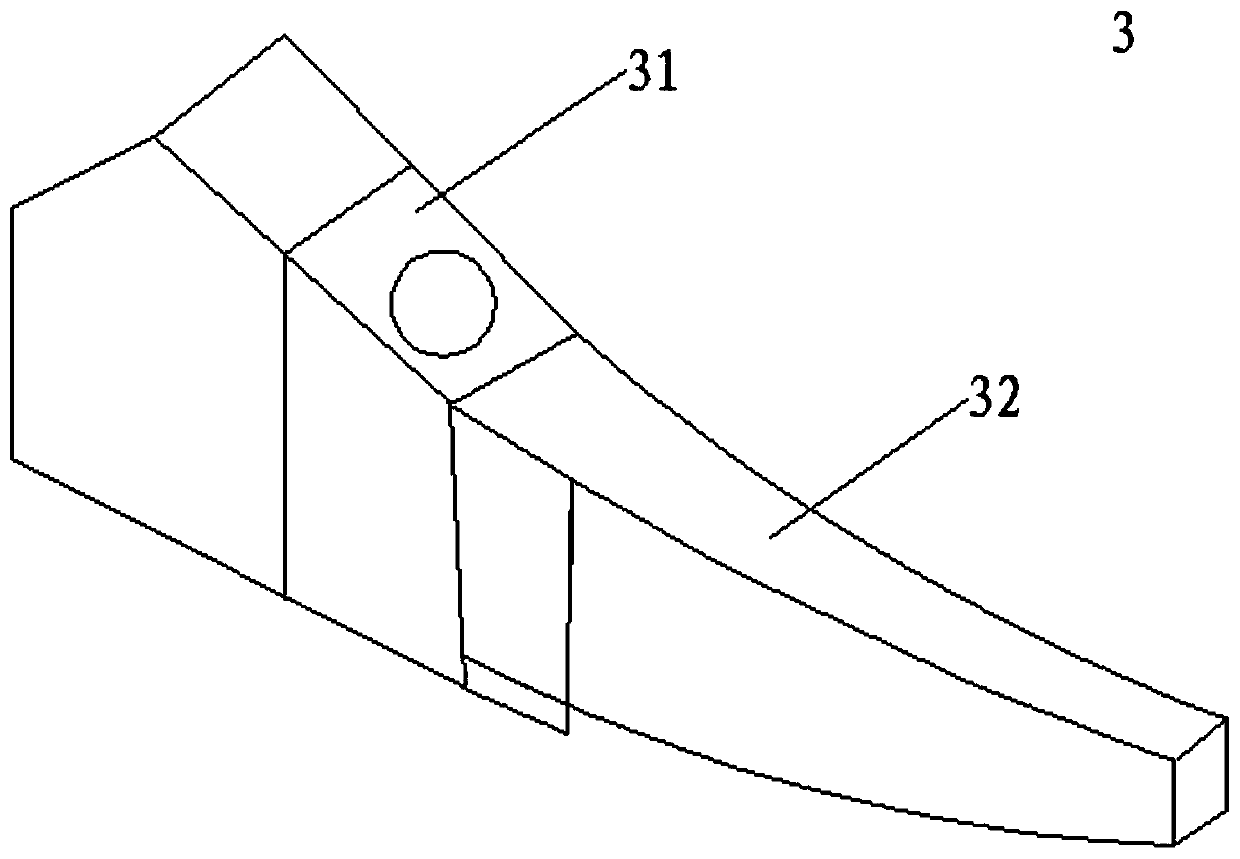

Combination guide device

ActiveCN109748077AImprove transmission efficiencyTeleportation does not affectConveyor partsLogistics managementTransmission belt

The invention discloses a combination guide device, and belongs to the technical field of logistics transmission. The combination guide device comprises a conveyor main frame and a conveyor part; a track is arranged on the conveyor main frame, and a conveyor belt is arranged in the track; one end of the conveyor part is located on the conveyor belt, and the other end of the conveyor belt is used for hanging a target part for conveyor; and a guide part is arranged at the outlet end of the conveyor main frame, one end of the guide part is connected with the track, the other end of the guide partis used for facing a main chain, so that the conveyor part slips from the guide part to the main chain and is away from the main chain after the conveyor part slips over the guide part. According tothe combination guide device, the conveyor part is driven to move through the movement of the conveyor belt in the track, then the target part on the conveyor part is driven to move to the guide part,and the conveyor part slips from the guide part to the main chain by the guide part facing the main chain. In the process of conveying the target part, the conveyor part does not fall or jam from a gap between the conveyor main frame and the main chain, the conveyor efficiency of the target part is improved, and the conveyor of other objects in the main chain is not affected.

Owner:BEIJING SANKUAI ONLINE TECH CO LTD

Conveyor

Owner:德清县凌鹰电器有限公司

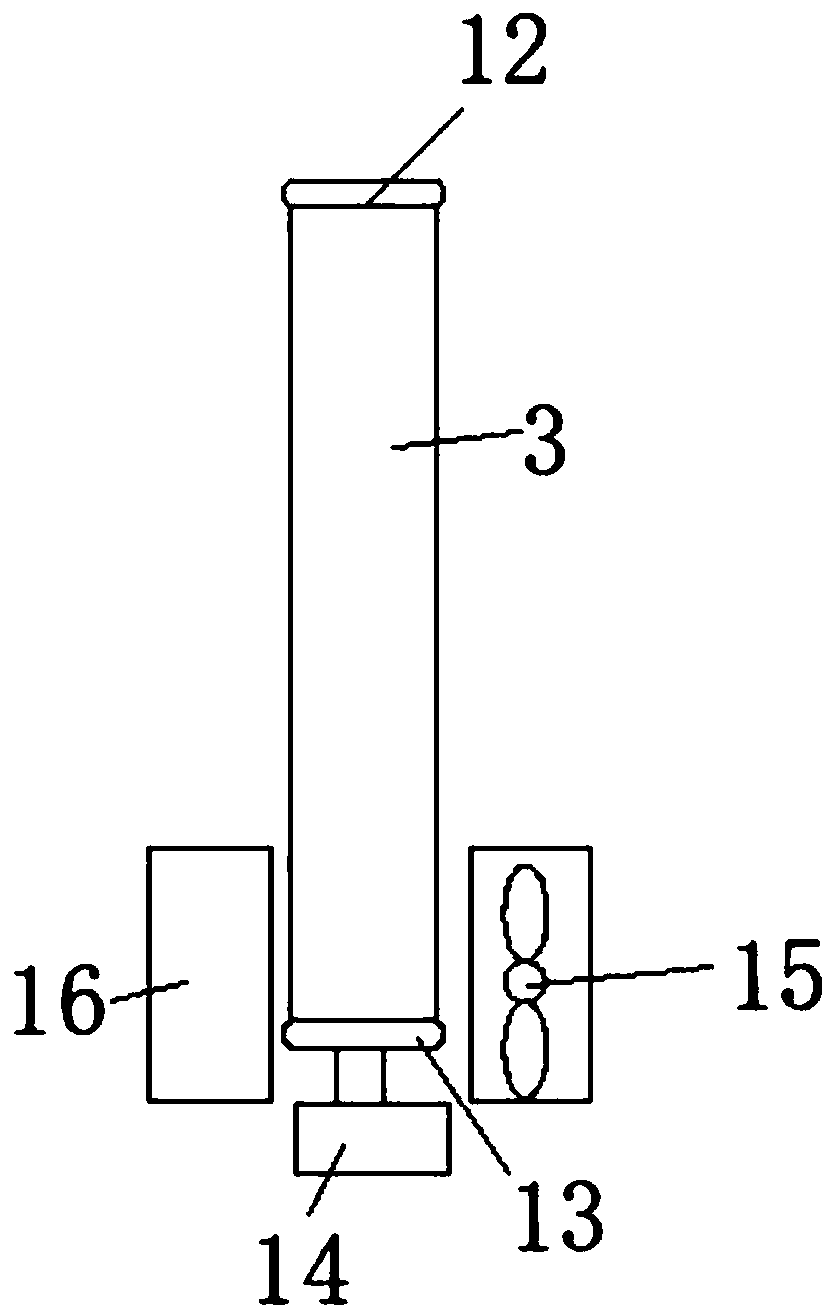

Auxiliary device for injection forming hole

The invention discloses an auxiliary device for an injection forming hole. The auxiliary device comprises an auxiliary box, wherein a die unloading channel is formed in one side of the auxiliary box;a conveying device is arranged below the die unloading channel and the auxiliary box separately; longitudinal slide rails are installed at the two sides of the inner wall of the auxiliary box; a die set is slidably connected between the longitudinal slide rails; a first motor is fixedly connected above the die set; a fixed plate is fixedly connected below the die set; and a first telescopic rod and a second telescopic rod are connected below the fixed plate, and the first telescopic rod is located at one side of the second telescopic rod. According to the auxiliary device disclosed by the invention, some residual burrs of the injection forming hole can be cut off by fixedly connecting a punching head below the first telescopic rod, and meanwhile, auxiliary grinding can be carried out on the injection forming hole through a burr grinding disc below the second telescopic rod, so that the quality of the injection forming hole can be greatly improved; and through the arranged fan and storage box, wastes above the conveying device can be cleaned.

Owner:嘉兴懿铄精密模具有限公司

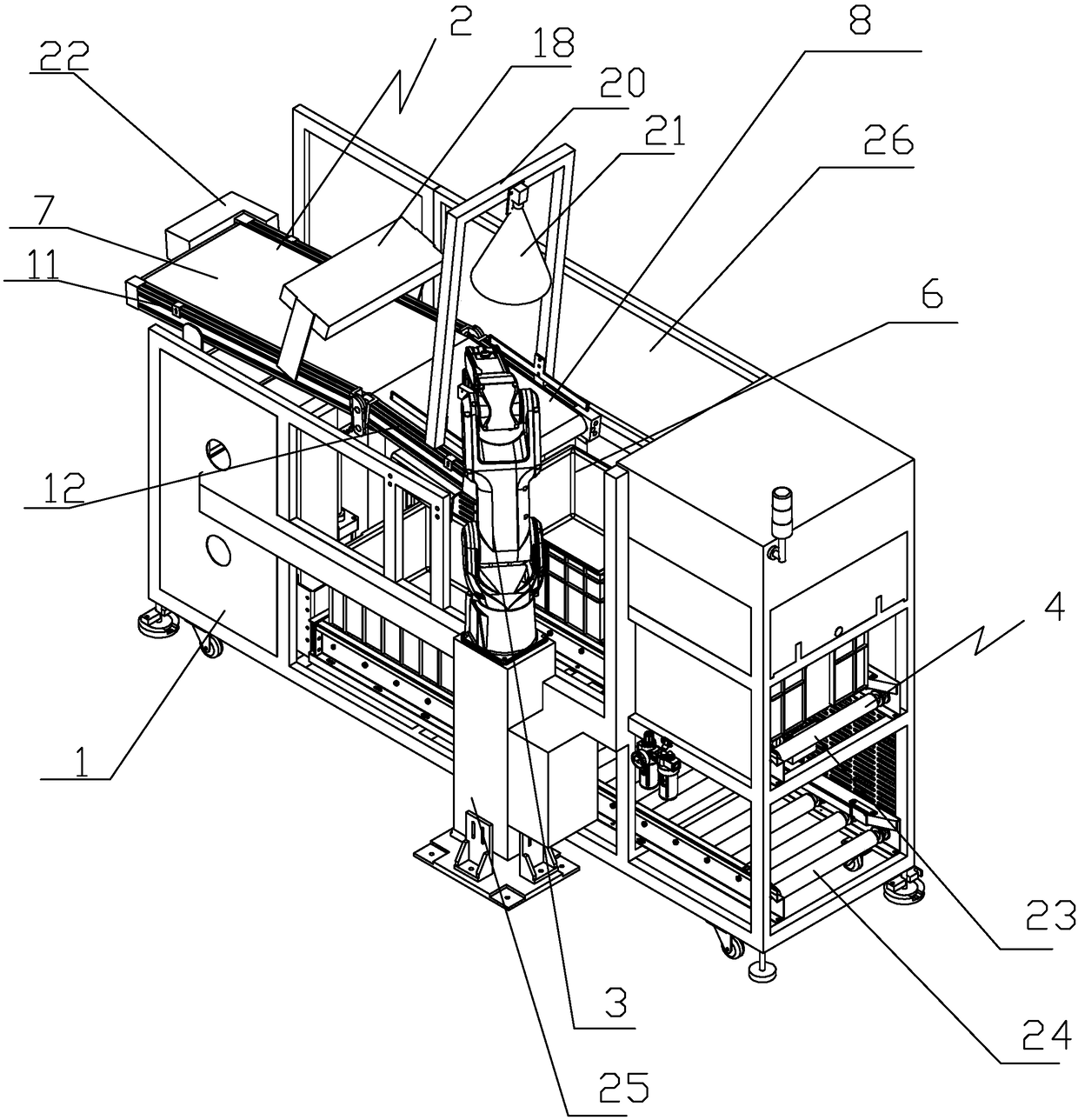

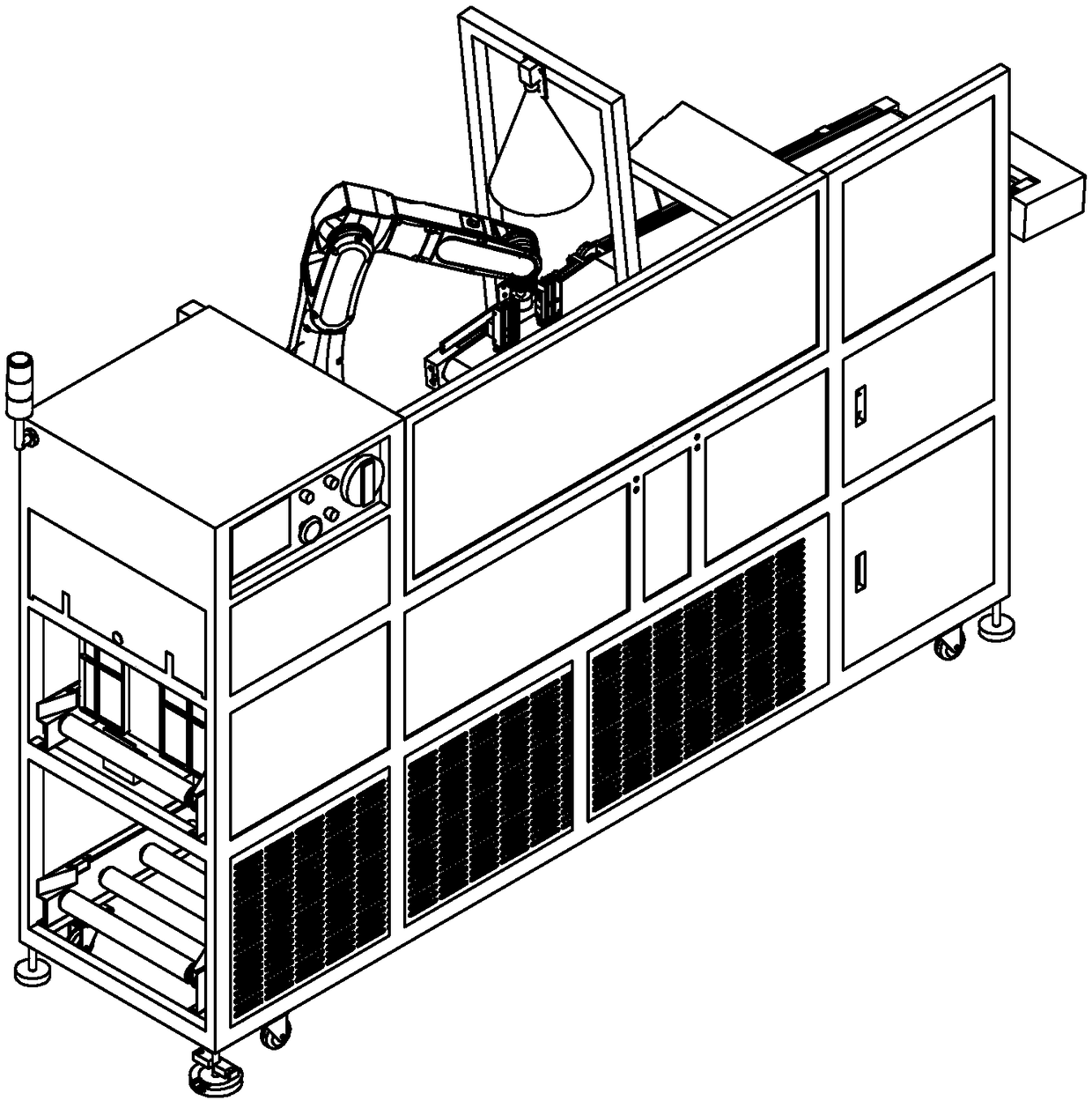

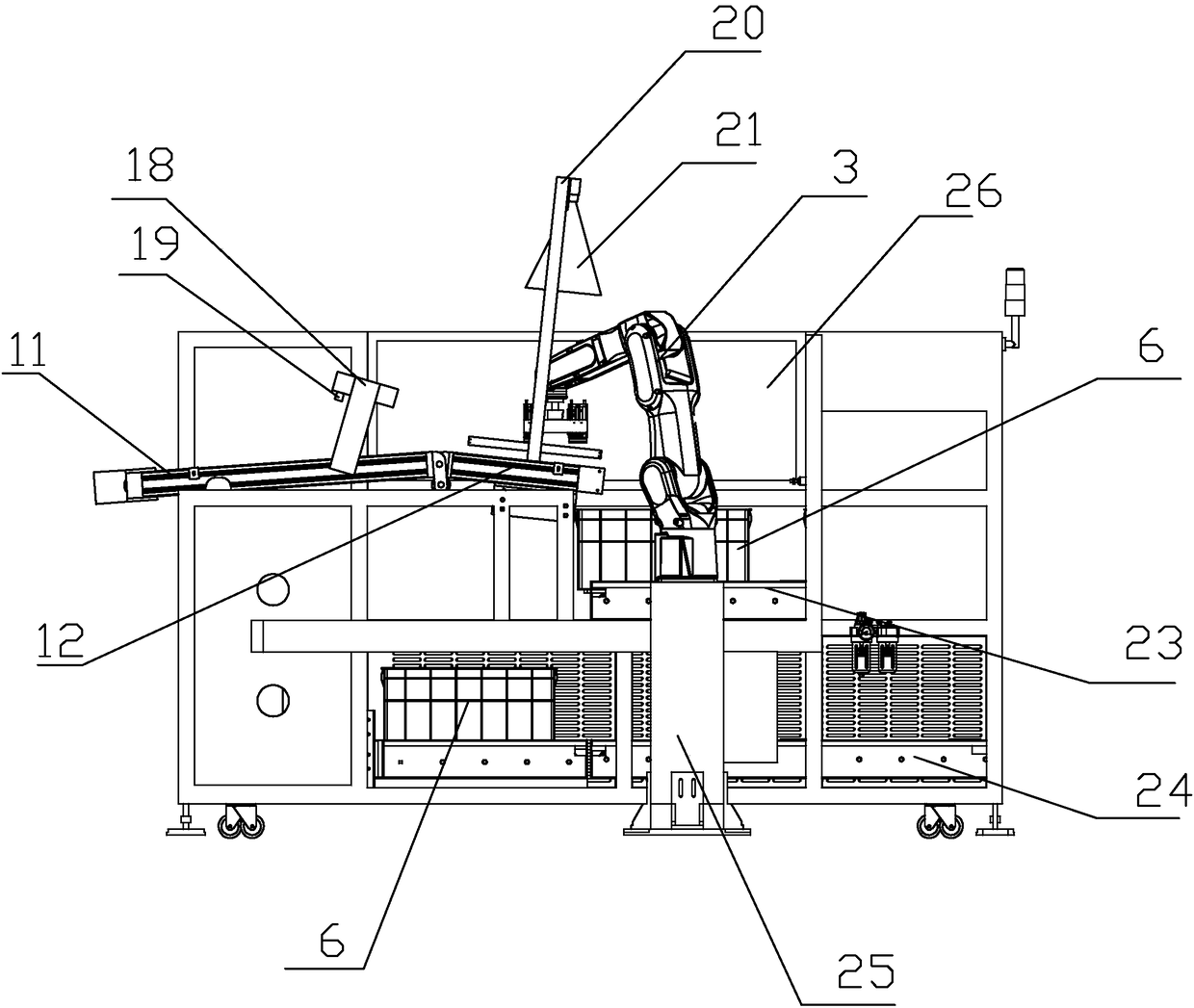

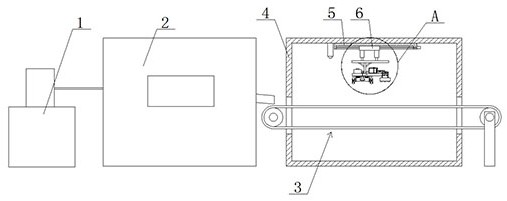

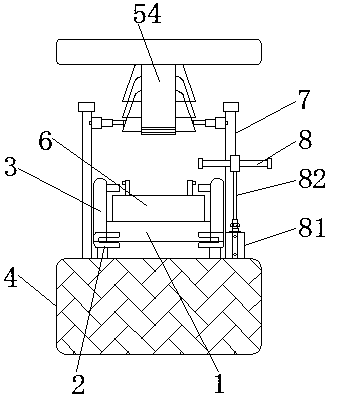

Intelligent box replacement machine for injection molding machine

The invention relates to an intelligent box replacement machine for an injection molding machine. The intelligent box replacement machine comprises a rack (1), and further comprises a first conveyingdevice (2) used for conveying injection molding products, a mechanical arm (3) used for placing the injection molding products, a circulating box (6) used for containing the injection molding productsand a second conveying device (4) used for conveying the circulating box (6); and the first conveying device (2) and the second conveying device (4) are arranged at the two ends of the rack (1), themechanical arm (3) is arranged on one side of the rack (1), the circulating box (6) is located on the second conveying device (4), and the mechanical arm (3) can place the injection molding products located on the first conveying device (2) into the circulating box (6). Compared with the prior art, the intelligent box replacement machine has the beneficial effects that the automatic degree is high, efficiency is high, and cost is low.

Owner:DELI GROUP CO LTD

Paper cutting device for digital printing and capapble of being directly stacking

ActiveCN112476525AEnsure stabilityRealize automatic stackingMetal working apparatusRolling paperElectric machinery

The invention discloses a paper cutting device for digital printing and capable of directly stacking. The paper cutting device comprises a fixed bottom plate, a roll paper tube, a motor, fan blades and a cutter, a side baffle is fixed to the edge of the fixed bottom plate, the outer side of a guide roller is sleeved with a conveyor belt, and a limiting plate is fixed on the side baffle at the sideof the guide roller; and a fixed plate is fixed to the upper portion of a guide plate, a stacking plate is fixedly arranged at the edge of the side baffle, the motor is installed on the upper end face of a fixed top plate through bolts, the fan blades are fixedly installed at the bottom of a motor shaft, and the motor shaft is connected with a movable cylinder through a belt wheel mechanism. According to the paper cutting device for digital printing and capable of directly stacking, printing paper is automatically cut, the stability of the paper can be guaranteed in the cutting process, the situation that the cutting flatness is affected due to skewing and sliding is avoided, meanwhile, automatic stacking of the paper can be achieved after cutting, the cutting efficiency is improved, andthe working intensity is relieved.

Owner:中煤(北京)印务有限公司

Battery piece coating system

PendingCN114351124ATeleportation does not affectReduce chance of downtimeChemical vapor deposition coatingPhotovoltaic energy generationCoating systemProcess engineering

The embodiment of the invention provides a battery piece coating system which comprises a conveying line used for conveying battery pieces and a plurality of coating modules arranged beside conveying stations of the conveying line, the conveying line is provided with a plurality of conveying stations, and the battery pieces are conveyed between the coating modules and the conveying stations. The plurality of coating modules comprise a first coating module comprising at least one first coating device; comprising at least one second coating device; comprising at least one second coating device; comprising at least one fourth coating device; wherein the number of at least one of the first coating devices, the second coating devices, the third coating devices and the fourth coating devices is not less than two. According to the battery piece coating system in the embodiment of the invention, the probability of occurrence of the situation that the conveying line needs to wait for treatment of a single coating device and is empty on the whole is reduced, and the number of battery pieces treated in unit time is increased.

Owner:YINGKOU JINCHEN MACHINERY

wood carving device

ActiveCN109649056BEasy to moveEasy to transportOther artistic work equipmentsModel makingMortise and tenonAgricultural engineering

The invention discloses a wood carving device. The wood carving device comprises a main support, a main rack and a carving device. The main rack is located above the main support. Side mounting racksare welded to the upper portions of the two sides of the main support. The main rack is of a U-shaped structure. Pin plates are welded to the lower portions of the two vertical ends of the main rack.The main rack is in mortise and tenon connection with the side mounting racks through the pin plates. A mounting groove is formed in the center of the upper surface of the horizontal end of the main rack. A mounting plate is clamped to the mounting groove through alignment clamps. Electric push rods are welded to the mounting plate. The bottoms of the electric push rods penetrate through the mounting plate and the main rack to be provided with a lifting plate in a welded mode. The carving device is fixed below the lifting plate through bolts. The wood carving device is suitable for wood carving. The position of wood is not prone to skewing in the carving process. The wood carving device can be applicable to wood with different widths and is convenient to install, dismantle and move.

Owner:安徽天盛家具有限公司

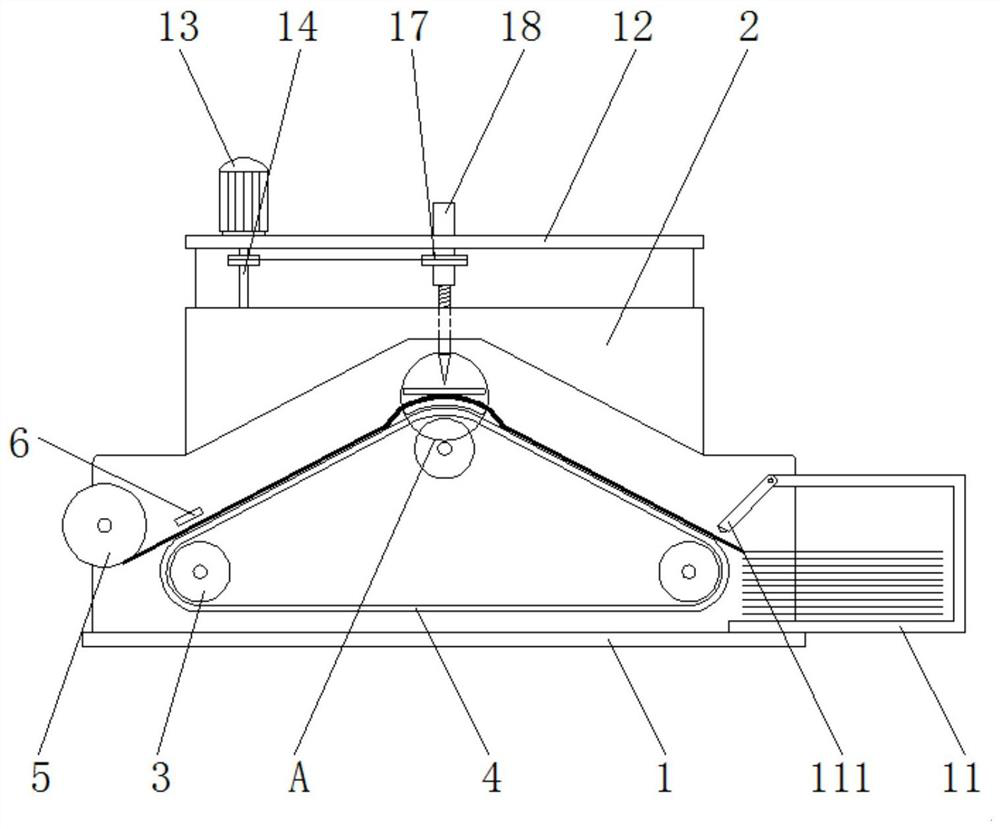

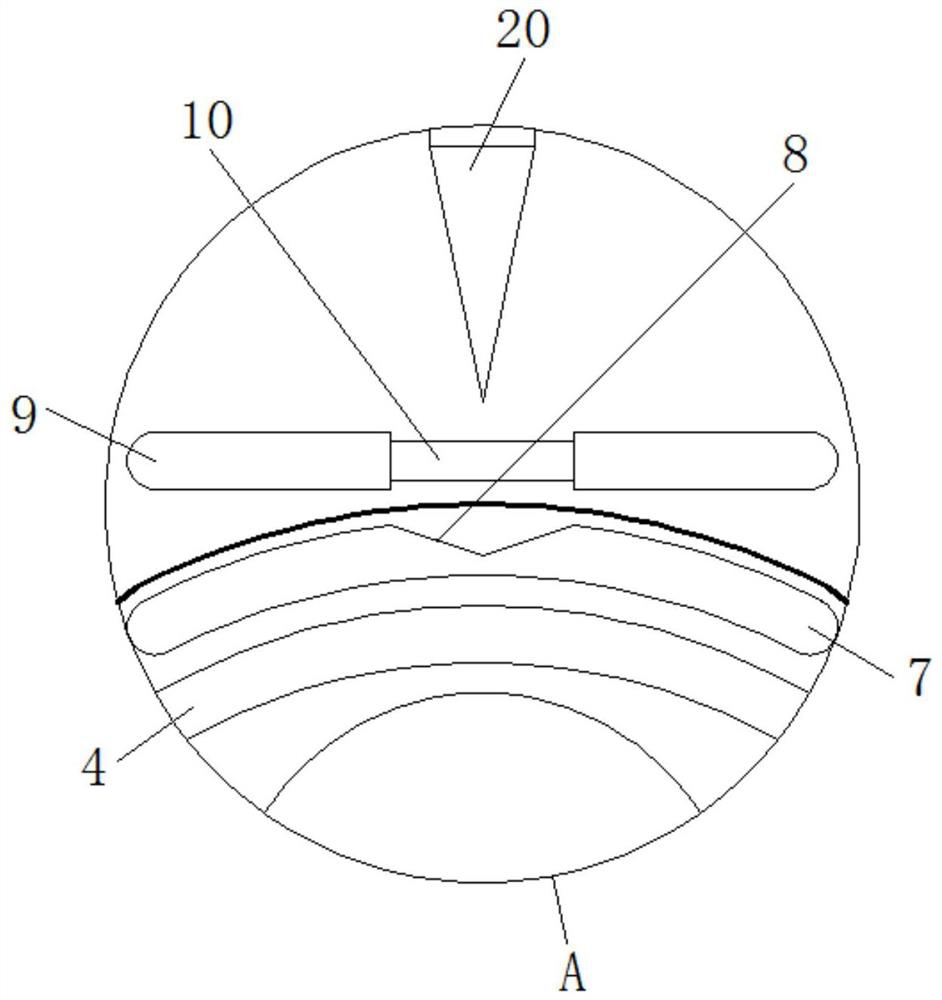

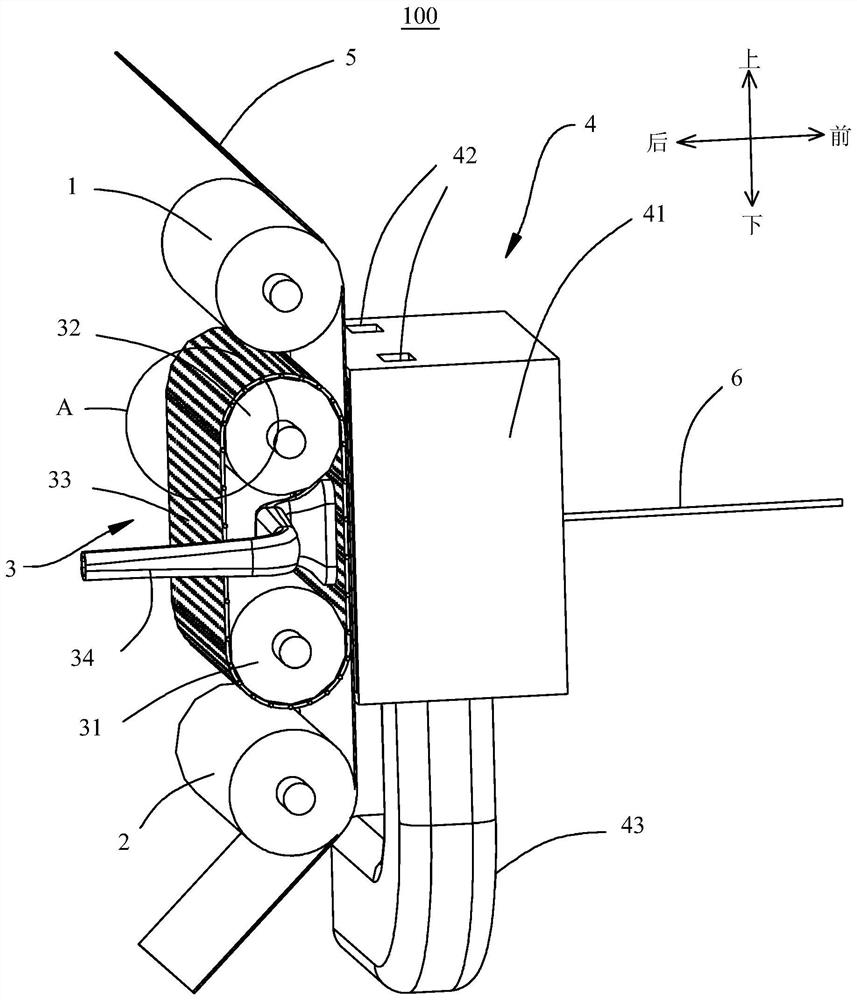

Laser cutting device

PendingCN111940920ATeleportation does not affectPlay a supporting roleMetal working apparatusLaser beam welding apparatusLaser cuttingMechanical engineering

The invention relates to a laser cutting device, and belongs to the technical field of laser cutting machinery. The laser cutting device comprises a first feeding roller and a second feeding roller which are used for conveying to-be-cut materials, and further comprises an anti-shaking mechanism which is arranged between the first feeding roller and the second feeding roller and comprises a drivingroller, a driven roller and a conveying belt, the driving roller, the driven roller, the first feeding roller and the second feeding roller are parallel to one another, the conveying belt is wound around the driving roller and the driven roller, and the conveying belt is used for synchronously moving with the to-be-cut materials and being attached to one side of the to-be-cut materials. Accordingto the laser cutting device, shaking of the to-be-cut materials during cutting can be overcome, and the cutting quality is improved.

Owner:GUANGDONG LYRIC ROBOT INTELLIGENT AUTOMATION CO LTD

Conveyer for preventing paperboard from upwarping during transportation process

ActiveCN106829569AAvoid affecting the efficiency of transmissionIncrease contactArticle feedersPaperboardEngineering

The invention discloses a conveyer for preventing a paperboard from upwarping during a transportation process. The conveyer comprises a conveyer belt, and support rods located under the conveyer belt, wherein connecting rods are connected onto the support rods; a telescopic pressing plate perpendicular to a conveying direction is connected onto the connecting rods; telescopic plates are connected to two sides of the pressing plate; flattening plates are connected onto the telescopic plates; one ends, far away from the telescopic plates, of the flattening plates are in tip shapes; the bottom faces of the flattening plates are parallel to the conveyer belt; heating layers are arranged on the bottom faces of the flattening plates; sensors used for sensing the position of the paperboard are arranged on the connecting rods.

Owner:CHENGDU ZHIRONG ZHICHUANG INTPROP MANAGEMENT CO LTD

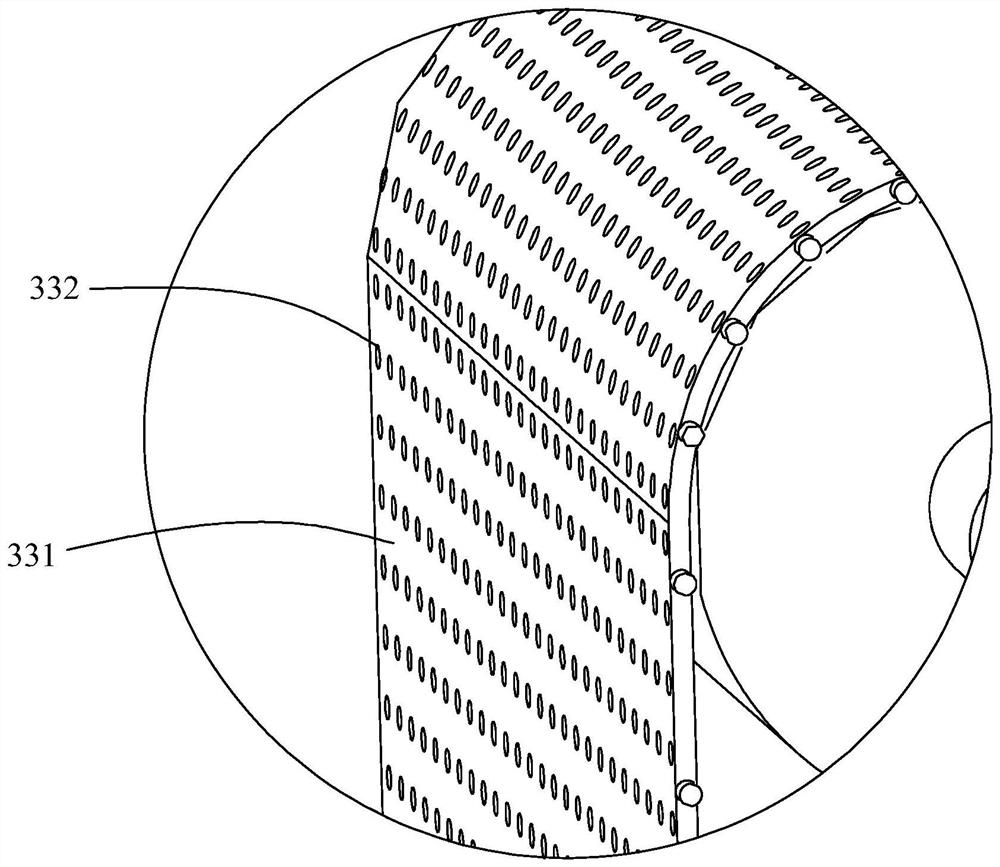

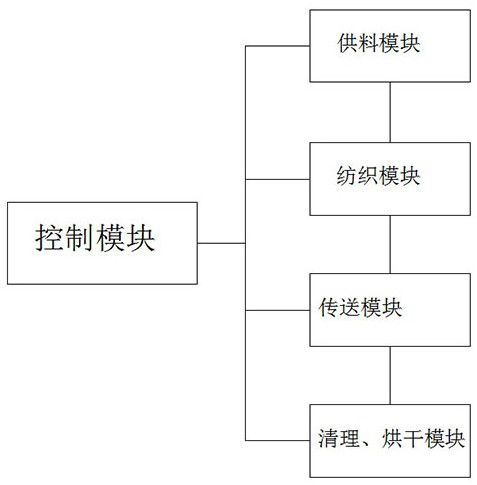

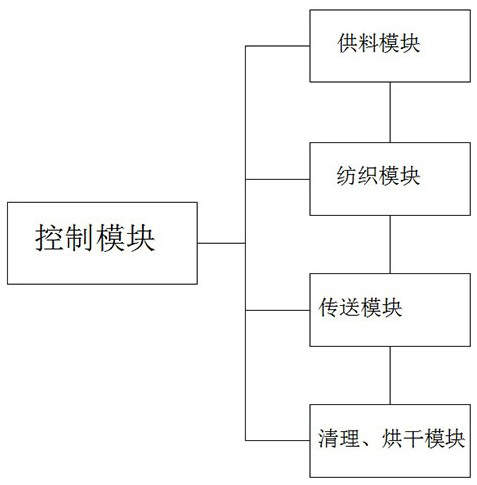

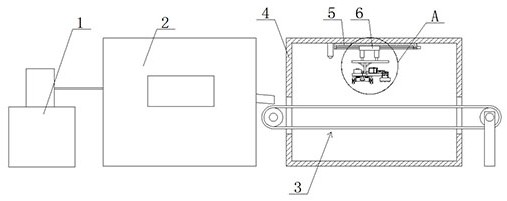

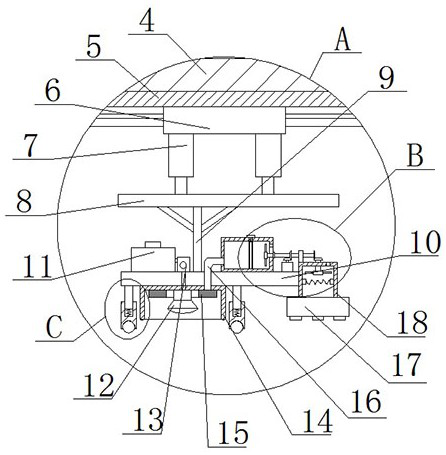

Woolen sweater full-forming step-by-step slicing system

ActiveCN112176516ATeleportation does not affectReduce frictionMechanical cleaningPressure cleaningSpinningProcess engineering

The invention belongs to the technical field of woolen sweater processing, particularly relates to a woolen sweater full-forming step-by-step slicing system, and provides the following scheme for solving the problems that in the prior art, a woollen sweater is usually separately cleaned and dried so that the working efficiency can be reduced, some woollen sweaters are even not cleaned, finished products are directly sewn and processed, and the product quality is seriously affected. The woolen sweater full-forming step-by-step slicing system comprises a control module, a feeding module, a spinning module, a conveying module and a cleaning and drying module, the feeding module, the spinning module, the conveying module and the cleaning and drying module are all connected with the control module, the control module is an intelligent controller, the feeding module is connected with the spinning module, the spinning module is connected with the conveying module, and the conveying module isconnected with the cleaning and drying module; and the feeding module is a wool pay-off machine, and the spinning module is an automatic spinning machine. The woolen sweater full-forming step-by-stepslicing system is convenient to operate, woolen sweater cloth can be washed and dried at the same time, and the work efficiency and the product quality are improved.

Owner:江苏扬帆服饰有限公司

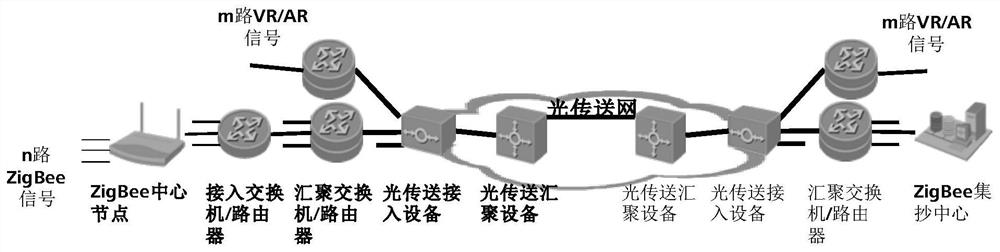

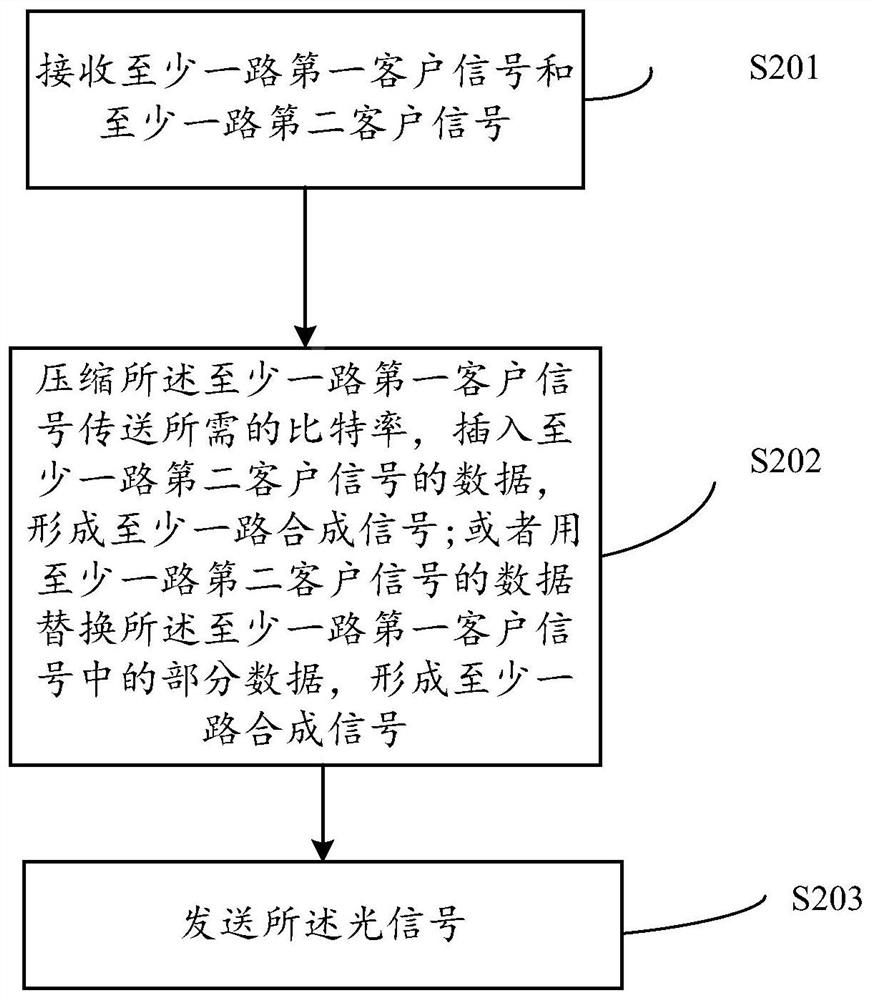

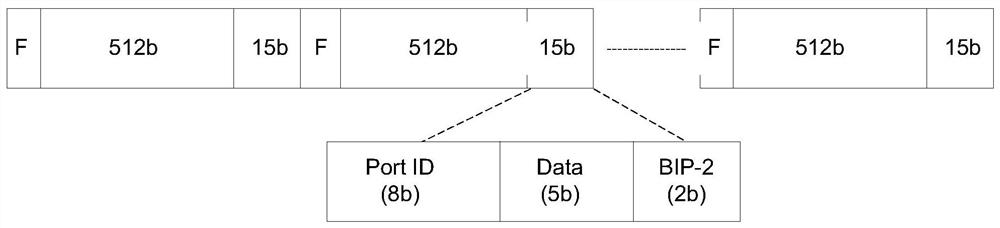

A signal transmission method, device and system

ActiveCN108270512BAchieve teleportationTeleportation does not affectTime-division multiplexTransmission format adaptationComputer hardwareEngineering

An embodiment of the present invention provides a signal transmission method, including: receiving at least one first client signal and at least one second client signal; compressing the bit rate required for transmission of at least one first client signal, and inserting at least one second client signal data, or replace part of the data in the at least one first client signal with the data of at least one second client signal to form at least one composite signal; and send at least one composite signal. Embodiments of the present invention also provide corresponding signal transmission devices and transmission systems. The embodiment of the present invention realizes the transmission of the second client signal without affecting the transmission of the first client signal, improves the transmission efficiency, and saves transmission resources at the same time.

Owner:HUAWEI TECH CO LTD

Electric heating furnace for hot stamping

InactiveCN112747592AImprove processing efficiencyImprove heat treatment effectFurnace componentsNon-rotating vibration suppressionHot stampingThermodynamics

The invention discloses an electric heating furnace for hot stamping. The electric heating furnace comprises a high-temperature-resistant conveying belt, a bearing frame, a servo motor and a temperature sensor, an assembly base plate is arranged at the bottom end of the bearing frame, the high-temperature-resistant conveying belt is fixed to the top end of the bearing frame, a controller is arranged at the end, below the high-temperature-resistant conveying belt, in the bearing frame, the servo motor is arranged at the other end, below the high-temperature-resistant conveying belt, in the bearing frame, and a heating furnace body welded to the bearing frame is arranged on the outer side of the high-temperature-resistant conveying belt in a covering mode. According to the electric heating furnace, by installing a fixing base, the heating furnace body, a reserved sliding strip and a reserved sliding groove, the structure of the device is optimized, during use, a user can assemble or disassemble the fixing base and the heating furnace body by utilizing a sliding connection structure formed by the reserved sliding strip and the reserved sliding groove under the cooperation of the locking and fixing effects of a locking sheet and a locking bolt, then an air curtain machine can be disassembled, assembled and maintained, and therefore the functionality of the device is enhanced.

Owner:HUBEI YONGZHE HOT STAMPING PARTS CO LTD

Steel plate cutting device

ActiveCN111250775BSimple structureLow costShearing machinesLarge fixed membersMechanical engineeringElectromagnet

The invention relates to the technical field of steel plate processing, and specifically discloses a steel plate cutting device, which includes a frame, a tilting mechanism, a transmission mechanism and a cutting mechanism. The tilting mechanism includes a universal ball platform and a turntable that is rotationally connected to the frame. Located above the universal ball platform, an electromagnet is slidably connected to the turntable, and a first elastic member is connected between the electromagnet and the turntable, and the electromagnet can move up and down along the turntable. This solution is used to solve the problems of complex equipment structure and long time-consuming adjustment of cutting angle existing in the cutting of trapezoidal steel plates in the prior art.

Owner:重庆市荣昌区永世光电设备有限公司

A paper cutting device for digital printing capable of direct stacking

ActiveCN112476525BEnsure stabilityRealize automatic stackingMetal working apparatusElectric machineryFan blade

The invention discloses a paper cutting device for digital printing capable of direct stacking, which comprises a fixed bottom plate, a paper roll, a motor, fan blades and a cutting knife, side baffles are fixed at the edge of the fixed bottom plate, and the guide The outer side of the roller is covered with a conveyor belt, a limit plate is fixed on the side baffle on the side of the guide roller, a fixed plate is fixed above the guide plate, and a stacking plate is fixed on the edge of the side baffle, The motor bolts are installed on the upper end surface of the fixed top plate, the fan blades are fixedly installed on the bottom of the motor shaft, and the motor shaft is connected to each other through a pulley mechanism and a movable cylinder. The paper cutting device for digital printing that can be directly stacked can automatically cut the printing paper, and can ensure the stability of the paper during the cutting process, avoiding skewed sliding that affects the flatness of the cutting, and at the same time can realize the paper after cutting. The automatic stacking improves the cutting efficiency and reduces the work intensity.

Owner:中煤(北京)印务有限公司

Confluence guide device

ActiveCN109748077BImprove transmission efficiencyTeleportation does not affectConveyor partsLogistics managementTransmission belt

The invention discloses a combination guide device, and belongs to the technical field of logistics transmission. The combination guide device comprises a conveyor main frame and a conveyor part; a track is arranged on the conveyor main frame, and a conveyor belt is arranged in the track; one end of the conveyor part is located on the conveyor belt, and the other end of the conveyor belt is used for hanging a target part for conveyor; and a guide part is arranged at the outlet end of the conveyor main frame, one end of the guide part is connected with the track, the other end of the guide partis used for facing a main chain, so that the conveyor part slips from the guide part to the main chain and is away from the main chain after the conveyor part slips over the guide part. According tothe combination guide device, the conveyor part is driven to move through the movement of the conveyor belt in the track, then the target part on the conveyor part is driven to move to the guide part,and the conveyor part slips from the guide part to the main chain by the guide part facing the main chain. In the process of conveying the target part, the conveyor part does not fall or jam from a gap between the conveyor main frame and the main chain, the conveyor efficiency of the target part is improved, and the conveyor of other objects in the main chain is not affected.

Owner:BEIJING SANKUAI ONLINE TECH CO LTD

Conveying device with protective and fixing functions for producing biomimetic robot

InactiveCN109018859ATeleportation does not affectSmooth transmissionConveyorsCleaningMotor driveProtection mechanism

The invention relates to a conveying device with protective and fixing functions for producing a biomimetic robot, and comprises a conveyor belt, a support rod, a guard bar, a dust suction mechanism,a protection mechanism, a fixing mechanism, a clamping mechanism and a reinforcing mechanism. The support rod is arranged under one side of the body wall of the conveyor belt, and the guard bar is disposed at the upper end of the support rod, the dust suction mechanism is disposed at the bottom of the conveyor belt, and the support rod is disposed at the upper end of the dust suction mechanism. The protection mechanism is arranged above the guard bar, and the clamping mechanism is installed on the lower side of the protection mechanism. The fixing mechanism is placed on the conveyor belt, andthe reinforcing mechanism is arranged on one side of the fixing mechanism. According to the conveying device with the protective and fixing function for producing the biomimetic robot, the dust suction ring of the invention can slide the bionic robot up and down under the driving of the servo motor, and the servo motor drives the screw to rotate, and the bevel gear drives the dust ring to slide onthe screw rod under the action of the screw rod. The dust-collecting area of the bionic machine is increased to make the bionic robot reduce the adhesion of dust as much as possible.

Owner:东莞市史雷帝三维数控科技有限公司

Conveyor to prevent cardboard from warping during transport

ActiveCN106829569BAvoid affecting the efficiency of transmissionIncrease contactArticle feedersCardboardEngineering

The invention discloses a conveyer for preventing a paperboard from upwarping during a transportation process. The conveyer comprises a conveyer belt, and support rods located under the conveyer belt, wherein connecting rods are connected onto the support rods; a telescopic pressing plate perpendicular to a conveying direction is connected onto the connecting rods; telescopic plates are connected to two sides of the pressing plate; flattening plates are connected onto the telescopic plates; one ends, far away from the telescopic plates, of the flattening plates are in tip shapes; the bottom faces of the flattening plates are parallel to the conveyer belt; heating layers are arranged on the bottom faces of the flattening plates; sensors used for sensing the position of the paperboard are arranged on the connecting rods.

Owner:CHENGDU ZHIRONG ZHICHUANG INTPROP MANAGEMENT CO LTD

A step-by-step sheeting system for woolen sweaters

ActiveCN112176516BTeleportation does not affectReduce frictionMechanical cleaningPressure cleaningProcess engineeringIndustrial engineering

Owner:江苏扬帆服饰有限公司

Feeding and piece arranging device for electric injection furnace

PendingCN111942872APrevent stackingTeleportation does not affectConveyor partsElectrical batteryEngineering

The invention discloses a feeding and piece arranging device for an electric injection furnace. The feeding and piece arranging device is characterized in that a first front-back correcting unit, a first left-right correcting unit, a piece taking position conveying line, a second left-right correcting unit and a second front-back correcting unit are sequentially and fixedly installed at the top face of a fixing plate from left to right, and a conveying rail fixing plate is located at the front side of the fixing plate; and a middle conveying line body is fixedly installed on the conveying railfixing plate and located at the front side of the piece taking position conveying line, a silicon wafer conveying line is fixedly installed on the conveying rail fixing plate and located at the frontside of the middle conveying line body, and a temporary storage piece box is installed on the conveying rail fixing plate and located at the left side of the silicon wafer conveying line. The feedingand piece arranging device is simple in structure and stable and reliable in work, the discharging speed is greatly increased, the situation that battery pieces are stacked due to the fact that the battery pieces cannot be conveyed in time is prevented, and extra damage to the battery pieces is avoided while the correction effect is guaranteed.

Owner:常州科瑞尔科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com