Heated mould continuous casting-continuous drawing method of cupronickel alloy condenser pipes

A technology of condenser tube and cupronickel tube is applied in the field of preparation of cupronickel alloy pipes, which can solve the problems of inability to produce super-long copper alloy condenser tubes, high cost, low product quality, etc., so as to reduce the loss of extrusion tools and the cost of personnel wages. , The effect of preventing product transfer bumps and eliminating pickling metal loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

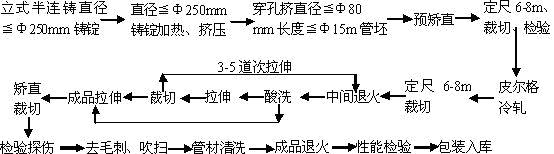

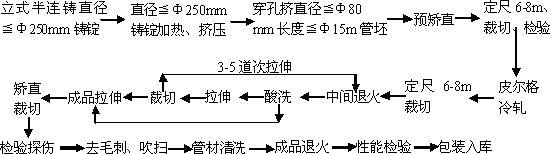

Image

Examples

Embodiment 1

[0022] In step 2), the tube blank with a diameter greater than or equal to 1mm and less than or equal to 50mm is subjected to joint drawing, and the three-pass drawing in step 3) is disk drawing.

Embodiment 2

[0024] In step 2), the pipe blank with a diameter greater than 50 mm and less than or equal to 108 mm is subjected to joint drawing, and the 3-pass drawing in step 3) is straight drawing.

Embodiment 3

[0026] In step 2), the pipe blank with a diameter greater than 108 mm and less than or equal to 319 mm is subjected to simultaneous drawing, and the 3-pass drawing in step 3) is diameter-expanding drawing.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com