Horizontal type double-pair-wheel multifunctional variable-size composite flexible spinning equipment

A technology of composite flexible and spinning equipment, applied in other manufacturing equipment/tools, manufacturing tools, etc., to achieve balanced force, good spinning effect, and easy manufacturing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

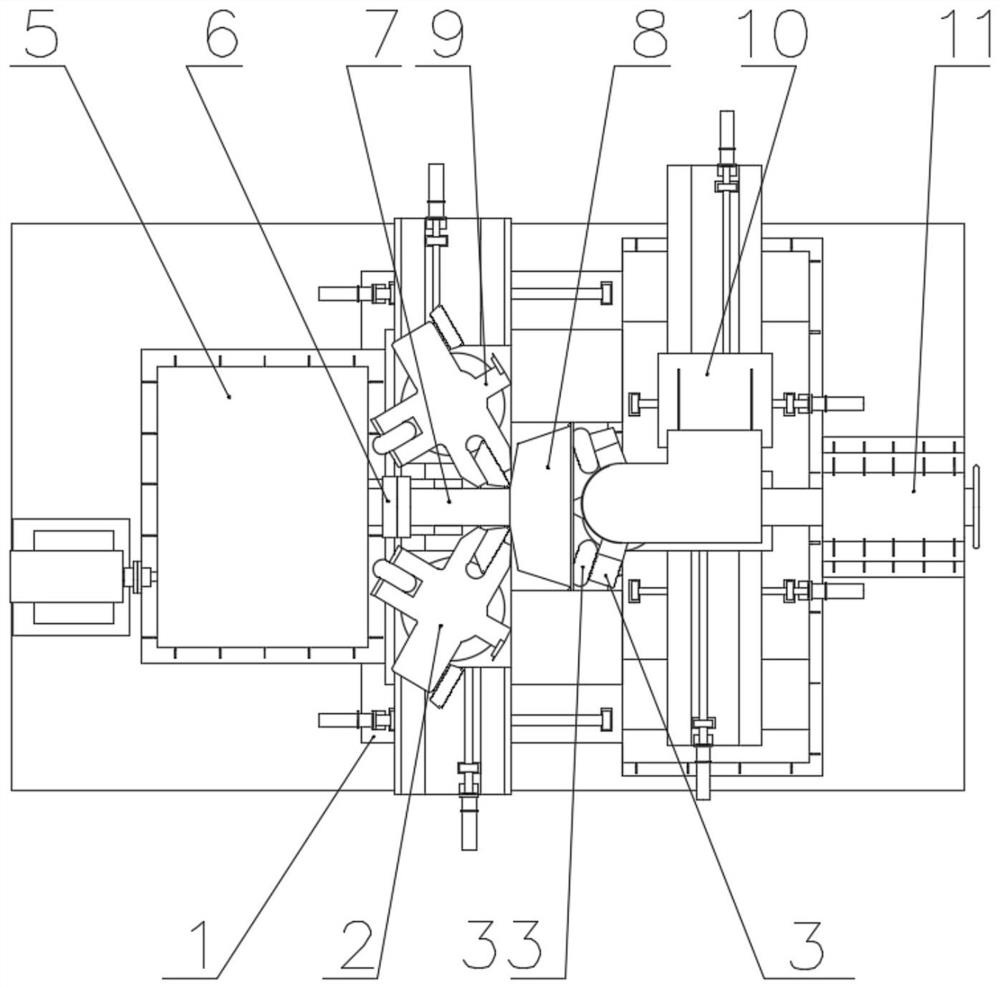

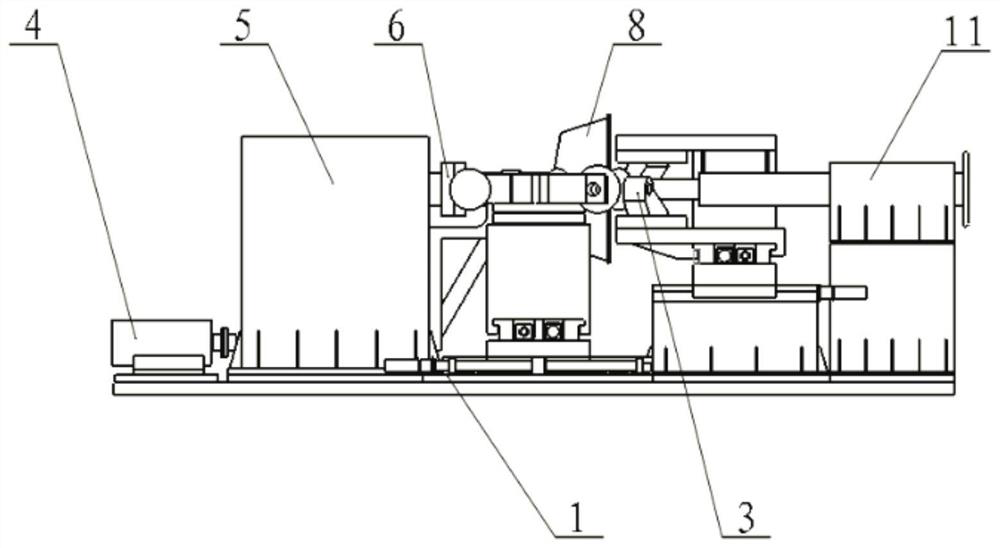

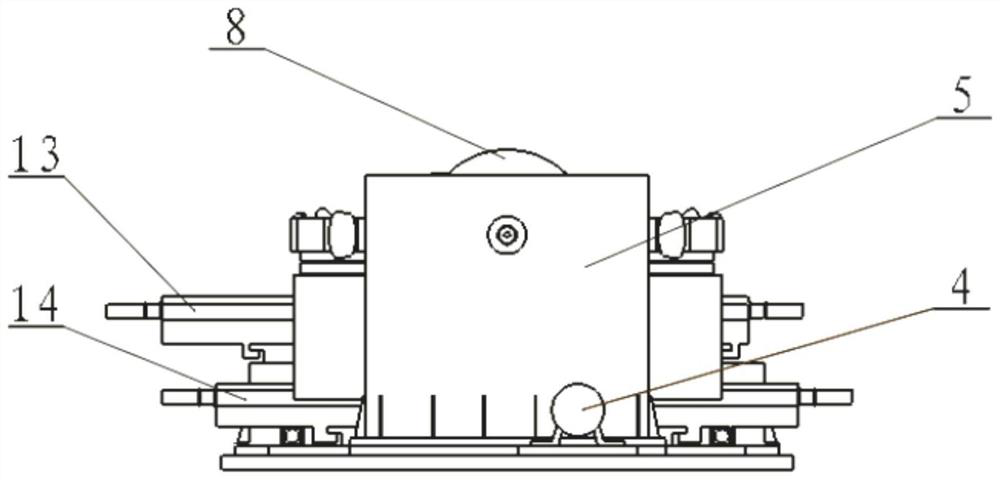

[0038] The structure of the spinning machine in this embodiment, the top view of the wheel flexible spinning equipment is as follows figure 1 As shown, the main components are: bed 1, outer rotation wheel assembly A2, inner rotation wheel assembly A3, spindle motor 4, gear box 5, main shaft 6, process axis 7, workpiece 8, outer rotation wheel assembly B9, inner rotation Wheel assembly B10, tail top 11 and inner rotation wheel 33;

[0039] The main shaft motor 4 of the equipment is connected with the gear box 5 through a coupling, and the interior of the gear box 5 is transferred to the main shaft 6 through gears to make the main shaft rotate. The main shaft 6 can be installed to extend the process shaft 7, and the spinning workpiece 8 is installed on the process shaft 7 and then connected to the main shaft 6. The main shaft and the process shaft are processed with a tapered surface for quick installation and disassembly. The outer rotary wheel assembly A2 and the outer rotary...

Embodiment 2

[0042] In this embodiment, the horizontal double pair of wheel multifunctional and variable-size composite flexible spinning equipment can be formed by one-time spinning, and the wheel seat of the wheel assembly is equipped with a normal wheel 24, an angle wheel 25, and a flanged fixed wheel 28 and cutter 32, such as Figure 8 As shown, the angled rotary wheel is used in the first pass of the initial spinning. Due to the limited space between the workpiece and the spindle, the normal rotary wheel 24 cannot be close to the root. Therefore, the normal spinning process is used first. Initial angle, then select the angle wheel 25, and use the angle wheel 25 to spin to the root, such as Figure 10 shown;

[0043] Then use the normal spinning wheel 24 to carry out the wheel spinning after the spinning space is opened, and use the normal spinning wheel 24 and the internal turning wheel 33 to form the wheel spinning, as figure 1 As shown, due to the small rounded corners at the inne...

Embodiment 3

[0047] In this embodiment, the horizontal double paired wheel multi-functional and variable-size composite flexible spinning equipment can expand the processing capacity. The inner wheel assembly platform of the opposite wheel flexible spinning equipment is a detachable structure, and the inner wheel assembly platform is arranged below. The lead screw guide rail, after being removed, the stroke of the equipment is enlarged, and the form of a single pair of wheels and a mandrel 27 is adopted, which can spin multi-angle, special-shaped, and large-sized workpieces 26 to realize a multifunctional machine, such as Figure 9 shown.

[0048] Therefore, the equipment has spinning, trimming, edge trimming, and can also have a multifunctional machine for mold spinning.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com