Patents

Literature

136results about How to "Improve workpiece quality" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

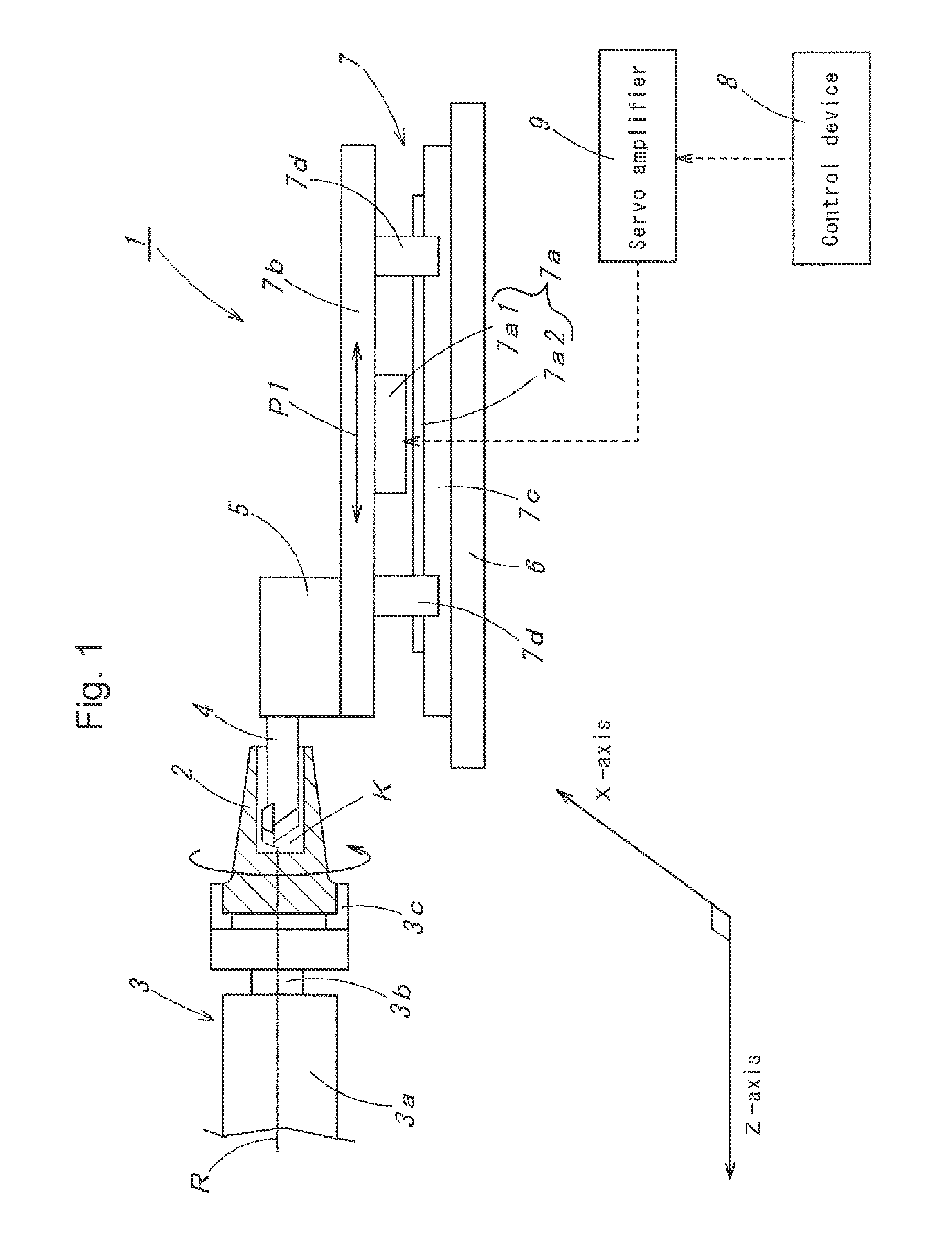

Machine Tool

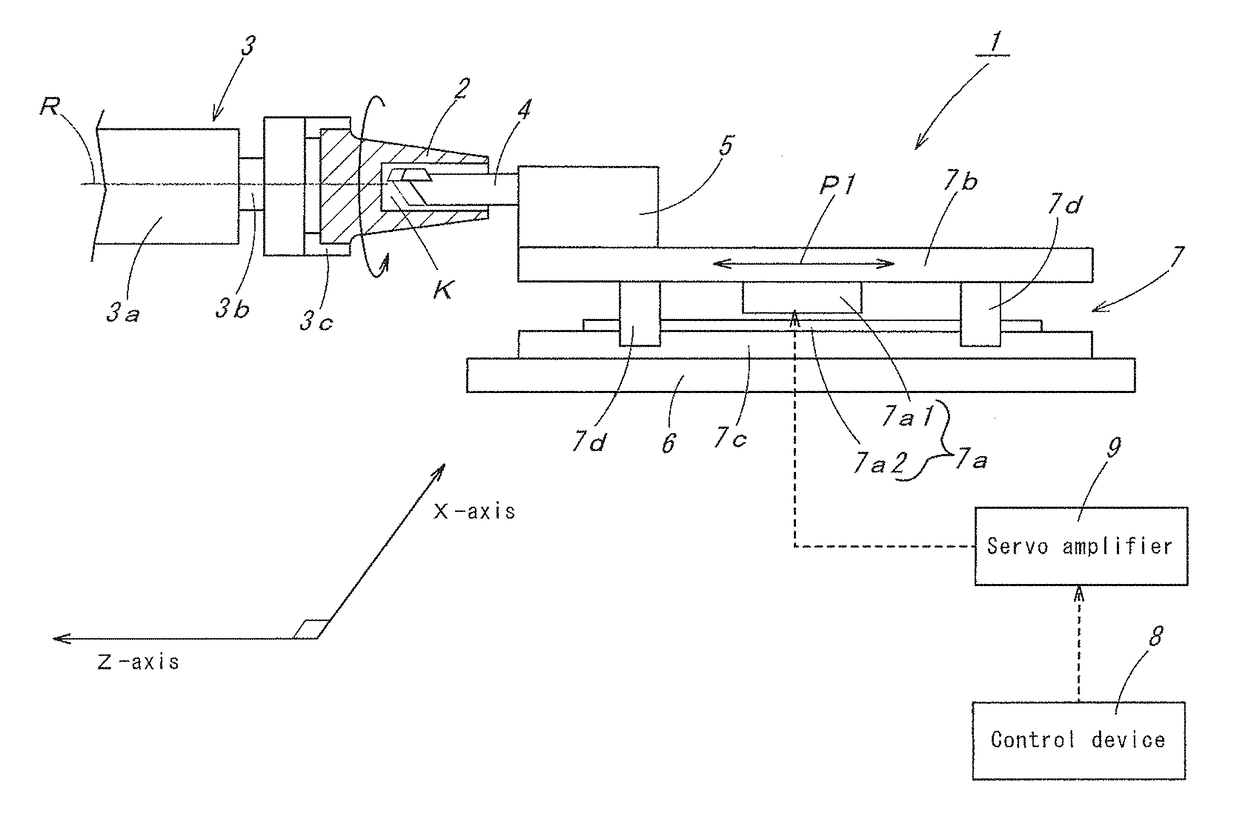

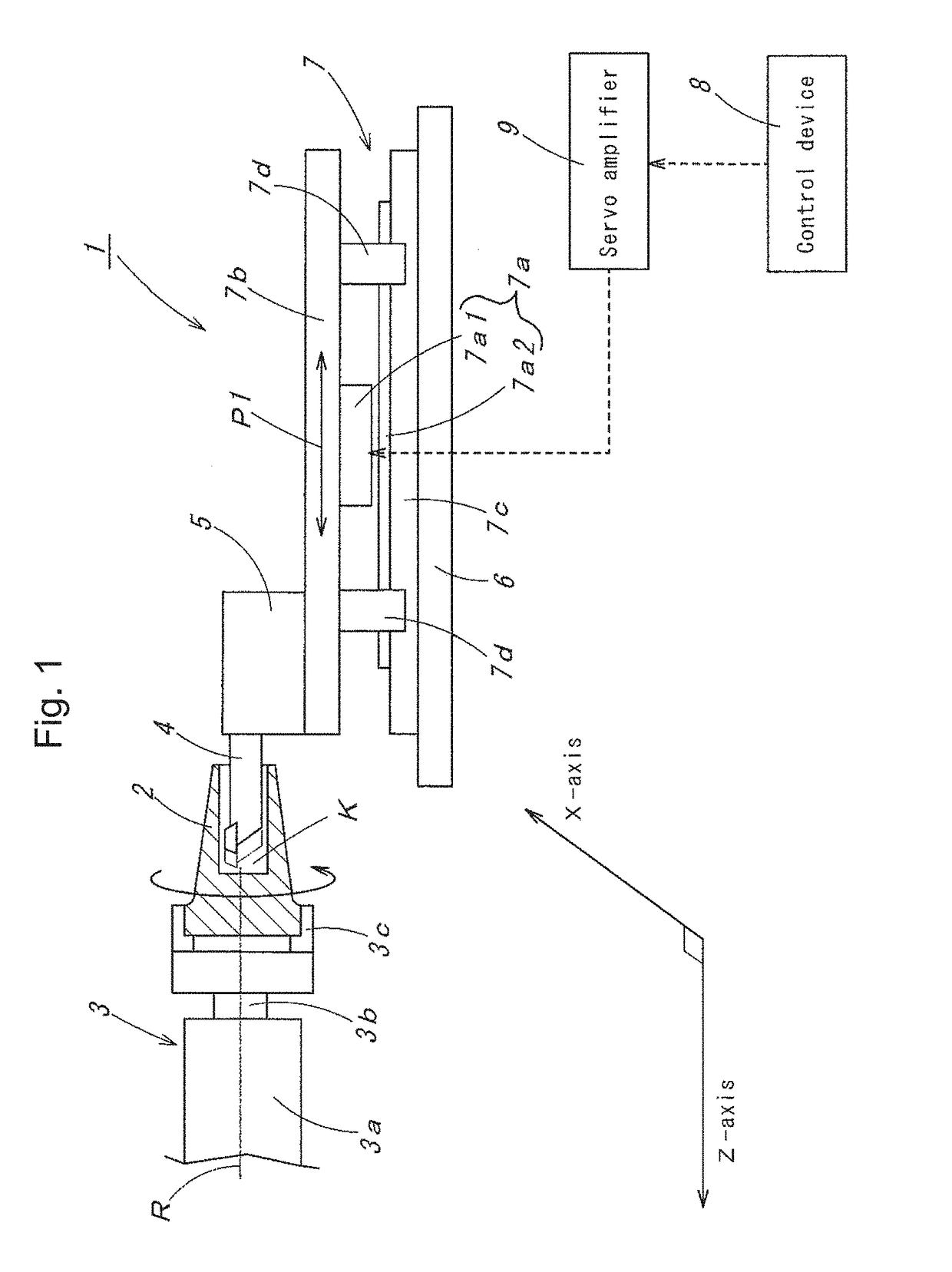

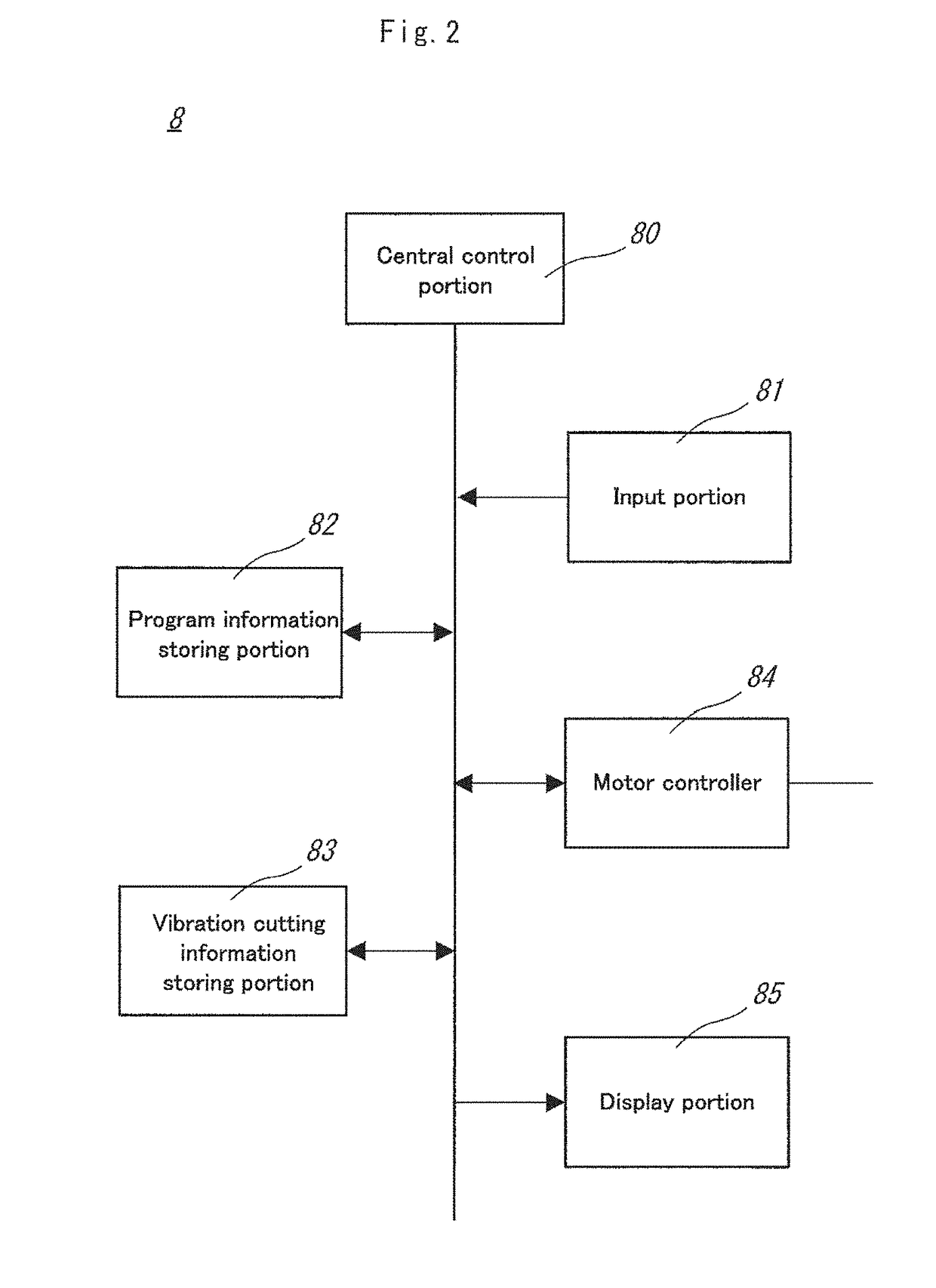

ActiveUS20140102268A1Improve vibrationReduce vibrationProgramme controlLathesMachine toolTool holder

A machine tool for machining a workpiece is provided with a cutting tool holder for holding a cutting tool and a rotation mechanism for holding the workpiece. One or both of the cutting tool holder and the rotation mechanism are movable on multiple axes so that the cutting tool is movable relative to the workpiece in multiple axial directions. A control device is provided for controlling the movement of one or both of the cutting tool holder and the rotation mechanism to synchronously vibrate the workpiece and the cutting tool relative to each other at a low frequency in multiple axial directions.

Owner:CITIZEN WATCH CO LTD

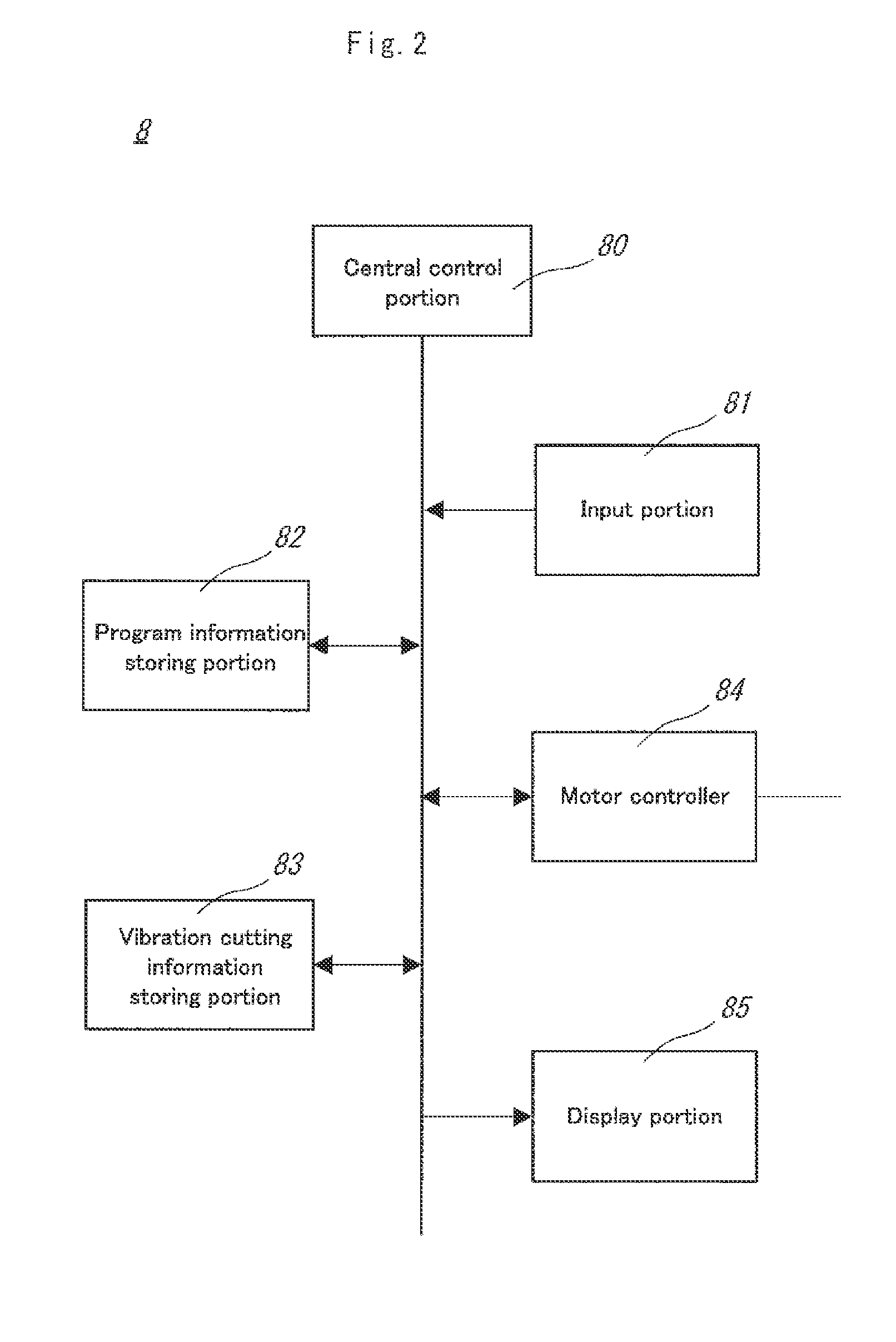

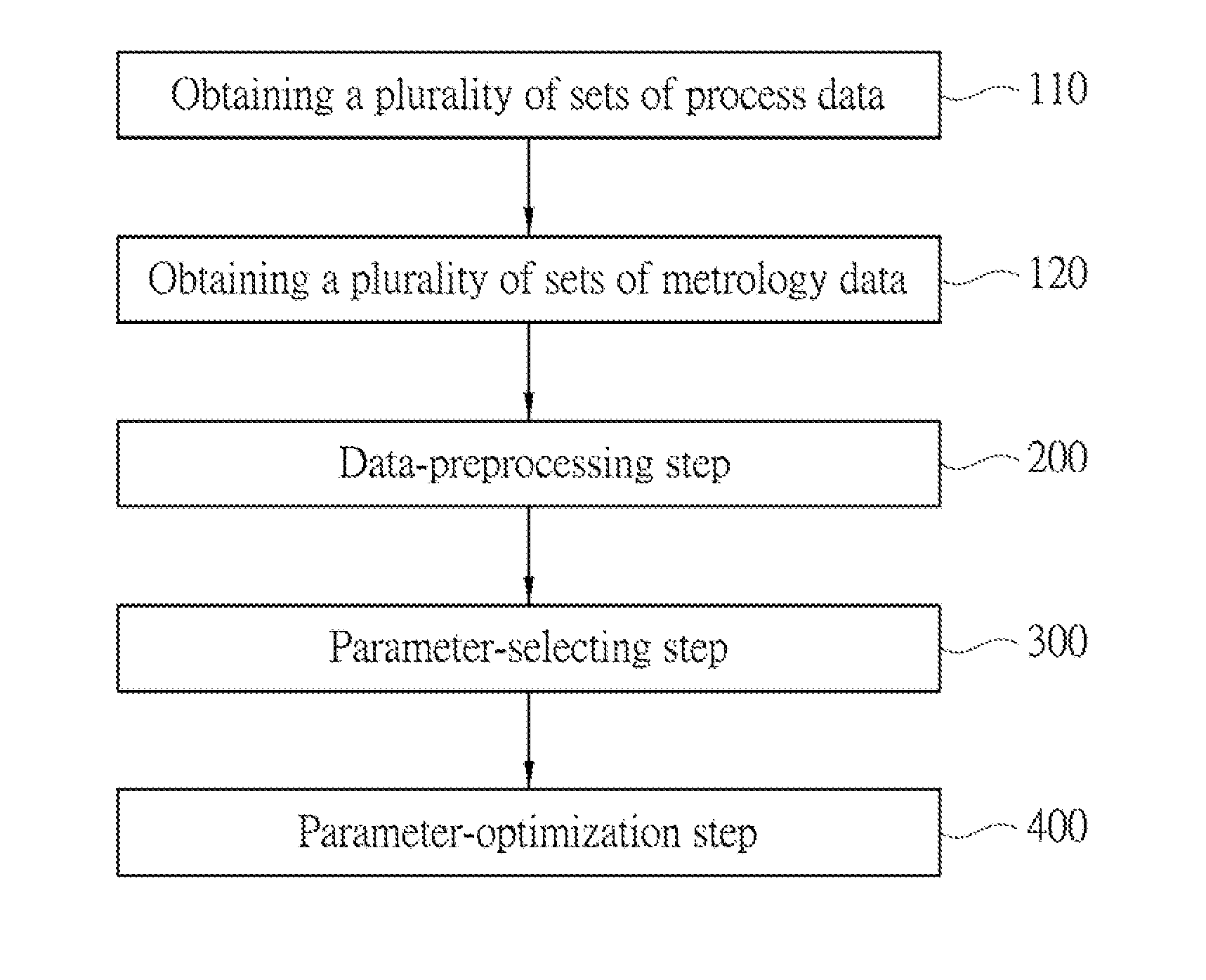

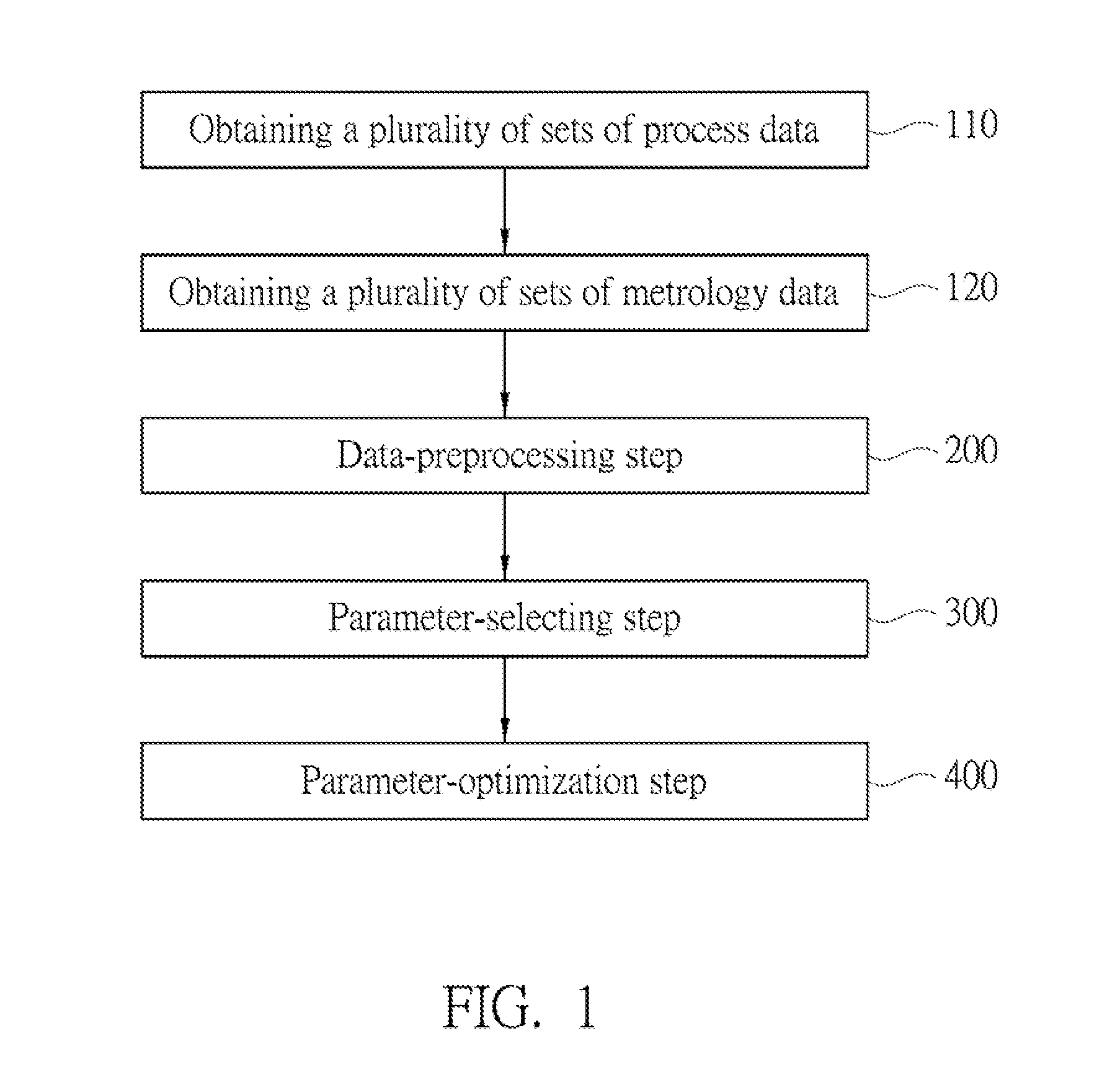

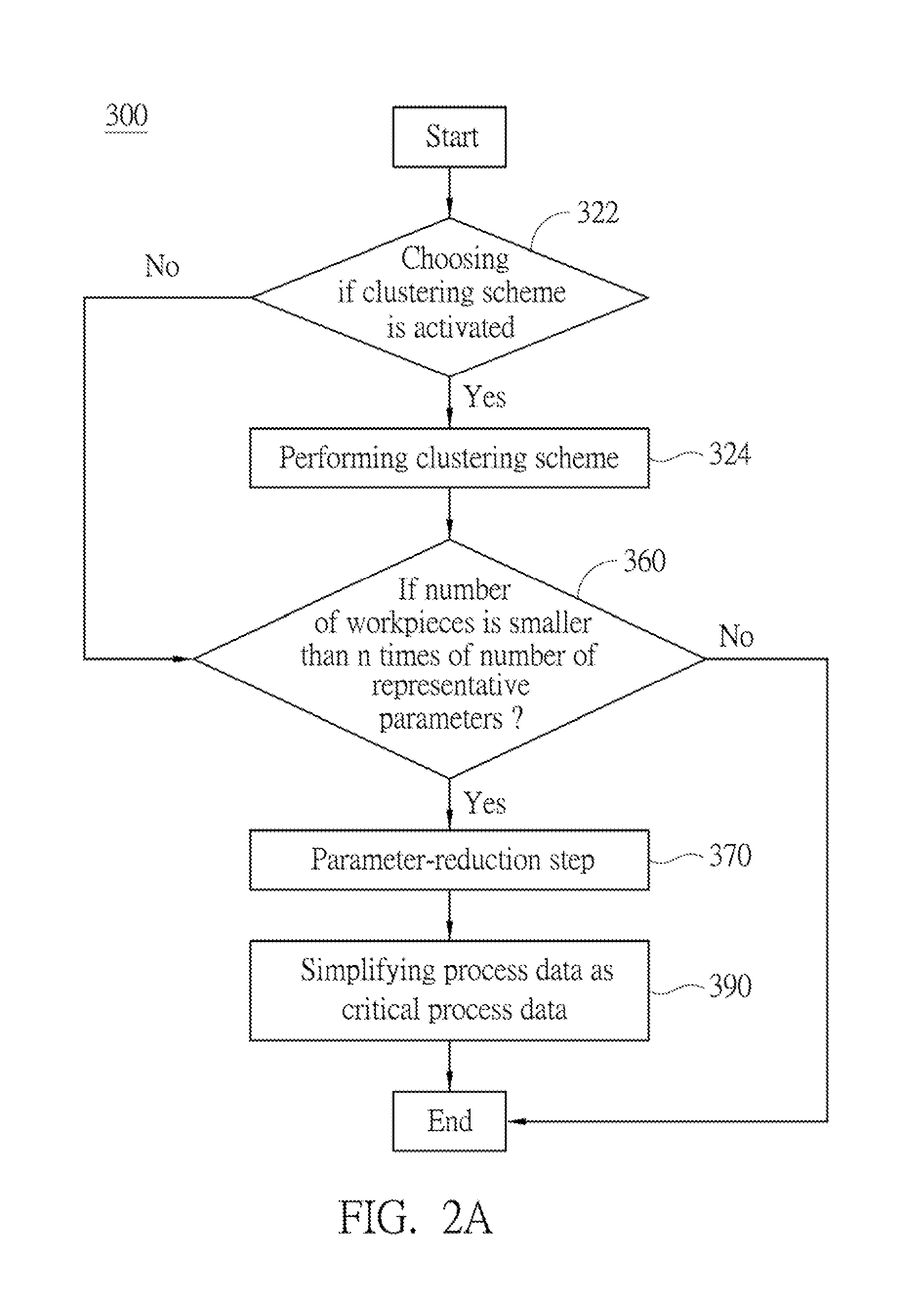

Method for searching, analyzing, and optimizing process parameters and computer program product thereof

InactiveUS20140222376A1Save amountValid choiceProgramme controlSemiconductor/solid-state device testing/measurementMetrologyMeasurement point

A method for searching, analyzing, and optimizing process parameters and a computer product thereof are provided. At first, sets of process data that are generated when a process tool processes workpieces are obtained respectively, each set of process data including process parameters. Then, sets of metrology data measured by a metrology tool are obtained, wherein the sets of metrology data are corresponding to the sets of the process data in a one-to-one manner, each workpiece having at least one measurement point, each set of metrology data including at least one actual measurement value of at least one measurement item at the at least one measurement point. Thereafter, critical parameters are selected from the process parameters. Then, values of the critical parameters are adjusted to enable predicted measurement values of the measurement points of one workpiece to meet a quality target value.

Owner:FORESIGHT TECH +1

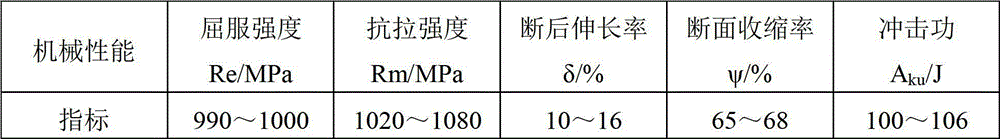

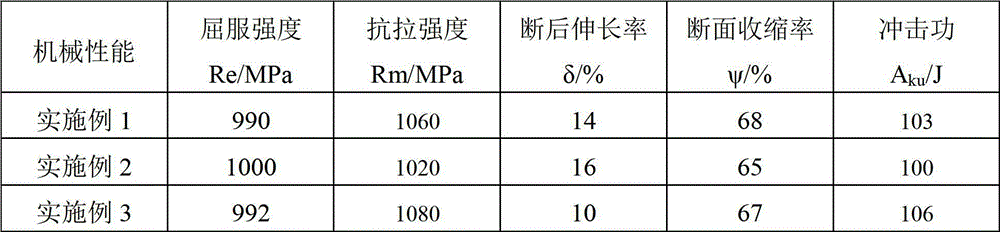

Technology for processing CrNiMo series steel material

ActiveCN102877073AGuaranteed purityHigh strengthSolid state diffusion coatingIngotMaterials processing

The invention discloses a technology for processing a CrNiMo series steel material. The technology comprises the steps of adopting an electroslag remelting technology to obtain a steel ingot which contains 0.14-0.19% of C, 1.5-1.8% of Cr, 0.17-0.35% of Si, 0.4-0.6% of Mn, 0.25-0.36% of Mo, 1.4-1.7% of Ni, 0-0.035% of P and 0-0.030% of S according to percent by weight, forging the steel ingot, then carrying out normalizing and high temperature tempering, carburizing, high temperature tempering and oil quenching, and finally, carrying out low temperature tempering to complete the processing. According to the technology, a heat treatment processing technology which is simple and easy to operate is utilized to ensure the product quality, the problem that a loading part of a coal machine fails to work is solved, the service life of a product is prolonged, and the producing and processing costs are lowered.

Owner:常熟天地煤机装备有限公司

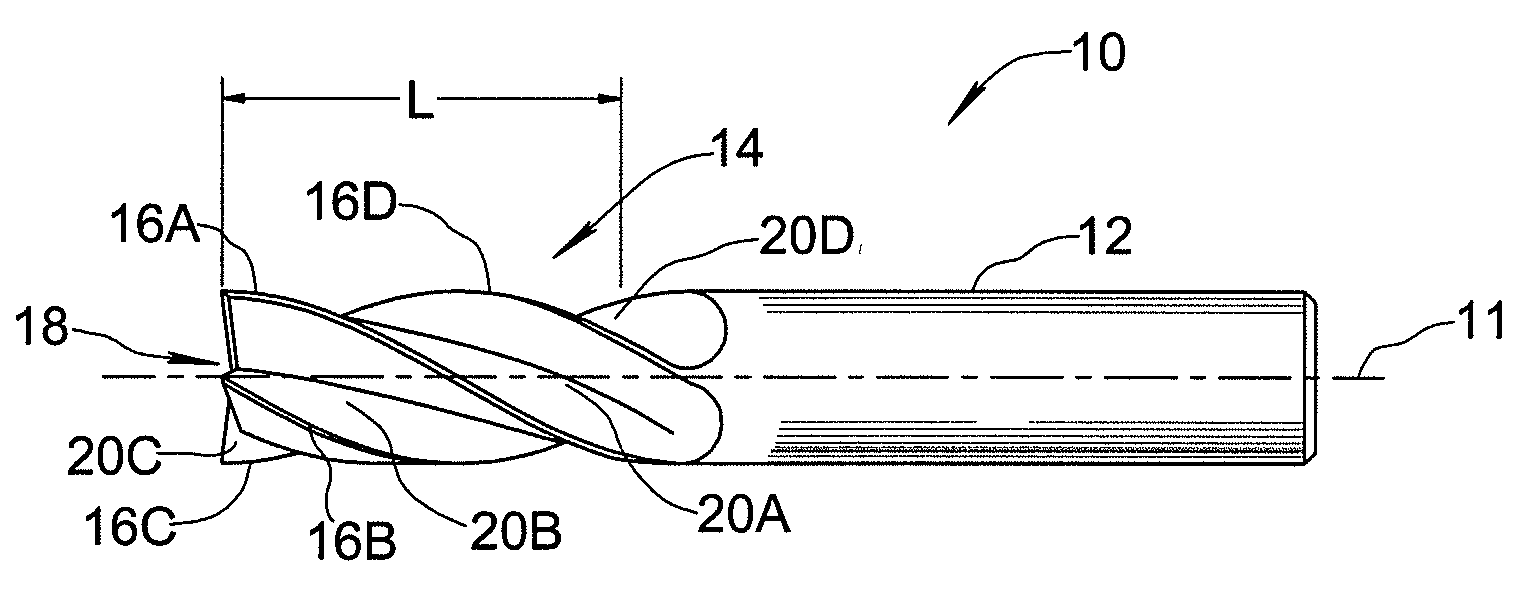

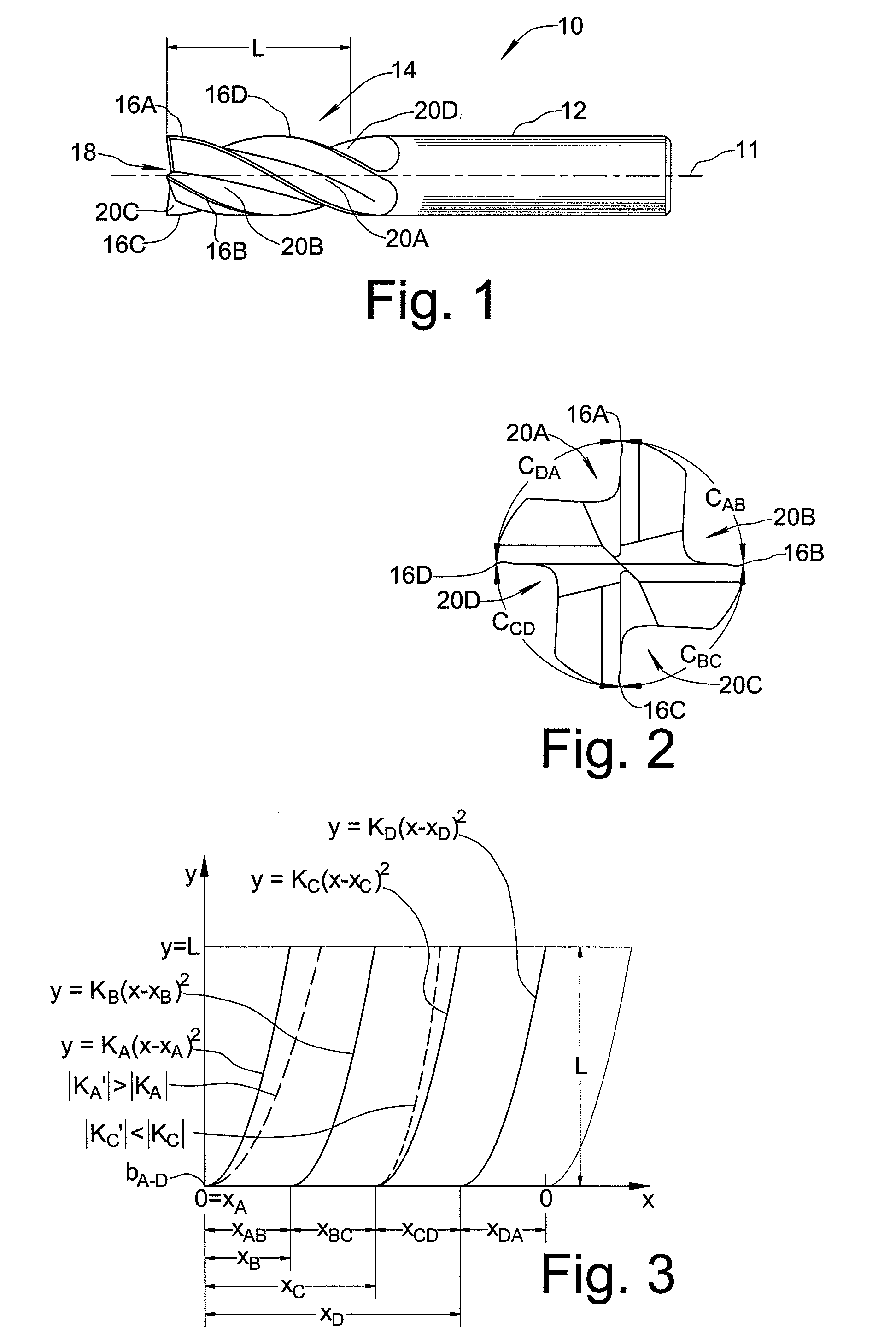

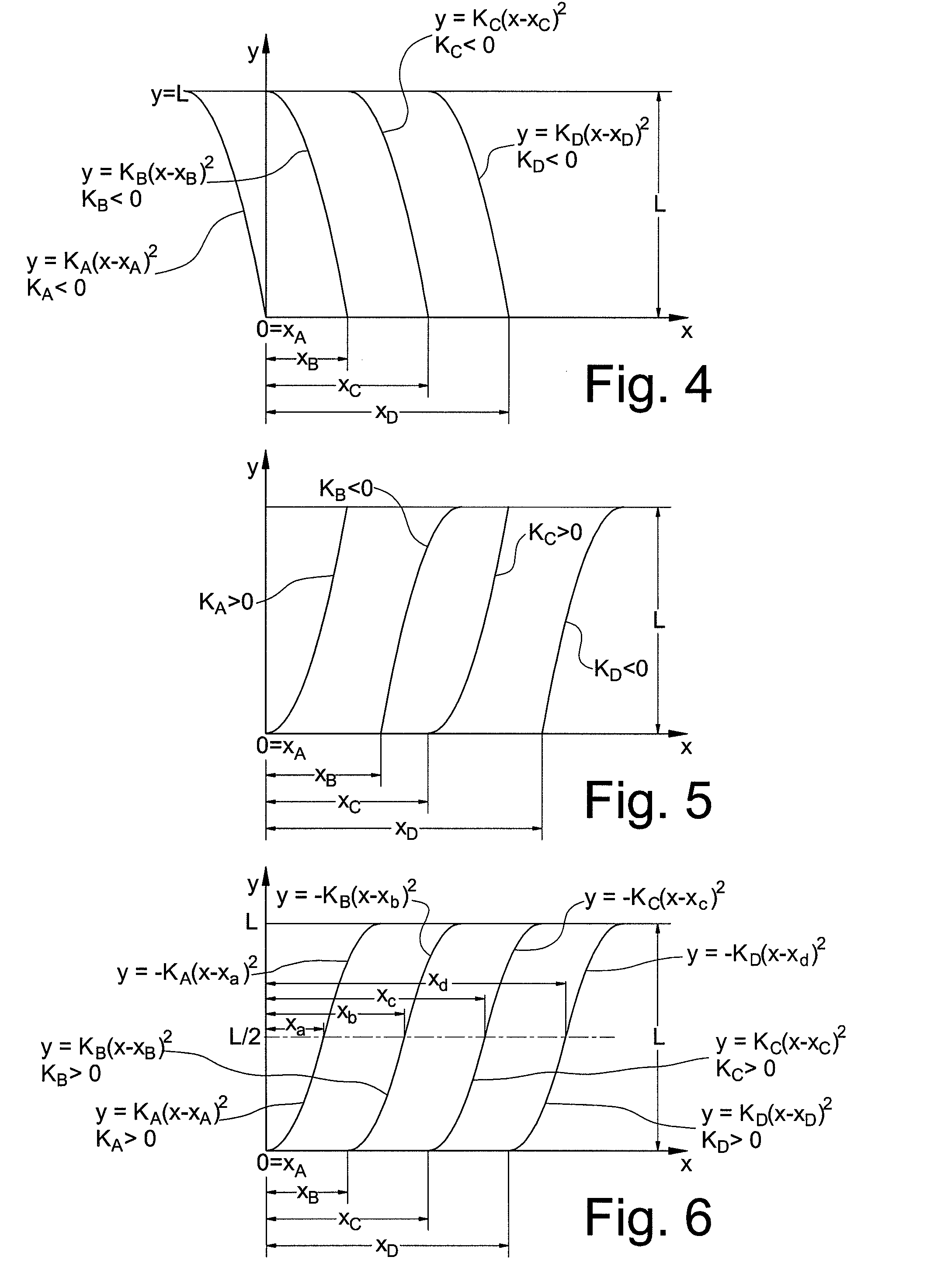

Fluted Rotary Cutting Tool

InactiveUS20070297864A1Improve tool lifeImprove workpiece qualityMilling cuttersAdverse effect compensationFluteMechanical engineering

A rotary cutting tool comprises a shank extending along an axis of rotation of the cutting tool and a fluted portion adjacent the shank, the fluted portion having an effective flute length and a plurality of peripheral cutting edges indexed about the axis of rotation. At least one of the plurality of peripheral cutting edges is formed such that a two-dimensional representation of the peripheral cutting edge in schematic development view follows a quadratic curve over the effective flute length.

Owner:DE BOER TOOLS

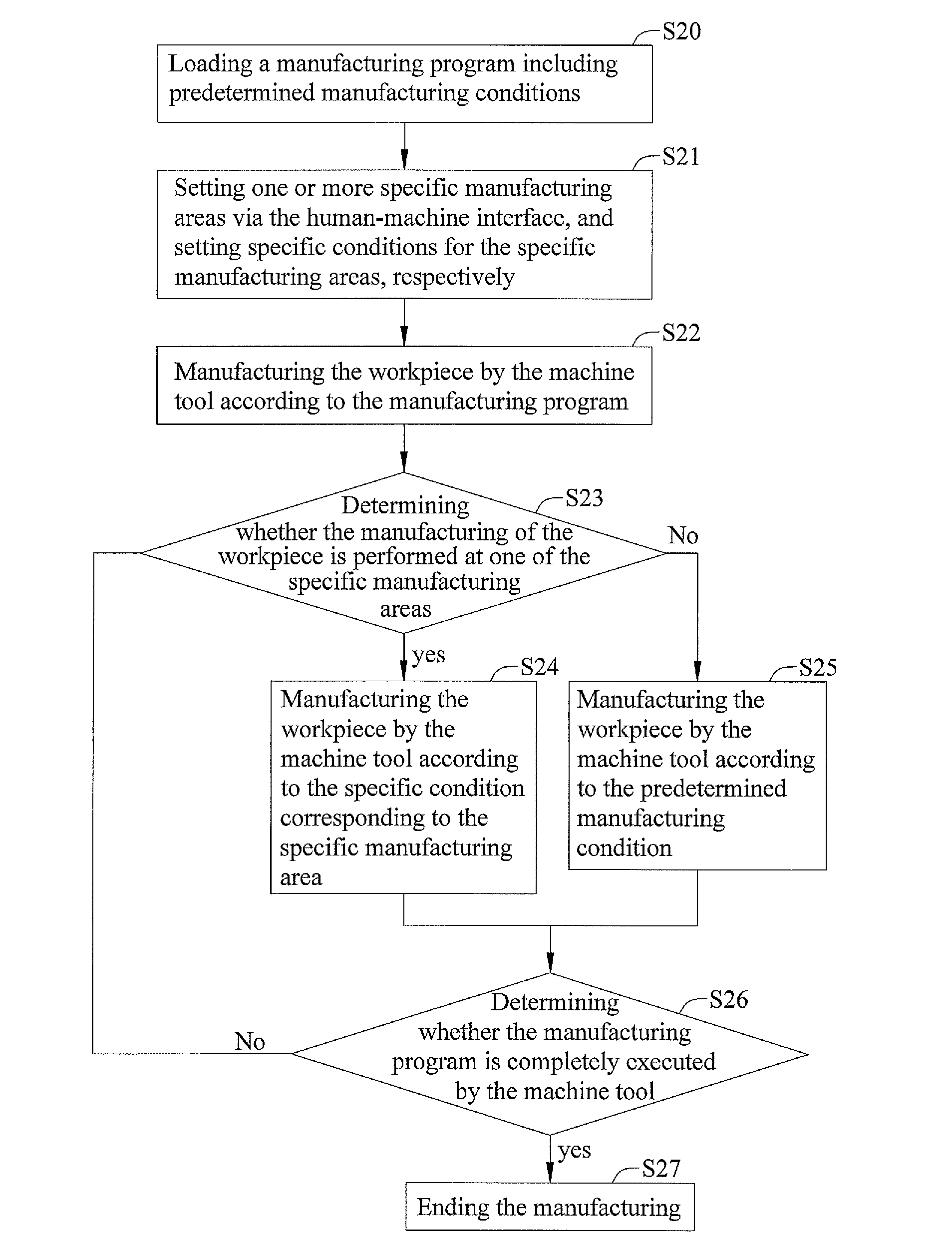

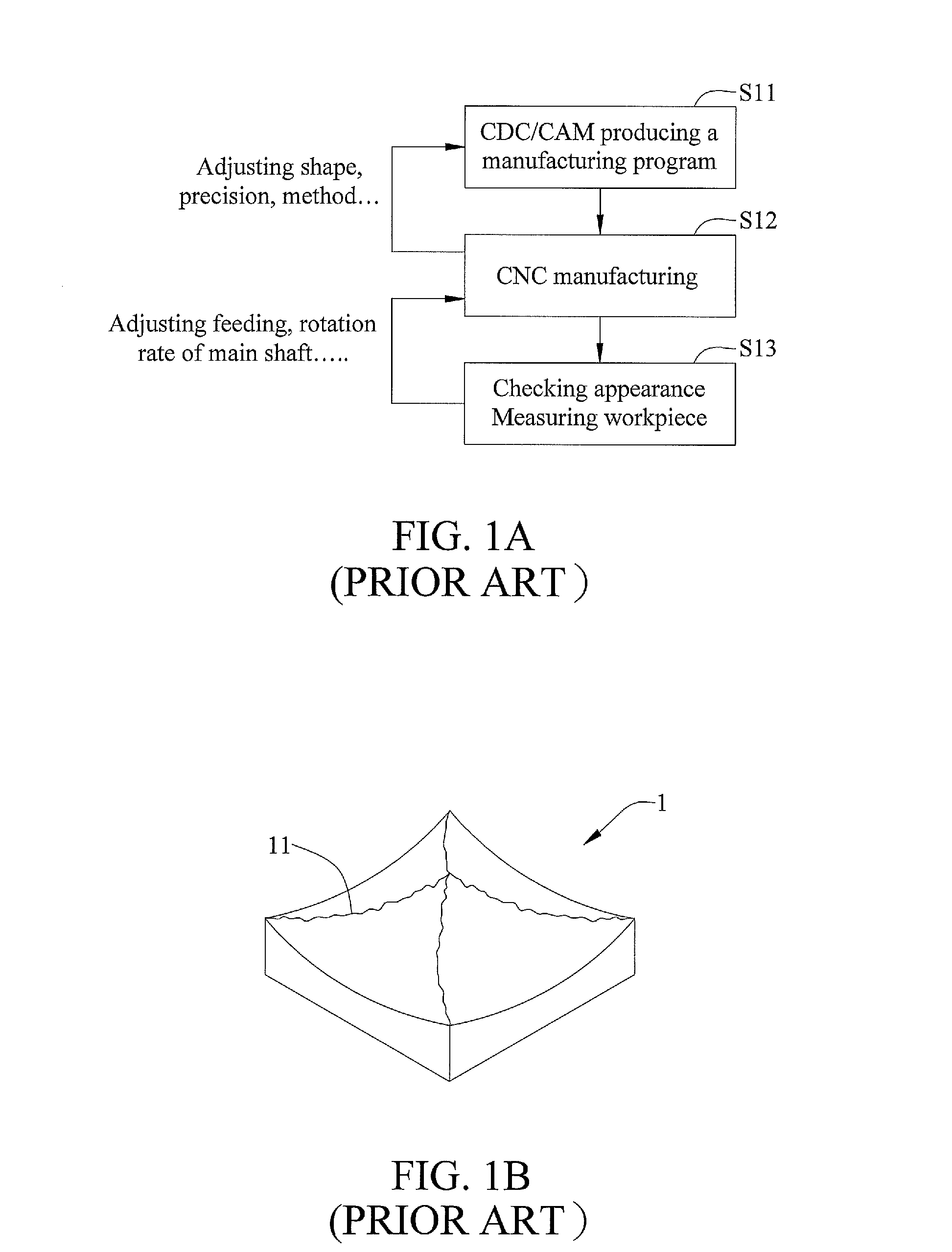

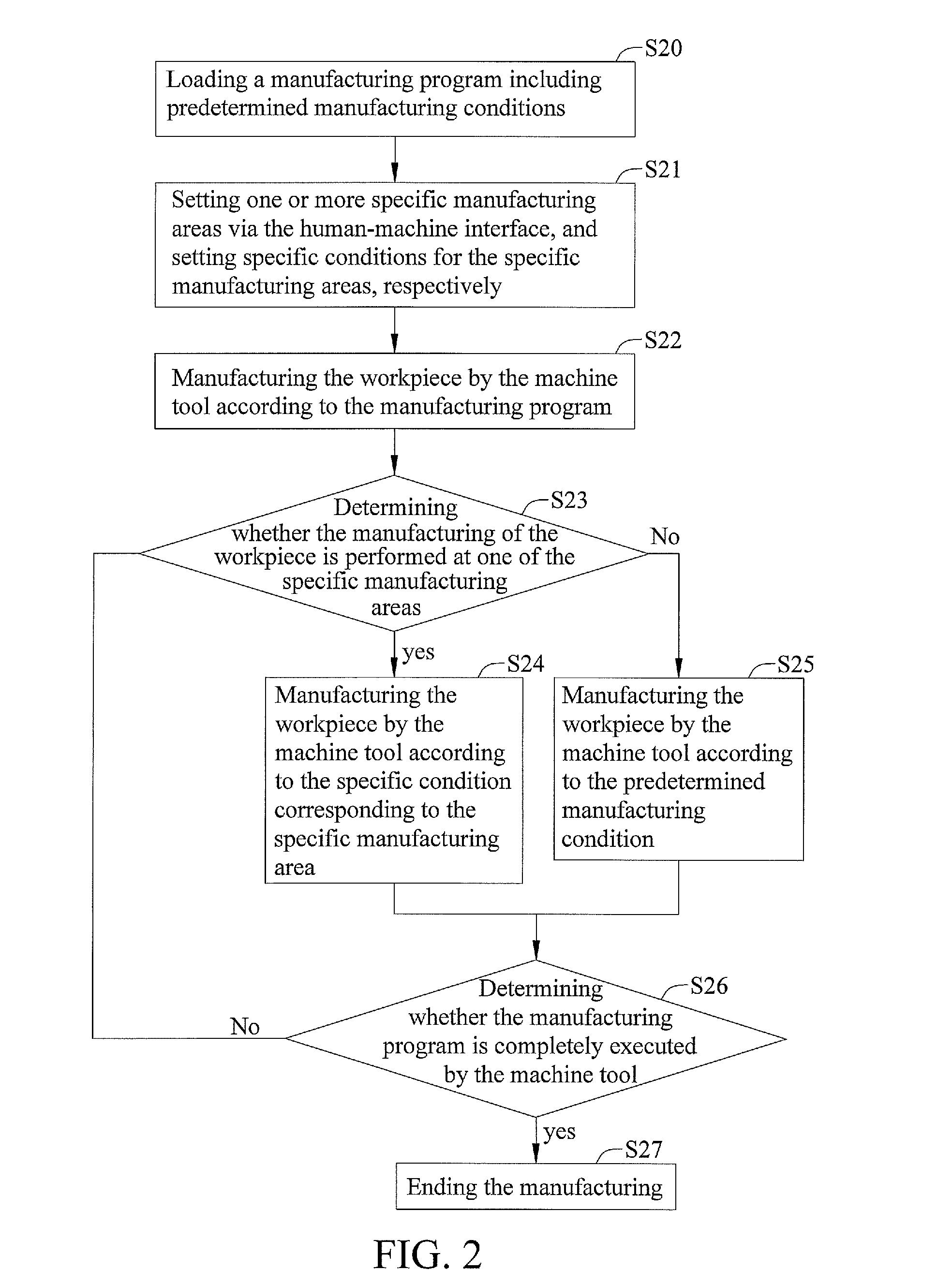

Manufacturing method for machine tool

ActiveUS20120117787A1Simplify conventional methodImprove workpiece qualityProgramme controlHuman–machine interfaceMachine tool

The present invention provides a manufacturing method for a machine tool having a human-machine interface and a program with predetermined manufacturing conditions. The manufacturing method includes (1) setting, via the human-machine interface, one or more specific manufacturing areas of the workpiece and specific conditions for the specific manufacturing areas; (2) determining by the controller whether the manufacturing of the workpiece is performed at one of the specific manufacturing areas; (3) performing the manufacturing of the workpiece under one of the specific conditions corresponding to the one of the specific manufacturing areas via the controller and monitoring continuously the manufacturing status of the machine tool if the manufacturing of the workpiece is performed at one of the specific manufacturing areas; and (4) performing the manufacturing of the workpiece according to the predetermined manufacturing conditions via the controller if the manufacturing of the workpiece is not performed at the specific manufacturing areas.

Owner:IND TECH RES INST

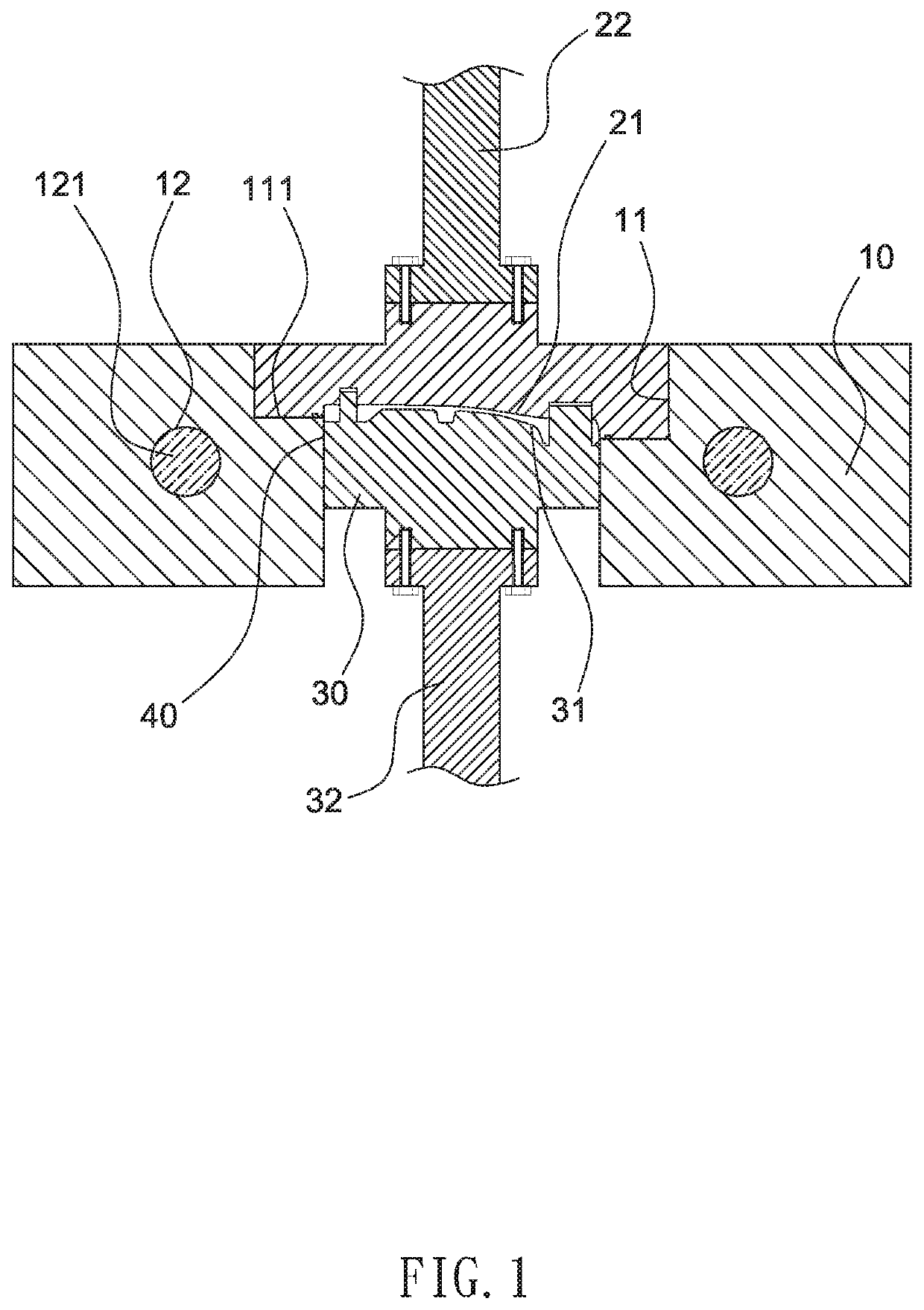

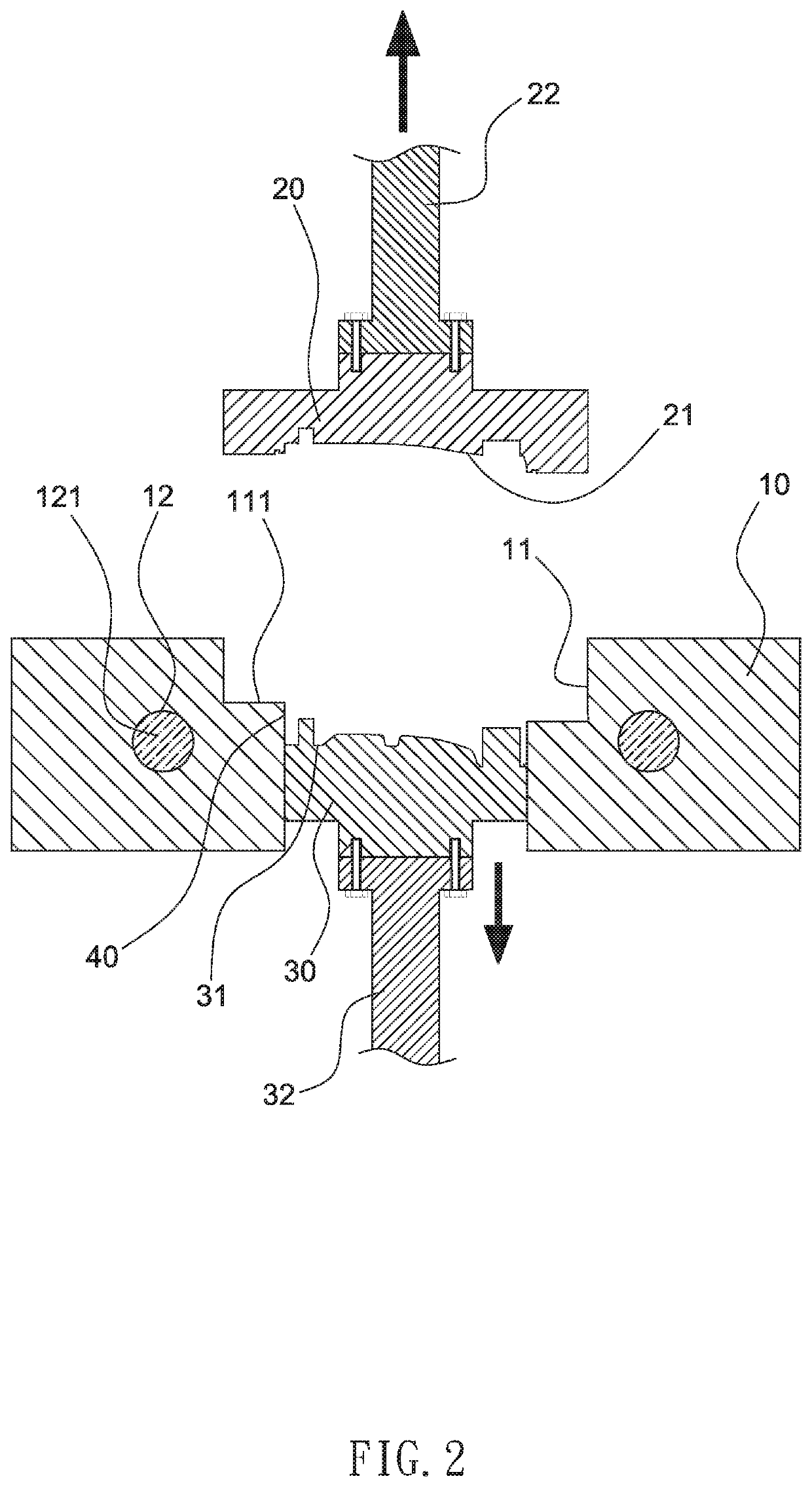

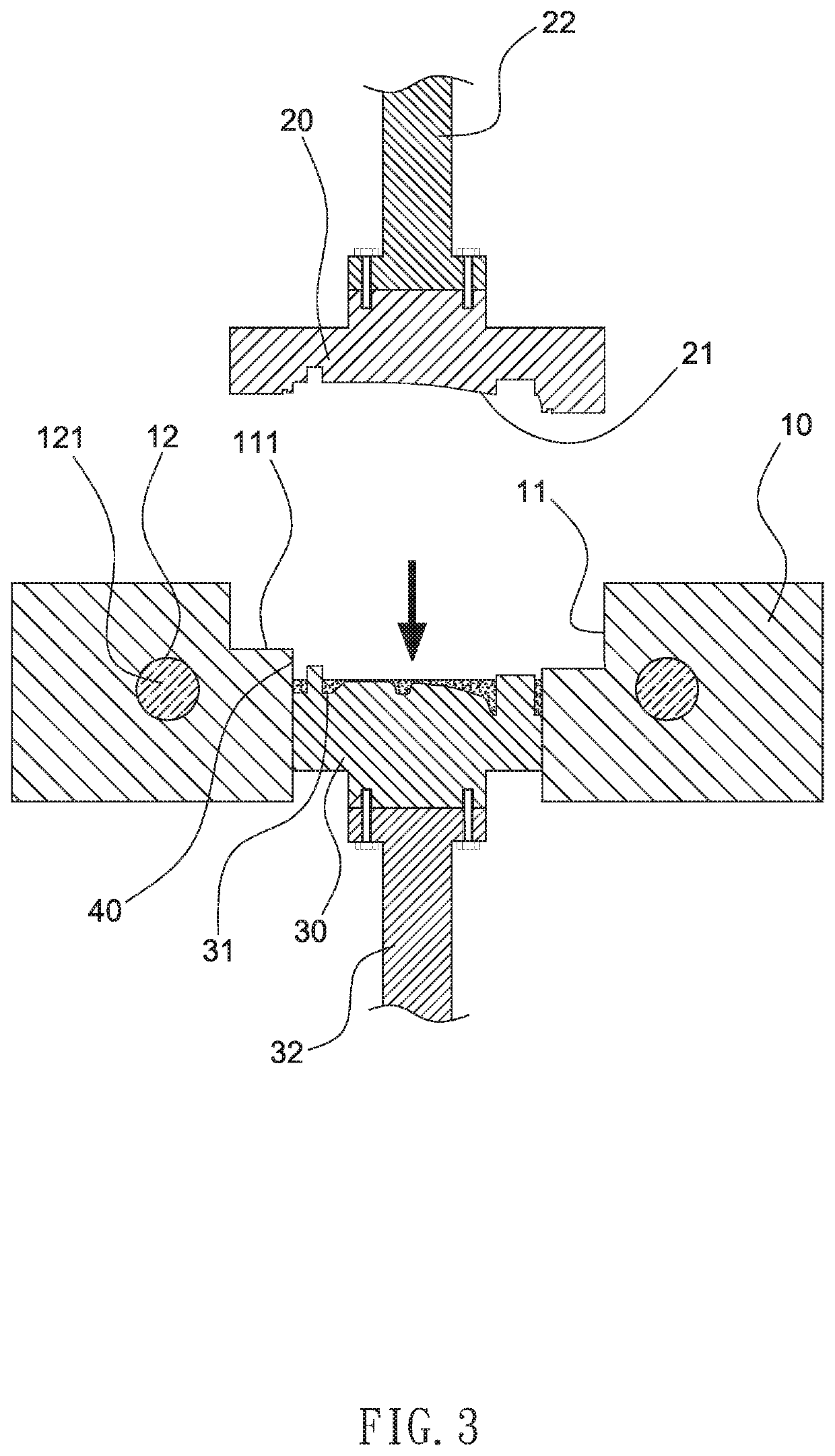

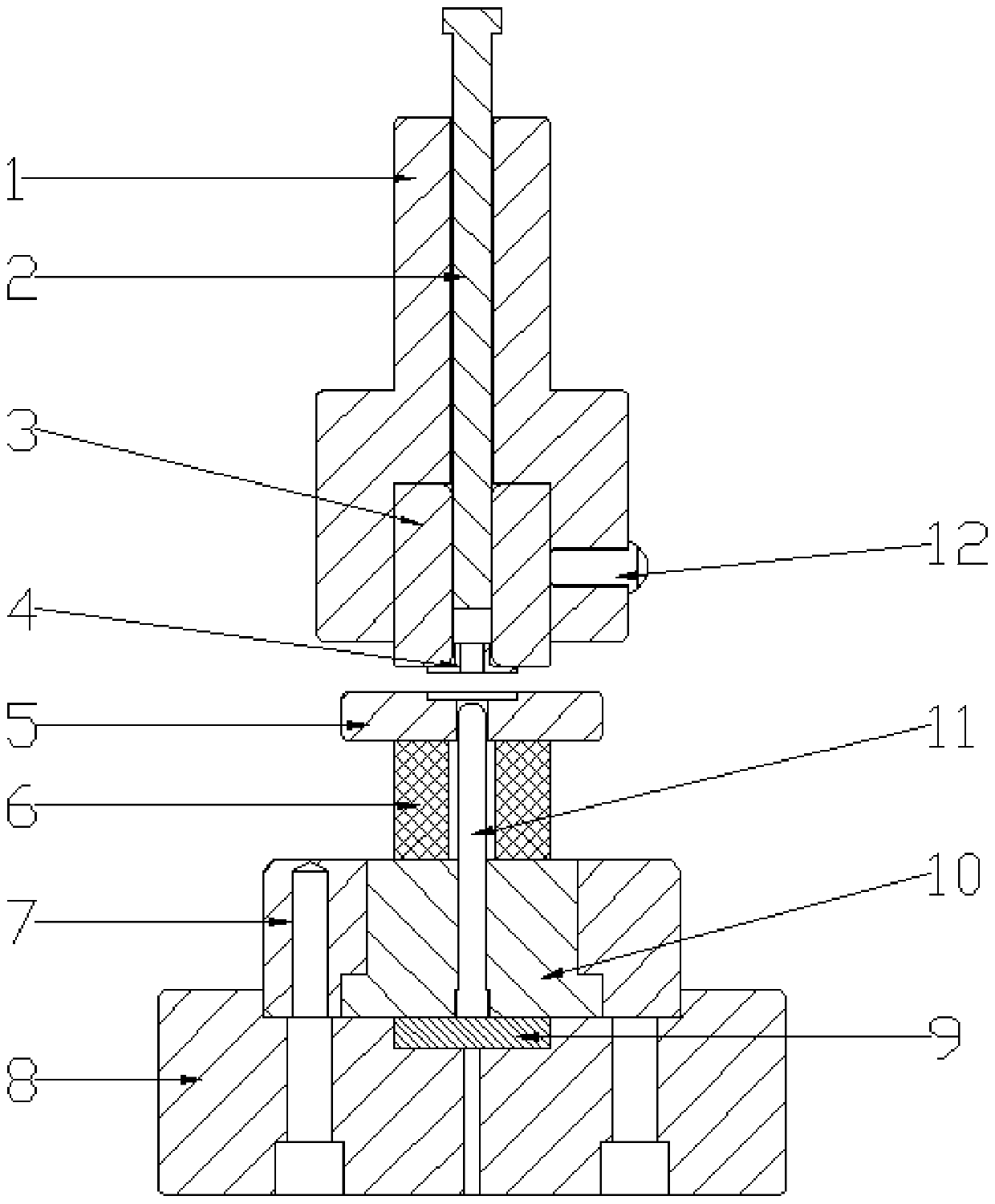

Forging device for molten metal

InactiveUS20200086377A1High saturationHigh qualityCutting toolsPower hammersEngineeringMechanical engineering

A forging device for molten metal includes first and second die bodies that are linked by first and second power arms to move back and forth in a cavity of a die base so as to open and close a workpiece shaping space defined between first and second die faces of the first and second die bodies. When the workpiece shaping space is opened, a molten metal is poured, and then the workpiece shaping space is closed to cast a semi-finished workpiece. After that, the first and second power arms axially press and forge the semi-finished workpiece in the workpiece shaping space into a high-strength workpiece. The high-strength workpiece is shaped by casting and forging in the same process.

Owner:JOIN YIUH IND

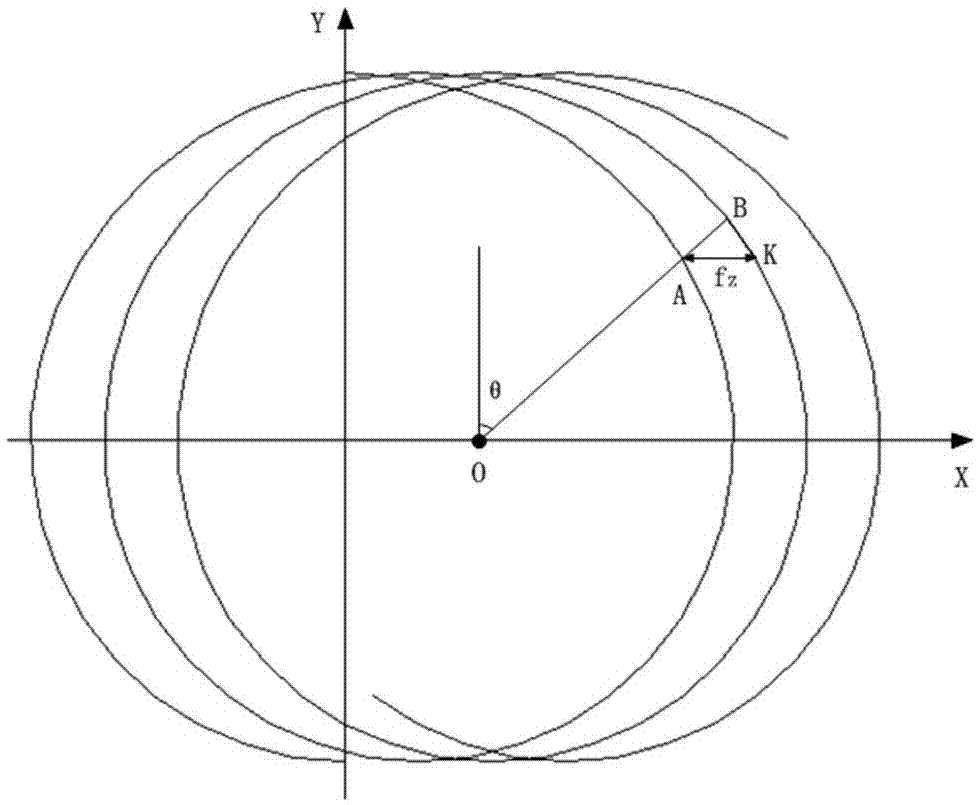

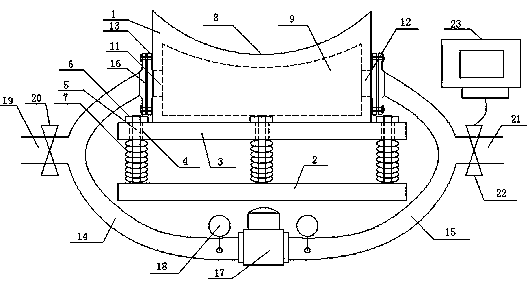

Method for predicting and compensating machining deformation error of miniature trough

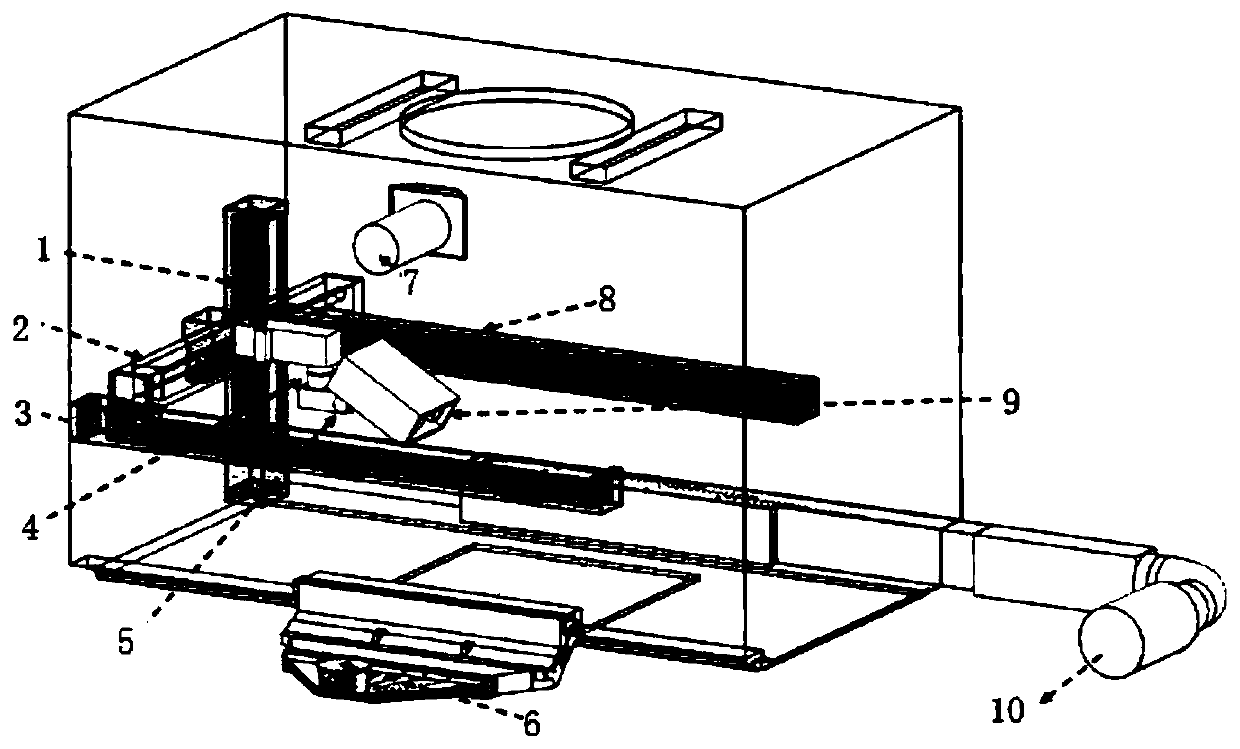

ActiveCN107511516AEliminate uncertaintyImprove machining accuracyMeasurement/indication equipmentsMilling equipment detailsMilling cutterDevice form

The invention relates to the field of machining, in particular to a method for predicting and compensating a machining deformation error of a miniature trough. A device form predicting and compensating the machining deformation error of the miniature trough comprises a machine tool working table, a micro milling cutter, a miniature groove piece, a dynamometer and a support, and the dynamometer and the support are arranged on the machine tool working table in parallel. According to the method, a displacement sensor is utilized to online monitor machining deformation of the miniature groove piece in real time, a sensing working table is utilized to transmit the adjusting information so as to conduct real-time adjustment on the miniature groove piece, uncertain factors caused by manual adjusting and radial undercut caused by workpiece deformation are eliminated, and accordingly the machining accuracy and the workpiece quality are improved. An adjuster is independent of a machine tool control system, a tool path planed by an existing program cannot be affected, the programming time is saved greatly, and accordingly the production efficiency is improved.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

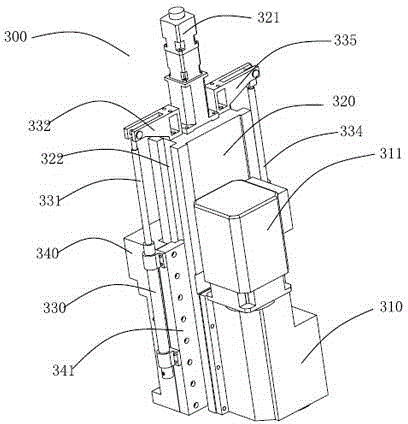

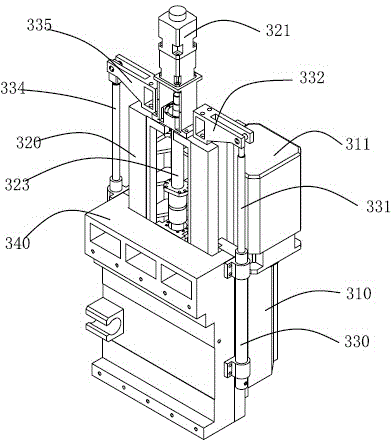

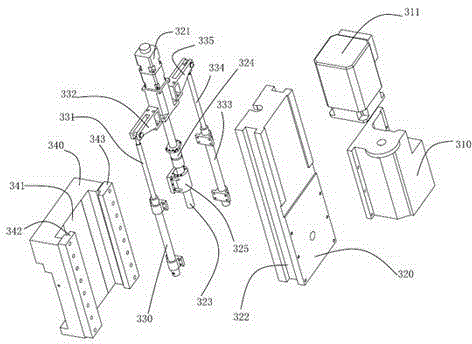

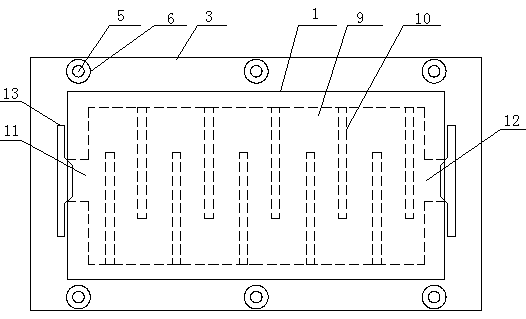

Vertical finish-milling machine

InactiveCN104607702AImprove machining accuracyImprove workpiece qualityMilling machinesFeeding apparatusMilling cutterMetal machining

The invention relates to a metal processing machine tool, in particular to a vertical finish-milling machine which comprises a gantry column, a transverse beam, a main shaft box mechanism and a working table mechanism, wherein balance oil cylinders are respectively and symmetrically arranged on two sides of a ram of the main shaft box mechanism; one end of each balance oil cylinder (the shaft end of the oil cylinder) is fixed on the ram; the other ends of the balance oil cylinders (the body ends of the oil cylinders) are fixed on a drag plate. When the ram drives a main shaft box to move upwards and downwards, the situation that a cutter drops off can be avoided no matter what the moving amplitude is; moreover, when a milling cutter moves suddenly, the moving speed of the main shaft box can be effectively buffered by the balance oil cylinders; due to adoption of the balance oil cylinders on two sides of the ram, the ram is relatively stable, the processing precision of the finish-milling machine can be relatively high, and a processed workpiece is relatively good in quality. After the guide tracks of a working table base are lengthened, the working table can be completely supported, and the bearing property of the working table is improved. Three transverse beam guide tracks are provided, so that abrasion of the guide tracks is alleviated, and the service lives of the guide tracks are prolonged.

Owner:广东习铭模具工业有限公司

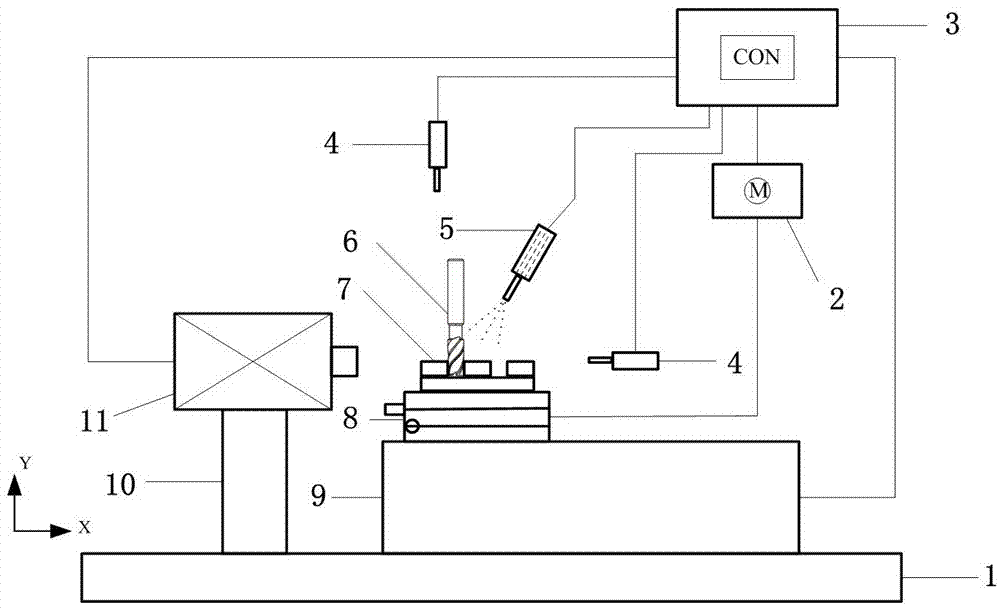

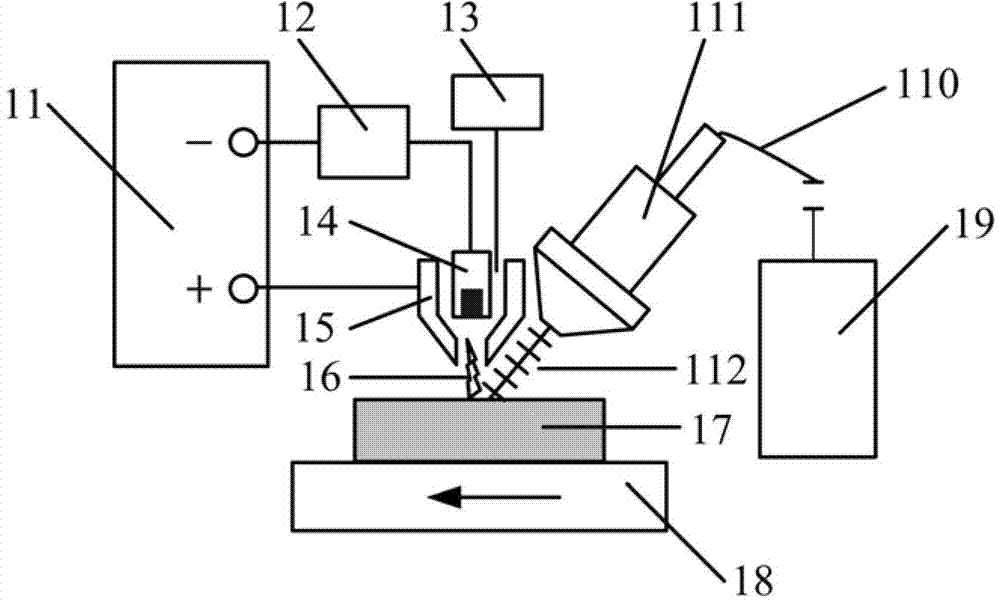

Laser heating auxiliary arc striking micro-explosion processing method and device for engineering ceramic material

InactiveCN102950387AControl outputImprove quality and efficiencyLaser beam welding apparatusMaterial removalSpray nozzle

The invention relates to a laser heating auxiliary arc striking micro-explosion processing method and a laser heating auxiliary arc striking micro-explosion processing device for an engineering ceramic material, and belongs to the technical field of the processing of hard and brittle materials. The method comprises the following steps of: focusing a laser beam, and then, obliquely irradiating the laser beam on the surface of a work piece to be processed; vertically aligning a jet nozzle of an arc striking micro-explosion generator with the surface of the work piece downwards; and enabling the work piece to continuously perform a feed movement along with a working platform, carrying out laser preheating first, raising the temperature of a micro cell to the softening temperature of the ceramic material, and then, carrying out arc striking micro-explosion processing until the processing of the engineering ceramic work piece to be processed is finished. The system mainly comprises a special pulse power supply, a pulse controller, a numeric control three-dimensional working platform, a micro-explosion generator, a gas supply device, a medium-low power laser apparatus, an optical fiber and a laser head. By using the laser heating auxiliary arc striking micro-explosion processing method and the laser heating auxiliary arc striking micro-explosion processing device, the material removal efficiency of the arc striking micro-explosion processing method is improved; the processing damage is reduced; and the practical application of the arc striking micro-explosion processing method in the processing of the engineering ceramic material is further promoted.

Owner:田欣利 +1

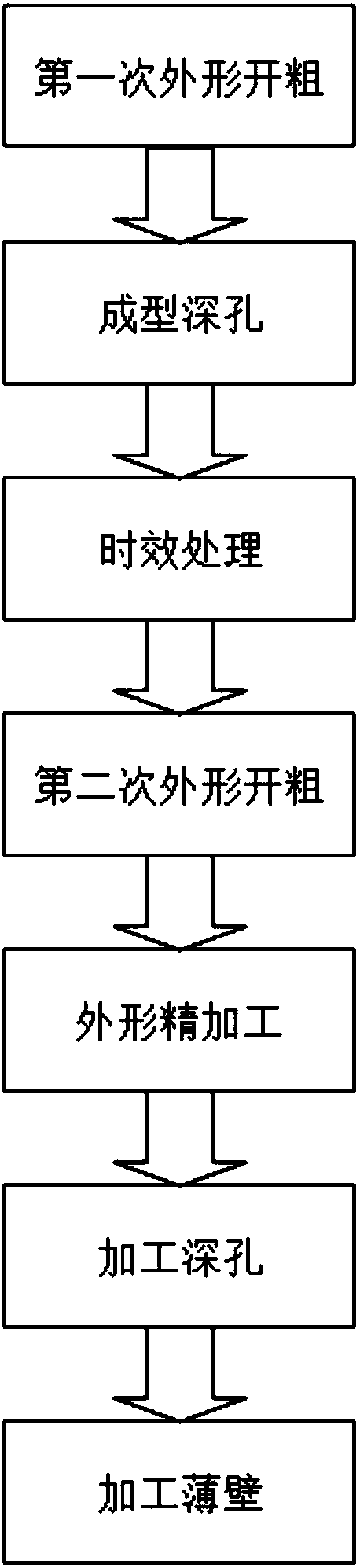

Machining process for deep hole thin-walled workpiece

InactiveCN108274202ASolve the deformationSolve the problem of vibration knife linesAircraft componentsMilling cutterEngineering

The invention relates to a machining process for a deep hole thin-walled workpiece. The machining process for the deep hole thin-walled workpiece comprises the steps that S1, primary appearance roughmachining is carried out, wherein a disc milling cutter is adopted to carry out primary rough machining on the appearance of a raw material, surface materials are removed, the milling cutter is used for removing residual materials at corners so that the external shape can be formed; S2, a deep hole is formed, wherein the two end portions of the raw material are drilled through a drill bit; S3, aging treatment is carried out, wherein the workpiece obtained in the step S2 is put into an oven to be subjected to high-temperature treatment, and internal stress is removed; S4, secondary appearance rough machining is carried out, wherein the milling cutter is used for carrying out secondary rough machining on the appearance of the workpiece obtained in the step S3; S5, appearance finish machiningis carried out, wherein the milling cutter is used for carrying out finish machining on the appearance of the workpiece obtained in the step S4; S6, the deep hole is machined, wherein a boring cutteris used for carrying out semi-finish machining and finish machining on the deep hole; and S7, the thin wall is machined. The problems that during machining of a large deep hole thin-walled workpiece,deformation and shaking cutter lines appear are solved, the machining efficiency and the workpiece quality are improved, and the defective percentage is reduced.

Owner:SUZHOU ERIC MECHANICS & ELECTRONICS CO LTD

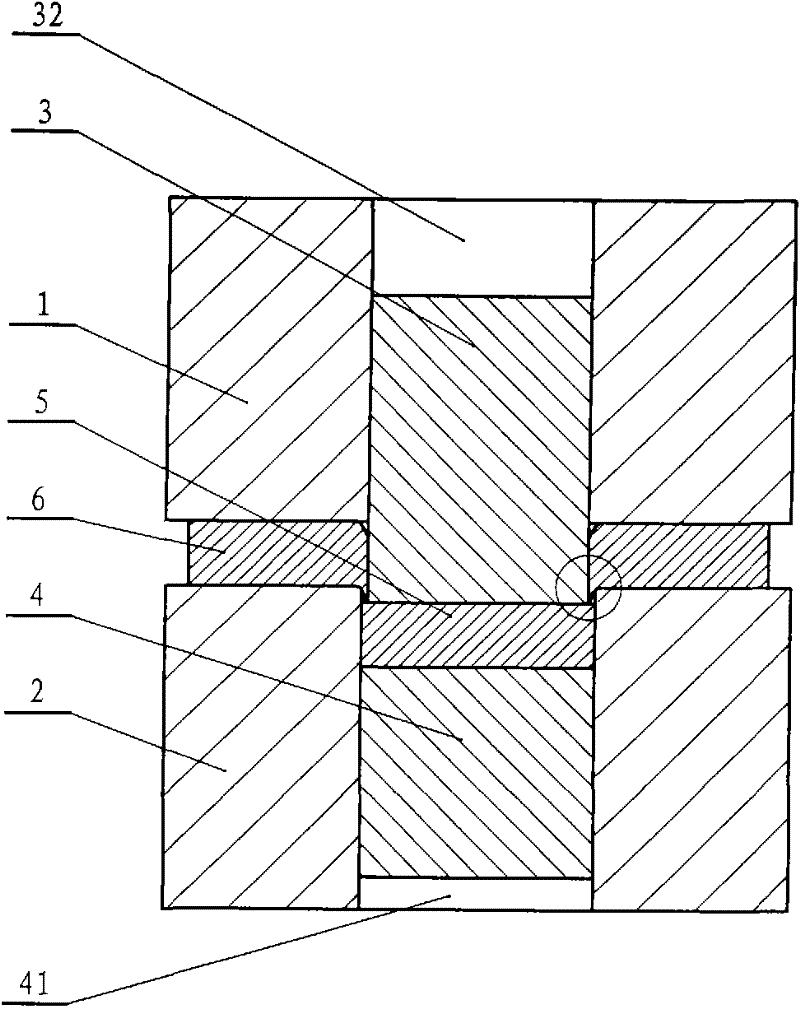

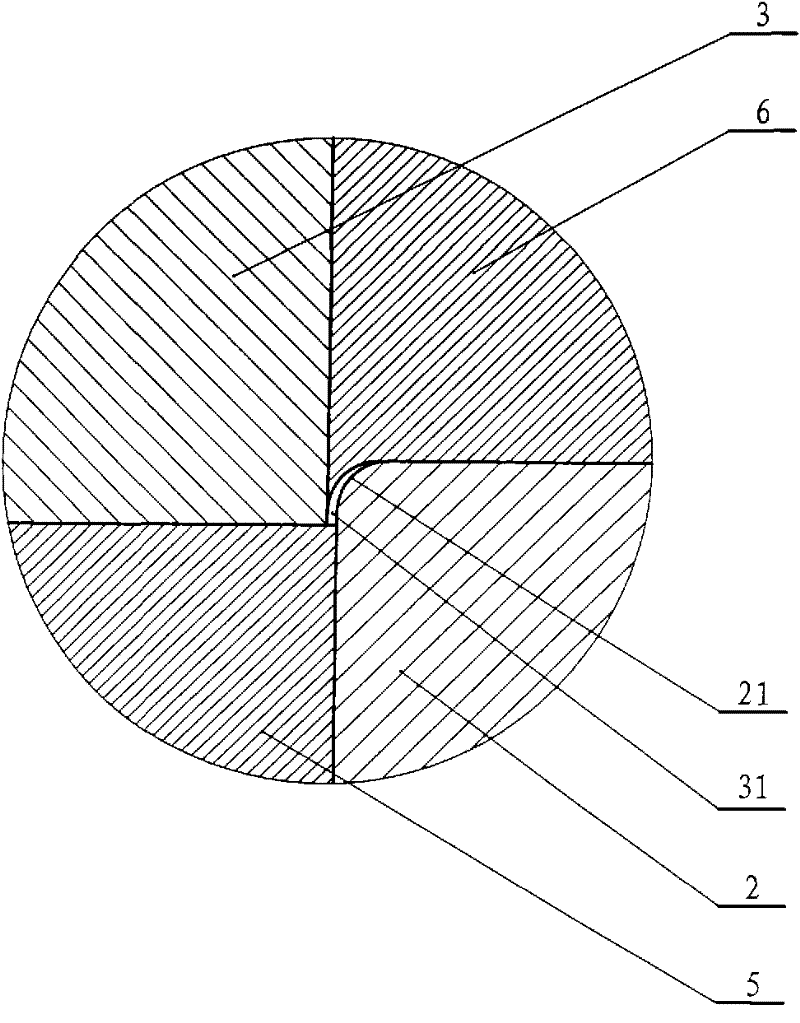

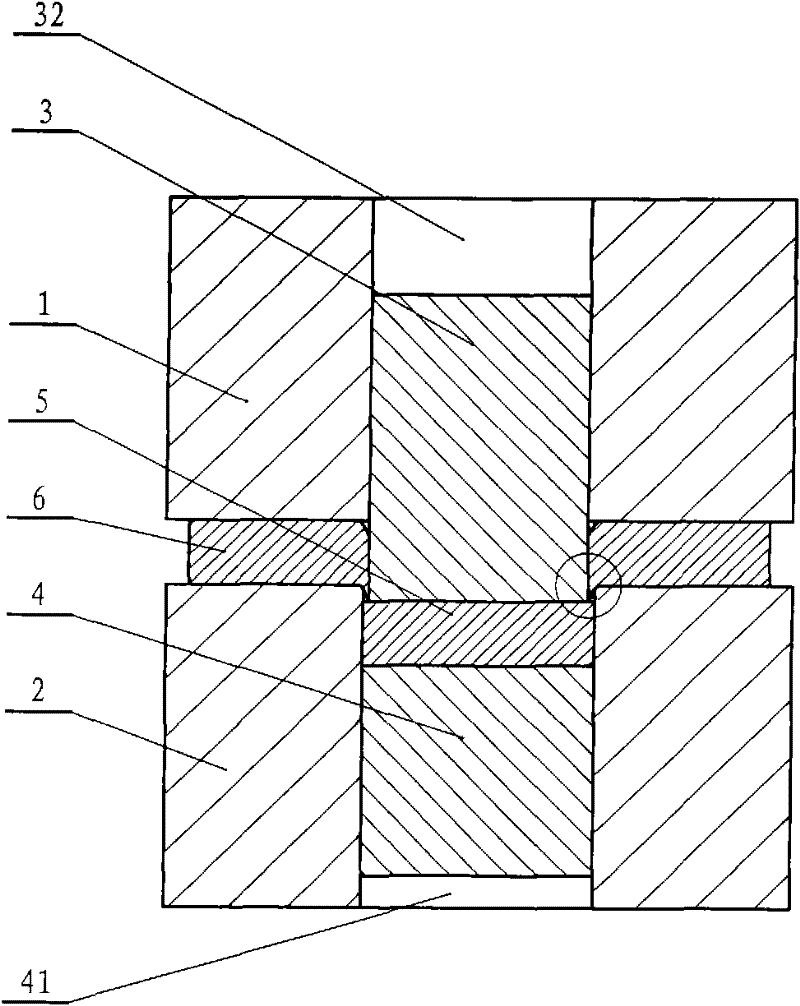

Plane edge-pressing and semi-fine blanking device and method

The invention relates to a plane edge-pressing and semi-fine blanking device and a method. The device is provided with a plane pressure plate and a concave die, when a workpiece is punched, the plane pressure plate needs to enable edge-pressing force to press on the outer edge of a profile of the workpiece on a workpiece blank, and the edge-pressing force can generate great friction force betweenthe surface of the workpiece blank and the plane pressure plate and between the surface of the workpiece blank and the concave die, so as to prevent the material of the workpiece blank from flowing out of the profile of the workpiece. The device is matched with punching force, three-dimensional pressure stress is generated in the material of the workpiece blank in an extrusion zone, and plastic flow is generated, so as to enable the numerical values of the pressure stress in the three-dimensional directions to tend to be consistent, enable the material of the workpiece blank in the profile ofthe workpiece to be in the hydrostatic pressure state and have a maximal plastic deformation range, reduce a region for generating tensile stress in a shearing deformation zone and prevent the emergence of cracks on the surface of a cross section of the workpiece. By using the plane edge-pressing and semi-fine blanking device and the method, an ordinary punch can be used, the processing of a die is simple, a pressurization region on the workpiece blank can not cause damages, the processing cost is low, the quality of the workpiece is high, and the device and the method are convenient to popularize and apply in the punching industry.

Owner:CHONGQING UNIV OF TECH

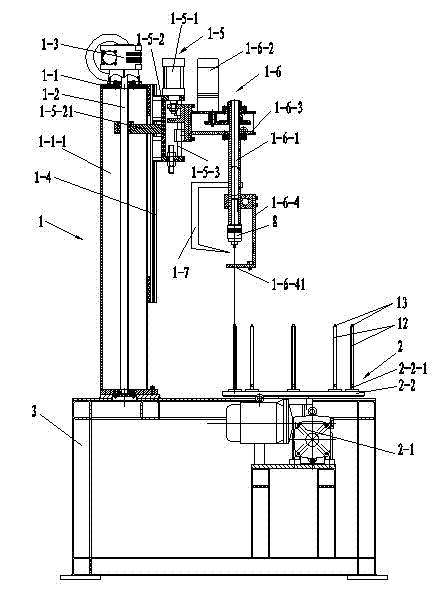

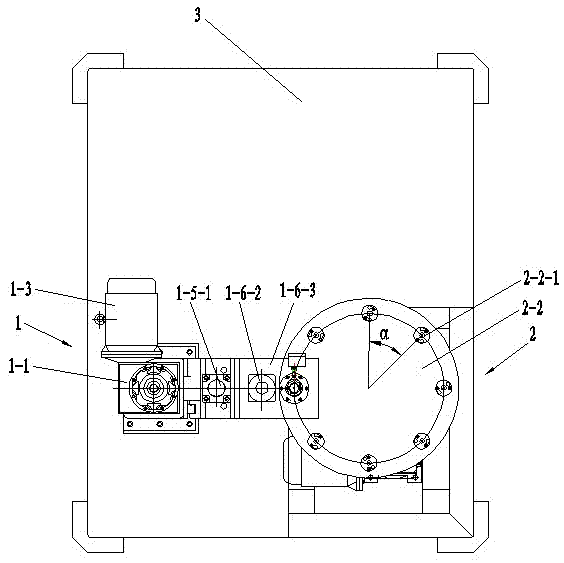

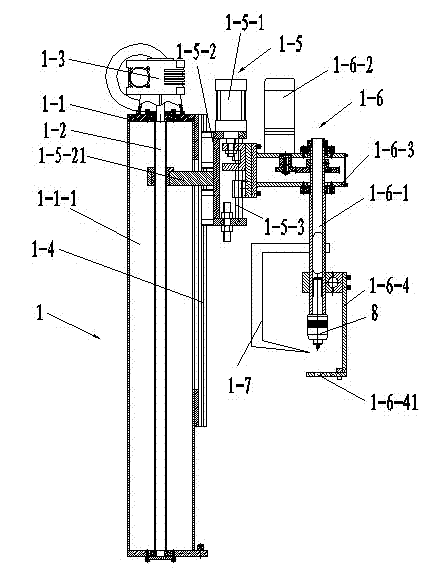

Multi-station automatic welding machine

InactiveCN102500973AReduce processing timeImprove workpiece qualityWelding/cutting auxillary devicesAuxillary welding devicesEngineeringCylinder block

The invention discloses a multi-station automatic welding machine which comprises a welding mechanism, a multi-station working table mechanism and a rack. The welding mechanism is fixedly connected with the rack. The welding mechanism comprises an upright, a transmission screw rod, a screw rod motor, a guide pillar, a cylinder device, a rotating shaft device and a welding gun. The screw rod motor is in transmission connection with the transmission screw rod. The upright is provided with an inner cavity. The transmission screw rod is positioned in the inner cavity. Both ends of the transmission screw rod are respectively arranged and connected on both upper and lower end faces of the upright. The cylinder device comprises a cylinder, a cylinder block and a cylinder guide pillar. The cylinder block is connected with the guide pillar in a slide mode. The cylinder block is provided with a cylinder transmission arm. The cylinder transmission arm is in transmission connection with the transmission screw rod. The rotating shaft device comprises a rotating shaft, a rotating shaft motor, a rotating shaft seat and a positioning plate. The rotating shaft seat is connected with the cylinder guide pillar in a sliding mode. The rotating shaft seat is in transmission connection with the cylinder. The rotating shaft motor is in transmission connection with the rotating shaft. According to the invention, the processing time is shortened and the workpiece quality is improved.

Owner:CHANGZHOU SENXU AUTOMATION TECH

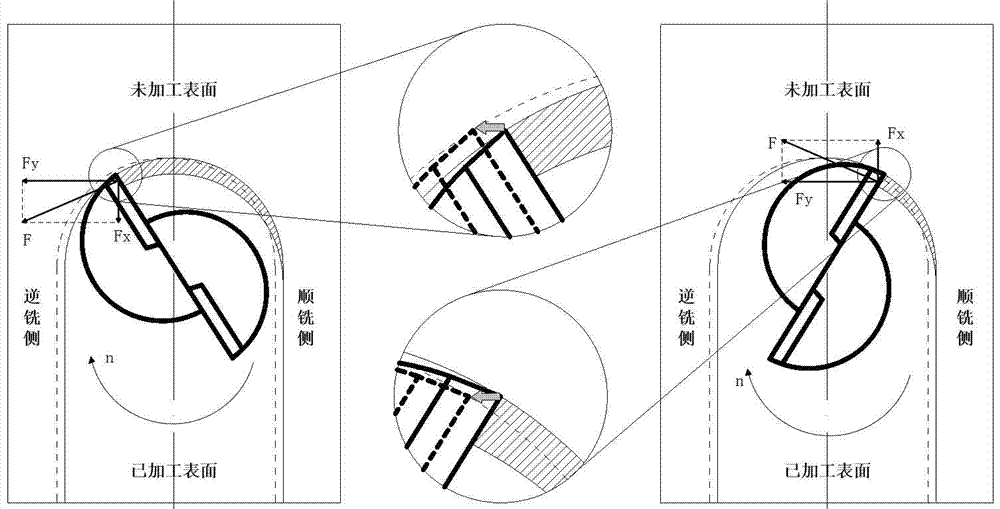

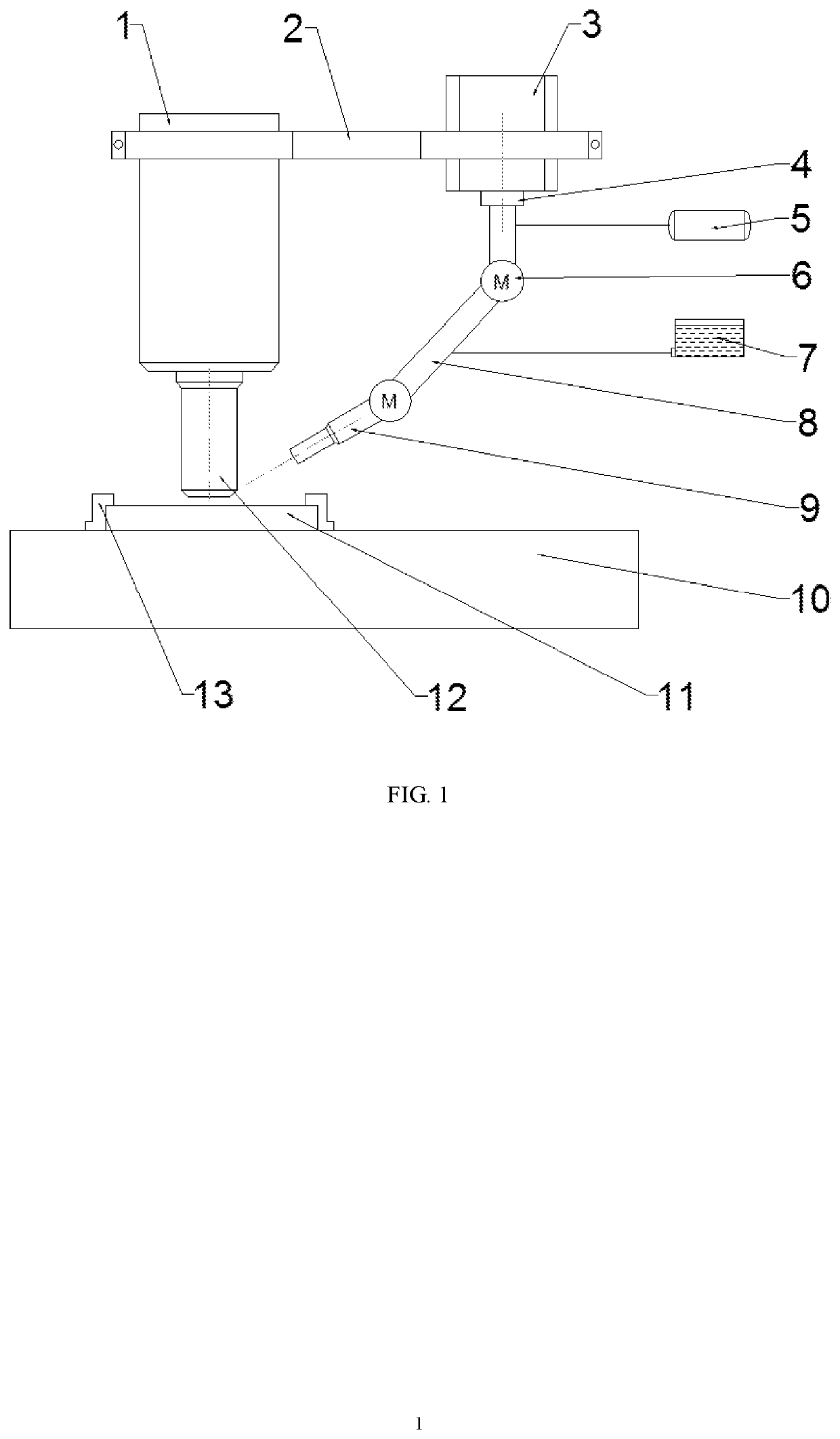

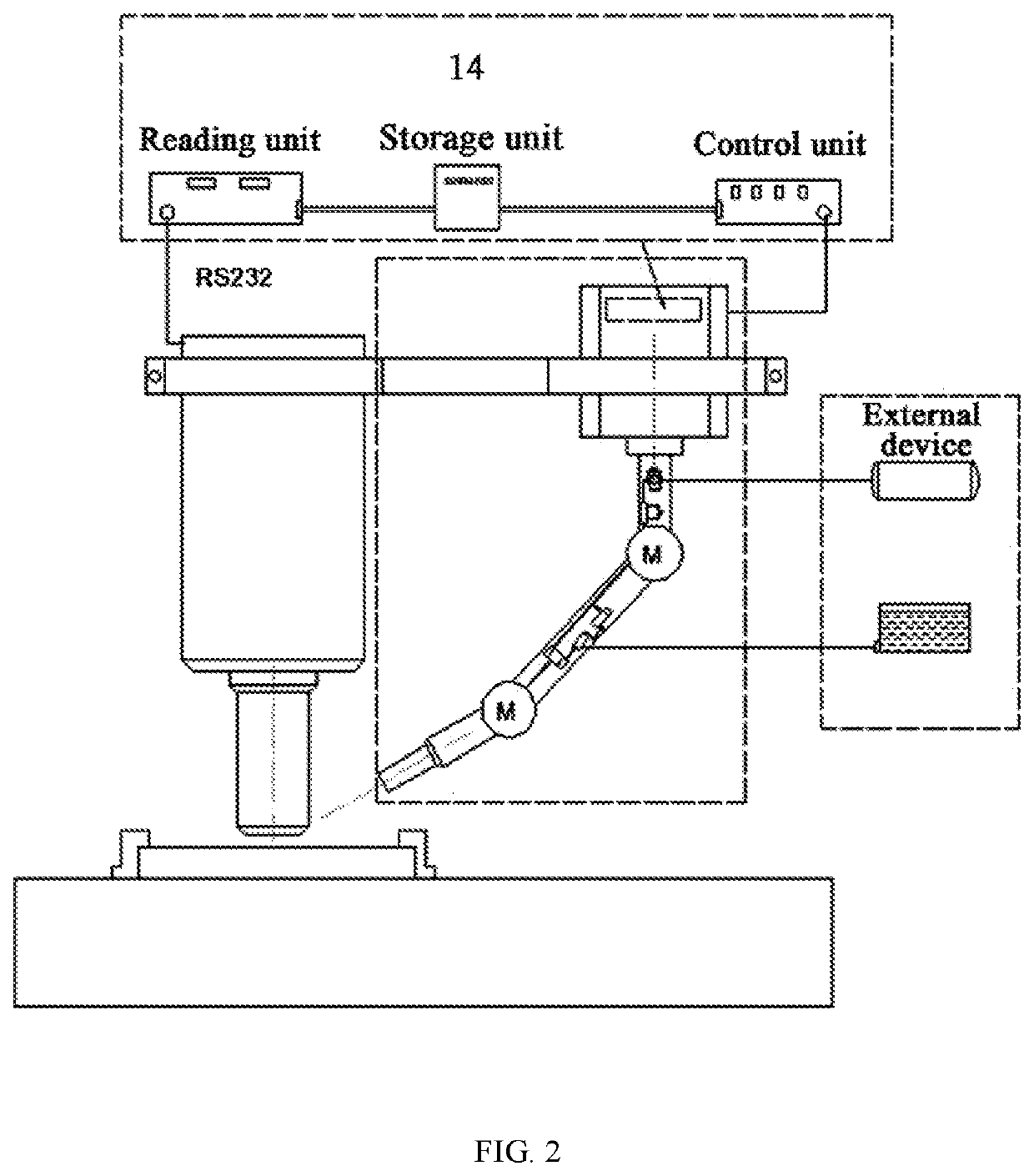

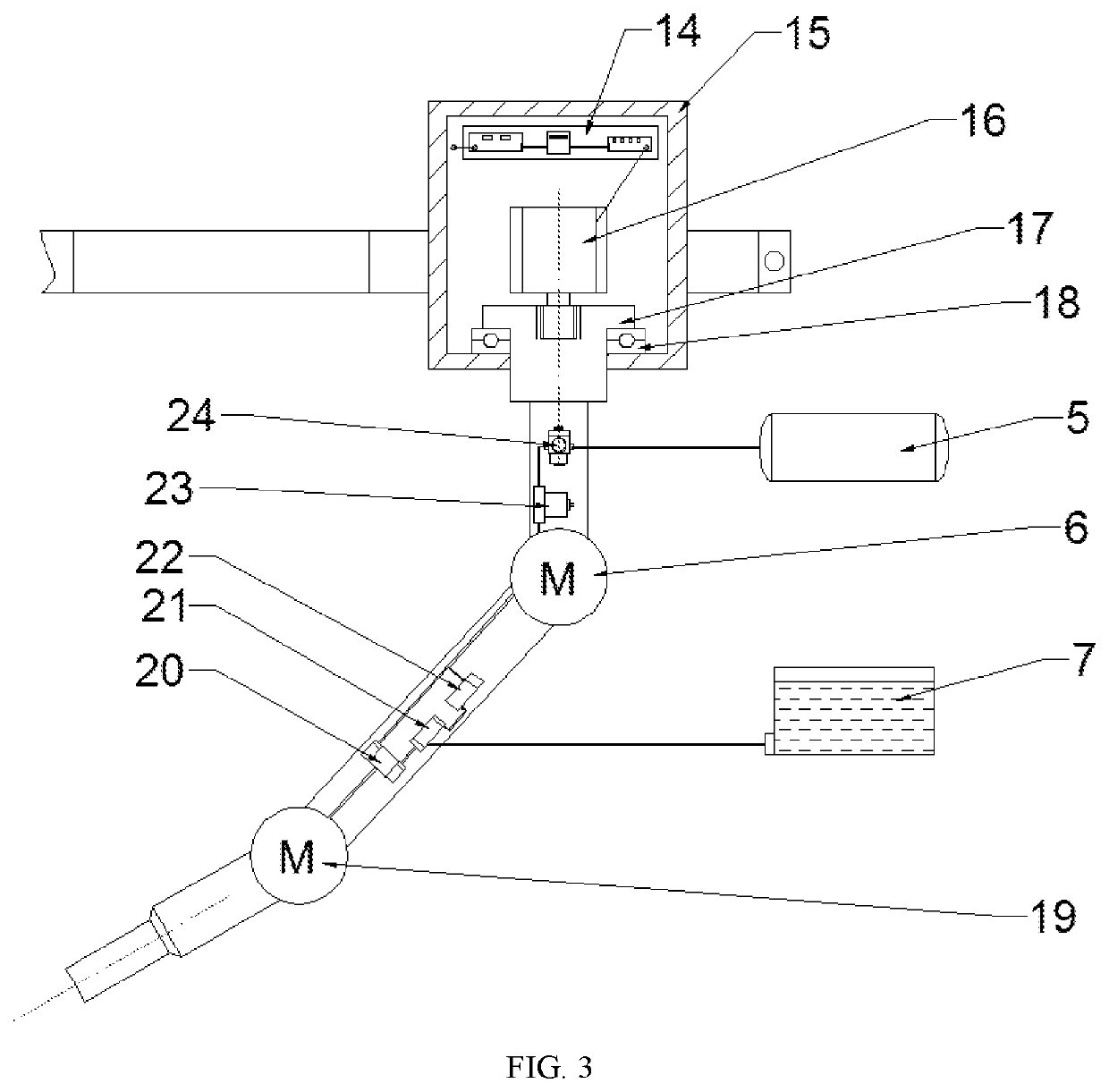

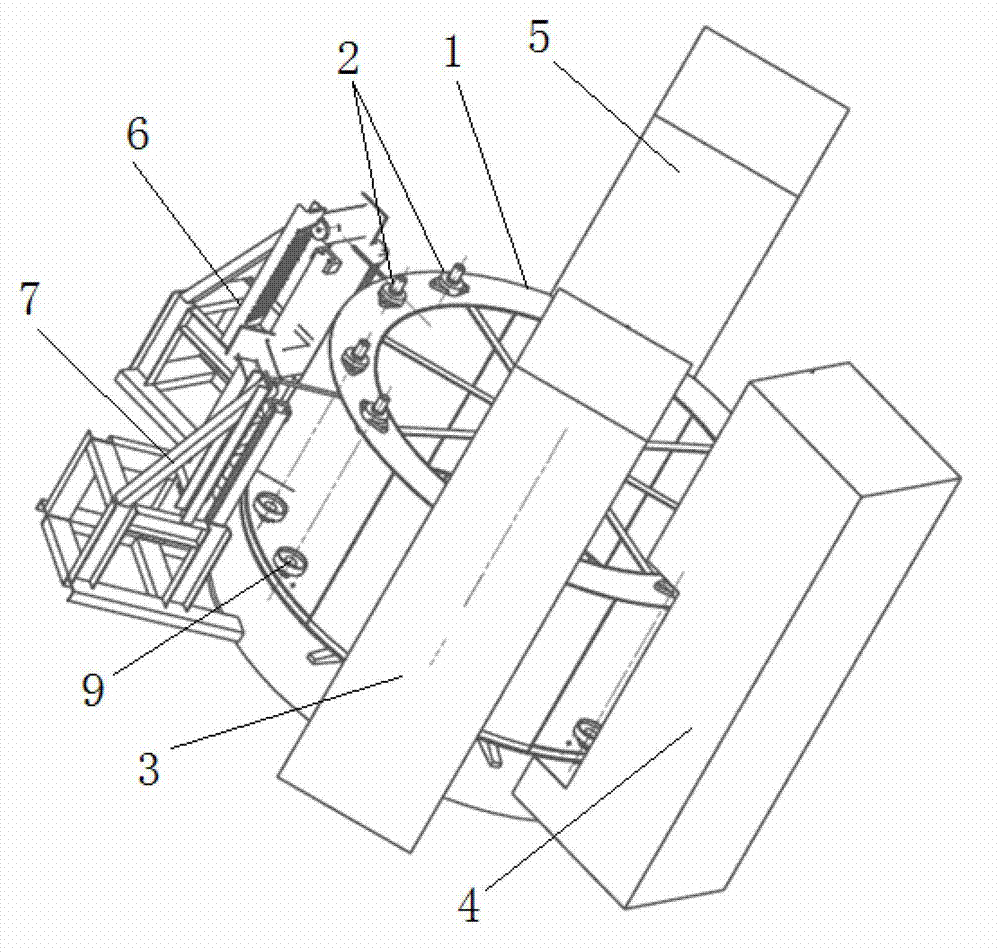

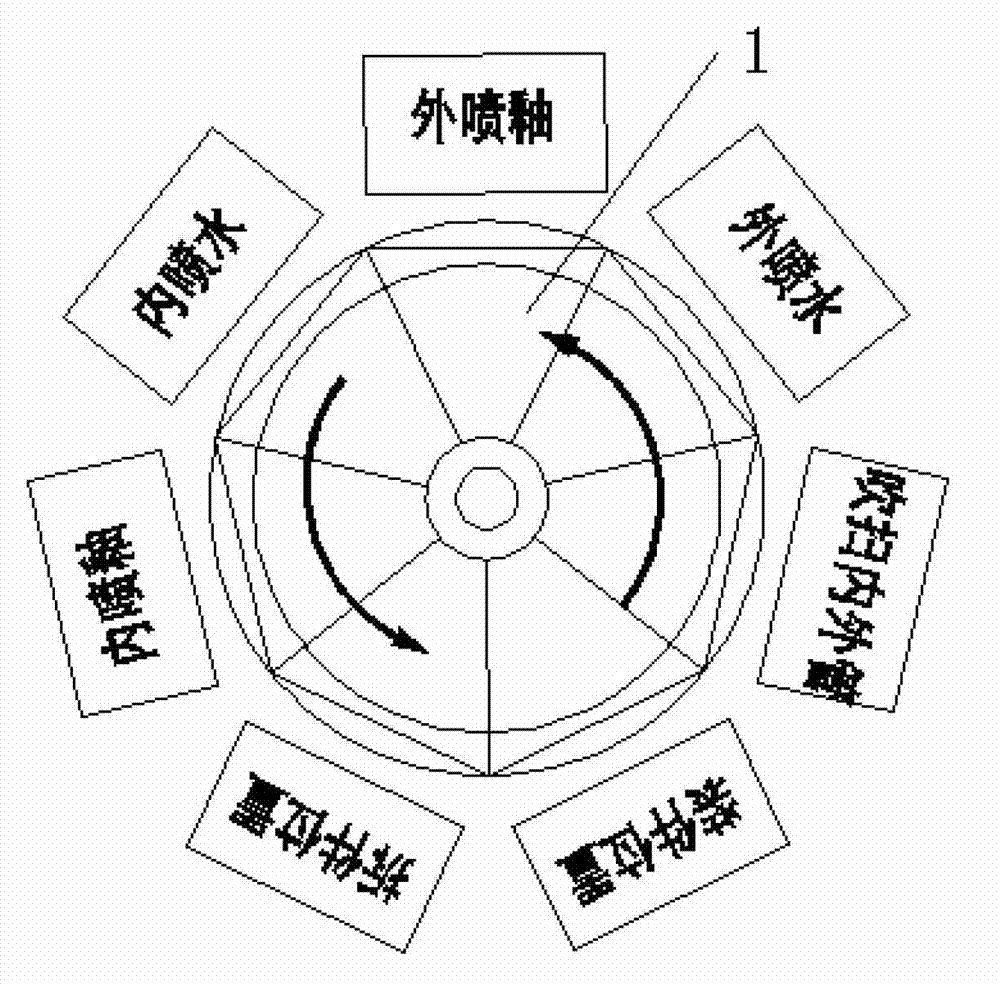

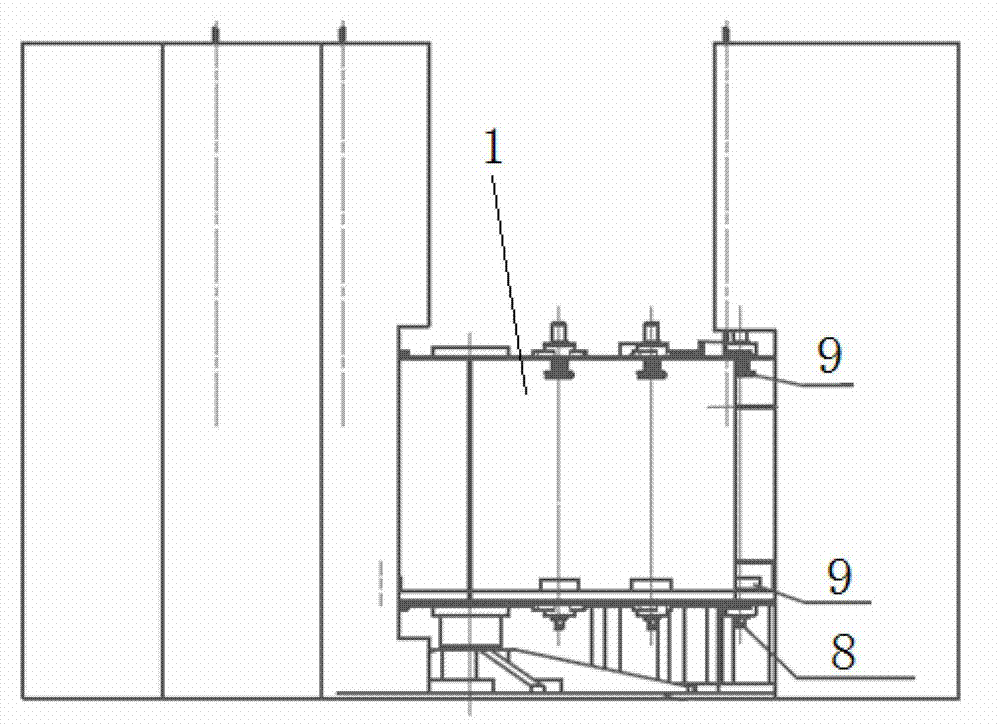

External cooling mql manipulators and machine tools and lubrication method using machine tools

ActiveUS20200230767A1Effectively and constantly lubricate and coolAvoid wastingLarge fixed membersMaintainance and safety accessoriesControl engineeringEngineering

This application relates to lubrication, and more particularly to an external cooling MQL manipulator and a machine tool and a lubrication method using the machine tool. The external cooling MQL manipulator includes a suspension structure, a robot arm, a controller and an oil mist generator. The suspension structure fixedly connects the robot arm and a frame, and a nozzle is provided on a free end of the robot arm; an oil mist generator is connected to the nozzle for ejecting oil mists to a processing area. When the machine tool works, the controller selects the corresponding lubrication parameters according to the processing parameters such as the cutter type and the workpiece material. The first motor and the second motor are controlled to rotate by the controller according to real-time changes of the processing positions detected by the detecting component, thereby adjusting the position of the nozzle.

Owner:SICHUAN UNIV

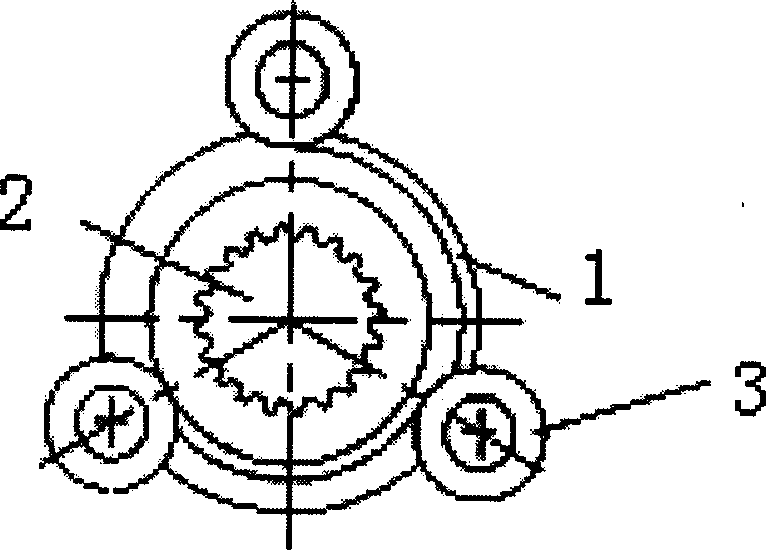

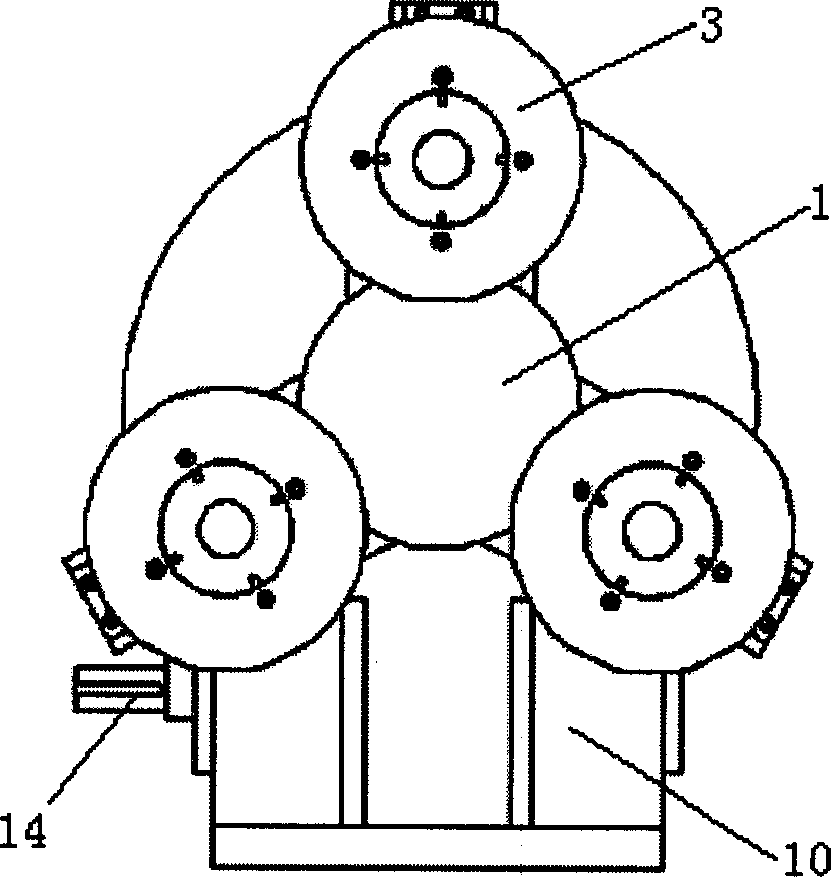

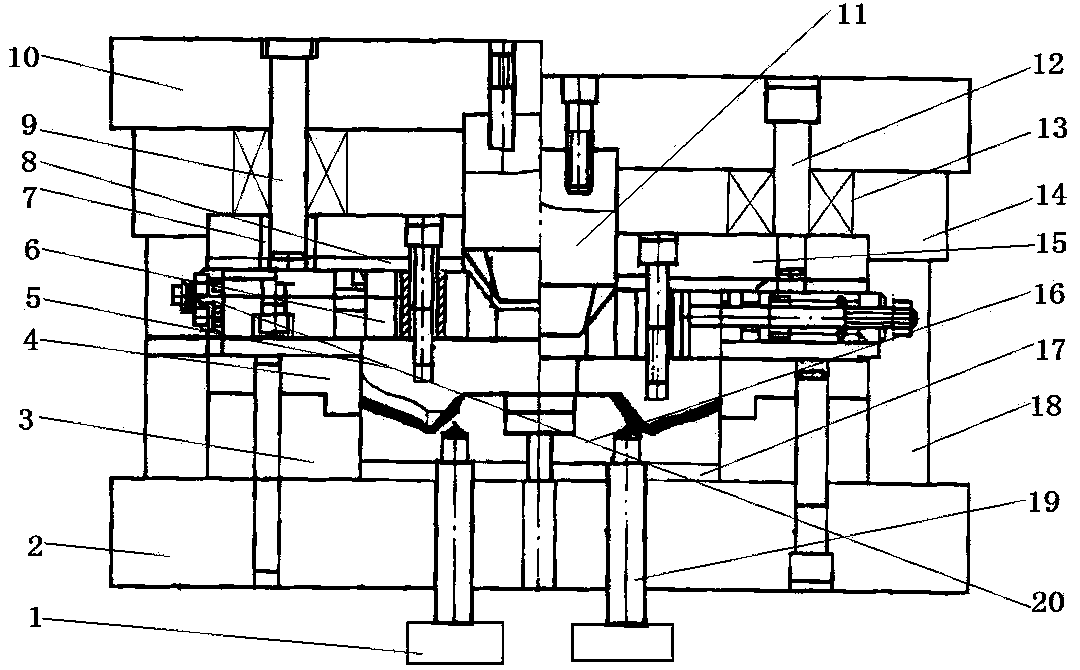

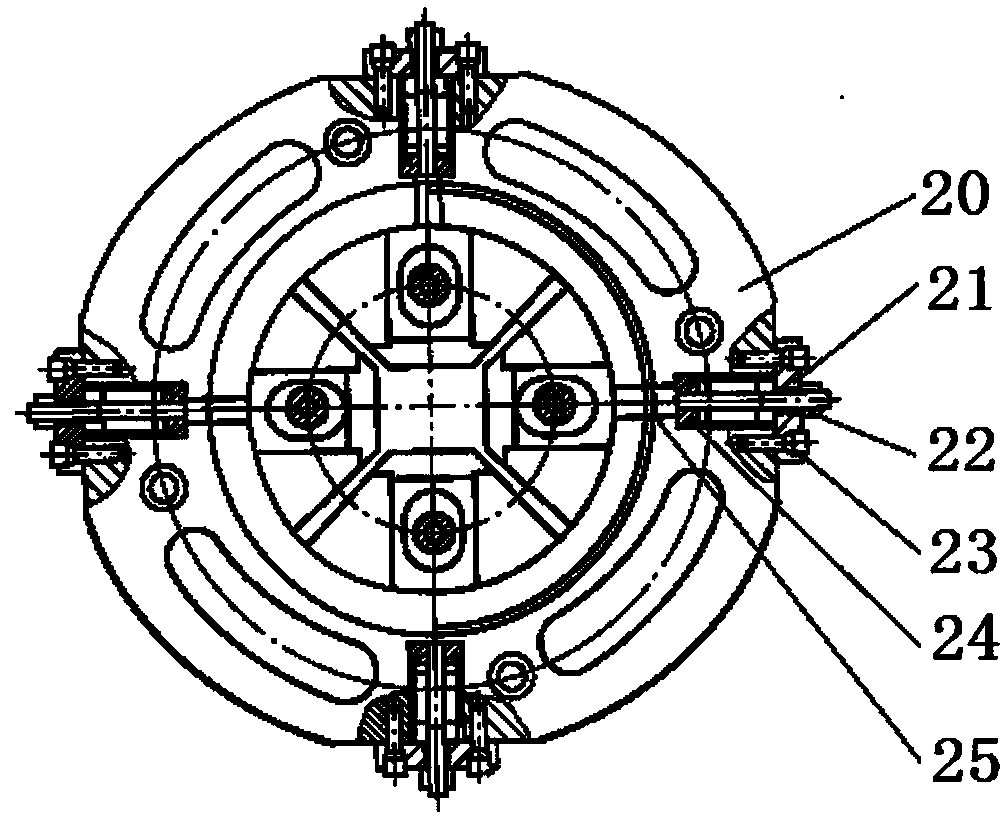

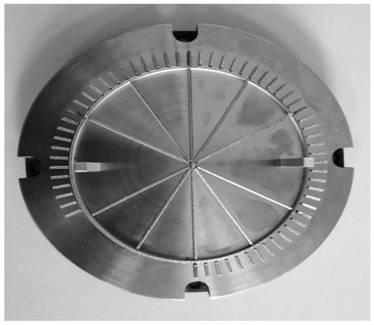

Gear spin pressure forming method and its device

A spinning method for shaping a gear includes such steps as installing a cup-shaped gear blank onto a gear mould rotating with mainshaft, uniformly installing three spinning wheels at intervals of 120 deg to surround said gear blank, and driving said three spinning wheels by motor via worm-gear unit and Archimedes' spiral disc to squeeze said blank to form a gear. Its apparatus is composed of machine frame, Archimedes' spiral disc and three spinning wheels.

Owner:SOUTH CHINA UNIV OF TECH

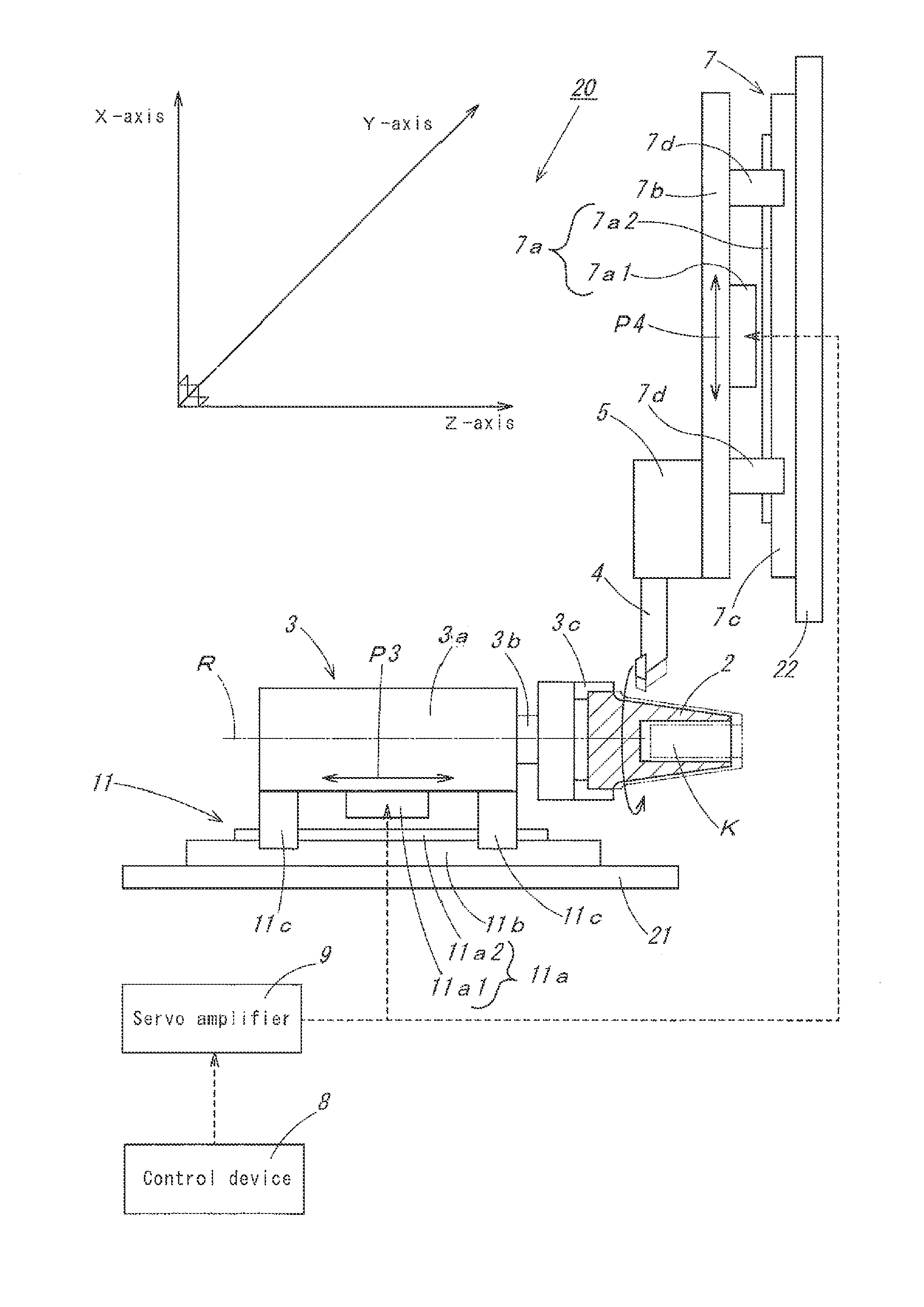

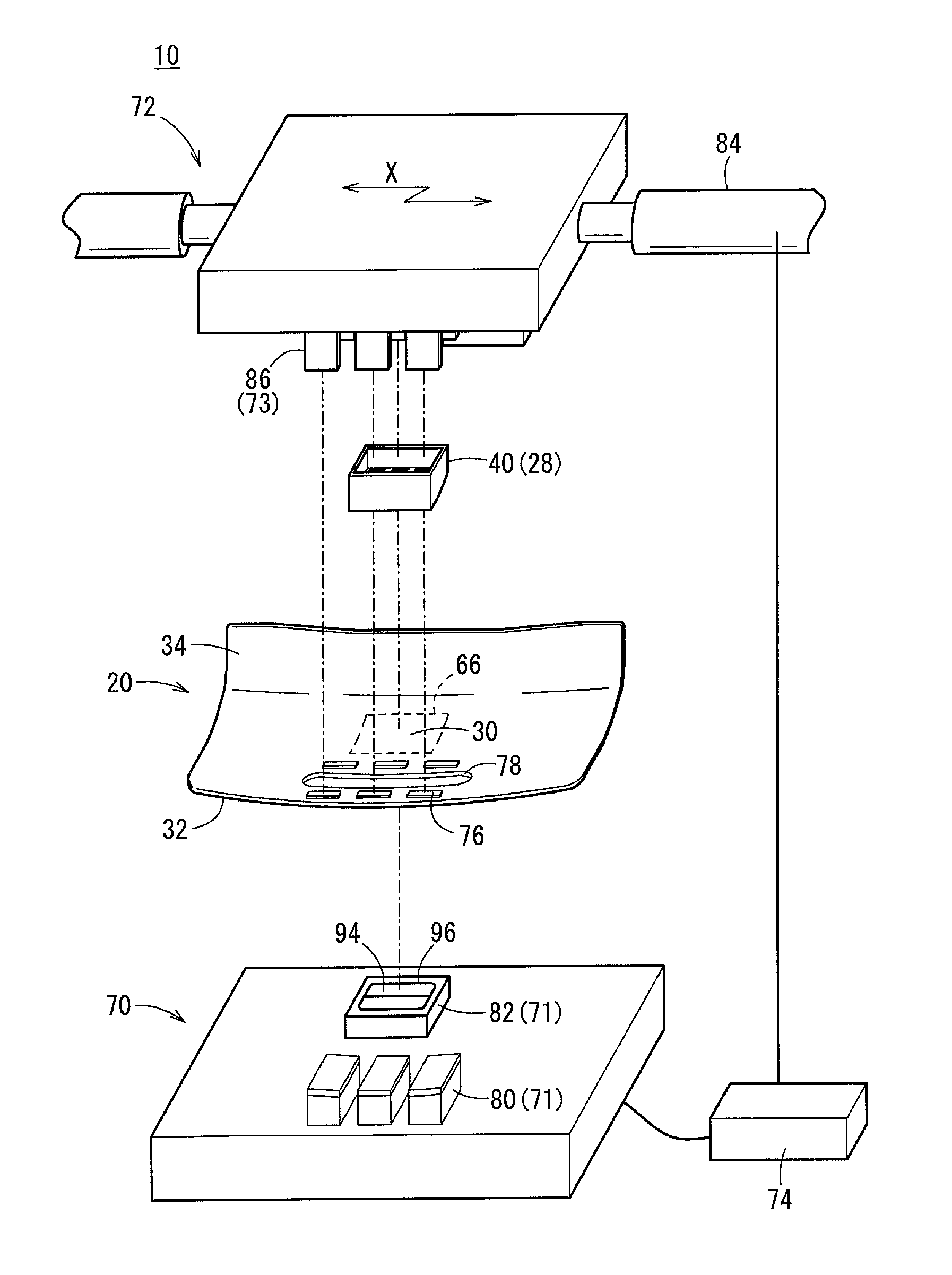

Machine tool

ActiveUS9975211B2Avoid it happening againMachining quality of workpieces mainly composedProgramme controlLathesEngineeringMachine tool

A machine tool for machining a workpiece is provided with a cutting tool holder for holding a cutting tool and a rotation mechanism for holding the workpiece. One or both of the cutting tool holder and the rotation mechanism are movable on multiple axes so that the cutting tool is movable relative to the workpiece in multiple axial directions. A control device is provided for controlling the movement of one or both of the cutting tool holder and the rotation mechanism to synchronously vibrate the workpiece and the cutting tool relative to each other at a low frequency in multiple axial directions.

Owner:CITIZEN WATCH CO LTD

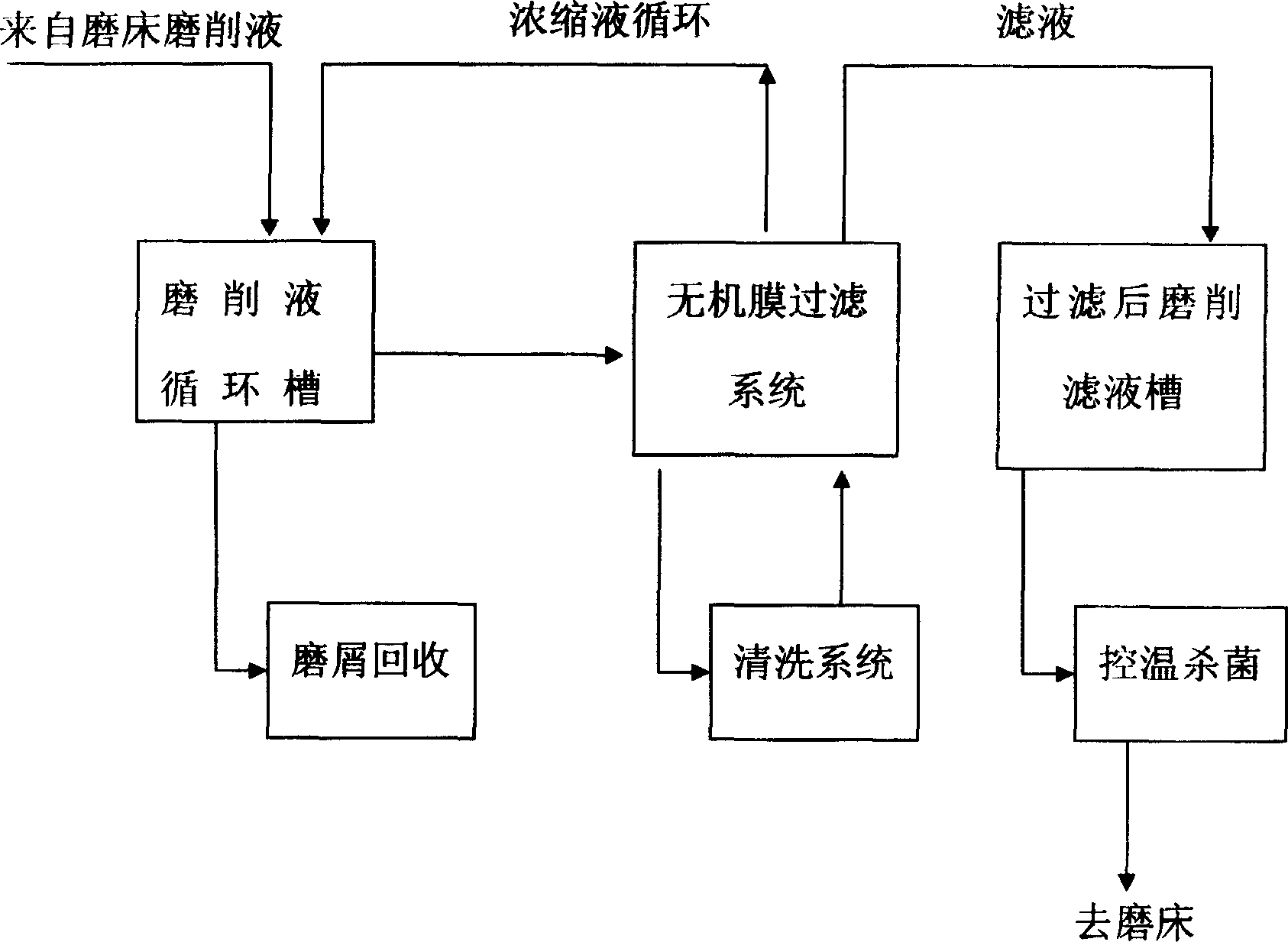

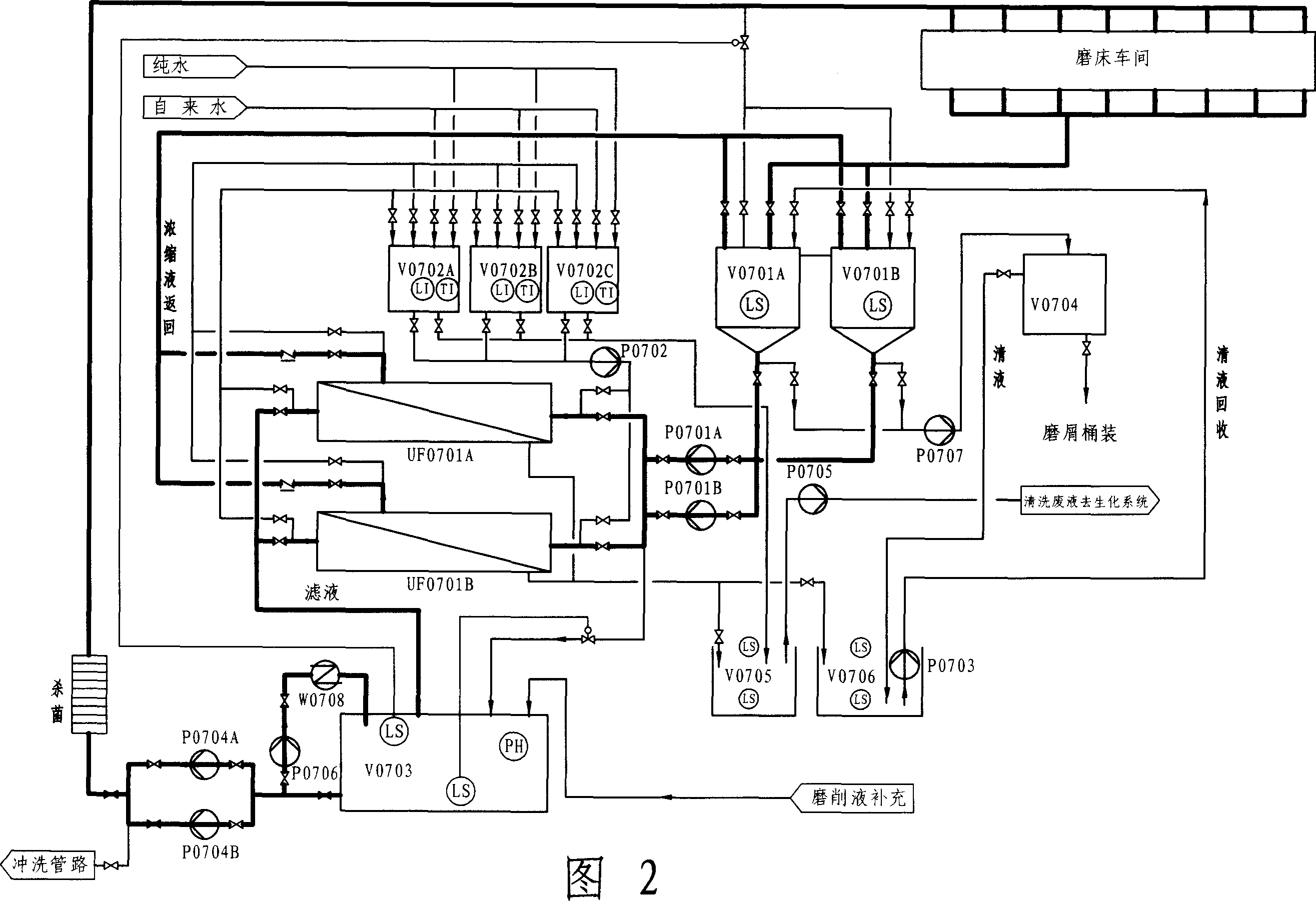

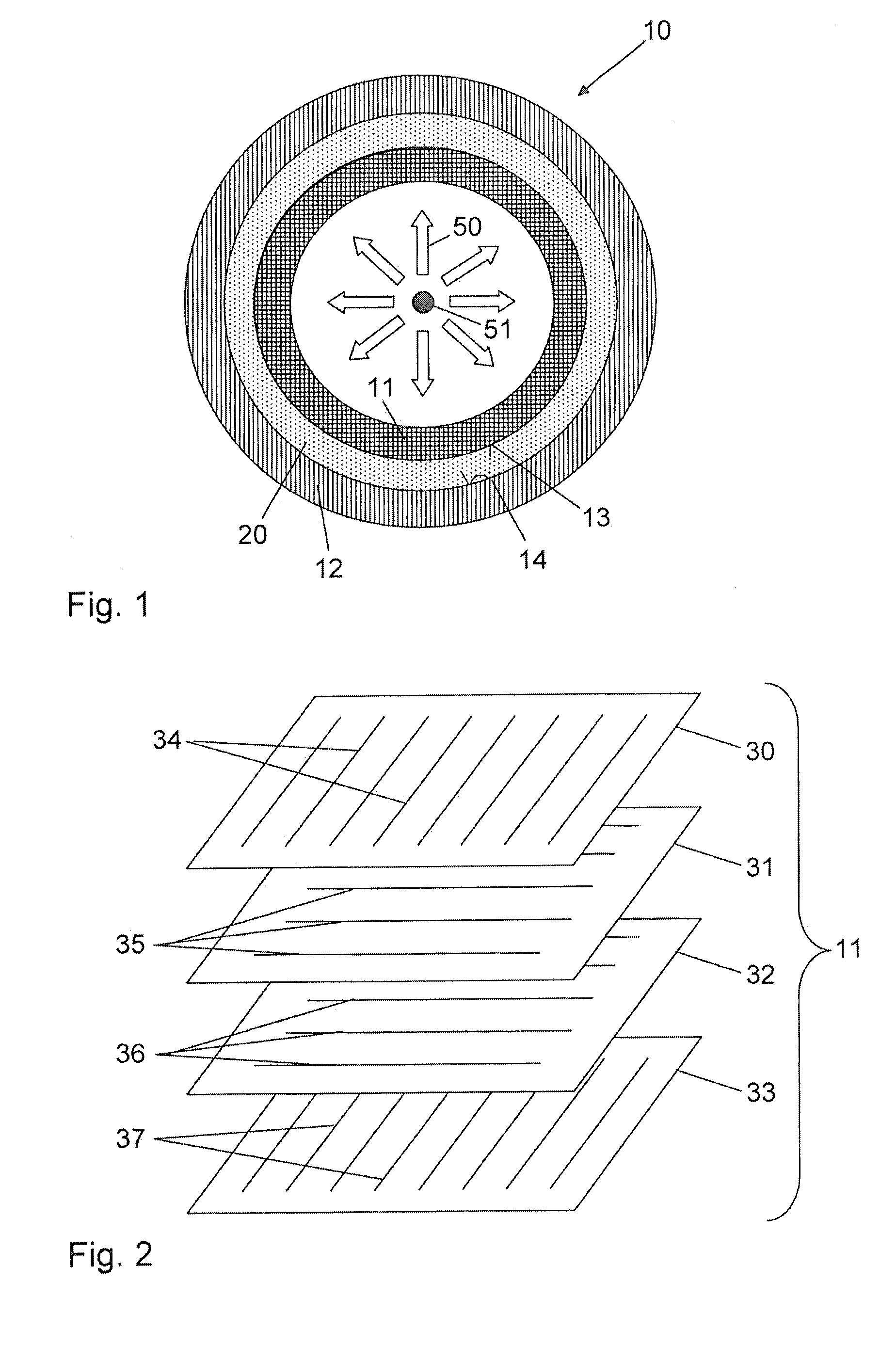

Organic film for use in process of centralized filtering of grinding liquid and the dedicated apparatus

InactiveCN1879948AIncreased durabilityImprove workpiece qualitySemi-permeable membranesSuspended particlesOrganic film

The invention relates to an inorganic film, used to concentrated filter abrasion liquid, wherein it is characterized in that: the cycle abrasion liquid, via deposition, flows from tube to the cycle groove, via the pressure to flow the surface of inorganic film; the water and the soluble matter penetrates the inorganic film to form the penetrated liquid to flow out to the filter liquid groove; then via adjusting the temperature and disinfecting, it is pumped into each grinder; the suspended particles, ash and oil of cycle abrasion liquid are stopped and separated via the film to be the concentrated liquid, to be discharge and pumped to the concentrated liquid groove; then depositing and separating, to feedback clear liquid to the system; and recycling the abraded bits. The invention has simple operation and lower cost.

Owner:湖南恒辉膜技术有限公司

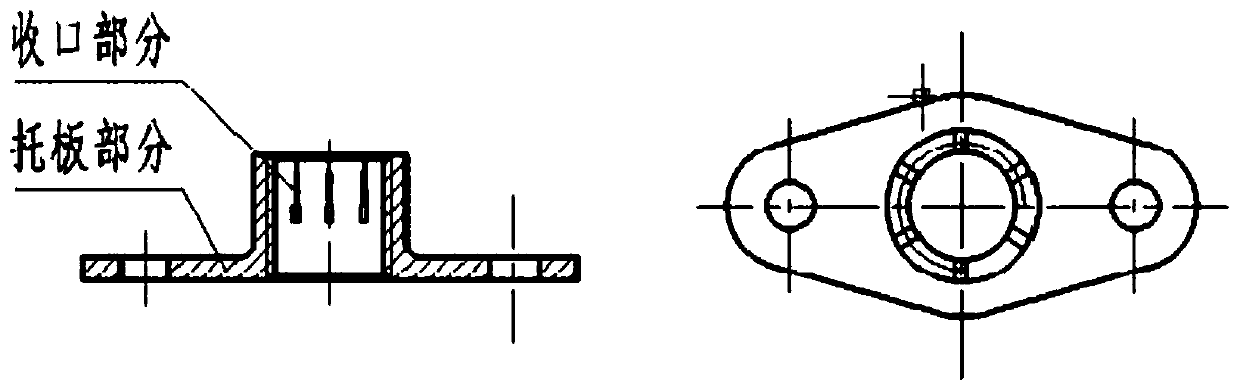

High temperature support plate self-locking nut processing technology

ActiveCN110253222ASatisfy the problem of excessive consumptionGuaranteed locking effectDissolutionSelf locking

The application discloses a high temperature support plate self-locking nut processing technology in the mechanical technology field. The high temperature support plate self-locking nut processing technology includes concrete steps: (1) preparing material; (2) blanking; (3) stretching for forming: fixing a mold for high temperature alloy sheet material, pulling two ends of the mold according to shape of a product for repeated stretch forming, and adding lubricant between the mold and the high temperature alloy sheet material when necessary; (4) performing machining for fine trimming; (5) performing linear cutting; (6) performing thread tapping; (7) performing in-process inspection; (8) performing heat treatment: performing solid dissolution and aging treatment, wherein in solid dissolution, setting solid dissolution temperature at 900+ / -10DEG C, keeping solid dissolution time for 60min, and then adopting oil cooling; in aging treatment, setting aging temperature at 710+ / -10DEG C, keeping aging time for 15-17h, and then adopting air cooling; (9) blasting sand; (10) detecting fault; (11) performing surface treatment: plating silver on the surface of the high temperature alloy sheet material after being processed through the above steps; (12) inspecting. The high temperature support plate self-locking nut processing technology solves the problem that cutter consumption is high in production of support plate self-locking nuts in the prior art.

Owner:GUIZHOU JINGLI HANGTAI TECH

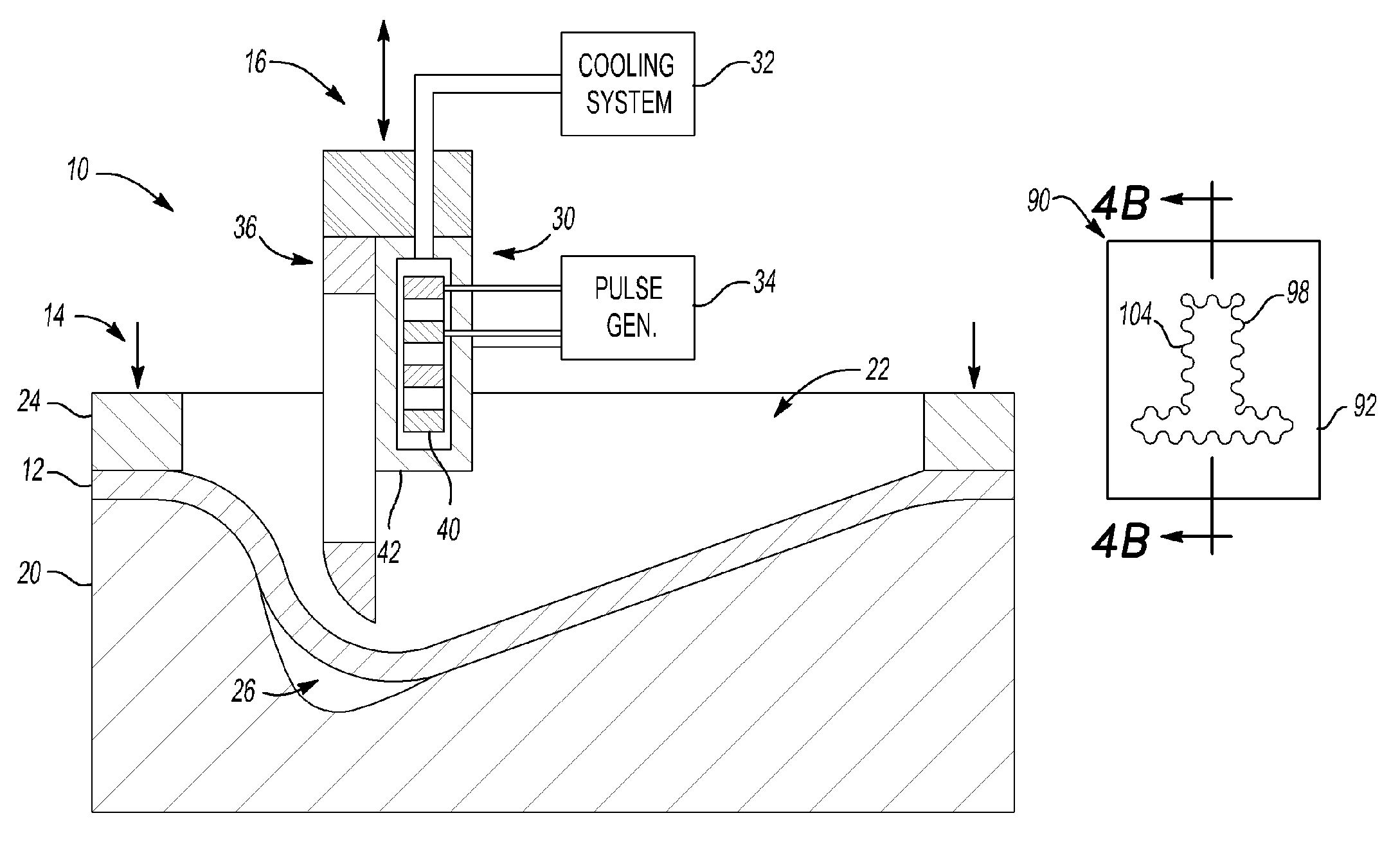

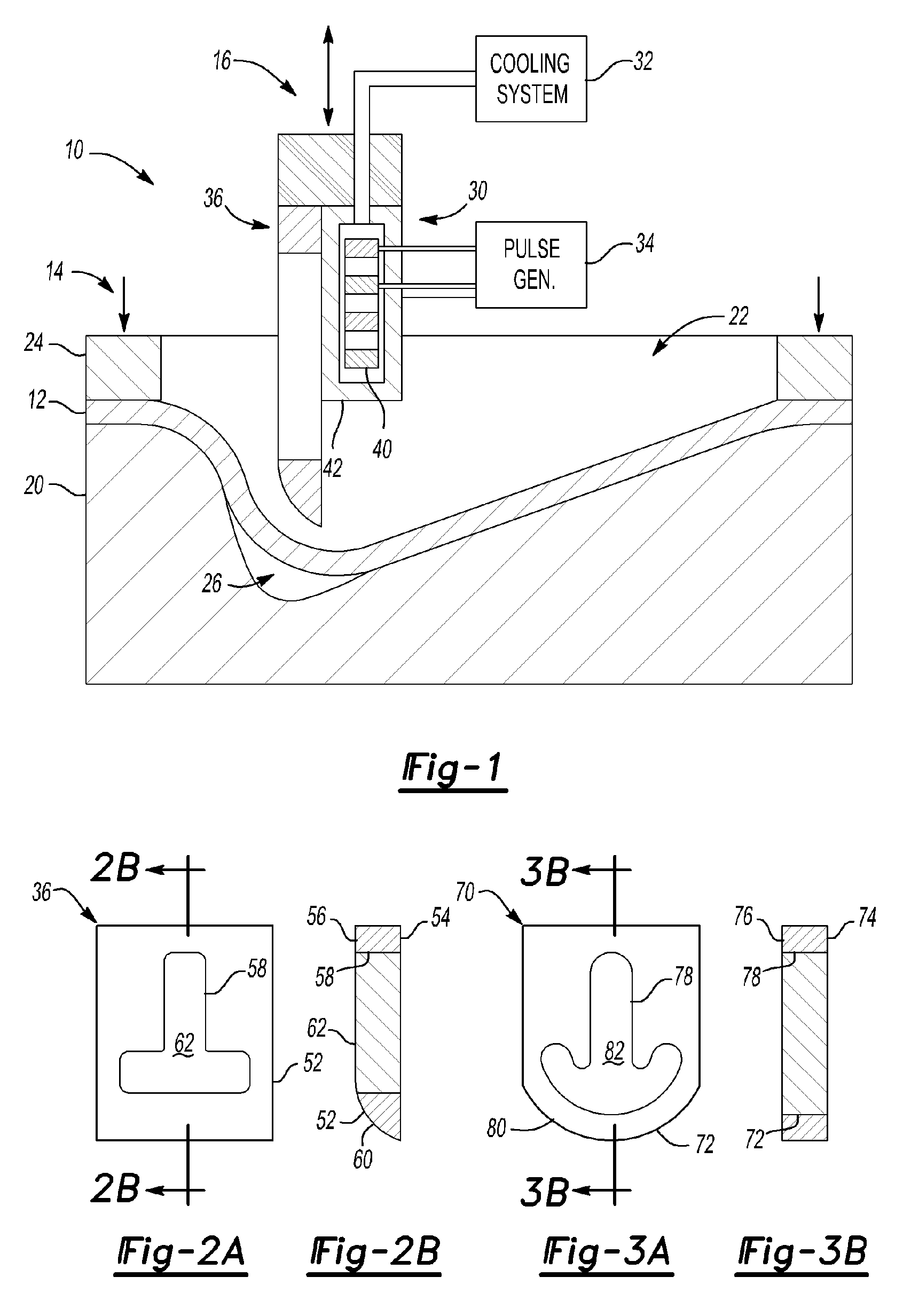

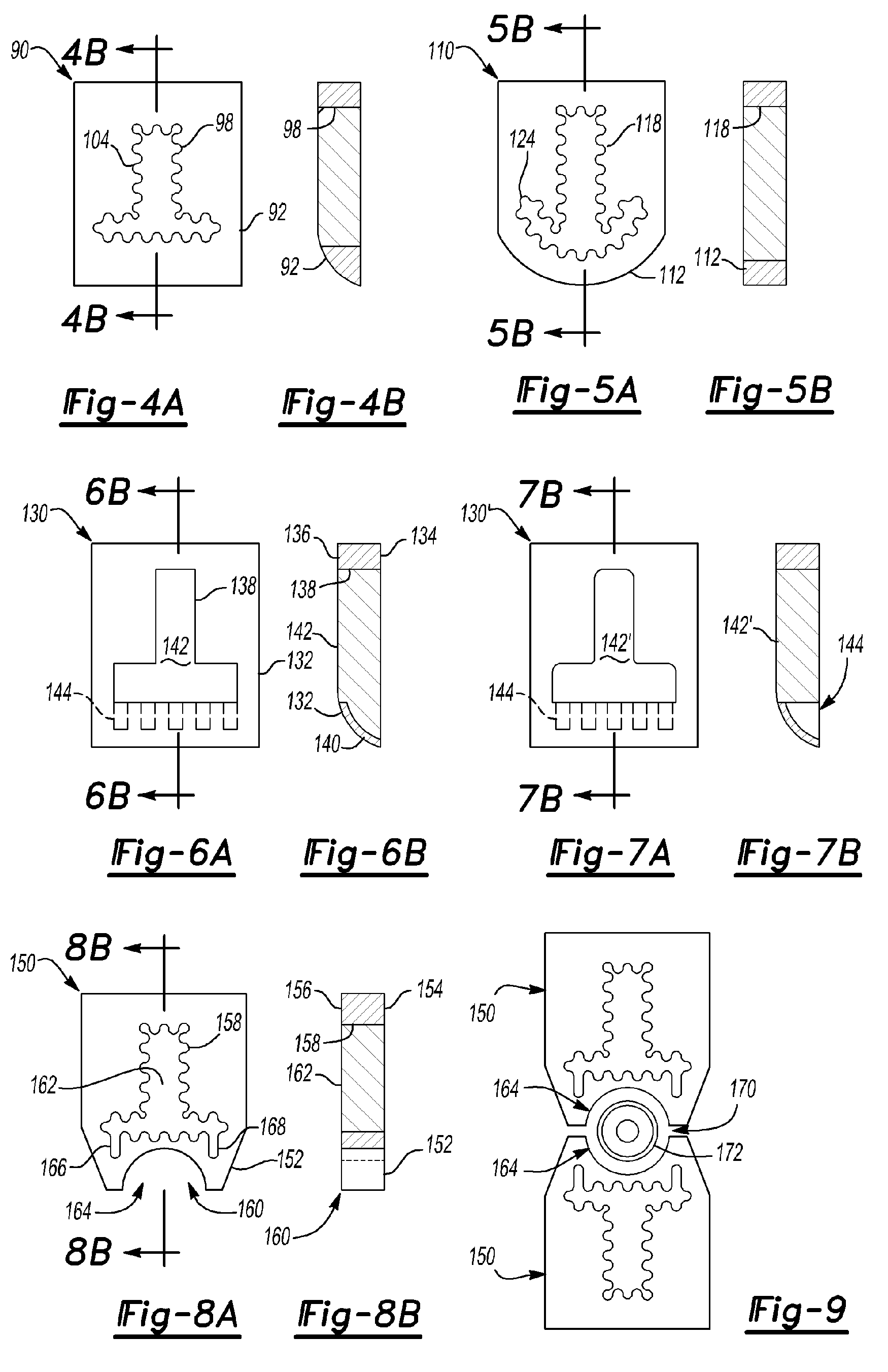

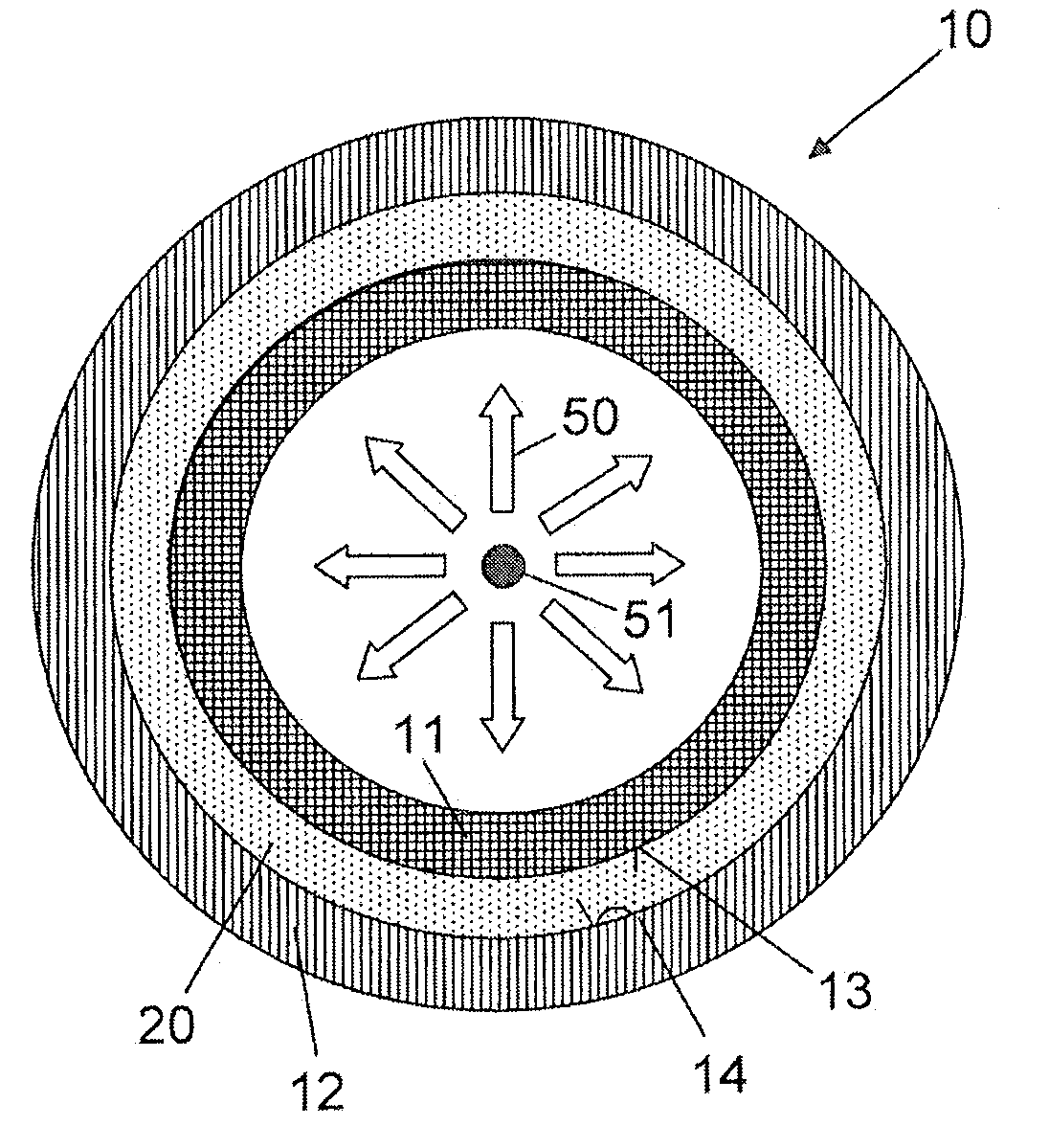

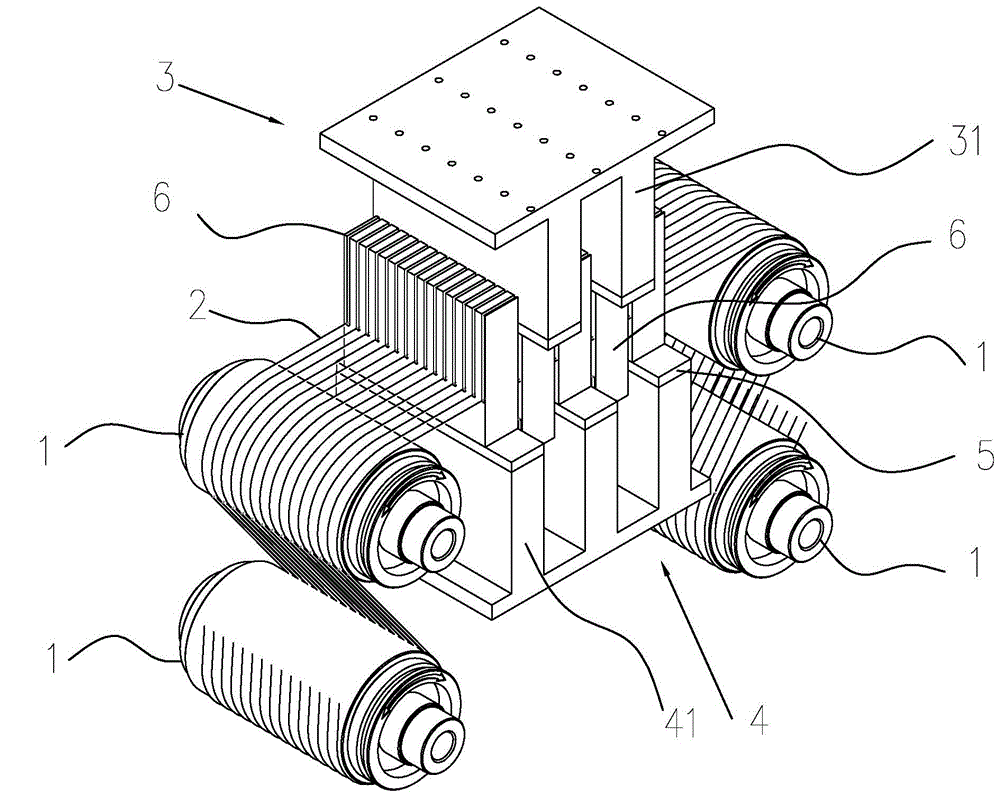

Apparatus for electromagnetically forming a workpiece

InactiveUS7467532B2Well formedImprove workpiece qualityTransformers/inductances coils/windings/connectionsForging press detailsEngineeringElectromagnetic forming

An apparatus for electromagnetically forming a workpiece. The apparatus includes a solenoid coil for generating an electromagnetic force and a tool for concentrating electromagnetic force against the workpiece. The tool includes an electrically conductive body having an aperture and an insulator disposed in the aperture.

Owner:FORD GLOBAL TECH LLC

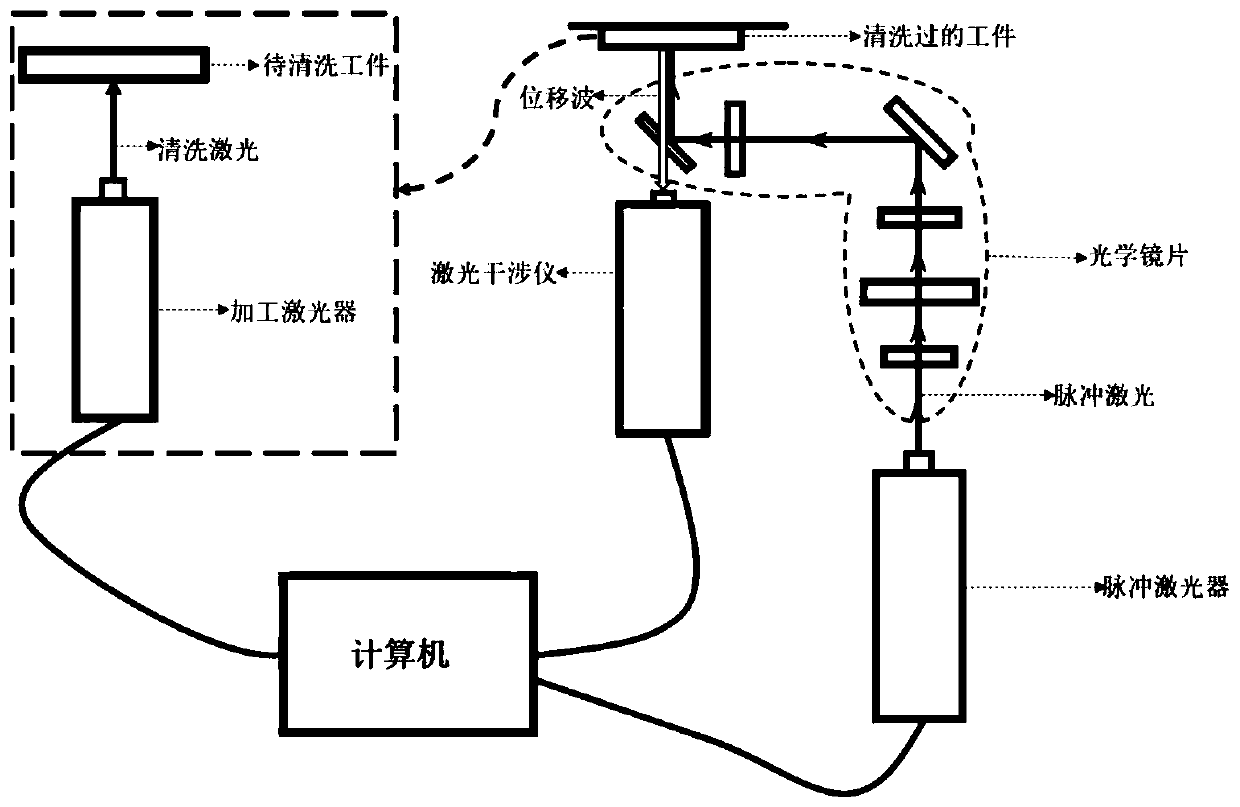

SLM metal additive manufacturing defect real-time detection method and detecting device

InactiveCN110465661AImprove surface roughnessImproving real-time processingAdditive manufacturing apparatusOptically investigating flaws/contaminationDisplacement waveNondestructive testing

The invention discloses a SLM metal additive manufacturing defect real-time detection method and a detecting device. In existing metal additive manufacturing equipment, an ultrasonic laser generator and a signal receiver are integrated into a same device, a workpiece is detected in real time in the manufacturing process by ultrasonic laser, a receiving device receives displacement waves, the simulation processing is firstly performed and a laser cleaning process is obtained, and geometric information and position information of internal defects of the workpiece are obtained. Lasers do not needto be additionally arranged, and original processing laser is improved. By adjusting the processing laser, laser cleaning of the surface of the workpiece is achieved to improve the surface roughnessof the workpiece, and the instant processing of pore defects can be realized to improve the quality of the workpiece. The detecting device solves the problems that the detection precision of the traditional detection technology is not high, the workpiece detection process is separated from the production process, and the pore defects cannot be processed online after being detected, the high-precision online non-destructive detection and processing are realized, and the SLM additive manufacturing product quality is improved.

Owner:SHENZHEN RES INST OF WUHAN UNIVERISTY

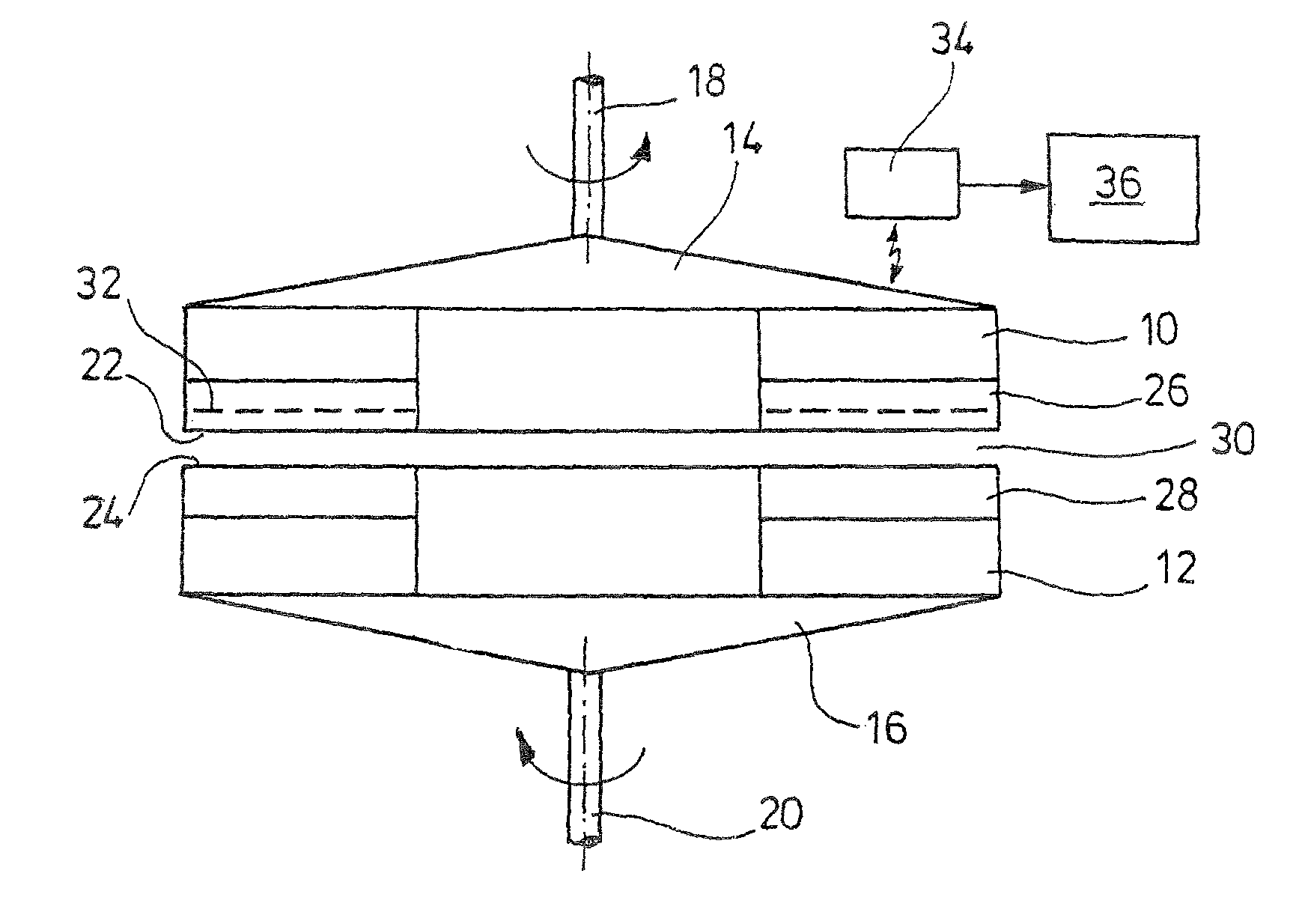

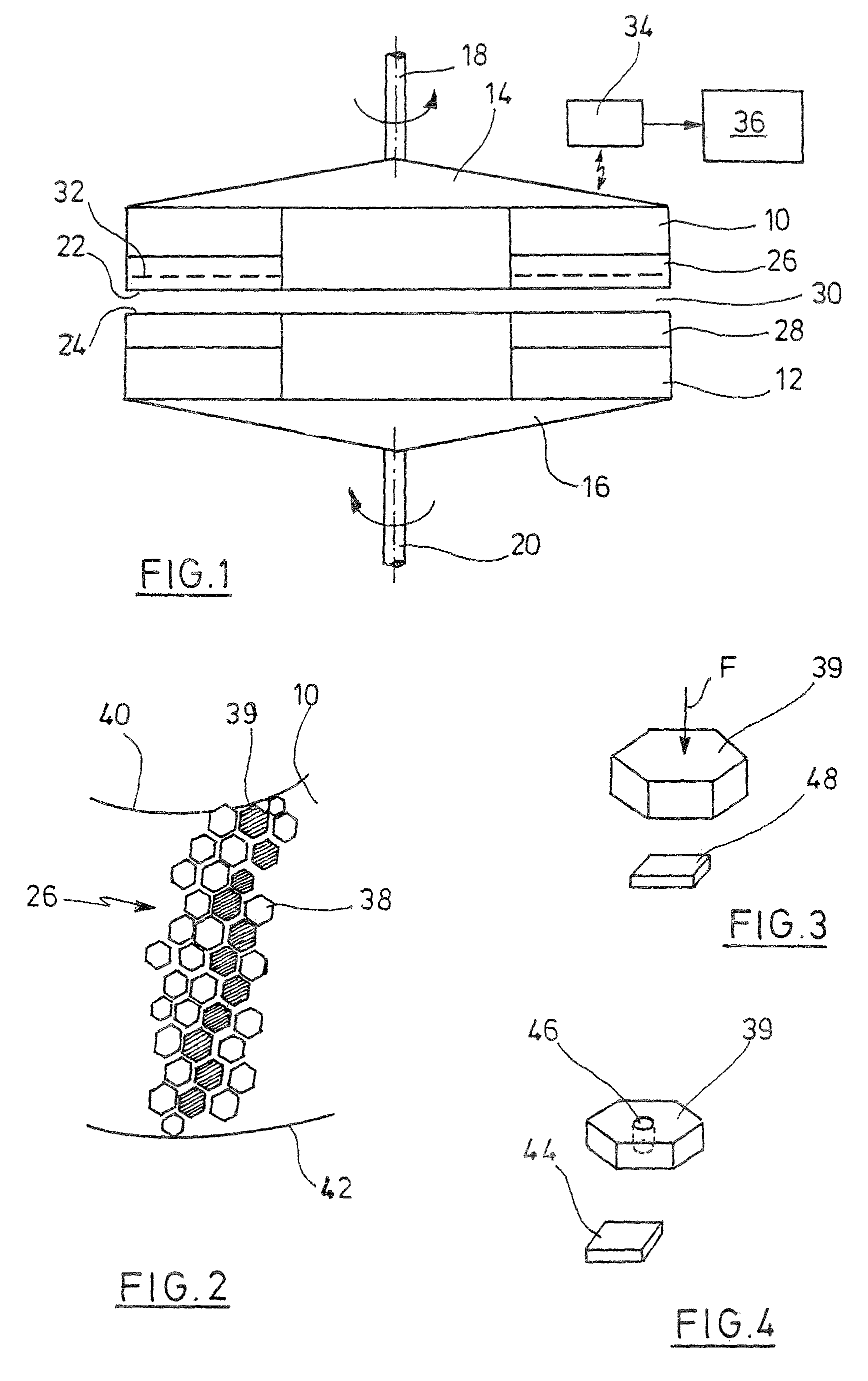

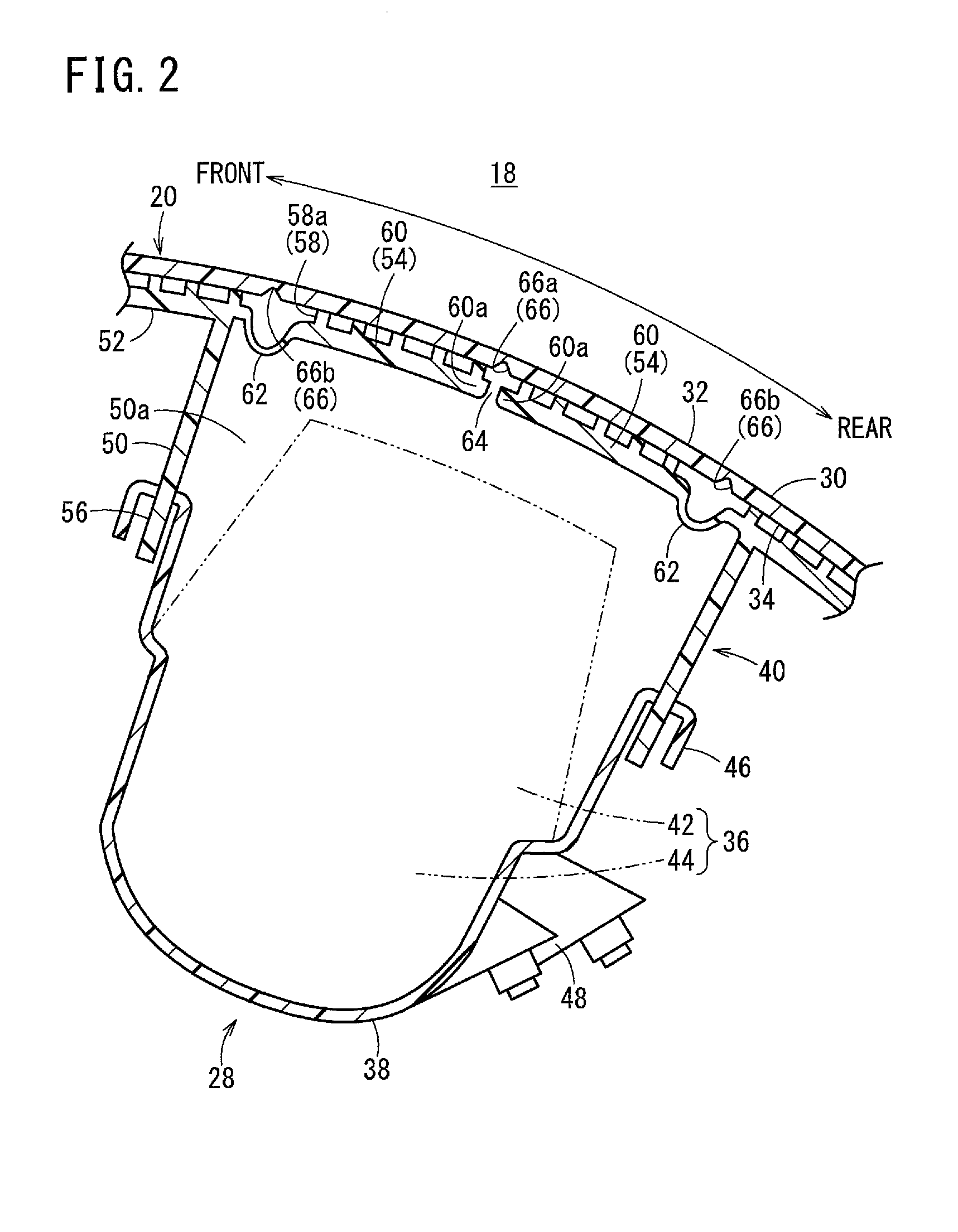

Device for Shaping a Workpiece

ActiveUS20120119060A1Quality improvementAvoid fiber bondingSynthetic resin layered productsTubular articlesThermal expansionMaterials science

A device for shaping a workpiece is provided. The device includes at least one first and one second component between which the workpiece to be shaped can be molded under the effect of heat. The design and / or the material properties of the first and / or the second component are selected such that the component's thermal expansion is different in different directions.

Owner:AIRBUS DEFENCE & SPACE

Horizontal trimming mold

The invention provides a horizontal trimming mold which comprises an upper mold holder and a lower mold holder. The lower mold holder is provided with a female mold body, a female mold fixing base, a base plate and a retainer plate. A wedge central spindle and a supporting plate are installed on the upper mold base. A pressing plate is arranged below the supporting plate. A cutter is arranged between the supporting plate and the pressing plate. The cutter is clamped between the supporting plate and the pressing plate through a limiting sleeve and attached to the slope of the wedge central spindle. A gap adjustment plate is further connected to the supporting plate. Reset mechanisms are arranged in the gap adjustment plate. According to the horizontal trimming mold, the wedge central spindle and the movable cutter are matched with the female mold body to work, trimming work on the periphery of a workpiece can be completed at a time, and the production efficiency is high. Meanwhile, the reset mechanisms and a locating mechanism of the workpiece are further arranged in the horizontal trimming mold, therefore, the horizontal trimming mold is stable on the whole, stable in operating and balanced, the machined workpiece is not prone to being deformed, the quality of the workpiece is high, and the follow-up work requirement can be well met.

Owner:TAICANG WEIGUAN ELECTROMECHANICAL

Bidirectional grinding machine

InactiveCN106271994AImprove work efficiency and workpiece qualityImprove work efficiencyEdge grinding machinesGrinding drivesFeed driveMechanical engineering

The invention discloses a bidirectional grinding machine which comprises a machine frame, a holding device mounted on the machine frame and used for holding a workpiece, and a holding drive device used for driving the holding device to rotate, and further comprises a plurality of grinding wheels used for grinding the workpiece, a plurality of feed drive devices used for driving feeding of the plurality of grinding wheels respectively, and a plurality of rotation drive devices used for driving rotation of the plurality of grinding wheels respectively and capable of controlling rotation directions of the grinding wheels respectively. The bidirectional grinding machine enables the rotation directions of part of the grinding wheels to be the same as the rotation direction of the holding device, and the rotation directions of part of the grinding wheels to be opposite to the rotation direction of the holding device; two opposite ridges formed by holes or grooves successively become an entering face and a leaving face of each rotating grinding wheel, and alternate grinding in two directions can remove burrs on the two ridges at the same time, so that the working efficiency and the workpiece quality can be improved.

Owner:JILIN DAHUA MACHINERY MANUFACTURING CO LTD

Machining machine with means for acquiring machining parameters

InactiveUS7963823B2Convenience to workImprove workpiece qualityEdge grinding machinesTelemetry/telecontrol selection arrangementsEngineeringMachining

A machining machine with an upper rotatingly drivable machining disc, the annular machining plane of which has a machining coating and is facing a lower machining plane, wherein the machining planes form a machining gap between each other. Plural rotor discs are arranged in the gap, which accommodate workpieces in recesses and which can be brought into rotation by means of a roll-off device, wherein the workpieces move along a cycloid path, wherein plural sensor elements for acquiring at least one machining parameter are arranged in the upper machining disc, distributed across its cross section, the sensor elements are each one coupled to an active or passive RFID chip and a reading device is assigned to the upper machining disc for reading out the RFID chips.

Owner:PETER WOLTERS GMBH

Porcelain tube blank glazing machine

The invention discloses a porcelain tube blank glazing machine, which comprises a main rotating disk, wherein the outer edge of the main rotating disk is provided with a plurality of workpiece fixing and rotating mechanisms; the main rotating disk is connected with a main motor; each workpiece fixing and rotating mechanism is connected with a single secondary motor; each workpiece fixing and rotating mechanism rotates automatically along with the revolution of the main rotating disk; the periphery of the main rotating disk is provided with a plurality of station working areas in sequence; and the main motor, the secondary motor and a power device in each station working area are connected with a control system. The porcelain tube blank glazing machine has the advantages of high efficiency, low cost, low environmental pollution, contribution to body health of working personnel, saving in raw materials and high workpiece quality.

Owner:杨茂生

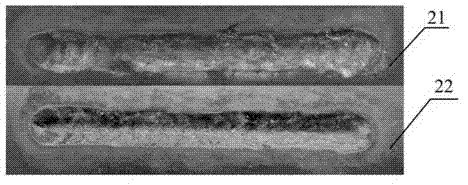

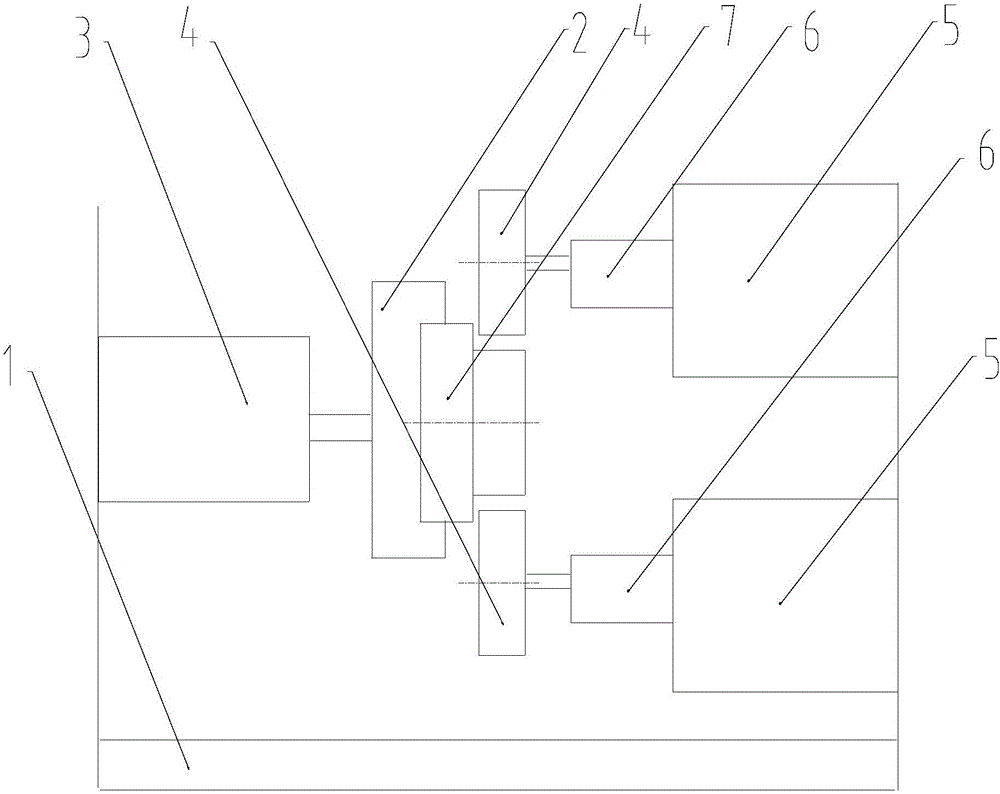

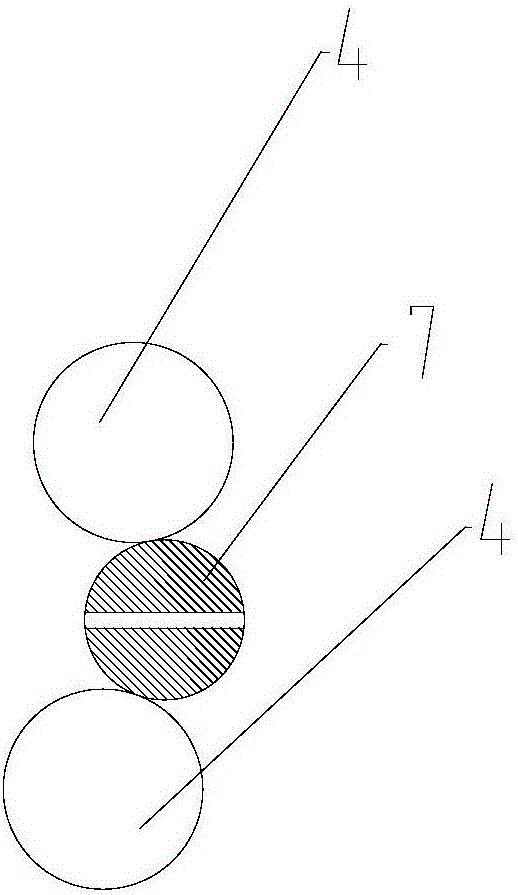

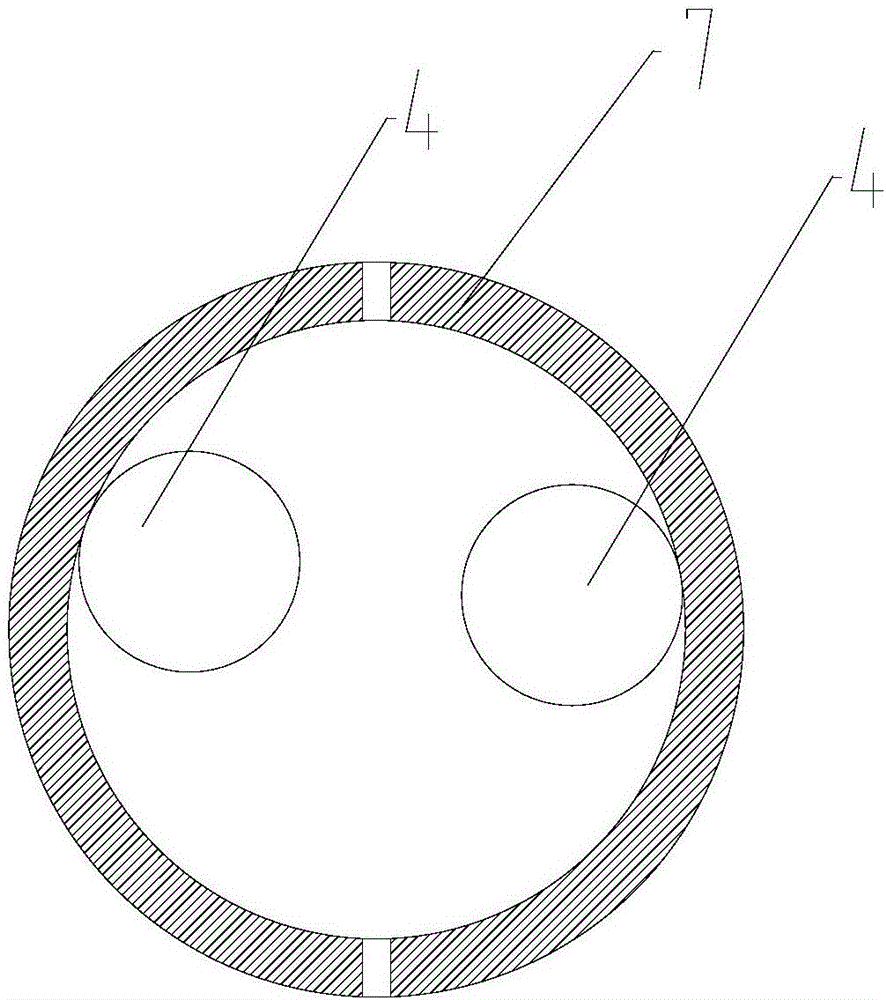

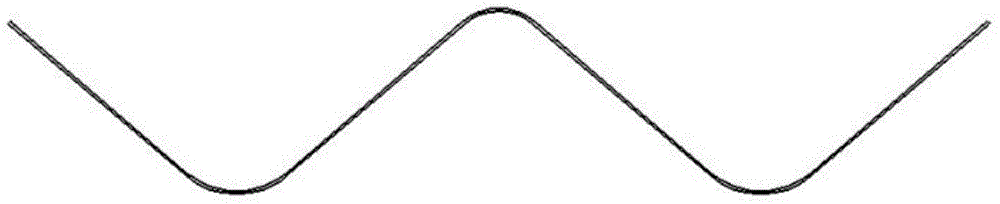

Multi-wire sawing method and multi-wire sawing machine

ActiveCN104589522AImprove workpiece qualityImprove machining accuracy and qualityFine working devicesEngineeringMechanical engineering

The invention discloses a multi-wire sawing method and a multi-wire sawing machine. The multi-wire sawing method uses at least two parallel sawing wires wound on a wire roller, and at least two workpieces, wherein the workpieces are staggered at the upper and lower sides of the sawing wires, and respectively move to the directions of the sawing wires for sawing. The multi-wire sawing method uses a vertical compound sawing mode for eliminating wire arches; and the wire arched generated in sawing are shorter, so that the wire marks of the sawing wires left on the surfaces of the workpieces are reduced, and the workpiece quality is improved.

Owner:FUJIAN CHANGJIANG GOLDEN DRAGON RARE EARTH CO LTD

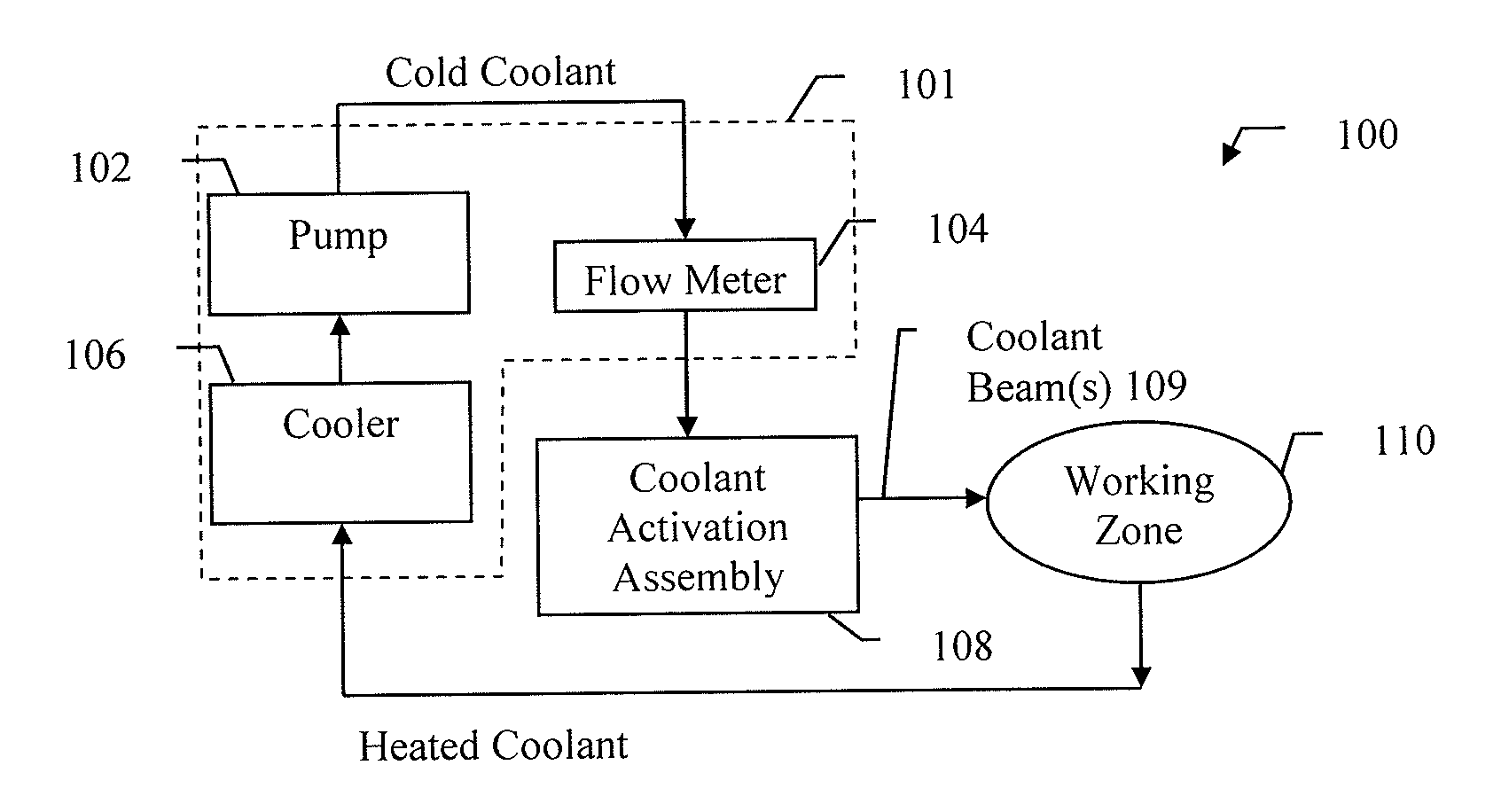

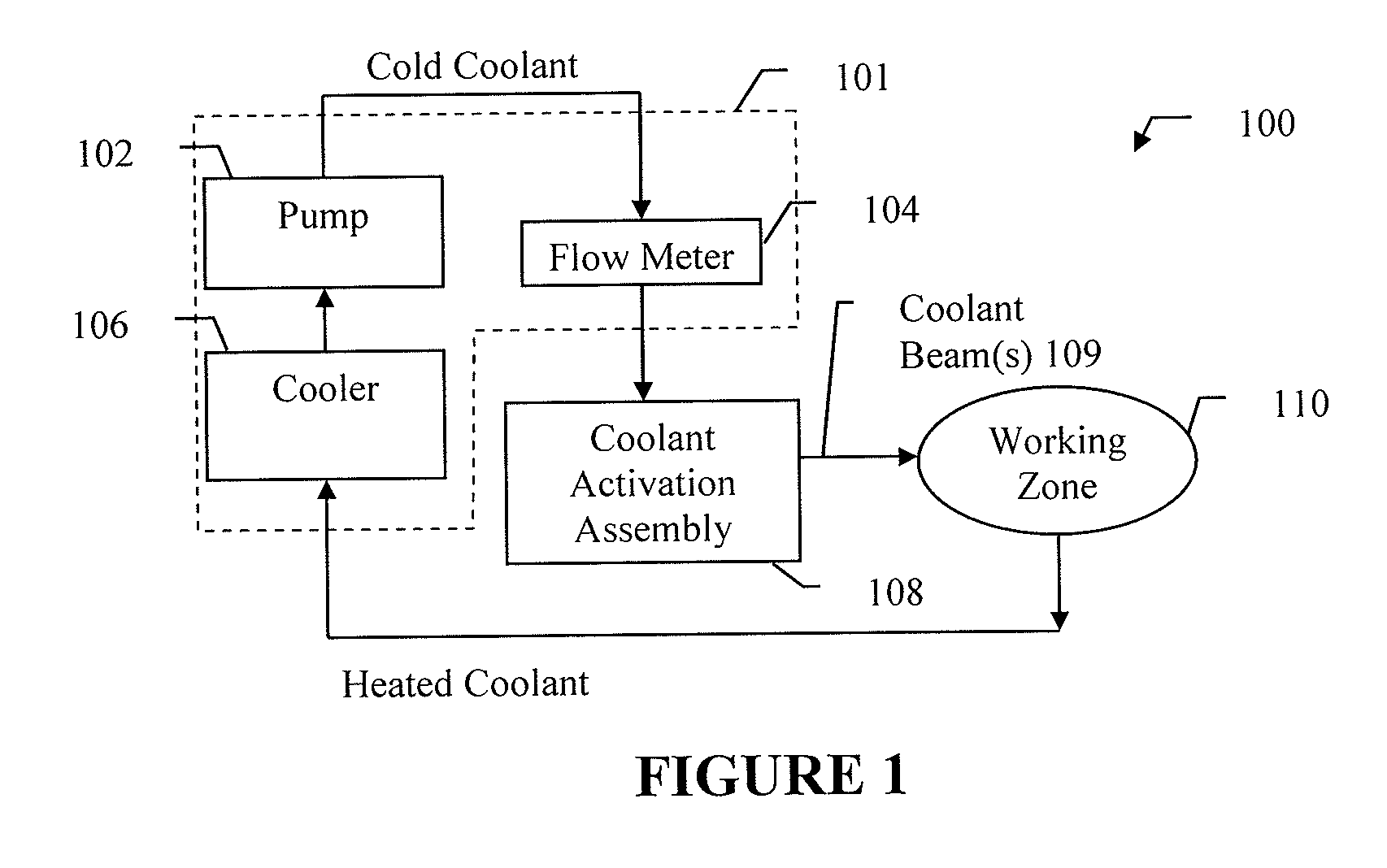

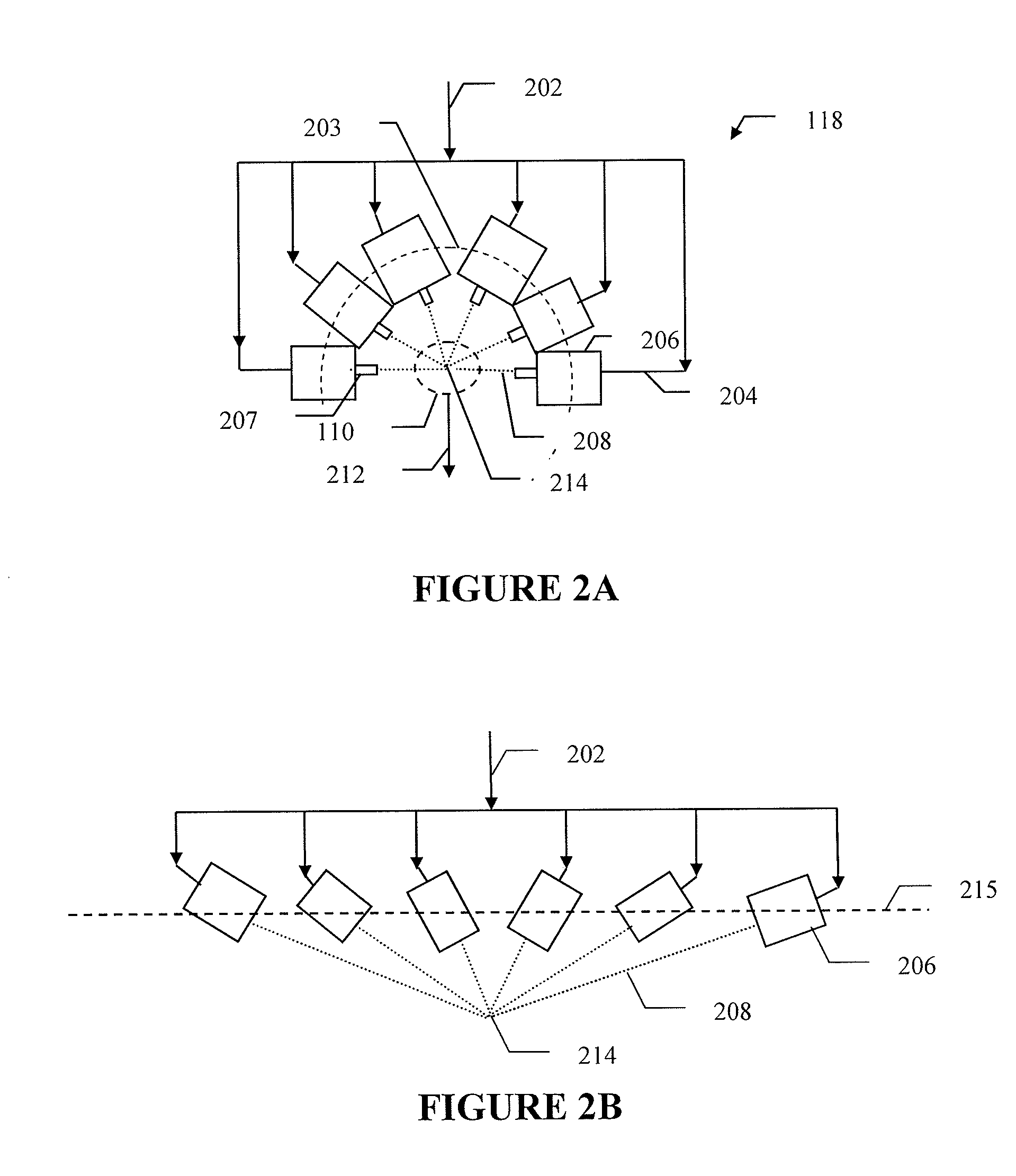

System, apparatus and method for providing cooling

ActiveUS20100150674A1Improve cooling effectAdjustable intensityTransportation and packagingCompression machines with non-reversible cycleSurface roughnessAcoustic wave

Described herein is a system for generating a plurality of coolant beams that converge at a focal point for advanced heat transfer. The system utilizes a variable strength activation of coolant and superposition of coolant beams generated by multiple actuators for increased cooling strength increase, thereby avoiding activation saturation in conventional systems. Each coolant beams is activated to carry an ultrasonic or megasonic vibration component. In addition, the system includes a coolant activation assembly having a plurality of actuators for generating the coolant beams. The coolant activation assembly further includes supporting components for positioning the actuators so that all of the coolant beams generated by these actuators converge at the focal point. Experimental results show that the system provides significantly improved workpiece quality in a machining process. Compared with the most advanced existing system, this system offers a further improvement of up to 12.30% on surface roughness of the finished workpiece.

Owner:THE HONG KONG UNIV OF SCI & TECH

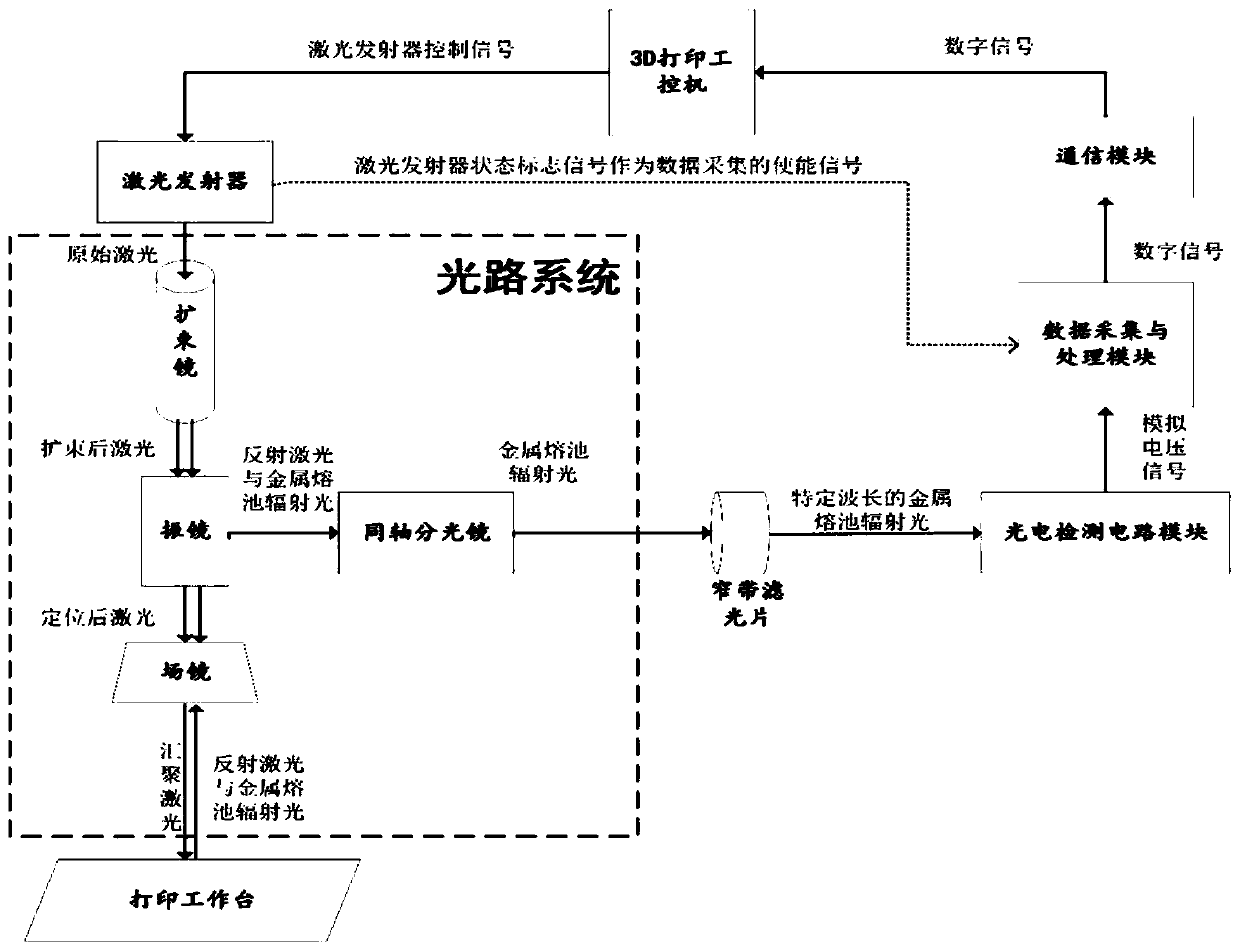

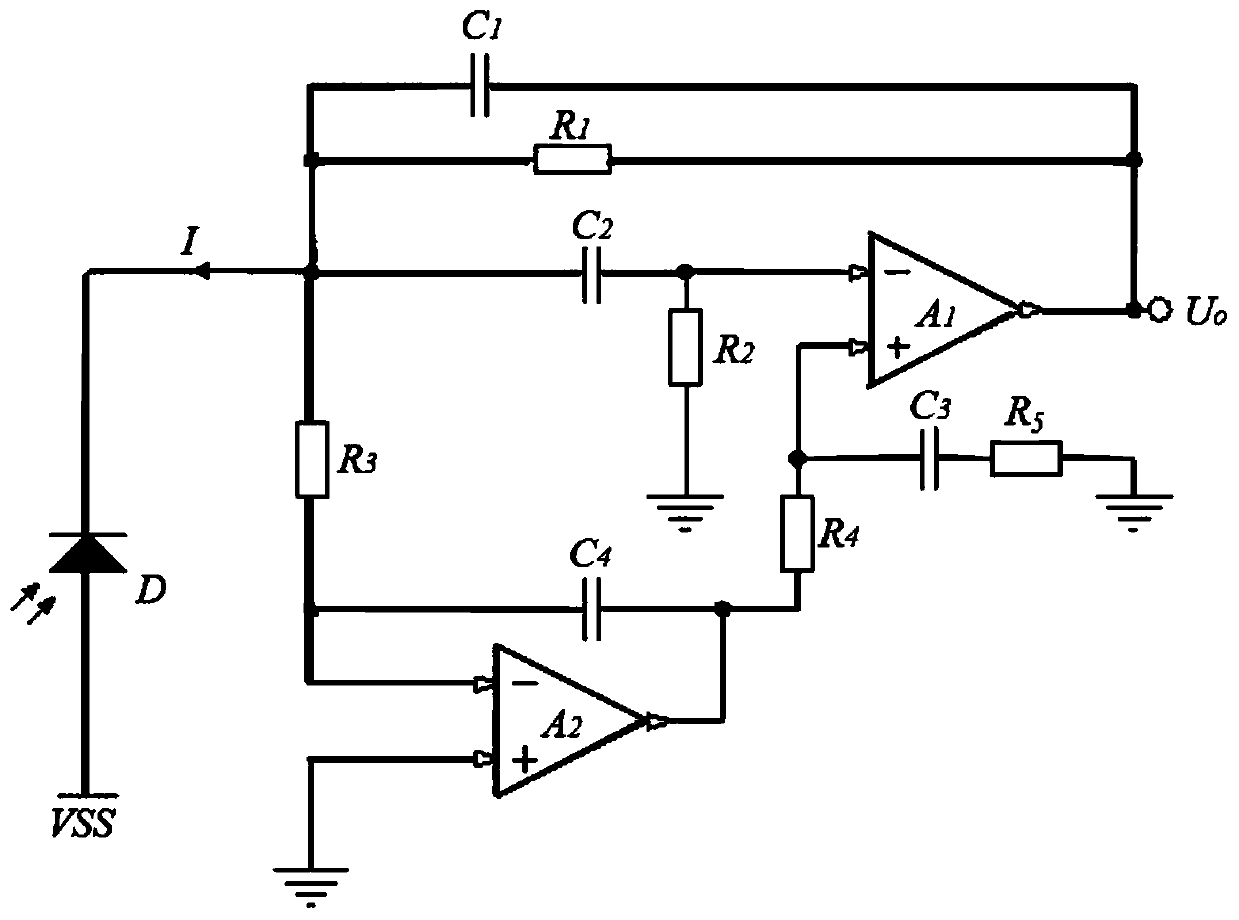

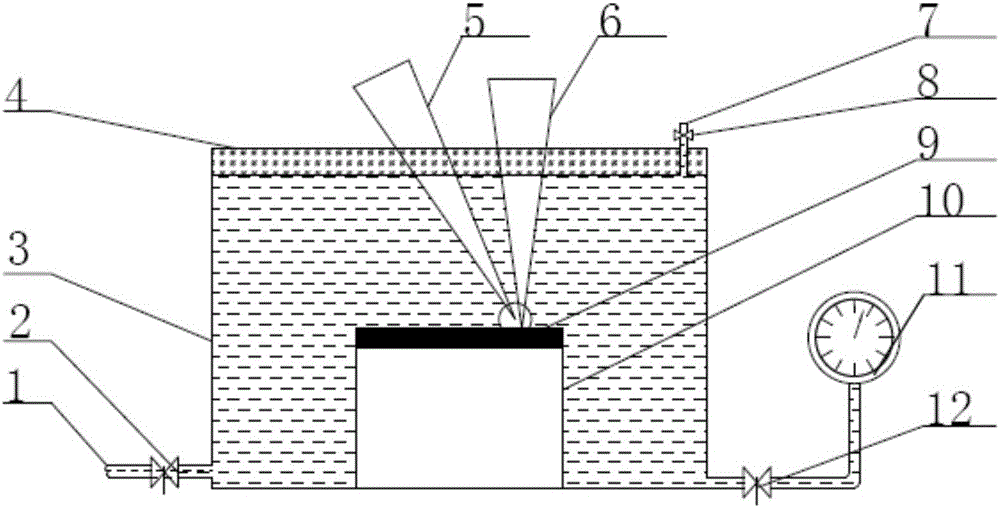

Molten pool temperature detection system and method for selective laser melting 3D printer

InactiveCN111375765AImprove workpiece qualityQuality improvementAdditive manufacturing apparatusThermometers using physical/chemical changesSelective laser meltingBeam splitter

The invention discloses a molten pool temperature detection system and method for a selective laser melting 3D printer. Under the situation that an original equipment structure and an original opticalpath system of the SLM 3D printer are not changed, photoelectric information of a molten pool in the machining process is obtained only by additionally arranging a narrow-band optical filter, a photoelectric detection circuit and a data acquisition and processing system module at an interface of a coaxial spectroscope, and real-time closed-loop control over the temperature of the molten pool is achieved through acquisition, operation and processing of the information. According to the molten pool temperature detection system and method, higher printing quality and efficiency are obtained, theapplication range of the SLM 3D printing technology is further widened, the detection speed is high, the control effect is good, the compatibility with original equipment is high, and the cost performance of application implementation is high.

Owner:SOUTHEAST UNIV

Method and system for processing immersed workpiece by double laser light

ActiveCN105728954AReduce the development of microstructural defects to microcracksReduce the effects of local overheatingWelding/soldering/cutting articlesLaser beam welding apparatusLaser processingGas laser device

The invention discloses a method and a system for processing an immersed workpiece by double laser light. The method includes focusing the laser light A with the wavelength of 1064 nm on the surfaces of the workpiece in water and locally softening the heated workpiece; focusing the laser light B with the wavelength of 10640 nm on the water above the workpiece; breaking through the water by the aid of the laser light B to generate impact waves, enabling the impact waves to act on locally softened regions of the surfaces of the workpiece and removing softened materials so as to groove and process the workpiece. A focus point of the laser light A and a focus point of the laser light B are distanced from each other by hundreds of micrometers. Solid for generating the laser light A and the laser light B and a laser head of a CO2 gas laser device of the system are positioned above a water tank, the center line of laser beams A is a plumb line, the center line of laser beams B intersects with the laser beams A at the focus point of the laser light A on the upper surface of the workpiece, and an intersection angle of the center line of the laser beams B and the laser beams A is 10-30 degrees. The height of a worktable can be adjusted. The thicknesses of water layers on the surfaces of the workpiece are 1-3 millimeters. Compared with laser melt cutting processing, the system and the method have the advantages that the heating temperature of the laser light A is lower than melting points of the materials, accordingly, influence of local overheating can be reduced, and the quality of machined finished products can be guaranteed.

Owner:GUILIN UNIV OF ELECTRONIC TECH

Tool special for submerged-arc welding

InactiveCN105499768AImprove installation stabilityImprove processing efficiencyHeat exchange apparatusMetal working apparatusEngineeringFlange

The invention relates to a tool special for submerged-arc welding. The tool comprises a liner and a base. The bottom of the liner is provided with a connecting seat, a plurality of mounting holes are formed in the connecting seat, and connecting columns are arranged in the mounting holes. Springs are arranged outside the connecting columns, a groove is formed in the surface of the liner, the section of the groove is in an arc shape, a cavity is formed in the liner, a water inlet is formed in one side of the cavity, and a water outlet is formed in the other side of the cavity. First pipe flanges are arranged on the water inlet and the water outlet, the water inlet is connected with a water inlet pipe, the water outlet is connected with a water outlet pipe, second pipe flanges are arranged between the water inlet pipe and the corresponding first pipe flange and between the water outlet pipe and the corresponding first pipe flange, and a circulating water pump is mounted between the water inlet pipe and the water outlet pipe. The tool is reasonable in structural design, a machined workpiece is convenient to cool, pipe mounting stability is improved, and the machining efficiency of submerged-arc welding and workpiece quality can be improved conveniently.

Owner:YANGZHONG SHENYANG HEAT EXCHANGE EQUIP

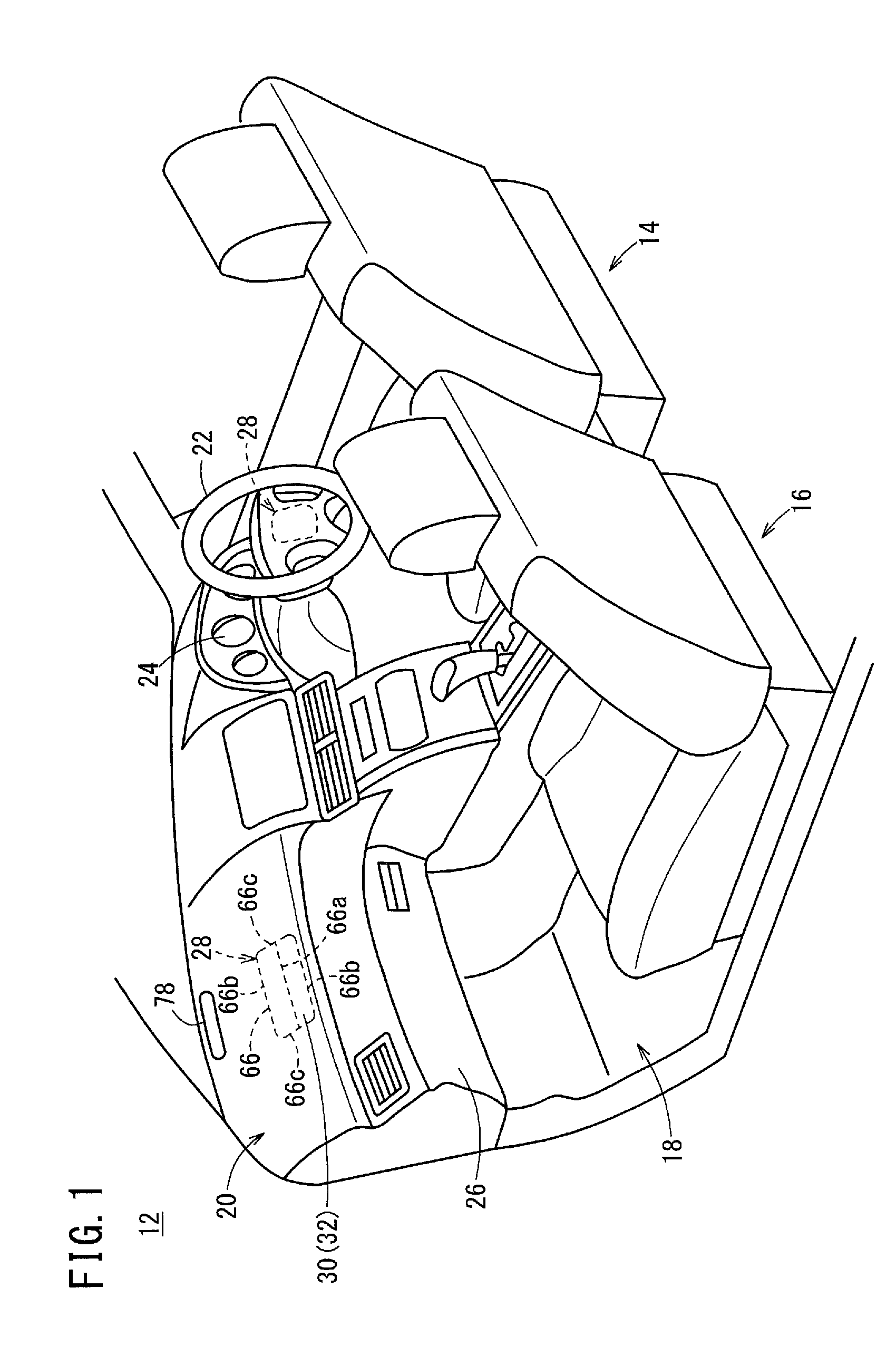

Vibration welding device and vibration welding method

ActiveUS20160144557A1Improve workpiece qualityImprove product qualityPedestrian/occupant safety arrangementWelding/cutting auxillary devicesEngineeringThermal expansion

This vibration welding device is a device that vibration welds an airbag holding box and an installment panel having a tear line. The vibration welding device is provided with a support jig that carries and affixes the installment panel during vibration welding. The support jig is provided with a groove that permits thermal expansion during vibration welding of the installment panel at a position differing from the tear line.

Owner:HONDA MOTOR CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com