Method for producing paper tubes by waste paper pulp

A production method and technology for waste paper pulp, which are applied in paper/cardboard containers, envelope/bag manufacturing machinery, containers, etc., can solve the problems of low efficiency and high production cost of paper tubes, and achieve high commercial value, high production speed and low cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

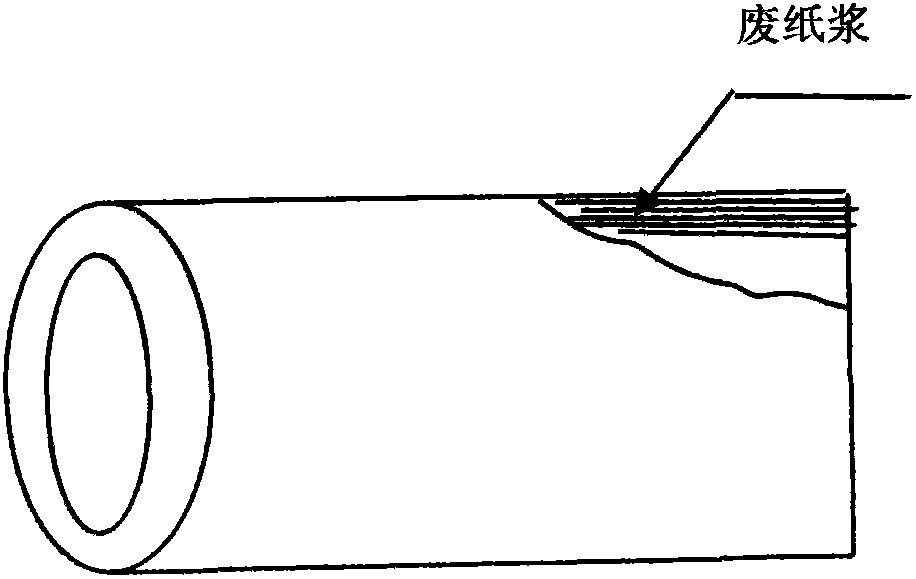

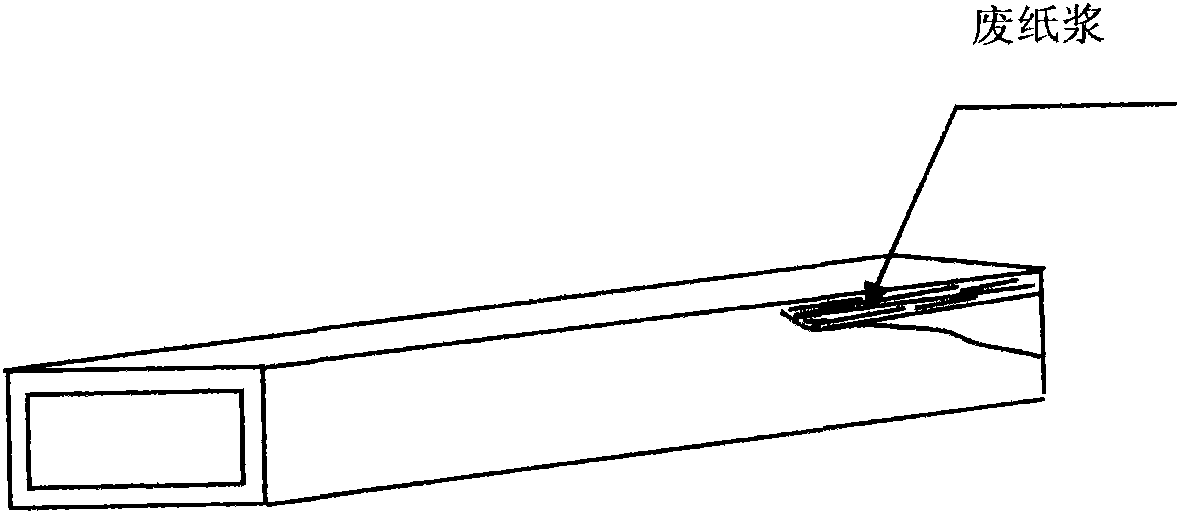

Image

Examples

Embodiment 1

[0023] Embodiment 1: Get 500 kilograms of waste paper pulp extracted with environmental protection technology in the production of paper mills, pulverize it evenly for future use with a pulverizer, get 50 kilograms of stone powder for future use, get 45 kilograms of water to boil, get 5 kilograms of polyvinyl alcohol, and stir Put the waste paper pulp, stone powder and glue into the mixer to mix evenly, send the mixed waste paper pulp into the hopper of the extruder through the conveyor, open the extruder to extrude the waste paper pulp Extruder die mouth output, turn on the cutting knife motor, the paper tube will be cut off automatically with the cutting knife after reaching the required length, the conveyor will automatically send the cut paper tube into the high-temperature drying tunnel, and the paper tube will be dried through the high-temperature drying tunnel Send it out after drying, and it will become a qualified paper tube.

Embodiment 2

[0024] Embodiment 2: Take 500 kilograms of waste cardboard, put it into a beater and beat it into pulp for later use, take 50 kilograms of stone powder for later use, take 45 kilograms of water and boil it, take 5 kilograms of polyvinyl alcohol, put it in while stirring, and make glue, put Put the waste paper pulp, stone powder and glue into the mixer and stir evenly, send the mixed waste paper pulp into the hopper of the extruder through the conveyor, open the extruder to extrude the waste paper pulp and output it from the die mouth of the extruder, and open the cutting knife Motor, after the paper tube reaches the required length, it is automatically cut off with a cutting knife, and the conveyor automatically sends the cut paper tube into the high-temperature drying tunnel, and the paper tube is sent out after being dried in the high-temperature drying tunnel, and it becomes a qualified paper tube .

Embodiment 3

[0025] Embodiment 3: Get 250 kilograms of waste paper pulp obtained with an environmentally friendly method in the production of a paper mill, pulverize it evenly for future use with a pulverizer, get 250 kilograms of waste cardboard, beat it into pulp with a beater for future use, get 50 kilograms of stone powder for future use, and get 45 kilograms of water Boil, take 5 kg of polyvinyl alcohol, put it into the glue while stirring, put the pulp, stone powder, and glue into the mixer and stir evenly, send the mixed waste paper pulp into the hopper of the extruder through the conveyor, and start the extrusion After the waste paper pulp is extruded by the extruder, it is output from the die mouth of the extruder, and the cutting knife motor is turned on. After the paper tube reaches the required length, it is automatically cut off by the cutting knife, and the conveyor automatically sends the cut paper tube into the high-temperature oven. Road, the paper tube is sent out after be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com