Tool special for submerged-arc welding

A submerged arc welding and tooling technology, applied in arc welding equipment, applications, household appliances, etc., can solve the problems affecting the welding quality and pipe quality of submerged arc welding, affecting the arc welding process, and unstable installation, so as to improve processing efficiency. and workpiece quality, improve installation stability, and the effect of reasonable structure design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

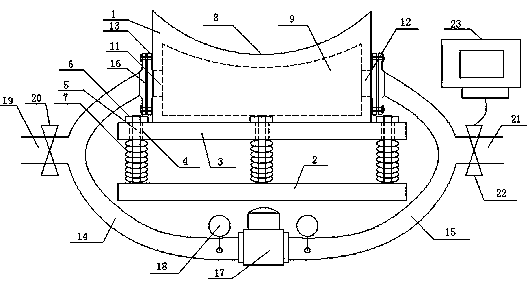

[0016] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

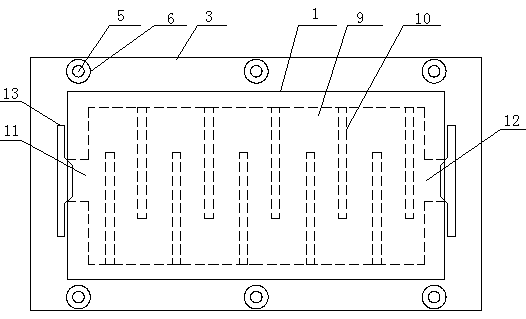

[0017] A tool for submerged arc welding, comprising a liner 1 and a base 2, wherein the liner 1 is made of heat-conducting copper, the liner 1 is located on the surface of the base 2, and the bottom of the liner 1 is provided with a connecting seat 3, The connecting seat 3 is provided with mounting holes 4, and there are six mounting holes 4, and the six mounting holes 4 are evenly distributed in two rows and three columns, and the four mounting holes 4 are all provided with connecting columns 5 , one end of the connecting post 5 is connected to the base 2, the other end passes through the connecting seat 3, and is connected with a nut 6, the connecting post 5 is provided with a spring 7, and the two ends of the spring 7 are respectively connected to the connecting seat 3 and the base 2 paste settings;

[0018] The surface of the liner 1 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com