Clamp for template reinforcing

A formwork reinforcement and fixture technology, which is applied in the connection of formwork/formwork/work frame, the preparation of building components on site, construction, etc., can solve the problem of fastening and dismantling, cleaning and recycling of materials, labor-intensive man-hours, and turnover of materials Unfavorable unified storage management, increased project labor costs and other issues, to achieve the effect of unified recycling management, cost control, and cost control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with the accompanying drawings of the description.

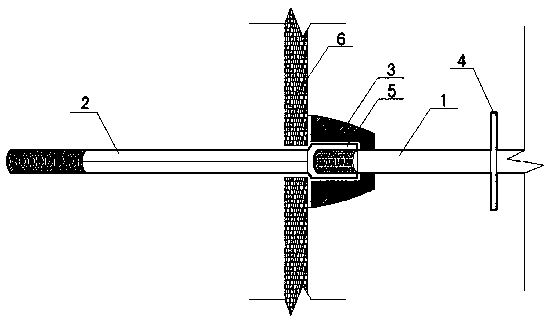

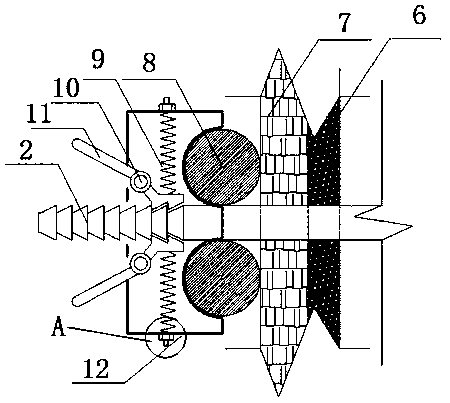

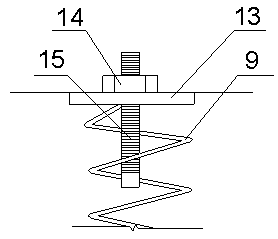

[0027] Such as Figure 1-4 As shown, a fixture for formwork reinforcement, including fixed screw 1, detachable wall bolt 2, rubber bowl 3, water stop piece 4, internal thread sleeve 5, formwork 6, square wood 7, steel pipe 8, pressure Tighten spring 9, fixed shaft 10, trigger 11, clamp housing 12, spring seat 13, adjusting nut 14, thread adjusting rod 15, trigger lever 16, trigger head 17 and connecting sleeve 18.

[0028] The detachable wall-through bolt 2 is connected with both ends of the fixed screw 1, and the two ends of the fixed screw 1 are provided with external threads, and the middle position is fixed with a water-stop sheet 4. One end of the detachable wall-through bolt 2 is provided with an internal thread sleeve 5, and the other end There is a first inverted tooth structure, and the detachable wall-through bolt 2 is fixedly connected wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com