Steel plate cutting device

A cutting device and steel plate technology, which is applied in the field of steel plate processing, can solve the problems of complex equipment structure, time-consuming adjustment of cutting angle, etc., and achieve the effect of simple and convenient adjustment, simple structure and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

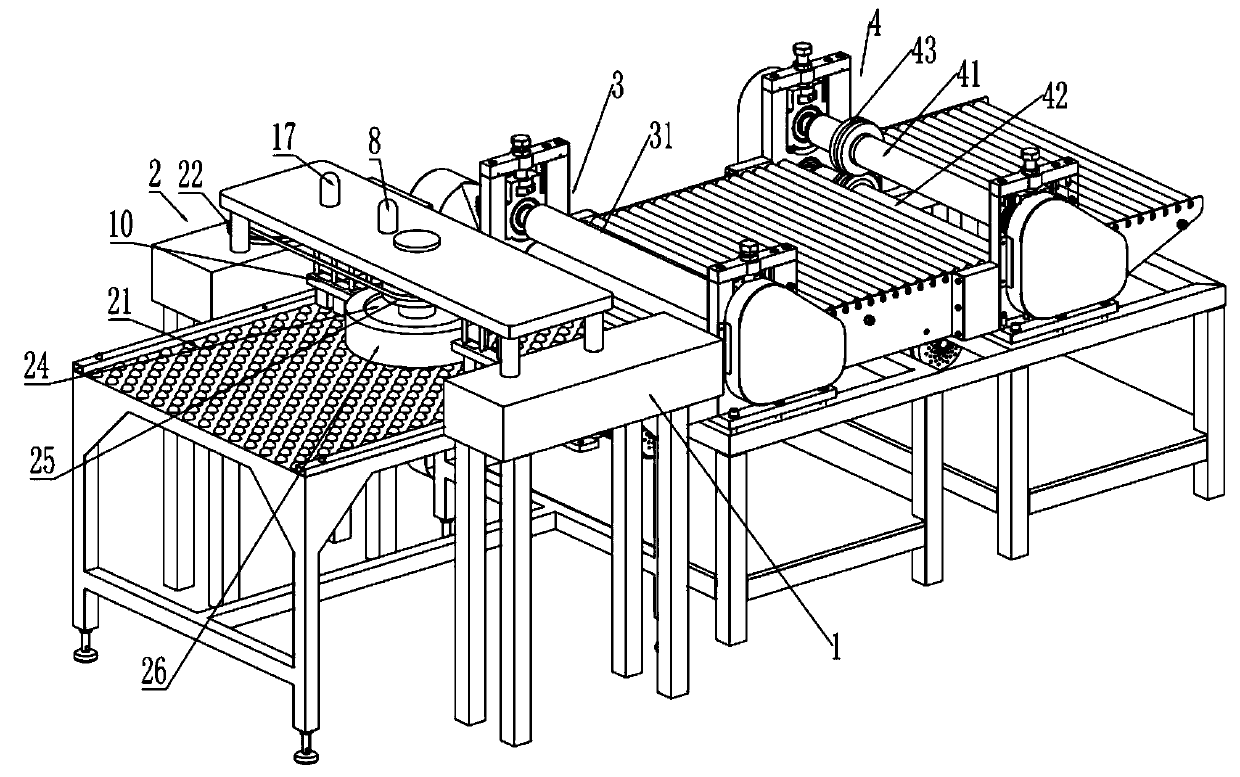

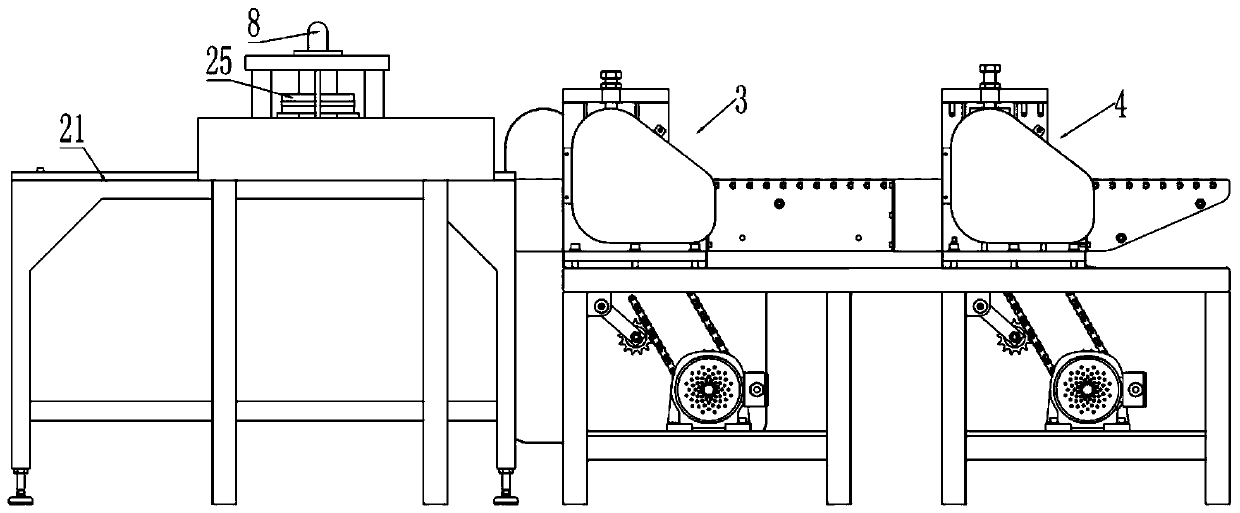

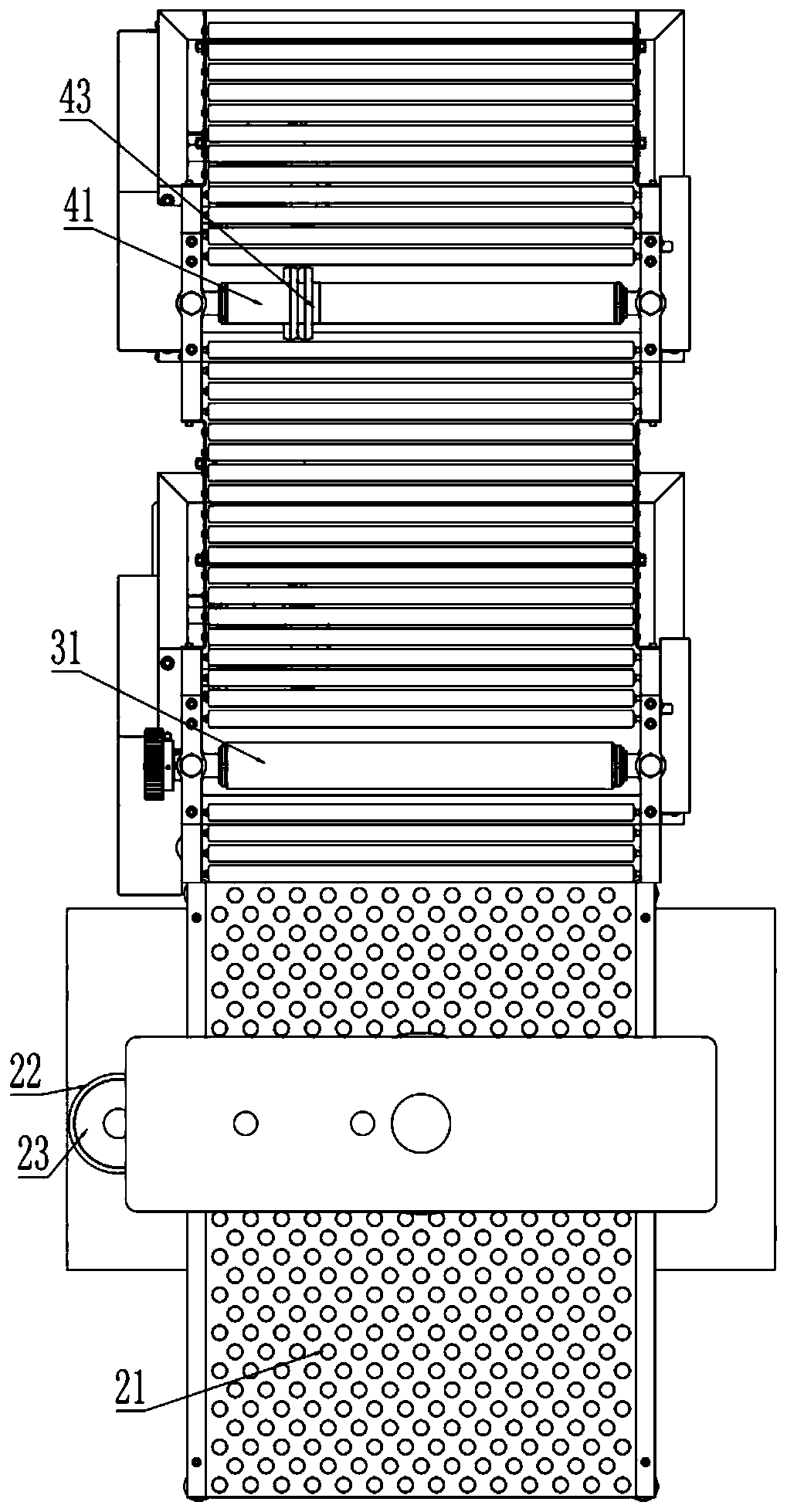

[0039] Embodiment one is basically as attached Figure 1 to Figure 9 Shown:

[0040] combine Figure 1 to Figure 3 , steel plate cutting device, including frame 1, pushing mechanism 2, transmission mechanism 3 and cutting mechanism 4, pushing mechanism 2, transmission mechanism 3 and cutting mechanism 4 are all installed on the frame 1, and transmission mechanism 3 includes several rollers And the pair of rollers 31, by the pair of rollers 31, the steel plate on the push-off mechanism 2 will be delivered to the cutting mechanism 4, the cutting mechanism 4 includes an upper turning roller 41 and a lower turning roller 42, both on the upper turning roller 41 and the lower turning roller 42 The key is connected with a rolling shear blade 43, and realizes cutting of the steel plate by the rolling shear blade 43 distributed up and down.

[0041] combine figure 1 , Figure 5 and Figure 6, the tilting mechanism 2 includes a universal ball platform 21, a disc 22, an adjustment d...

Embodiment 2

[0059] combine Figure 10 As shown, on the basis of the first embodiment, the second embodiment adds two pushing units symmetrically along the center of the turntable 24, and each pushing unit includes a cylinder 19 and a pushing plate 20, and the pushing plate 20 is fixedly connected to the At the end of the piston rod, the two flushing plates 20 are parallel to the conveying direction of the transmission mechanism 3, and the two flushing plates 20 are arranged facing each other.

[0060] Before the steel plate is rotated by the tilting mechanism 2, the cylinder 19 of the pushing unit is started first, so that the two pushing plates 20 are close to the steel plate at the same time, and then the steel plate is pushed to the central position of the bottom of the turntable 24, and the steel plate is positioned at the bottom of the turntable 24. After the central position, start the pushing mechanism 2 again to rotate the steel plate at a certain angle, so as to ensure the consis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com