Manufacturing method of corrugated heat exchange tube

A manufacturing method and technology for heat exchange tubes, applied in program control, tubular components, computer control, etc., can solve the problems of unsatisfactory surface quality of machined surfaces, irregular shape of heat exchange tubes, low heat exchange efficiency, etc., so as to improve processing Quality and heat transfer efficiency, increase processing contact area, good heat transfer efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] In order to deepen the understanding of the present invention, the present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments, which are only used to explain the present invention and do not limit the protection scope of the present invention.

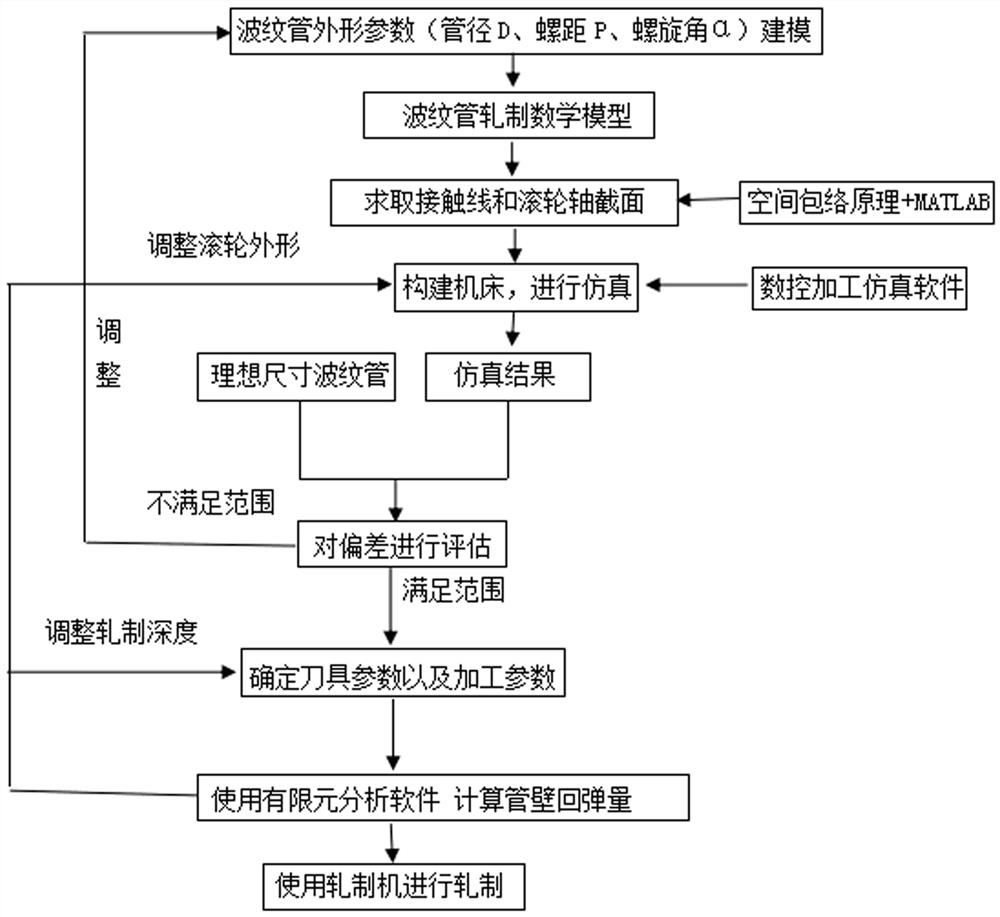

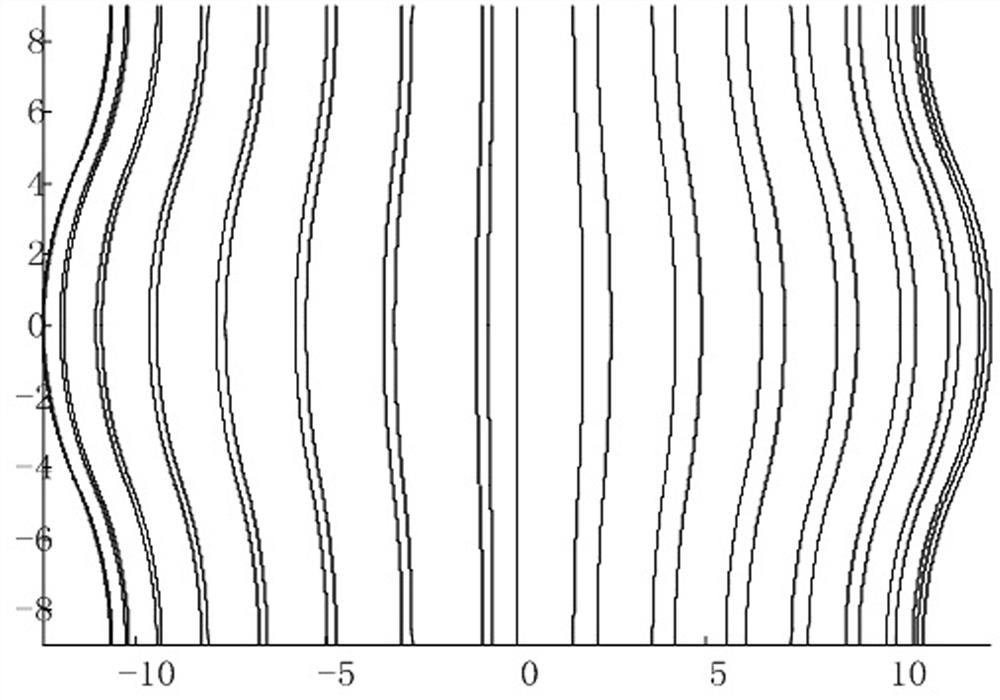

[0044] Such as Figure 1-12 As shown, the present invention is a method for manufacturing corrugated heat exchange tubes. In this embodiment, the rotary surface of the corrugated tube is used as a tool to envelop the helical surface of the tool. Because the two curved surfaces conform to the conjugate relationship, this solution conforms to Conjugate conditions, first establish the mathematical model of bellows processing, and use the space envelope principle to solve the contact line between the rotary surface of the bellows and the tool helical surface, and project it to the axial section of the roller helical surface, according to the data on the contact line Poin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com