Intelligent welding tool for blades of petroleum drill bit

A technology of blades and drill bits, which is applied in the field of blade intelligent welding tooling, can solve the problems of low overall efficiency, and achieve the effects of high work efficiency, short training period and simple training

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

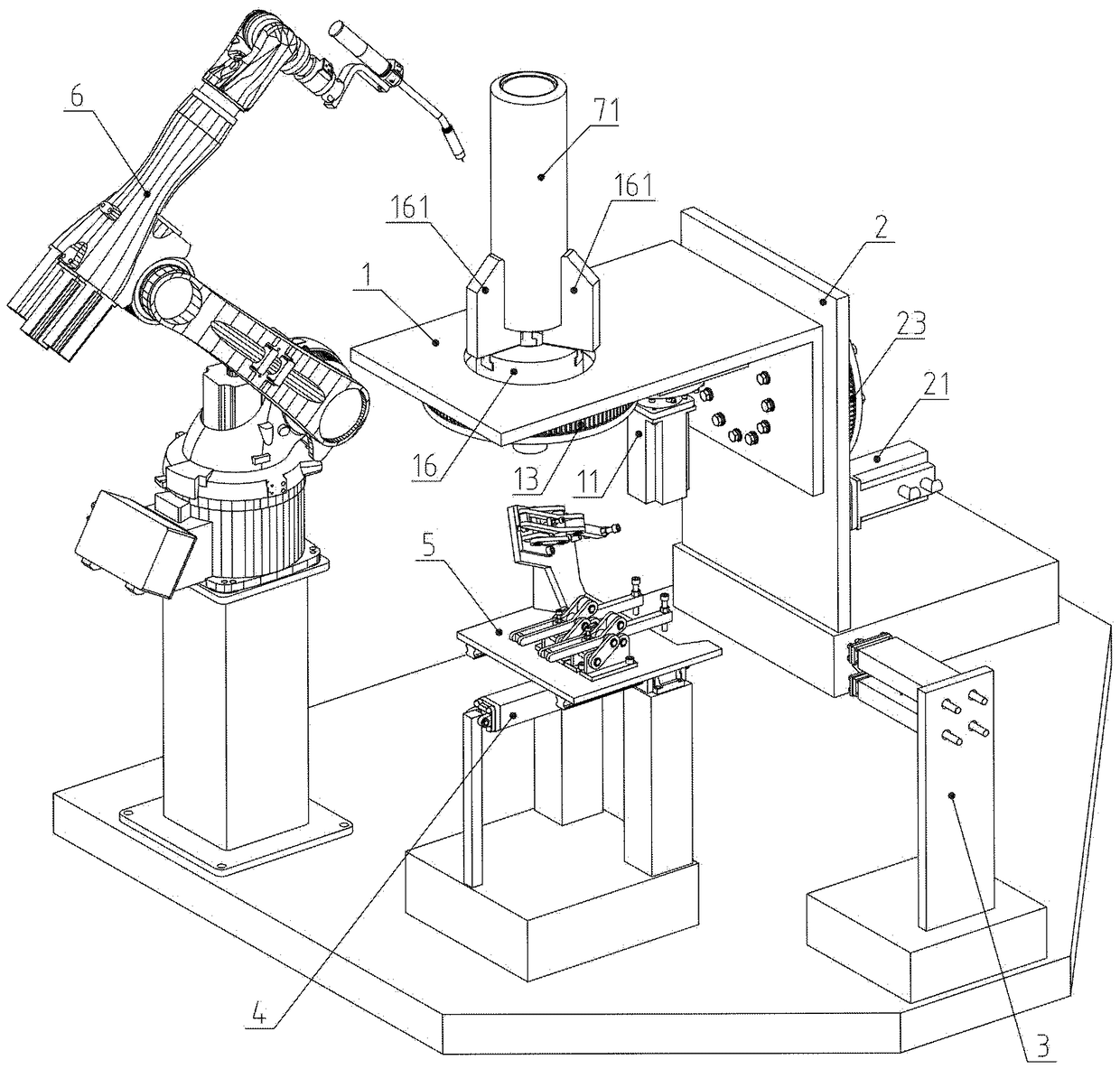

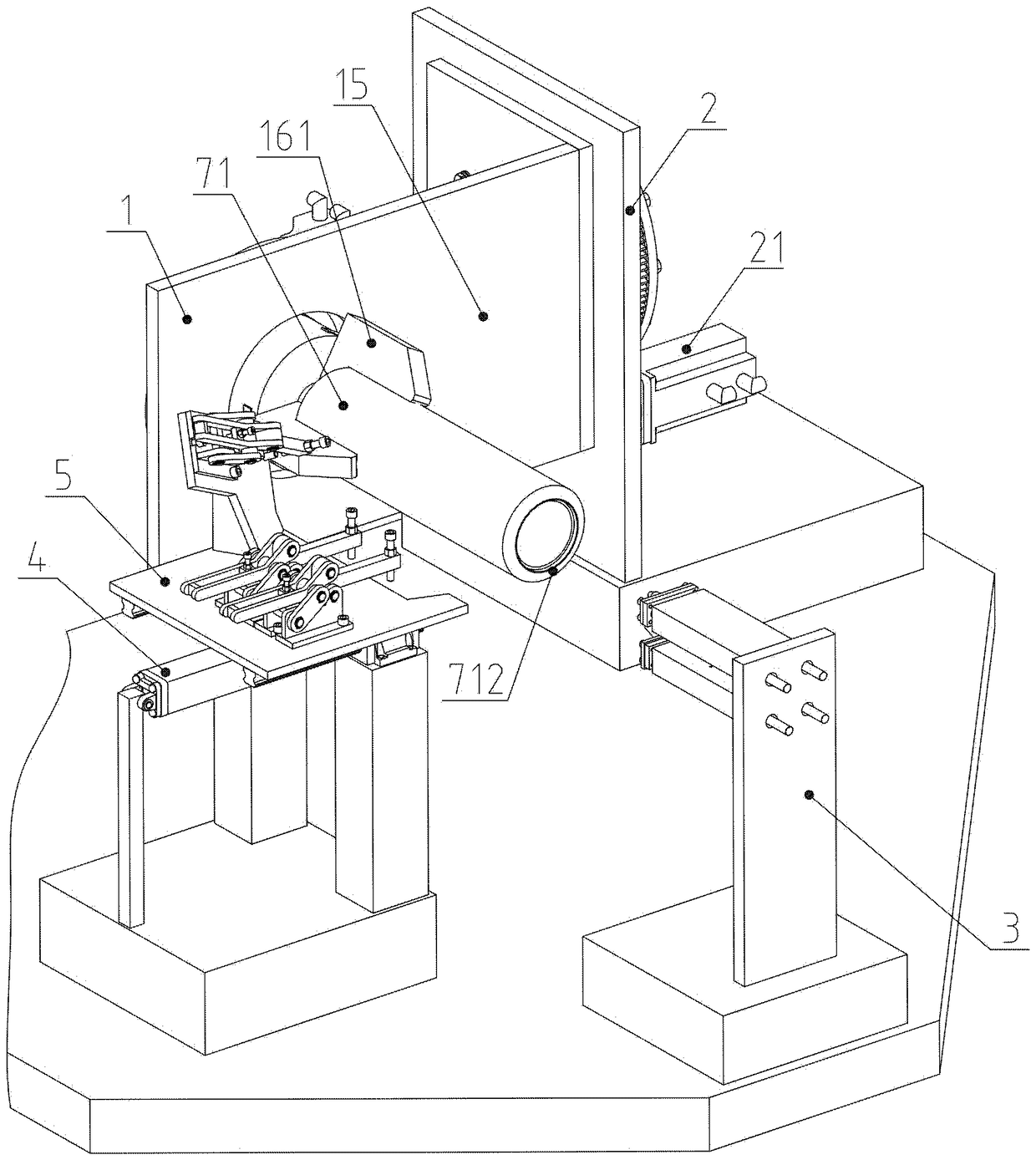

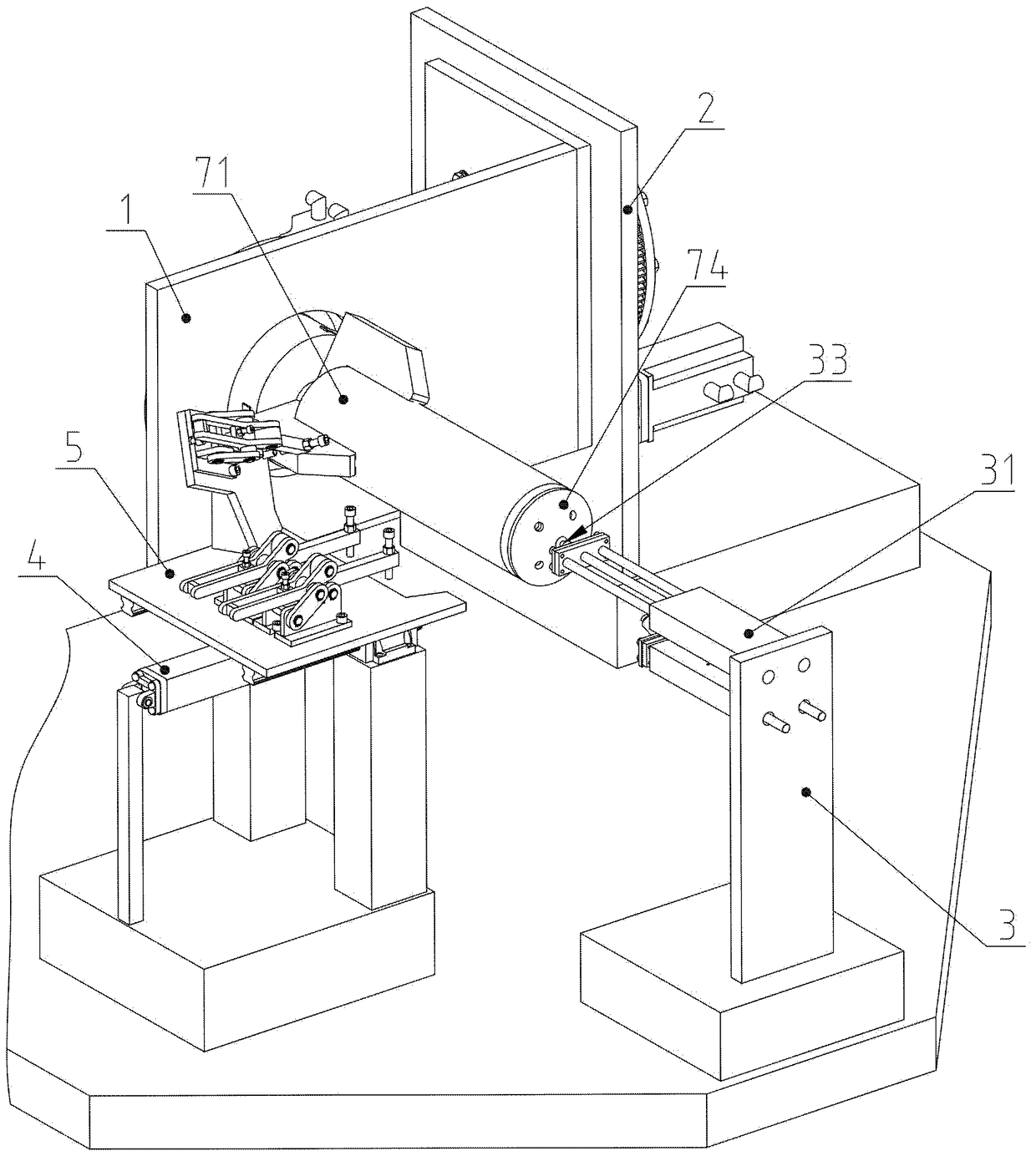

[0059] Example: see Figure 1 to Figure 20 .

[0060] An intelligent blade welding tool for an oil drill bit, including a chuck assembly 1, a flip driving assembly 2, a round cap positioning assembly 3, a pushing assembly 4, a blade pressing assembly 5 and a welding robot 6;

[0061] Chuck assembly 1 comprises servomotor-reducer combination-11, drive gear-12, slewing bearing-13, chuck support 15 and hydraulic pressure chuck 16; Chuck support 15 comprises two rectangular plates, wherein a rectangular plate is Chuck support rotating plate 151, another rectangular plate is chuck support vertical plate 152, and chuck support vertical plate 152 is vertically arranged, and a limit of chuck support rotating plate 151 is fixedly connected with a limit of chuck support vertical plate 152 The slewing bearing 13 includes a support outer ring 131 and a support inner ring 132, and the support outer ring 131 has cylindrical gear outer teeth, and the support inner ring 132 is fixedly connec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com