Method for predicting and compensating machining deformation error of miniature trough

A technology of deformation error and compensation method, which is applied in the direction of metal processing equipment, metal processing machinery parts, manufacturing tools, etc., can solve the problems that cannot be corrected in real time, affect the processing quality of micro grooves, errors, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0073] The present invention will be described in detail below in conjunction with the accompanying drawings and specific examples.

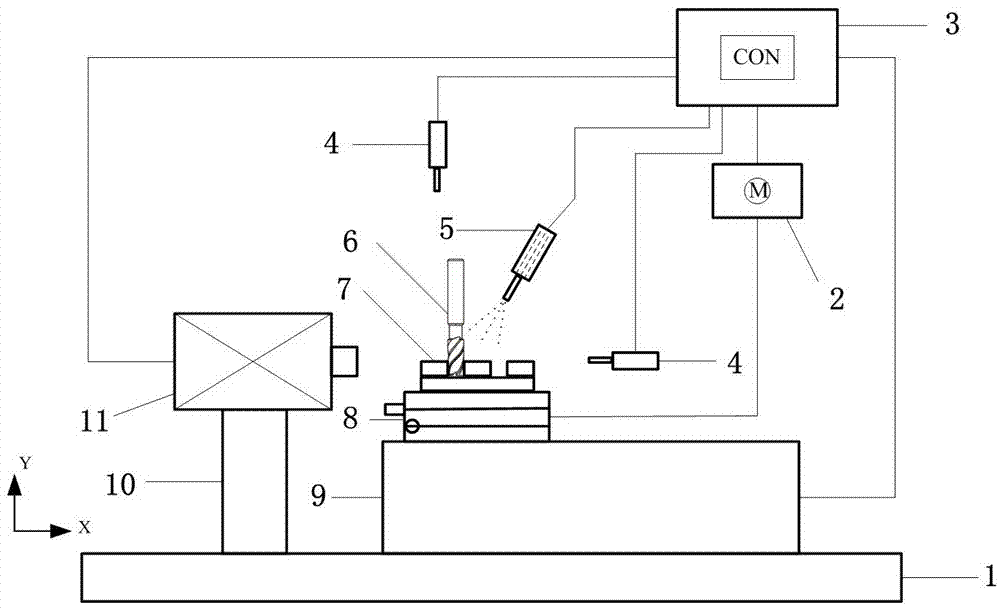

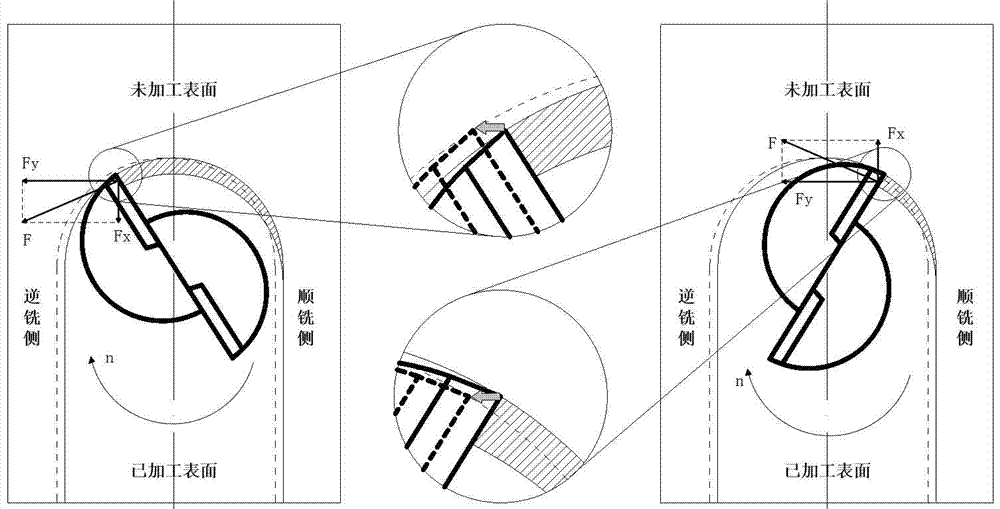

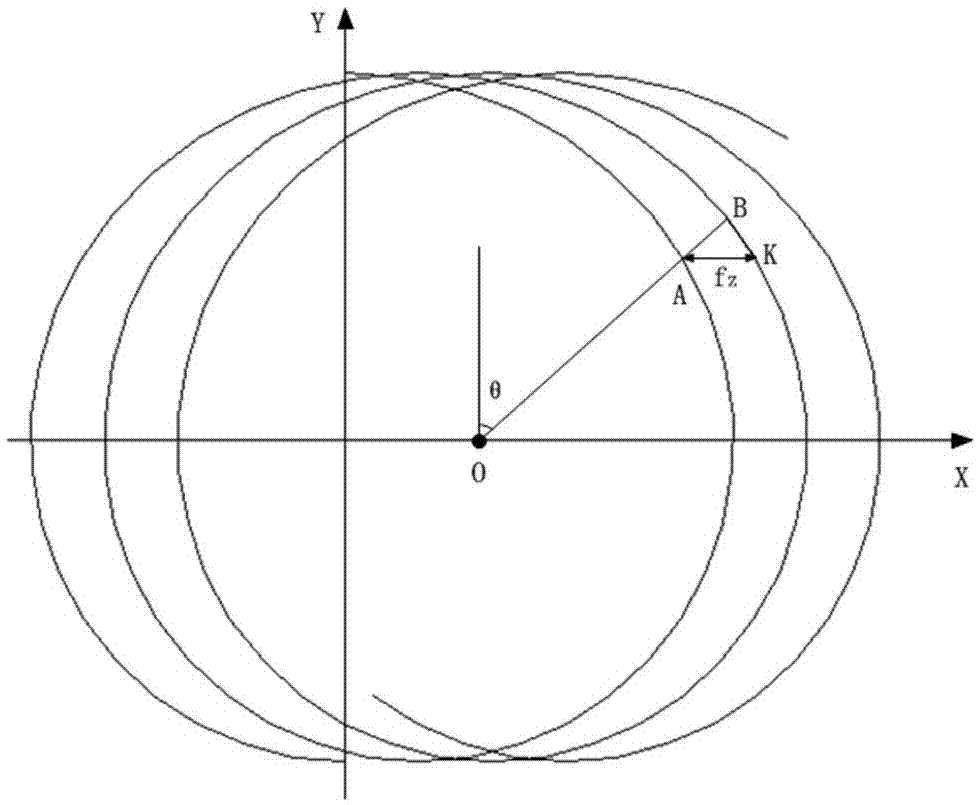

[0074] The present invention is aimed at micromachining (mesoscopic scale) which requires higher processing quality and compensation, and both the scale of the workpiece and the scale of the required features are relatively small. By building a micro-groove processing system, calibrate the cutting force and each cutting force coefficient and compare it with the measured micro-cutting force, and use the theoretical model of the micro-groove as a reference standard to calculate the total deformation value during the micro-grooving process in real time. The total deformation value obtained by real-time measurement and calculation is used to adjust the processing parameters and offset, so as to complete the online deformation prediction and compensation requirements of micro groove workpiece processing.

[0075] Such as figure 1 , 2 , 3, 4, 5, 6, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com