Plane edge-pressing and semi-fine blanking device and method

A flat blanking and flat pressing plate technology, applied in the field of semi-fine blanking, can solve the problems of damage to the blank surface of the workpiece, complex equipment, high mold cost, etc., and achieve the effects of reducing the generation and expansion of cracks, improving quality, and simplifying the structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

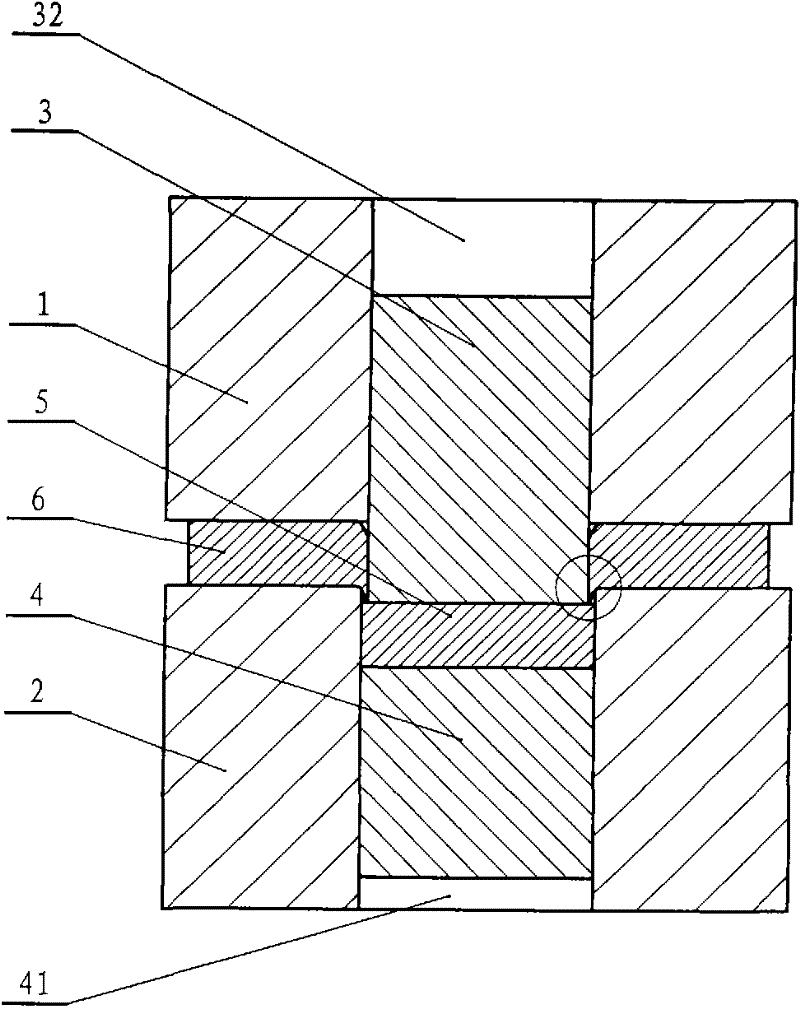

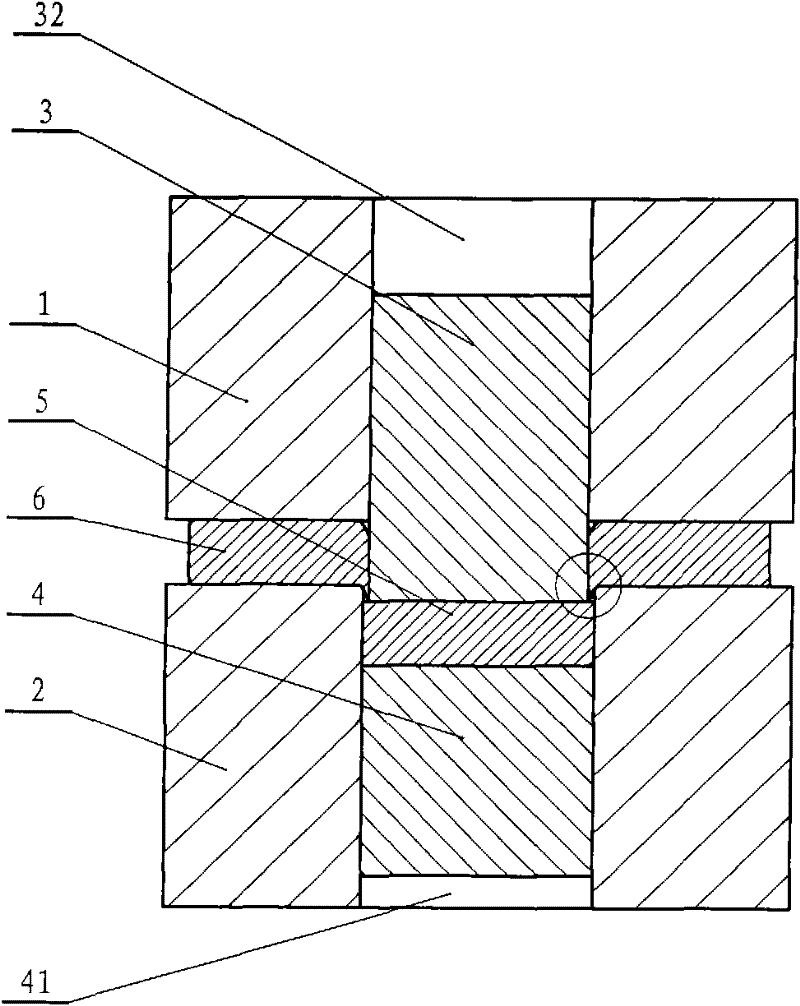

[0038] The planar blanking semi-fine blanking device and method of the present invention adopt ordinary presses and stamping dies for stamping processing, and the structure of the stamping dies is as attached figure 1 shown.

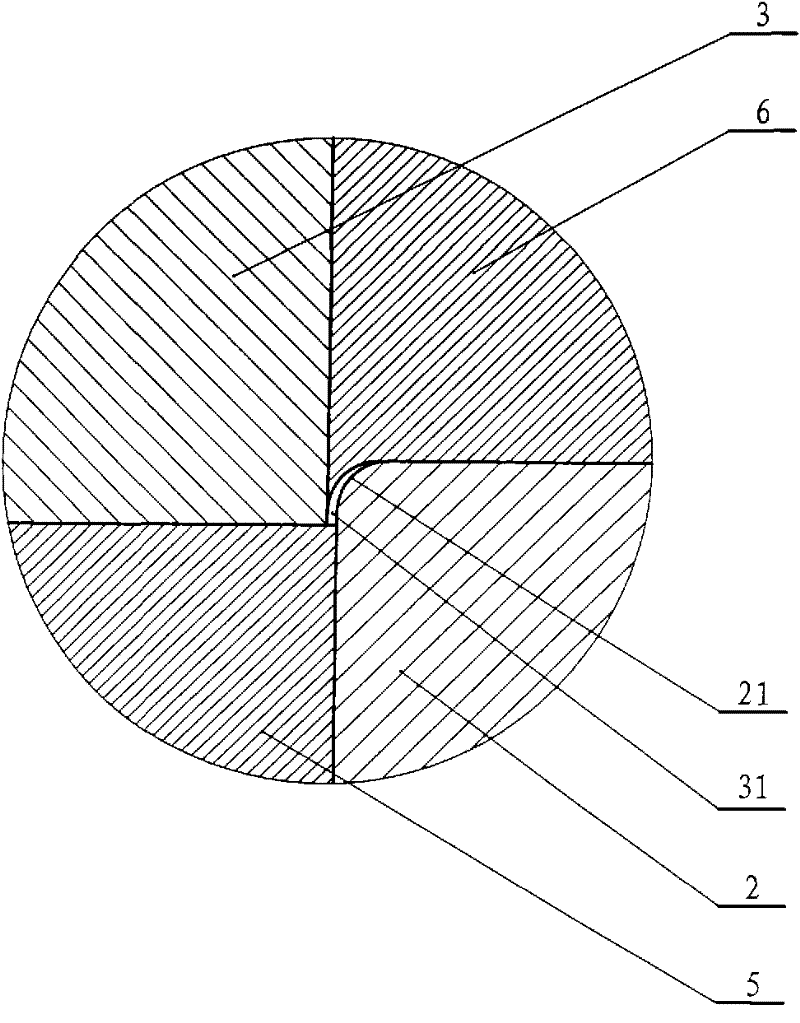

[0039] On the upper side of the axial joint surface of the stamping die, a plane pressing plate 1 is provided. The outline and size of the plane pressing plate 1 are larger than the outline and size of the workpiece 5. A punch slide 32 is set on the plane pressing plate 1 along the stamping direction, and the punch slide A columnar punch 3 is arranged in the road 32, the shape and size of the cross section of the punch 3 are adapted to the shape and size of the workpiece 5, and the shape and size of the section of the punch slideway 32 are adapted to the shape and size of the cross section of the punch 3 , the punch 3 is slidingly connected with the punch slideway 32, and a die 2 is provided on the lower side of the axial joint surface of the stamping di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com