Feeding and piece arranging device for electric injection furnace

A chip box and silicon wafer technology, applied in the directions of transportation and packaging, conveyor objects, etc., can solve the problems of cell collapse, edge defect, uneven cell, complicated structure, etc., and achieve the effect of improving the speed of chip removal.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The specific embodiment of the present invention is further described below in conjunction with accompanying drawing:

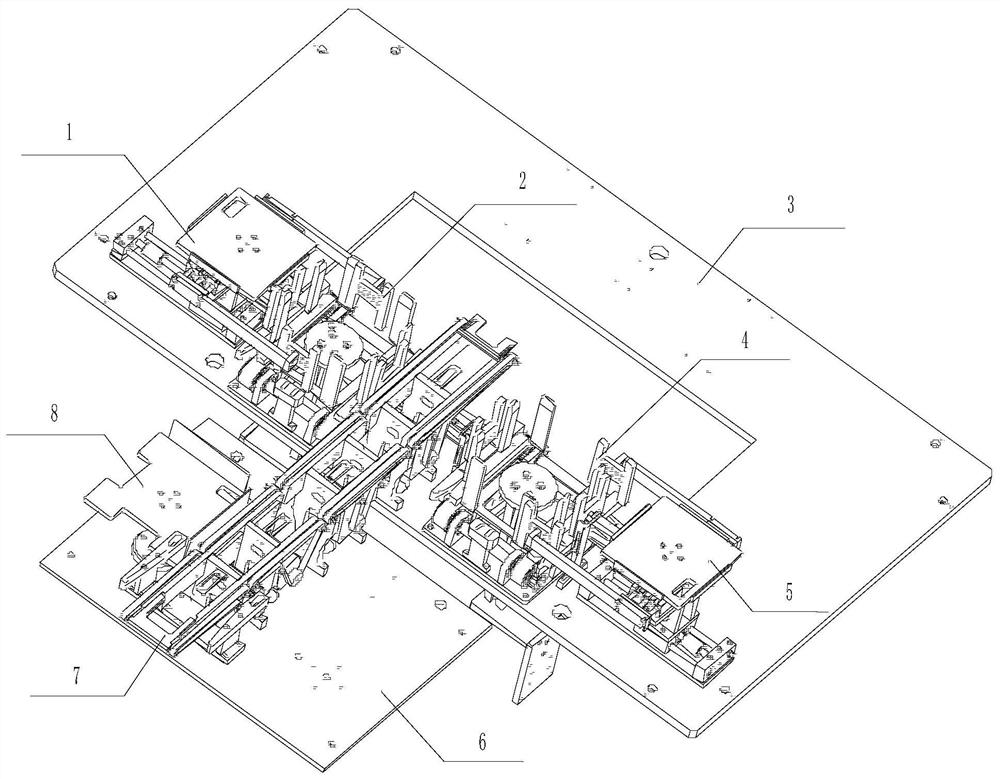

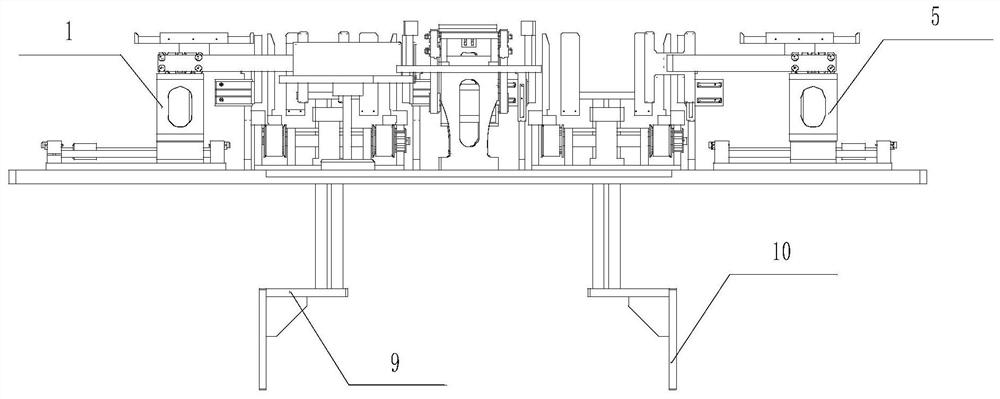

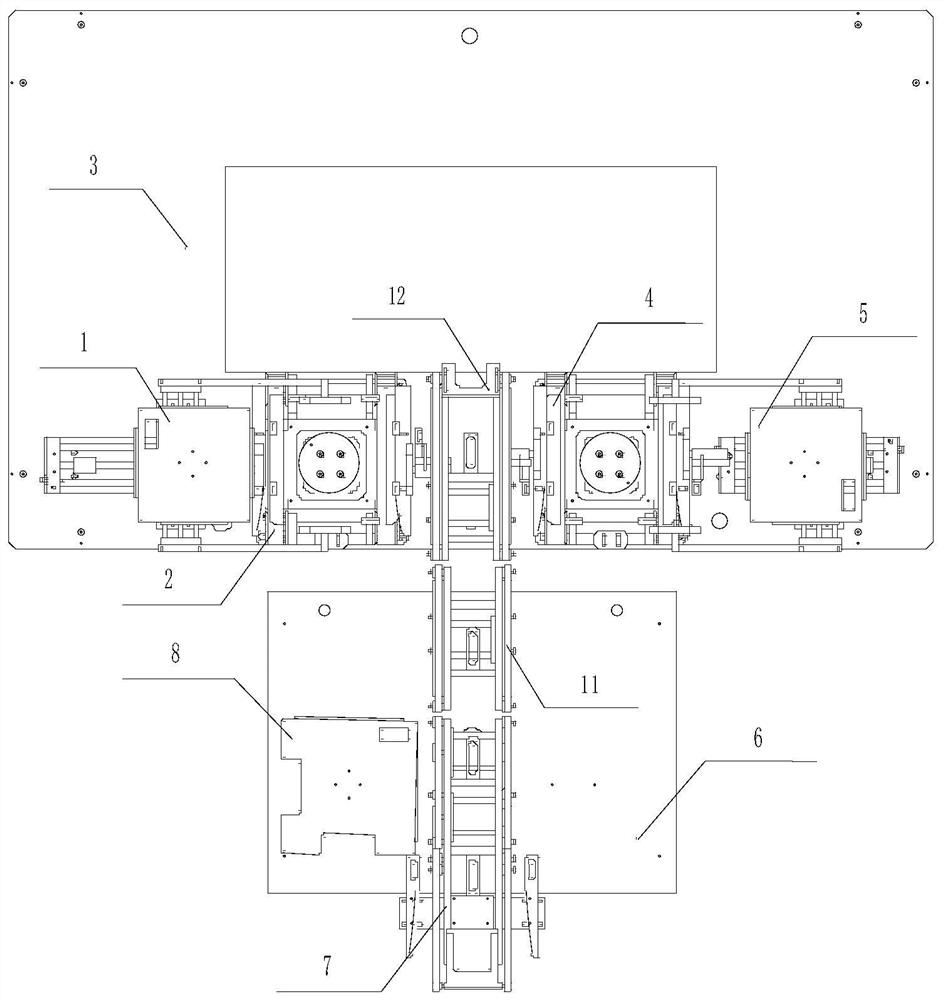

[0030] An electric injection furnace feeding device, characterized in that it includes a first front and rear straightening unit 1, a first left and right straightening unit 2, a fixing plate 3, a second left and right straightening unit 4, a second front and rear straightening unit 5, and a transmission rail Fixed plate 6, silicon wafer conveying line 7, temporary film cassette 8, first jacking rod 9, second jacking rod 10, middle conveying line body 11 and slice taking position conveying line 12, the first front and rear correction The unit 1 is installed on the top surface of the fixed plate 3, the first left and right correction unit 2 is fixedly installed on the top surface of the fixed plate 3 and the first left and right correction unit 2 is located on the right side of the first front and rear correction unit 1, and the first left and right corr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com