Automatic berthing device for ship

An automatic device and ship technology, which is applied to ship cleaning devices, ship hulls, ship parts, etc., and can solve problems such as major safety hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

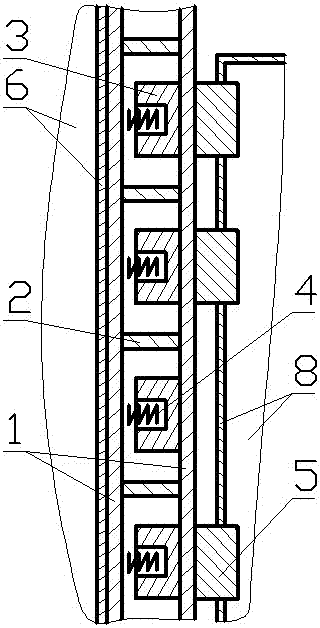

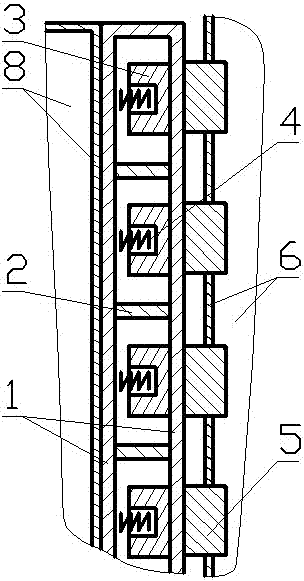

[0031] The ship docking automatic device of the present invention includes two parts, a cushioning airbag and a suction device; the buffer airbag includes an airbag shell 1 and a compartment 2; the described suction device includes an electromagnet 3, a buffer spring 4, a touch Body 5;

[0032]One side of the airbag shell 1 is fixed on the lateral ship's side of the pontoon 6 or fixed on the lateral ship's side of the boat 8, and the airbag shell 1 is divided into several independent airbags by compartments 2 in the airbag shell 1. Chamber; a buffer spring 4 and an electromagnet 3 are installed in the gas chamber, and one end of the buffer spring 4 is fixed on the wall of the chamber in the airbag shell 1 on the side of the side of the barge 6 or on the side of the side of the boat 8 On the wall of the chamber in the airbag shell 1, the other end of the buffer spring 4 is pushed against the bearing hole or ring groove of the iron core at one end of the electromagnet 3, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com