Patents

Literature

42results about How to "Lower wage costs" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

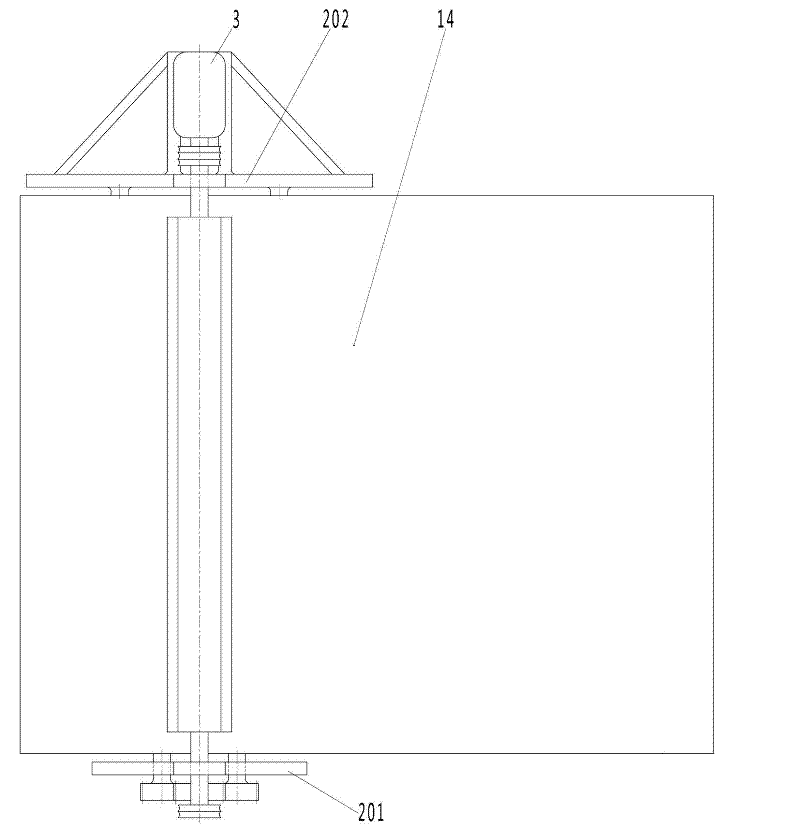

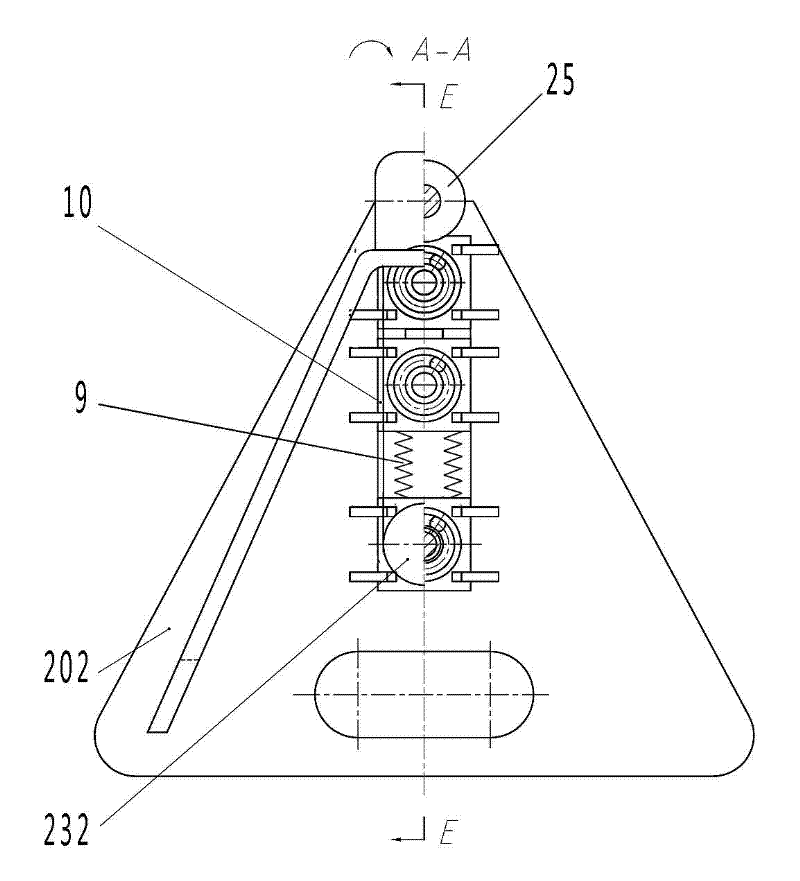

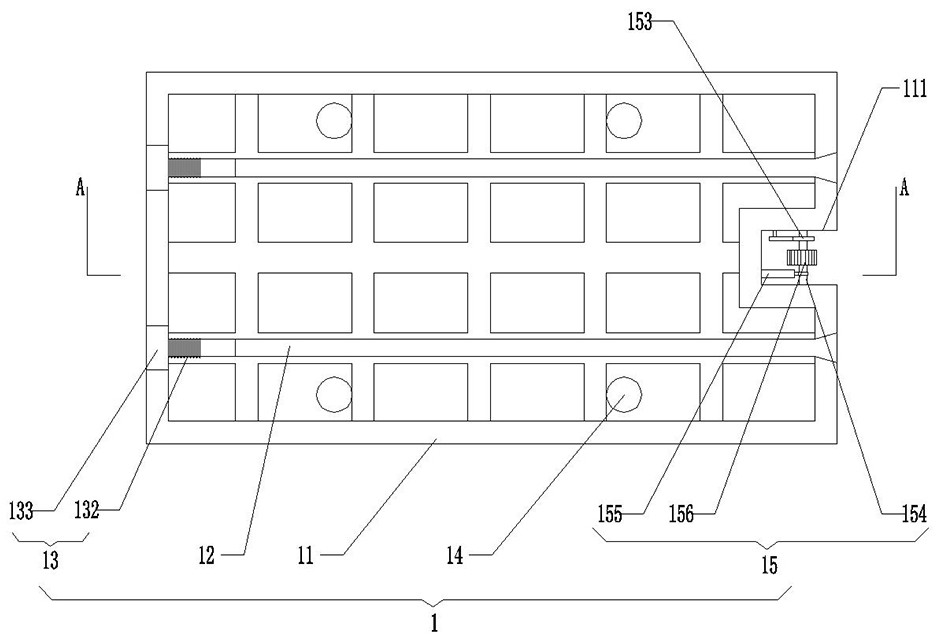

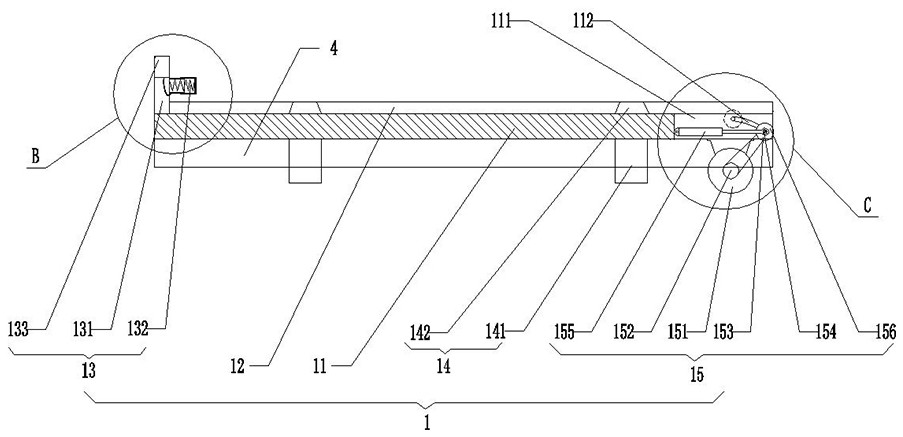

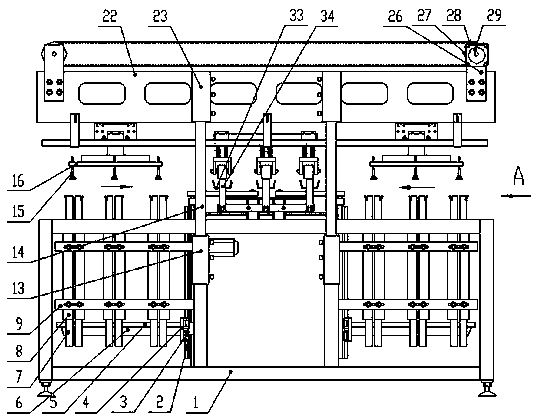

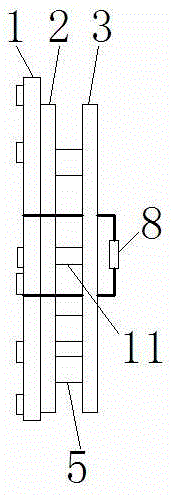

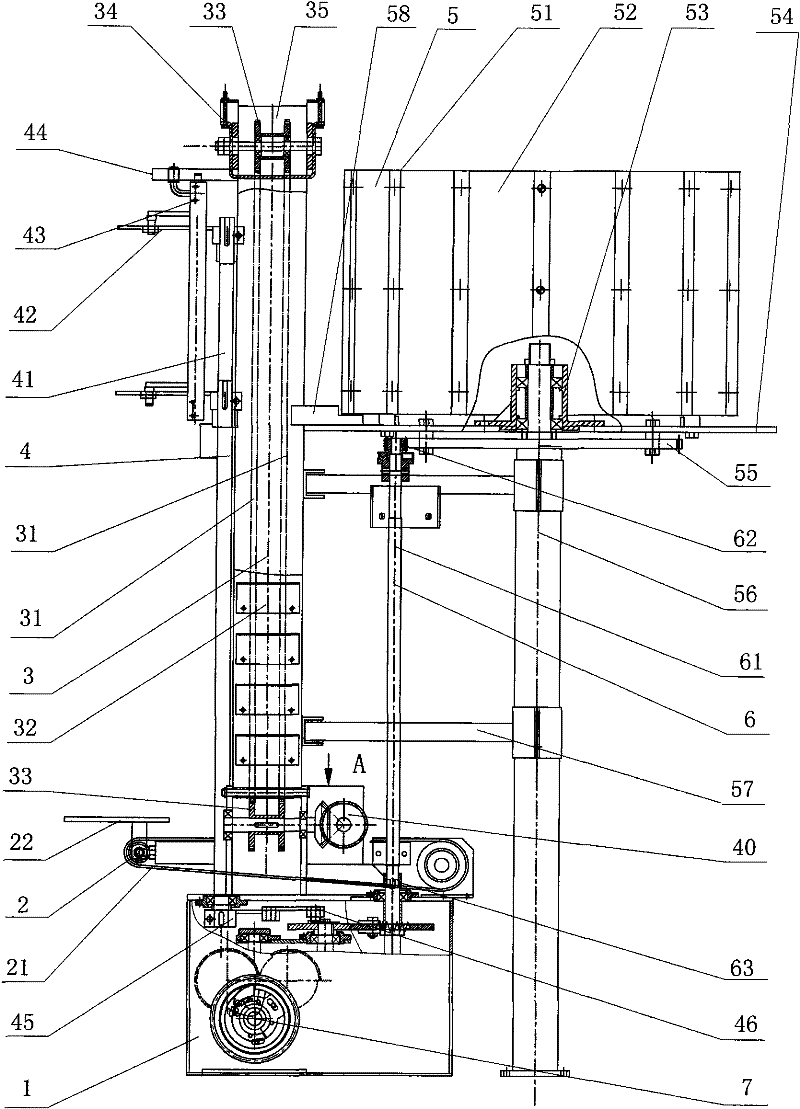

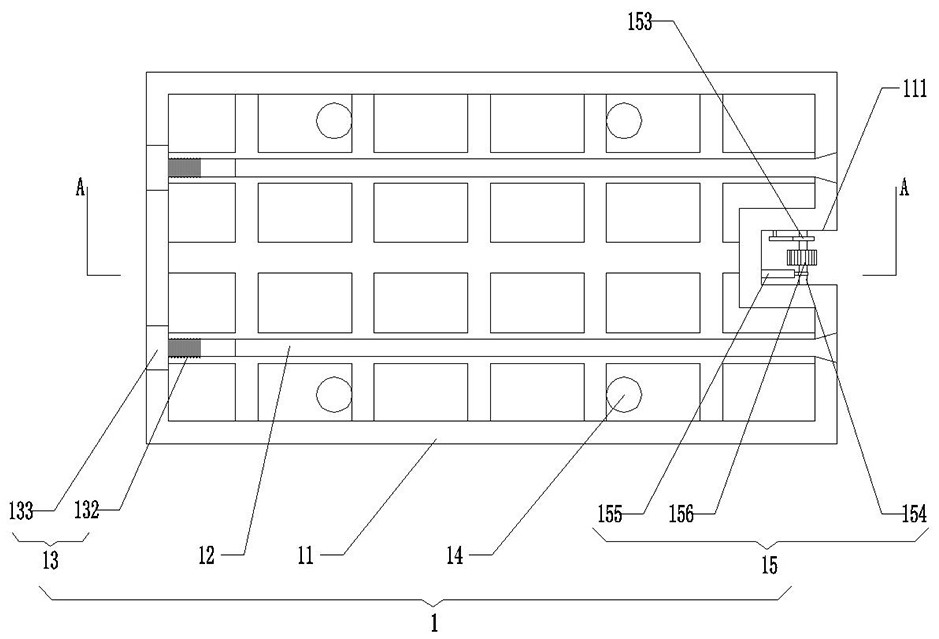

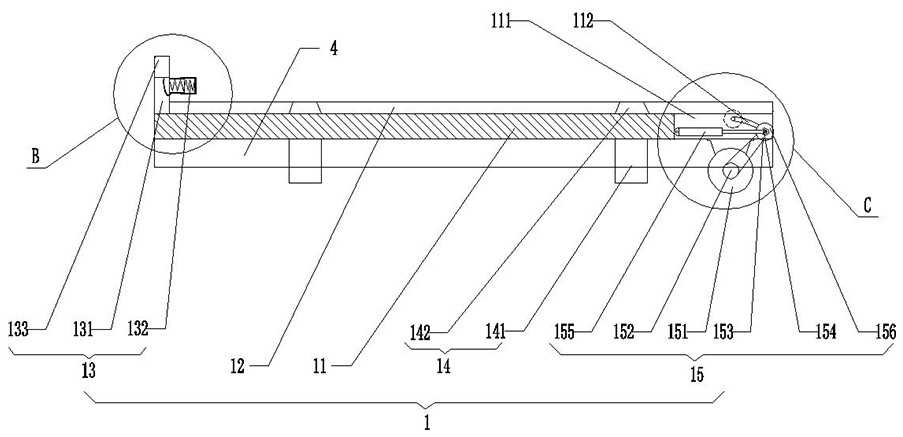

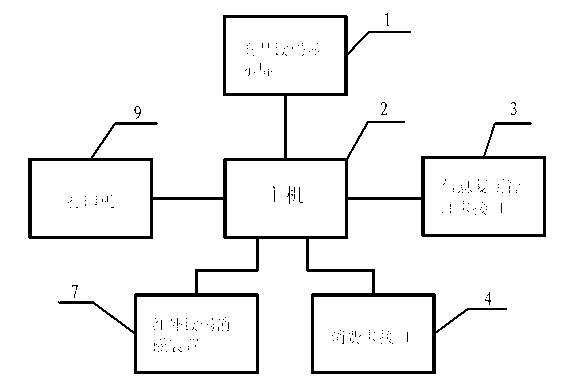

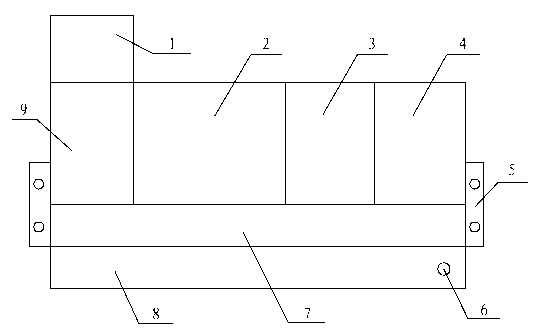

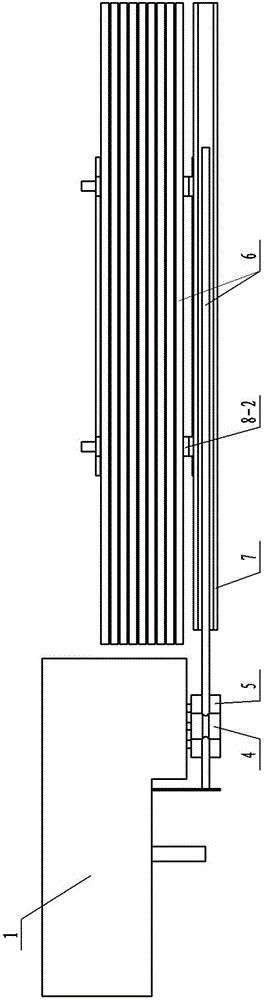

Solar panel automatic detection machine

InactiveCN101339223AReduce labor intensityHigh speedSortingIndividual semiconductor device testingGear wheelReciprocating motion

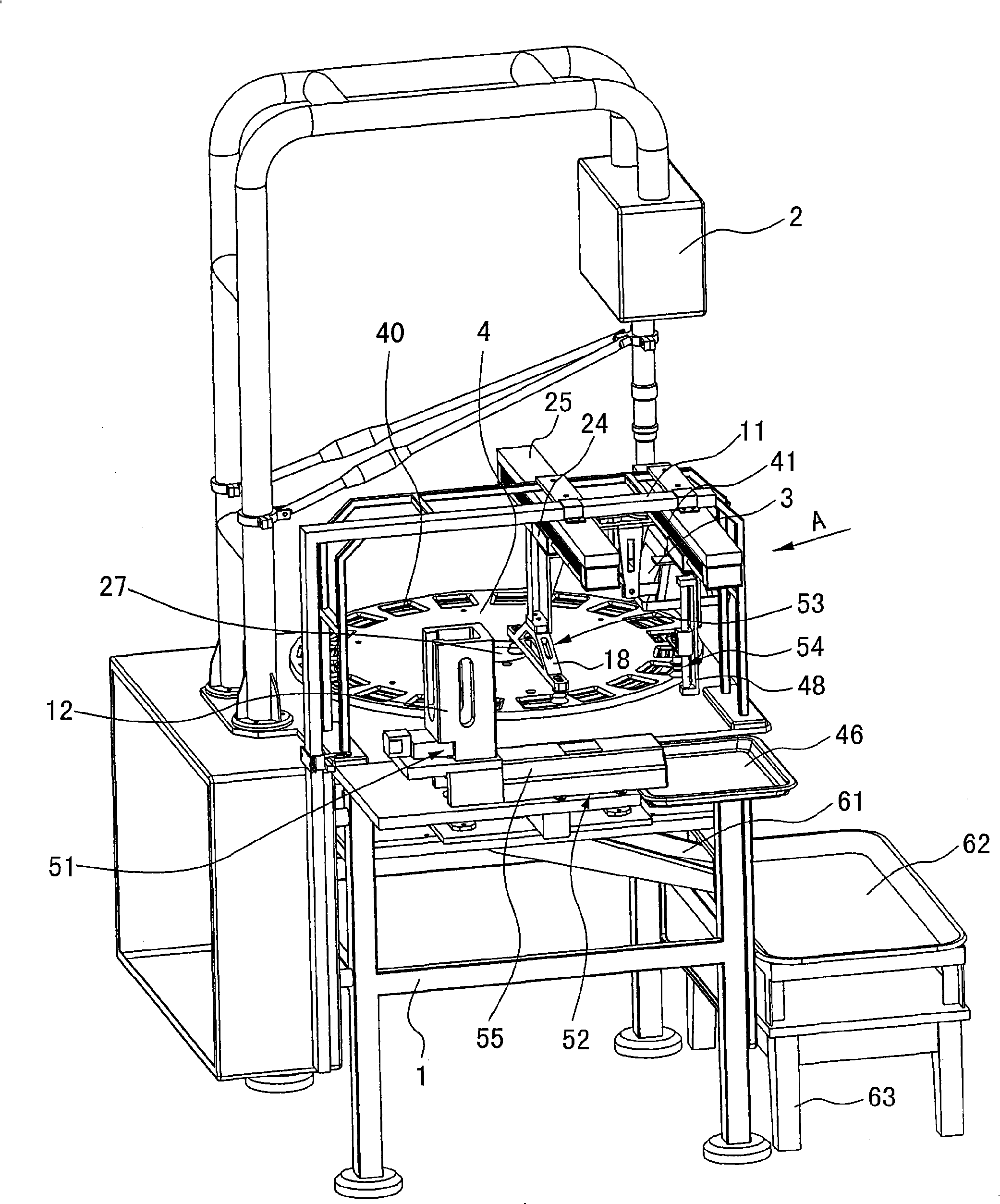

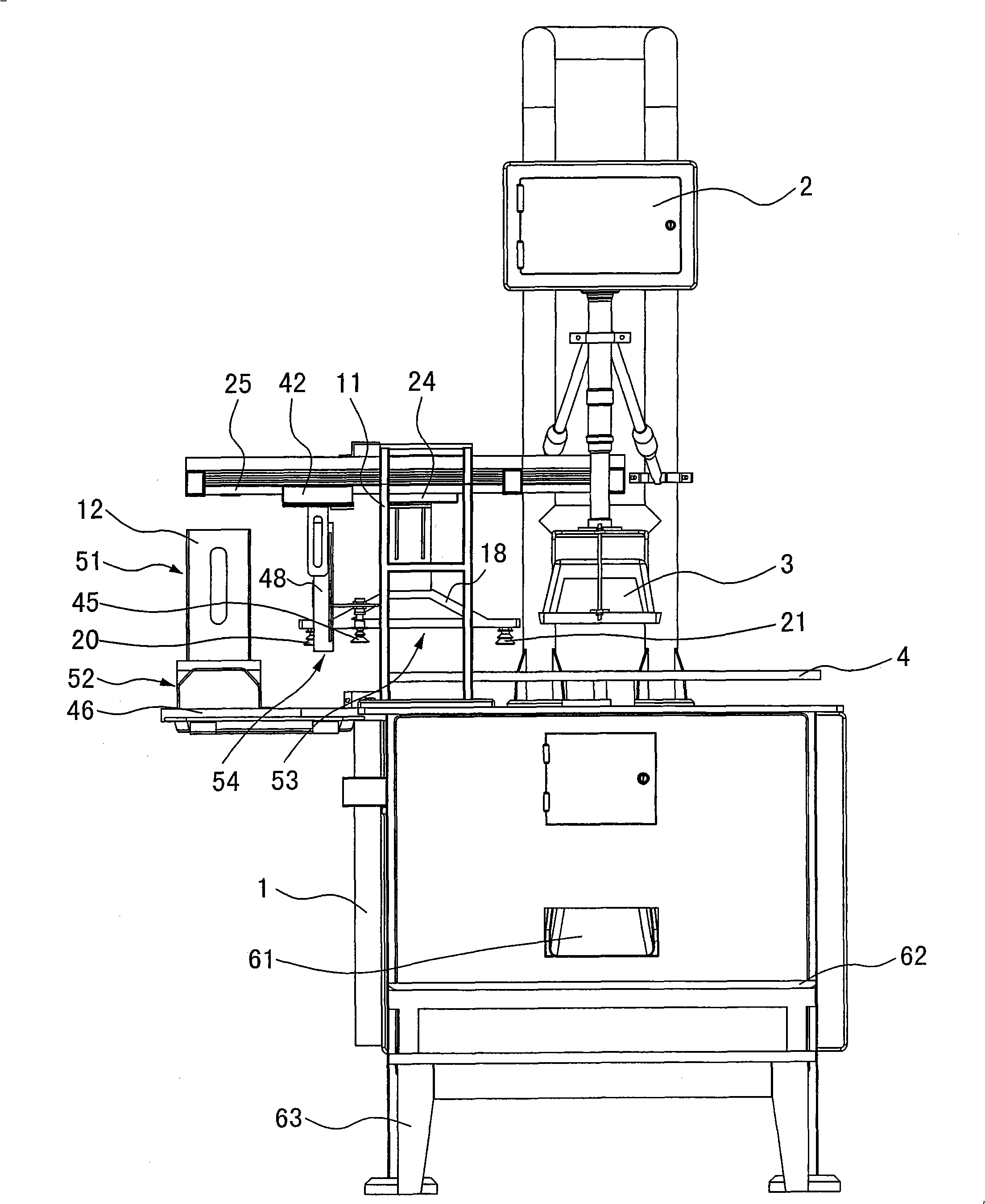

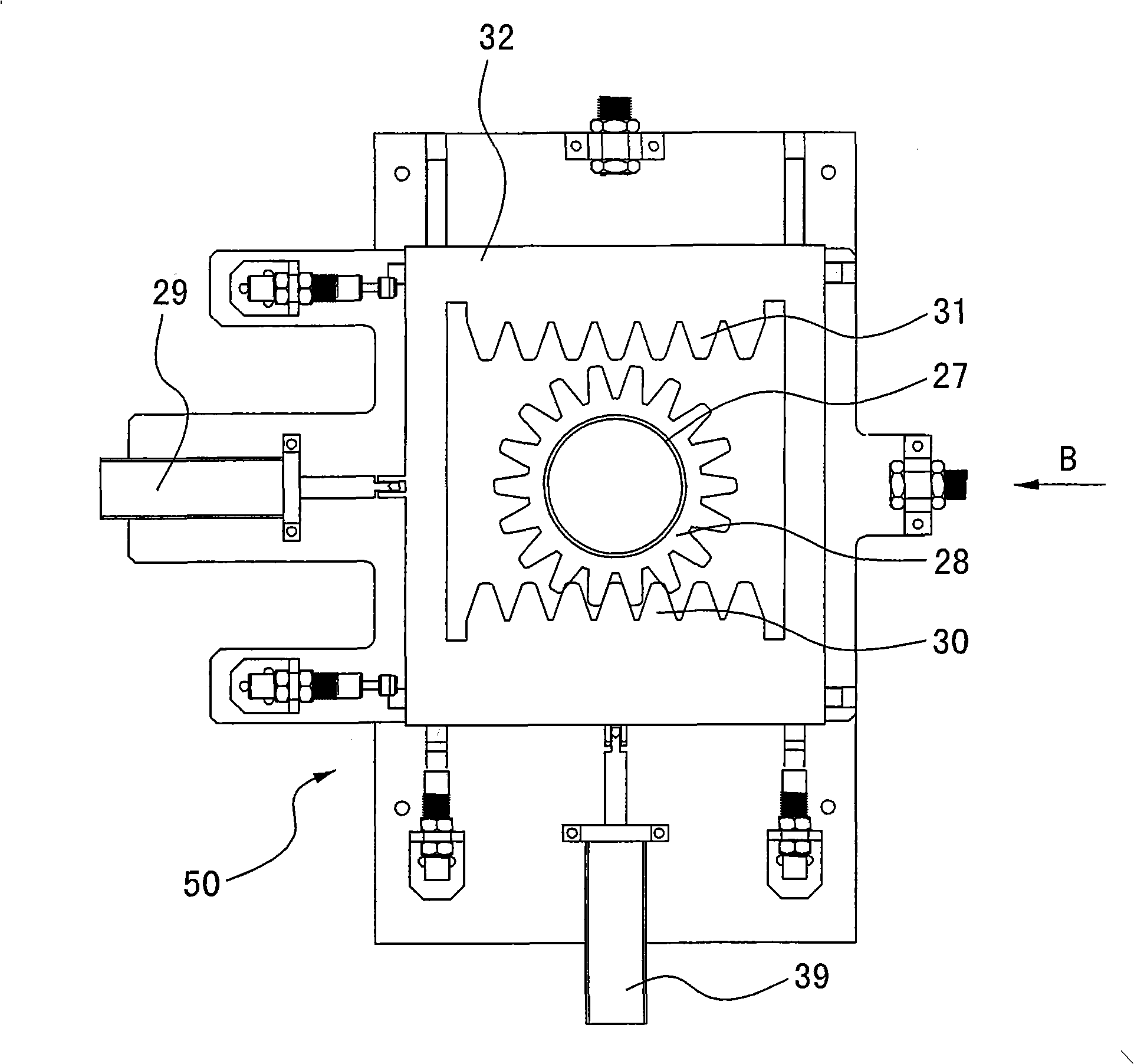

An automatic detector for a solar panel is characterized in that the detector comprises a frame, an input device of the panel installed on the frame, a numeration turntable, a rotary actuator, a detecting control box, a detecting light, a screener and a delivery storage device. The input device comprises a put-in mechanism, a left-right shifting mechanism and back-and-forth conveying mechanism. The put-in mechanism comprises a mounting frame. A stopping chip is arranged on the bottom of the frame. A terminal disk is arranged under the frame. The left-right shifting mechanism comprises a slide block that is matched with a slide bar. The back-and-forth conveying mechanism comprises a conveying frame. A conveying sucker and a delivery sucker are arranged on the conveying mechanism, contact the panel and are driven by the back-and-forth conveying mechanism. An actuator is installed on a bracket. The rotary actuator comprises a hollow rotating shaft. The outer wall of the rotating shaft is provided with a gear that is engaged with a rack. The gear is driven by a cylinder. The screener comprises a parallel-moving mechanism and an up-and-down reciprocating motion mechanism. The up-and-down motion mechanism is connected with a screening sucker. The delivery storage device comprises a slide way arranged under the hollow rotating shaft, and a large tray is arranged at the outlet of the slide way.

Owner:浙江公元新能源科技股份有限公司

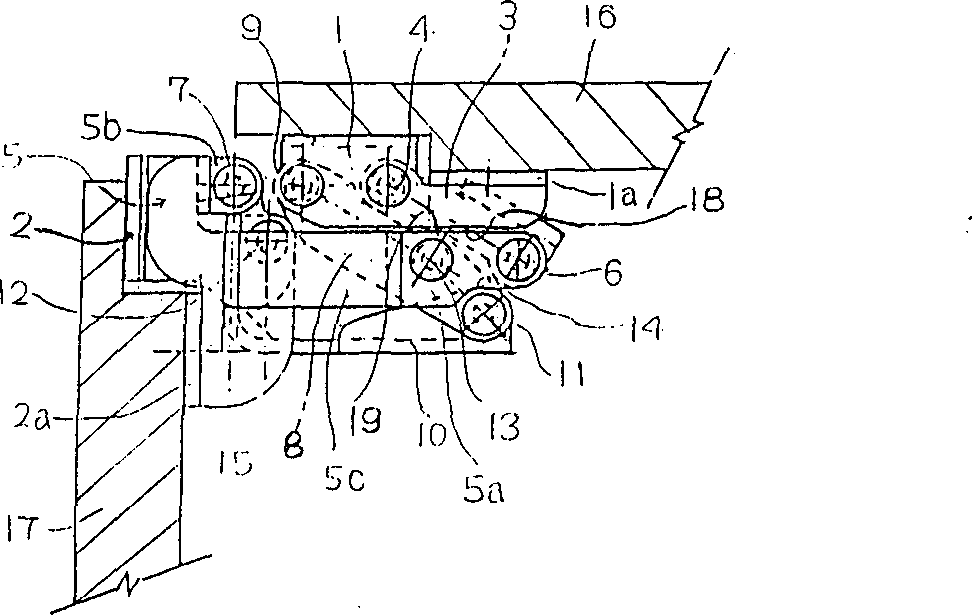

Die cutting machine

InactiveCN102161208AReduce manufacturing costEasy maintenanceMetal working apparatusTransmitted powerScrap

The invention discloses a die cutting machine, belonging to the field of die cutting machinery. The die cutting machine comprises a rack, a motor assembly and a die cutting platen. The die cutting machine is characterized by further comprising a die cutting assembly, wherein the die cutting assembly comprises a bracket, a pressure roller, a working roller, a supporting roller and a walking wheel; the motor is connected with the supporting roller by virtue of a motor transmission mechanism and transmits power to the supporting roller for rolling the supporting roller; the supporting roller is connected with the pressure roller by virtue of a homodromous transmission mechanism and transmits power to the pressure roller, the supporting roller and the pressure roller roll in the same direction; two ends of the supporting roller is connected with the walking wheel by virtue of a reverse transmission mechanism and transmit power to the walking wheel for reversely rotating the walking wheel; and the walking wheel can move along a horizontal guide rail on the rack. Compared with the prior art, the die cutting machine disclosed by the invention ensures that the transmission manner of traditional round planishing die cutting machine is changed, and has the characteristics that the labour is saved, the efficiency is improved, the scrap rate is reduced, and the quality of products is high.

Owner:魏祥国

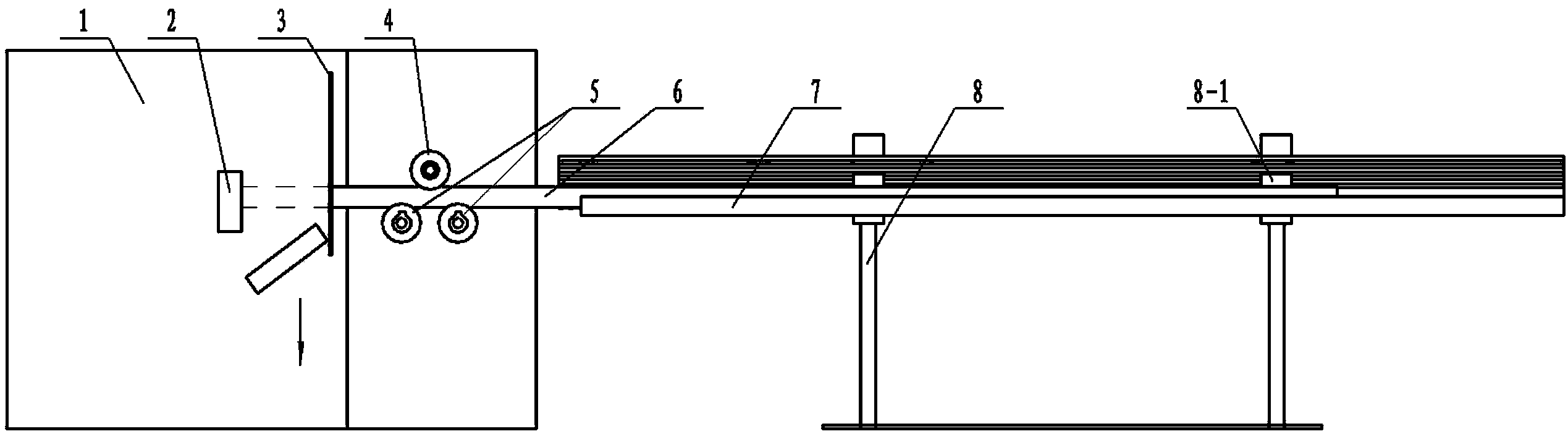

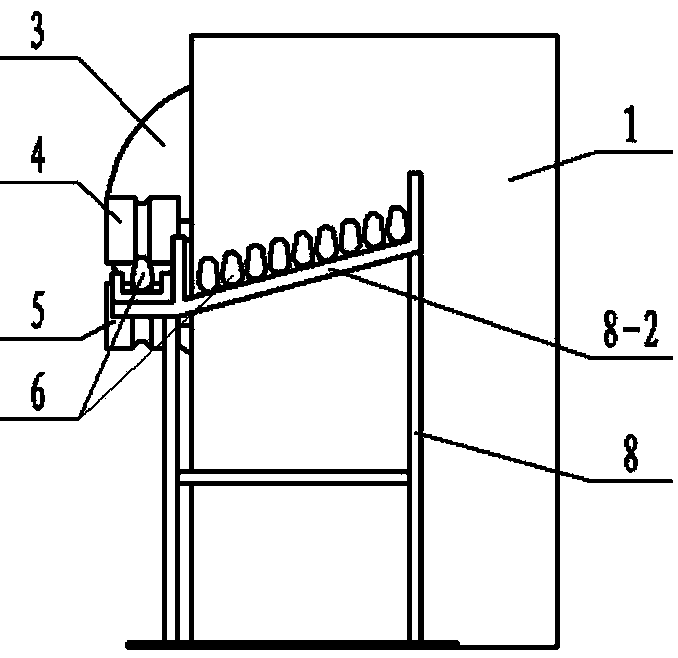

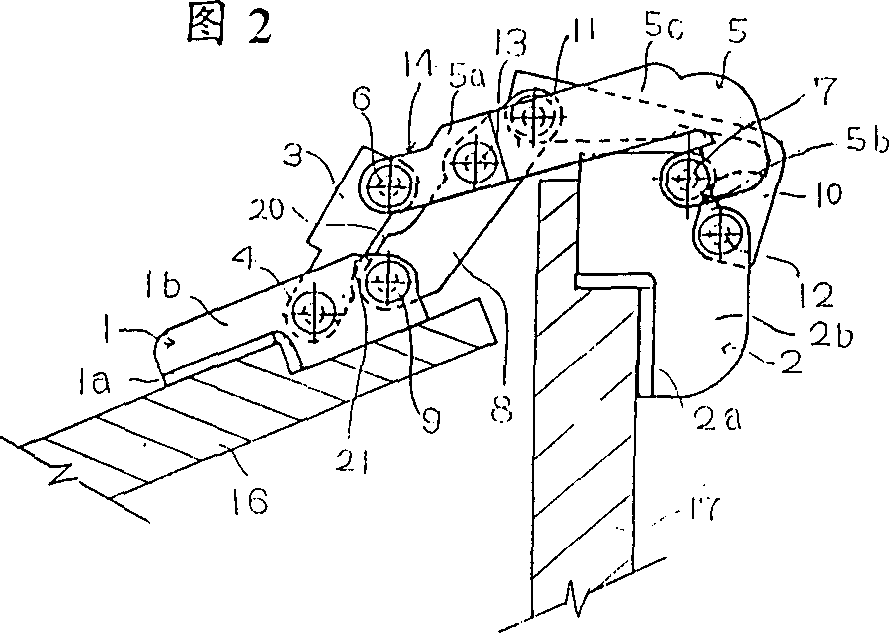

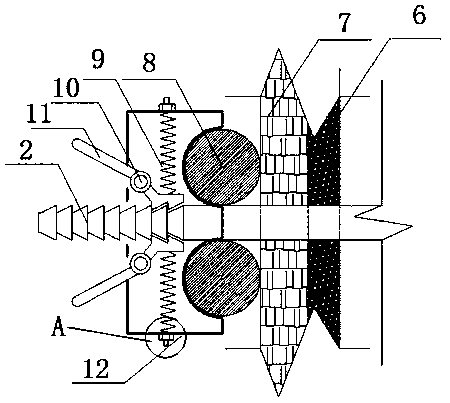

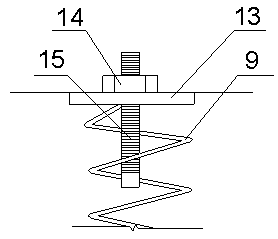

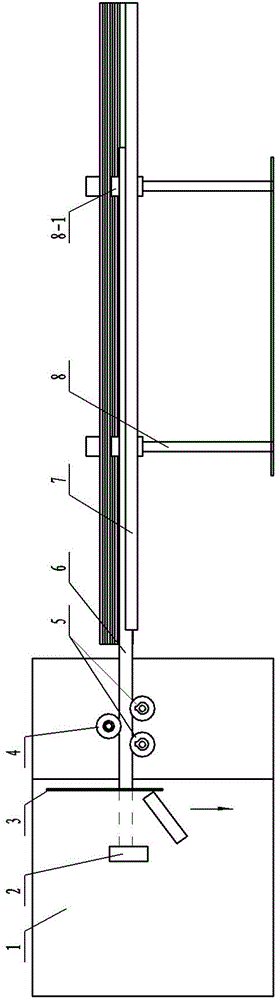

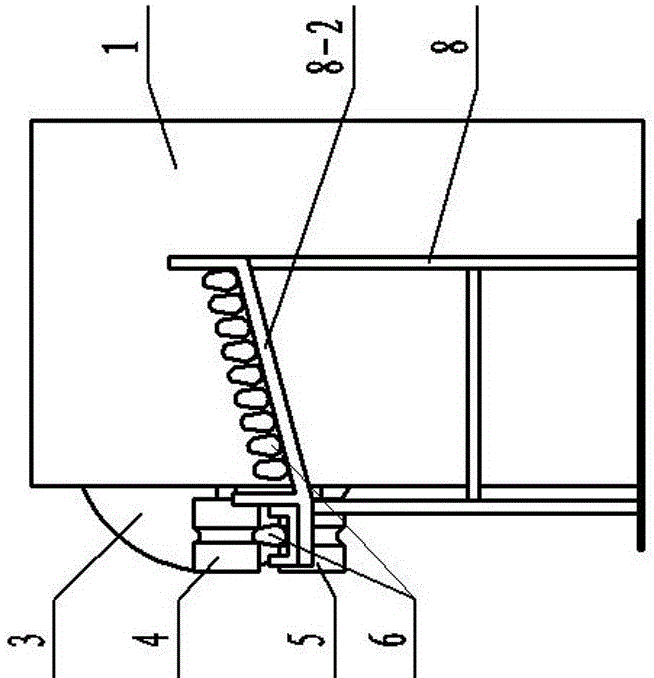

Profile feeding device for feeding machine

ActiveCN104128656AUniform processing forcePrevent slippingMetal sawing devicesUltimate tensile strengthMachining

The invention discloses a profile feeding device for a feeding machine and relates to the technical field of mechanical machining. The device comprises a limiting block and conveying rollers mounted on the feeding machine, one side of the feeding machine is provided with a feeding guide rail facing to the feeding rollers, the feeding rollers include a pressing roller and two holding rollers arranged below the pressing roller, the pressing roller and the two holding rollers are arranged in a staggered manner, and the surfaces of the pressing roller and two holding rollers are provided with positioning grooves matching with the profile respectively; a material rack is arranged besides the feeding guide rail and comprises a loading plate inclined downwardly facing to the feeding guide rail. Compared with the prior art, the profile bears the force evenly, skidding occurs rarely, the machining accuracy is high, and labor force of workers is lower.

Owner:柳州万众汽车部件有限公司

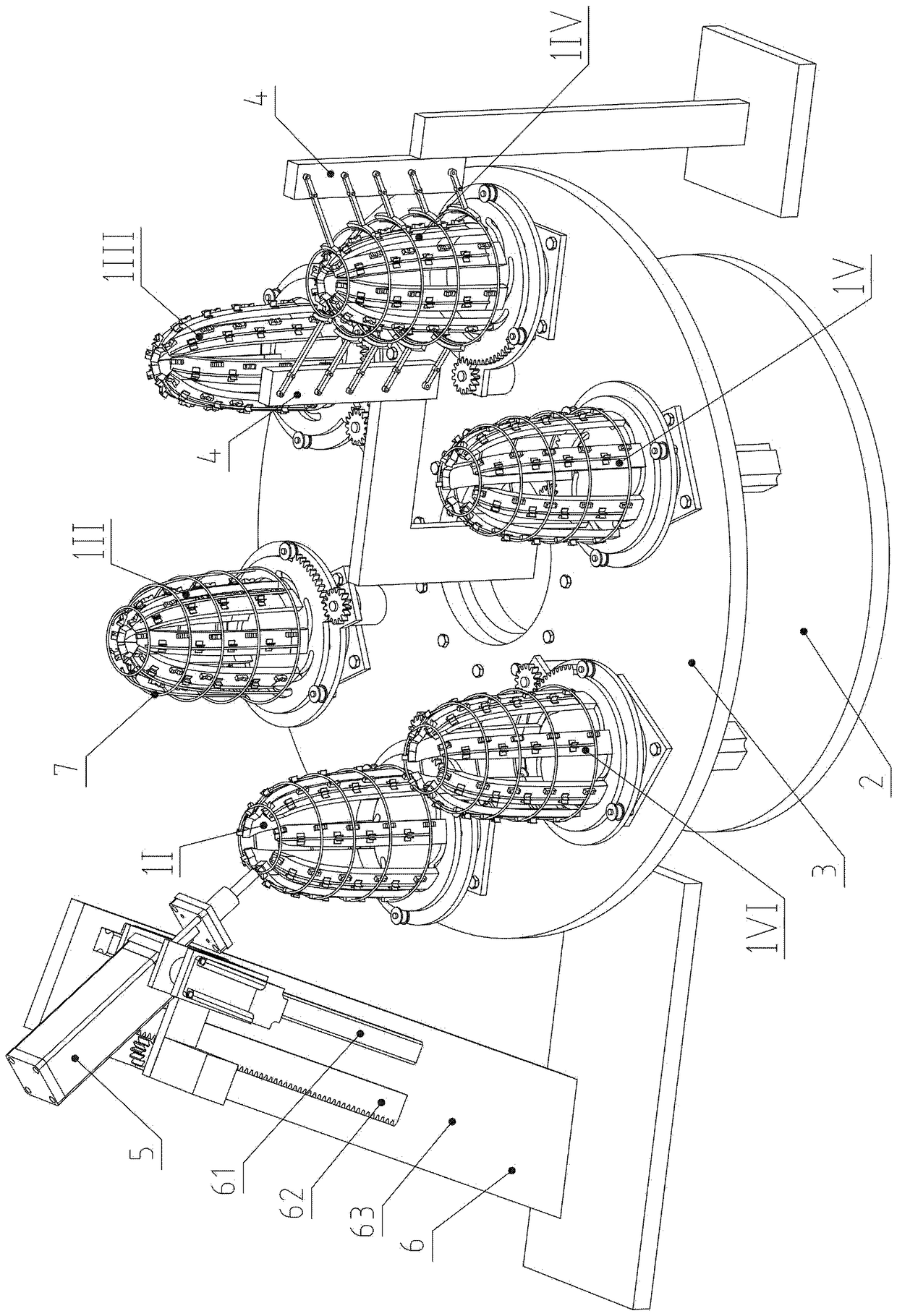

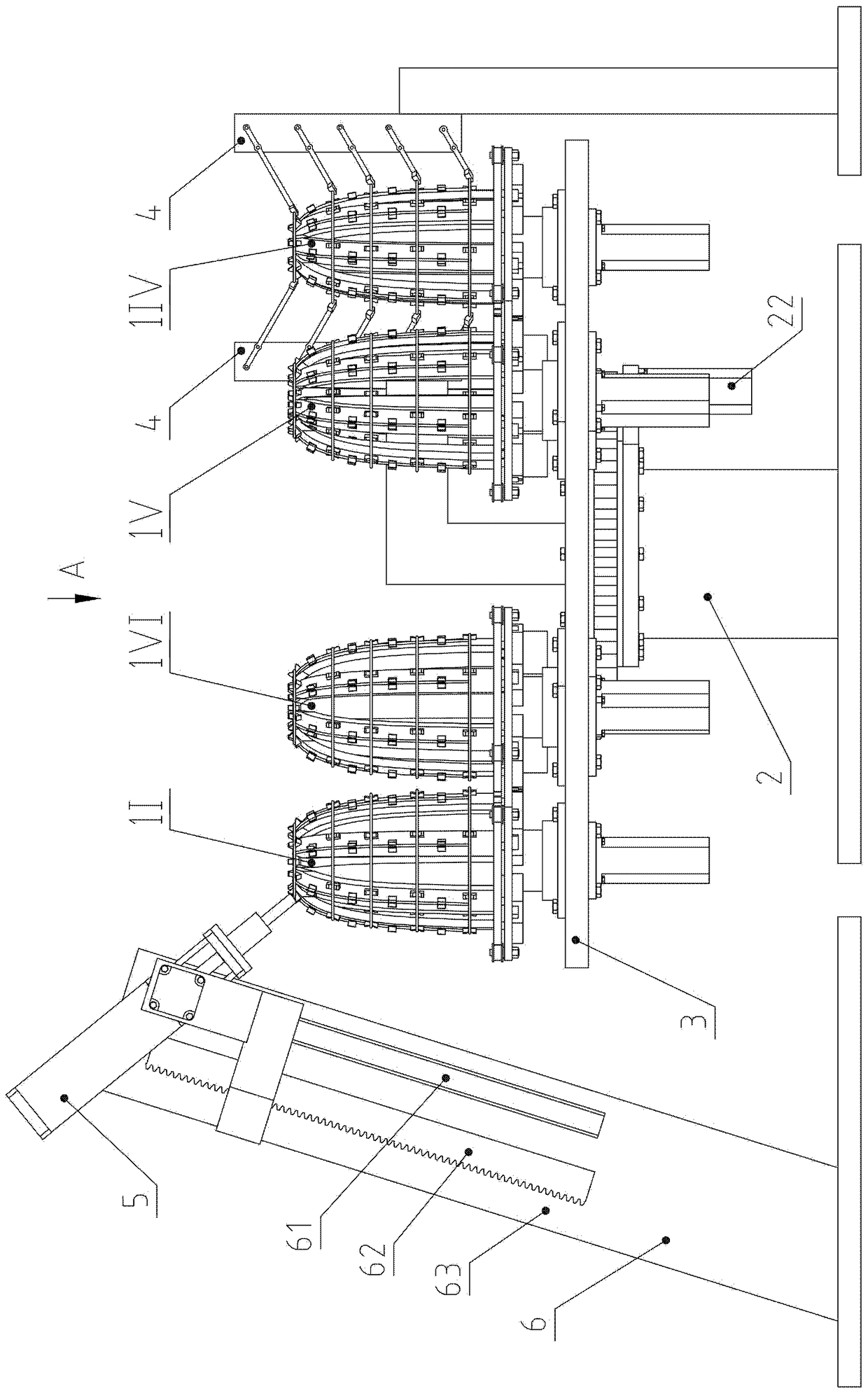

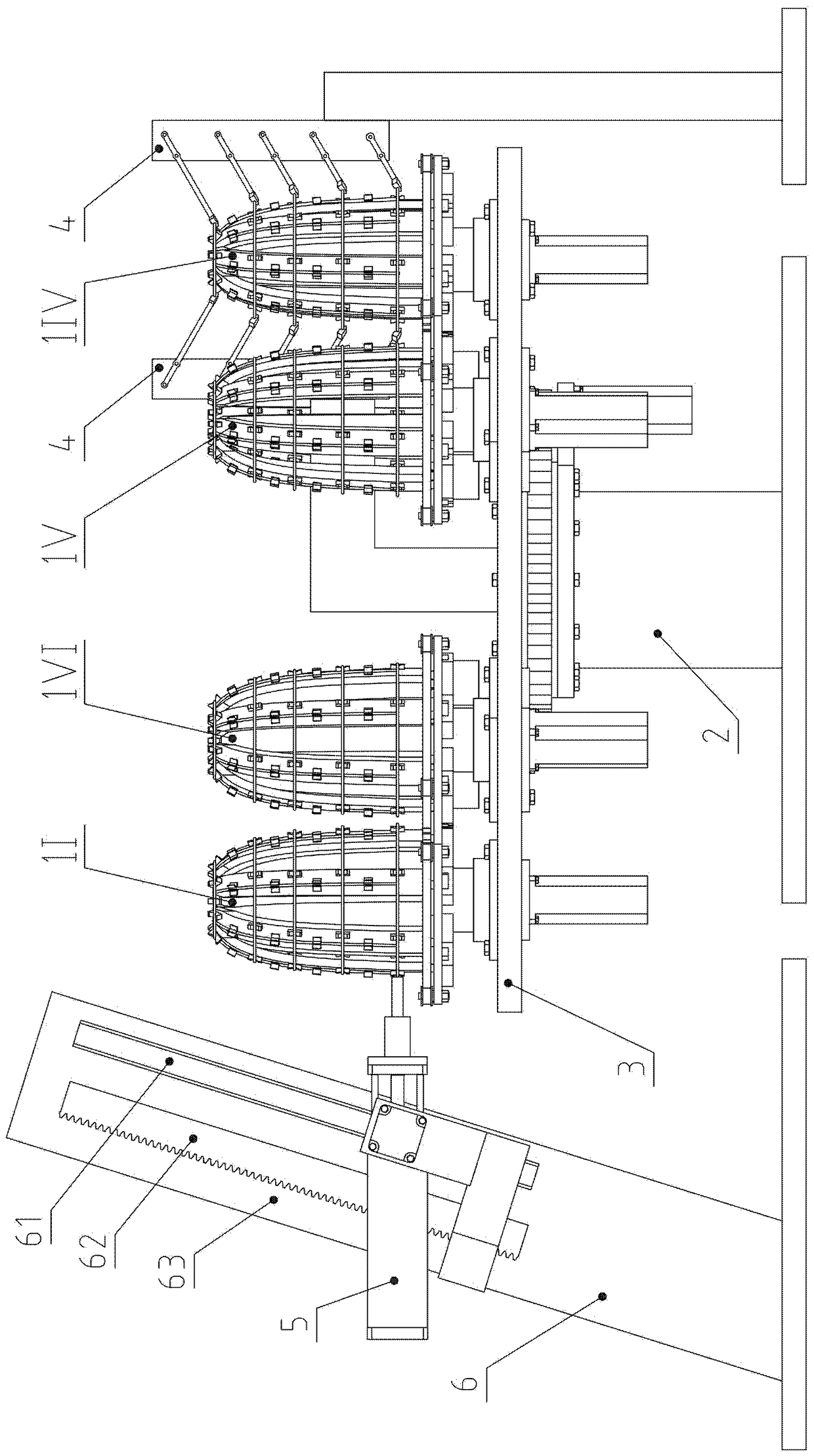

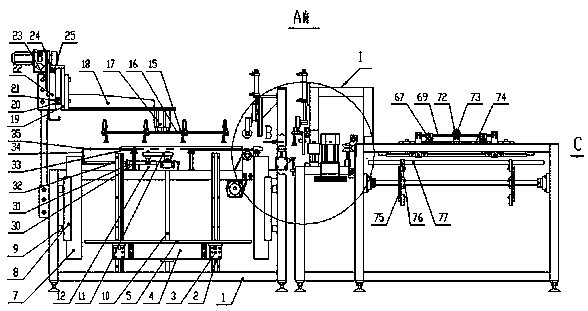

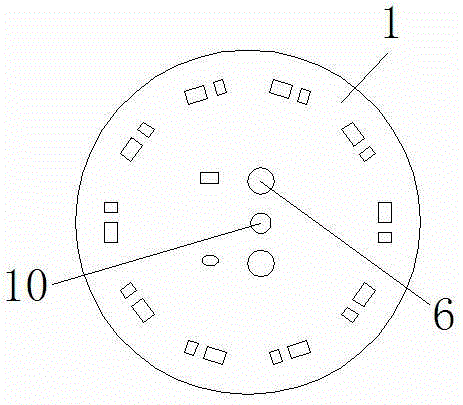

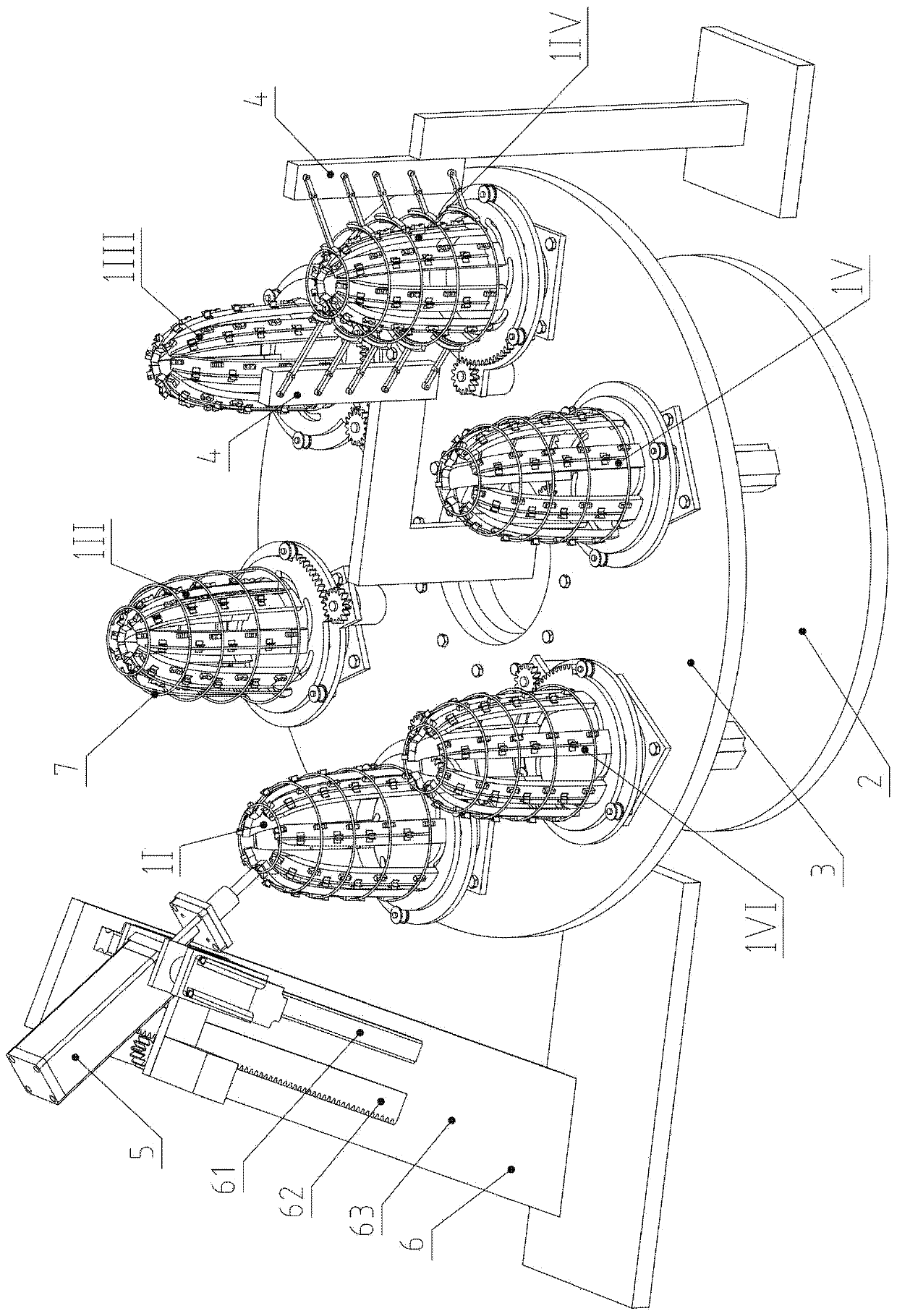

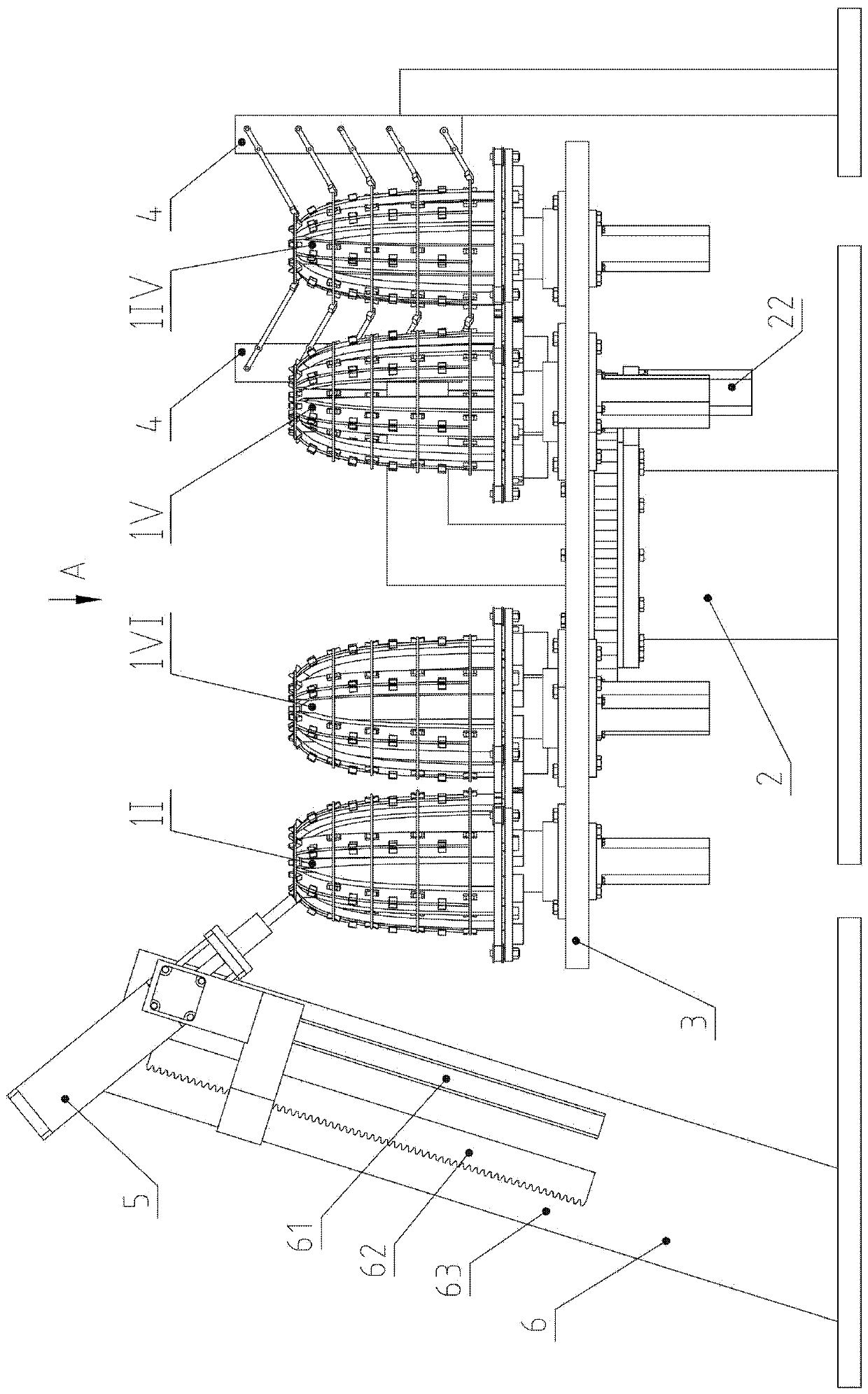

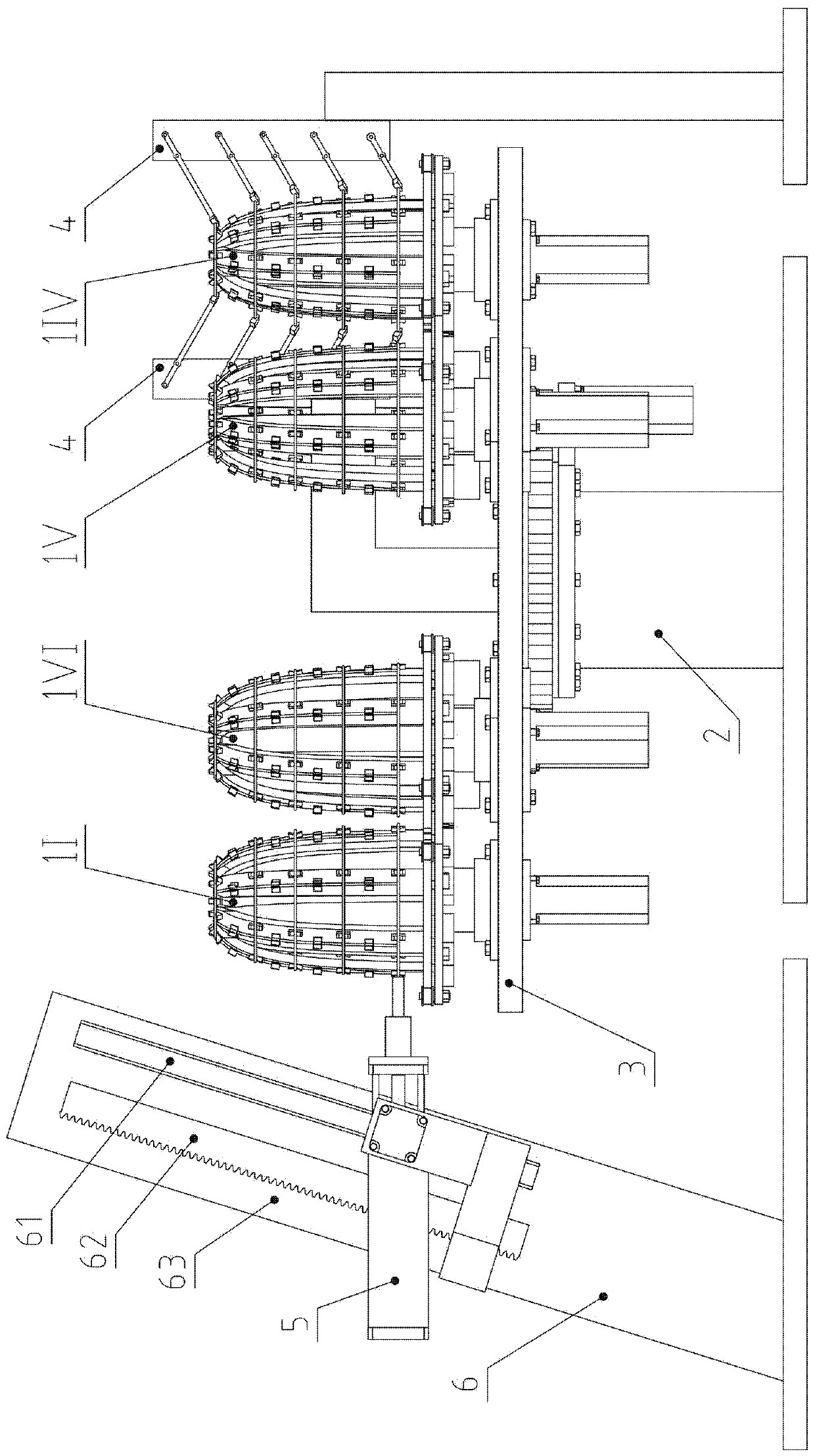

Semi-automatic welding device for protecting cover of explosion-proof light

ActiveCN108326406AAvoid hiringImprove welding efficiencyWelding/soldering/cutting articlesMetal working apparatusCircular discSemi automatic

The invention belongs to the technical field of explosion-proof tool manufacturing equipment, relates to a manufacturing device for a protecting cover of an explosion-proof light, and specifically relates to a semi-automatic welding device for the protecting cover of the explosion-proof light. The device is characterized in that longitudinal ribs are manually mounted on a curved supporting plate assembly; mould assemblies are automatic to rotate; the curved supporting plate assembly faces an operator; steel rings are manually mounted and positioned through steel ring positioning grooves; a curve slot disc is capable of synchronously shifting seven round shifting pins; seven mould assemblies are automatically expanded and fixed; revolution servo motors are used for driving to realize station switching; compressing cylinders are automatically lifted and swung in place; intersection points of the longitudinal ribs and the steel rings are compressed through high-voltage electrodes; then power supply is connected; the positions of the intersection points are automatically exchanged, and the spot welding is performed; the seven mould assemblies are automatically closed; and then a finished product is manually taken out. With the adoption of the device, the welding efficiency and the outline dimension accuracy are improved; the labor is saved; electric welding workers are saved, so that the salary cost is decreased, and the employment pressure is reduced.

Owner:威海鹏飞自动化技术有限公司

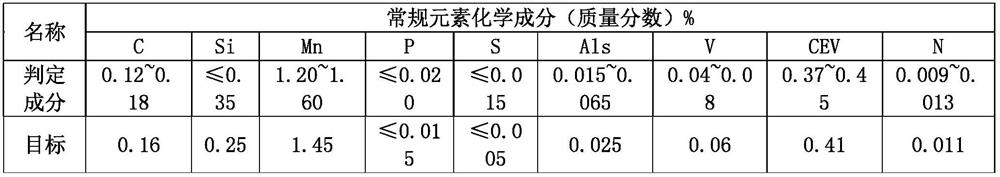

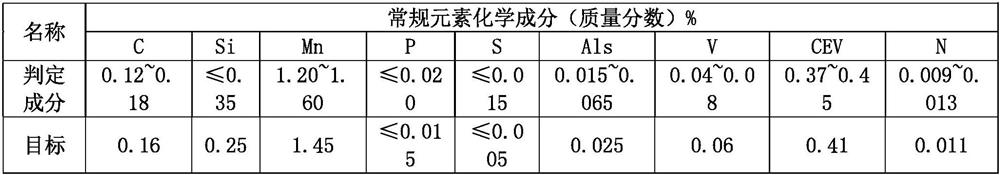

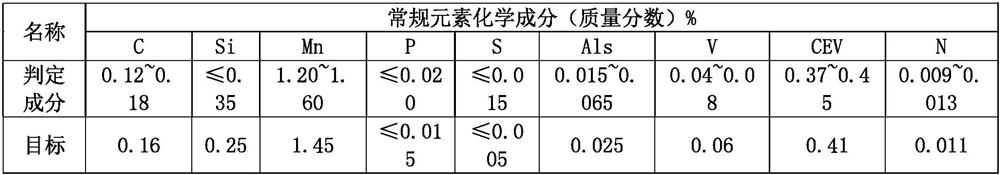

RH nitrogen-blowing alloying process capable of accurately controlling nitrogen content of nitrogen-containing steel grade

ActiveCN112899440AImprove hit rateReduce manufacturing costManufacturing convertersProcess efficiency improvementVacuum pumpingNitrogen gas

The invention discloses an RH nitrogen-blowing alloying process capable of accurately controlling the nitrogen content of a nitrogen-containing steel grade. The RH nitrogen-blowing alloying process capable of accurately controlling the nitrogen content of the nitrogen-containing steel grade comprises the following steps: desulfurized molten iron and scrap steel are smelted in a converter, oxygen is blown from the top, and nitrogen is blown from the bottom; LF refining and RH vacuum refining are sequentially carried out on molten steel, a mechanical pump vacuum system is adopted for RH, specifically, argon / nitrogen switching is carried out on RH circulation gas, the nitrogen flow is 90-150 Nm<3> / h, the nitrogen pressure is 1.0-1.8 Mpa, RH vacuum air-pumping is carried out, the pressure is reduced to 273 Pa or below from atmospheric pressure, and RH air-pumping lasts for 5-10 min; temperature measurement and sampling are carried out, and the chemical components and the nitrogen component content of the molten steel are analyzed; the component content of the molten steel is adjusted according to the sampling analysis result, the RH vacuum degree is adjusted to 4-15 kpa, nitrogen is rapidly increased in the molten steel, and the average nitrogen increasing amount is 3.0-3.50 ppm / min; and after the molten steel meets the technical requirements of the steel grade, the RH is finished, re-pressing is carried out, a steel ladle is opened for blowing argon from the bottom, and calcium treatment in a metal calcium feeding line is carried out. According to the invention, the nitrogen content fluctuation of the molten steel can be accurately controlled to be + / -5ppm, the technical requirements of the steel grade are met, the quality of the steel grade is ensured, and the production cost is reduced.

Owner:CHONGQING IRON & STEEL CO LTD

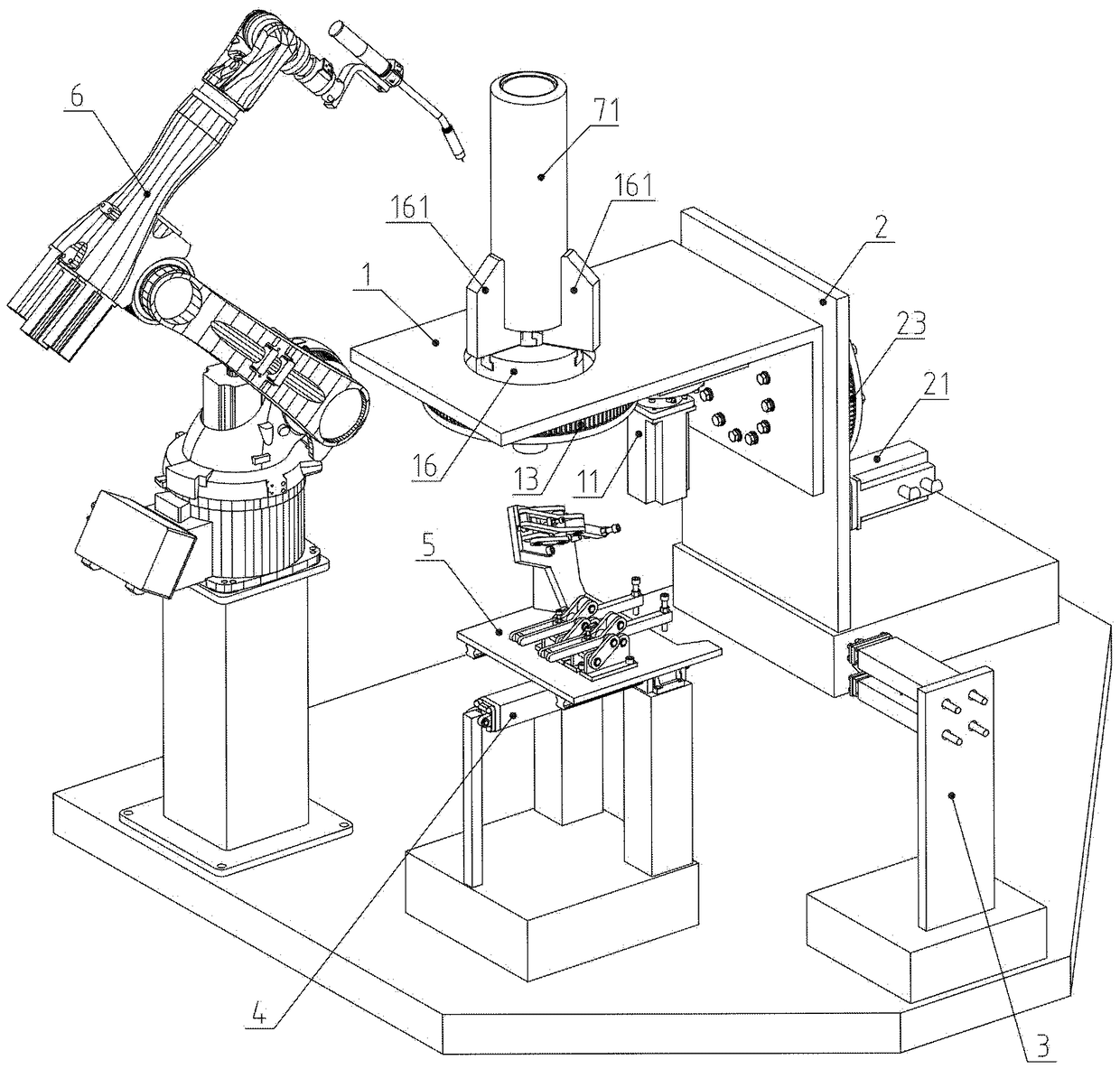

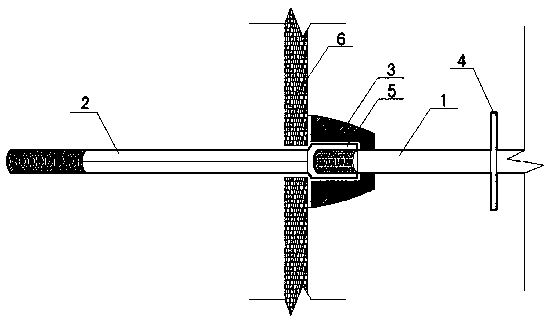

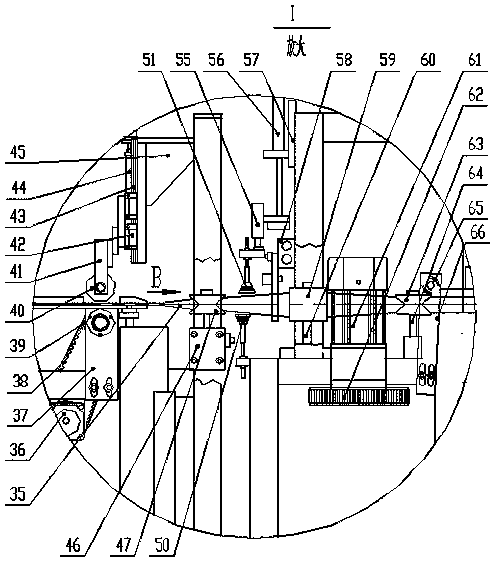

Intelligent welding tool for blades of petroleum drill bit

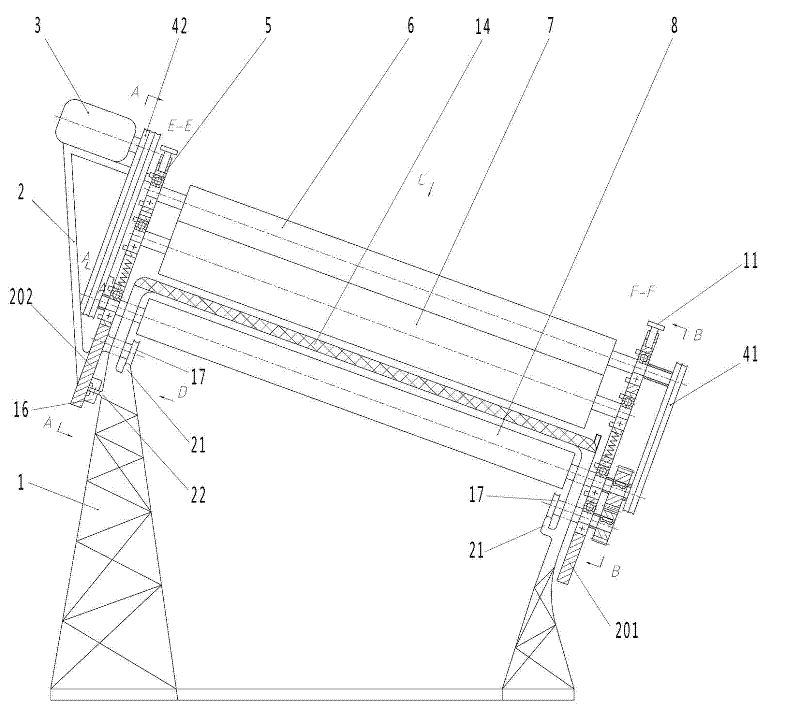

InactiveCN108526787AUniform sizeEasy to trainWelding/cutting auxillary devicesAuxillary welding devicesSpiral bladeWeld seam

The invention belongs to the technical field of petroleum drill bit manufacturing equipment, and relates to an intelligent welding tool for blades of a petroleum drill bit. Three claws enclasp a drillstock, the drill stock rotates horizontally, the tip of the center of the drill stock is propped against a top plane, a V-shaped groove is welded by a welding robot, a water hole rotates to a position at an angle of 45 degrees, a blade compressing assembly is close to the drill stock, flat blades and spiral blades are placed, first rapid pincers, second rapid pincers and third rapid pincers are used for compressing the blades, the welding robot carries out point welding, the first rapid pincers, the second rapid pincers and the third rapid pincers are pulled open, the blade compressing assembly leaves away from the drill stock and a round cap, the blades upwards overturn at an angle of 90 degrees and then stop, the foregoing steps are repeated, thus, the four flat blades and the four spiral blades are uniformly arranged on the drill stock and the round cap by point welding, then full-length welding is carried out, and the petroleum drill bit overturns upwards to be disassembled. The intelligent welding tool for the blades of the petroleum drill bit is accurate in positioning, specifications and dimensions of welding seams are unified, weld defects are avoided, the working efficiency is high, the intelligent welding tool is simple to operate, the training period is short, health hazards are small, and manpower costs are saved.

Owner:杜宗英

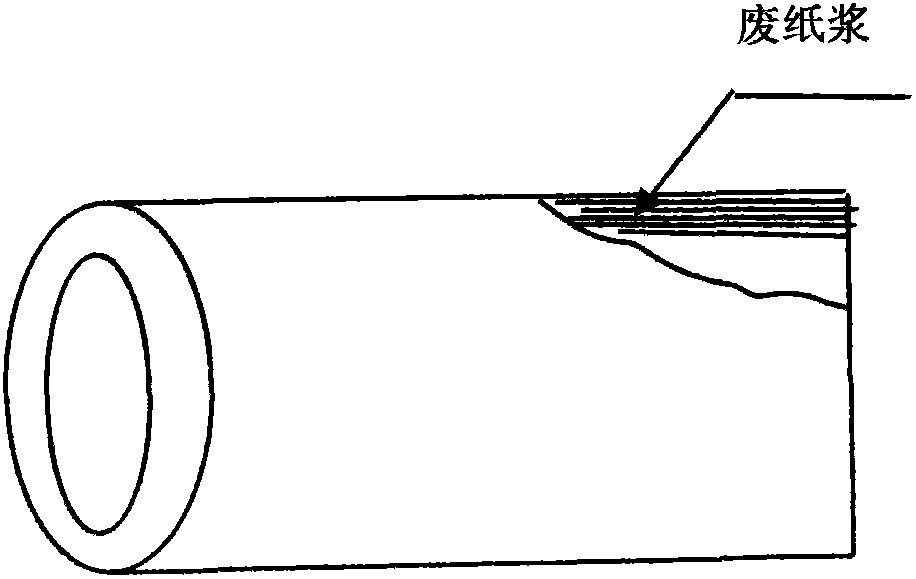

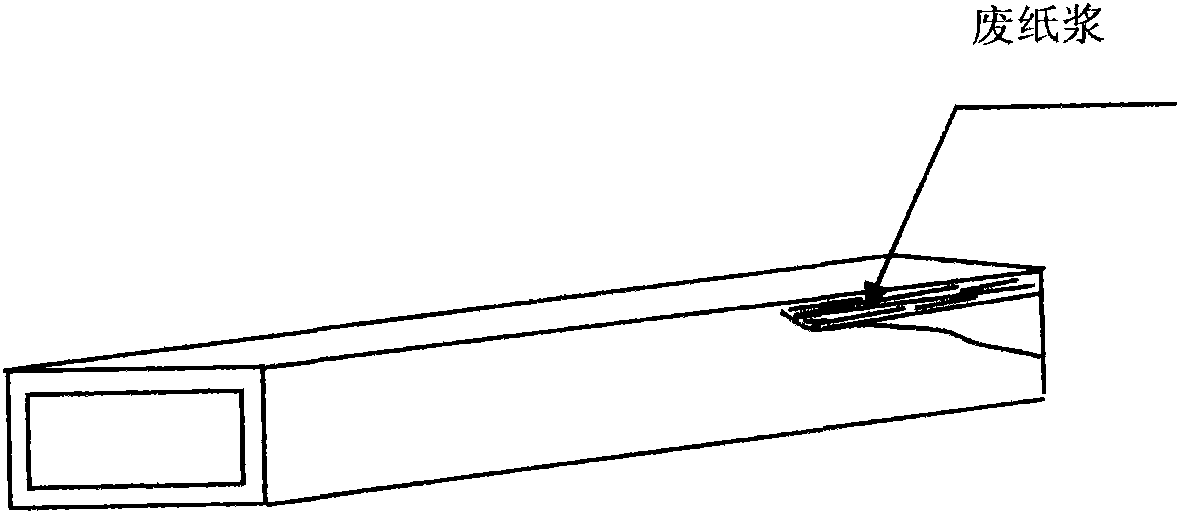

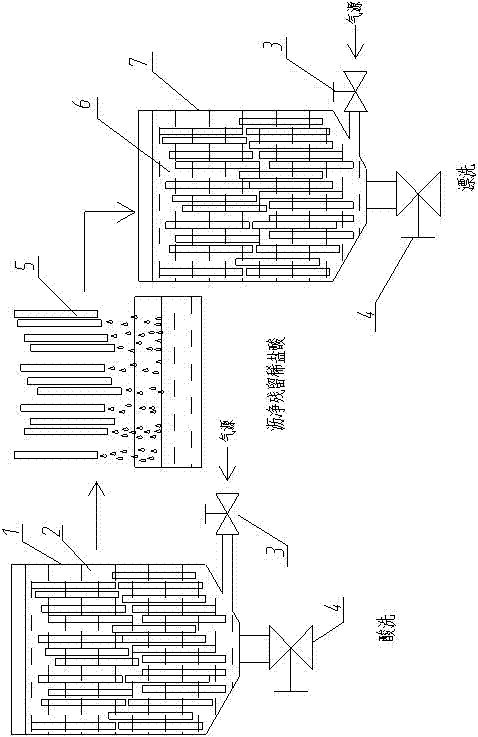

Method for producing paper tubes by waste paper pulp

InactiveCN102700174ALow costHigh speedEnvelopes/bags making machineryPaperboardPulp and paper industry

The invention relates to a method for producing paper tubes by waste paper pulp. The method is characterized in that the waste paper pulp used as a raw material is blended with glue and stone powder to produce the paper tubes by a squeezing method. Paper pulp is manufactured by steps including 1, uniformly grinding the waste paper pulp disposed during production of a paper mill by a grinder; 2, beating waste paperboards by a beater to obtain paper pulp; and 3, mixing the waste paper pulp and the paper pulp manufactured from the waste paperboards into mixed waste paper pulp. The glue is manufactured by steps including 1, boiling water and adding polyvinyl alcohol into the water to prepare glue; and 2, adding borax and caustic soda flakes into corn starch to prepare glue. The paper tubes made of the waste paper pulp have the advantages of low production cost, fast speed, good quality, simplicity in operation, wide production range and high applicability, and have an excellent commercial prospect, and the method is an ideal paper tube production method at present.

Owner:任立群

Fast cleaning method for building plastic templates

InactiveCN103752554ALower wage costsReduce labor intensityCleaning using liquidsForm treatmentMetallurgyCement slurry

The invention relates to the field of building plastic templates, in particular to a cleaning method for the building plastic templates. The fast cleaning method is characterized by including: adding sufficient diluted hydrochloric acid solutions in a plastic container; soaking the building plastic templates to be cleaned into the diluted hydrochloric acid solutions which are kept rolling and flowing till cement slurry blocks remained on the templates are cleaned up; taking out the building plastic templates and draining off the diluted hydrochloric acid solutions remained on the templates; putting the templates into a clean water pool for rinsing and keeping clean water rolling for a couple of minutes during rinsing before taking out the templates. The fast cleaning method has the advantages of being free of causing damage to the templates, high in speed and efficiency, laborsaving, less in amount of work and low in cost.

Owner:李德福

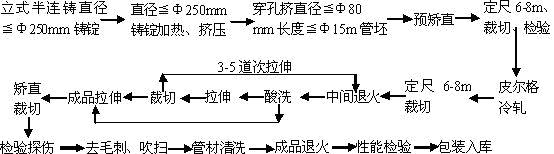

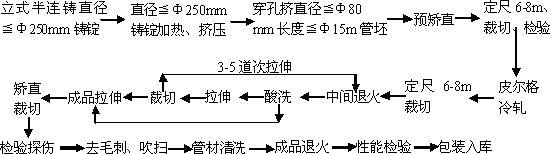

Heated mould continuous casting-continuous drawing method of cupronickel alloy condenser pipes

The invention discloses a heated mould continuous casting-continuous drawing method of cupronickel alloy condenser pipes, which is characterized by comprising the following steps: 1, obtaining cupronickel pipe blanks by the heated mould continuous casting method; 2, drawing the pipe blank; 3, carrying out 3-pass drawing; and 4, carrying out combined drawing, finishing, washing and final annealing to obtain the finished product. The pipe blanks of which the diameter is more than or equal to 1mm and less than or equal to 50mm are subject to combined drawing, and 3-pass disk drawing; the pipe blanks of which the diameter is more than 50mm and less than or equal to 108mm are subject to combined drawing, and 3-pass straight drawing; and the pipe blanks of which the diameter are more than 108mm and less than or equal to 319mm are subject to combined drawing, and 3-pass hole enlargement drawing. In the heated mold continuous casting-continuous drawing method provided by the invention, the processes are reduced, the casting yield is improved, the energy consumption of the ingot casting heating-extrusion process is lowered, and the cost is reduced greatly.

Owner:JINCHUAN GROUP LIMITED

Hinge with seven pivots

Owner:TAKIGEN MFG CO LTD

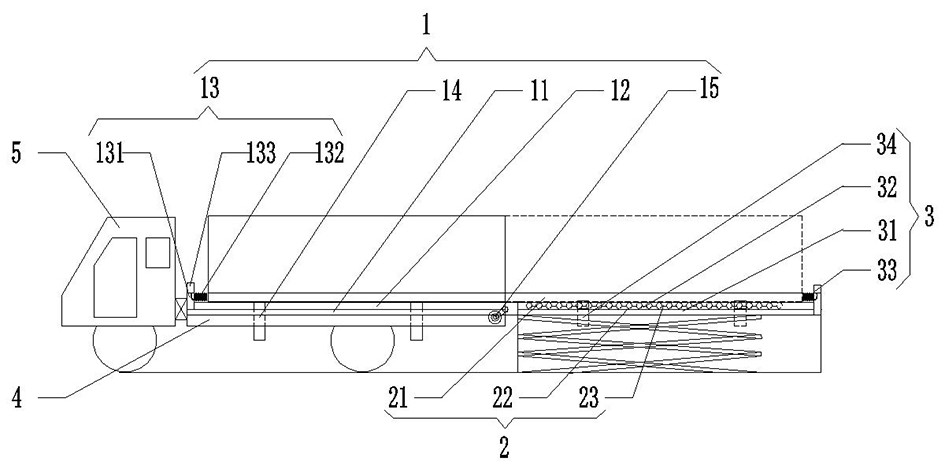

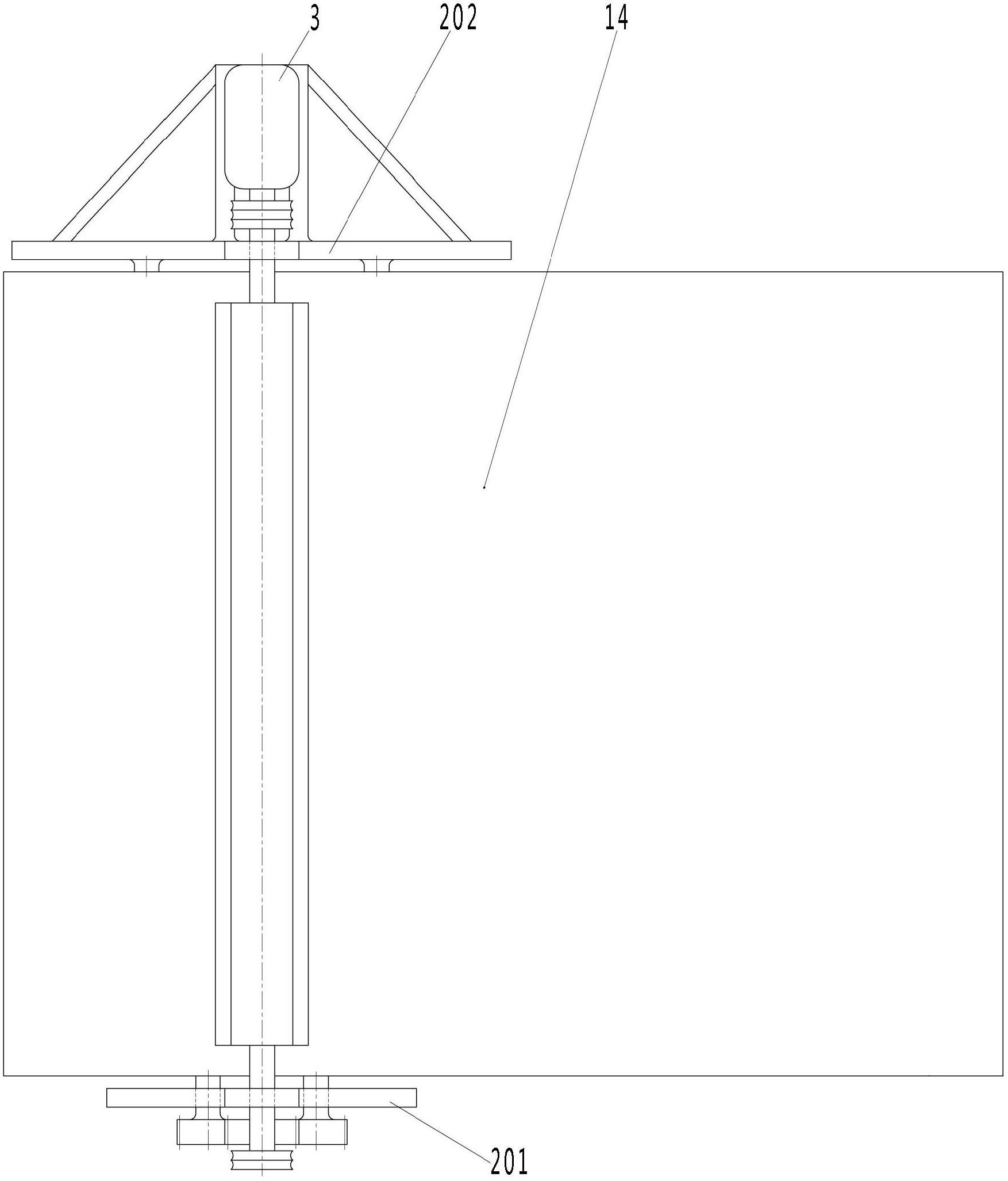

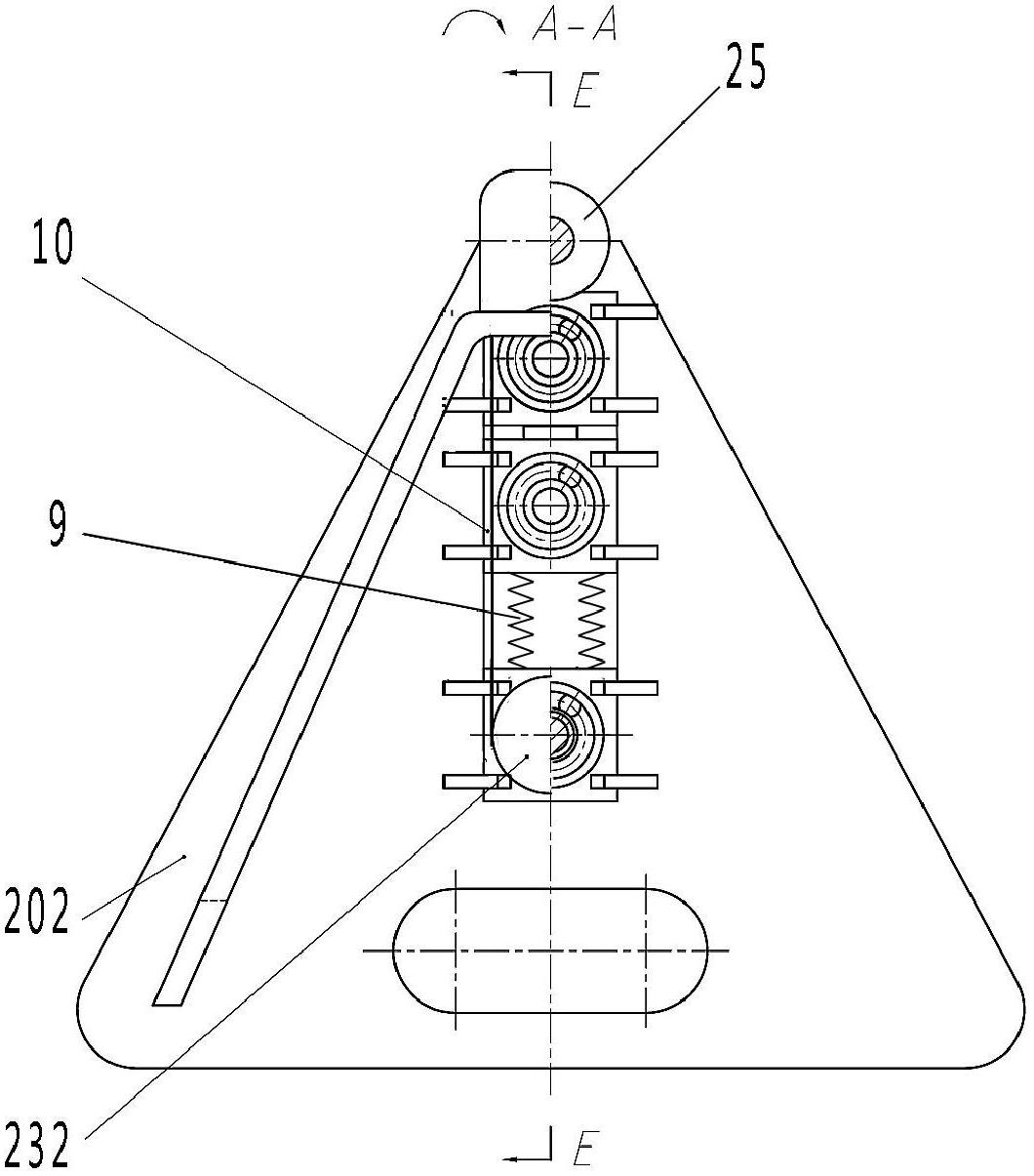

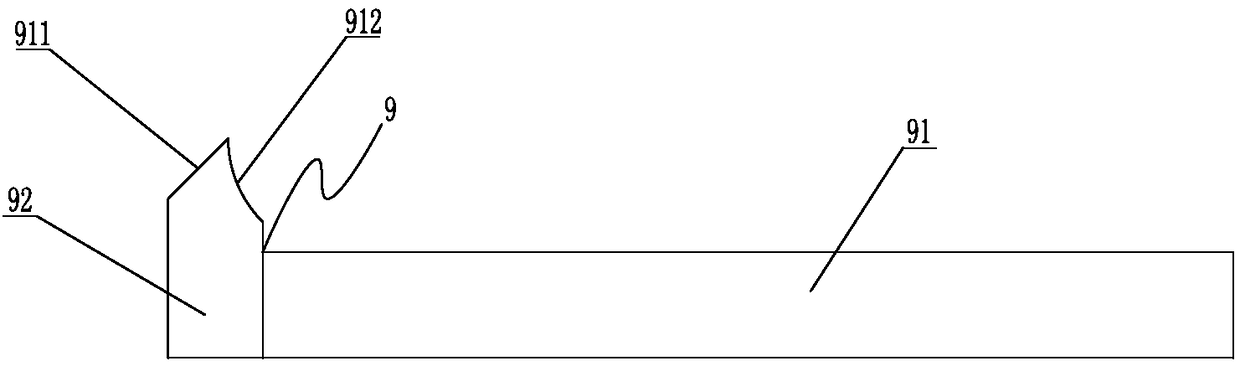

Logistics truck reset device based on cloud computing

ActiveCN112810528AHigh cost of settlementImprove transportation efficiencyItem transportation vehiclesLogisticsLogistics managementVehicle frame

The invention relates to a logistics truck reset device based on cloud computing, which comprises a truck body and a carriage, wherein the truck body comprises a cab and a frame, the carriage and the frame are detachably connected together. The logistics truck reset device further comprises a reset device for connecting the frame and the carriage, and the carriage and the frame are detachably connected through the reset device. The reset device comprises a truck body part, a carriage part and a loading part. According to the logistics truck reset device based on cloud computing, a small truck for logistics can be transformed into a drop-and-pull transport vehicle, the problem that a large trailer is high in cost is solved, complex manual orders and certificates do not need to be handled, the logistics truck reset device based on cloud computing can be suitable for small logistics enterprises, on the premise that the burden of an enterprise is not increased, the transportation efficiency is improved, the logistics speed is increased, and the core competitiveness of the enterprise is improved.

Owner:ZHOUKOU NORMAL UNIV

Automatic berthing device for ship

An automatic berthing device for a ship belongs to the fields of pontoon wharf and ship berthing. The automatic berthing device for the ship comprises buffering airbags and a solid suction device. The buffering airbags comprise airbag shells, compartments and buffering springs, and the solid suction device comprises an electromagnet and a contact body; the airbag shells are fixed on the sides of a pontoon or the sides of a navigating ship, and each airbag is divided into a plurality of independent air chambers by the compartments; and the buffering spring and the electromagnet are arranged in the air chamber, the buffering spring abut against the airbag shell on one side of the pontoon or the navigating ship and a bearing hole of an iron core or an annular groove, and the other end of the electromagnet abut against an chamber wall of one face of the airbag shell without being fixed on the sides of the pontoon or the navigating ship. After the automatic berthing device for the ship which is simple in structure and convenient to produce is adopted, the production cost is low, the investment is small and the process is simple; the navigating ship is connected with the pontoon through the electromagnet when the navigating ship is berthing on the pontoon, and the circuit of the electromagnet is disconnected to make the navigating ship separate with the pontoon when the navigating ship leaving the pontoon without a sailor untying the cable rope ; and the external operating parts are not visible, and the degree of automation is high.

Owner:黄岸标

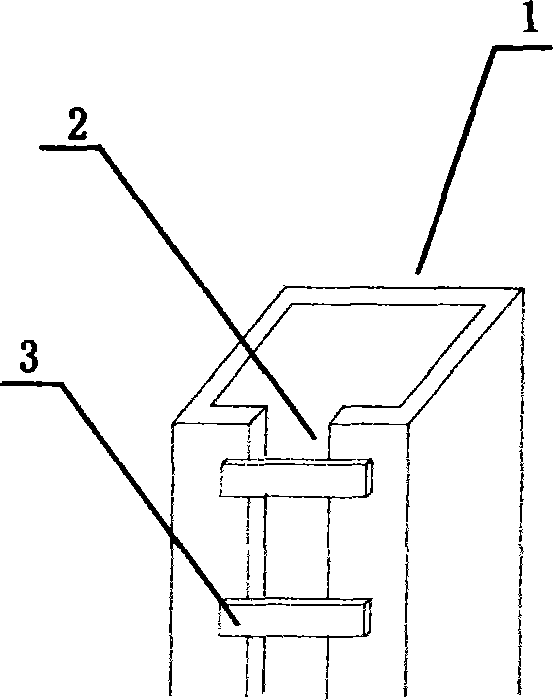

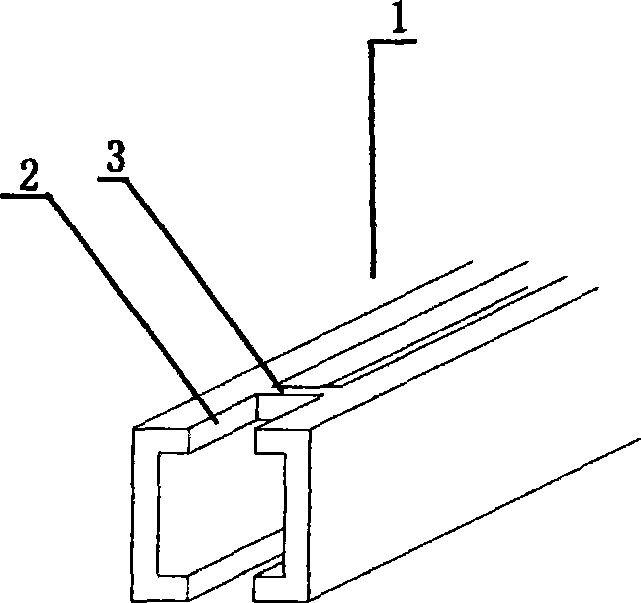

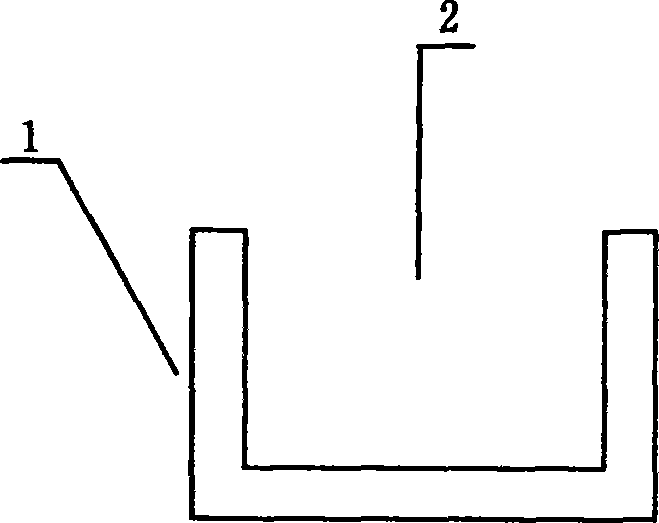

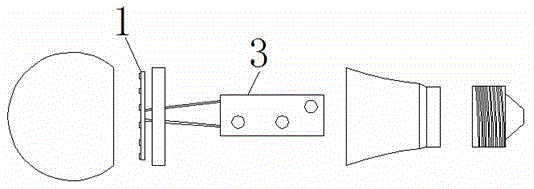

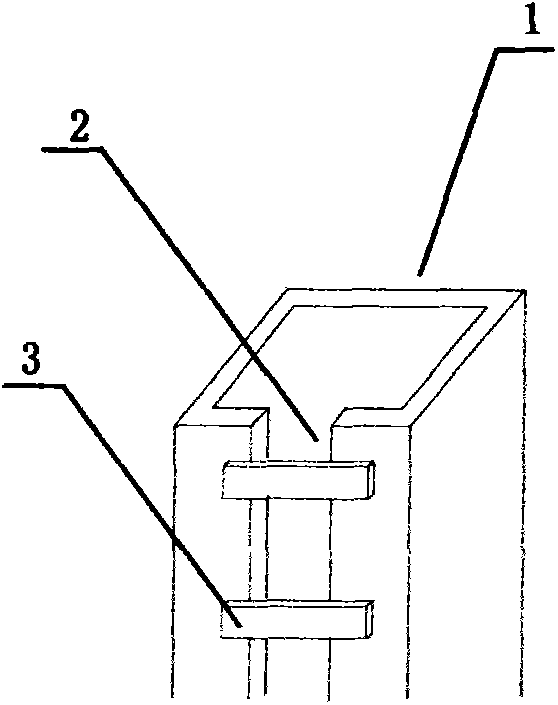

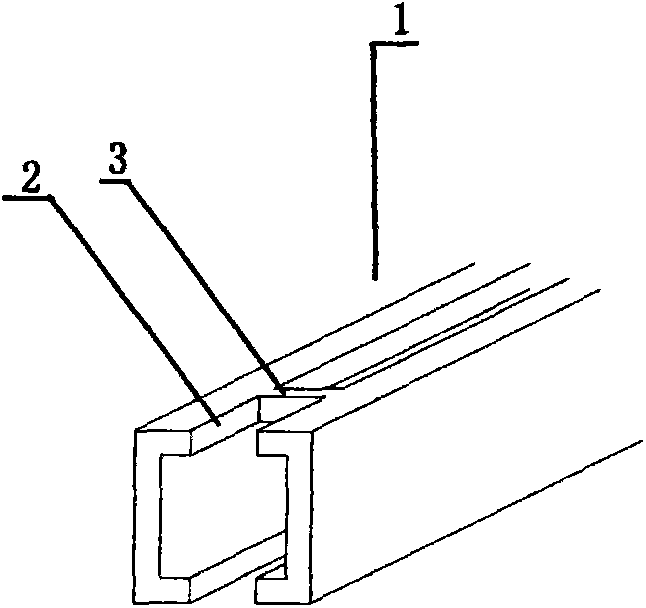

One-time wall body pouring die and manufacturing and use of die

A disposable wall casting mold, manufacture and use thereof. The mold is formed through the solidification of a gelatinization material, being produced into a trough (1) with two ends communicated and a certain length. At least one connecting strip (3), crossing a notch (2) and with two ends fixed on both sides of the notch (2), is provided at the port side of the trough (1). The connecting strip (3) is a pole with a length no less than the width of the notch (2) and no greater than the profile width of one side of the notch (2). The mold has a simple manufacturing process and is operated fast.

Owner:姚景祥

Clamp for template reinforcing

PendingCN108952158AEasy to operateImprove construction progressAuxillary members of forms/shuttering/falseworksHydro energy generationBiochemical engineeringSelf locking

The invention discloses a clamp for template reinforcing and relates to the technical field of building template fixing. The clamp comprises a fixing screw, detachable through-wall bolts connected with the two ends of the fixing screw, and a clamp device arranged on the detachable through-wall bolts. The clamp device comprises a clamp shell, a fixing shaft arranged on the clamp shell, and a trigger arranged on the fixing shaft in a matched mode. A pressing spring is arranged on the clamp shell, one end of the pressing spring is connected with the clamp shell, and the other end of the pressingspring is fixedly connected with the trigger. A clamping groove is formed in one side of the clamp shell, and bolt mounting holes are formed in the middle of the clamp shell. The detachable through-wall bolts are arranged in the bolt mounting holes in a penetrating mode to be matched with the trigger, and a backing stopping self-locking structure is constituted. The clamp has the beneficial effects that operation is convenient, the construction schedule is accelerated advantageously, connecting is tight, and the engineering quality is guaranteed advantageously.

Owner:ZHEJIANG CONSTR INVESTMENT GRP CO LTD

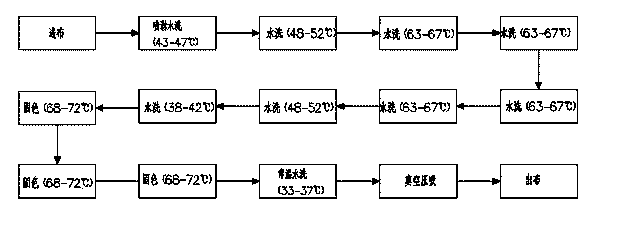

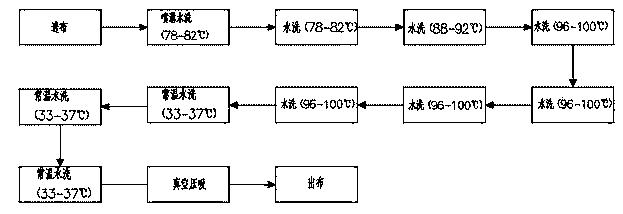

After-printing washing process

ActiveCN104195812ALow costEmission reductionDry-cleaning apparatus for textilesDyeing processAcetic acidAutomatic control

The invention discloses a after-printing washing process, comprising the following concrete operation steps: feeding cloth; spraying and washing; performing fixation; spraying and washing again; and discharging cloth by vacuum pressure suction, wherein a CD anti-staining agent, a KNR dye-fixing agent, sodium carbonate, acetic acid and an anti-staining soaping agent are used in the spraying and washing process. The process has the advantages that the assistant cost can be effectively saved, water consumption can be saved, sewage discharge is reduced, and the positive impelling action is taken for energy conservation and emission reduction. The process is capable of achieving automatic control, so that the quality of a washed product is consistent from beginning to end, dyelot chromatism and spline difference, which easily appear in a traditional cylinder scoring intermittent water washing process, are avoided, and the quality of the washed product is relatively stable; complex operations such as manual feeding, warming and cloth feeding in the traditional cylinder scoring washing process are avoided, meanwhile, two procedures of dehydration and scutching during the later period of cylinder scoring washing are omitted, and thus the operation is relatively simple; therefore, the payroll cost is effectively saved, meanwhile, the production efficiency is greatly improved, control on energy consumption is effectively improved, and the energy consumption is reduced.

Owner:FUJIAN FORTUNES TEXTILE PRINTING & DYEING TECH

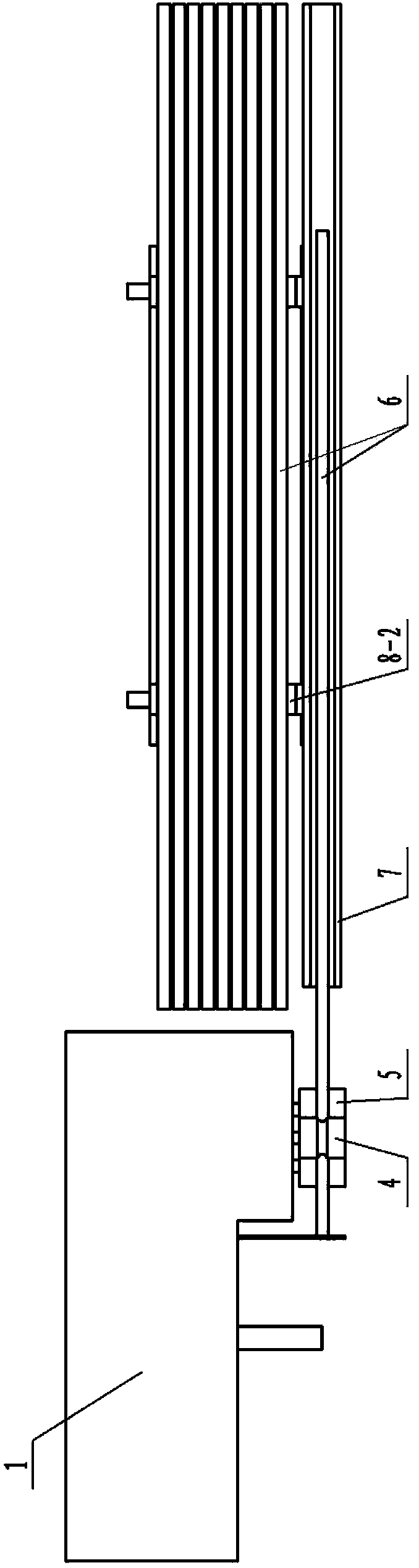

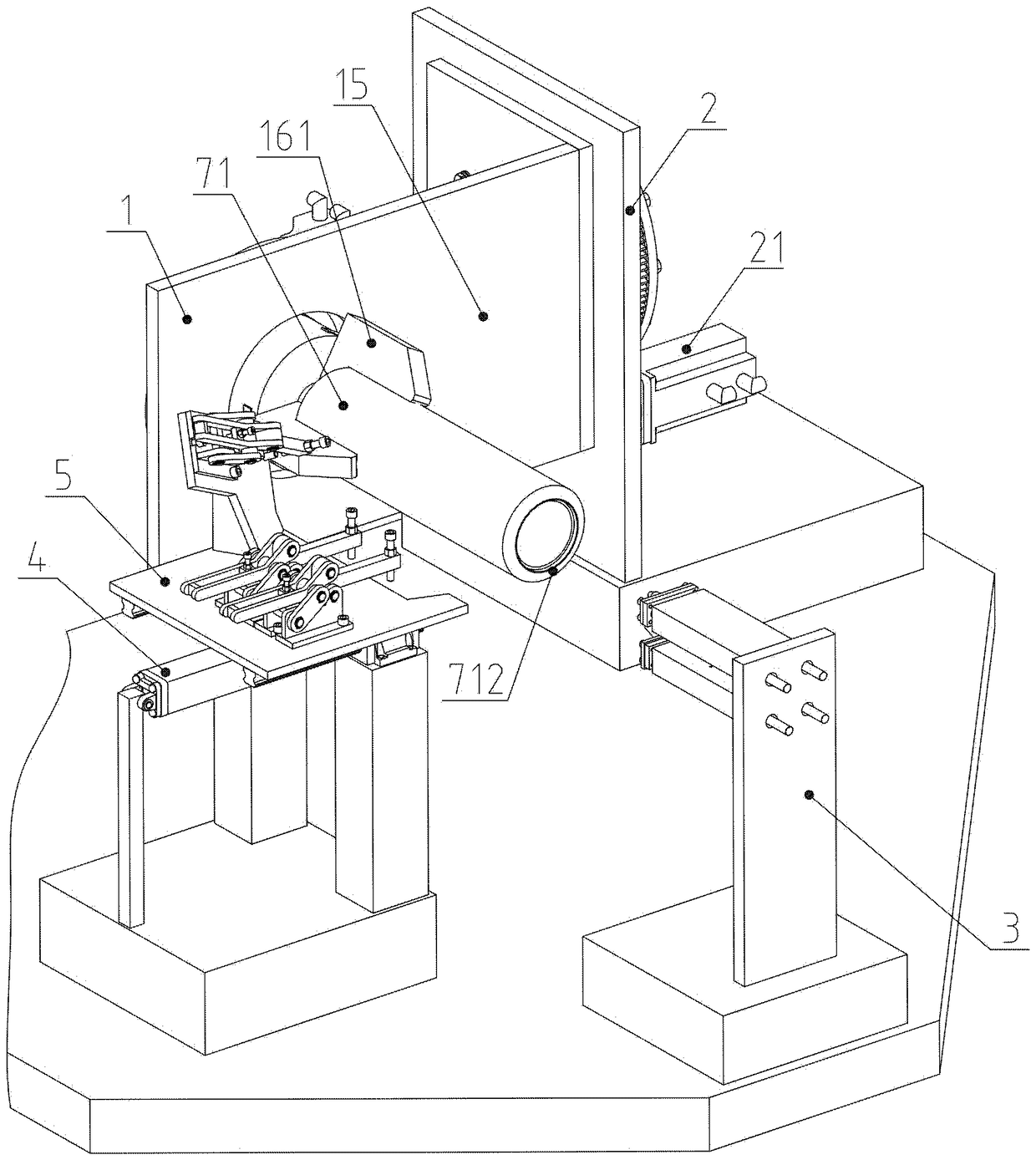

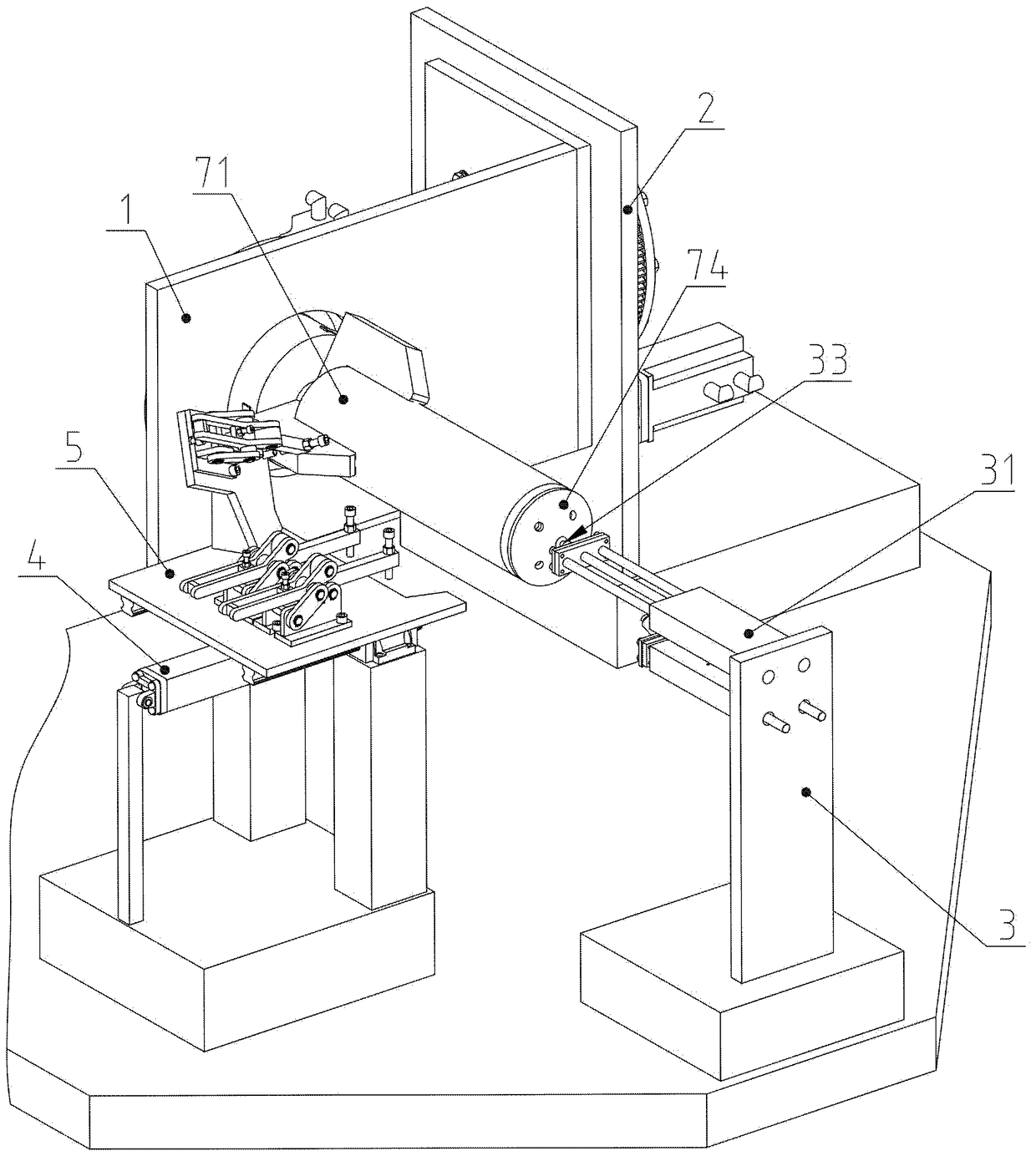

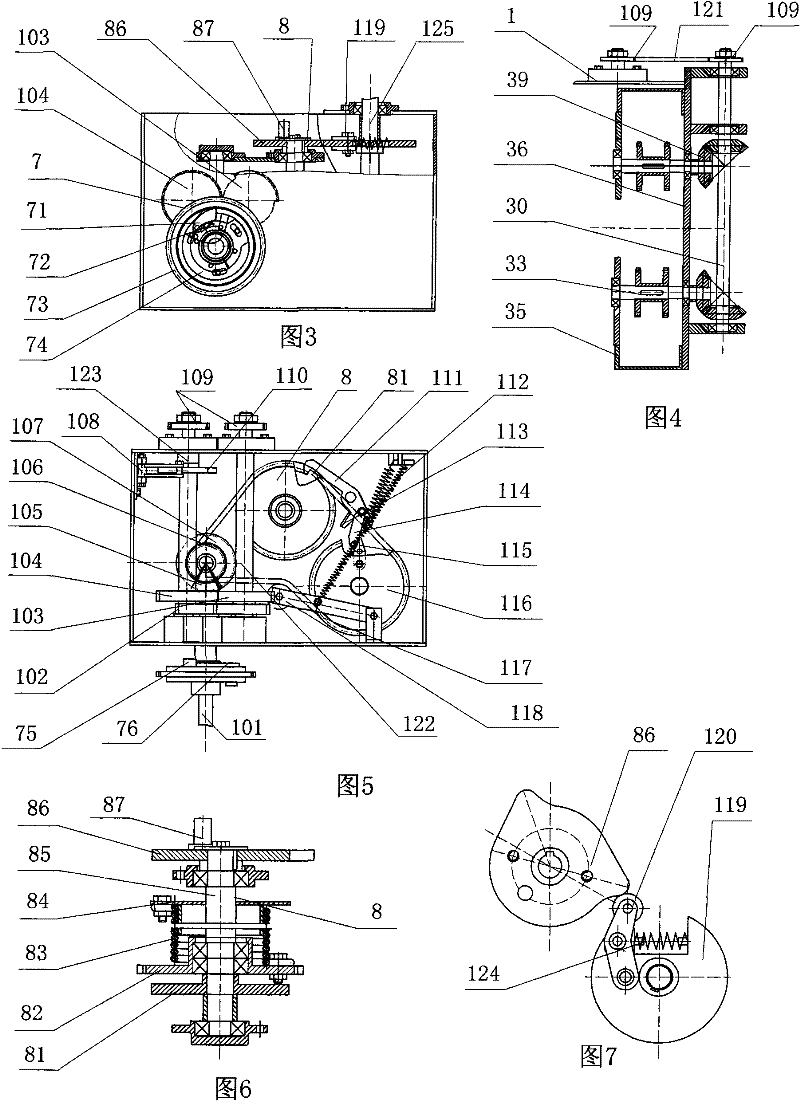

Lamp tube packaging box molding machine applied to full-automatic packaging line for LED lamp tube

PendingCN108860798AReduce lossReduce loss and reduce production costsWrapper twisting/gatheringShock-sensitive articlesMolding machineMachining process

The invention provides a lamp tube packaging box molding machine applied to a full-automatic packaging line for an LED lamp tube. The lamp tube packaging box molding machine comprises a rack; the rack(1) is provided with a feeding device; the feeding device comprises a feed bin base plate (5); a feed bin base plate reinforcing plate (6) is arranged by the side of the feed bin base plate (5); therack is provided with a rail (2); an open rail bearing (3) is arranged at the side of the feed bin base plate; and an open rail bearing cushion board (4) is arranged outside the open rail bearing (3).The molding machine provided by the invention can greatly reduce the amount of workers, lowers the wage cost, prevents a problem that the lamp tube is fragile due to frequent transfer operation, reduces wear and loss of the lamp tube in a machining process, lowers the production cost, improves the packaging efficiency of the lamp tube and optimizes the packaging process of the lamp tube.

Owner:JIANGSU HAOMING PHOTOELECTRIC TECH

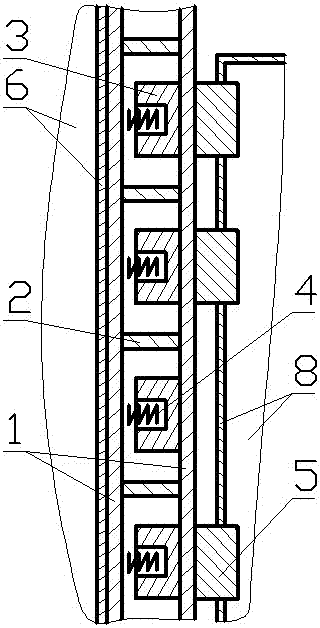

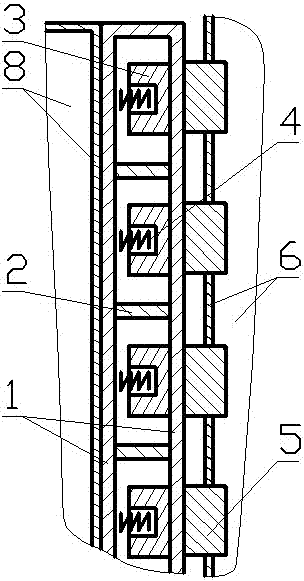

Substituted power line connecting structure for pins of discharge resistor for plastic coated aluminum LED (light-emitting diode) lamp

InactiveCN105485642ALower wage costsResolve premature failureLighting support devicesElectric circuit arrangementsElectrical resistance and conductanceLED lamp

The invention relates to a substituted power line connecting structure for pins of a discharge resistor for a plastic coated aluminum LED (light-emitting diode) lamp. The substituted power line connecting structure comprises a light source plate, an insulating plate and a drive source plate, wherein the side, close to the light source plate, of the insulating plate is provided with at least two light source plate connectors; the side, close to the drive source plate, of the insulating plate is provided with at least two drive source connectors; the discharge resistor is arranged on the drive source plate; the pins of the discharge resistor pass through discharge resistor pin through holes, and are connected to the light source plate; a mounting fixing hole is formed in the light source plate; a mounting connecting post is arranged on the insulating plate corresponding to the mounting fixing hole; and a post screw connecting hole is formed in the mounting connecting post. According to the substituted power line connecting structure, the two terminals of the discharge resistor at the output end of a LED drive plate are used as pins, proper length is kept after the pins are inserted into the LED drive plate for welding, and the pins are directly connected to the input end of the light source plate, so that connection by use of two power lines is avoided, and the light source plate is driven to enable the LED to emit light.

Owner:江苏宇杰光电有限公司 +1

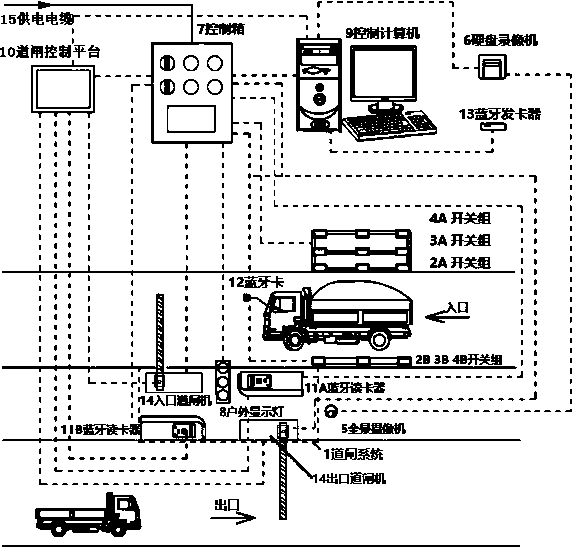

Automatic material height detection device used in transportation process and method

InactiveCN108318106AEasy to operateSimple detectabilityMachines/enginesLevel indicatorsElectricityYard

The invention discloses an automatic material height detection device used in the transportation process and a method. The detection device comprises gate systems, infrared opposite ejection switch groups, control boxes and outdoor display lamps, wherein the gate systems are arranged at the entrance and the exit of a raw material stack yard and constructed in a manner of one entrance and one exit;the infrared opposite ejection switch groups are arranged on two sides of an entrance channel of one gate system and used for detecting the heights of materials loaded by vehicle cargo tanks; the control boxes are respectively and electrically connected with the gate systems and the infrared opposite ejection switch groups and used for receiving connection point signals of the infrared opposite ejection switch groups, and used for transmitting alarm signals after the connection point signals are compared with preset values; the outdoor display lamps are electrically connected with the controlboxes and used for receiving signals to display states of the materials of the vehicle cargo tanks. The problems that transportation vehicles run without cargos or with insufficient cargos, the cargos are not completely unloaded and effective monitoring is not available when raw materials are transported with vehicles in the sylvite production process, can be effectively solved, and the safety production management level can be increased.

Owner:JINCHUAN GROUP LIMITED

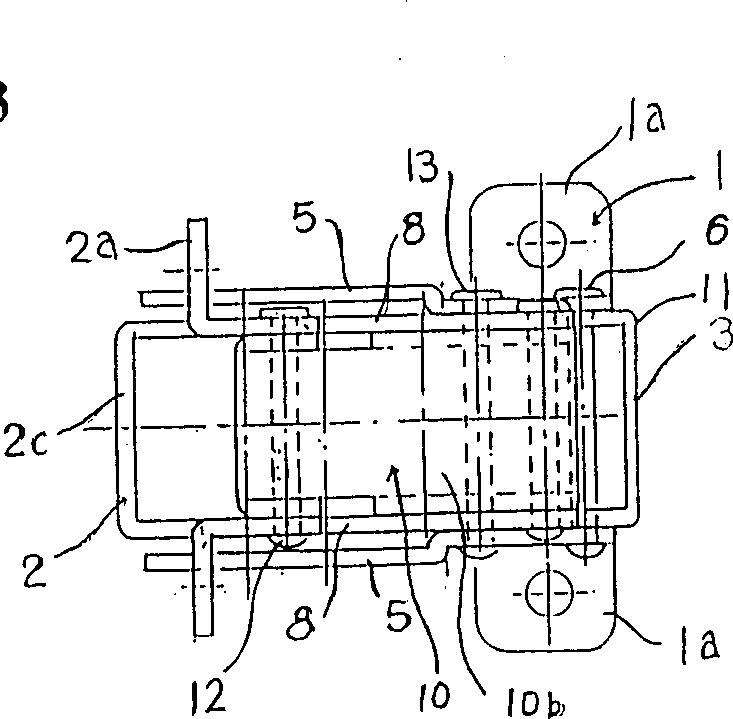

Die-cutting machine for flexible material

InactiveCN102672738AReduce manufacturing costEasy maintenanceMetal working apparatusPulp and paper industryScrap

The invention discloses a die-cutting machine for a flexible material and belongs to the field of die-cutting machinery. The die-cutting machine for the flexible material comprises a machine frame and a motor assembly and is characterized by also comprising a die-cutting assembly, wherein the die-cutting assembly comprises a bracket, a pressure roller, a working roller, a supporting roller and a travelling wheel; supporting plates are arranged at two ends of the bracket respectively; two ends of the pressure roller, the two ends of the working roller and the two ends of the supporting roller are movably arranged on the supporting plates; the pressure roller, the working roller and the supporting roller are parallel mutually; supporting components are arranged between two ends of the pressure rollers and two ends of the working rollers; a horizontal guide rail is arranged along the inner side of each of two edges, contacted with the die-cutting assembly, of the machine frame; the direction of the horizontal guide rails is vertical to the axial direction of the working roller; the horizontal guide rails are contacted with the travelling wheel; a motor is connected with the supporting roller through a motor transmission mechanism; the supporting roller is connected with the pressure roller through a homodromous transmission mechanism; the working roller is contacted with the supporting roller; a roller cylinder of the pressure roller is a die-cutting roller cylinder; crease lines and connecting holes are formed on the surface of the die-cutting roller cylinder; and a plurality of die-cutting knife blocks are embedded into the connecting holes. Compared with the prior art, the die-cutting machine for the flexible material has the characteristics of saving labor, improving efficiency and having low scrap rate and high product quality.

Owner:魏文臣

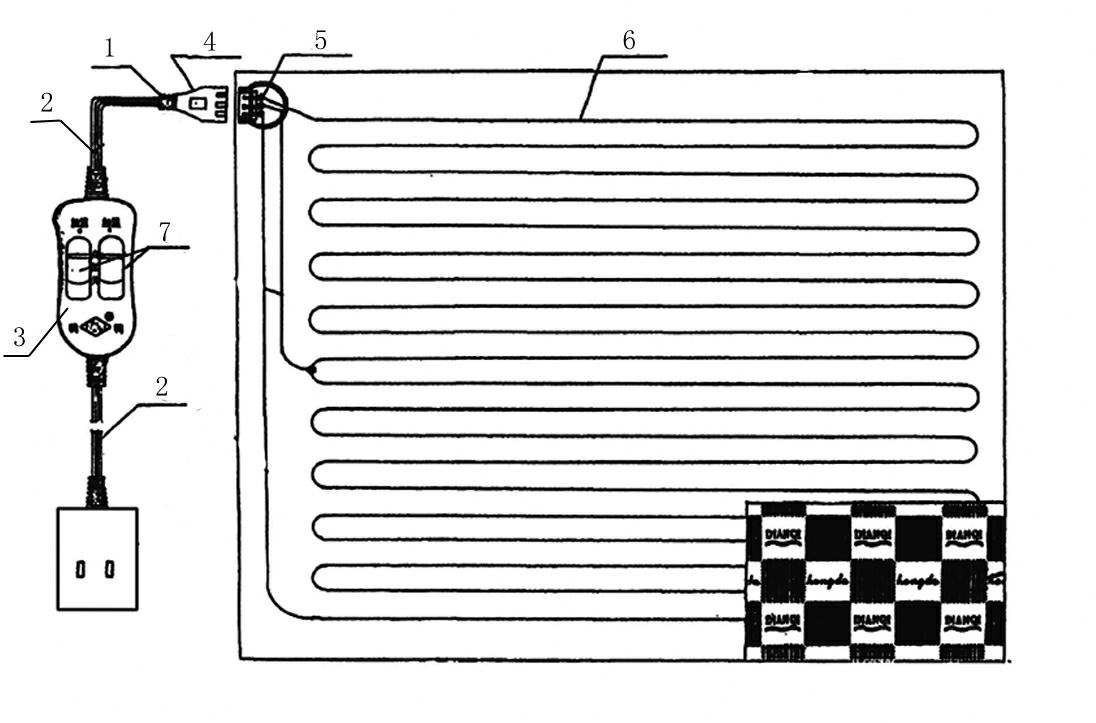

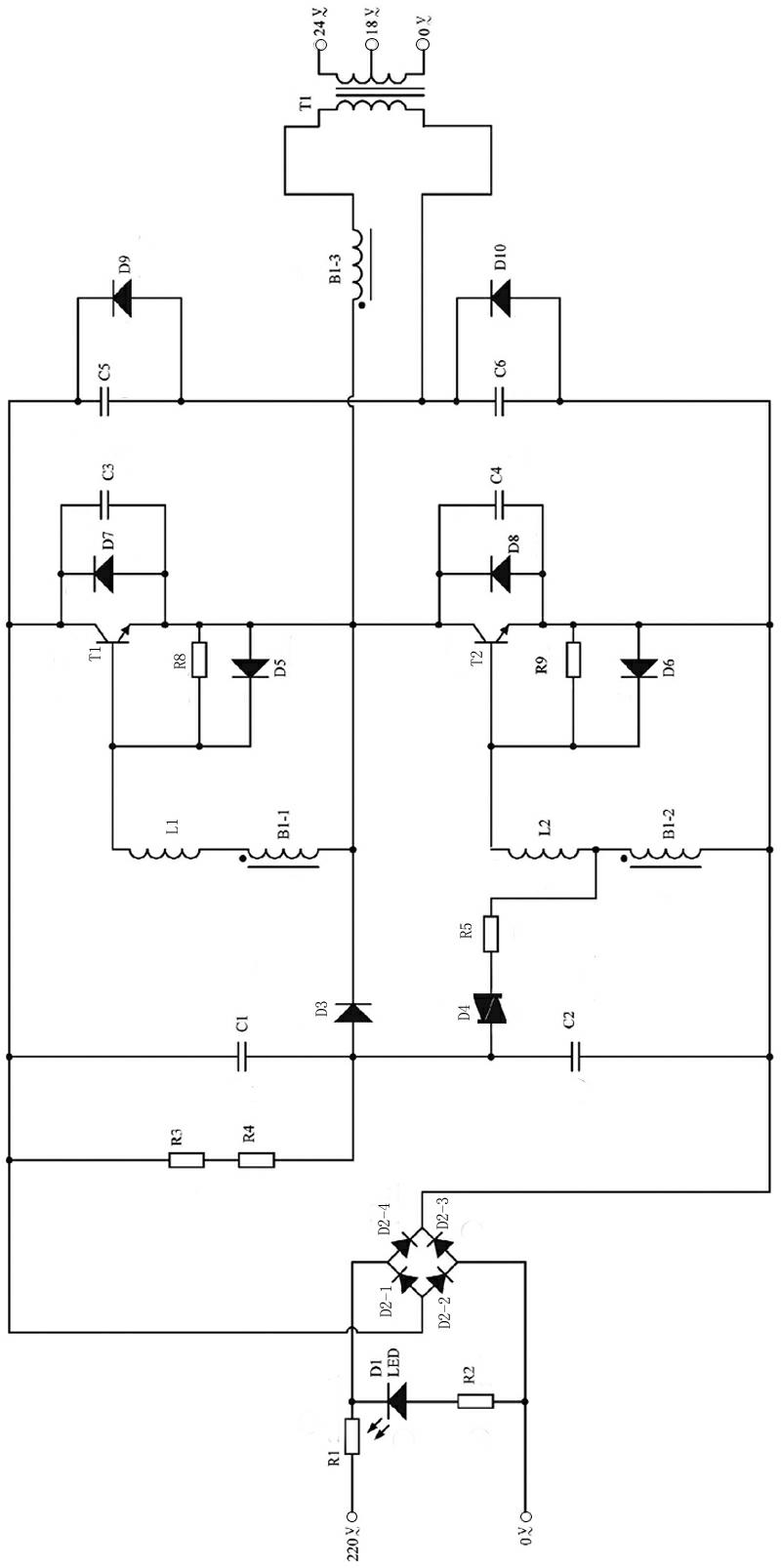

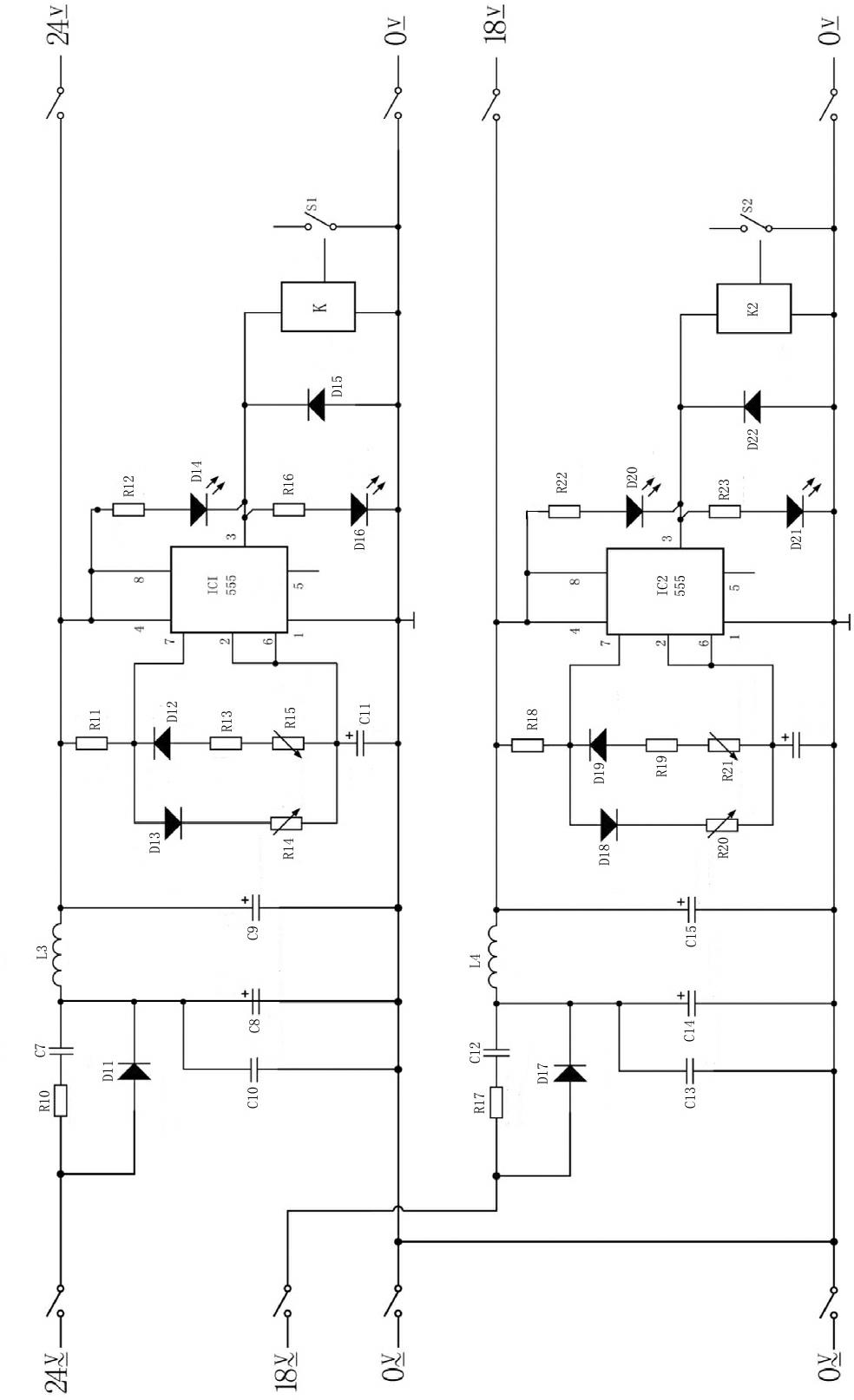

Uncharged time-control overlapped combustion-resistant treatment and rehabilitation electric blanket

The invention discloses an uncharged time-control overlapped combustion-resistant treatment and rehabilitation electric blanket, in particular a time-control overlapped combustion-resistant treatment and rehabilitation electric blanket in which an ultralow safety voltage of less than or equal to 24V is adopted and a phenomenon of electricity leakage can be avoided. The electric blanket comprises a surface layer, a bottom layer, an electronic step-down transformer, a power supply lead, a control switch box, a power supply lead connector, a socket and an overlapped combustion-resistant heating element, wherein the surface layer and the bottom layer are compounded together; the surface layer is made of fabrics of the surface of the needled non-woven electric blanket; the bottom layer is made of fabrics of the bottom surface of the needled non-woven electric blanket; the overlapped combustion-resistant heating element is arranged in a gap channel of the bottom layer; an output end of the electronic step-down transformer is connected with one end of the control switch box through the power supply lead; the other end of the control switch box is connected with the socket of the electric blanket through the power supply lead and the power supply lead connector; the tail part of a plug in the socket is connected with the overlapped combustion-resistant heating element; the control switch box is independently arranged outside the electric blanket; and a time control switch is arranged on the control switch box.

Owner:洪德全

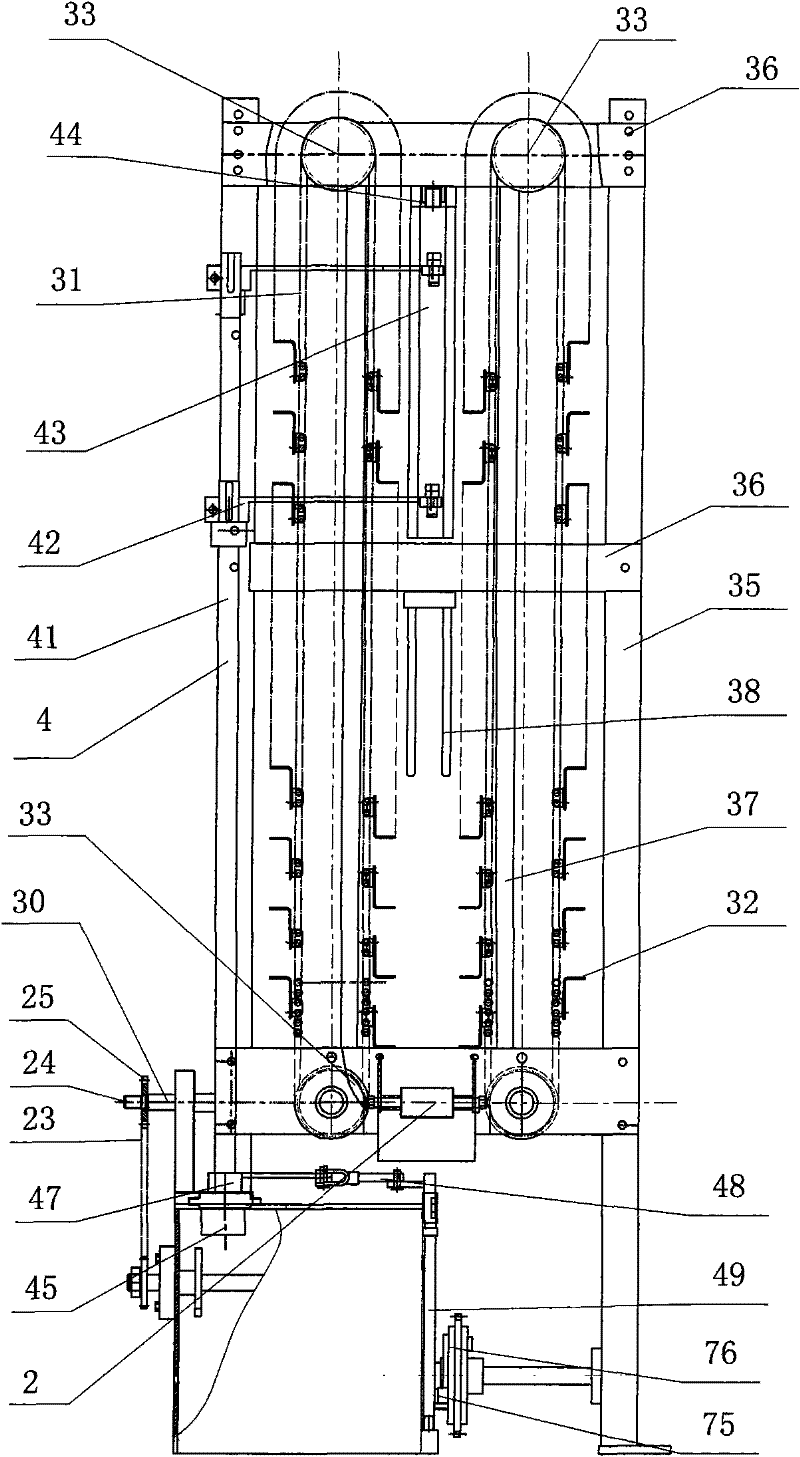

Honeycomb briquette stacking machine

The invention relates to a honeycomb briquette stacking machine. Power is transmitted into a gear I of a gearbox and a conical gear I by a power shaft and a clutch; the gear I is meshed with a gear I on a transmission shaft I; an edentulous gear is arranged on the transmission shaft I and meshed with a gear II of a transmission shaft II; the transmission shaft I is provided with a chain wheel I which is connected with a chain wheel V on a long shaft of a belt transmission mechanism by a chain II and drives a belt to transmit honeycomb briquette; the transmission shaft II is provided with a chain wheel I which is connected with the chain wheel I on a main shaft of a lifting mechanism by a chain IV; the power is transferred to double chain wheels by a conical gear pair to drive a chain III to move; a support plate on the chain III supports the honeycomb briquette; 5 mounds of honeycomb briquette is flatly pushed on a honeycomb briquette stacking plate of a rotating disk mechanism by a honeycomb briquette pushing device once; a gear ring I on a rotating disk is rotated by a gear sleeve transmitting a vertical shaft; the honeycomb briquette pushing device is supplied with kinetic energy by an energy storage device; and the scheme that the power of the energy storage device is transferred by the conical gear I realizes the honeycomb briquette stacking mechanization for replacing manual working and is suitable for being matched with a honeycomb briquette making machine to mechanically stack the honeycomb briquette.

Owner:周运芳

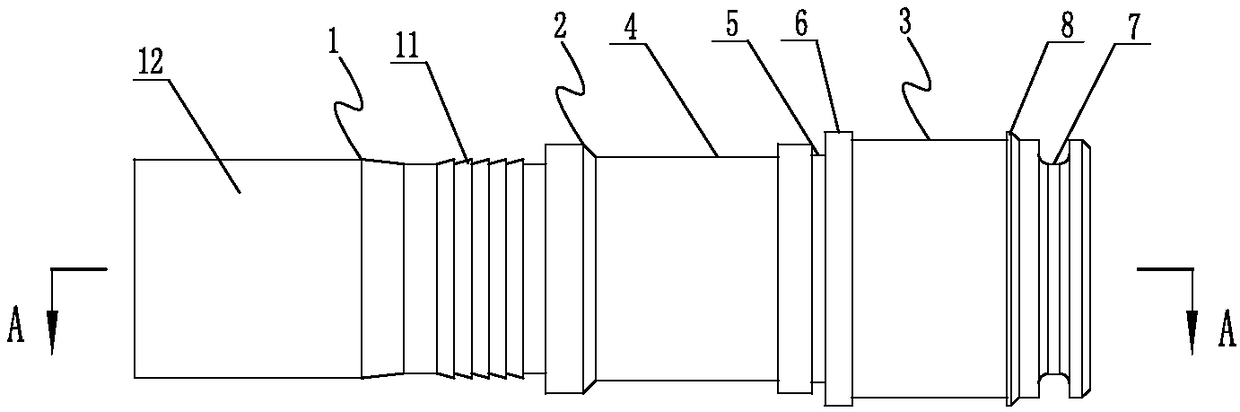

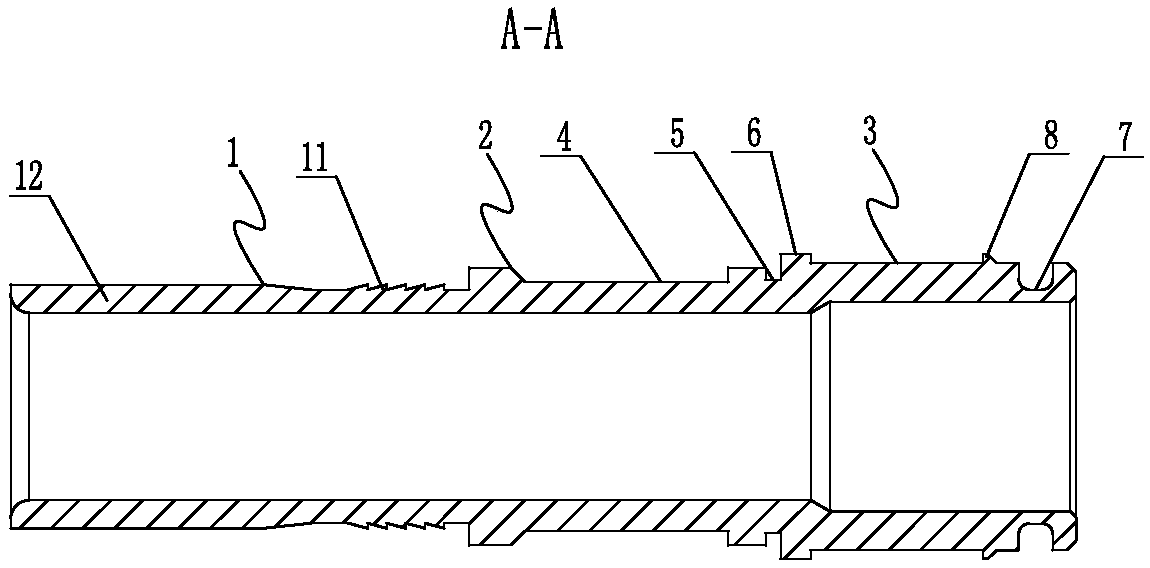

Copper connector and production method thereof

A copper connector comprises a pipe body. The pipe body is divided into a connecting part (1), a transition part (2) and a fixing part (3). The outer diameter of the transition part (2) is larger thanthat of the connecting part (1), the outer diameter of the transition part (2) is smaller than that of the fixing part (3), and the peripheral face of the transition part (2) is provided with a firstannular groove (4). The corresponding diameter of the bottom face of the first annular groove (4) is larger than the outer diameter of the connecting part (1). The connecting part (1) is divided intoa sawtooth section (11) and a smooth section (12). A copper connector production method comprises the first step of blank pipe cutting, the second step of machining and the third step of collecting and checking of falling materials in the second step and then packaging. Compared with the prior art, the copper connector and the copper connector production method have the beneficial effects that connecting stability and applicability are good, and the production cost is low.

Owner:NINGBO CHANGHUA COPPER PRODS

A logistics truck reset device based on cloud computing

ActiveCN112810528BHigh cost of settlementImprove transportation efficiencyItem transportation vehiclesLogisticsLogistics managementVehicle frame

Owner:ZHOUKOU NORMAL UNIV

Disposable wall casting mould and its manufacture and use

A disposable wall casting mold, manufacture and use thereof. The mold is formed through the solidification of a gelatinization material, being produced into a trough (1) with two ends communicated and a certain length. At least one connecting strip (3), crossing a notch (2) and with two ends fixed on both sides of the notch (2), is provided at the port side of the trough (1). The connecting strip (3) is a pole with a length no less than the width of the notch (2) and no greater than the profile width of one side of the notch (2). The mold has a simple manufacturing process and is operated fast.

Owner:姚景祥

Semi-automatic welding equipment for explosion-proof lamp protection cover

ActiveCN108326406BAvoid hiringImprove welding efficiencyWelding/soldering/cutting articlesMetal working apparatusCircular discSemi automatic

The invention belongs to the technical field of explosion-proof tool manufacturing equipment, relates to a manufacturing device for a protecting cover of an explosion-proof light, and specifically relates to a semi-automatic welding device for the protecting cover of the explosion-proof light. The device is characterized in that longitudinal ribs are manually mounted on a curved supporting plate assembly; mould assemblies are automatic to rotate; the curved supporting plate assembly faces an operator; steel rings are manually mounted and positioned through steel ring positioning grooves; a curve slot disc is capable of synchronously shifting seven round shifting pins; seven mould assemblies are automatically expanded and fixed; revolution servo motors are used for driving to realize station switching; compressing cylinders are automatically lifted and swung in place; intersection points of the longitudinal ribs and the steel rings are compressed through high-voltage electrodes; then power supply is connected; the positions of the intersection points are automatically exchanged, and the spot welding is performed; the seven mould assemblies are automatically closed; and then a finished product is manually taken out. With the adoption of the device, the welding efficiency and the outline dimension accuracy are improved; the labor is saved; electric welding workers are saved, so that the salary cost is decreased, and the employment pressure is reduced.

Owner:威海鹏飞自动化技术有限公司

Wireless mobile paying device

ActiveCN102184605BSimplify the tedious manual charging operationPassenger flow speed increasesCash registersPaymentDemagnetizing device

The invention belongs to the field of electronic consumption service and particularly relates to a wireless mobile paying device. The wireless mobile paying device is characterized by comprising a host, an infrared code-reading and demagnetizing device, a printer, a consumer card interface, an information duplication management card interface, a commodity code-reading display screen and a storagebattery, wherein the host is internally provided with a control circuit board; the control circuit board is respectively and electrically connected with the information duplication management card interface, the consumer card interface, the printer and the infrared code-reading and demagnetizing device, and stores information sent by each module; and the storage module supplies power to each module. The wireless mobile paying device is compact and reasonable in structure, convenient to install and attractive and practical. As the wireless mobile paying device does not need an external power supply and a signal transmission wire, the complicated manual charging operation of shopping malls is simplified, the salary cost of shopping mall personnel is saved, the time for customers to line up for payment is also omitted, and an easy shopping environment is boosted. Especially in important holidays or festivals gathered by particularly many shoppers, the paying device fixed on a shopping mart allows the shoppers to complete shopping by swiping a card alone, thus fast increasing the customer flow of the shopping malls.

Owner:浙江公原前智能科技有限公司

Material feeding device for unloading machine

The invention discloses a material feeding device for a blanking machine, which relates to the technical field of mechanical processing. It includes a limit block and a feeding roller installed on the blanking machine. The feeding guide rail of the wheel, the feeding roller wheel includes a pressure roller and two idler rollers arranged below the pressure roller, the pressure roller wheel and the two idler rollers are alternately arranged, the pressure roller and the The surfaces of the supporting rollers are respectively provided with positioning grooves matching the profiles; a material rack is arranged beside the feeding guide rail, and the material rack has a material receiving plate inclined downward toward the feeding guide rail. Compared with the prior art, the present invention has the advantages of uniform stress during profile processing, not easy to jump, high processing precision and low labor intensity of workers.

Owner:柳州万众汽车部件有限公司

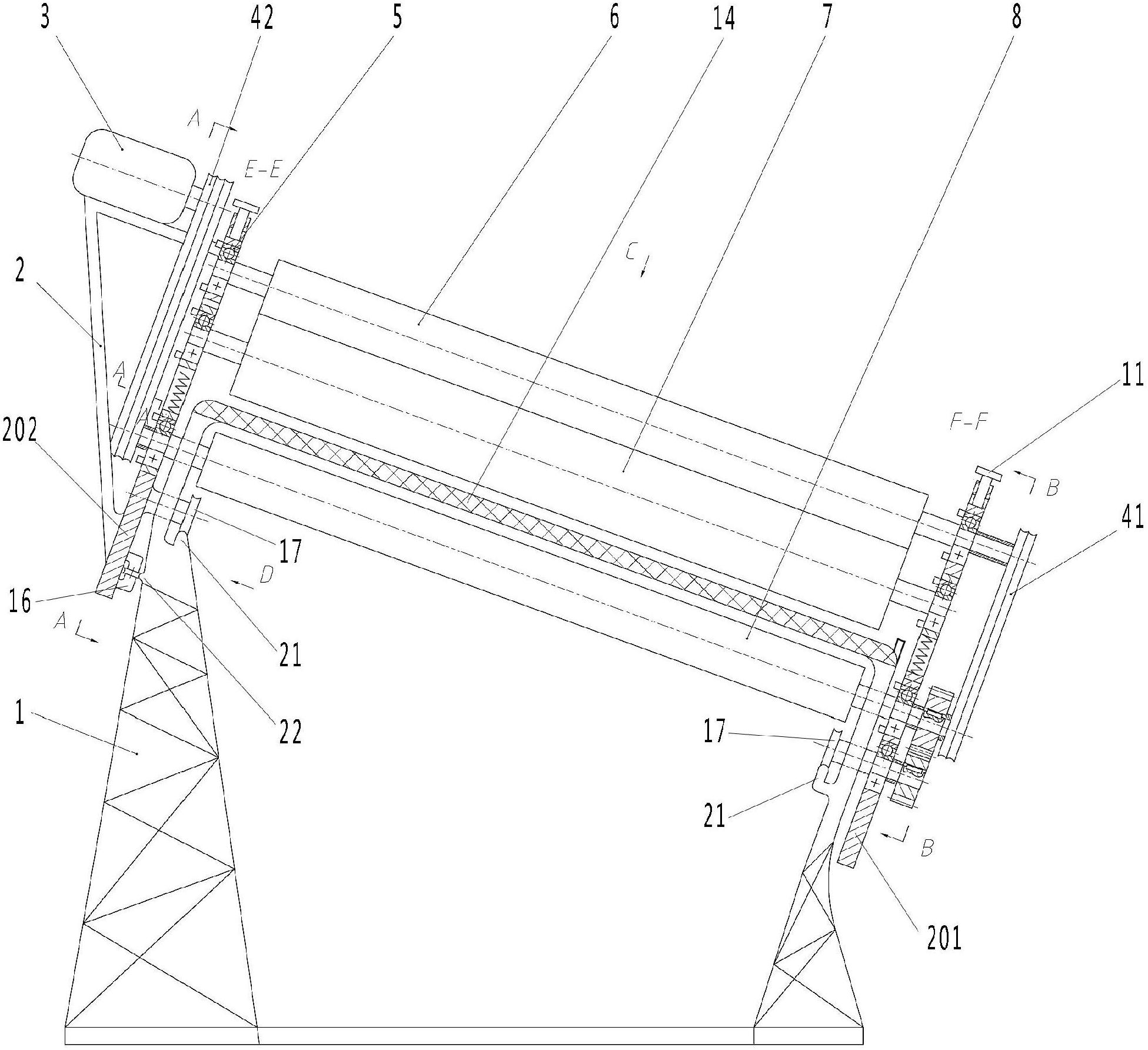

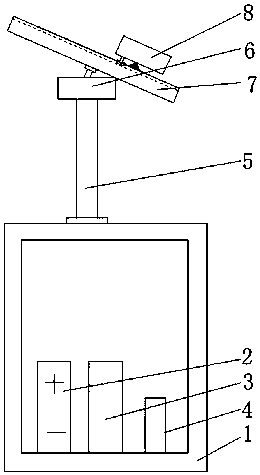

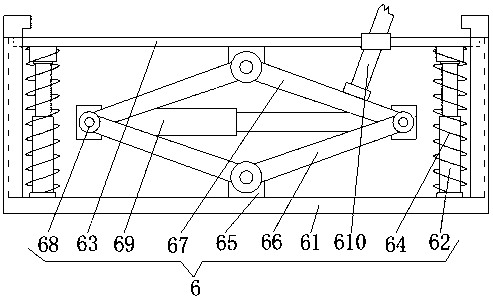

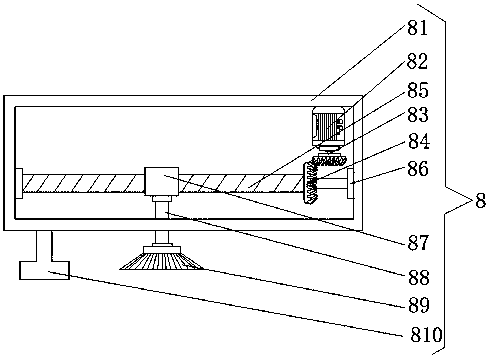

New energy charging pile

InactiveCN108340799AImprove conversion rateSolve the problem of sky angle adjustment that cannot follow the sunPhotovoltaic supportsCharging stationsSkyNew energy

The present invention relates to the technical field of new energy charging piles and discloses a new energy charging pile, which comprises a box body. The bottom of the inner wall of the box body isfixedly connected to a battery, an inverter and a controller. The top of the box body is fixedly connected to a support rod. A swinging device is fixedly connected to the top end of the support rod. Asolar panel is fixedly connected to the top of the swinging device. A cleaning device is slidably connected to the top of the solar panel. The swinging device comprises a bottom frame. Telescopic rods are fixedly connected to the both sides of the bottom of the inner wall of the bottom frame. A sliding plate is slidably connected between the two sides of the inner wall of the bottom frame. One end of each telescopic rod is fixedly connected to the bottom of the sliding plate. The new energy charging pile solves the problem that the solar panel cannot be adjusted by following the sky angle ofthe sun, the solar panel can closely follow the incident angle of sunlight at any time, the utilization of solar energy is maximized, and the conversion rate of new energy is improved.

Owner:FOSHAN SANMENG NEW ENERGY CO LTD

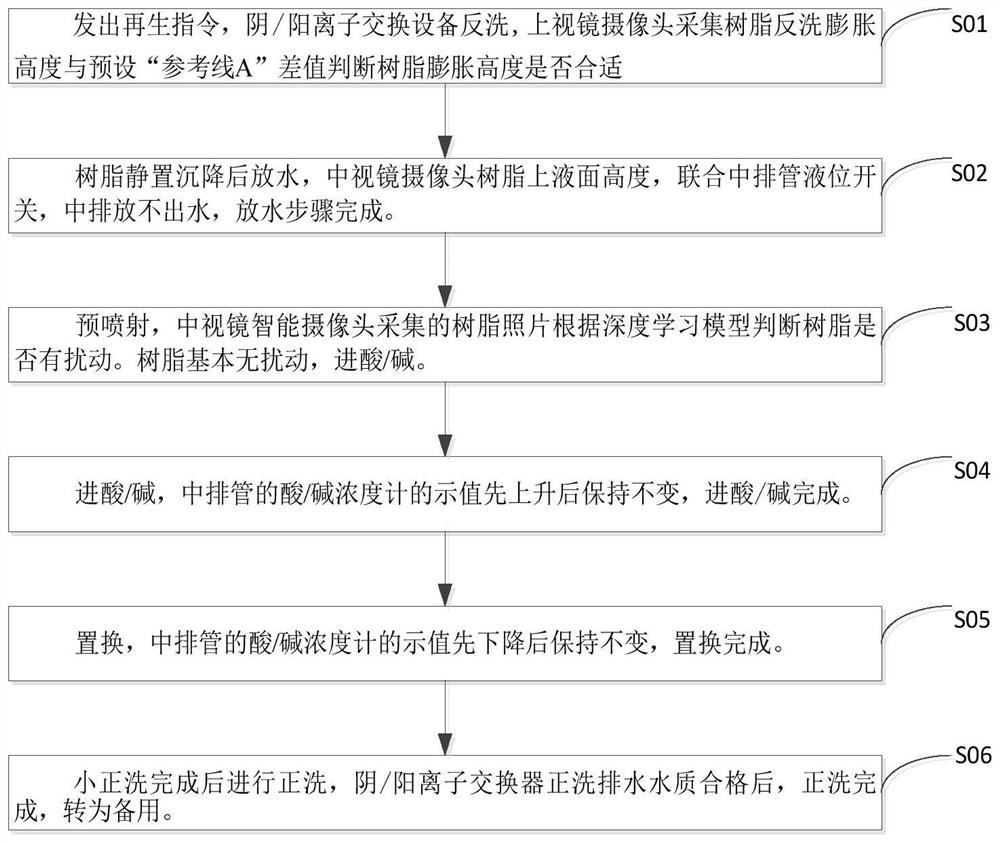

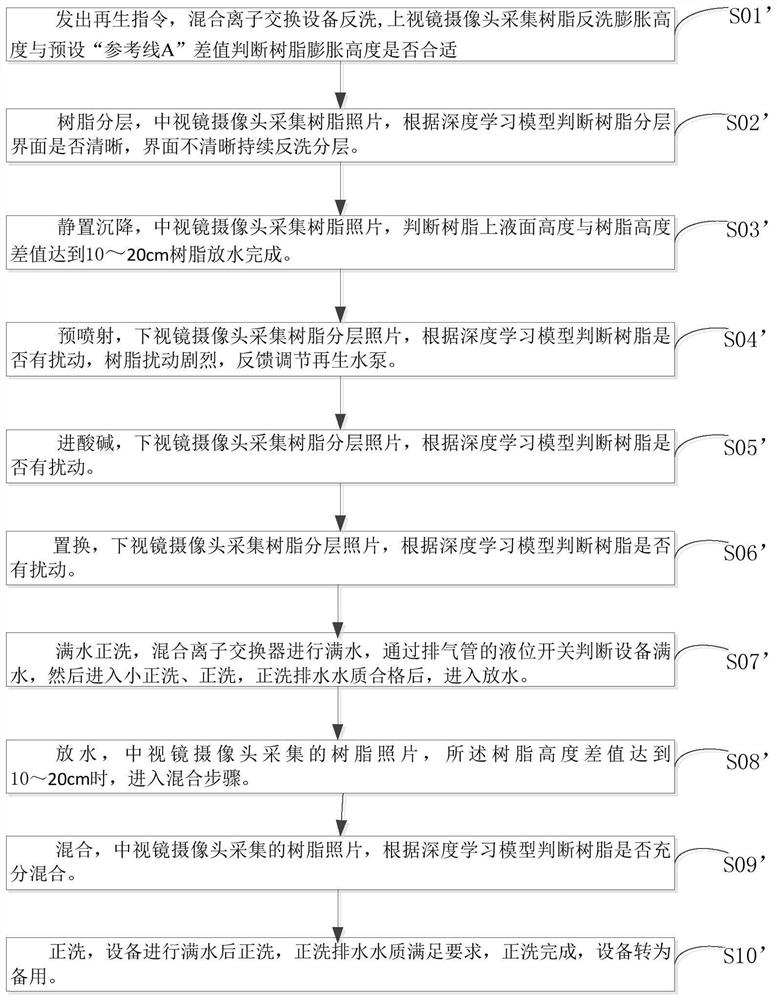

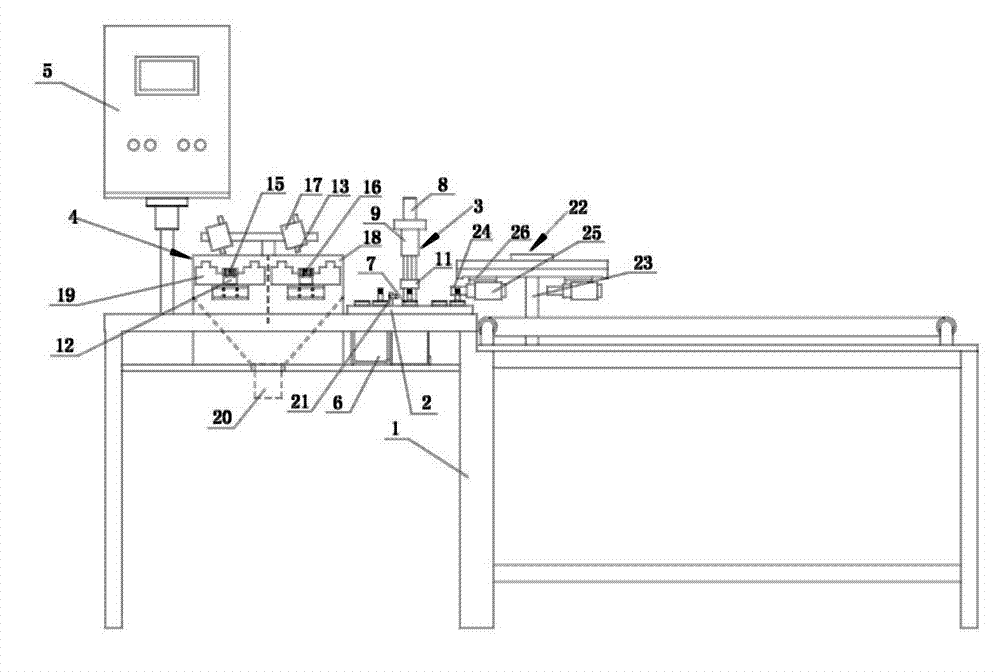

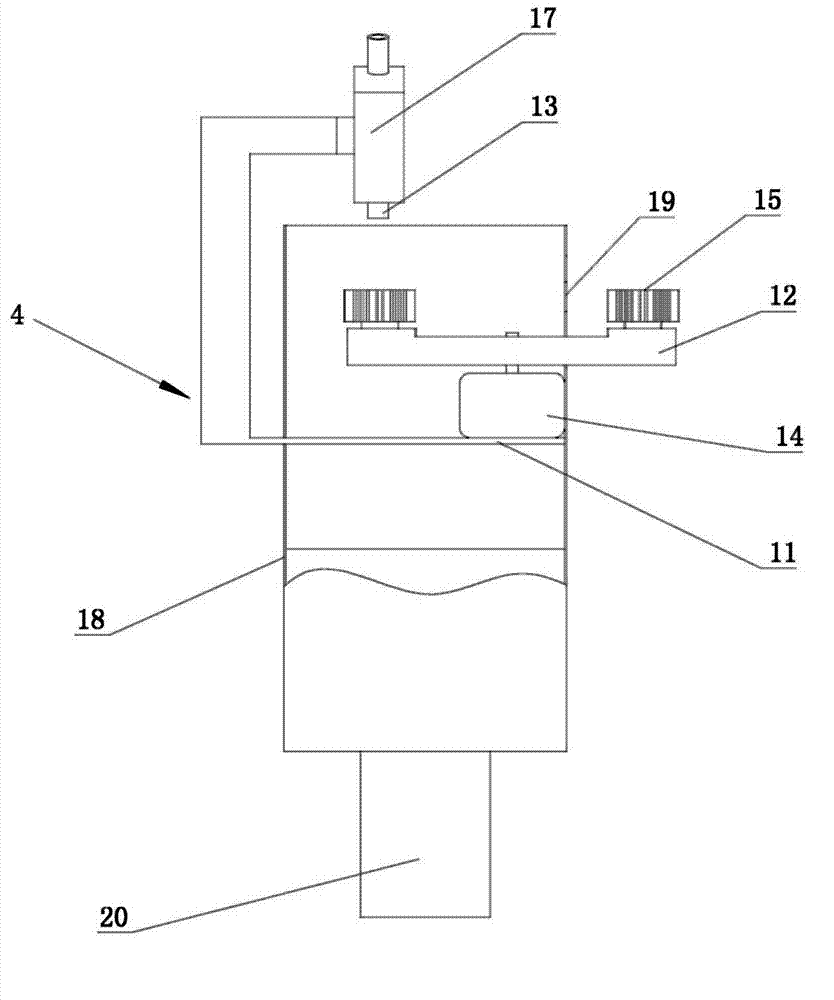

Ion exchange system intelligent regeneration control method and system based on image recognition

PendingCN114798005AImprove regeneration efficiencyAvoid reproduction quality fluctuationsIon-exchanger regenerationProgramme total factory controlControl engineeringProcess engineering

The invention provides an ion exchange system intelligent regeneration control method and system based on image recognition. The method comprises the steps that a regeneration instruction is sent out, mixed ion exchange equipment is subjected to backwashing, an upper sight glass camera collects the difference value between the resin backwashing expansion height and a preset reference line A, and whether the resin expansion height is appropriate or not is judged; a middle sight glass camera collects a resin picture, and whether a resin layering interface is clear or not is judged according to a deep learning model so as to control backwashing layering; a middle sight glass camera collects a resin picture, and the difference value between the resin upper liquid level height and the resin height is judged to complete water drainage; a lower sight glass camera collects layering pictures of the resin, whether the resin is disturbed or not is judged according to a deep learning model, and pre-injection, acid-base feeding and replacement are carried out according to the judgment result; full water conventional well-washing: judging that the equipment is full of water through a liquid level switch of an exhaust pipe, and then entering small conventional well-washing and conventional well-washing; and resin mixing images collected by water and a middle sight glass camera are used for controlling mixing and forward washing of the resin. The technical problems of time and labor consumption and low operation safety are solved.

Owner:CHINA DATANG CORP SCI & TECH RES INST CO LTD EAST CHINA BRANCH +4

Automatic blowing and pressing machine for electromagnetic valves

ActiveCN102922259AReduce in quantityReduce energy consumptionMetal working apparatusEngineeringMechanical engineering

The invention discloses an automatic blowing and pressing machine for electromagnetic valves, which comprises a base (1), a turntable (2), a laminating mechanism (3), a blowing mechanism (4) and a control box (5), wherein the base (1) is provided with a graduator (6), the turntable (2) is rotatablely connected to the base (1), a rotating shaft of the graduator (6) is connected with the lower end face of the turntable (2), the axis of the rotating shaft of the graduator (6) and the axis of the turntable (2) are in a same straight line, a position on the upper end face of the turntable (2) and close to the outer edge of the upper end face is circumferentially provided with at least three electromagnetic valve clamps (7), the at least three electromagnetic valve clamps (7) are uniformly distributed along the circumferential direction of the turntable (2), the circle center of a circumference formed by the centers of the at least three electromagnetic valve clamps (7) and the circle center of the turntable (2) are concentric, the laminating mechanism (3) is fixed in a position on the base (1) and close to the outer edge of the turntable (2), the control box (5) is fixed on the base (1), the blowing mechanism (4) is fixed in a position on the base (1) and close to the turntable (2), the blowing mechanism (4) and the laminating mechanism (3) are sequentially arranged along the rotating direction of the turntable (2), and the graduator (6), the blowing mechanism (4) and the laminating mechanism (3) are all electrically connected with the control box (5). Compared with the prior art, the automatic blowing and pressing machine disclosed by the invention has the characteristics of higher production efficiency, lower wages, relatively low energy consumption, and capability of enabling the production cost of electromagnetic valves to be lower.

Owner:NINGBO AOKAI COMBUSTION GAS APPLIANCE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com