Cam shaft intelligent grinding process software database system based on numerical control system

A technology of numerical control system and database, applied in general control system, control/regulation system, program control and other directions, can solve the problems of lack, poor compatibility of numerical control system, lack of self-learning ability of rule knowledge, etc., to achieve performance and improve processing efficiency , the effect of shortening decision-making processing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

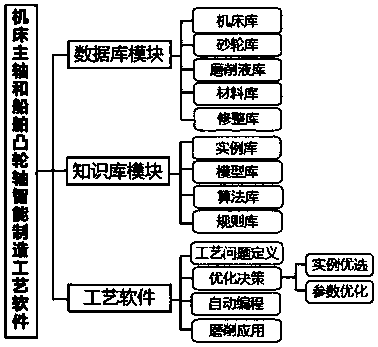

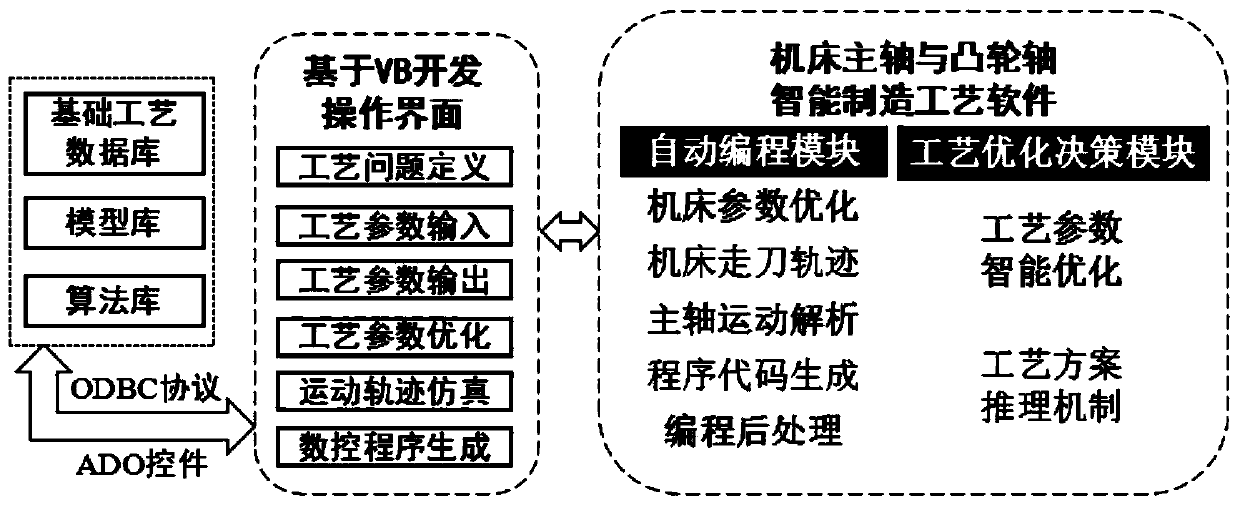

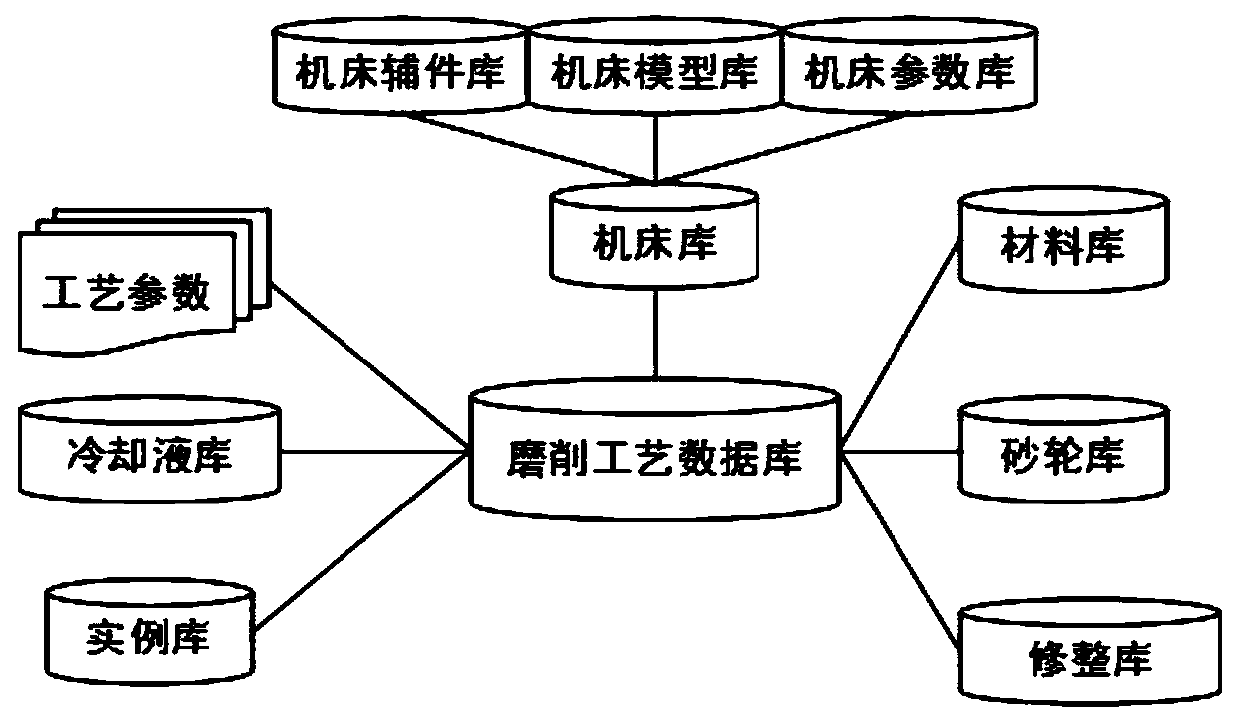

[0033] 1. The overall design of camshaft intelligent grinding process software

[0034] Aiming at the characteristics of large amount of information and frequent data cross-use of camshaft process data sources, a process software that supports machine tool spindle and ship camshaft machining process parameter optimization decision-making and NC automatic programming is constructed. The research ideas are as follows: figure 1 shown. The framework of the software includes six modules: process problem definition, basic database, knowledge base, decision optimization, automatic programming and grinding application. The basic database stores a large amount of data information such as machine tools, grinding wheels, materials, and grinding fluids; the knowledge base stores examples, models, algorithms, rules, and charts used in the intelligent grinding proce...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com