Porcelain tube blank glazing machine

A technology for spraying glaze and blanks, which is applied to the field of glaze spraying machines for porcelain tube blanks, can solve the problems of unfavorable health of workers, the quality does not meet international standards, and the environment is easy to cause pollution. , the effect of less environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

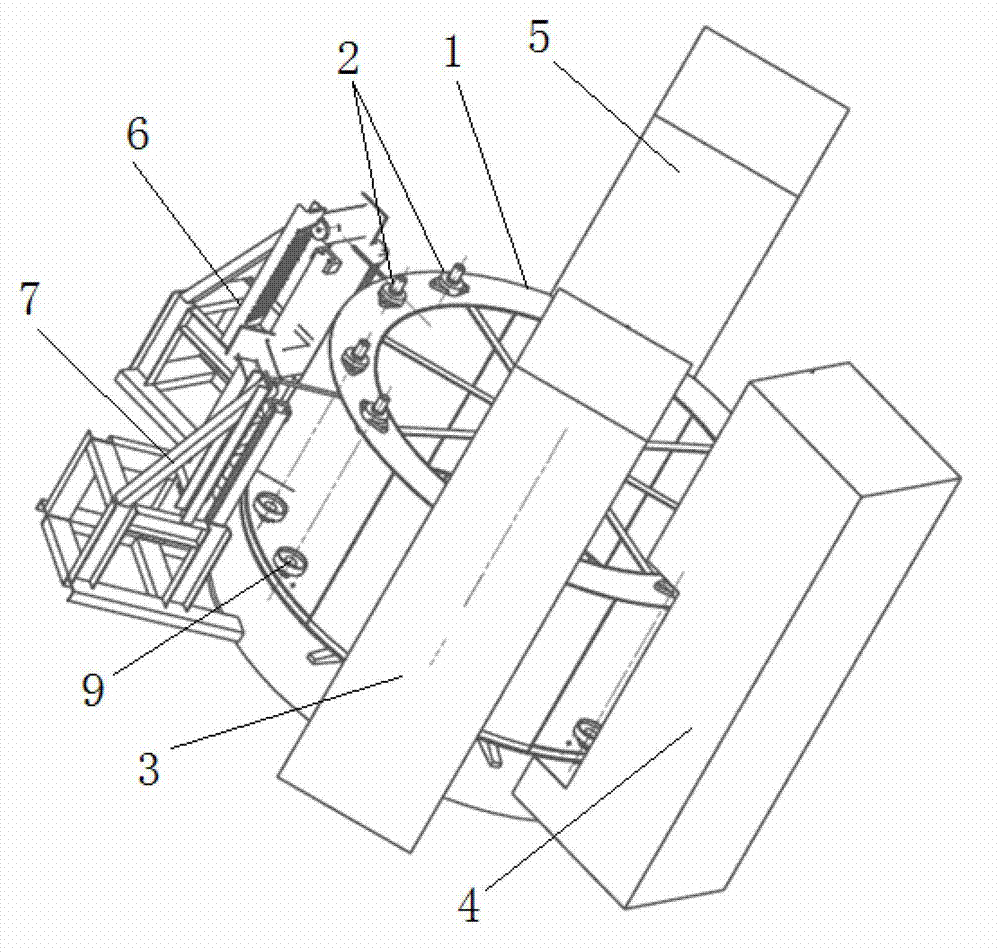

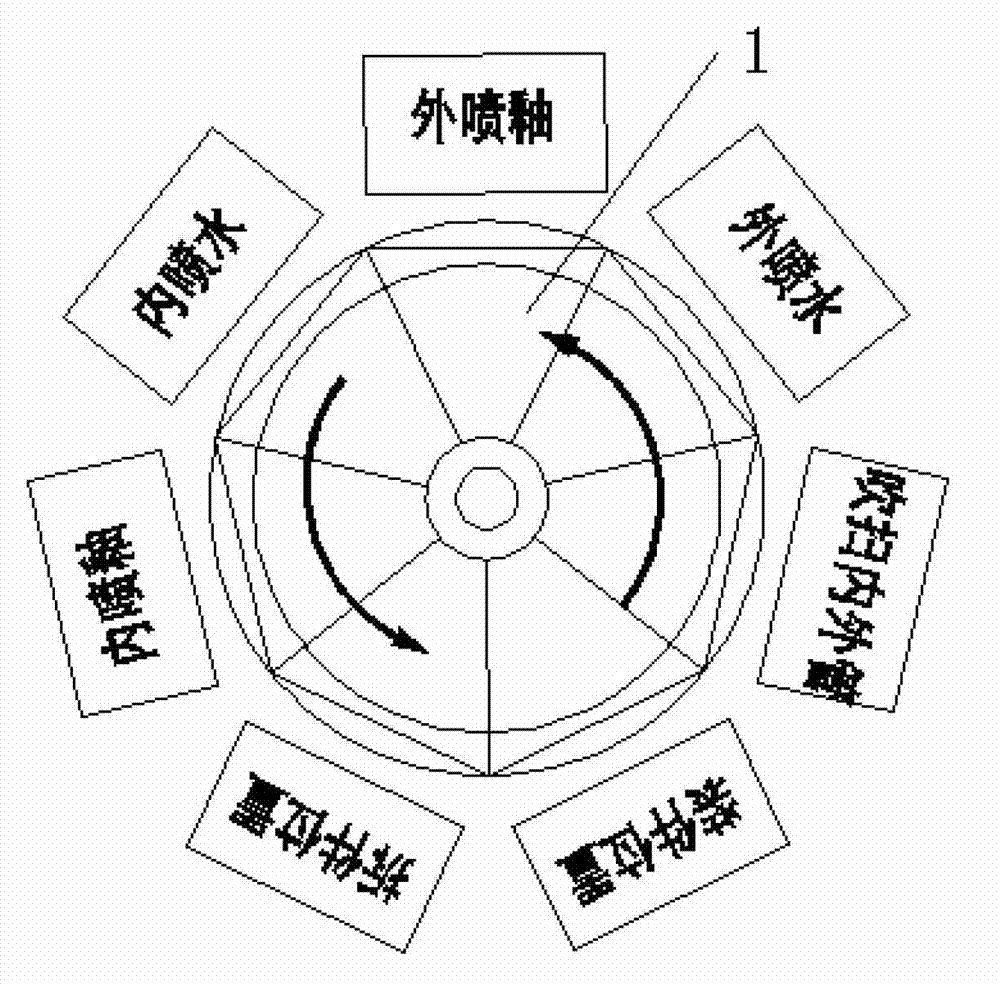

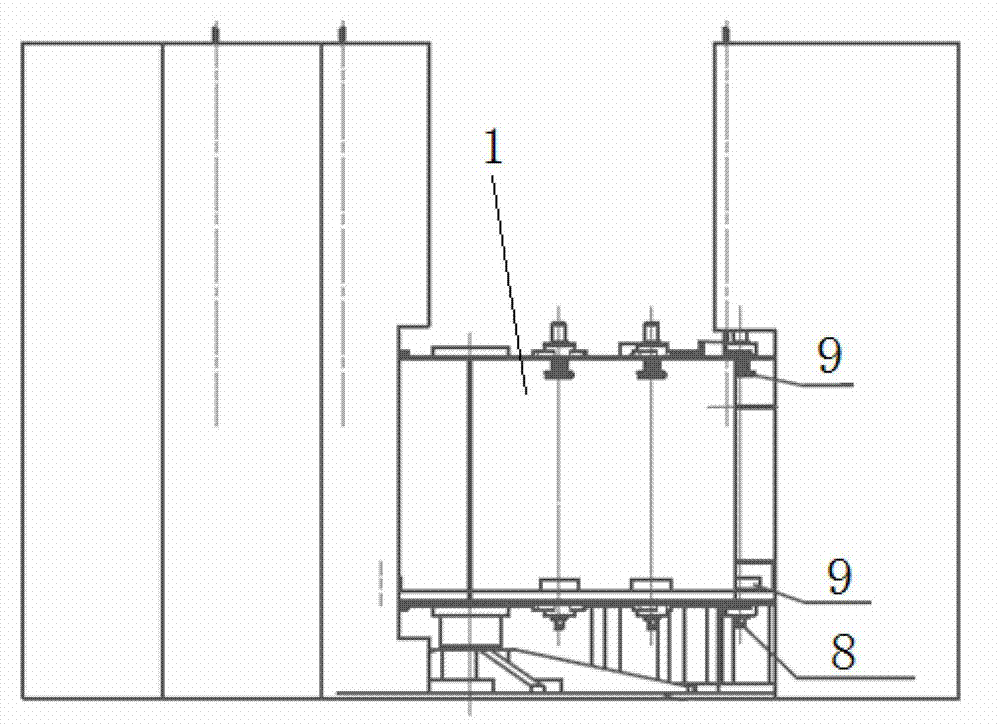

[0031] Such as Figure 1-Figure 3 As shown, the glaze spraying machine for porcelain tube blanks includes a main turntable 1, and a plurality of workpiece fixing rotation mechanisms 2 are arranged on the outer edge of the main turntable 1. The main turntable 1 is connected with the main motor, and each pair of workpiece fixing rotation mechanisms 2 They are all connected with a separate auxiliary motor, and each workpiece fixed rotating mechanism 2 rotates simultaneously with the revolution of the main turntable 1; a number of station work areas are arranged in sequence around the main turntable 1, and the main motor, the auxiliary motor and the The power unit of each station working area is connected with the control system.

[0032] The main turntable 1 includes a central shaft, which is connected to a cylindrical support frame through connecting pla...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com