Automatic material height detection device used in transportation process and method

An automatic detection device and transportation process technology, applied in the direction of measuring devices, lubrication indicator devices, engine components, etc., can solve the problems of inconsistency in the specifications and models of the cargo boxes of transport vehicles, restrictions on the level of accurate accounting of production costs, and high labor intensity of billing workers and drivers. , to achieve the effect of improving the level of safety production management, greatly promoting the value of use, and reducing the use of billing personnel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

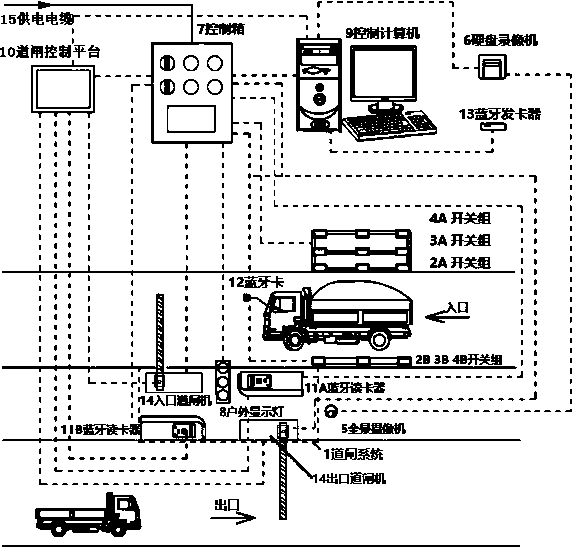

[0026] First build and install the one-entry-one-exit gate system 1 (including sentry boxes, passages, speed bumps, lights, etc.), adopt the construction method of one entry and one exit, and close the entrances and exits of other vehicles in the yard at the same time. In the vehicle parking area of the barrier gate system, install height detection infrared beam switch groups 2, 3, and 4 (24VDC power supply, contact output, each group has 3 pairs of infrared beam switches), and the installation height of switch groups 2, 3, and 4 depends on transportation Vehicle's low limit, normal height and overrun height installation settings. The specific installation is: switch group 2 corresponds to the lower limit monitoring point of the car material, the installation height is 15 cm above the upper edge of the carriage, switch group 3 is installed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com