Mesoscale elastic thin-walled workpiece deformation on-line prediction and compensation method

A technology of elastic thin wall and compensation method, which is applied in the direction of instruments, computer control, simulators, etc., can solve the problems that affect the processing accuracy, cannot effectively guarantee the processing quality, real-time deformation and timely control, etc., and achieve reliable radial compensation value, Improve machining accuracy and quality, eliminate the effect of radial undercut

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

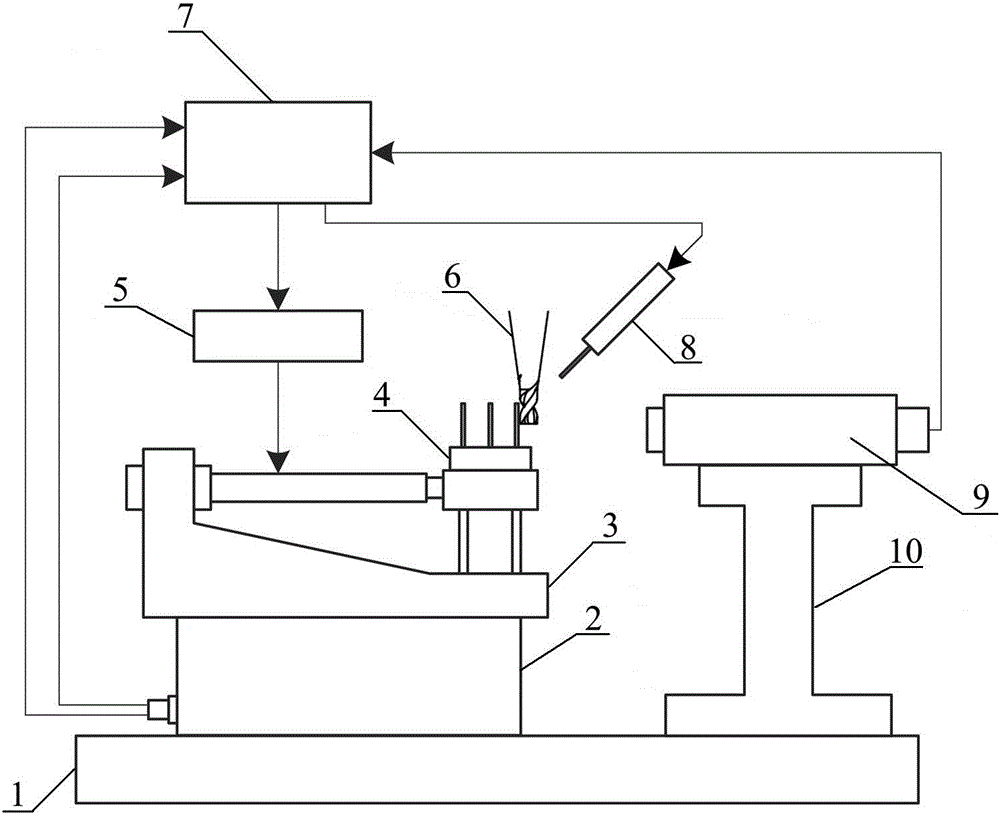

[0040] The present invention will be described in detail below in conjunction with the accompanying drawings and specific examples.

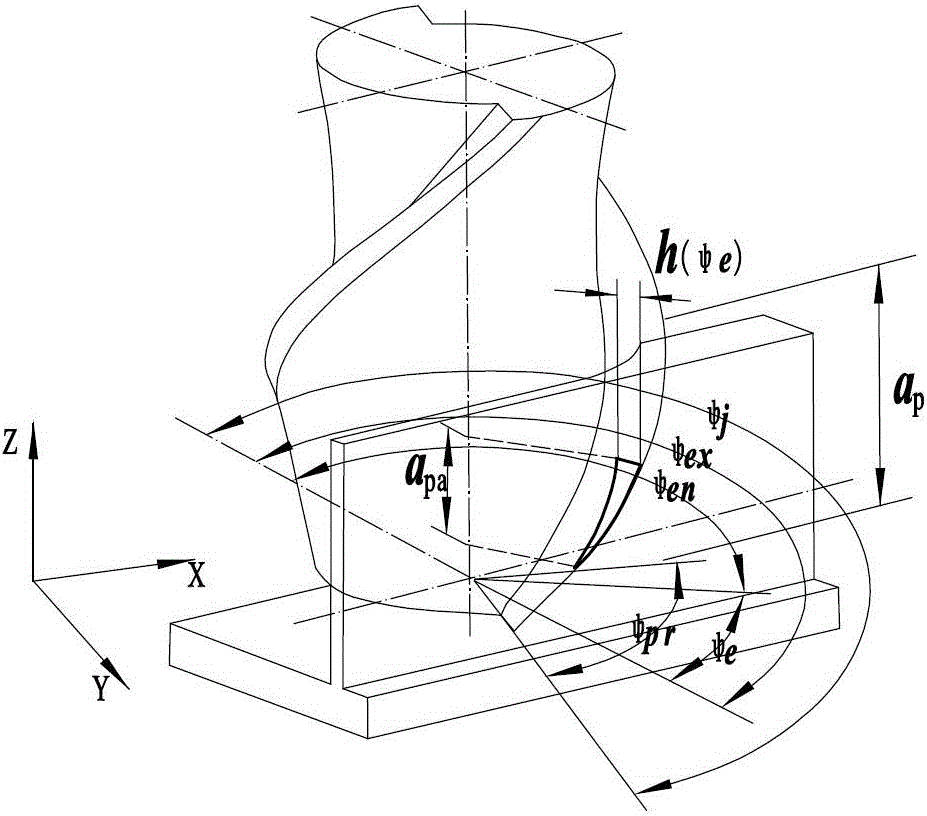

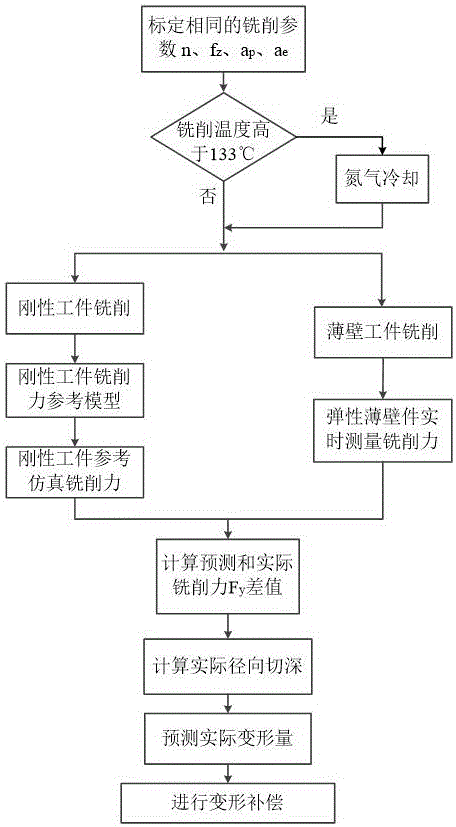

[0041] The processing scale targeted by the present invention is the mesoscopic scale, that is, the processing accuracy requirement is between nanometers and millimeters. Compared with the macro scale, the online prediction and compensation requirements are higher. Therefore, by building a system and calibrating the cutting force parameters, the same process Under the same condition (the same spindle speed n, the same feed per tooth f z , axial depth of cut a p , radial depth of cut a e ) micro-down milling cutting force comparison, relying on the theoretical model of rigid thin-walled parts as a standard reference value, through real-time collection of cutting force data (mainly refer to Y-direction cutting force) to adjust the radial immersion value in real time, so as to complete online prediction and compensation needs.

[0042] Such as ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wall thickness | aaaaa | aaaaa |

| Wall thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com