Cutter for cutting machining of blade lug boss characteristics

A technology of cutting and bossing, which is applied to lathe tools, cutting blades, manufacturing tools, etc., can solve the problems of low surface quality of blade bosses, high production costs, and low processing efficiency, and increase the processing contact area , surface quality assurance, and the effect of improving processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

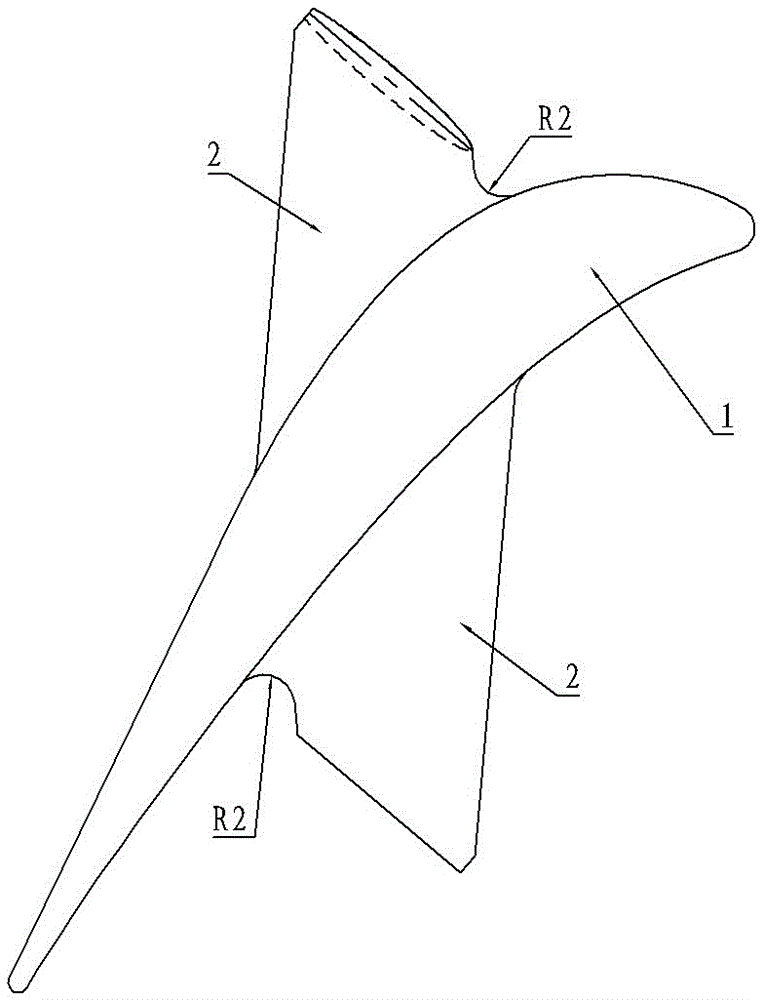

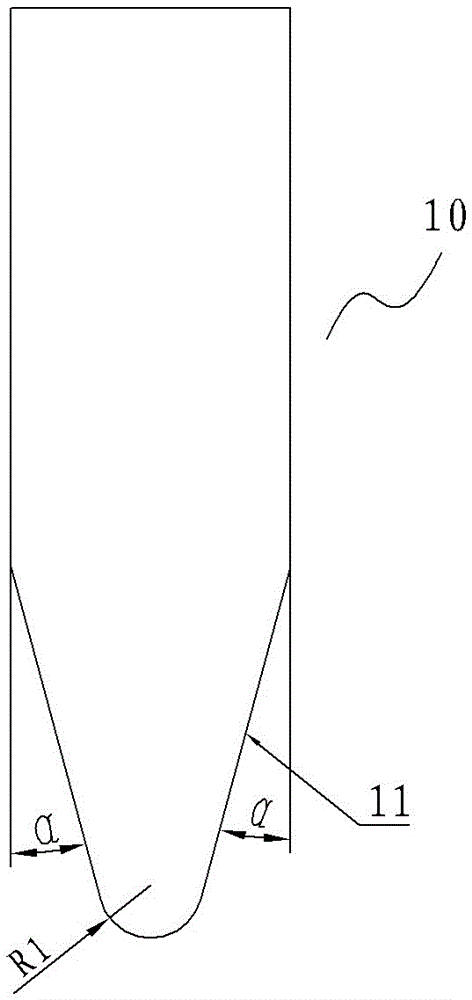

[0010] See figure 2 , the cutting tool 10 used for cutting the blade boss features is a large-angle taper cutter, which includes a side conical surface 11 and a bottom R1 angle. Consistent with the R2 angle of the boss feature of the blade to be processed, the side conical surface is the cutting edge of the tool; the taper α of the side conical surface 11 is 15°; the surface of the side conical surface 11 is sprayed with a titanium nitride coating , so that the wear resistance of the tool can be greatly improved, so the number of blades that can be processed after each tool grinding is greatly increased, and the cost of the tool can also be effectively reduced. After adopting the cutting tool of the present invention, since the machining contact area between the cutting tool and the boss of the blade is greatly increased, the program efficiency is increased by more than 60%, and the number of blades that can be processed in a single grinding is increased from 2 pieces of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com