Horizontal trimming mold

A horizontal cutting and mold technology, applied in the field of molds, can solve the problems of large height difference at the mouth of the workpiece, affect the processing work, and high mold costs, and achieve high production efficiency, stable operation, and high workpiece quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention is further elaborated below in conjunction with accompanying drawing.

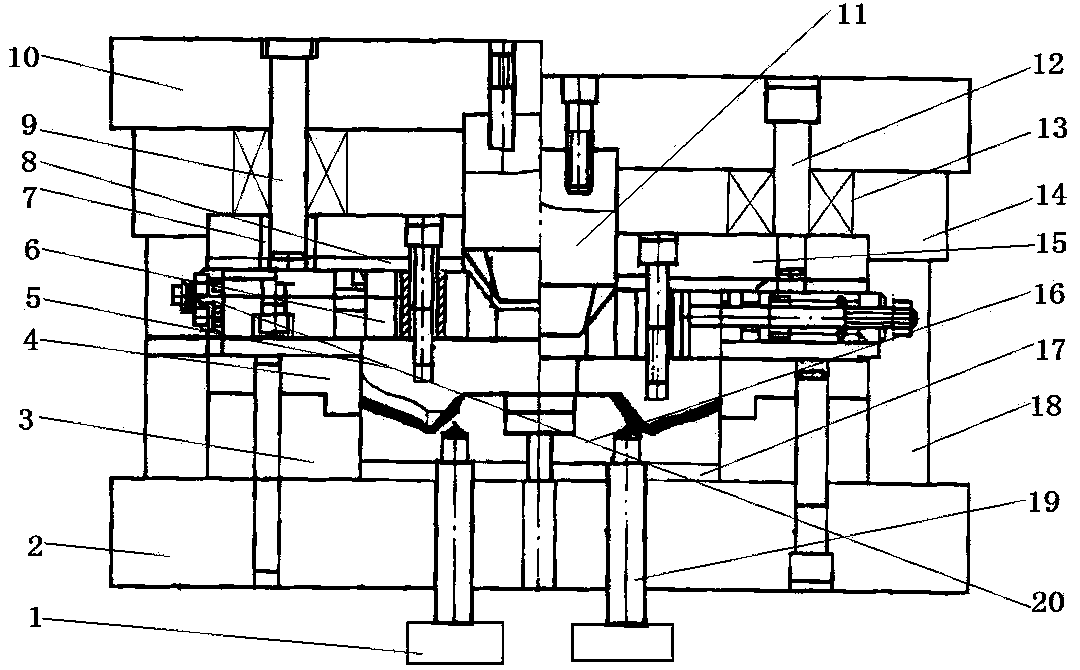

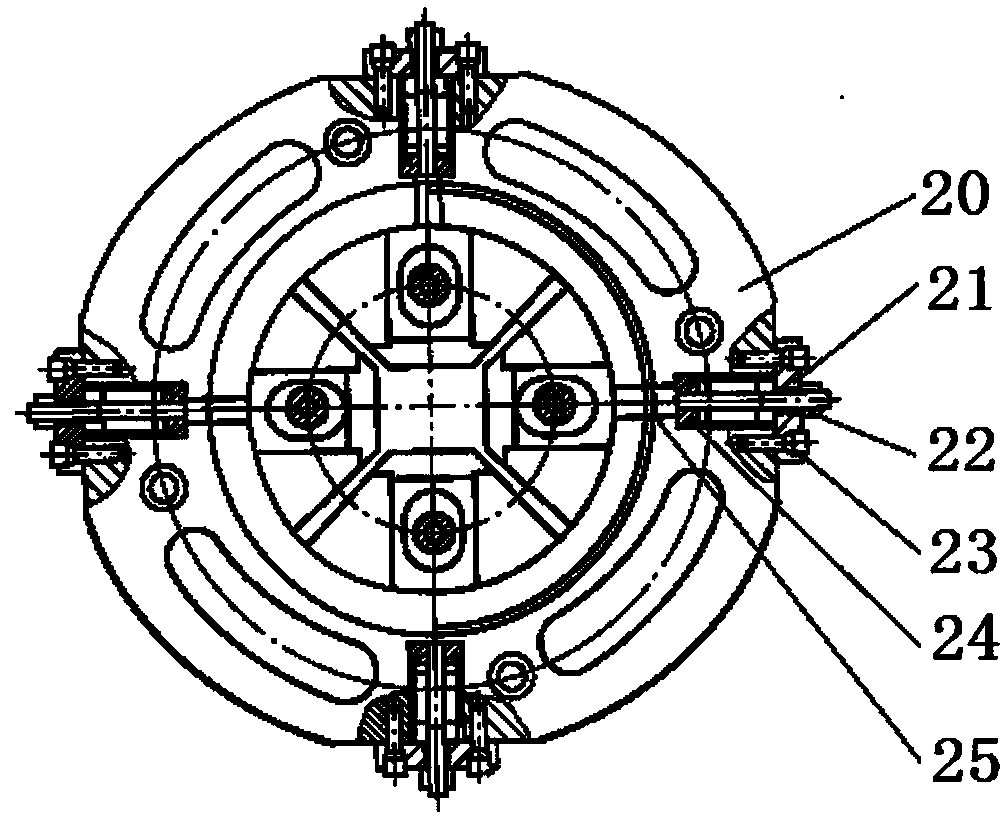

[0018] As shown in the figure: a kind of horizontal trimming mold of the present invention is characterized in that: it comprises upper mold base 10 and lower mold base 2, and described lower mold base 2 is provided with die 4, die holder 3, pad Plate 17, supporting plate 16, the die 4 is fixed on the lower mold base 2 through the die holder 3, the supporting plate 16 is arranged under the die 4, the backing plate 17 Set between the supporting plate 16 and the lower mold base 2, the inside of the lower mold base 2 and the supporting plate 16 is provided with a push rod 19, and the upper mold base 10 is equipped with a wedge mandrel 11, Springs 13 are respectively suspended at the two ends of the upper mold base 10, and the ends of the springs 13 are connected with a support plate 15, and a binder plate 6 is arranged below the support plate 15. Between the support plate 15 and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com