Method for achieving machining program processing through conversational parameters in computer numerical control grinding machine system

A CNC grinding machine and processing program technology, which is applied to the parts of grinding machine tools, metal processing equipment, manufacturing tools, etc., can solve the problems of unpopular CAD/CAM software, inconsistent definition of processing instructions, single processing tools, etc., and achieve improvement The efficiency of programming and processing, the effect of simple and convenient processing, and a wide range of applications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to describe the technical content of the present invention more clearly, further description will be given below in conjunction with specific embodiments.

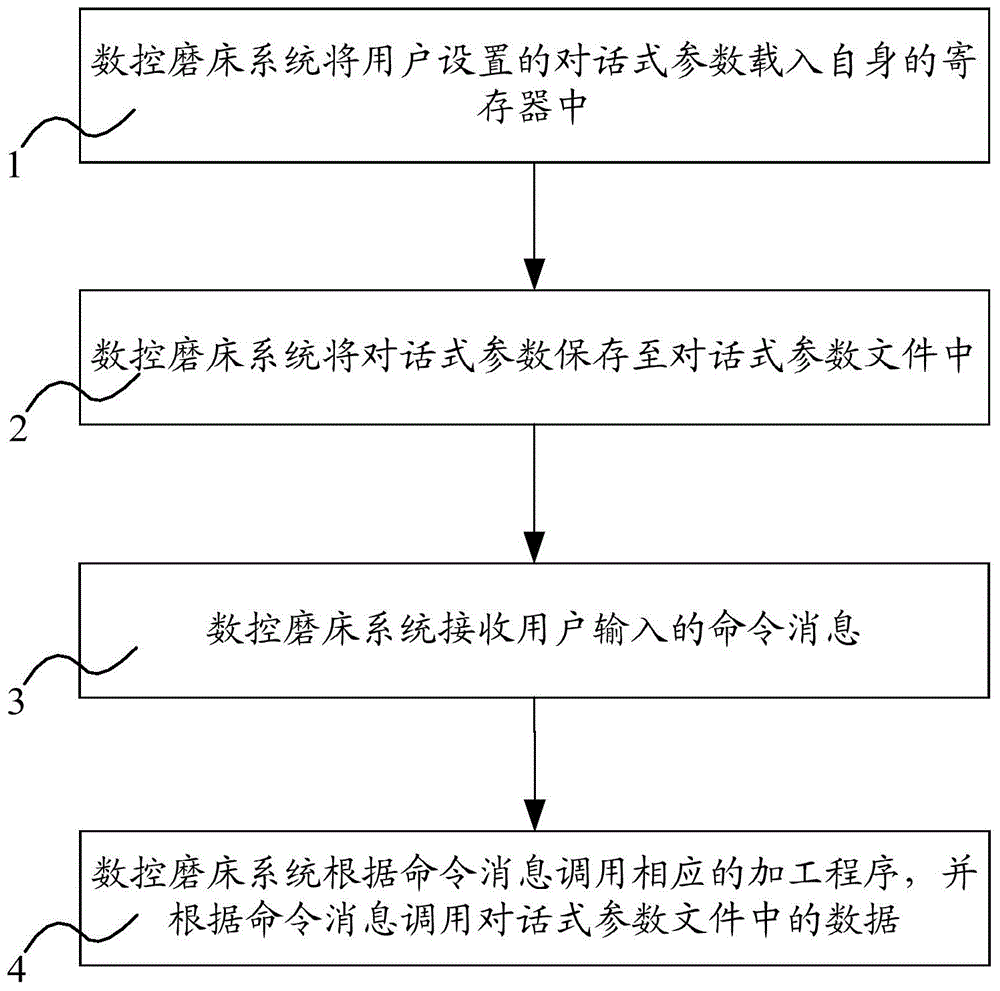

[0025] like figure 1 As shown, in one embodiment, the method for realizing processing program processing through dialogue parameters in the CNC grinding machine system of the present invention includes the following steps:

[0026] (1) The CNC grinding machine system loads the dialogue parameters set by the user into its own register;

[0027] (2) The described NC grinding machine system saves the described conversational parameters into the conversational parameter file;

[0028] (3) The CNC grinding machine system receives the command message input by the user;

[0029] (4) The CNC grinding machine system invokes the corresponding processing program according to the command message, and invokes the data in the conversational parameter file according to the command message.

[0030] In a preferred embod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com