Profile feeding device for feeding machine

A technology of feeding device and profile, which is applied in the direction of sawing device, metal sawing equipment, metal processing equipment, etc. It can solve the problems of high labor intensity, low processing precision, and easy jumping of profiles, so as to reduce processing hours and reduce processing costs. The effect of uniform force and reducing the amount of scrapped tailings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

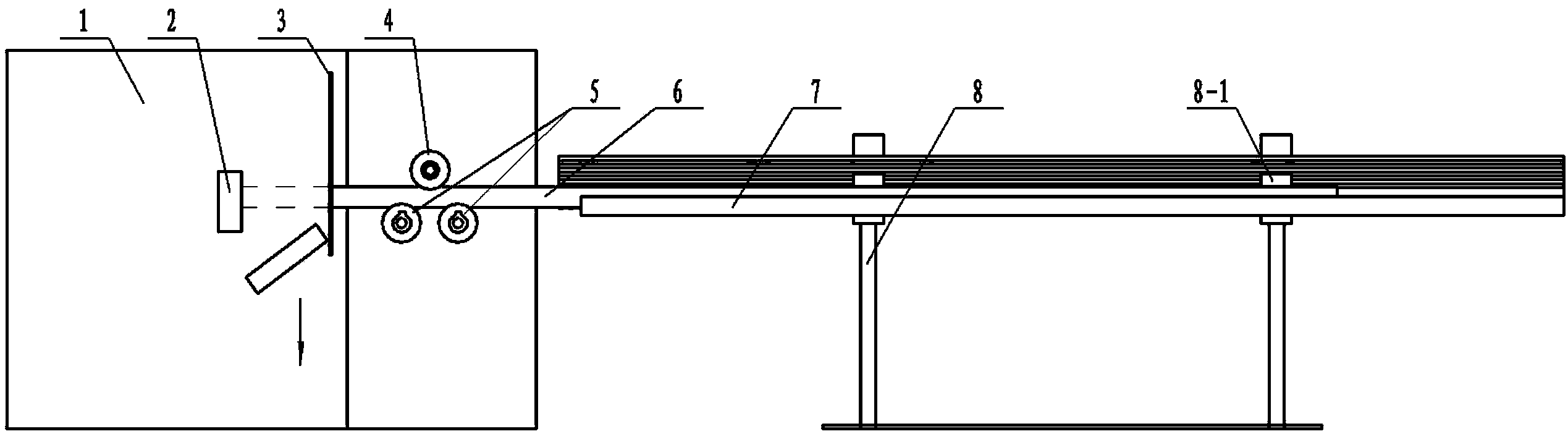

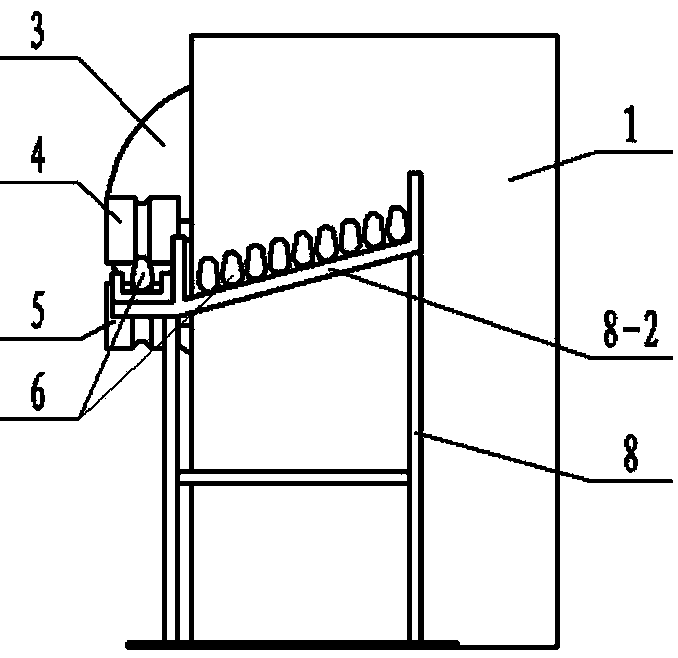

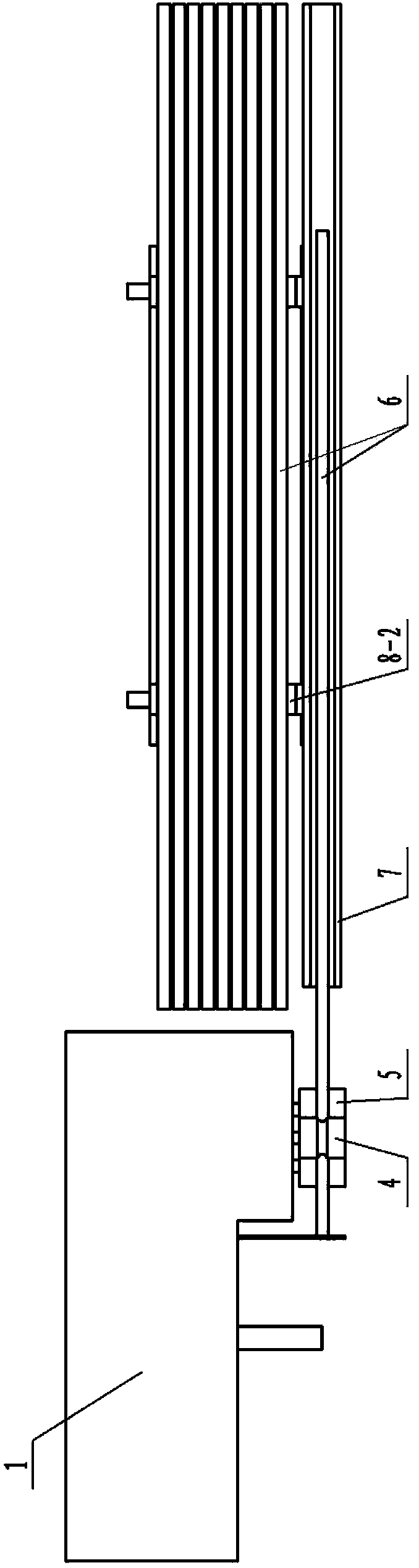

[0023] Figure 1 to Figure 3 The material feeding device of the blanking machine shown mainly includes a limit block 2, a feeding roller, a feeding guide rail 7 and a material rack 8. The limit block 2 and the feeding roller are installed on the blanking machine 1, and the feeding guide rail 7 is arranged on the One side of the feeder 1 is also facing the feeding roller. The feeding roller includes a pressing roller 4 and two supporting rollers 5 arranged below the pressing roller 4. The pressing roller 4 and the two supporting rollers 5 are arranged alternately. The pressing roller 4 The surface of the idler roller 5 is provided with positioning grooves 4-1, 5-1 matching the outer contour of the profile to be processed, and the surface roughness of the positioning grooves 4-1, 5-1 of the pressure roller 4 and the idler roller 5 is 3.2 microns, see Figure 4 and Figure 5 The material rack 8 is arranged on the side of the feeding guide rail 7, and the material rack 8 has a m...

Embodiment 2

[0026] The shape of the positioning groove 9-1 of the pressure roller 9 and the positioning groove 11-1 of the supporting roller 11 in the present embodiment are different from that of Embodiment 1, and the positioning groove 9-1 of the pressing roller 9 and the positioning groove of the supporting roller 11 The groove 11-1 is arranged symmetrically according to the profile 10, so as to process positioning grooves of the same shape and size, see Figure 6 and Figure 7 , the surface roughness of the positioning groove 9-1 of the pressure roller 9 and the positioning groove 11-1 of the idler roller 11 is 1.6 microns, and the rest of the features are the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com