Fast cleaning method for building plastic templates

A technology for plastic formwork and construction, applied in cleaning methods and utensils, cleaning methods using liquids, construction, etc., can solve the problems of formwork damage and damage, unsatisfactory cleanliness, high wage costs, etc., to achieve small workload and low cost , the effect of not hurting the template

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

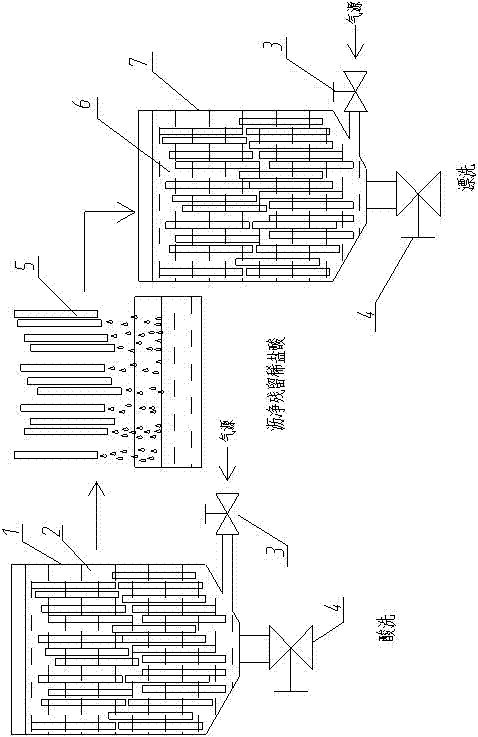

[0013] As shown in the figure, add enough dilute hydrochloric acid solution 2 into the plastic container 1, immerse the architectural plastic template 5 to be cleaned in the dilute hydrochloric acid solution 2, and then open the plastic air valve 3 to let the dilute hydrochloric acid solution 2 roll and flow until it remains on the template Clean the cement slurry blocks, take out the building plastic formwork 5, drain the dilute hydrochloric acid solution 2 remaining on the formwork, and then put it into a clear water pool 7 filled with clear water 6 for rinsing. When rinsing, open the plastic air valve 3 to let the clear water 6 tumble and flow Take it out in a few minutes.

[0014] The concentration of the above dilute hydrochloric acid can be controlled at 2mol-6mol according to the amount of residual cement slurry blocks on the formwork.

[0015] Using the above technical method to clean and treat the used building plastic formwork has the following significant advantage...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com