Organic film for use in process of centralized filtering of grinding liquid and the dedicated apparatus

An inorganic membrane and grinding fluid technology, applied in membrane technology, semi-permeable membrane separation, chemical instruments and methods, etc., to achieve low maintenance costs, long average service life, and simple process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

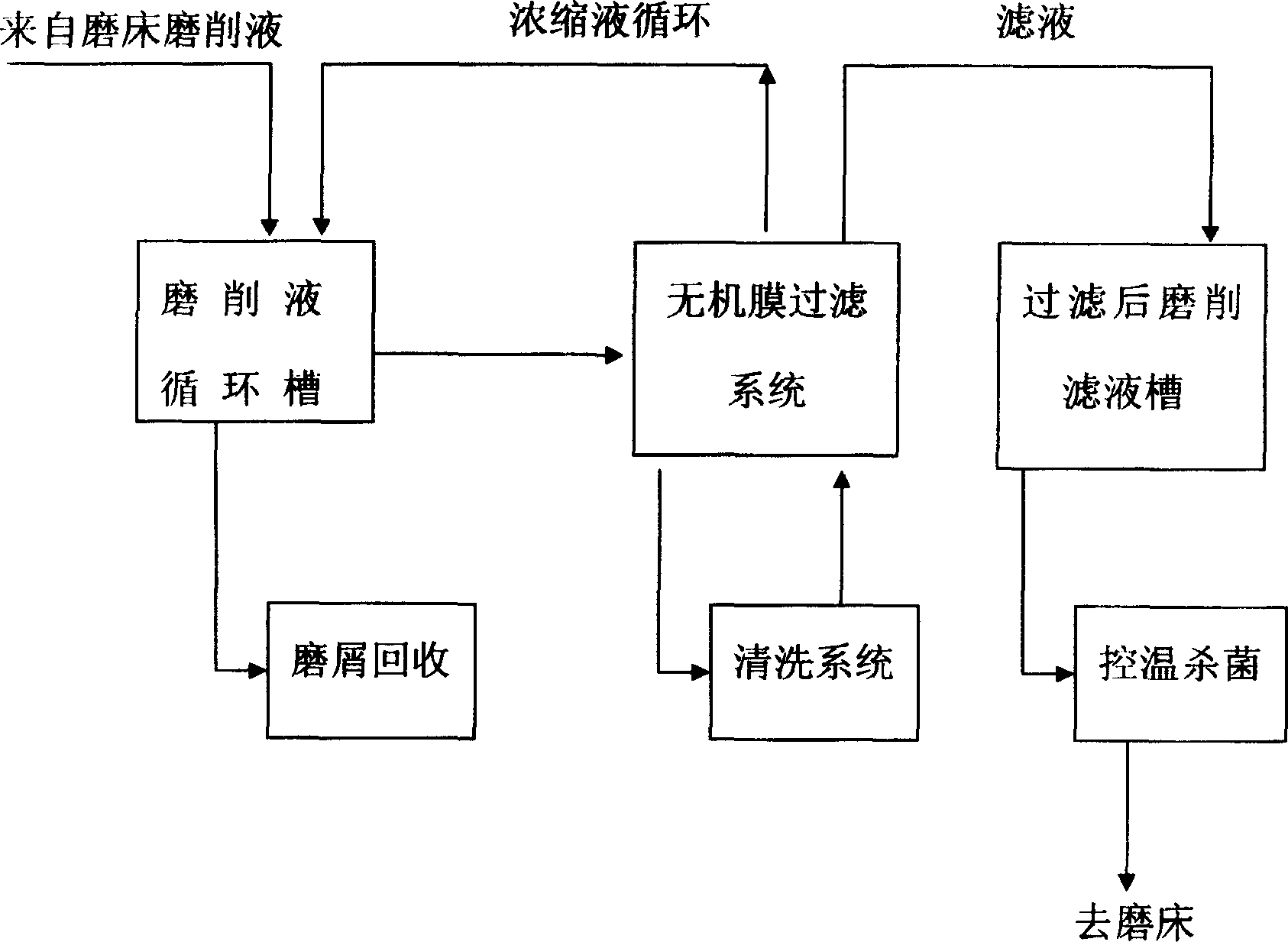

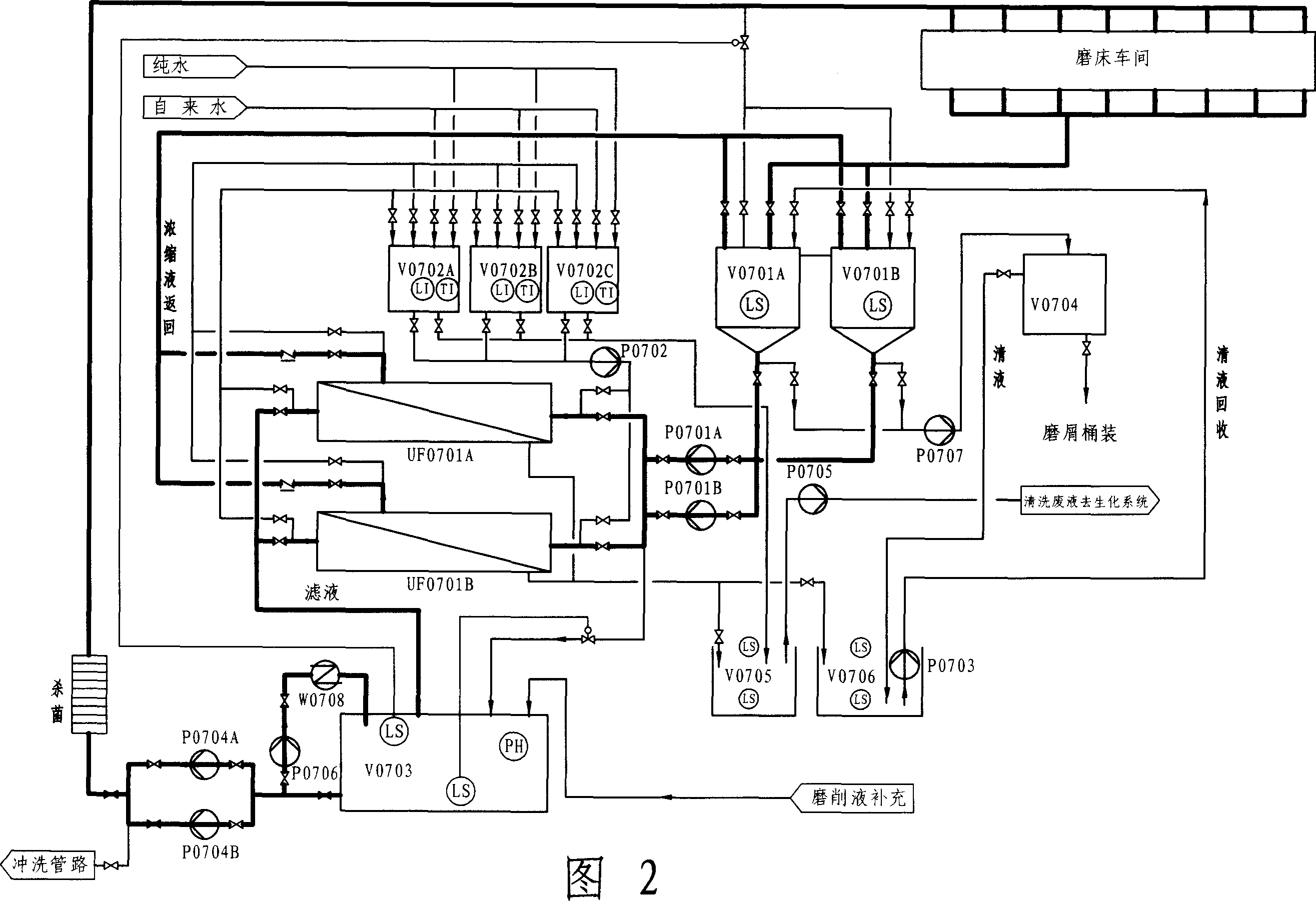

[0040] Example 1, after the circulating grinding fluid produced by each grinding machine is collected in the circulation tank, it enters the inorganic membrane filtration system after being pressurized by the raw material pump, and the circulating grinding fluid flows through the inorganic ceramic membrane under the low pressure drive in the inorganic membrane filtration system On the surface of the membrane, water and the water-soluble substances of the grinding fluid pass through the inorganic membrane to form a permeate that flows out, enters the filtrate tank, and then is cooled and sterilized and pumped to each grinding machine point; the suspended abrasive particles in the circulating grinding fluid, the grinding wheel The ash and oil are intercepted and separated by the inorganic membrane to become concentrated liquid, and then the concentrated liquid is regularly discharged and collected, pumped to the concentrated liquid tank, the clear liquid, grinding debris and sludg...

Embodiment 2

[0044] Embodiment 2, the present invention can also recover useful grinding debris: suspended grinding debris particles, grinding wheel ash and oil in the circulating grinding fluid are intercepted and separated by the inorganic membrane to become a concentrated solution (dope) of a certain concentration, and then concentrated The liquid is regularly discharged and pumped to the concentrated liquid tank (V0704), the debris is settled and separated, the clear liquid is collected in the membrane emptying collection tank (V0706), and then returned to the circulation tank (V0701) by the pump, and then enters the circulation system, and the abrasive debris The sludge is discharged into recycling barrels. refer to figure 1 With Fig. 2, all the other are with embodiment.

Embodiment 3

[0045] Embodiment 3, the present invention can adopt the inorganic membrane tube in the inorganic membrane filtration system (UF0701), preferably adopt the inorganic ceramic membrane tube with filtration accuracy less than 0.3 μm, the interception rate to the superfine wear debris particle can reach 99%, can Useful grinding particles are recovered.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com