Copper connector and production method thereof

A production method and technology of copper joints, applied in the direction of pipes/pipe joints/fittings, hose connection devices, mechanical equipment, etc., can solve the problems of thinning of hose joints, poor connection stability, and easy fall of hoses, etc., to achieve Low production cost, high production efficiency, and the effect of reducing wage costs and production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] The production method of the copper joint described in any one of the preceding claims, comprising the following steps:

[0031] 1. Cutting blank tube: the length of blank tube is 1000mm;

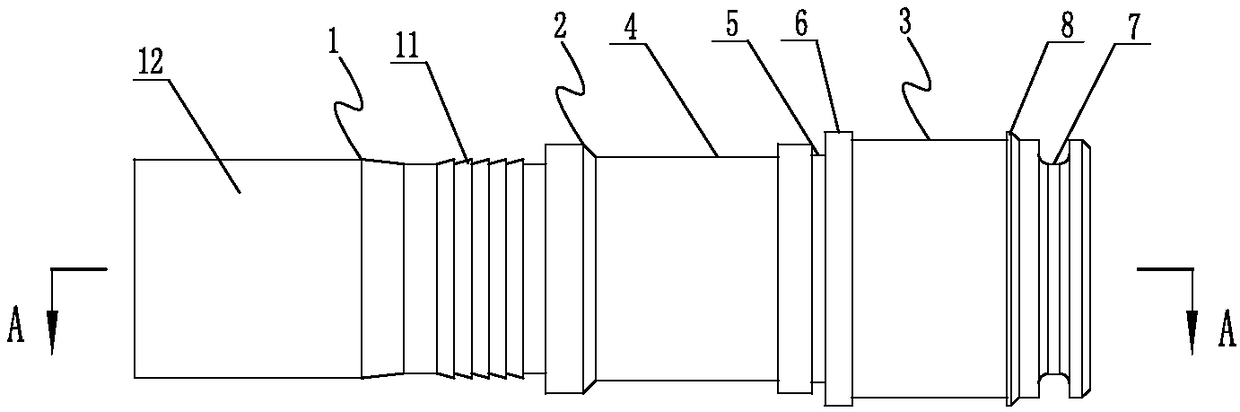

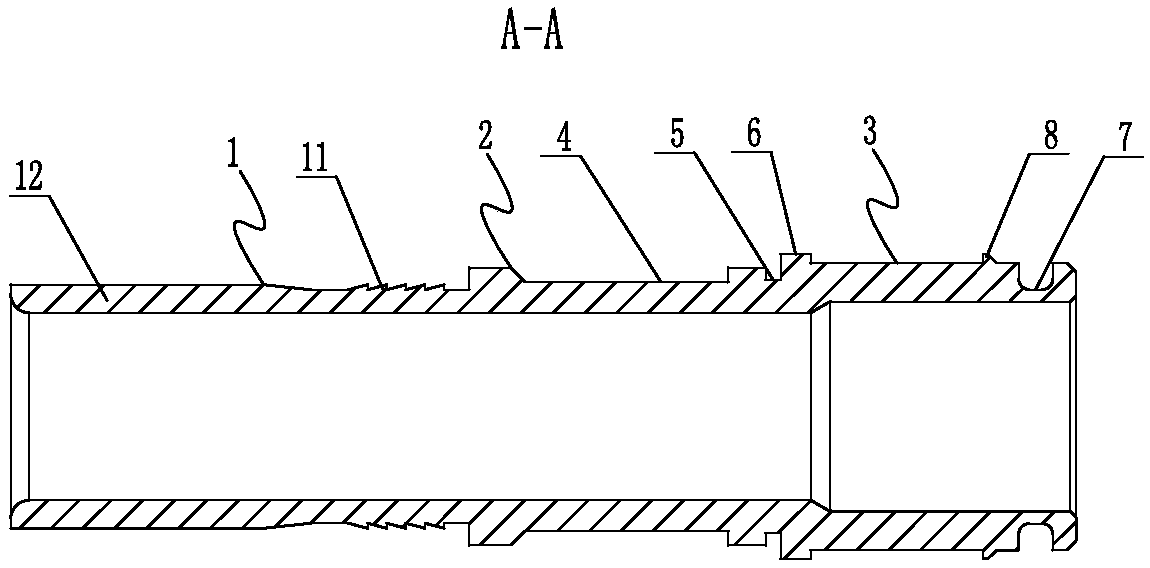

[0032] 2. Machining: During processing, the blank tube is inserted from the rear end of the CNC machine tool to the fixture, and the rear end of the CNC machine tool is equipped with an automatic feeding device for the blank tube; and the cutter head starts processing from the fixed part 3. The connection part 1 is cut off, and the process before cutting is the rounding of the inner hole of the connection part 1, that is, before cutting, the inner hole of the connecting part 1 is rounded; the inner hole rounding of the connection part 1 is performed using a special tool 9 ;

[0033] 3. After collecting and inspecting the blanks in step 2, they can be packed.

[0034] Described special cutter 9 comprises cutter bar 91 and cutter head 92, and described cutter head 91 is fixed on an e...

Embodiment 2

[0036] The production method of the copper joint described in any one of the preceding claims, comprising the following steps:

[0037] 1. Cut blank tube: the length of blank tube is 1500mm;

[0038] 2. Machining: During processing, the blank tube is inserted from the rear end of the CNC machine tool to the fixture, and the rear end of the CNC machine tool is equipped with an automatic feeding device for the blank tube; and the cutter head starts processing from the fixed part 3. Cut off at the connection part 1, and the previous process of cutting is the rounding of the inner hole of the connecting part 1; the rounding of the inner hole of the connecting part 1 is performed with a special tool 9;

[0039] 3. After collecting and inspecting the blanks in step 2, they can be packed.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com