Patents

Literature

79 results about "Program Efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Code efficiency is a broad term used to depict the reliability, speed and programming methodology used in developing codes for an application. Code efficiency is directly linked with algorithmic efficiency and the speed of runtime execution for software.

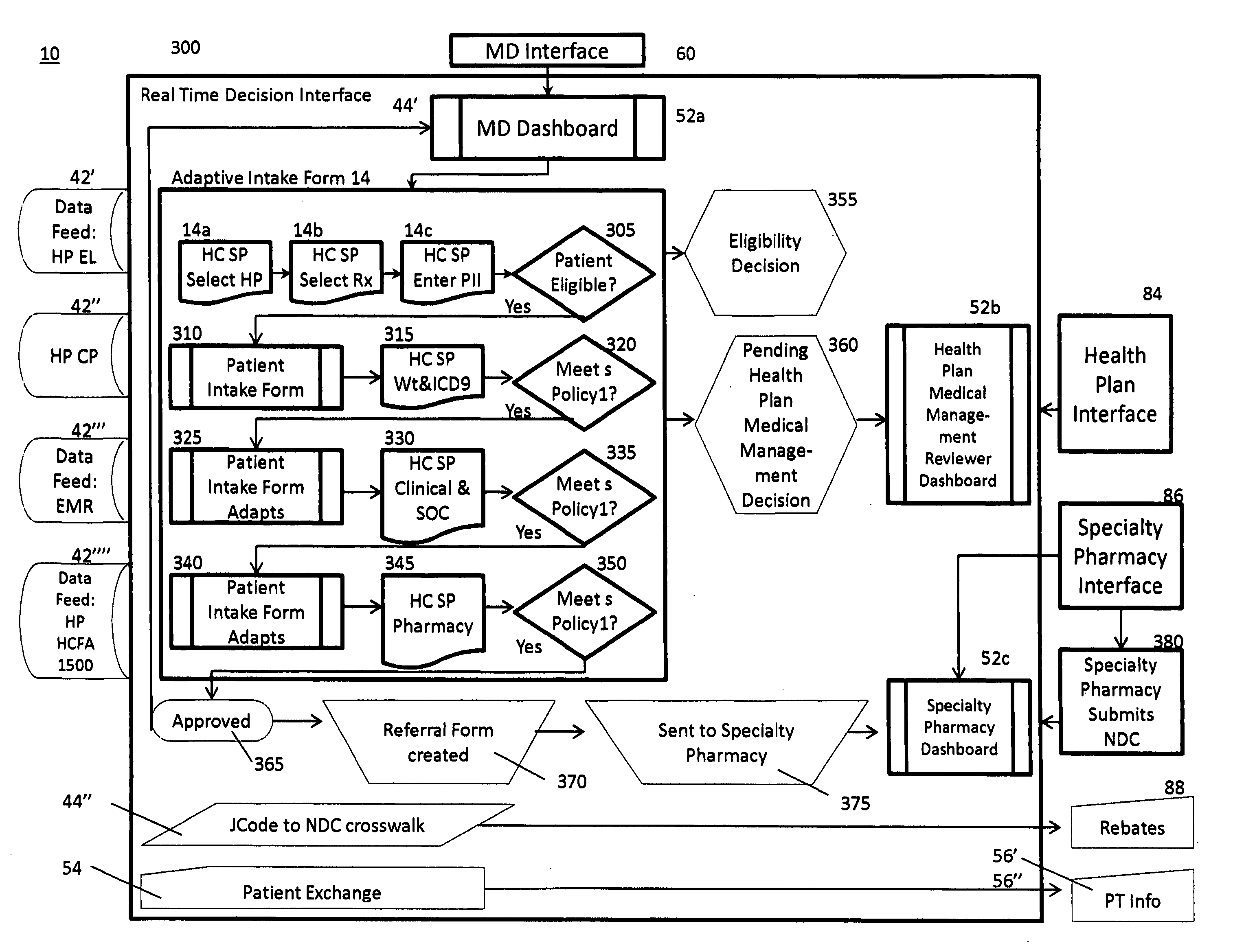

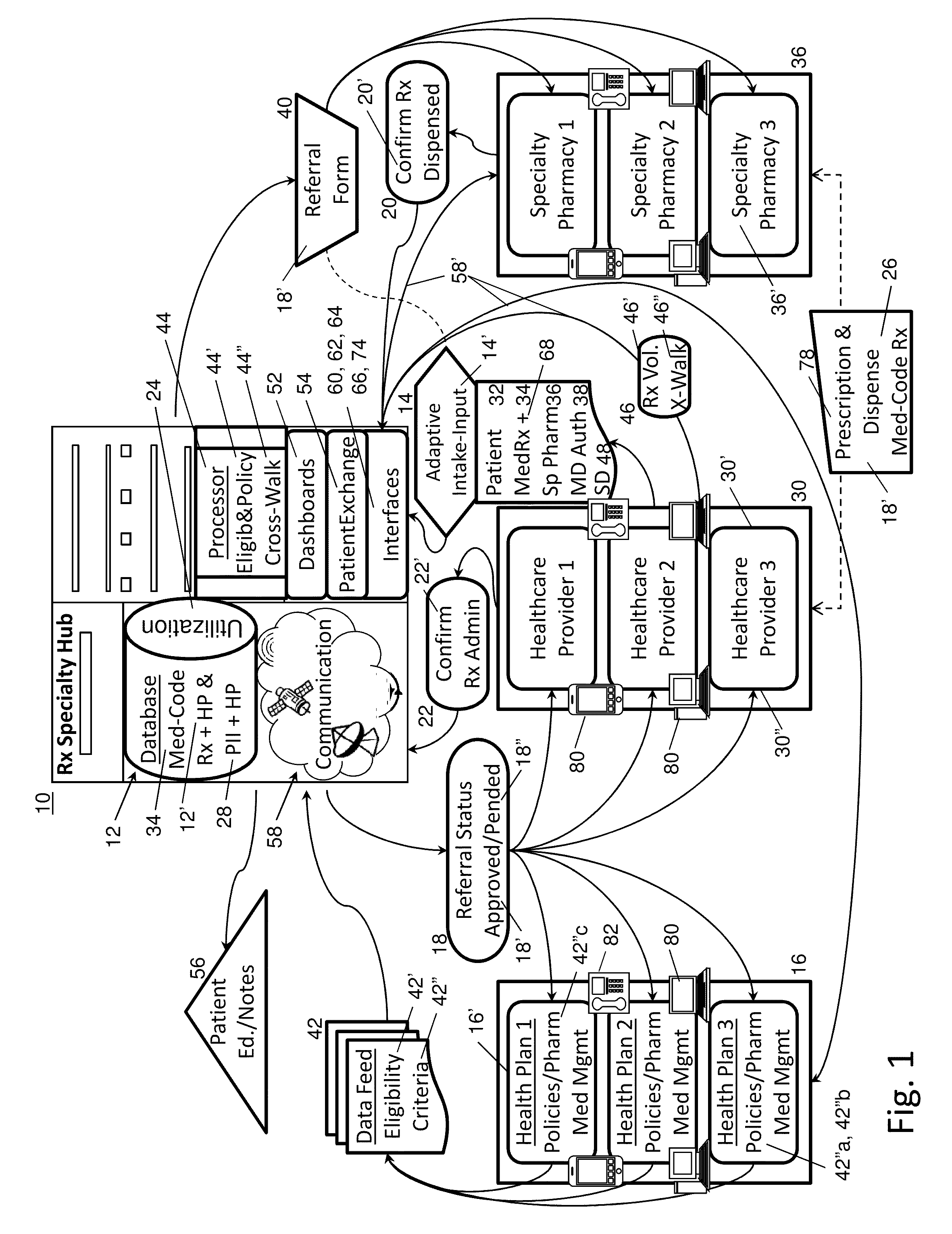

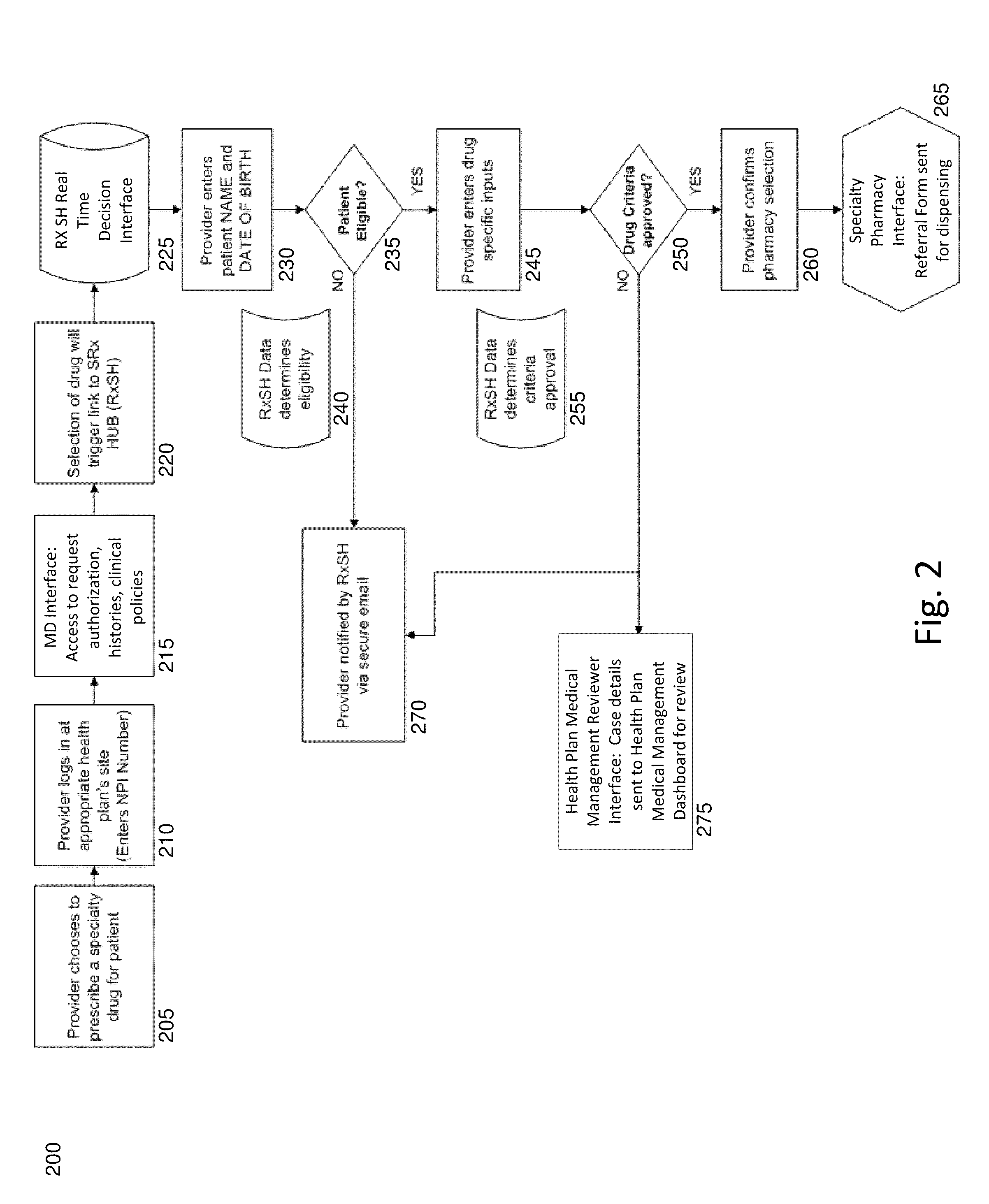

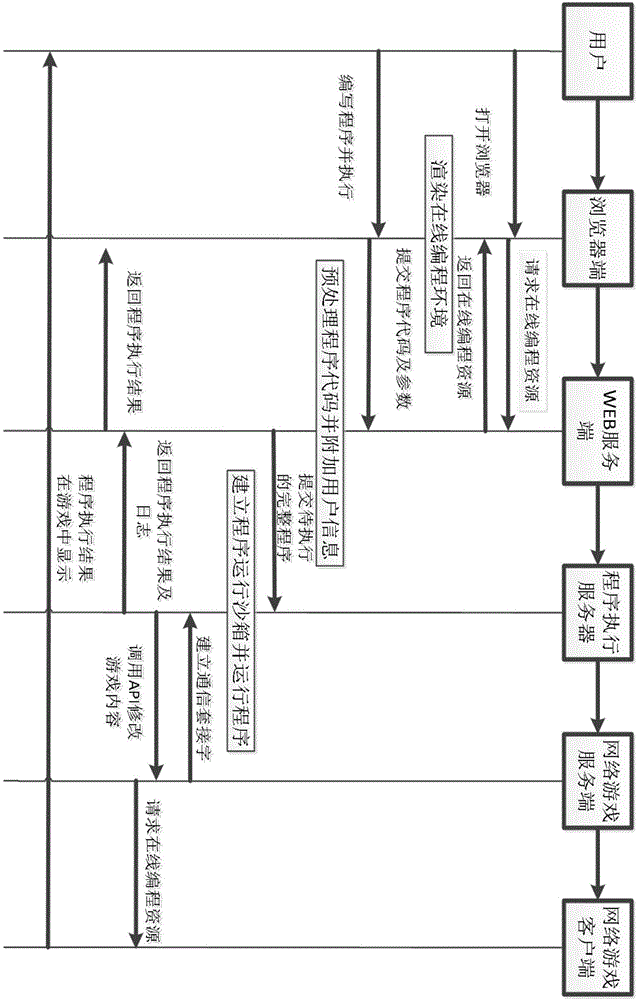

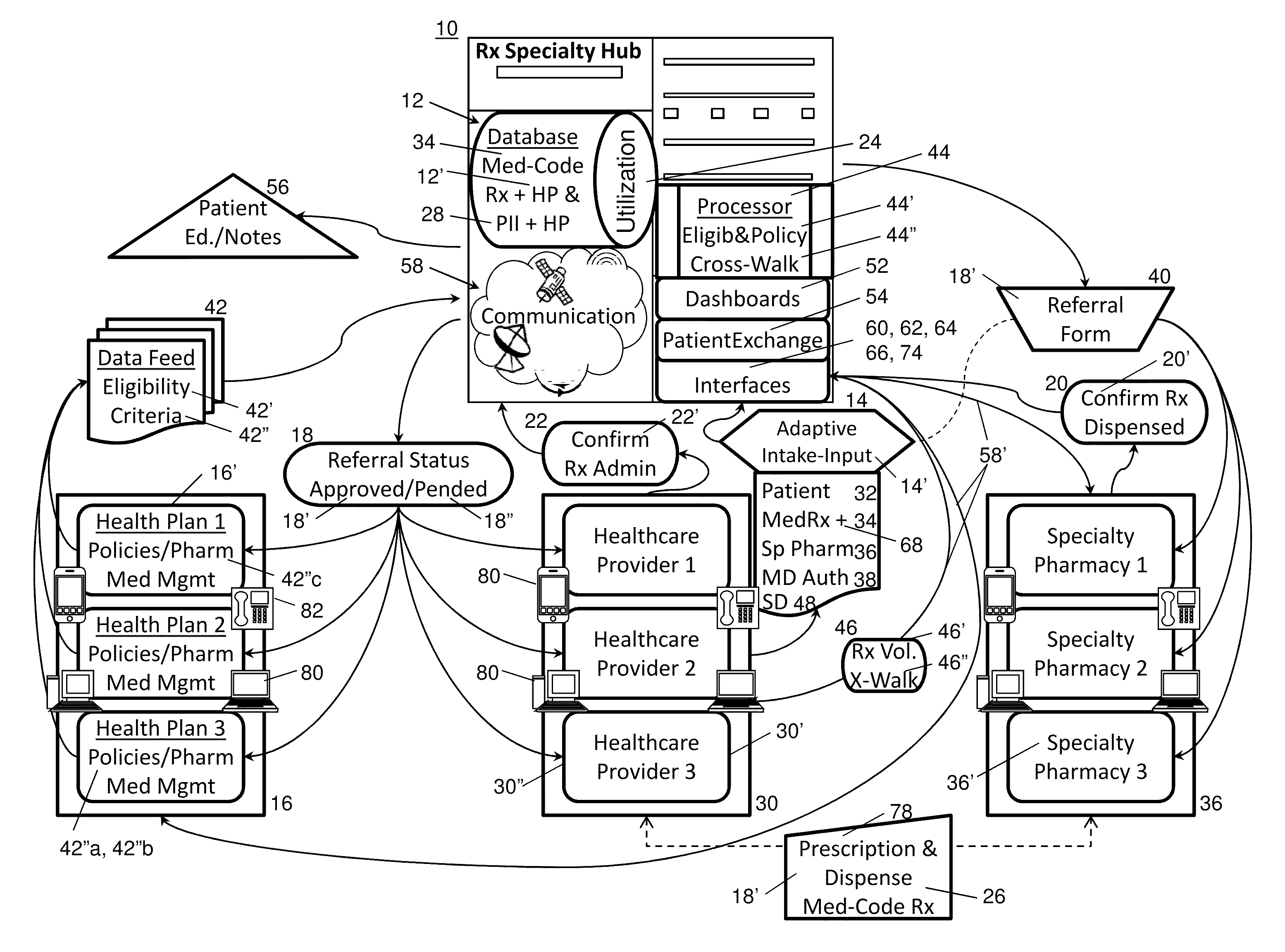

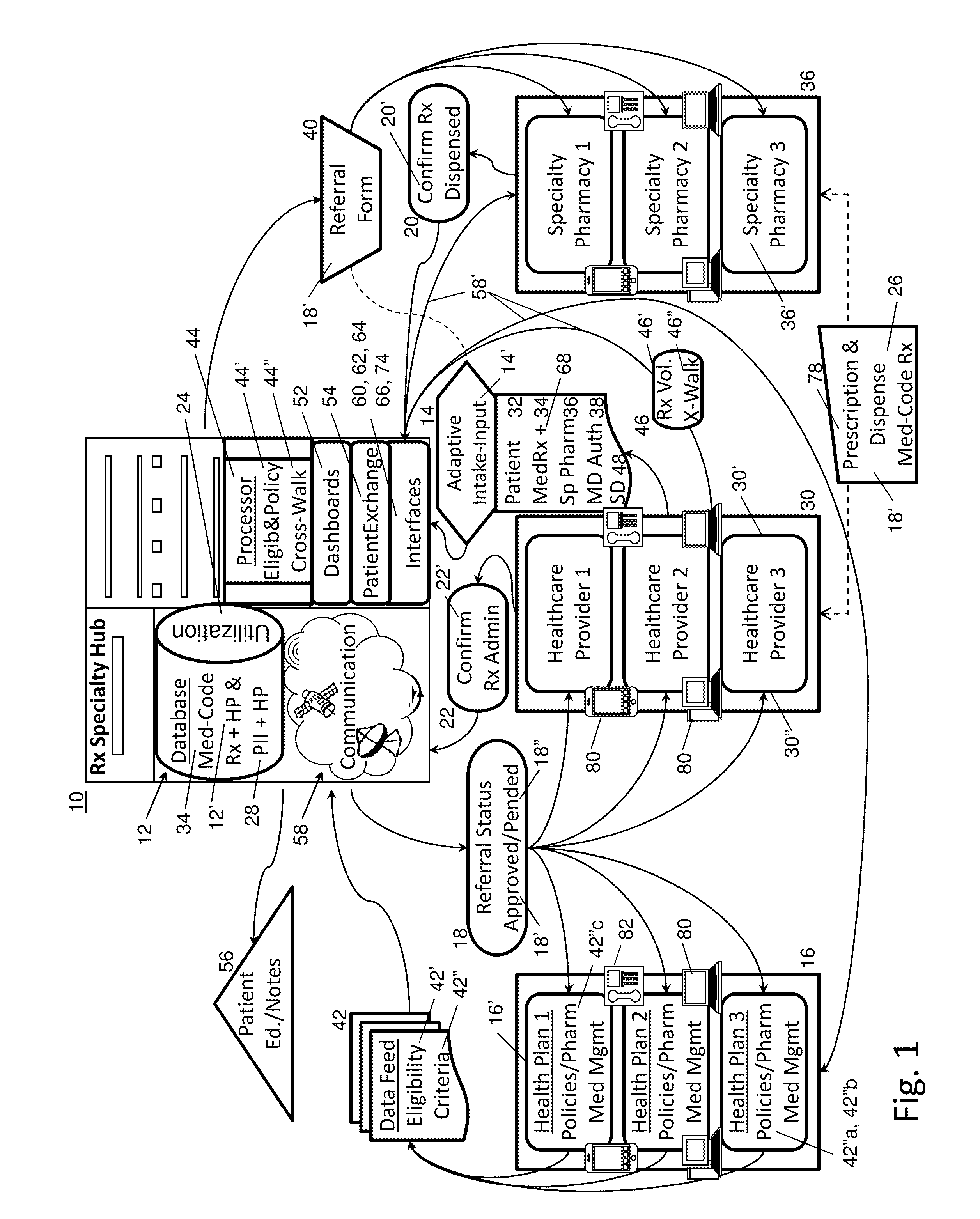

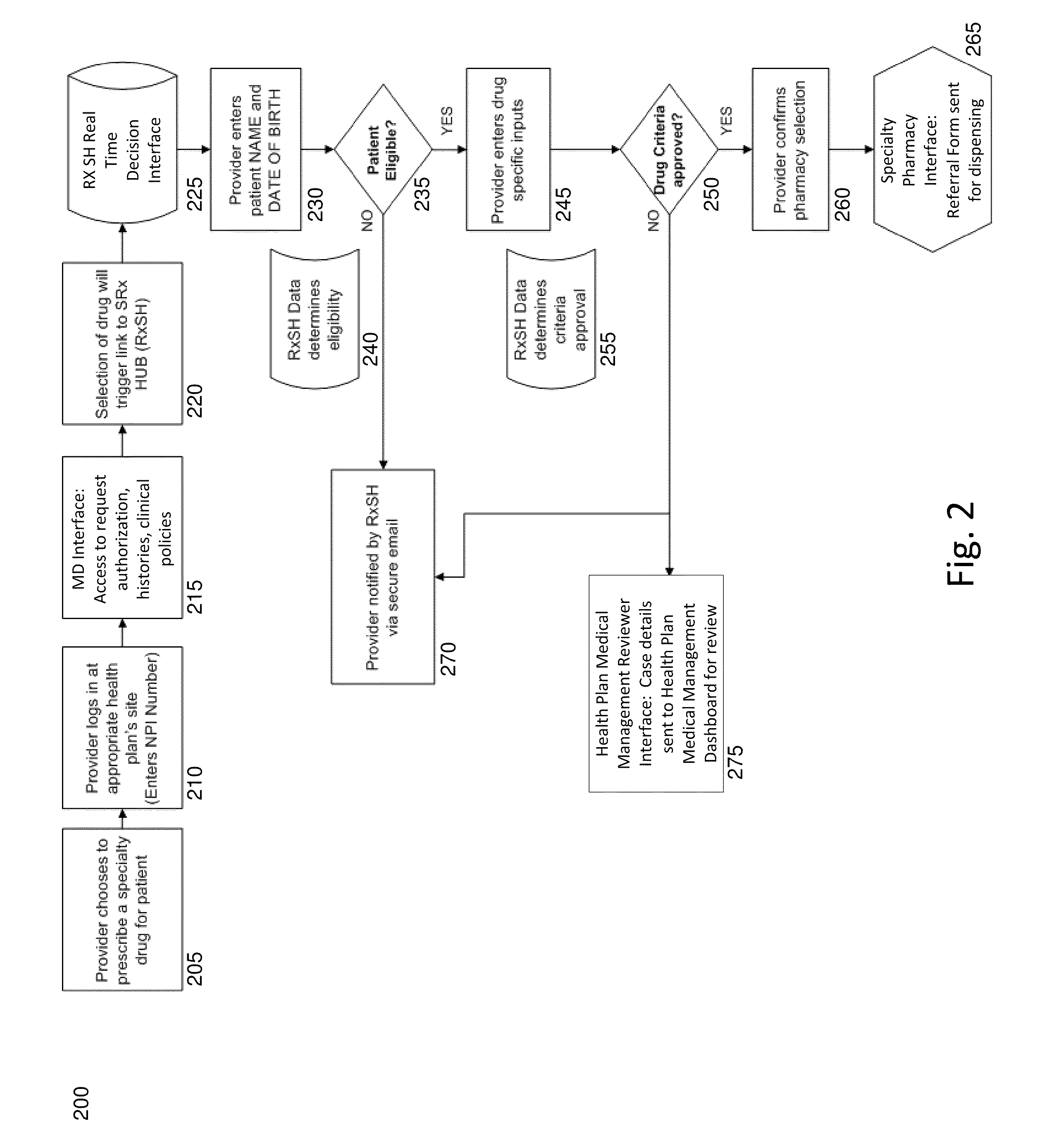

Prospective management process for medical benefit prescriptions

ActiveUS20110282690A1Faster and processingReduce wasteFinanceDrug and medicationsProgram EfficiencySpecialty pharmacy

The present invention provides an interactive, electronic, knowledge-based ordering process for specialty / biotech pharmaceuticals (medically coded drugs) which results in less waste, improved procedural efficiencies, and greater cost savings than the current ordering systems. The knowledge-base of the system is based on the health plan's clinical policies as well as the status of the patient and their entitled benefits with the health plan, and it is applied in an interactive manner through a web-enabled system which provides a real-time, prospective examination and control over requests for authorization to dispense the medically coded drugs. The system also includes a feedback loop from the specialty pharmacies to provide information on the medicines that have actually been dispensed. The system also provides to the patient, educational material and adherence reminders to affect therapeutic outcomes.

Owner:RX SPECIALTY HUB

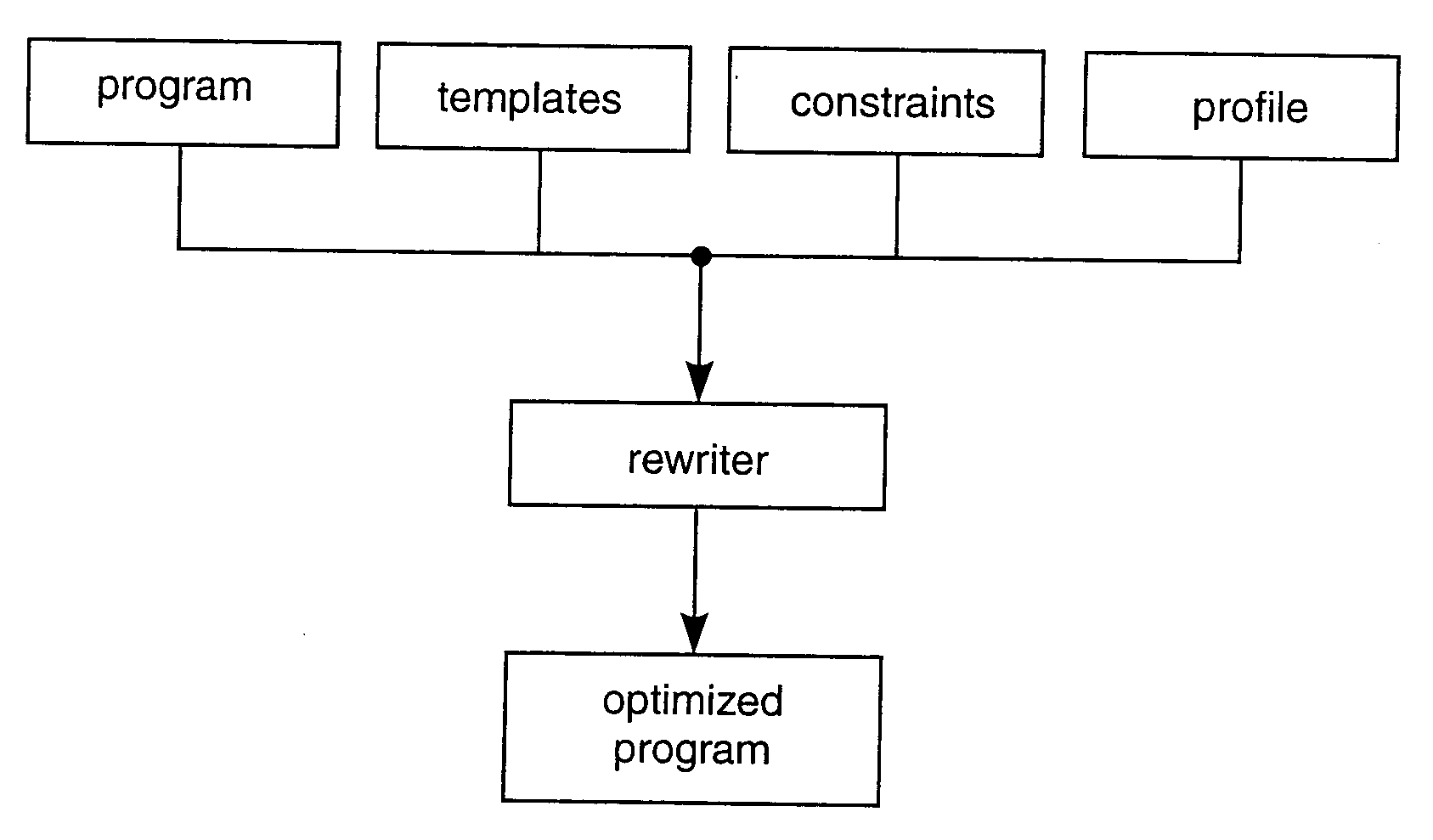

Automatic customization of classes

InactiveUS20050071810A1Improve programming efficiencySoftware reuseSpecific program execution arrangementsObject ClassProgram Efficiency

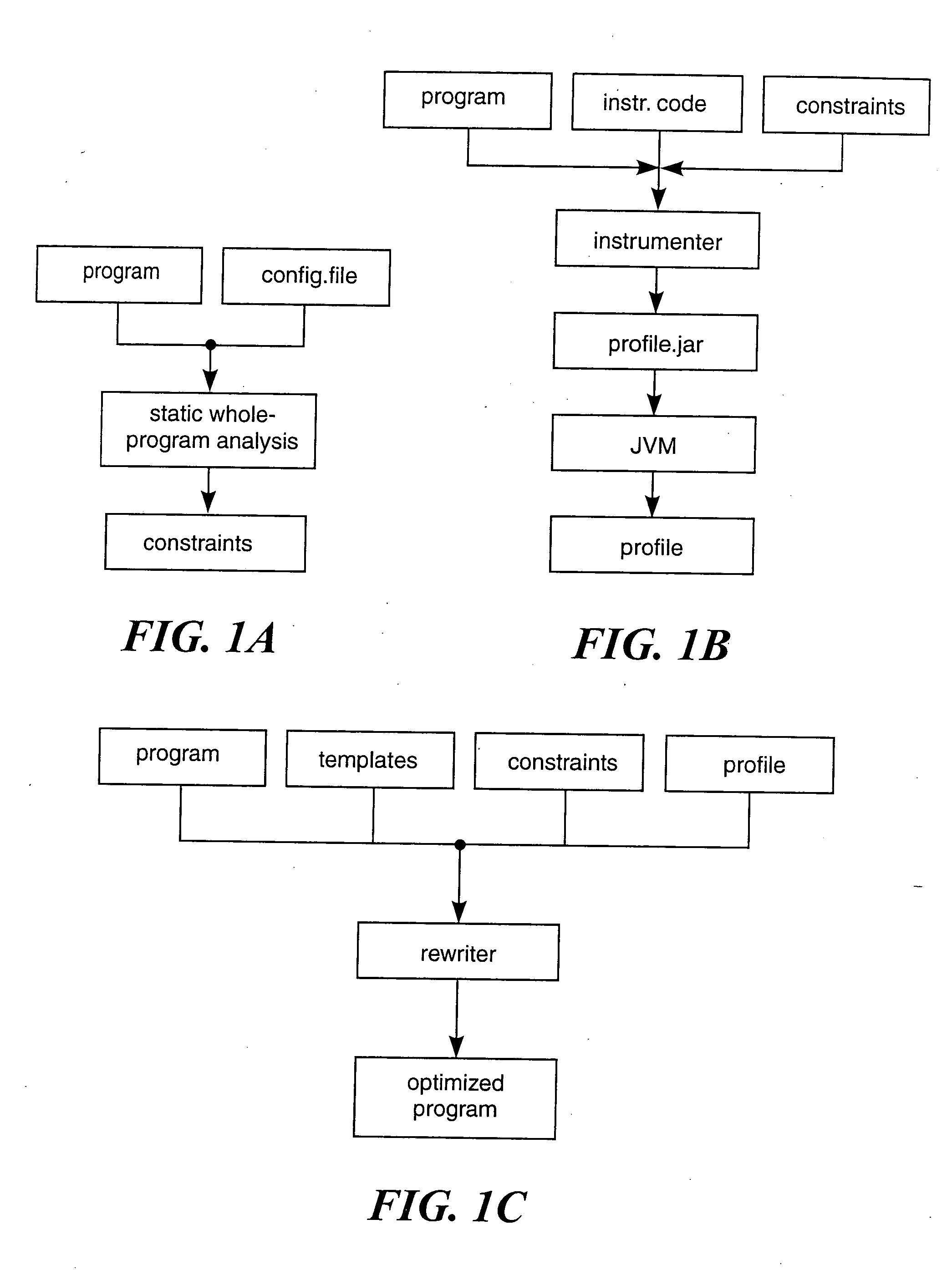

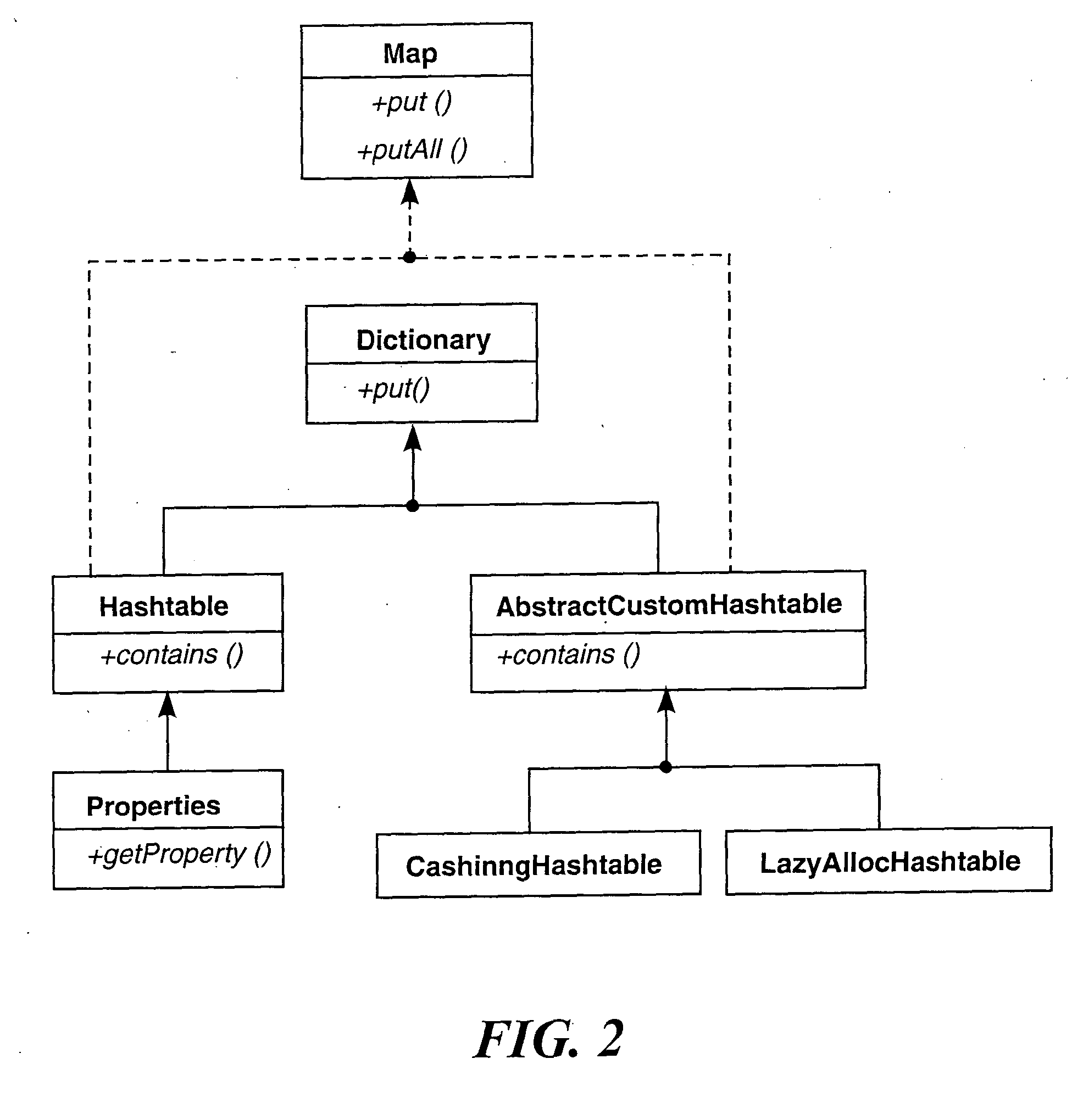

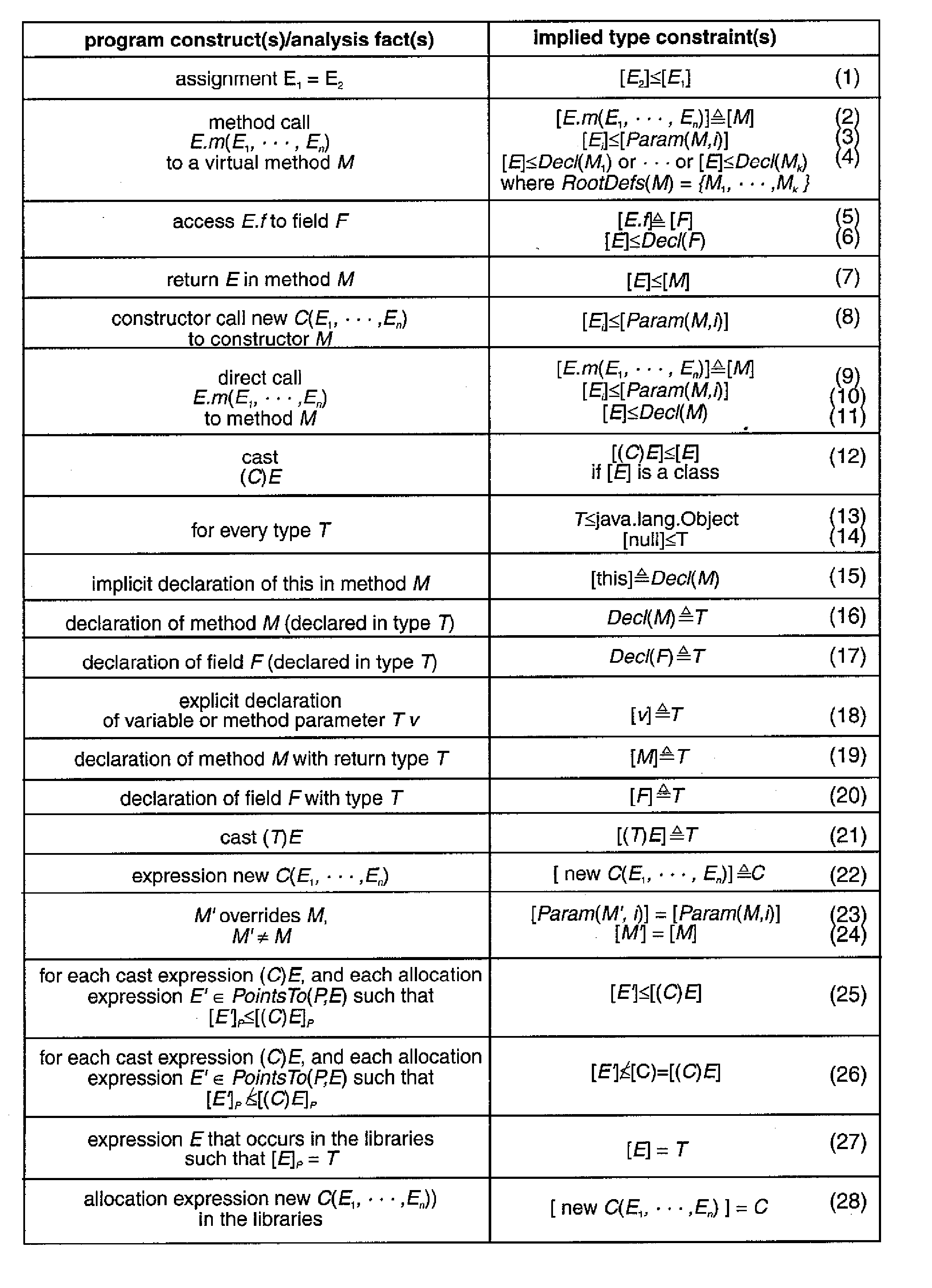

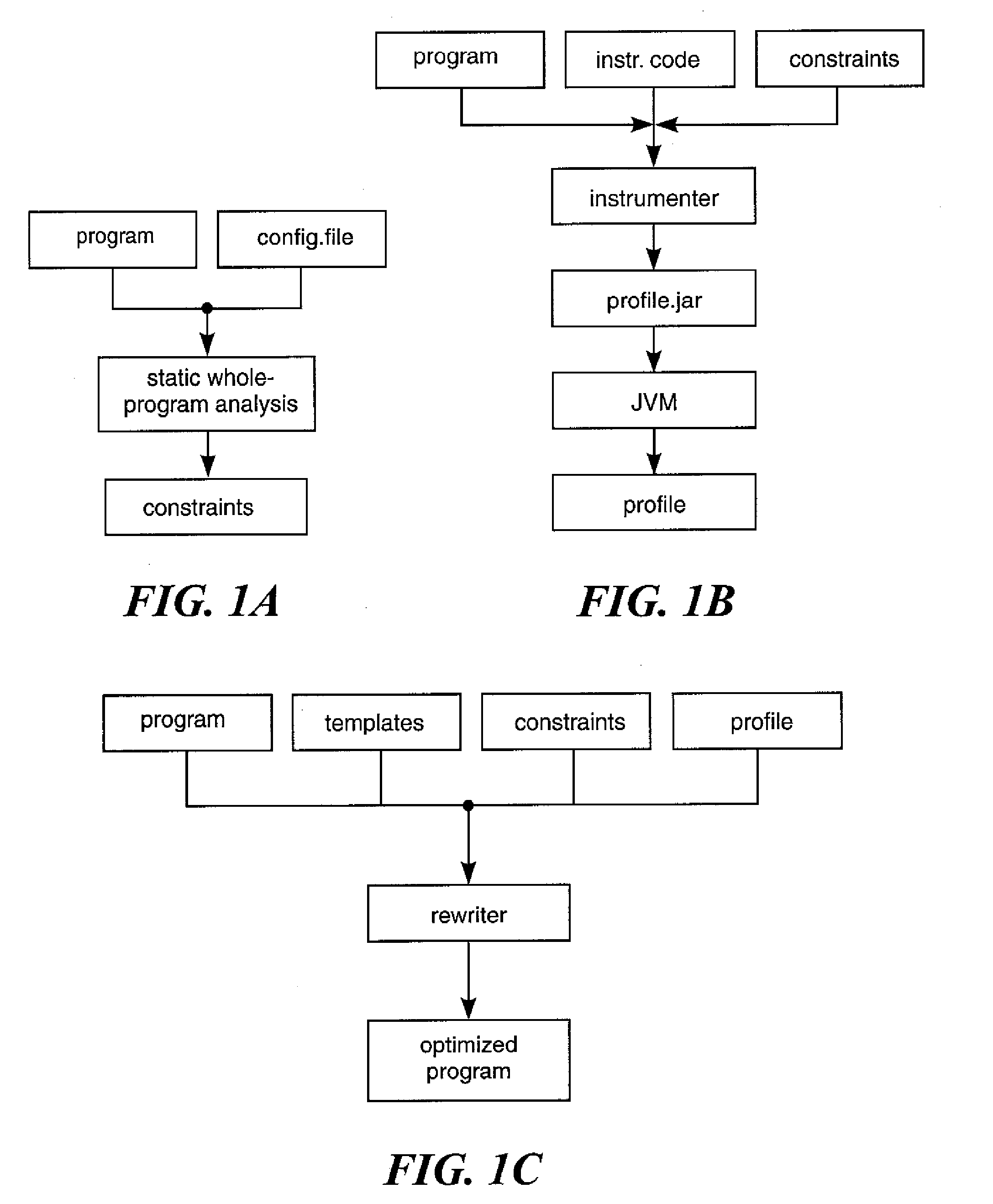

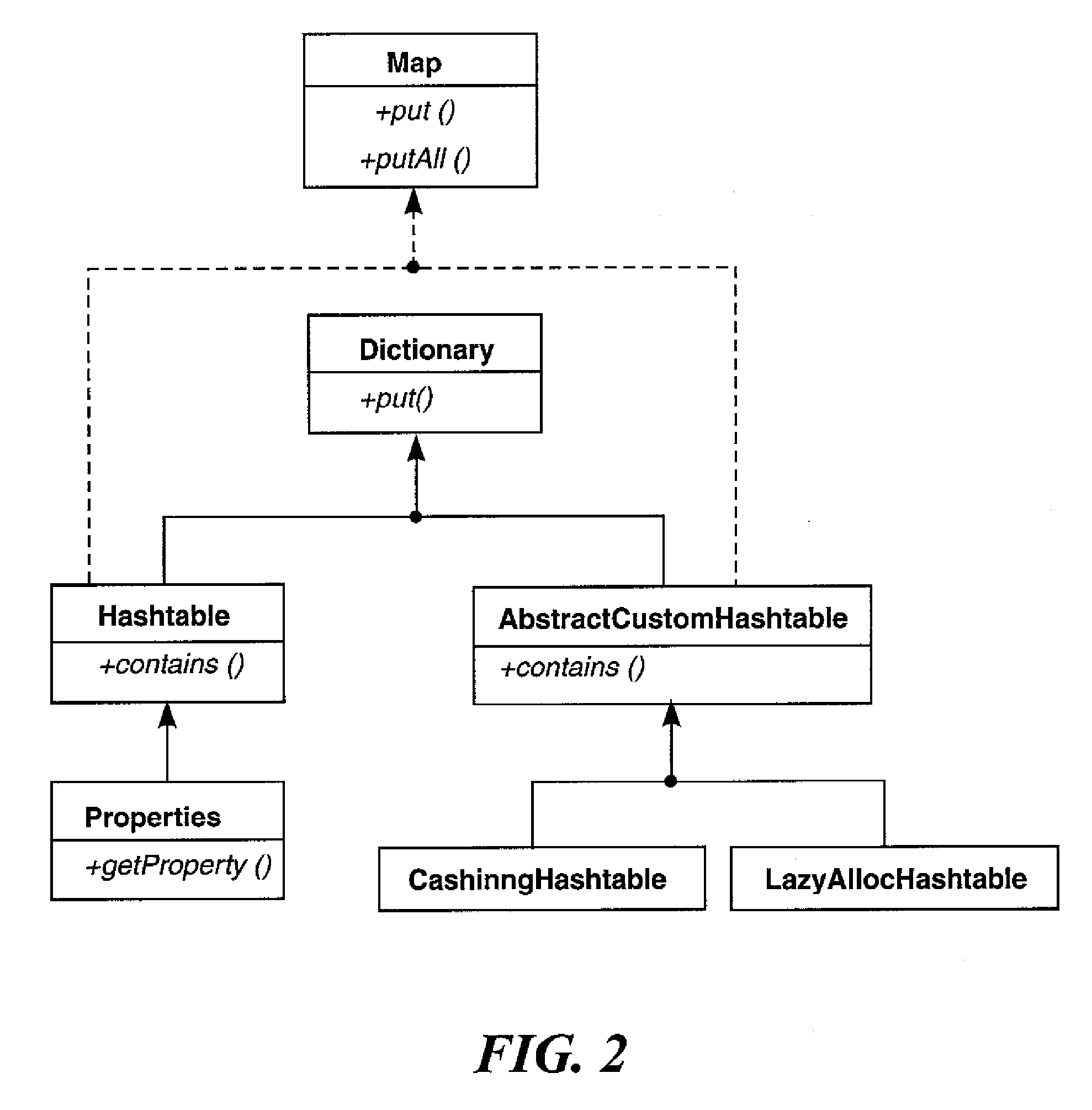

A method and computer readable medium for automatic replacement of object classes in a library with custom classes to improve program efficiency. The method begins with static analysis preformed on a program containing a plurality of objects in order to determine type-correctness constraints and to detect unused functionality in one or more of the objects to be replaced. The plurality of objects is instrumented to detect usage patterns of functionality in one or more objects. Customized classes are generated based upon the static analysis and usage patterns detected. Bytecode is rewritten which is used for generating classes. The present invention provides transparency in the replacement of the objects.

Owner:IBM CORP

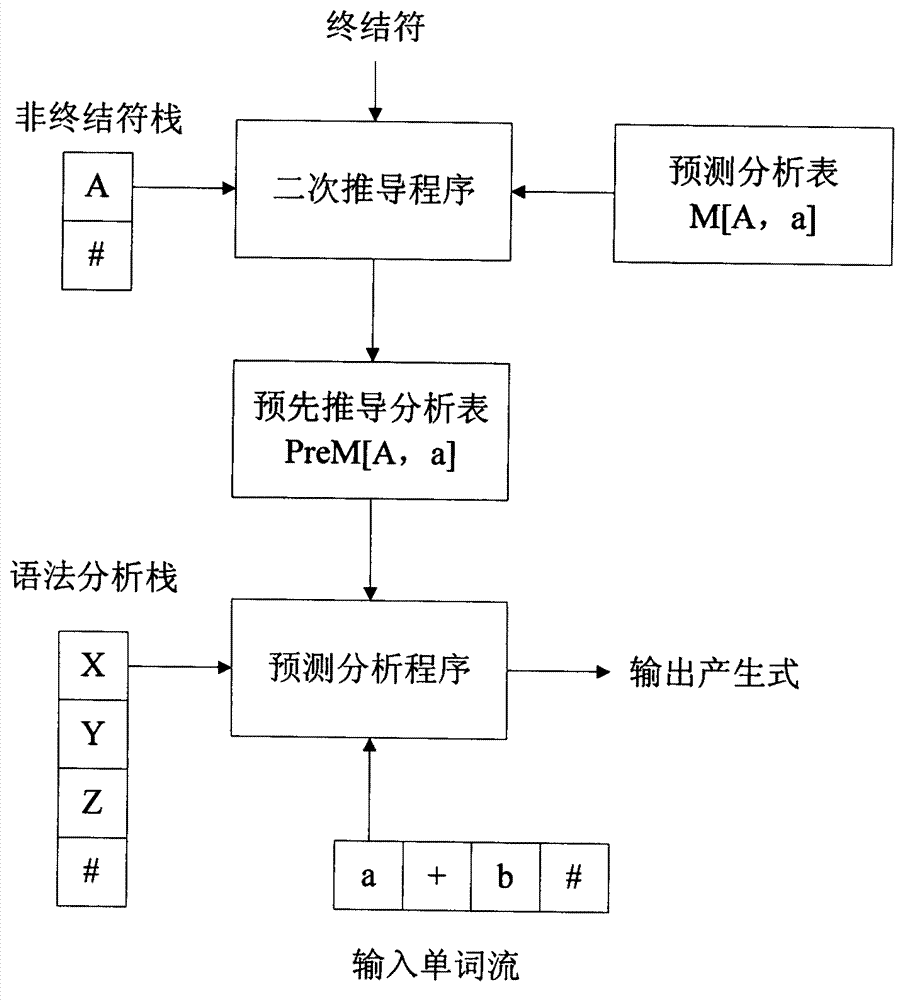

Programming and compiling design method in robot graphical programming system

ActiveCN104503754AQuick analysisIn the analysis phase, the pre-derivation mode is used for fast syntax analysisSoftware simulation/interpretation/emulationMemory systemsGraphicsProgram Efficiency

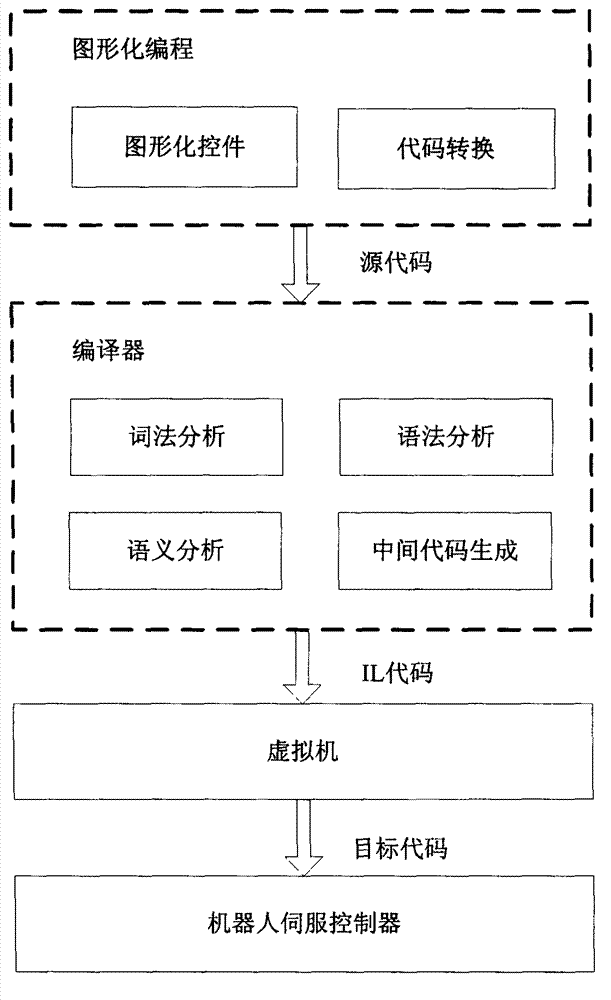

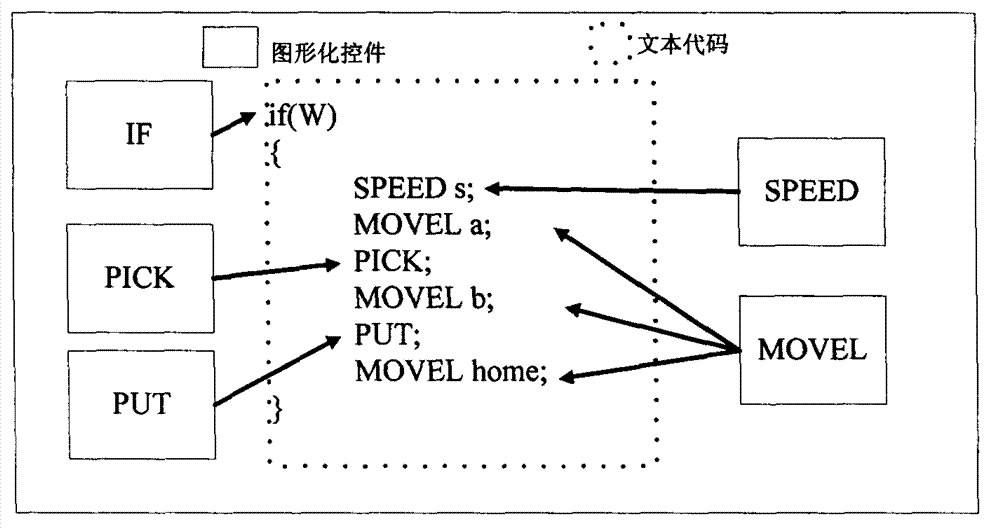

The invention provides a programming and compiling design method in a robot graphical programming system. According to robot motion control features, character codes are packaged into a graphical control form to be provided for a user, so that programming difficulty is lowered greatly and programming efficiency is improved; in a compiler syntactic analysis phase, a preliminary inference model is used for syntactic analysis, and accordingly, predictive query times are decreased, part of time required by syntax production type analysis is saved, quick analysis on a character string syntactic structure is achieved and compiling efficiency is improved; a mono operating environment is used as the back end of a compiler, so that architectures of a front end and the back end of the complier are independent relatively, and high expansibility and portability are achieved.

Owner:广东邦宝益智玩具有限公司

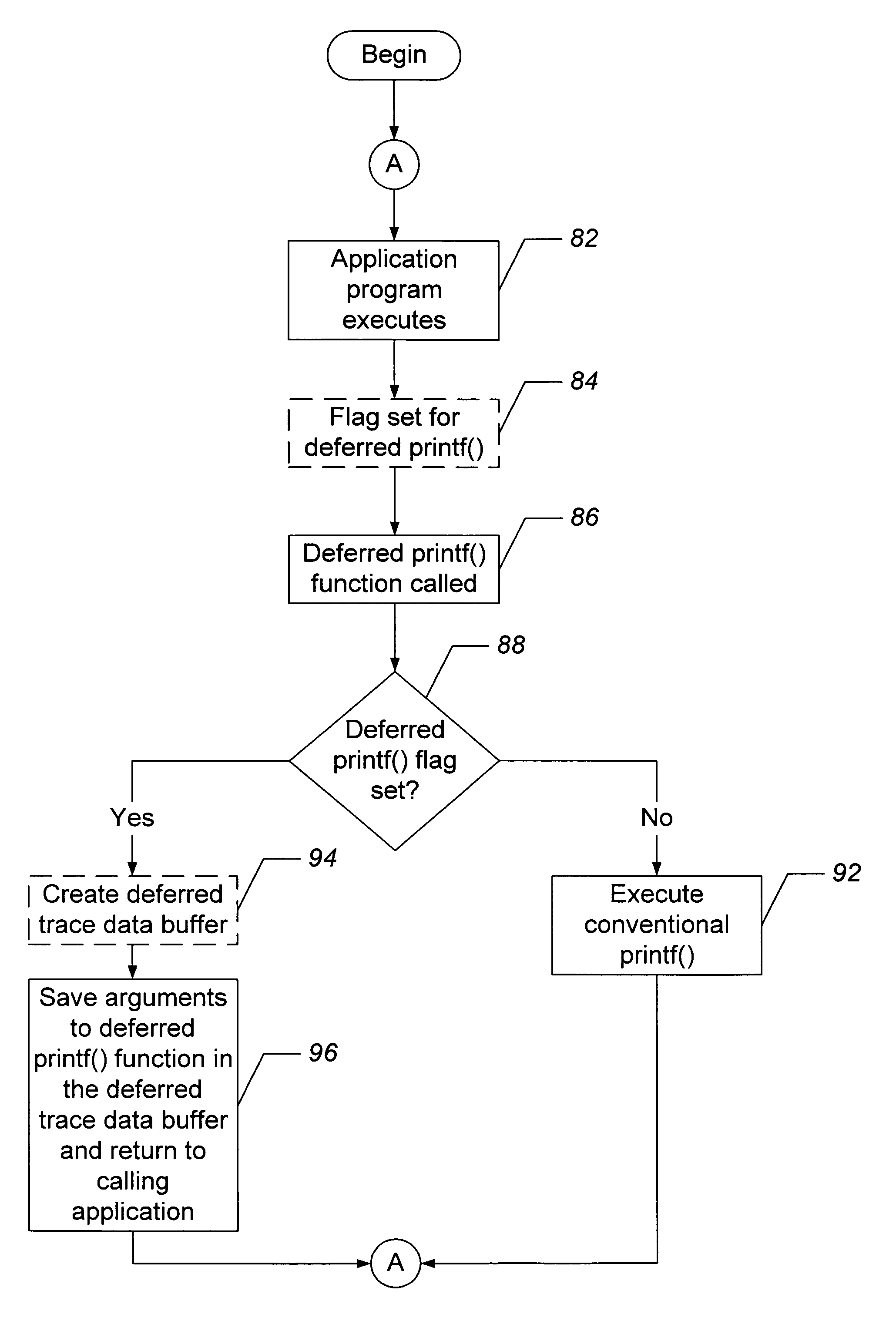

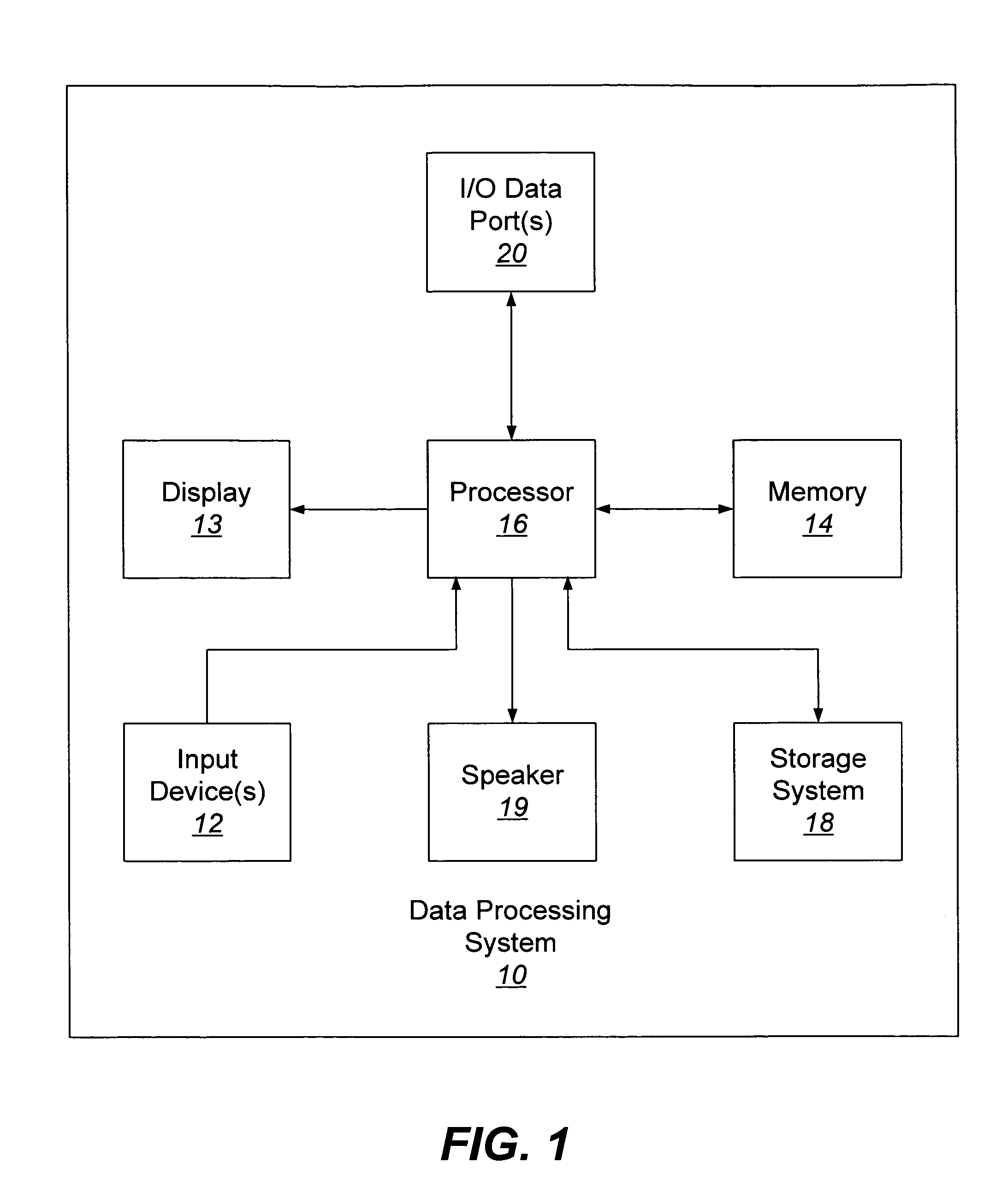

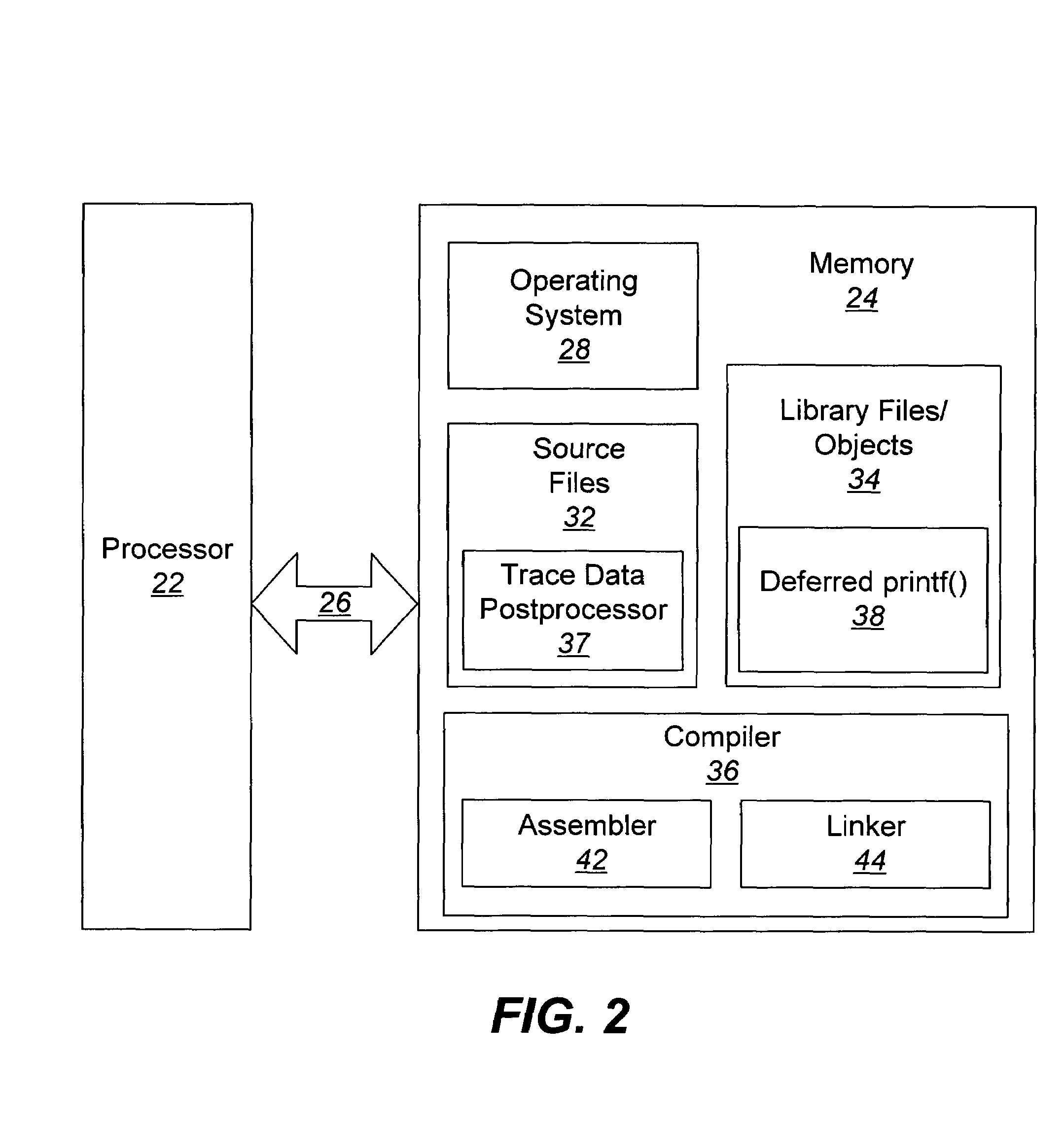

Methods, systems, and computer program products for deferred computer program tracing

ActiveUS7240334B1Improve programming efficiencyReduce the impactError detection/correctionSpecific program execution arrangementsProgram EfficiencyApplication software

An application (e.g., a computer program) prints data by invoking a print function with a format argument and, optionally, at least one data argument. The format argument and any data arguments are saved in a deferred trace data buffer. The print function returns to the application then, sometime after the print function has returned, the deferred trace data buffer is processed and the format argument and / or any data arguments are printed. By saving the format argument and any data argument(s) to a memory buffer instead of parsing and formatting the arguments in real-time, program efficiency may be improved and the impact of the print function on a software test scenario may be reduced.

Owner:TOSHIBA GLOBAL COMMERCE SOLUTIONS HLDG

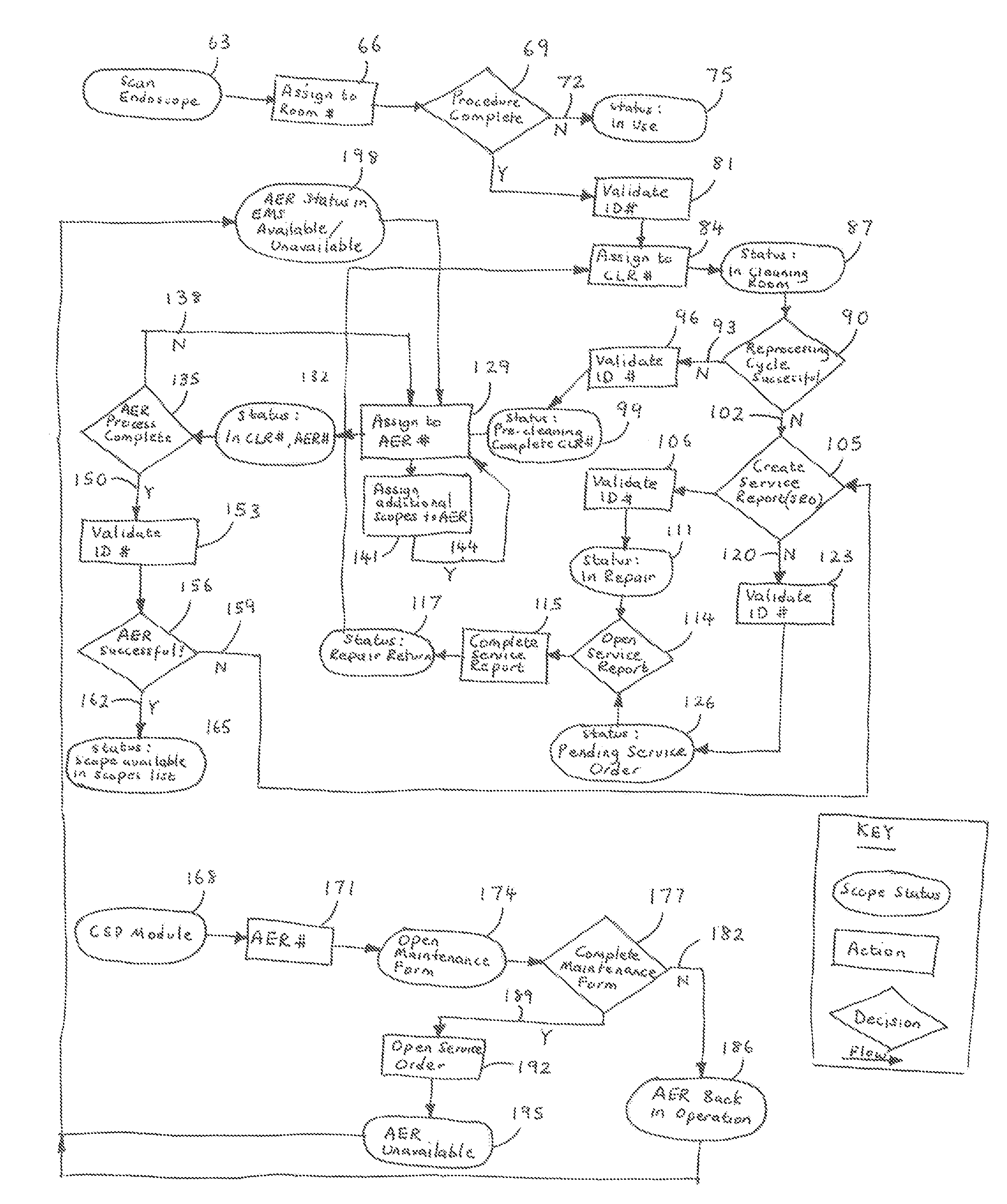

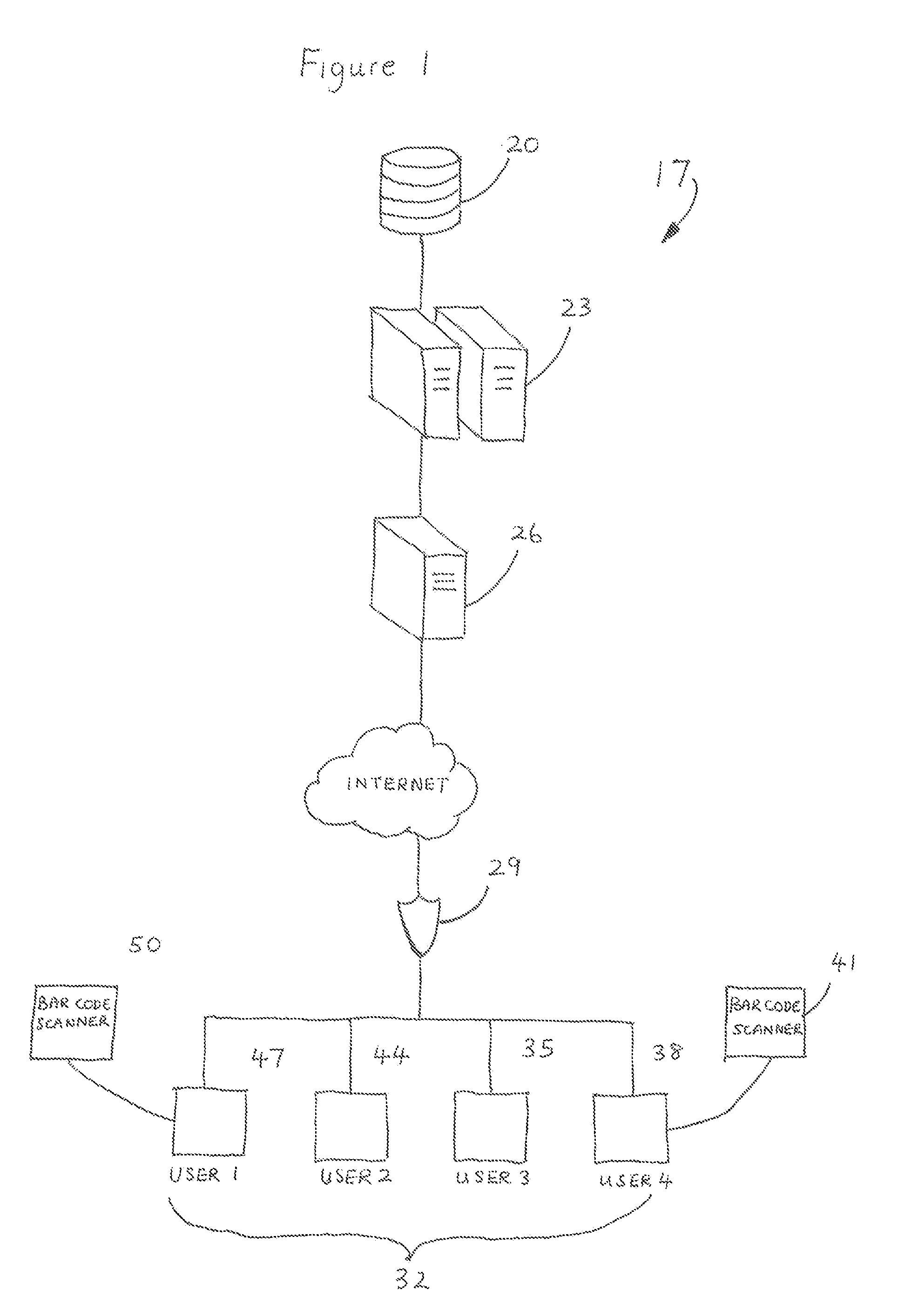

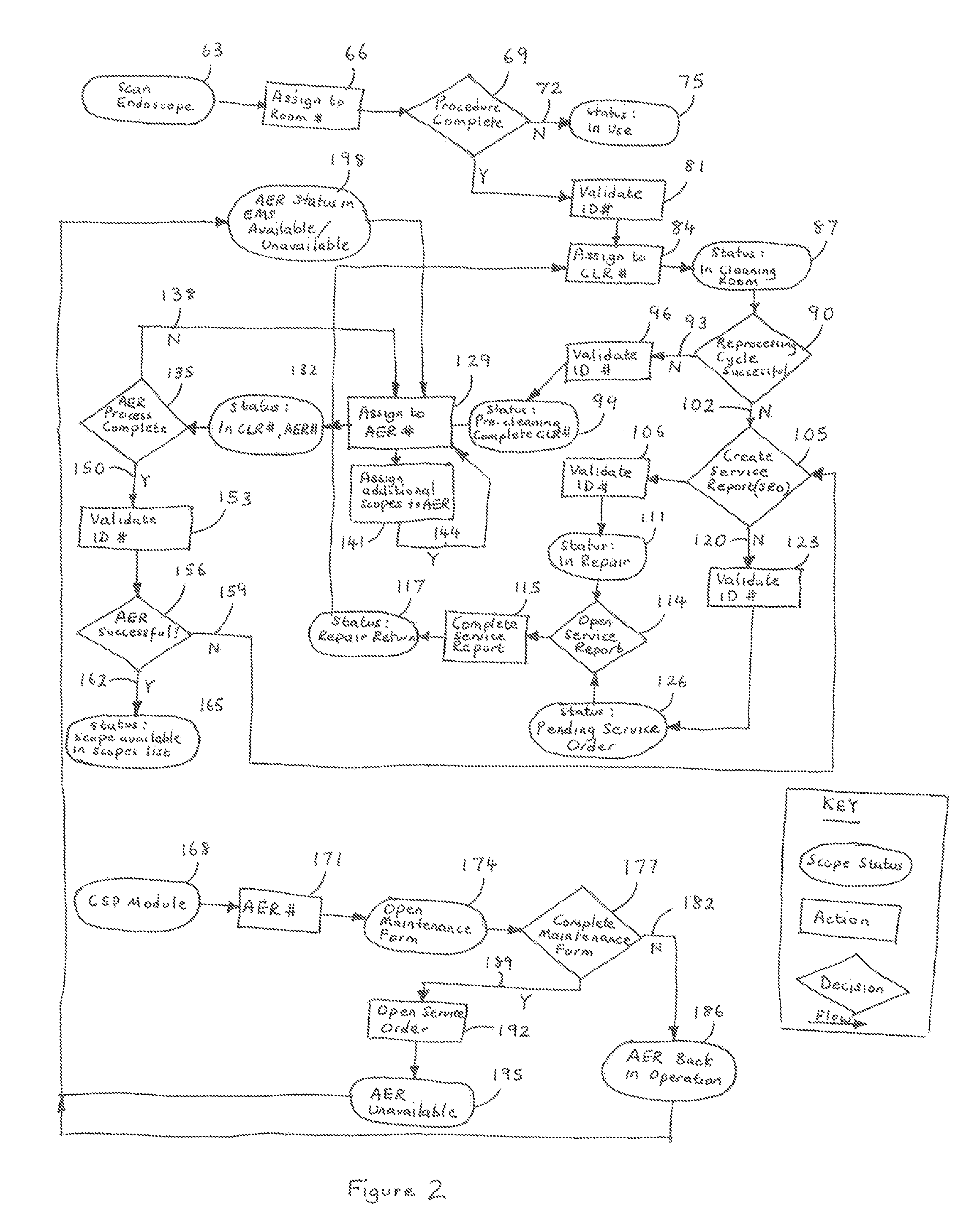

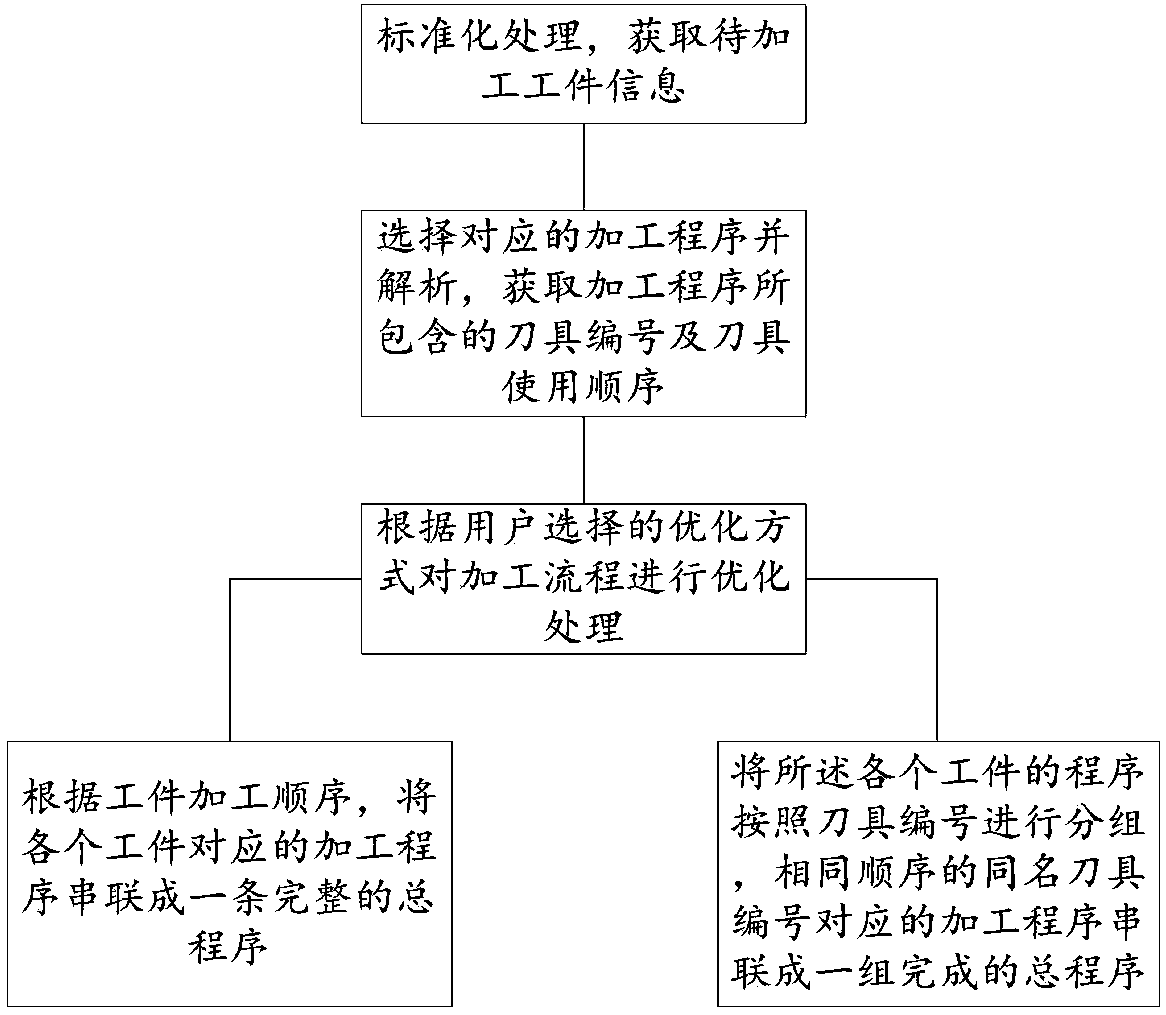

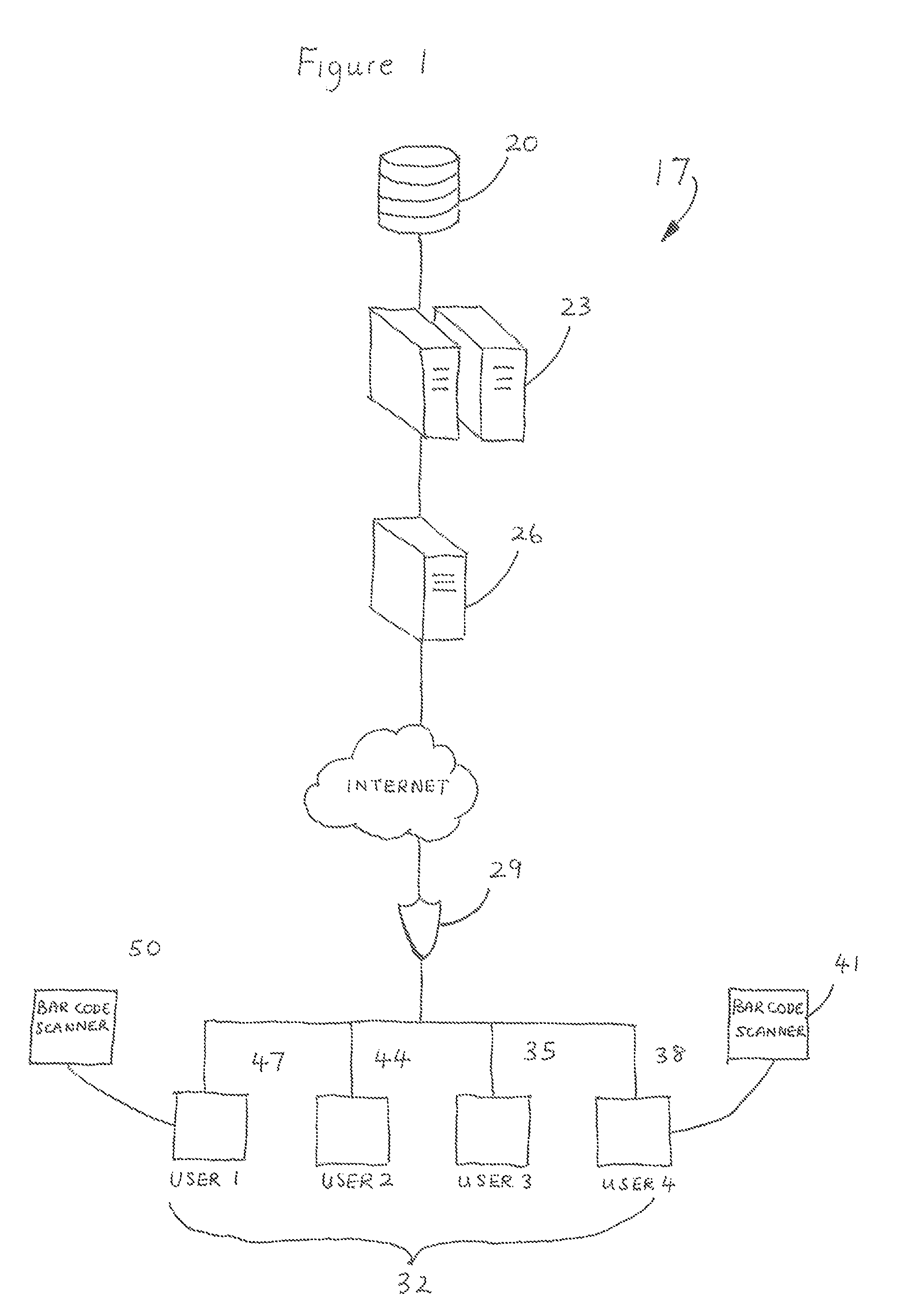

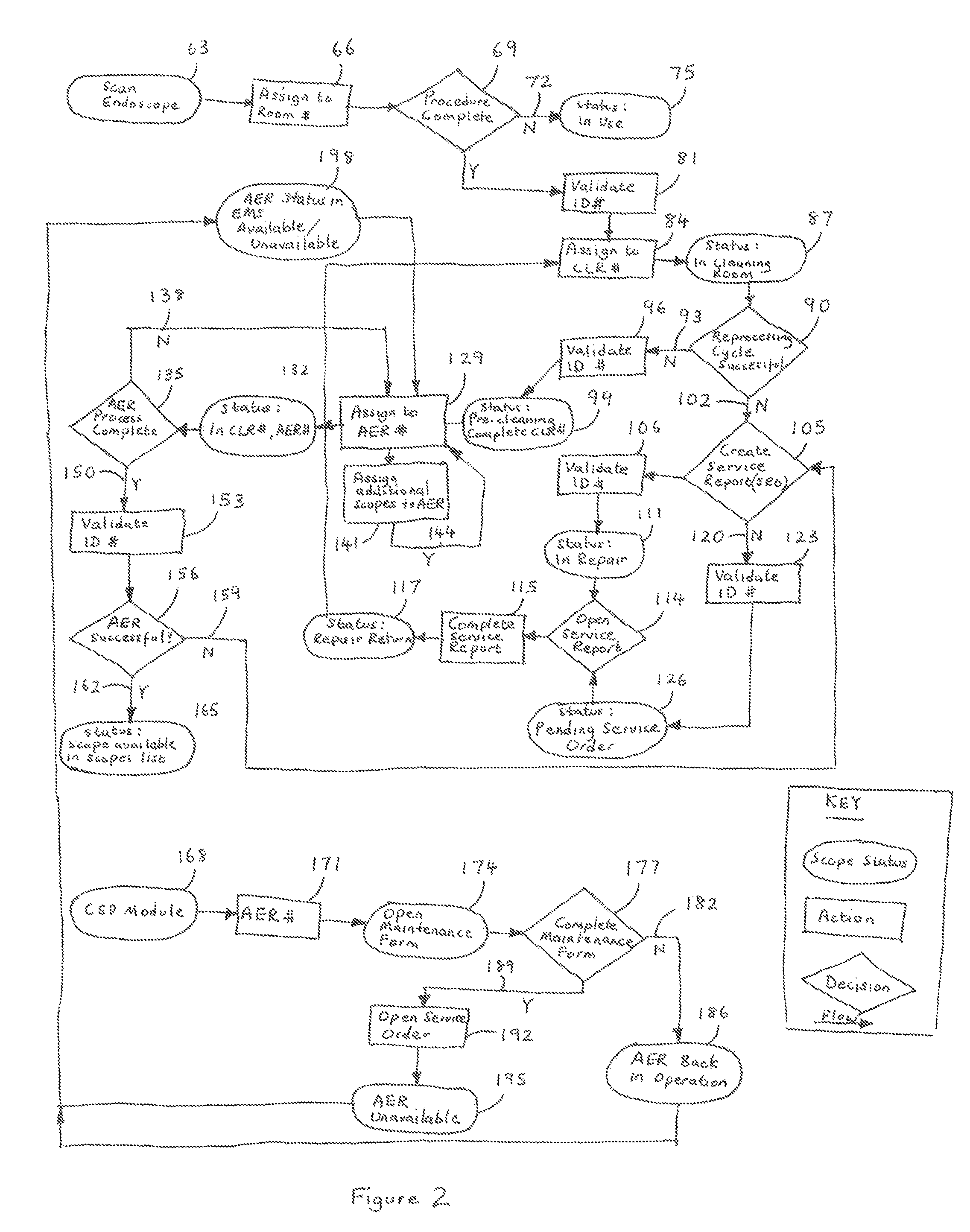

Endoscope management system

InactiveUS20090055215A1Highly user-friendly in operationEasy to set upData processing applicationsSurgical instrument detailsProgram EfficiencyDisplay device

A web-based endoscope management system and method for managing, scheduling and tracking in real-time the processing of endoscopy equipment in a single site or across multiple sites. The system allows various useful information relating to the managed endoscopy equipment and its processing history (such as equipment status, equipment movement, equipment repair history, cost and procedural efficiencies, what individuals have processed or come into contact with the equipment) to be tracked and analyzed. The system incorporates a user display and prompt to assist users in following the proper processing and cleaning protocols (preparation, pre-cleaning, automated reprocessing, repair, etc.) for the equipment. The system uses a colour-coded display so that pertinent information can be seen at a glance. This system is used in conjunction with a suitable colour-coded labeling scheme to reduce the possibility that users will process the wrong equipment or improperly store it.

Owner:ENDOLOGISTICS

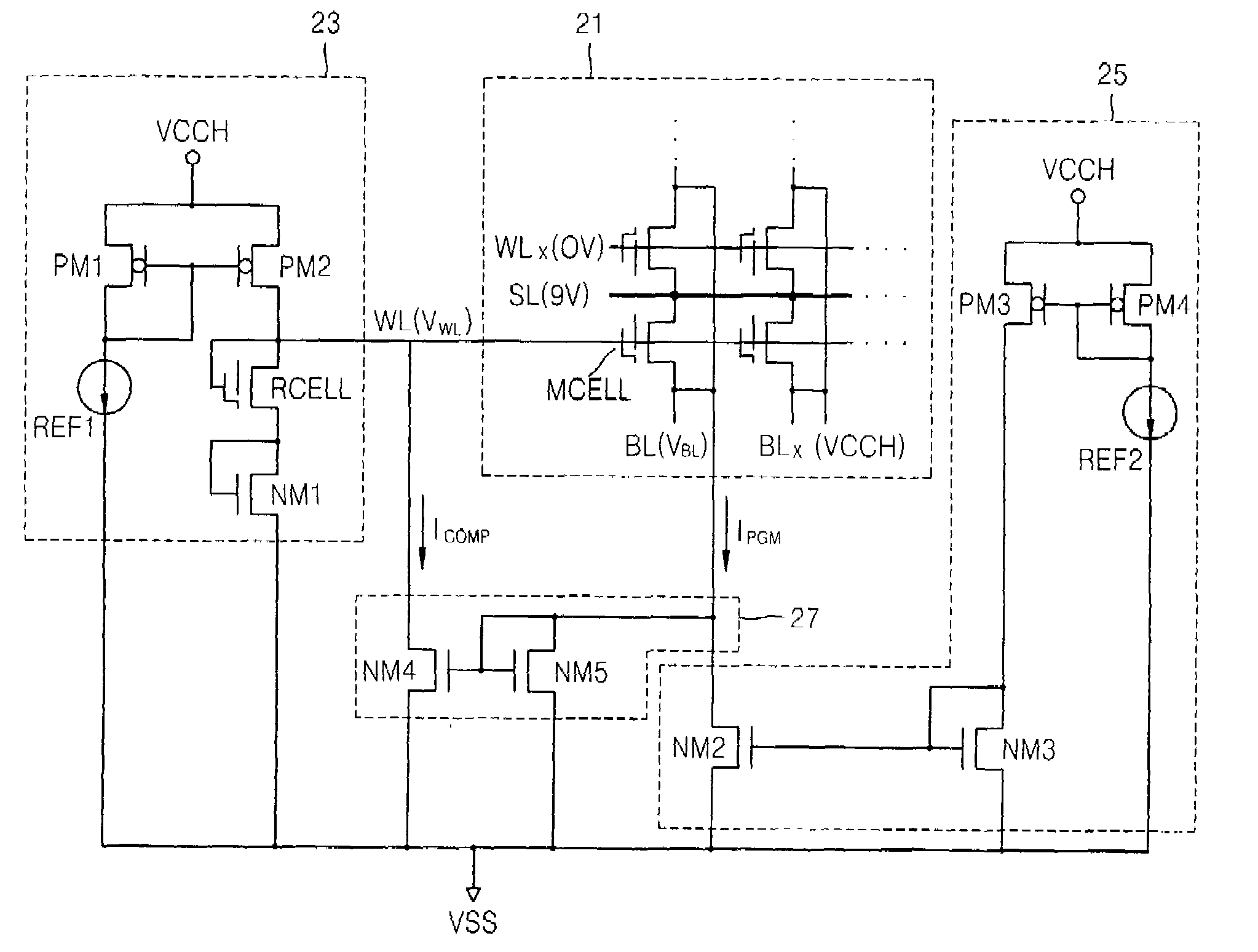

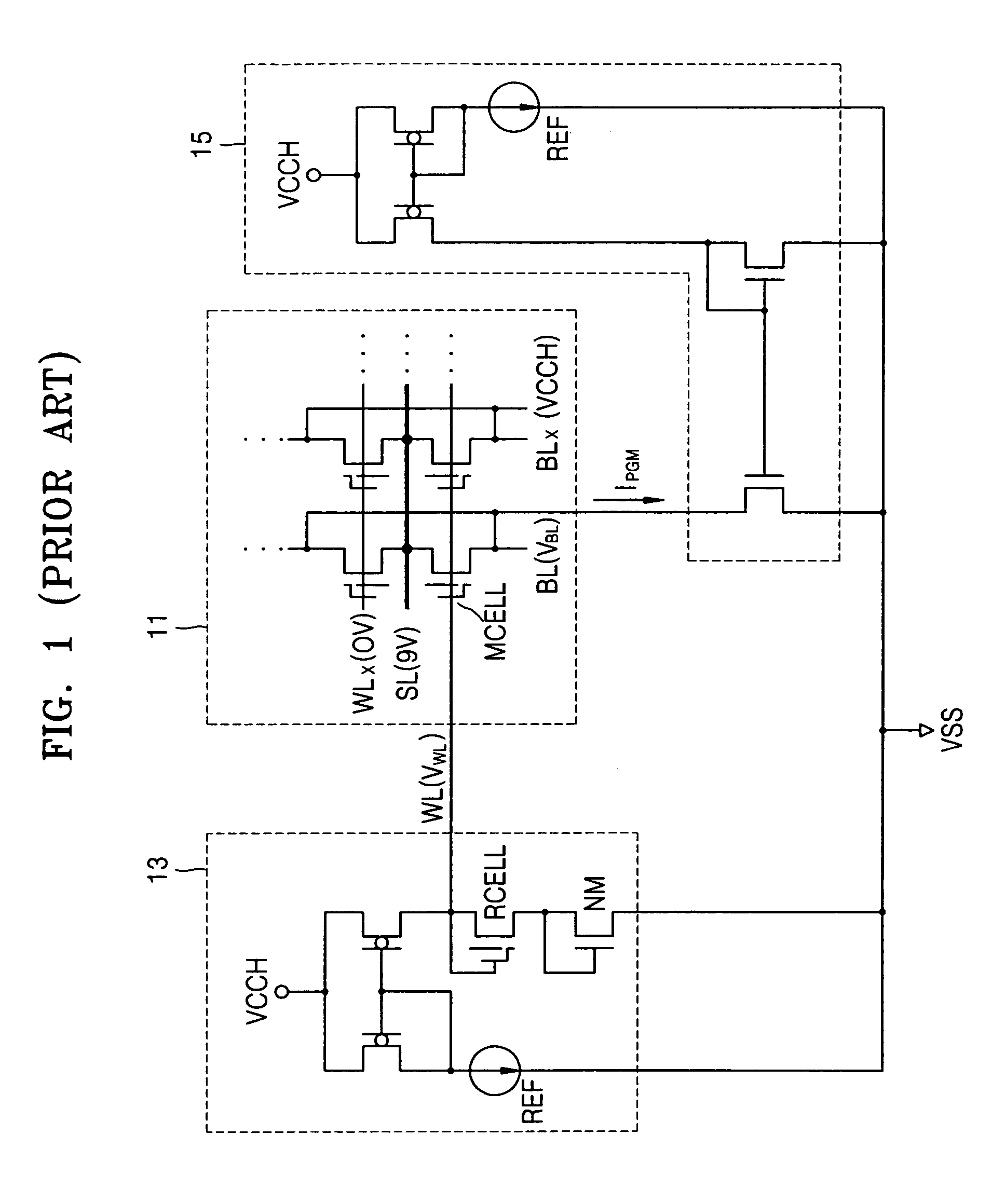

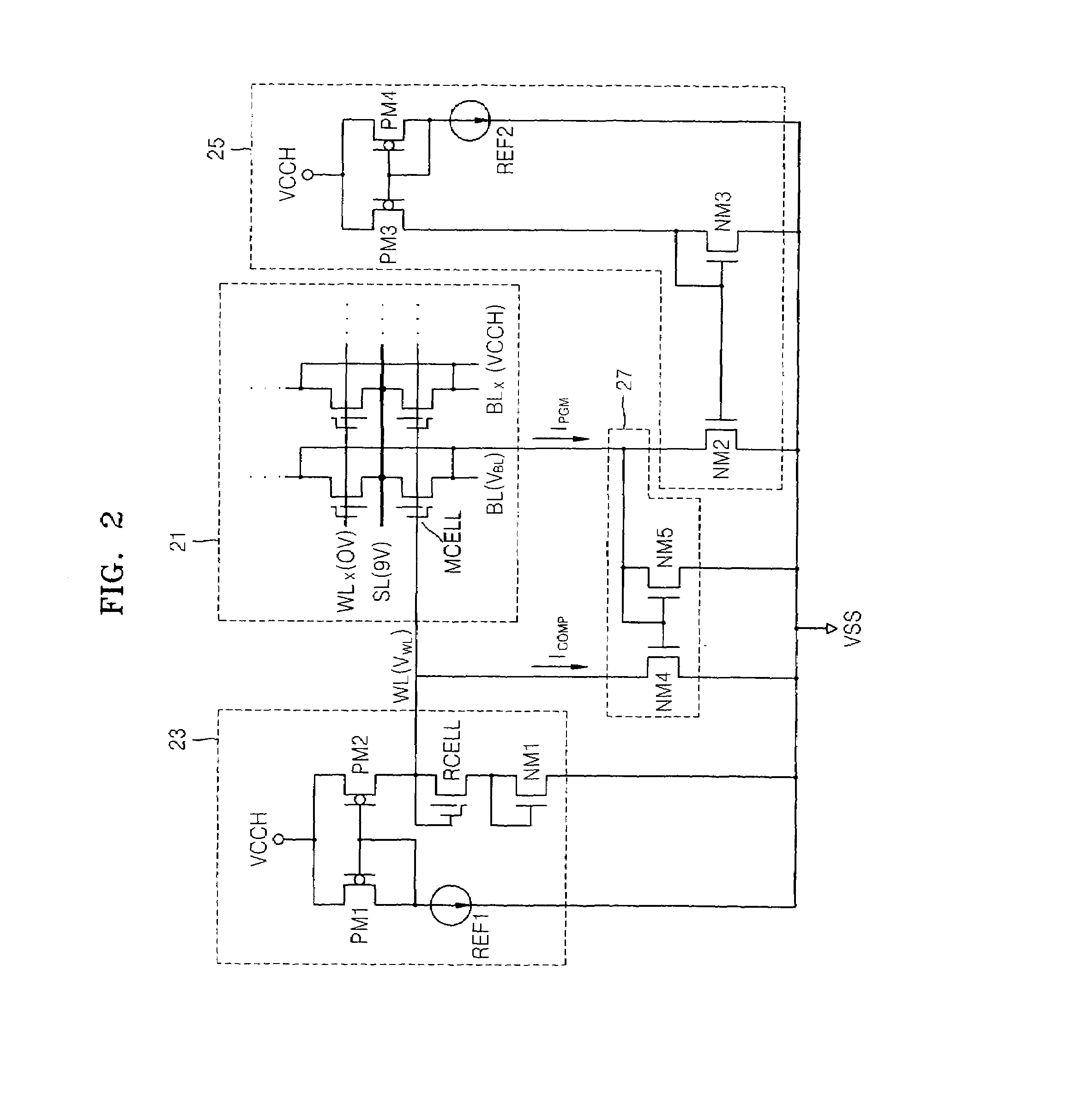

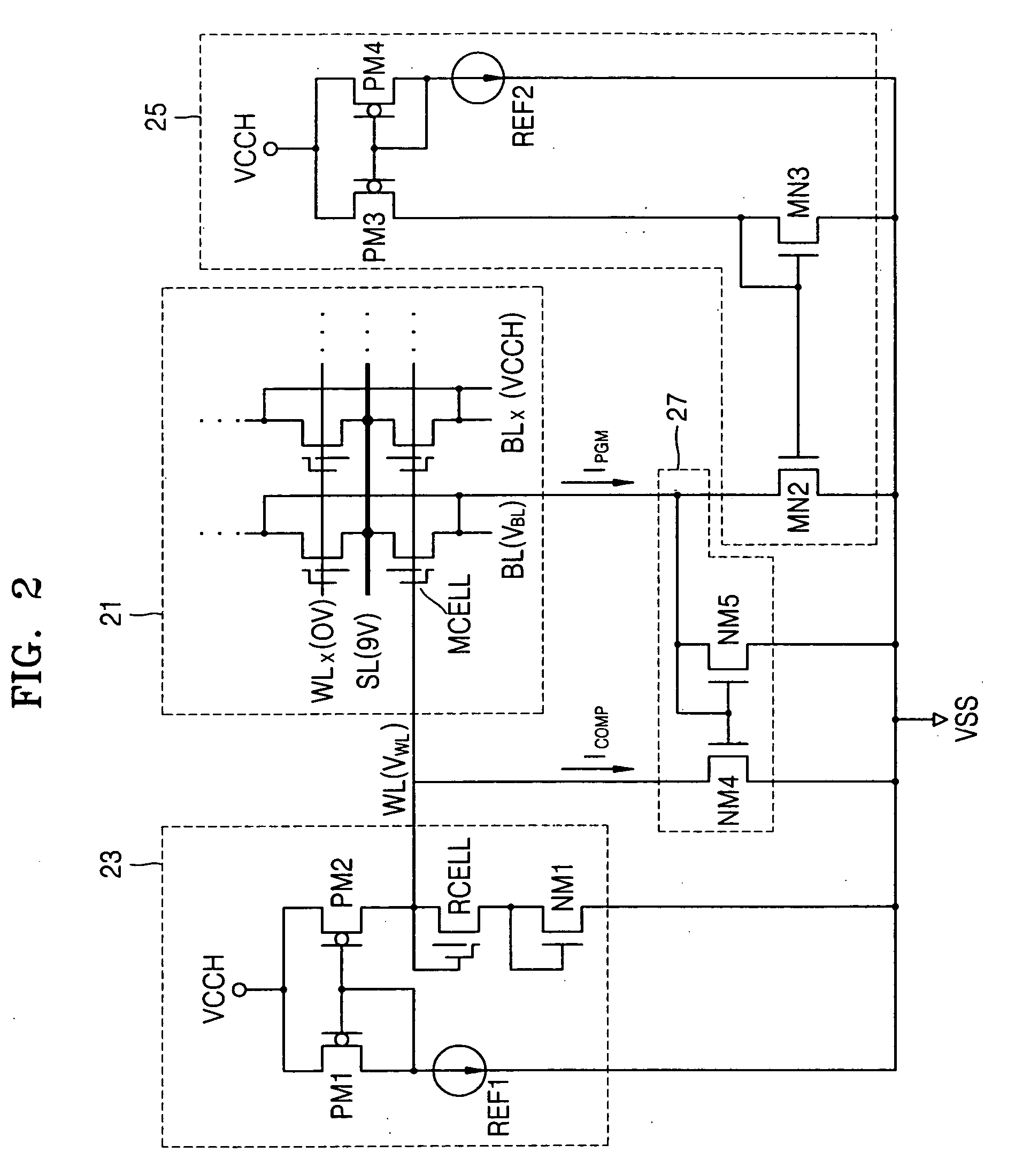

Flash memory device including bit line voltage clamp circuit for controlling bit line voltage during programming, and bit line voltage control method thereof

Owner:SAMSUNG ELECTRONICS CO LTD

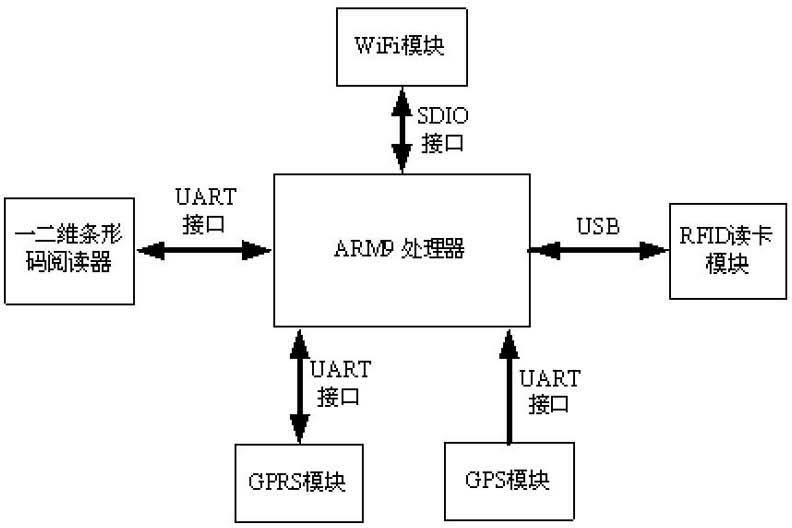

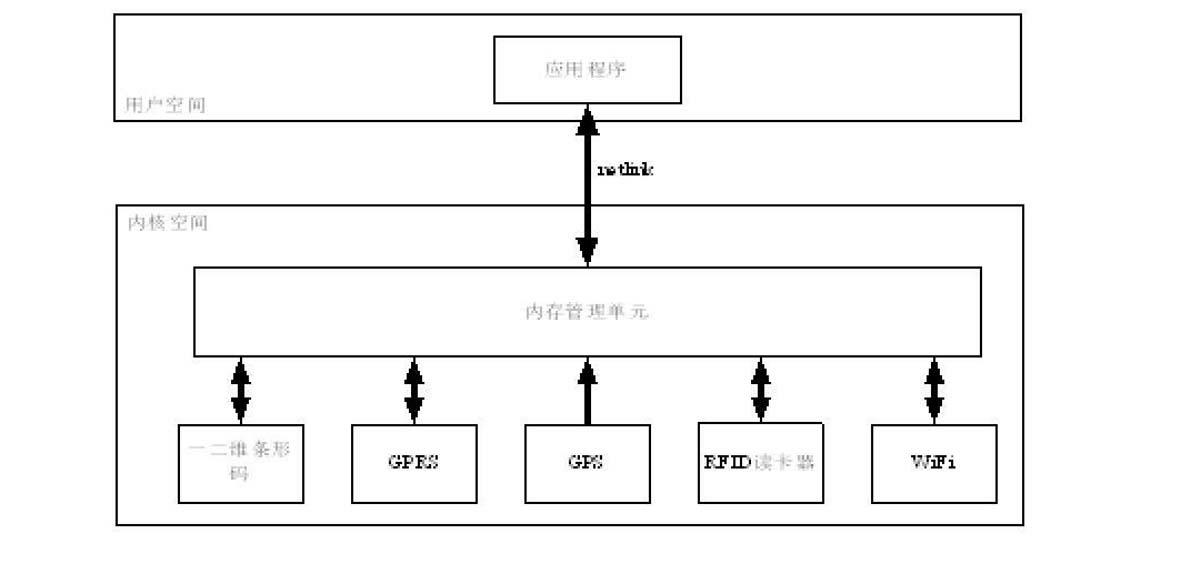

Method for processing embedded multi-module Internet of Things mobile terminal device data system

InactiveCN102629202ACo-operative working arrangementsSpecific program execution arrangementsProgram EfficiencyControl data

The invention relates to a method for processing an embedded multi-module Internet of Things mobile terminal device data system. The system comprises an application unit, a memory management unit and hardware modules, wherein the memory management unit comprises a Linux kernel module, the hardware modules comprise hardware kernel modules, a communication mode is established by the memory management unit between the application unit and the hardware modules, and each of the hardware modules communicates with the outside through an antenna. According to the method for processing the embedded multi-module Internet of Things mobile terminal device data system, a memory management unit driving module is designed to communicate with the rest of the hardware modules in a driving mode, and simultaneously a netlink mode is utilized to provide only one communication channel between an underlying driver and an upper-layer application program to control the distribution and collection of data. By means of the method for processing the embedded multi-module Internet of Things mobile terminal device data system, the programming is extremely flexible, and the program efficiency is extremely high.

Owner:VOTO COMM

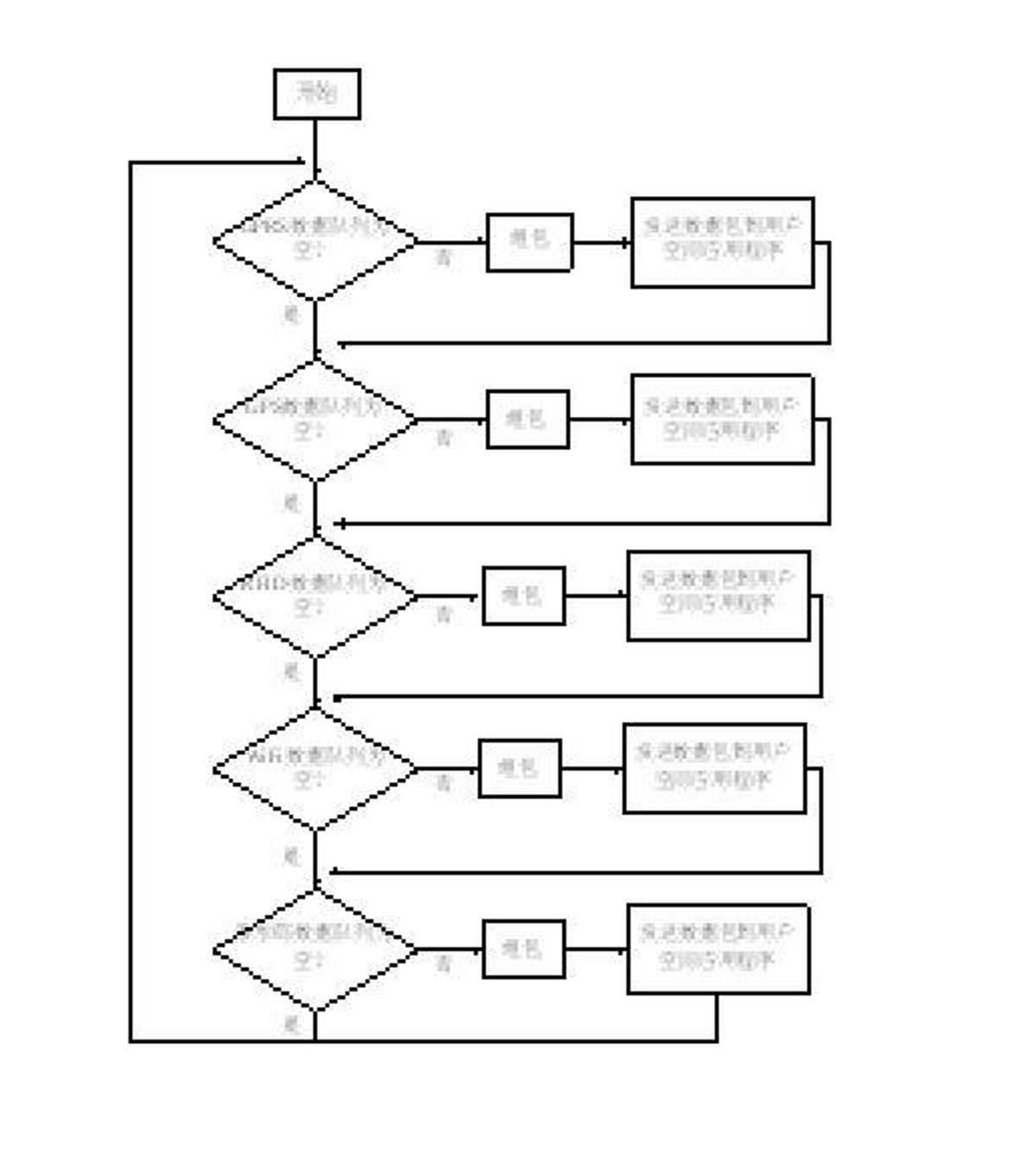

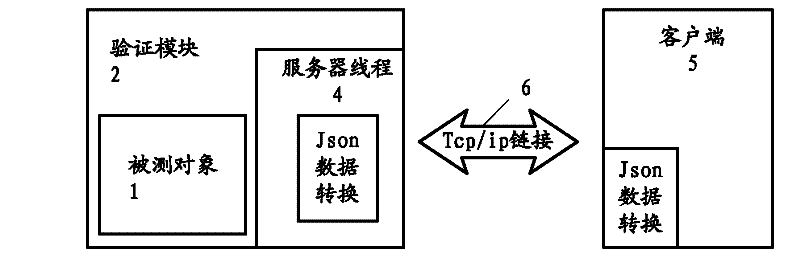

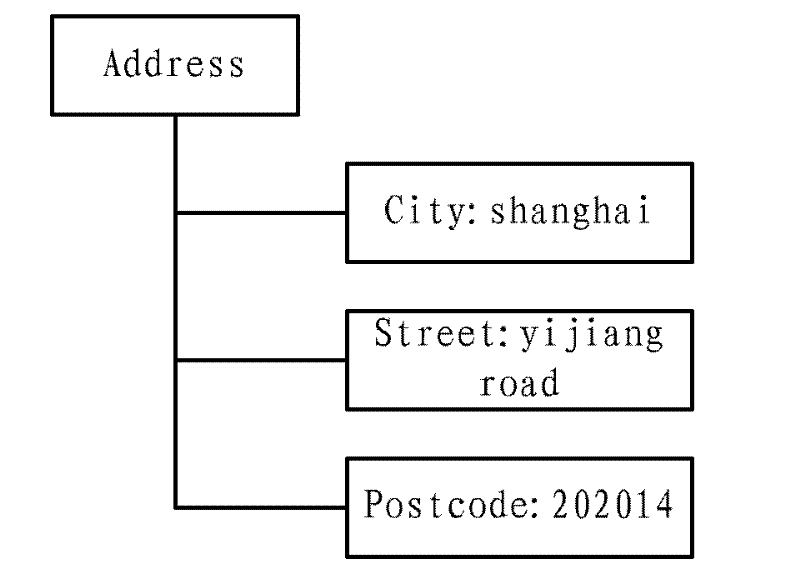

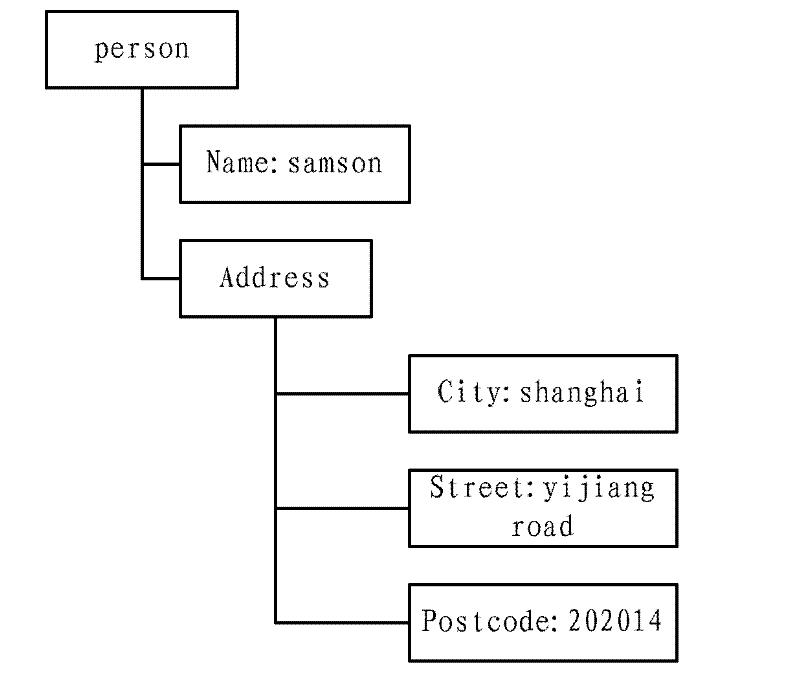

Method for checking cross-platform and cross-language single-chip system

InactiveCN102479130AEasy to manageGood for rollback testingFunctional testingData streamValidation methods

The invention discloses a method for checking a cross-platform and cross-language single-chip system. The method comprises the following steps of: constructing a checking module by using a system c, namely realizing a server thread to monitor an appointed port, establishing a transmission control protocol / Internet protocol (tcp / ip) link service, resolving a data stream of the port through a loop body, obtaining a data structure sent by a client by using a standard json resolving function, making a corresponding response according to branch judging, constructing a returned json data packet, and repeating the steps until the link is interrupted to quit the simulation, wherein a programming language can be freely selected from the client to compile a test case, i.e., the operation to the checking module is packed by a json base of a corresponding language and sent through the tcp / ip link so as to control the flow of the tested checking module. The method is higher in programming efficiency and is favorable for management and rolled-back test of the test case and error tracking.

Owner:上海宇芯科技有限公司

Automatic customization of classes

InactiveUS20080082972A1Improve programming efficiencySoftware reuseSpecific program execution arrangementsObject ClassProgram Efficiency

Owner:INT BUSINESS MASCH CORP

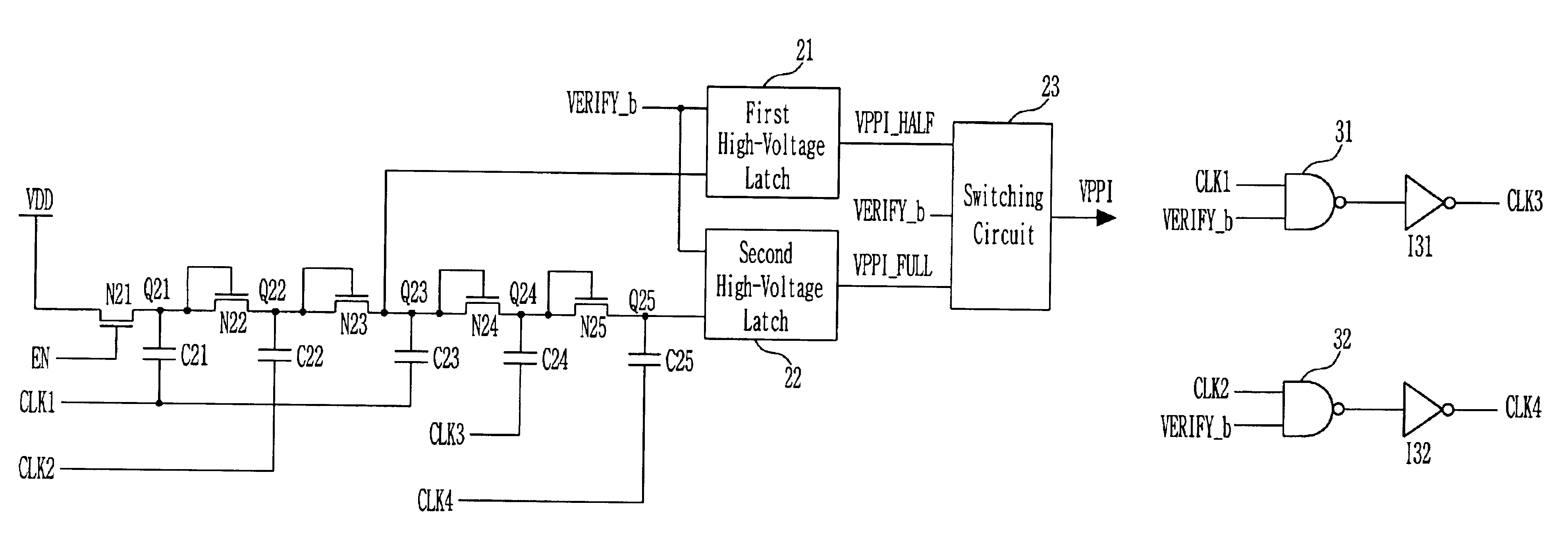

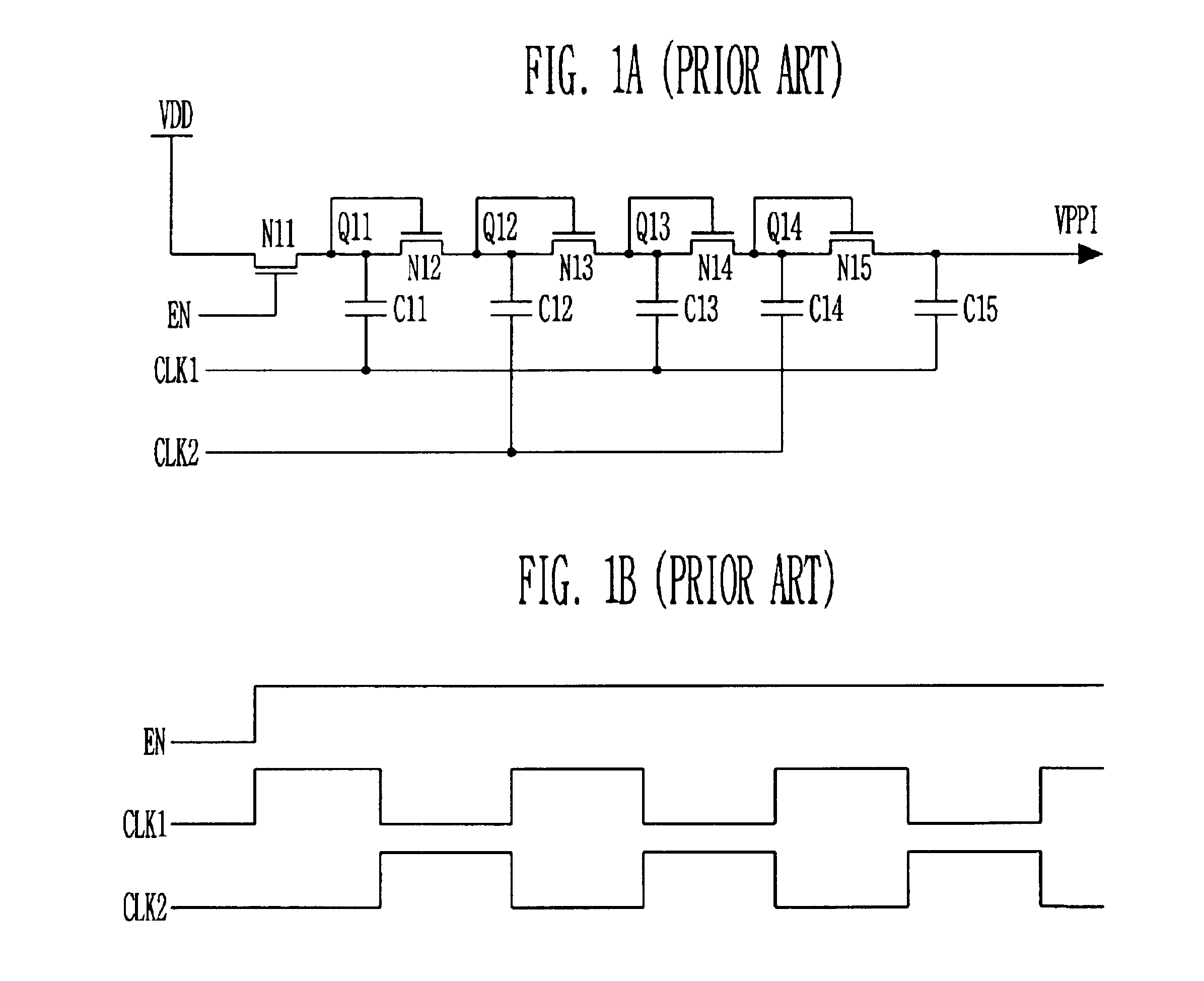

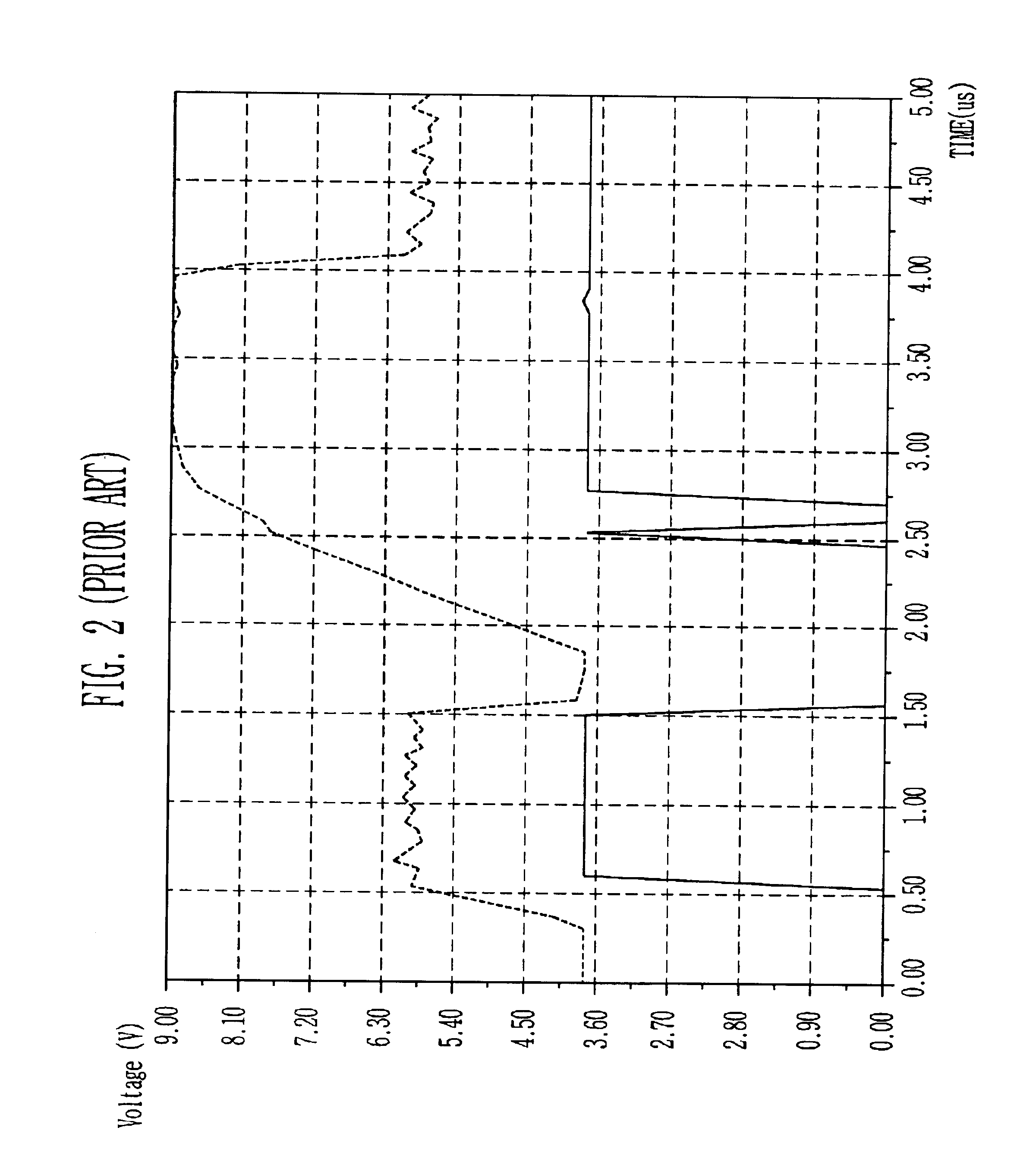

Pumping circuit for outputting program voltage and program verify voltage of different levels

The present invention relates to a pumping circuit. The pumping circuit comprises a first pumping block for pumping an input voltage, a first latch for latching the output of the first pumping block, a second pumping block for pumping the output of the first pumping block according to a control signal, a second latch for latching the output of the second pumping block, and a switching circuit for selectively outputting the outputs of the first and second latches according to the control signal. Thus, a program voltage and a program verify voltage of different levels are pumped. The ripple and active current can be reduced and the program efficiency can be increased.

Owner:SK HYNIX INC

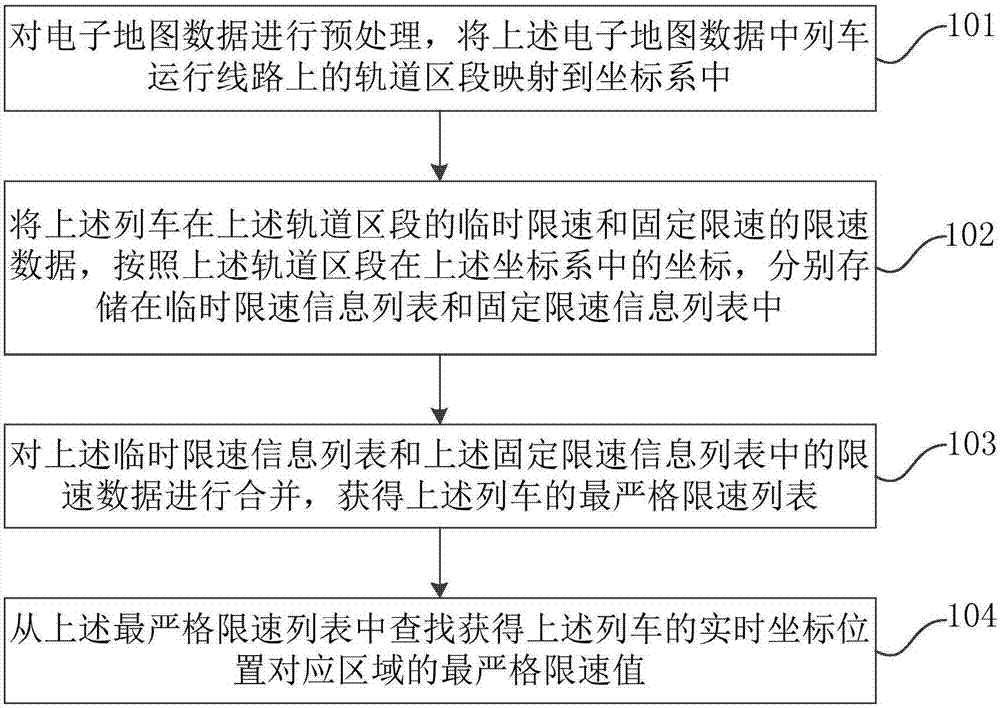

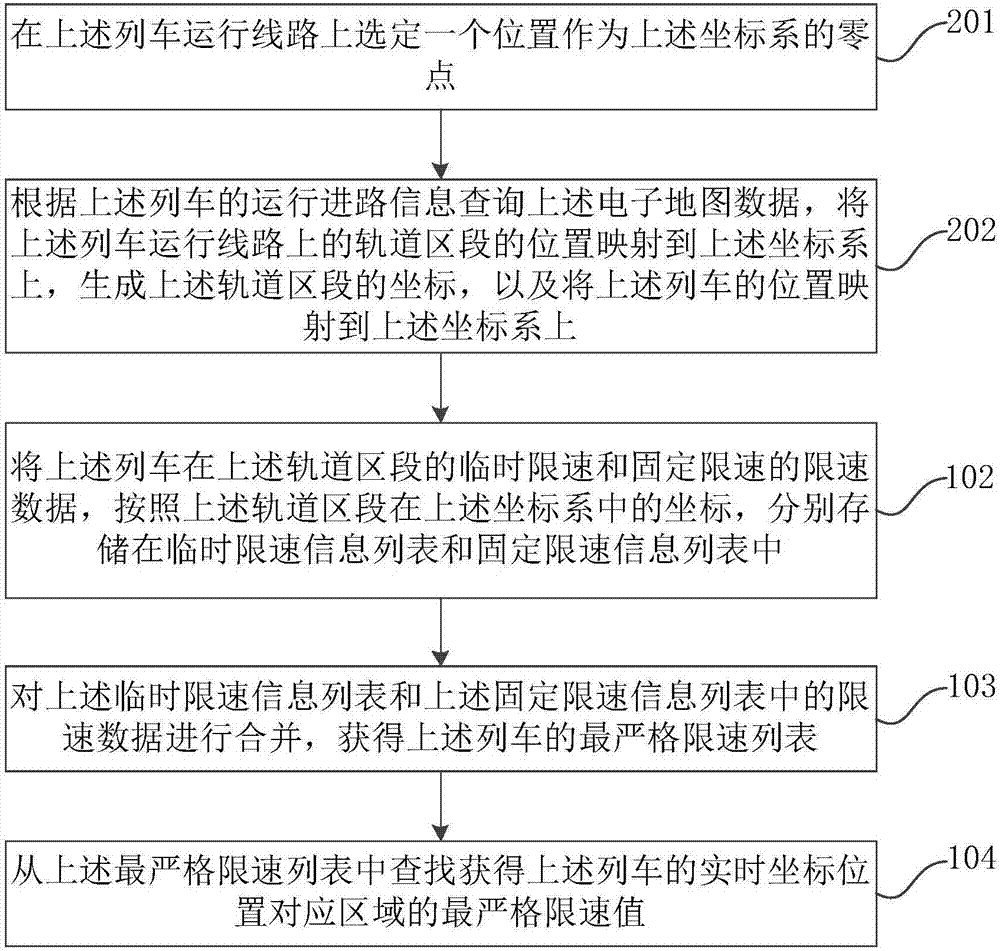

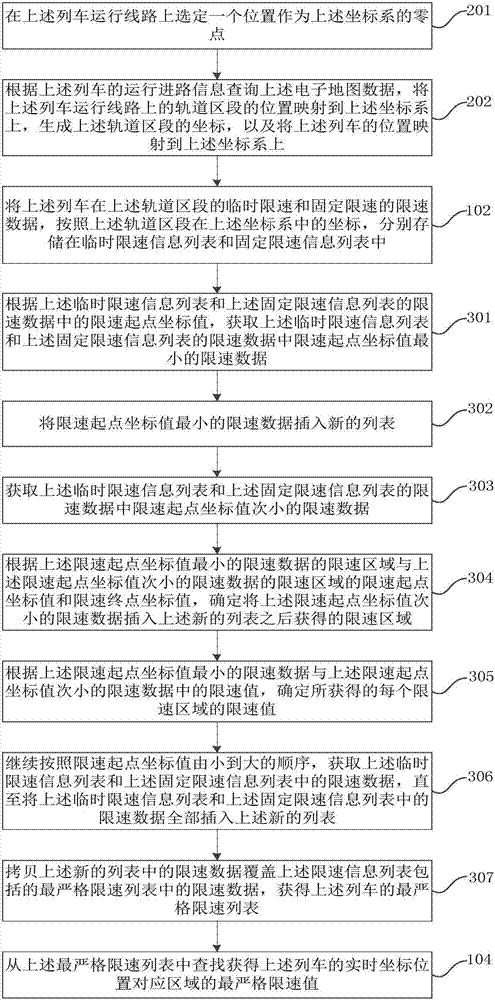

Regional speed limit value obtaining method, device and terminal device

InactiveCN107886461AReduce complexityImprove processing efficiencyData processing applicationsDetection of traffic movementProgram EfficiencyTerminal equipment

The present invention provides a regional speed limit value obtaining method, a regional speed limit value obtaining device and a terminal device. The regional speed limit value obtaining method includes the following steps that: electronic map data are preprocessed, track sections on a train running line in the electronic map data are mapped to a coordinate system; the speed limit data of the temporary speed limit and fixed speed limit of the train in the track sections are respectively stored in a temporary speed limit information list and a fixed speed limit information list according to the coordinates of the track sections in the coordinate system; speed limit data in the temporary speed limit information list and the fixed speed limit information list are combined, so that the most stringent speed limit list of the train is obtained; and the most stringent speed limit value of a region corresponding to the real-time coordinate position of the train is searched out form the most stringent speed limit. With the regional speed limit value obtaining method, regional speed limit value obtaining device and terminal device of the invention adopted, the plurality of temporary speed limit data are combined in a one-off manner into the most stringent speed limit list, and therefore, the logic processing of the query of the electronic map data is simplified, and program efficiency can be improved.

Owner:BYD CO LTD

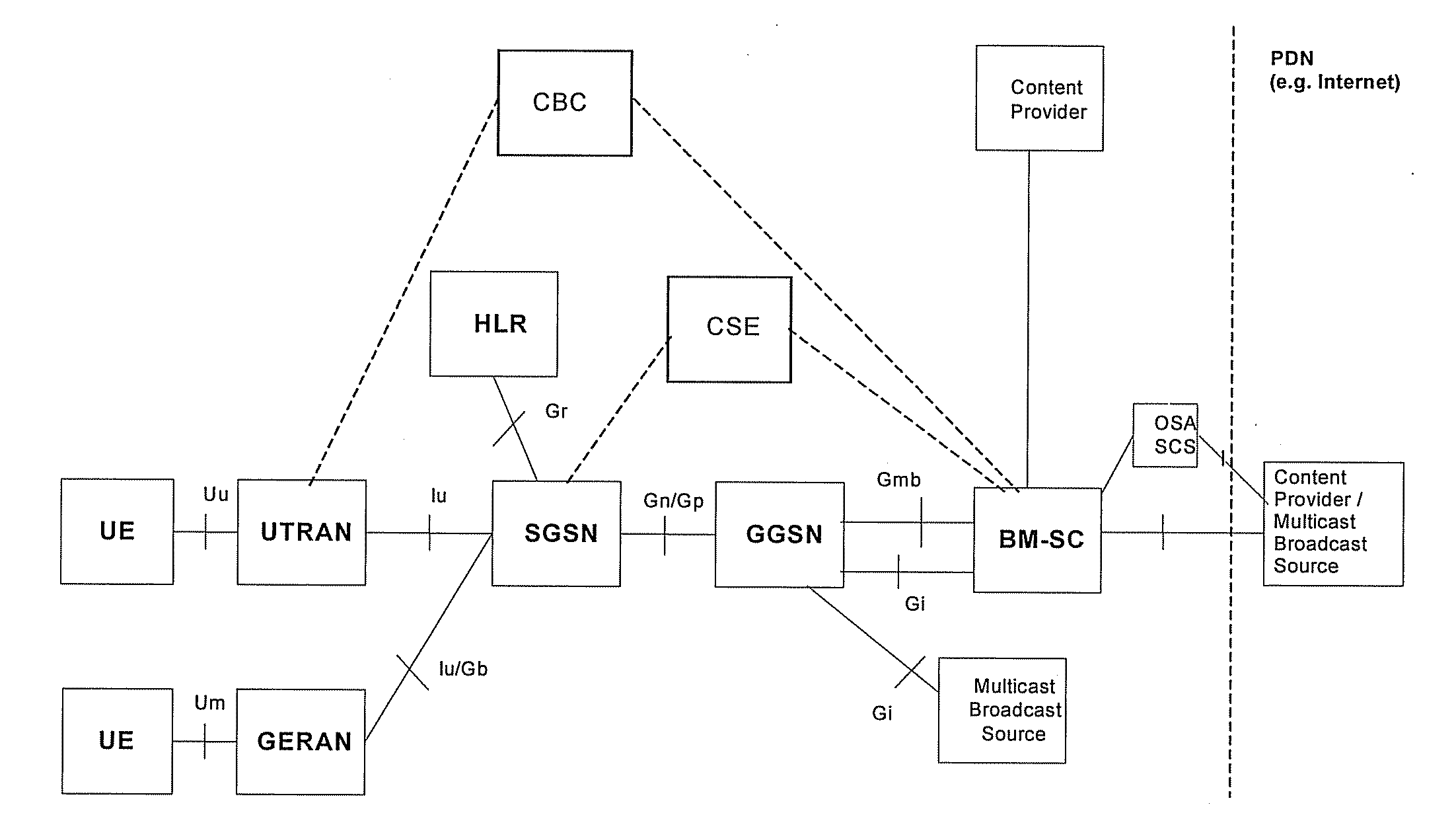

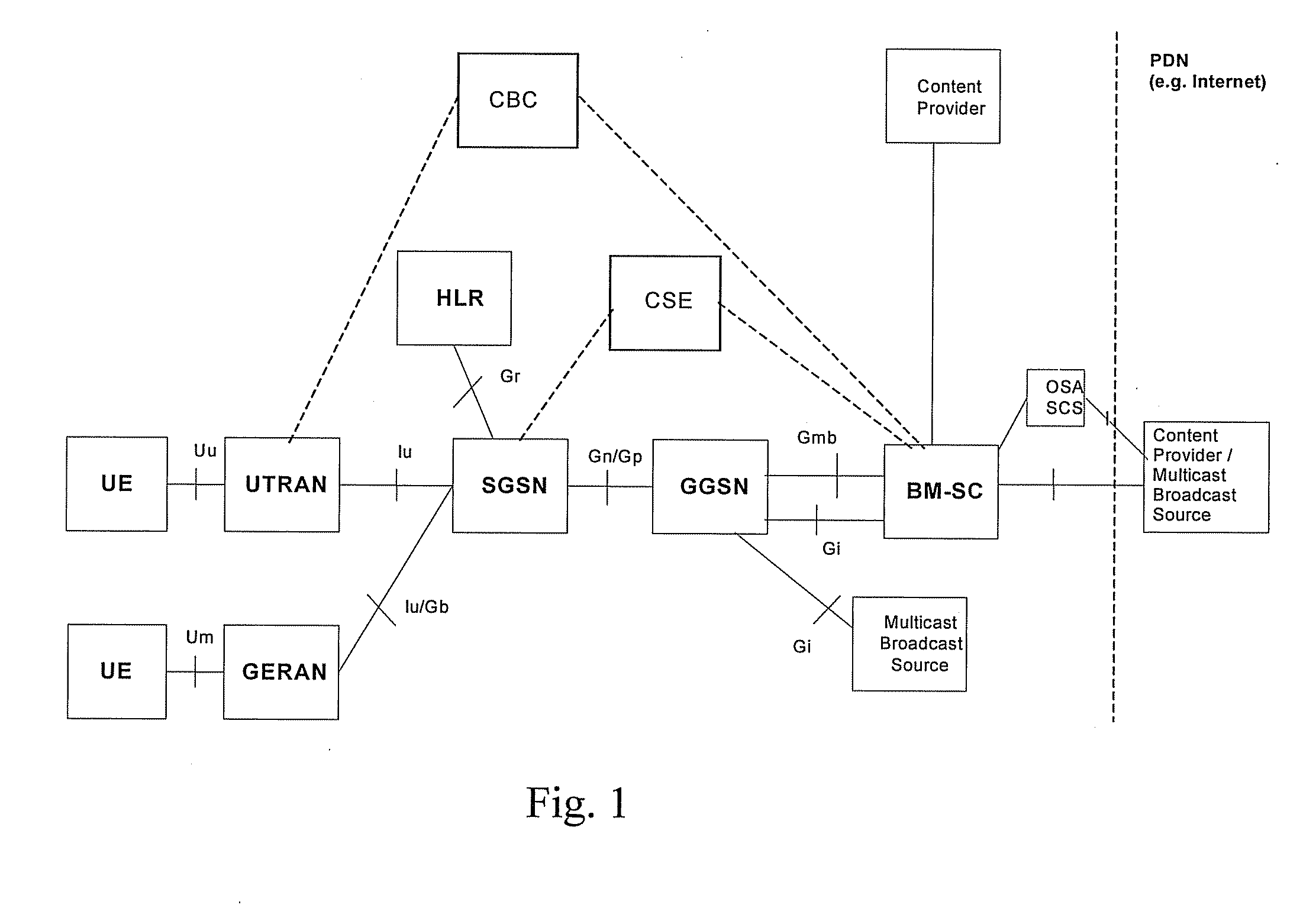

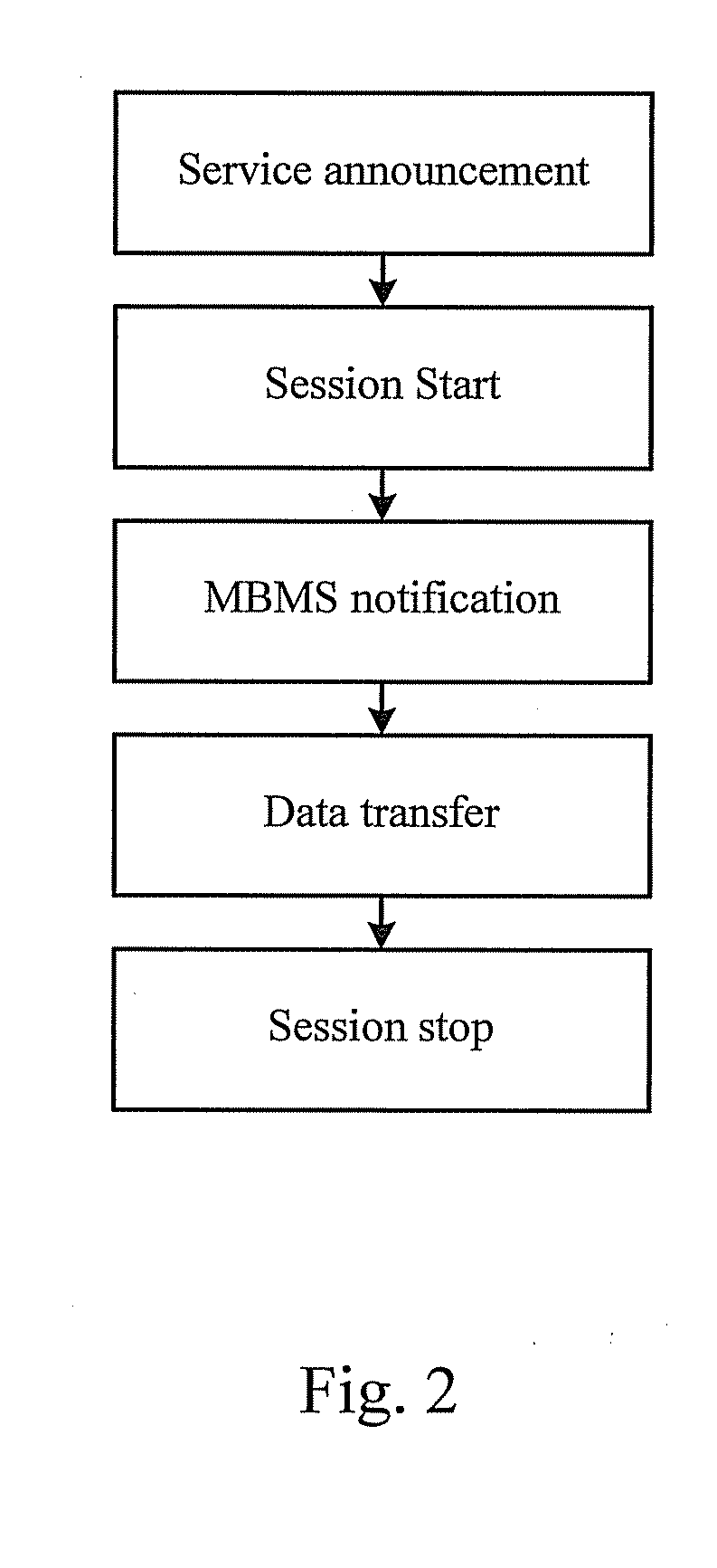

Method for a User Equipment Performing Frequency-Layer Operations in Multimedia Broadcast/Multicast Services

ActiveUS20090116417A1Improper operationImprove efficiencyBroadcast transmission systemsBroadcast service distributionProgram EfficiencyWrong frequency

A method for a User Equipment (UE) performing frequency-layer operations in Multimedia Broadcast and Multicast Services (MBMSs) is disclosed, with priorities preset for various frequency-layer operations, the procedure of performing frequency-layer operations includes the steps of: receiving control information of the MBMSs sent from the network; and performing the frequency-layer operations of the activated MBMSs included in the control information of the MBMSs according to the priorities of frequency-layer operations. By using the method in accordance with embodiments of the present invention, it is possible to avoid wrong frequency-layer operations under the circumstances of a UE joining multiple MBMSs, thus achieving the highest procedural efficiency with the least consumption and improving the efficiency of the UE.

Owner:HUAWEI TECH CO LTD

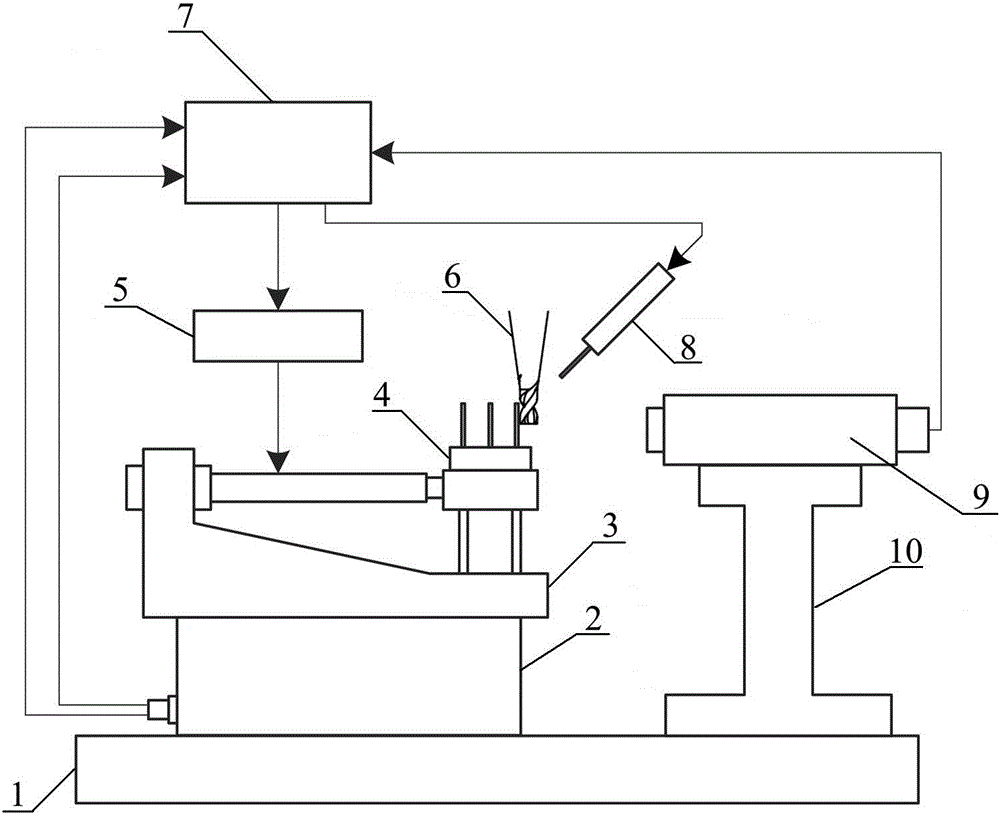

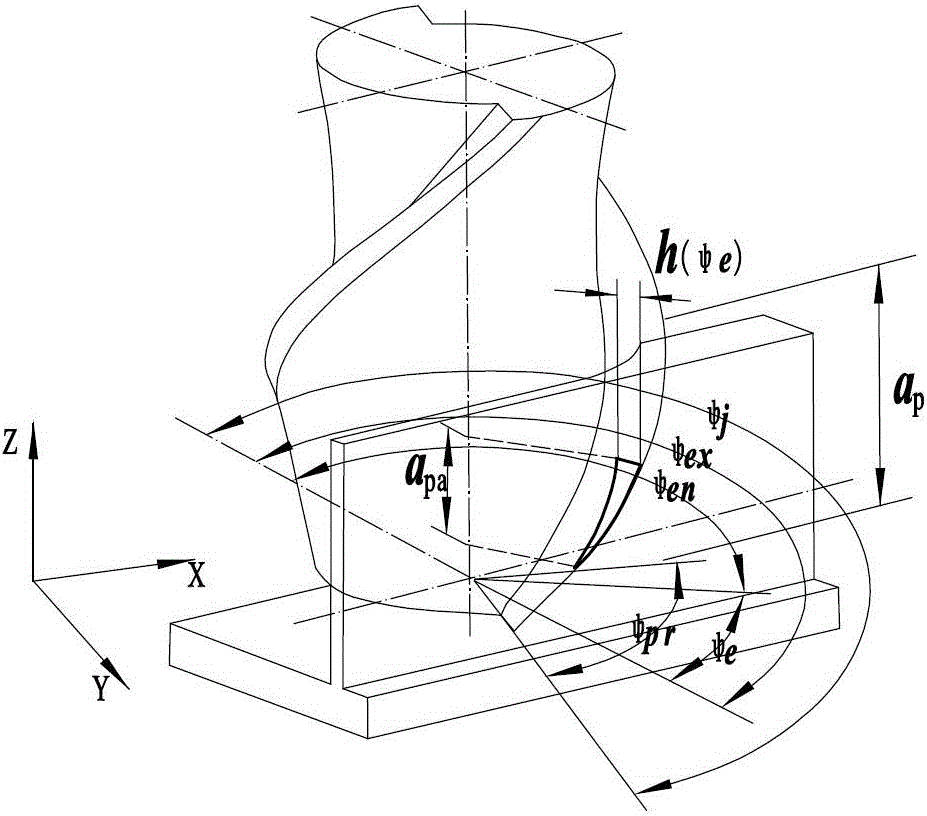

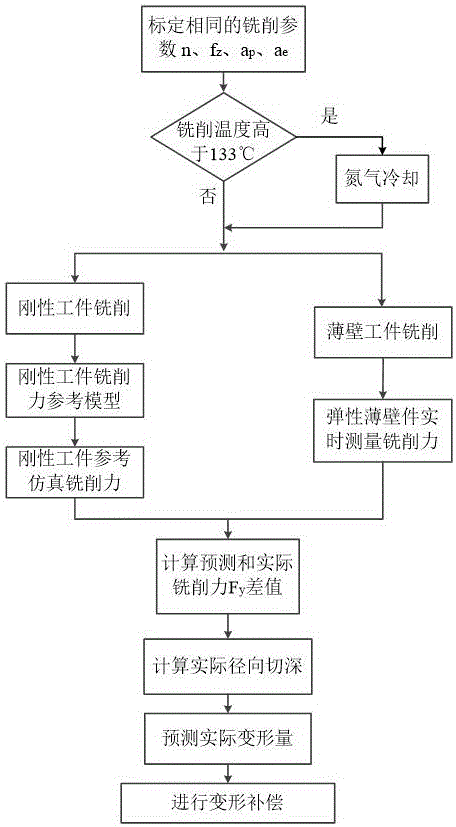

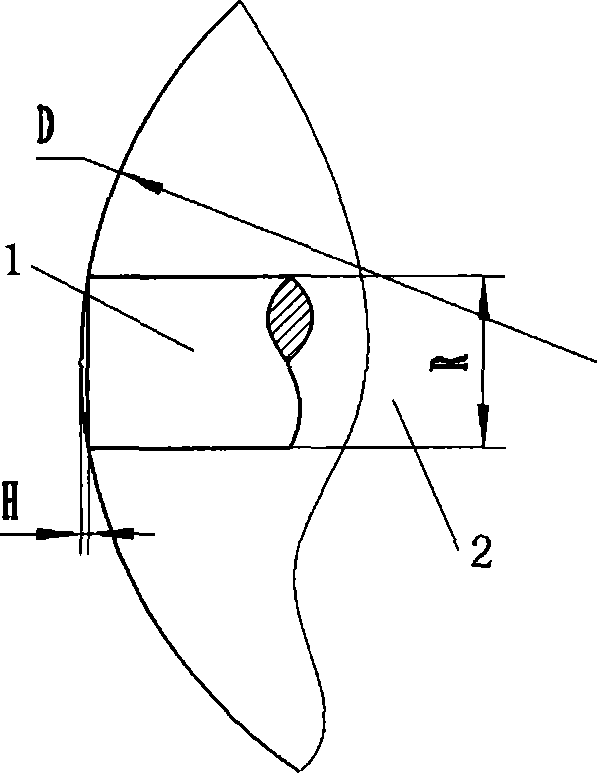

Mesoscale elastic thin-walled workpiece deformation on-line prediction and compensation method

ActiveCN106681274AIncrease rigidity supportGuaranteed rigid supportProgramme controlComputer controlProgram EfficiencyMilling cutter

The present invention relates to a mesoscale elastic thin-walled workpiece deformation on-line prediction and compensation method and belongs to the machining field. The mesoscale elastic thin-walled workpiece deformation on-line prediction and compensation method is realized by a machine turntable, a dynamometer, a driver, a controller, a cooler, a bracket, a fine milling cutter, an infrared thermal imaging instrument and an adjustment mechanism for compensating radial immersion. With the mesoscale elastic thin-walled workpiece deformation on-line prediction and compensation method of the invention adopted, the deformation condition of a processed thin-walled workpiece can be monitored online in real time; the adjustment mechanism controls a screw and a screw-nut pair to adjust a supporting table in real time, so that radial undercut caused by the deformation of the workpiece can be eliminated, and therefore, machining precision and quality can be improved; and the adjustment mechanism is independent of a machine tool control system and will not affect a tool path planned by an existing program, and therefore, programming efficiency can be greatly increased, and production efficiency can be improved.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

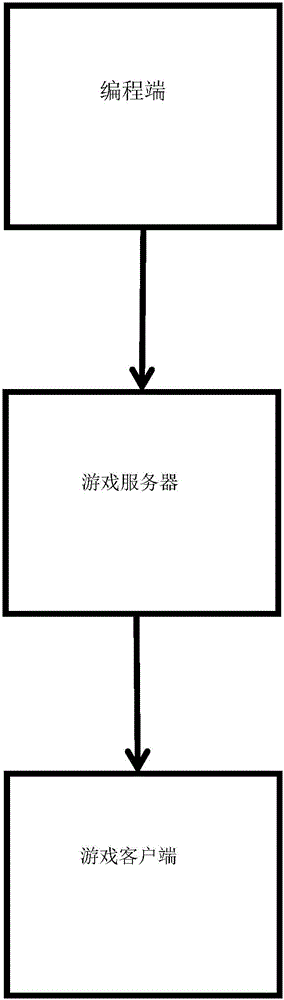

Remote game programming system

InactiveCN106843873AImprove comfortImprove programming efficiencySpecific program execution arrangementsMemory systemsProgram EfficiencyGame programming

The invention discloses a remote game programming system, comprising a web-based programming end, a game server and a game client; the programming end includes a browser unit, a programming data unit and a server interface unit; the browser unit provides a graphic interface to acquire a user's access operation for the programming data unit, the server interface unit records the access operation and sends to the game server, and the record is marked as programming information; the game server receives the programming information, corrects the corresponding interfaces based on the programming information to change game data, transmits the changed game data to the game client, and calls the corresponding interfaces to correct game data. The remote programming end provided herein receives customer's operations of remote programming, code to change a game is output through the user's operations to change the content of the game, a programming training system is more comfortable for a user to use, and programing efficiency is improved.

Owner:深圳市编玩边学教育科技有限公司

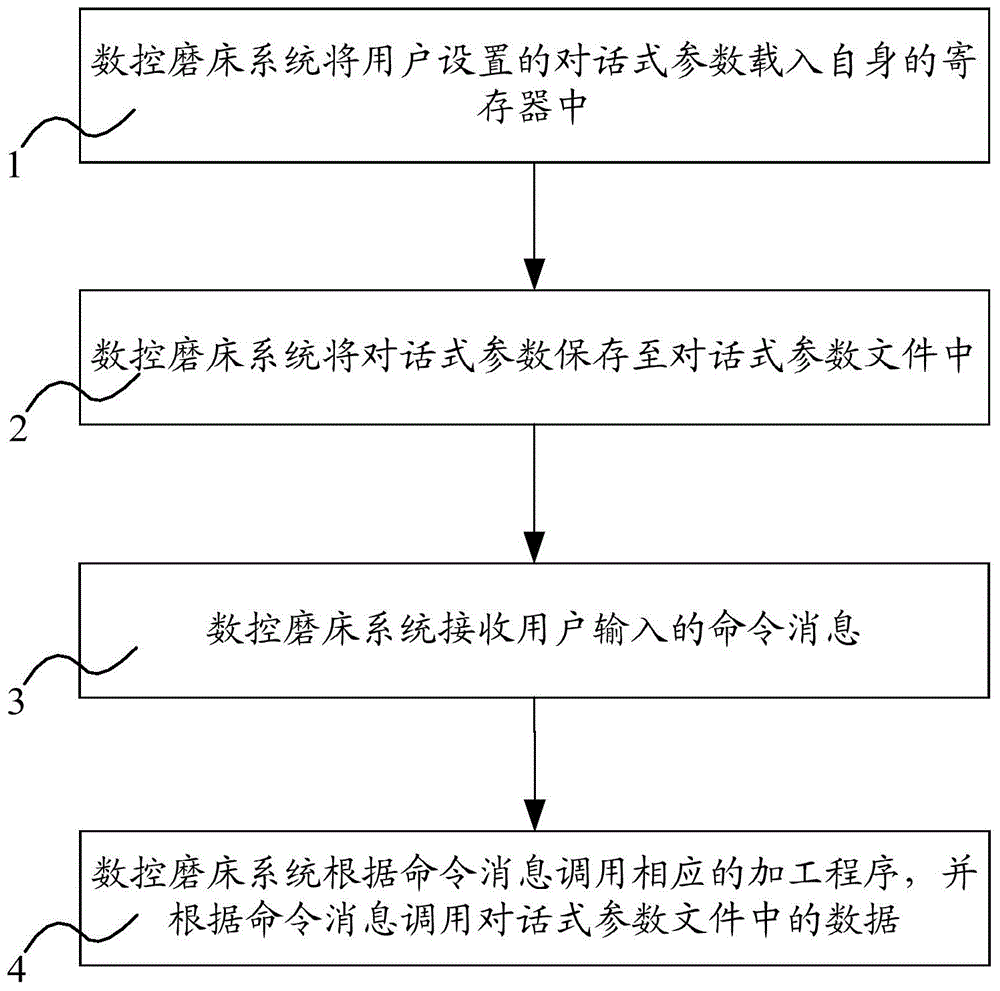

Method for achieving machining program processing through conversational parameters in computer numerical control grinding machine system

ActiveCN104907932ALower quality requirementsEasy to handleAutomatic grinding controlNumerical controlProgram Efficiency

The invention relates to a method for achieving machining program processing through conversational parameters in a computer numerical control grinding machine system. The method includes the following steps that the computer numerical control grinding machine system loads the conversational parameters set by a user into a register of the computer numerical control grinding machine system; the computer numerical control grinding machine system stores the conversational parameters in a conversational parameter file; the computer numerical control grinding machine system receives a command message input by the user; the computer numerical control grinding machine system calls the corresponding machining program according to the command message and calls data in the conversational parameter file according to the command message. By the adoption of the method for achieving machining program processing through the conversational parameters in the computer numerical control grinding machine system, different machining technological processes can be achieved only by setting different conversational parameters, and therefore the technical problem that programs need to be artificially modified and compiled according to different systems is solved effectively, the processing procedure is simple and convenient to implement, programming efficiency and the machining procedure are improved rapidly, requirements for quality of operators are lowered, and the method has a wider application range.

Owner:SHANGHAI WEIHONG ELECTRONICS TECH

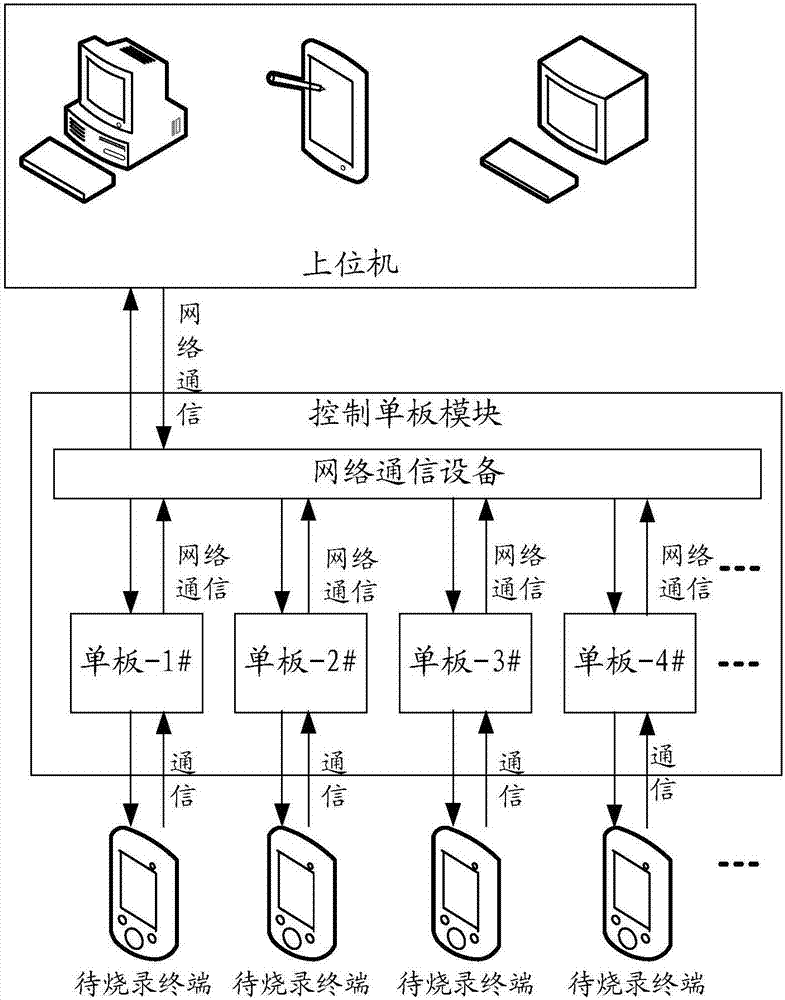

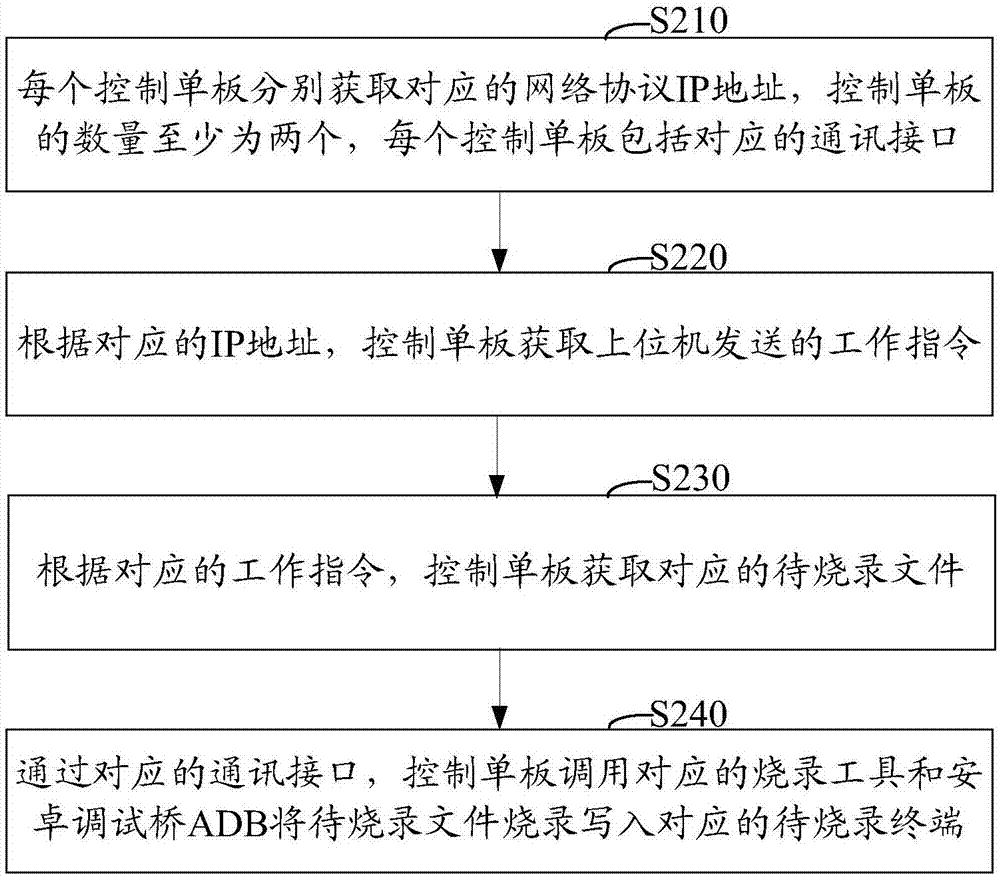

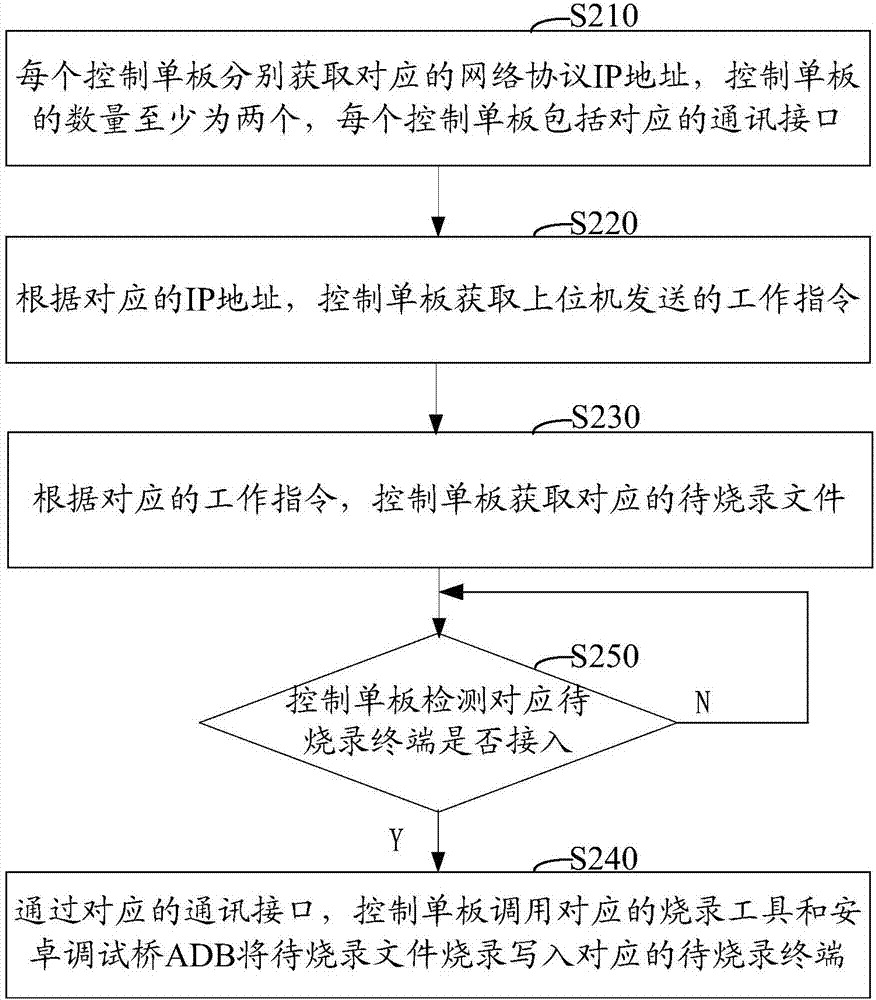

Firmware programming method and system

ActiveCN106970810AOvercome the disadvantage of low efficiency in the burning processImprove programming efficiencyProgram loading/initiatingSoftware deploymentCommunication interfaceProgram Efficiency

The invention relates to a firmware programming method. The method comprises the steps that each control single board acquires a corresponding network protocol IP address, wherein the number of the control single boards is at least two, and each control single board comprises a corresponding communication interface; the control single boards acquire work instructions sent by an upper computer according to the corresponding IP addresses; the control single boards acquire corresponding to-be-programmed files according to the corresponding work instructions; and the control single boards call corresponding Android debugging bridges (ADBs) through the corresponding communication interfaces to write the to-be-programmed files into a to-be-programmed terminal in a programming mode. Besides, the invention furthermore provides a firmware programming system. Through the firmware programming method and system, each control single board can separately call an ADB client to perform terminal programming, the number of the control single boards can be increased and configured at will according to needs, the defect that when an ADB client faces a one-to-multiple terminal application scene, programming efficiency is low because multiple terminals have resource competition is overcome, and programming efficiency is improved.

Owner:PAX COMP TECH SHENZHEN

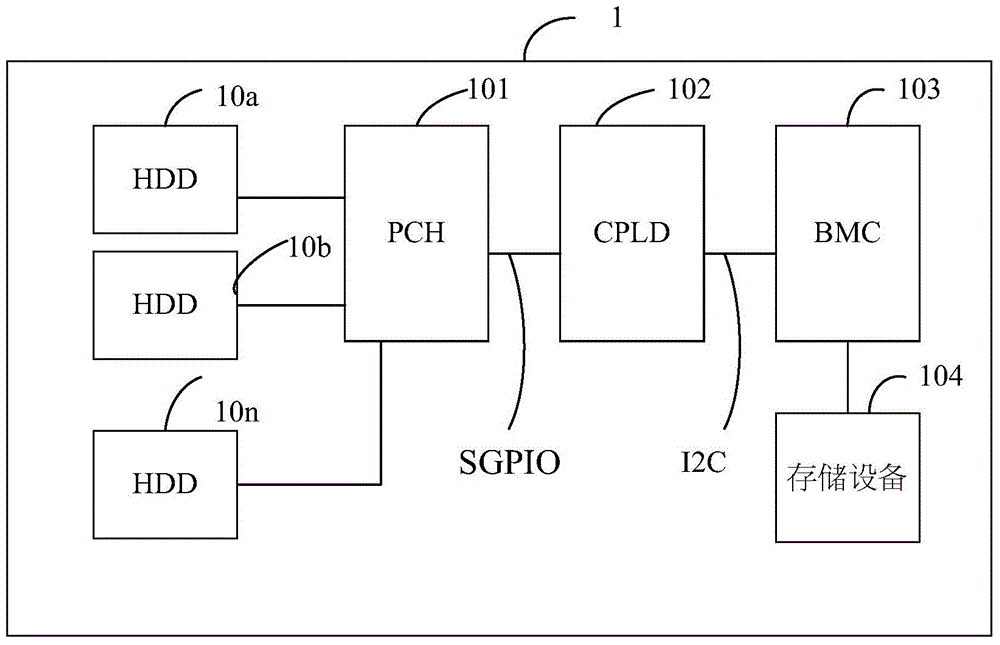

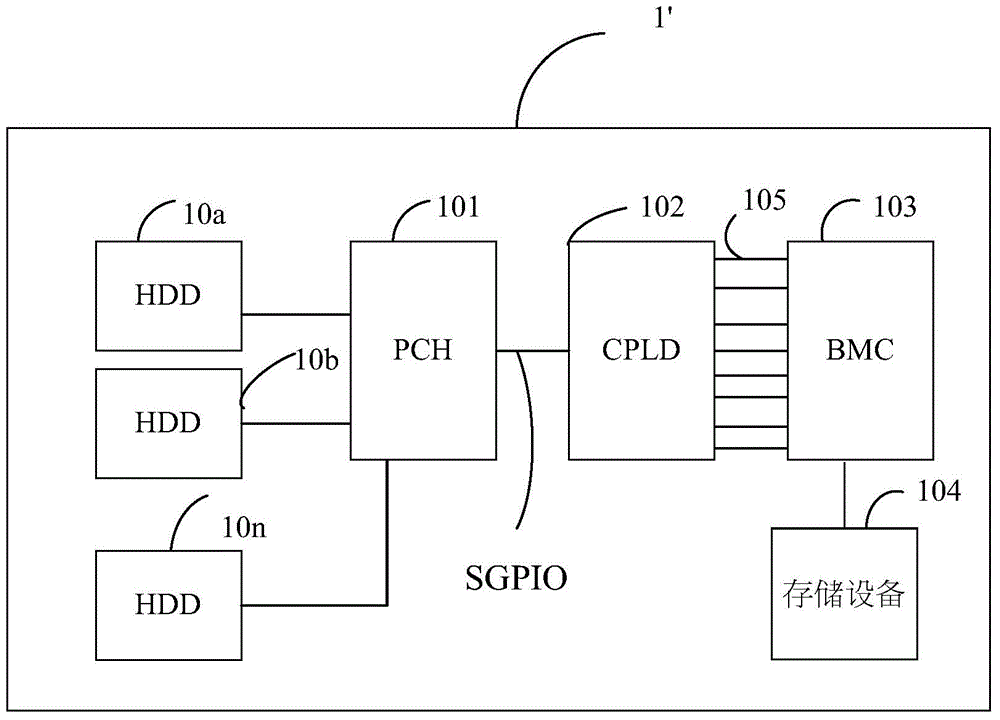

Electronic device capable of detecting hard disk state

InactiveCN104572362AReduce data volumeNo delay lostDetecting faulty computer hardwareHard disc driveProgramming complexity

The invention provides an electronic device capable of quickly and accurately detecting a hard disk state. The electronic device comprises a plurality of hard disk drivers, a south bridge PCH (Platform Controller Hub), a programmable device CPLD (Complex Programmable Logic Device), a substrate controller BMC (Block Multiplexer Channel) and a storage device, wherein the PCH is used for detecting the working states of the hard disk drivers, and sending a signal to the programmable device CPLD through a SGPIO (Serial General Purpose Input Output) protocol when the hard disk drivers have errors. The CPLD is used for decoding the signal, and transmitting the decoded data to the BMC through a GPIO mode. The electronic device can be used for transmitting the data by replacing the GPIO mode with an I2C mode, so that an internal data path of the CPLD cannot be blocked, and data delay and loss are avoided; the data volume processed by the CPLD is reduced greatly, so that the working efficiency is improved; moreover, a drive program corresponding to the I2C mode is not needed to be added to the CPLD, so that the programming complexity is lowered, and the programming efficiency is greatly improved.

Owner:HONG FU JIN PRECISION IND (SHENZHEN) CO LTD +1

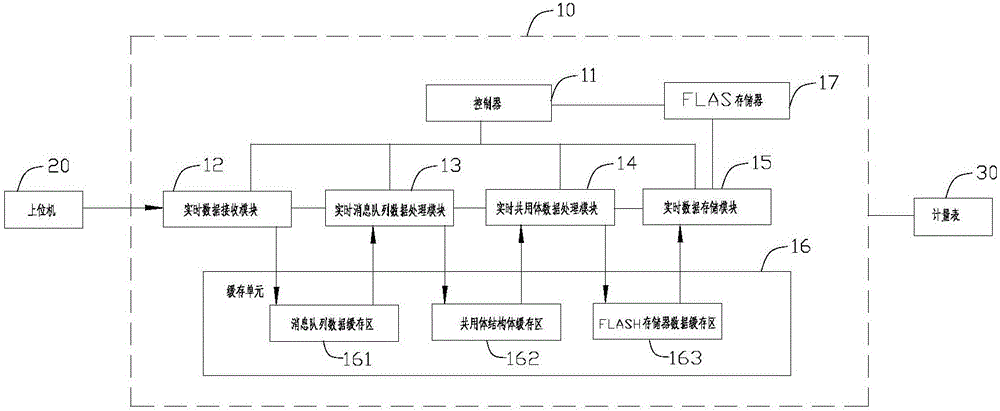

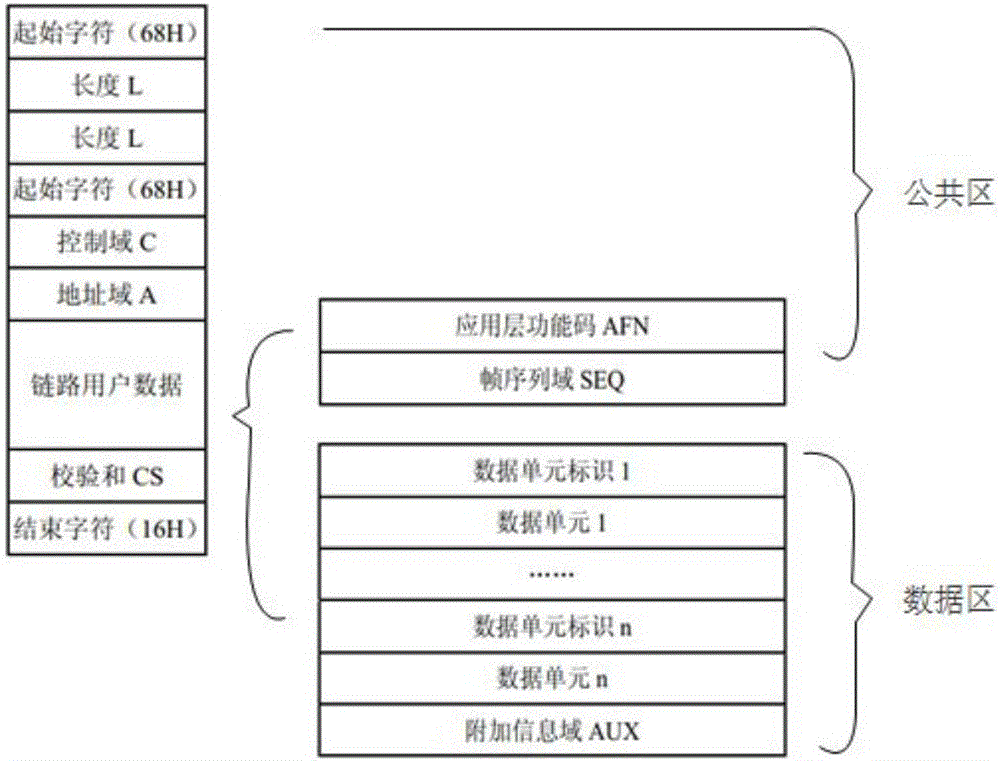

Intelligent concentrator and data processing method taking measurement point as tag

ActiveCN106383693AImprove work efficiencyImprove securityConcurrent instruction executionMessage queueReal-time data

The invention provides an intelligent concentrator. The intelligent concentrator comprises a controller, a cache unit, a real-time data receiving module connected with the controller, a real-time message queue data processing module, a real-time union data processing module, a real-time data storage module and a FLASH memory, wherein the real-time data receiving module, the real-time message queue data processing module, the real-time union data processing module and the real-time data storage module are connected in sequence; and the cache unit comprises a message queue data cache region, a union structure body cache region and a FLASH memory data cache region. The invention furthermore provides a data processing method taking the intelligent concentrator as a tag. According to the intelligent concentrator and the data processing method, the program efficiency of the intelligent concentrator can be effectively improved, the data security can be enhanced, and the service life of a FLASH memory chip can be prolonged.

Owner:武汉阿迪克电子股份有限公司

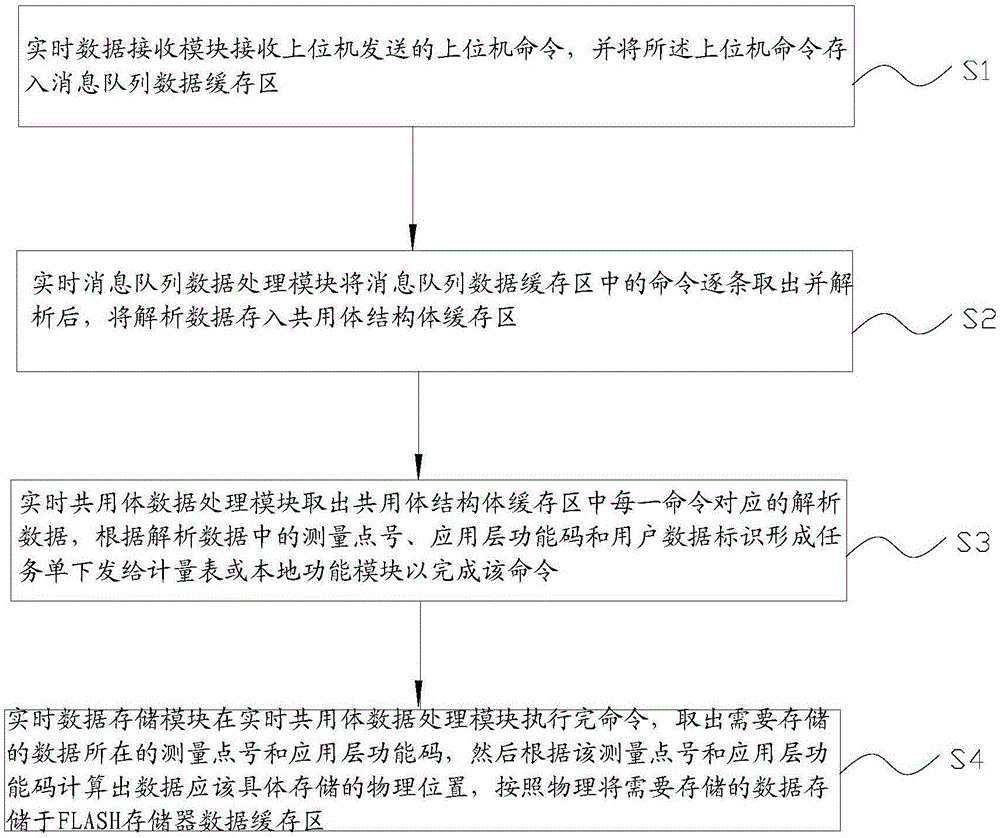

CNC machine tool machining flow optimization method

InactiveCN108197730AImprove efficiencyImprove accuracyForecastingOffice automationProcess optimizationProgram Efficiency

The present invention relates to a CNC machine tool machining flow optimization method. The method comprises the following steps: carrying out standardized processing on the machining program mode, the tool number and parameters of all models, and acquiring to-be-processed workpiece information; selecting the machining program corresponding to the to-be-processed workpiece information, and analyzing the machining program to obtain the tool number and the tool use sequence contained in the machining program; and carrying out optimization processing on the machining program in the machining process in series or in combination according to the optimization method selected by the user. According to the method disclosed by the present invention, the user can select a multi-program optimizationscheme: multi-program serial or multi-program tool combination, and the system automatically optimizes the processing program according to the user selected scheme, so that manual operation errors andrepeated operation fatigue can be reduced, program combination and serial can be improved, and program efficiency and accuracy can be optimized.

Owner:武汉益模科技股份有限公司

Endoscope management system

InactiveUS7818182B2Highly user-friendly in operationEasy to set upData processing applicationsSurgical instrument detailsProgram EfficiencyDisplay device

Owner:ENDOLOGISTICS

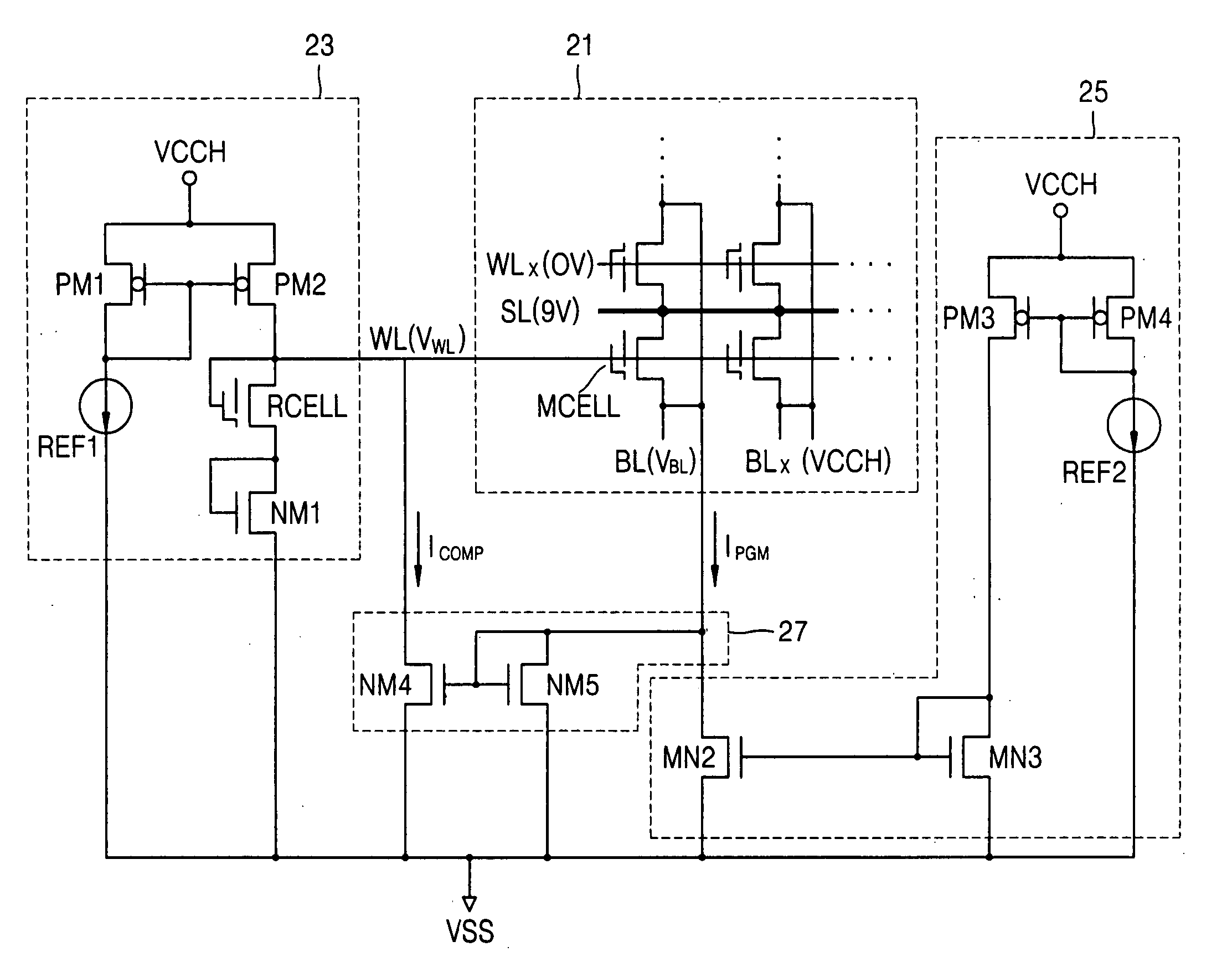

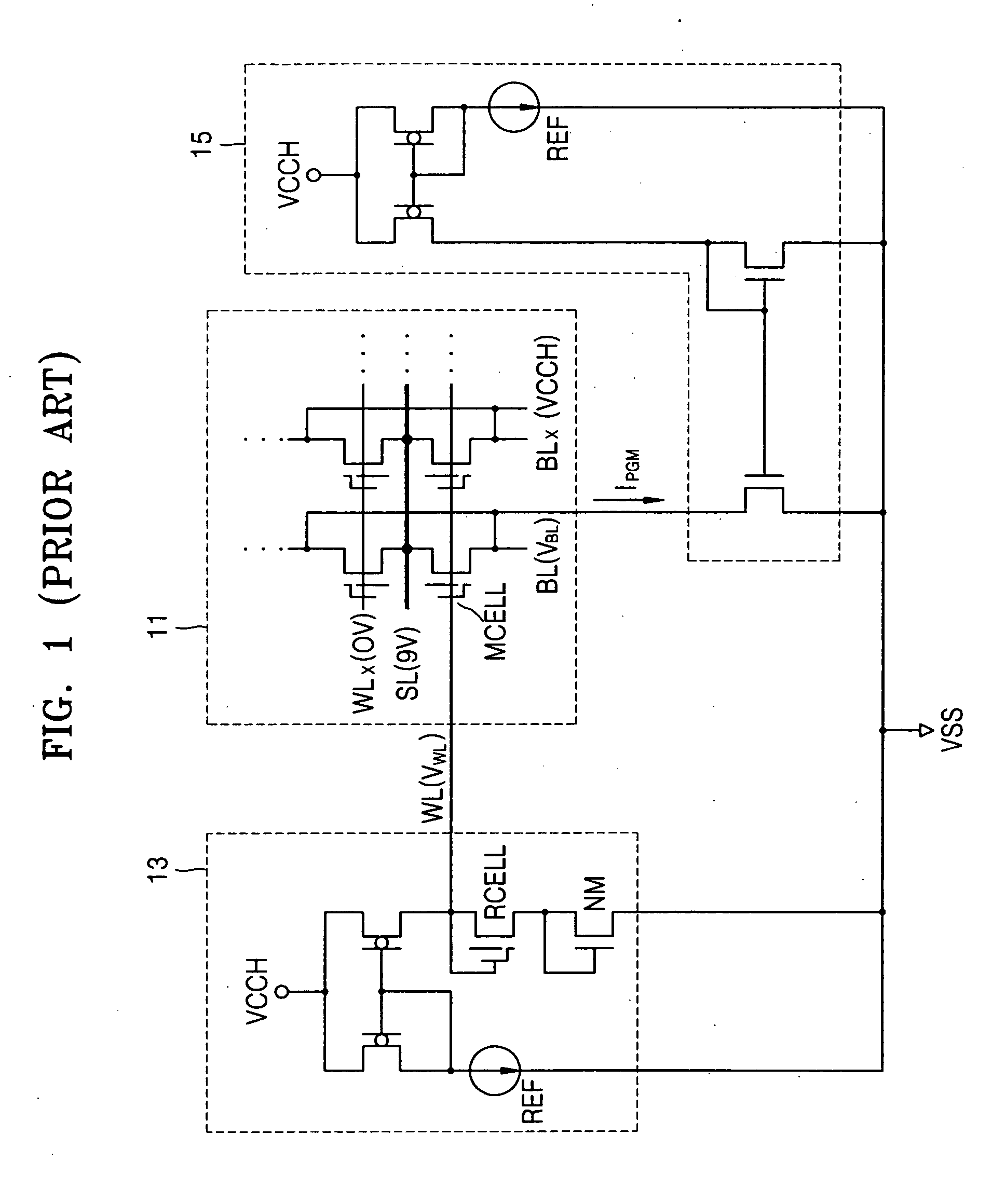

Flash memory device including bit line voltage clamp circuit for controlling bit line voltage during programming, and bit line voltage control method thereof

In a flash memory device and a bit line voltage control method thereof a circuit capable of reducing the change in a voltage of a bit line during programming. The flash memory device includes: a flash memory cell, a source of which is connected to a source line, a drain of which is connected to a bit line and a gate of which is connected to a word line; a word line voltage generation circuit connected to the word line, for generating and providing a word line voltage to the word line; a program current generation circuit connected to the bit line, for generating and providing a program current to the bit line; and a bit line voltage clamp circuit connected to the bit line and the word line, for sensing a voltage of the bit line and controlling a bias current of the word line voltage generation circuit to thereby control a voltage of the bit line, during a programming operation of the flash memory device. Therefore, it is possible to enhance program efficiency and reduce program disturbance by constantly maintaining the voltage of the bit line to a desired voltage using a bit line voltage clamp circuit during programming.

Owner:SAMSUNG ELECTRONICS CO LTD

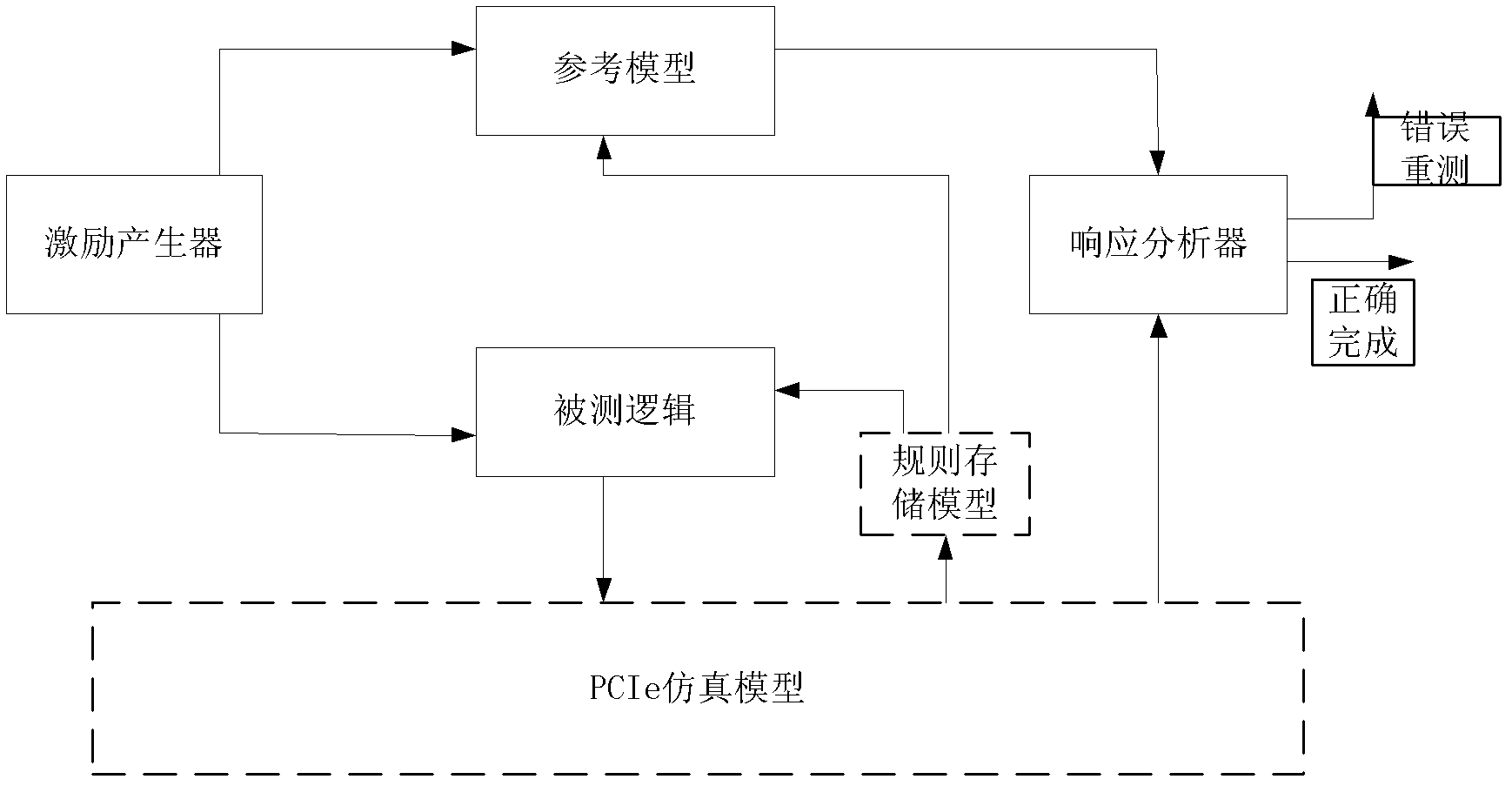

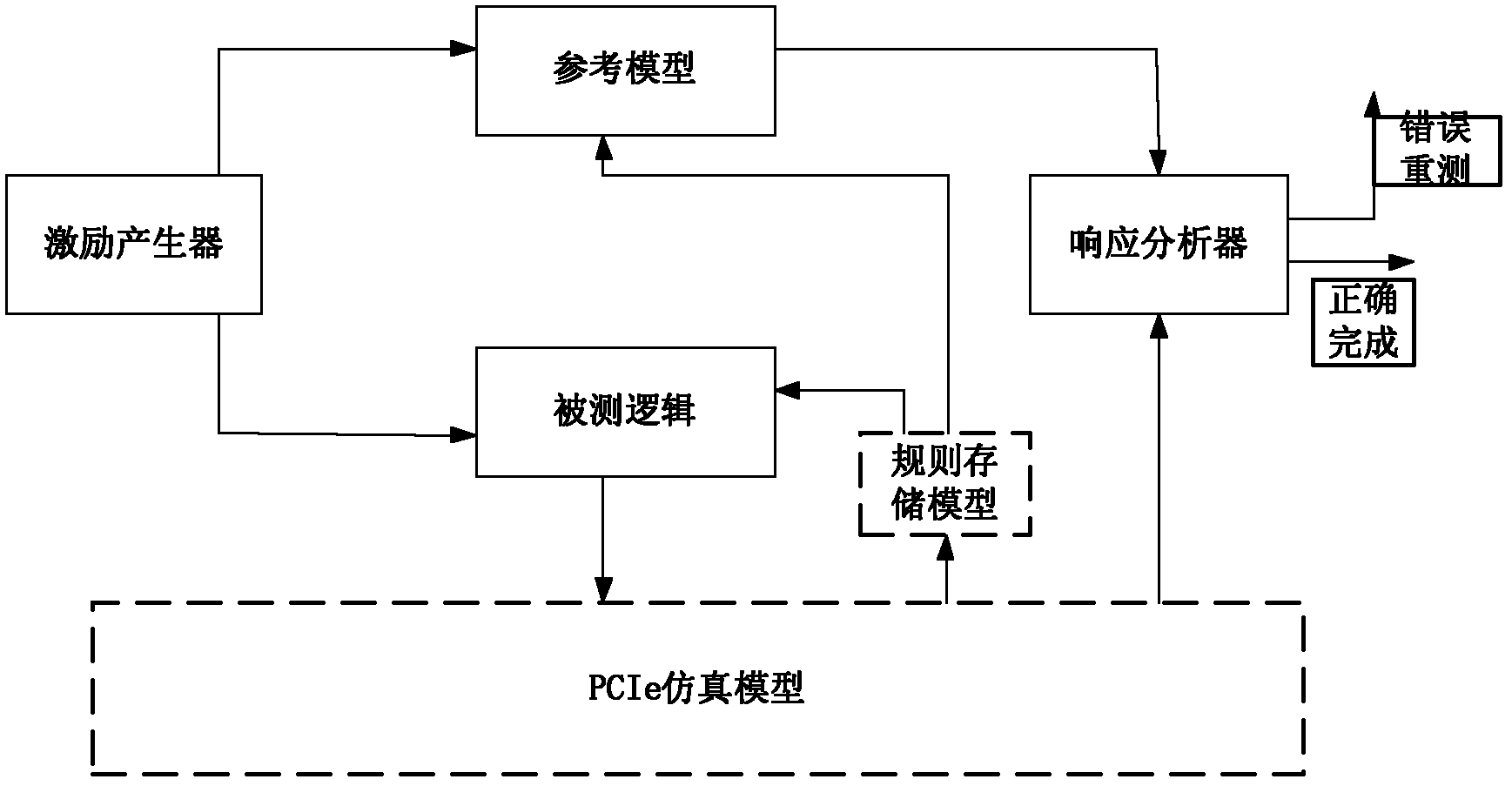

System and method for testing single-packet regular matching logic

ActiveCN102495778AImprove programming efficiencyImprove verification efficiencyLogical operation testingProgramming languageProgram Efficiency

The invention provides a method for testing single-packet regular matching logic. A peripheral component interface express (PCIe) simulation model simulates the characteristic of a PCIe bus and receives a host command which comprises a write command and a read command. Compared with the prior art, the method has the advantages that: 1) the efficiency of a program which is compiled by using a SystemVerilog language is quite high, a complicated function can be realized by using smaller code line number, and validation efficiency is improved; and 2) a constraint-based random simulation validation method using the SystemVerilog language is a high-efficiency function validation method, the validation efficiency of the function can be greatly improved, and the functional defect of a product which is sold in the market is avoided.

Owner:DAWNING INFORMATION IND BEIJING +1

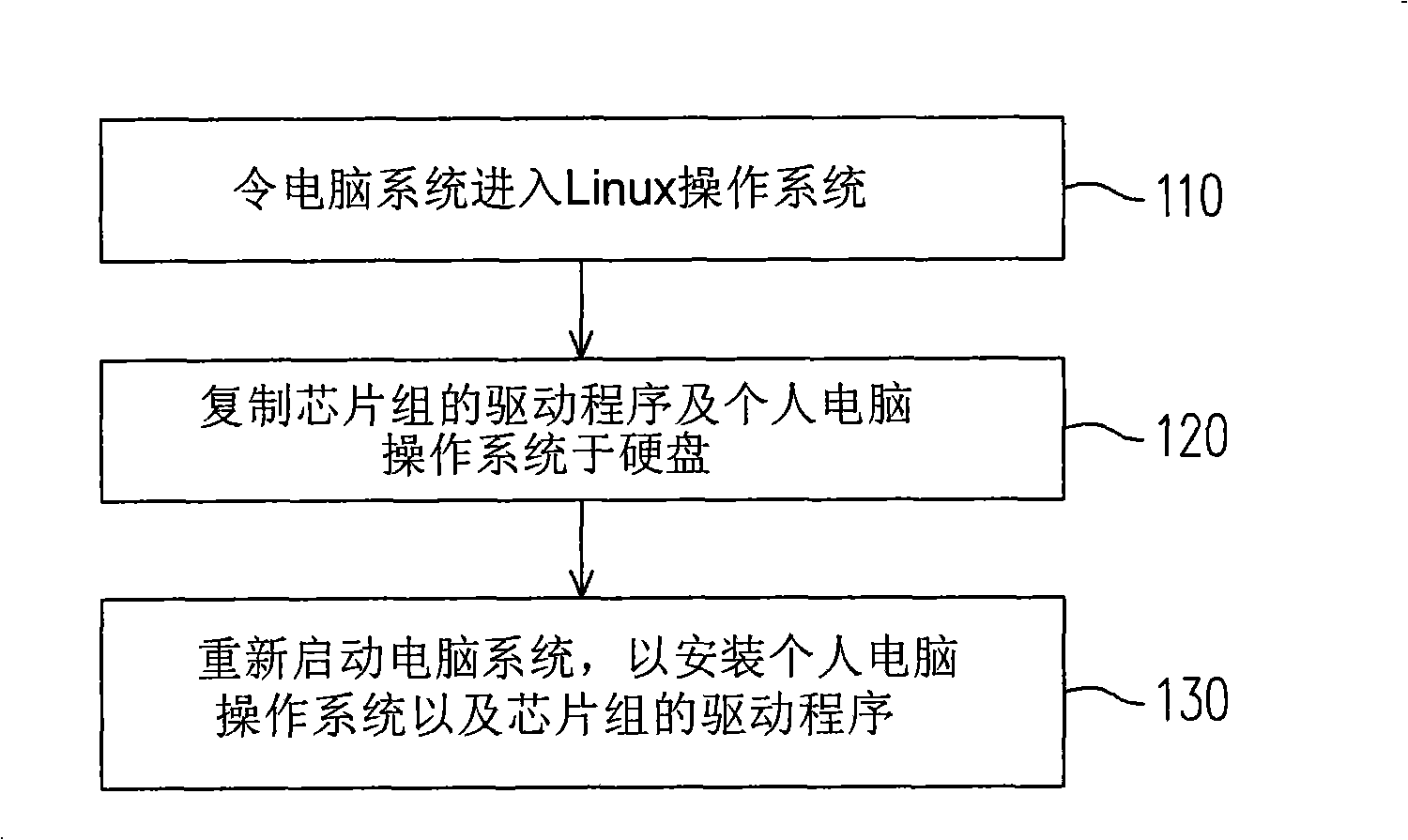

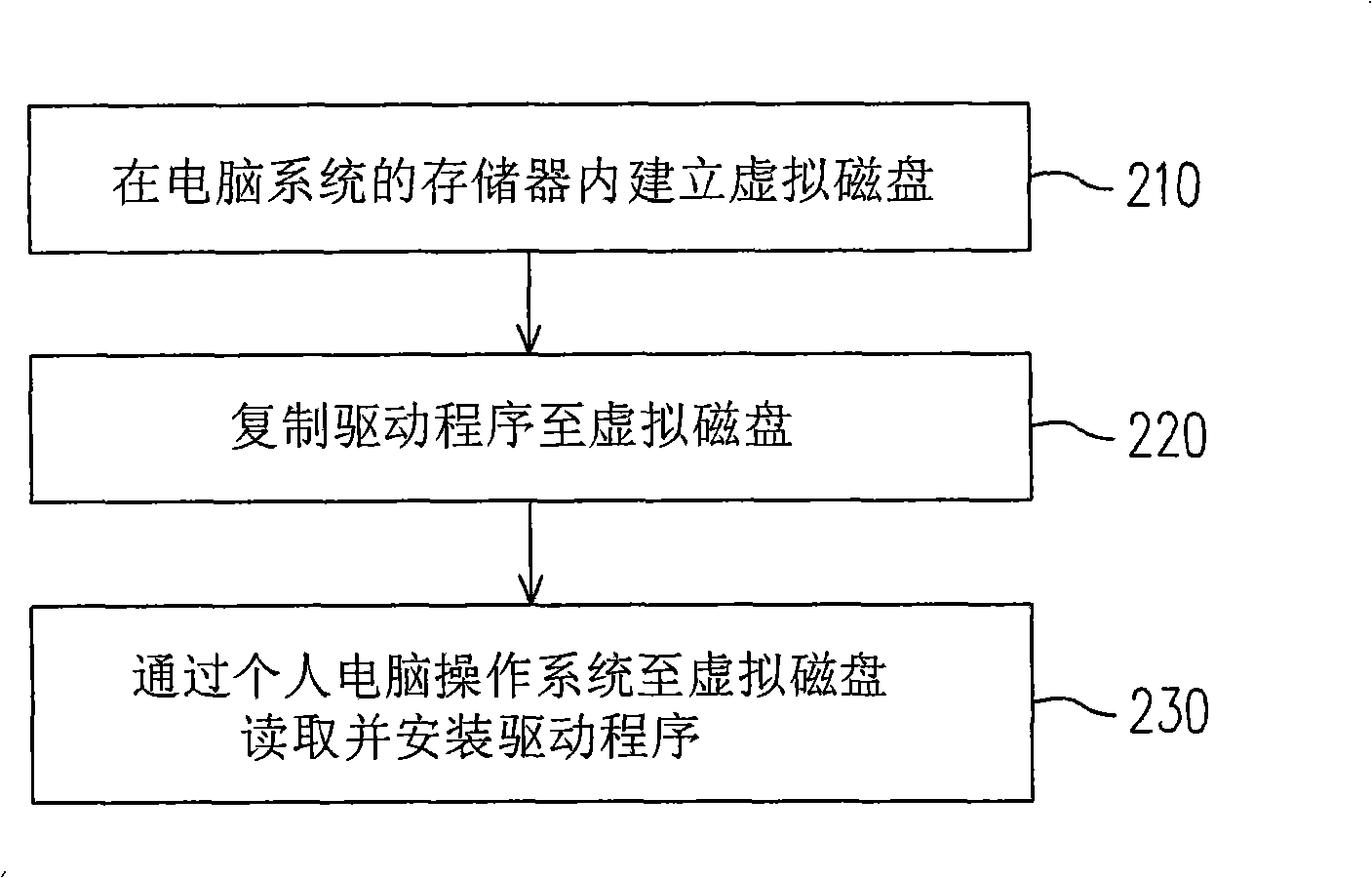

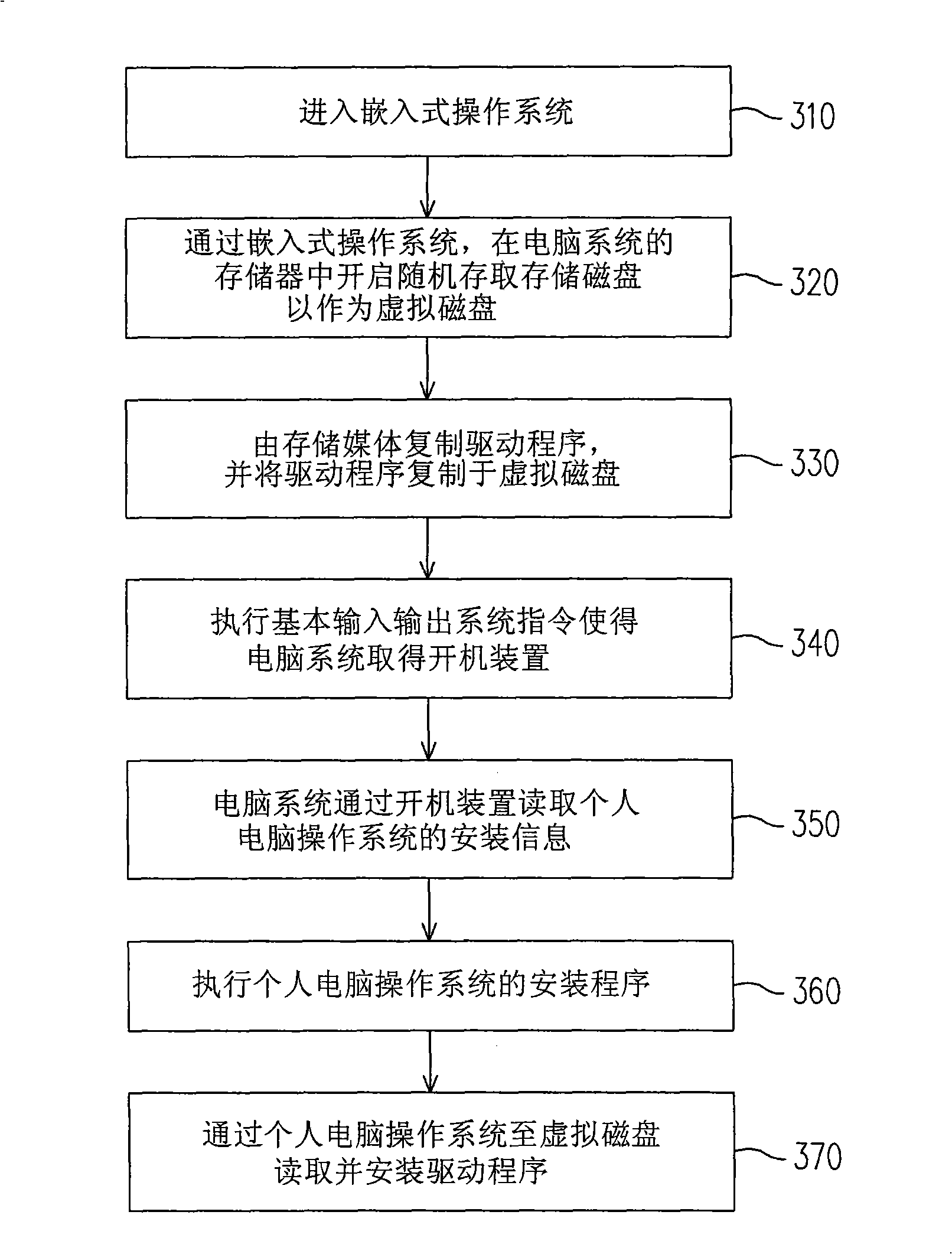

Method for installing driver

InactiveCN101276281AShorten the timeImprove efficiencyProgram loading/initiatingOperational systemProgram Efficiency

The present invention provides a mounting method of a driving program, firstly, establishing a virtual disk in the memory of computer system, then, duplicating the driving program to the virtual disk. The driving program is read and mounted by the individual computer operation system to the virtual disk. The driving program is directly read from the memory when mounted in a mode of storing the driving program to the memory in advance, this reduces the time consumed by searching proper driving program in the disk and transforming the format, achieving the aim of improving the efficiency of the mounting the driving program.

Owner:INVENTEC CORP

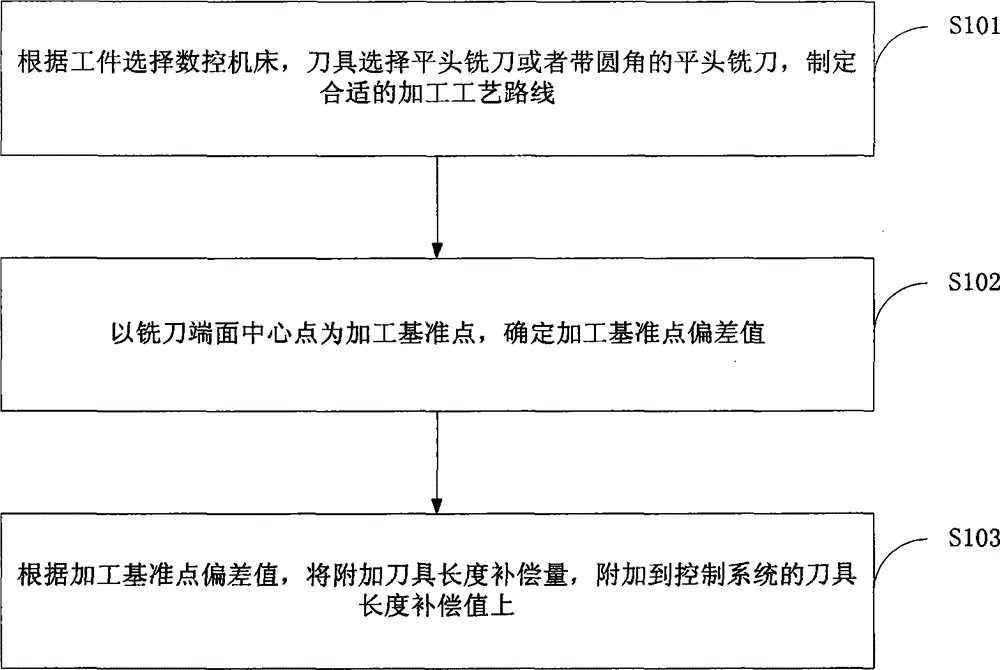

Orthogonal turning and milling method for inner rotary surface

InactiveCN105269398AGuaranteed production efficiencyGive full play to the efficiency of high-speed millingAutomatic control devicesFeeding apparatusProgram EfficiencyMilling cutter

The invention discloses an orthogonal turning and milling method for an inner rotary surface. According to the orthogonal turning and milling method for the inner rotary surface, the datum point deviation value and the additional cutter length compensation value of a flat-end milling cutter and a flat-end milling cutter with round corners in the workpiece machining process are acquired, and the additional cutter length compensation value is added to the cutter length compensation function of a numerical control system. By the adoption of the method, the axes of the milling cutters are perpendicular to the inner surface of a part all the time for machining in the machining process, programming efficiency and accuracy are improved, machining quality is guaranteed, and a machining period is shortened.

Owner:SHENYANG LIGONG UNIV

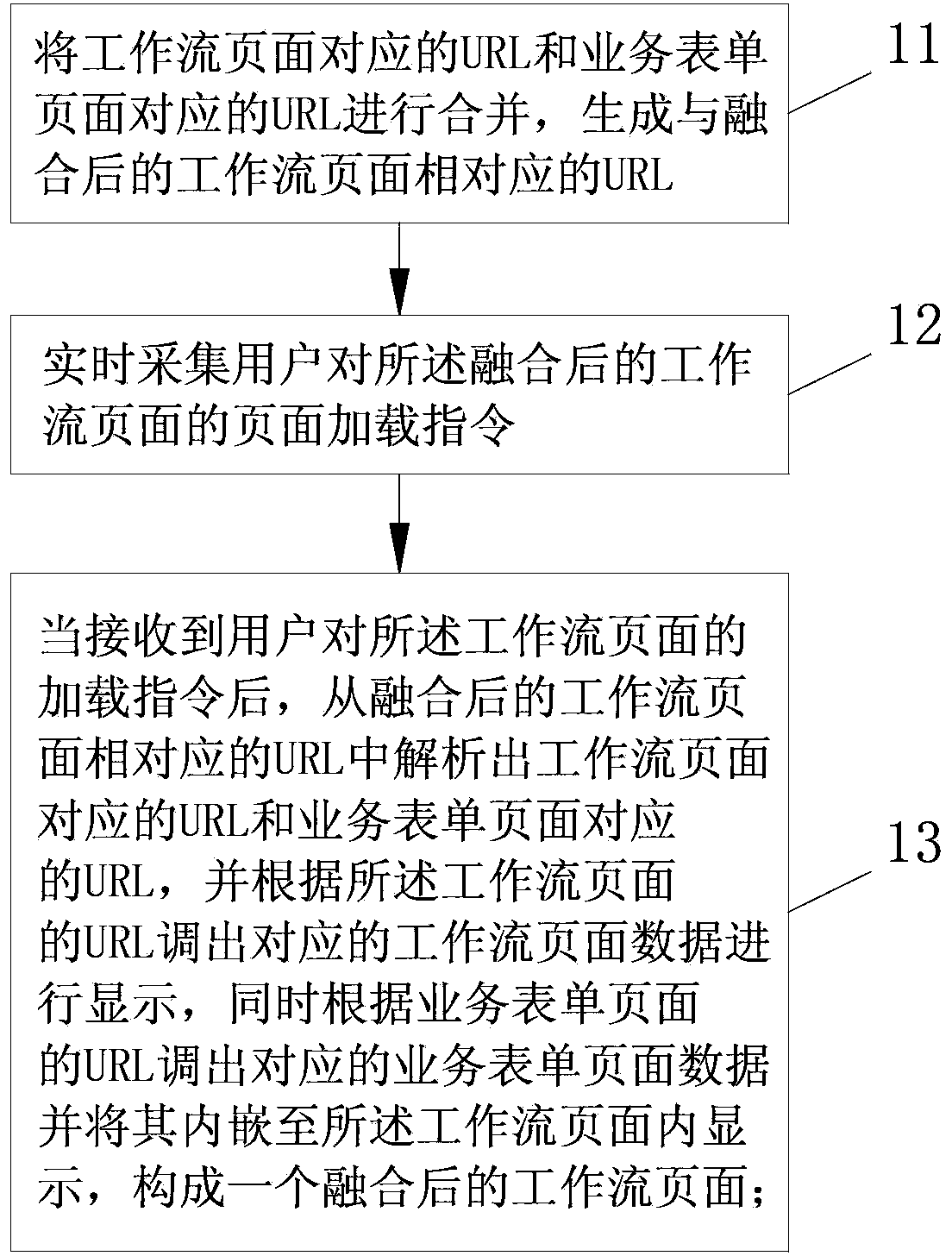

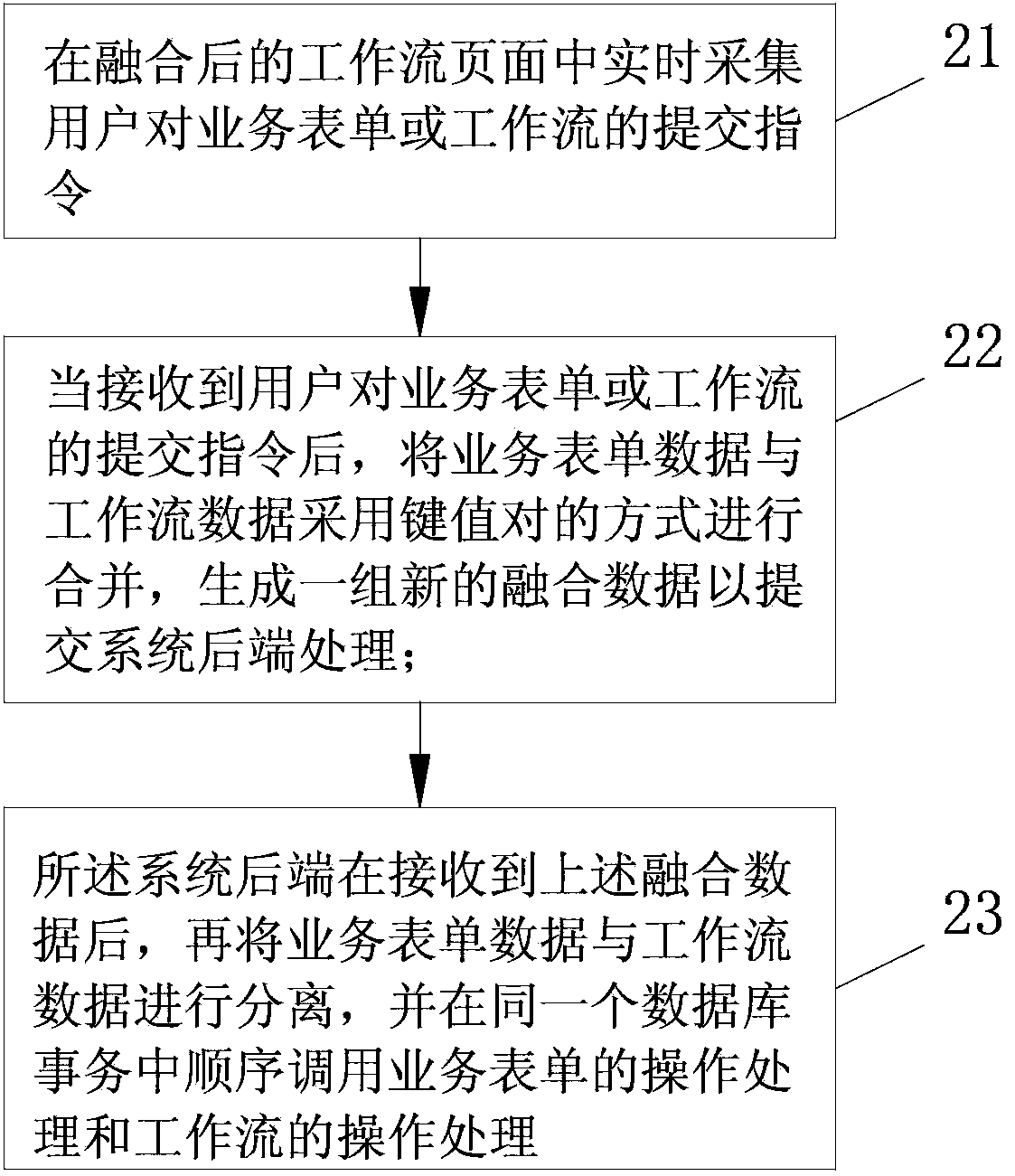

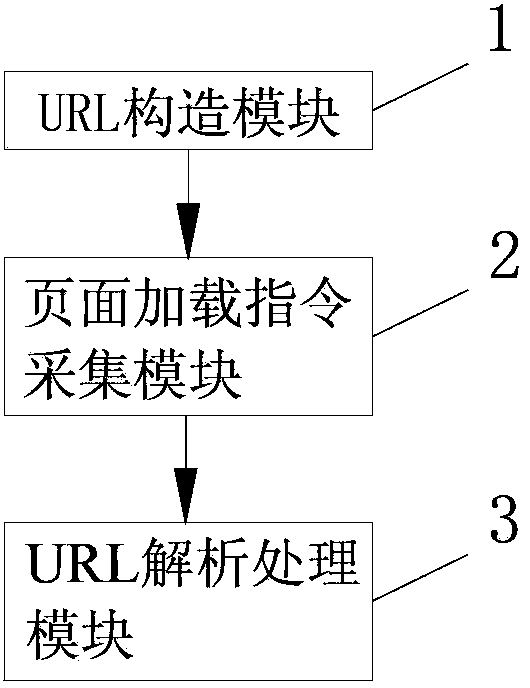

Method and system for fusing business form page and work flow page

ActiveCN104216694AImprove development efficiencyReduce the amount of developmentResourcesSpecific program execution arrangementsProgram EfficiencyWork flow

The invention discloses a method and system for fusing a business form page and a work flow page. The method comprises the steps of URL merging, page loading instruction collecting, URL analysis processing, submitted instruction collecting, submitted page data fusing and submitted page data separation processing. The system comprises modules exactly corresponding to the method. By means of the method or system for fusing the business form page and the work flow page, the business form page and the work flow page are fused on the same page to be displayed and processed under the premise that a business form is not modified, and thus programming efficiency can be improved.

Owner:INST OF SOFTWARE APPL TECH GUANGZHOU & CHINESE ACAD OF SCI

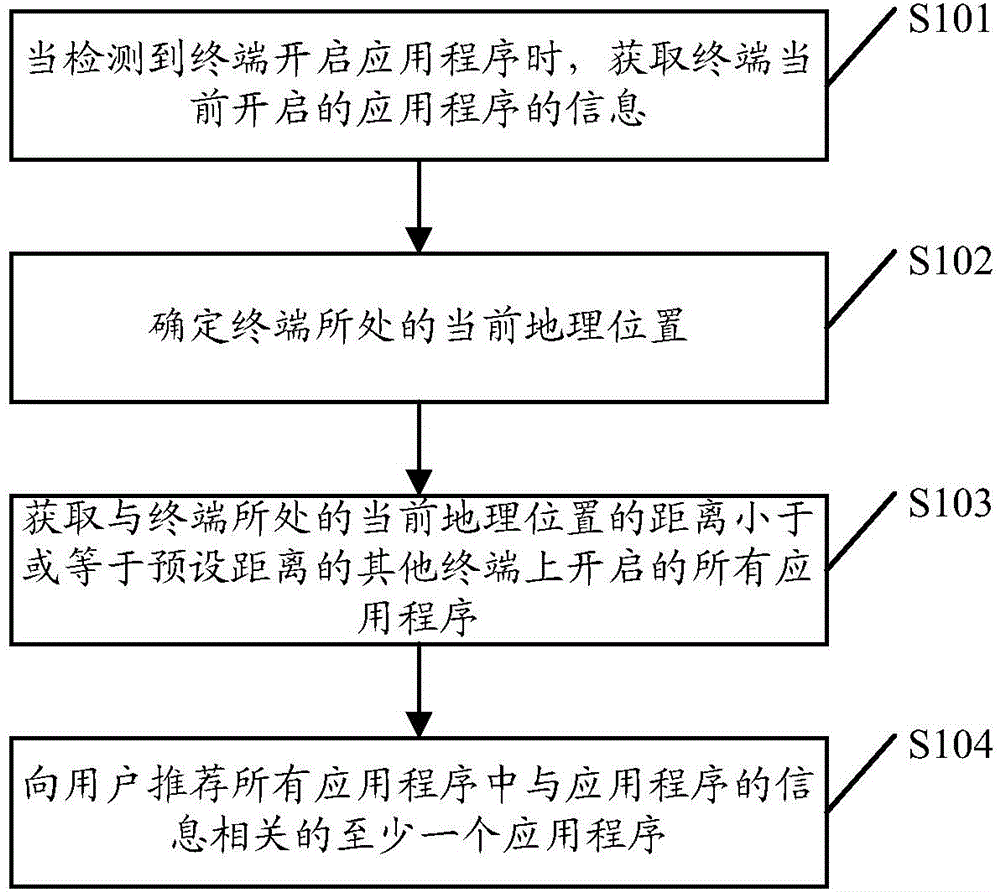

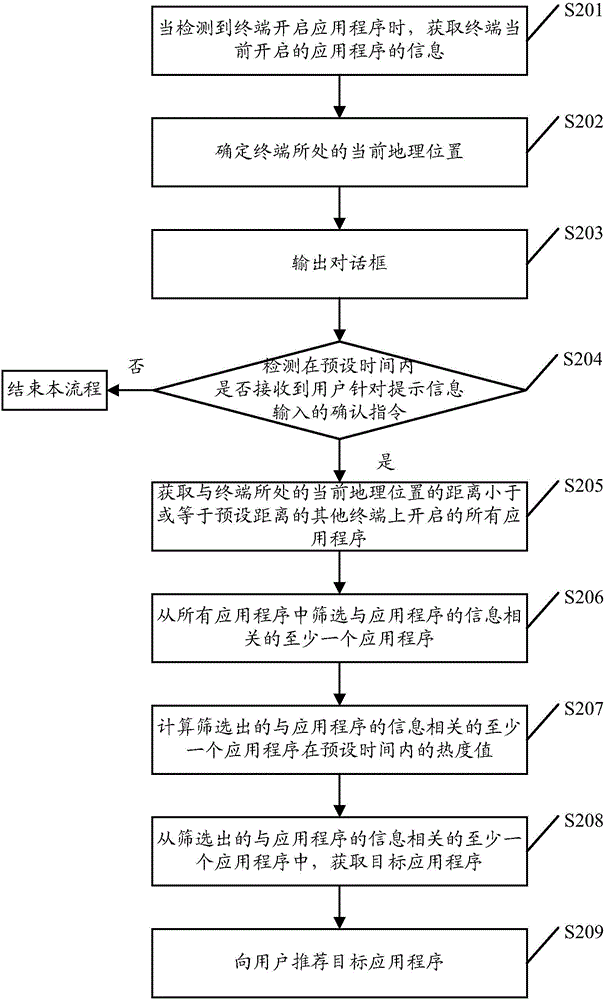

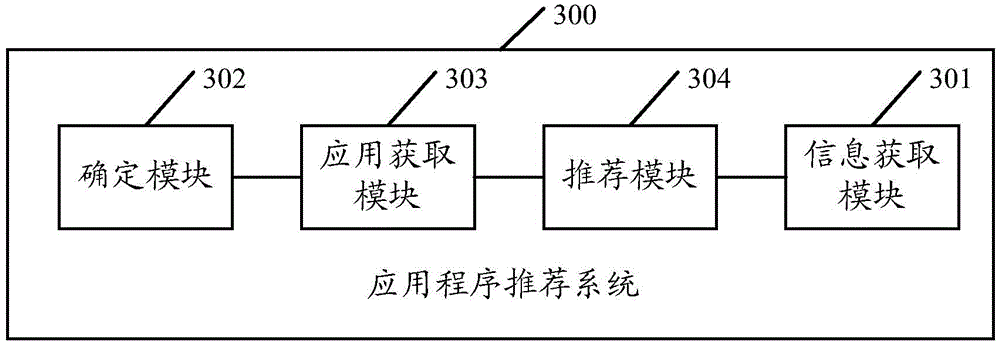

Application program recommendation method and application program recommendation system

InactiveCN105989113AImprove search efficiencyImprove satisfactionSpecial data processing applicationsProgram EfficiencyApplication software

The embodiment of the invention discloses an application program recommendation method and an application program recommendation system. The method comprises the following steps: when a detection result shows that a terminal starts an application program, obtaining the information of the application program which is started by the terminal at present; obtaining a current geographic position of the terminal; obtaining all application programs started on other terminals which are far away from the current geographic position of the terminal shorter than or equal to a preset distance; and recommending at least one application program associated with the information of the application program in all application programs to a user. The embodiment of the invention can be implemented to improve program search efficiency.

Owner:GUANGDONG OPPO MOBILE TELECOMM CORP LTD

Prospective management system for medical benefit prescriptions

ActiveUS20110282689A1Faster and processingReduce wasteFinanceDrug and medicationsBiotechnologyProgram Efficiency

The present invention provides an interactive, electronic, knowledge-based ordering process for specialty / biotech pharmaceuticals (medically coded drugs) which results in less waste, improved procedural efficiencies, and greater cost savings than the current ordering systems. The knowledge-base of the system is based on the health plan's clinical policies as well as the status of the patient and their entitled benefits with the health plan, and it is applied in an interactive manner through a web-enabled system which provides a real-time, prospective examination and control over requests for authorization to dispense the medically coded drugs. The system also includes a feedback loop from the specialty pharmacies to provide information on the medicines that have actually been dispensed. The system also provides to the patient, educational material and adherence reminders to affect therapeutic outcomes.

Owner:RX SPECIALTY HUB

Conversion method of synchronous interface and asynchronous interface

InactiveCN102486761AReduce stepsReduce the numberElectric digital data processingProgram EfficiencyData interface

The invention relates to a conversion method of a synchronous interface and an asynchronous interface. The method comprises the following steps of: 1) judging whether the synchronous interface carries out access operation on the asynchronous interface; if so, executing the step 2); and otherwise, directing finishing the step; and 2), realizing the access operation, which is carried out on the asynchronous interface by the synchronous interface, according to types of data interfaces. The invention provides the conversion method of the synchronous interface and the asynchronous interface, which has the advantages of supporting a processor core to carry out read-write access on 32 bits of a FLASH, obviously improving the efficiency of moving programs and obviously decreasing the quantity of external pins.

Owner:AVIC NO 631 RES INST

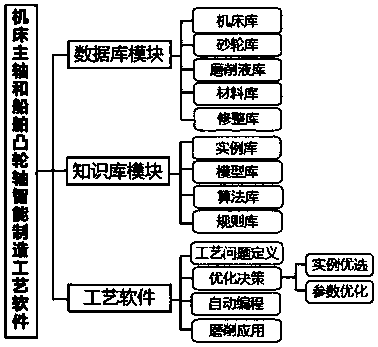

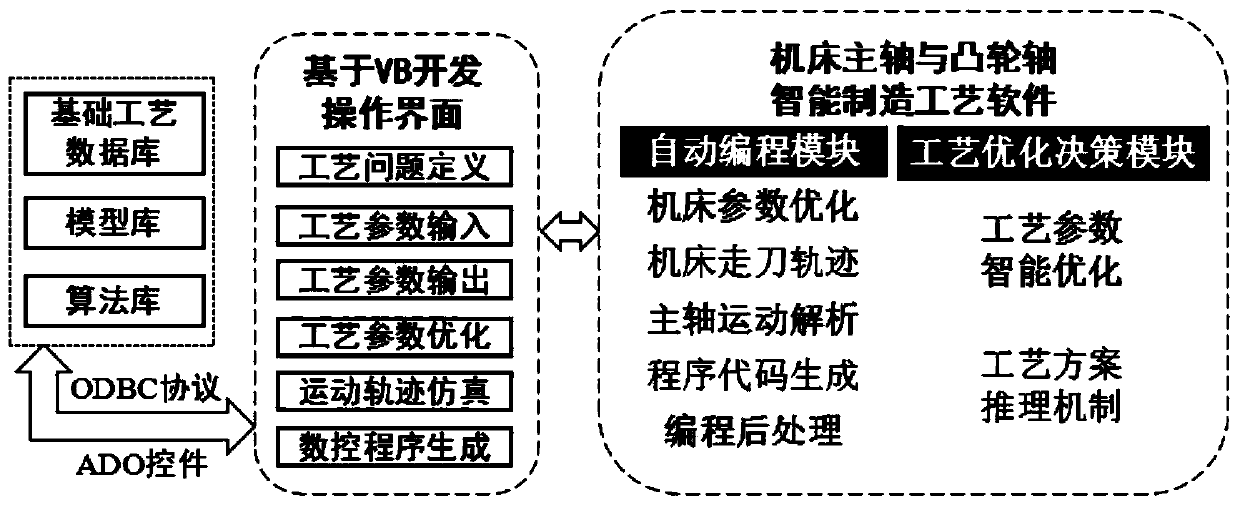

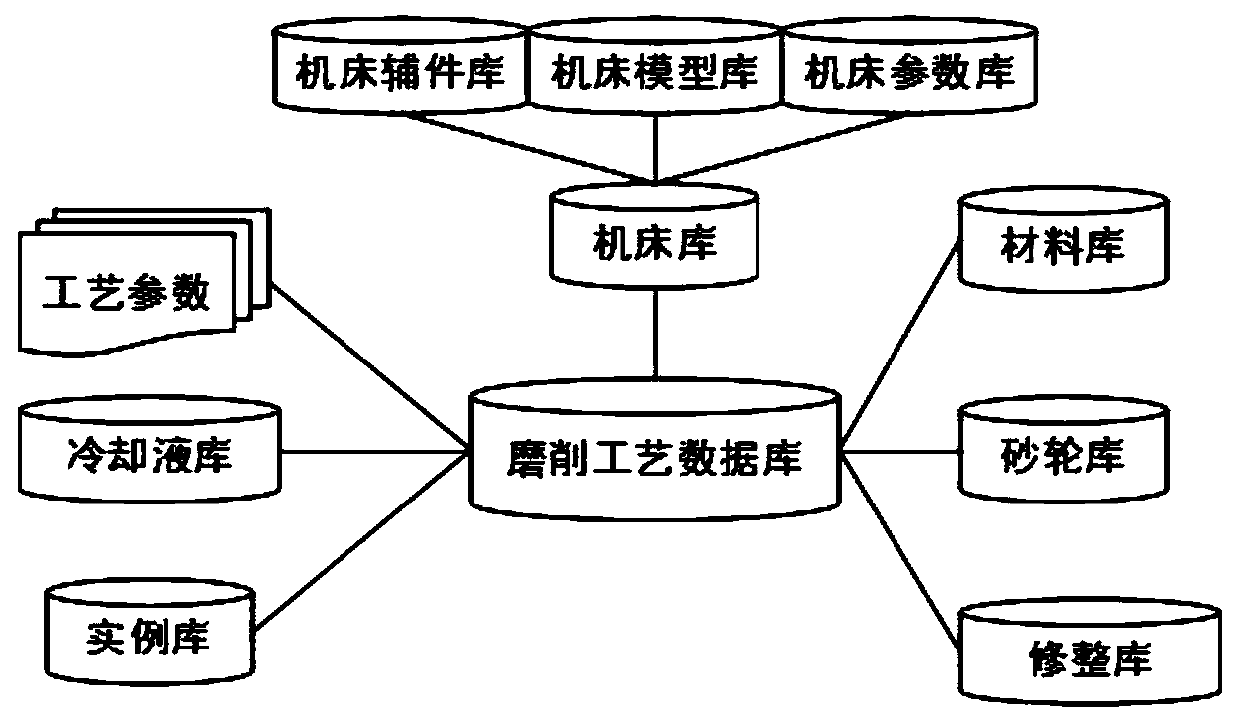

Cam shaft intelligent grinding process software database system based on numerical control system

ActiveCN109799787ASolve complexitySolve process problemsProgramme controlComputer controlProgram EfficiencyCam

The invention discloses a cam shaft intelligent grinding process software database system based on a numerical control system. The system comprises a technological problem definition module, a technological integrated database module, an expert knowledge base, a decision optimization module, an automatic programmable module and a grinding application module. The technological problem definition module is used for storing a plurality of pieces of process case information according to generalized technological problem definition information model normalization requirements and building other modules with data and knowledge mining and rule-knowledge self-learning ability. A complete set of software is integrated and embedded by the aid of Siemens (original equipment manufacturer) system development communication interface programs. The system solves the problems of complicated and changeable current cam shaft grinding environments, process parameter optimization and decision-making difficulty, complex numerical control programs, low similar part decision-making and programming efficiency and the like. Cam shaft part decision-making processing time can be remarkably shortened, processing efficiency is improved, and the performance of a numerical control machine tool is brought into full play.

Owner:HUNAN UNIV OF SCI & TECH

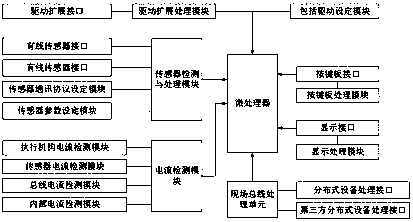

Intelligent controller suitable for multiple operation platforms

InactiveCN108089539ARapid deploymentFunction increaseProgramme control in sequence/logic controllersThird partyProgram Efficiency

The invention relates to the industrial automation equipment technology field and especially relates to an intelligent controller suitable for multiple operation platforms. The intelligent controllersuitable for the multiple operation platforms comprises a microprocessor, a field bus processing module, a current detection module, a sensor detection and processing module, a driving processing module, an input and output module, and a power supply module. The field bus processing module, the current detection module, the sensor detection and processing module, the driving processing module andthe input and output module are connected to the microprocessor. The field bus processing module comprises a distributed equipment processing interface and a third party distributed equipment processing interface. The driving processing module comprises a driving setting module, a driving expansion interface and a driving expansion processing module. The controller has advantages that through a configuration platform and visual programming, a control code can be directly generated and programming efficiency is increased; the equipment of a plurality of manufacturers is compatible; and flexibility of industrial equipment combination is increased.

Owner:FANER INTELLIGENT TECH GRP CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com