Patents

Literature

95 results about "Gas laser device" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for cutting crisp material substrate

InactiveCN101121220AAvoid defectsGuaranteed cutting qualityFine working devicesGlass severing apparatusSolid-state laser deviceHigh energy

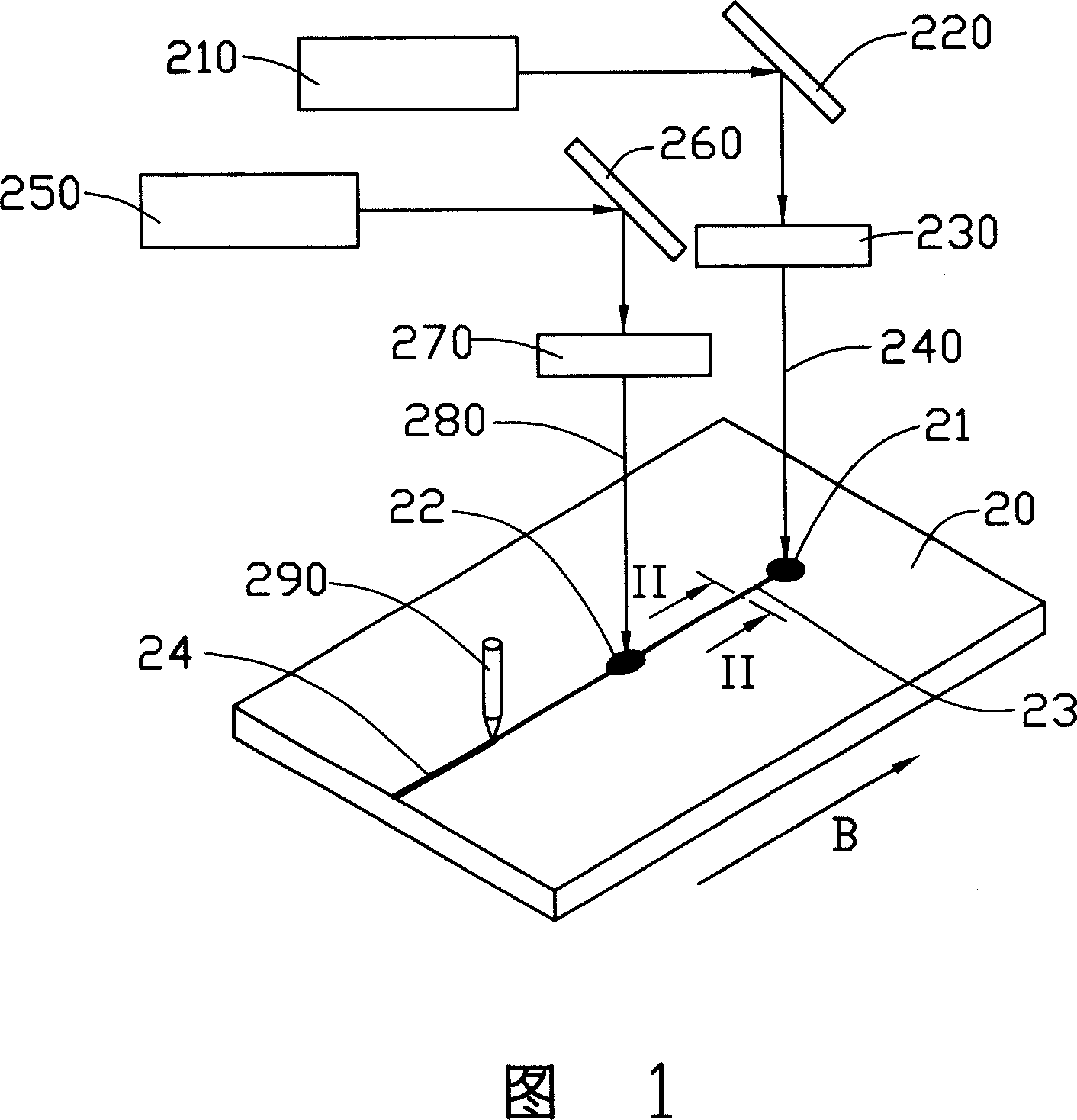

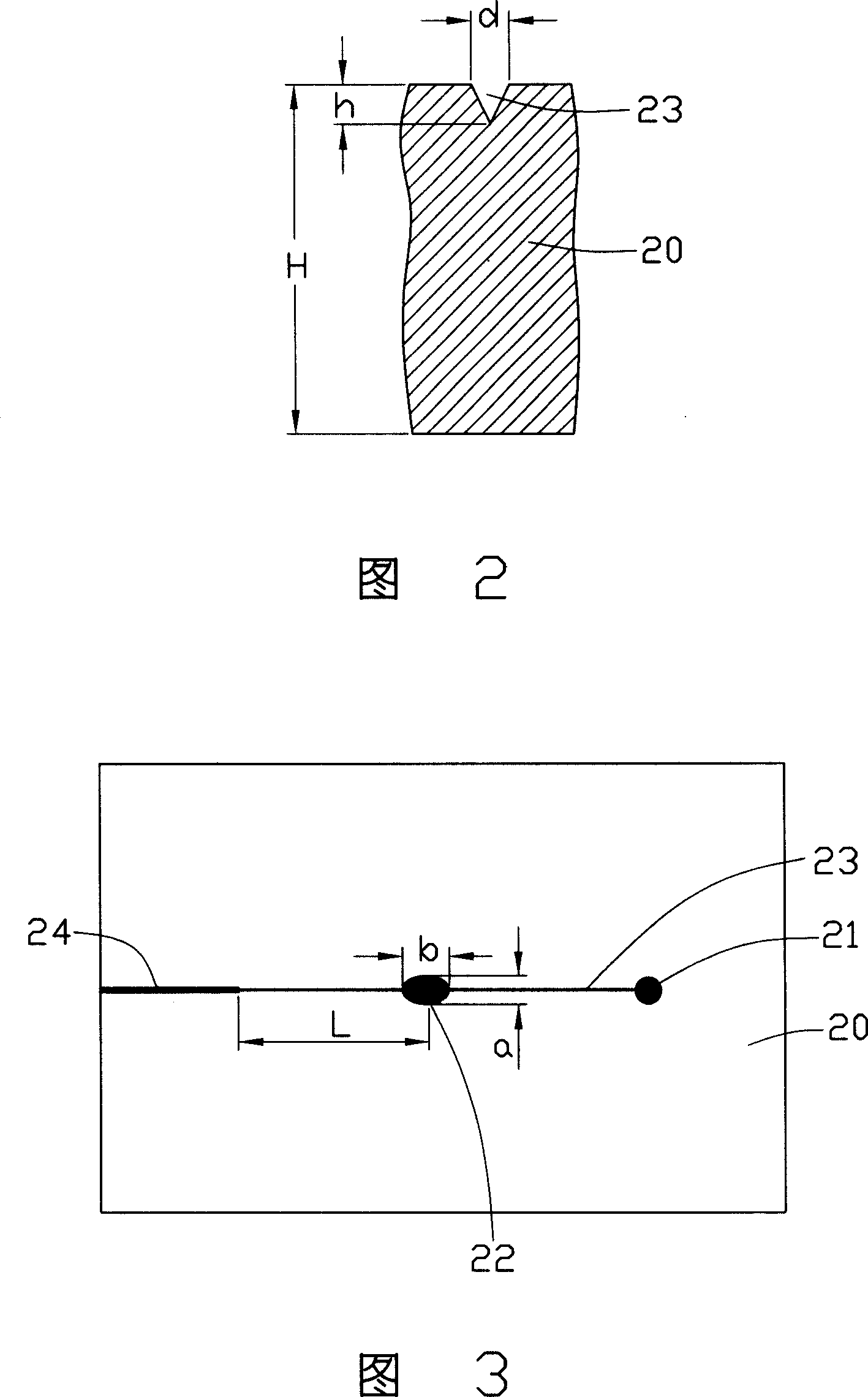

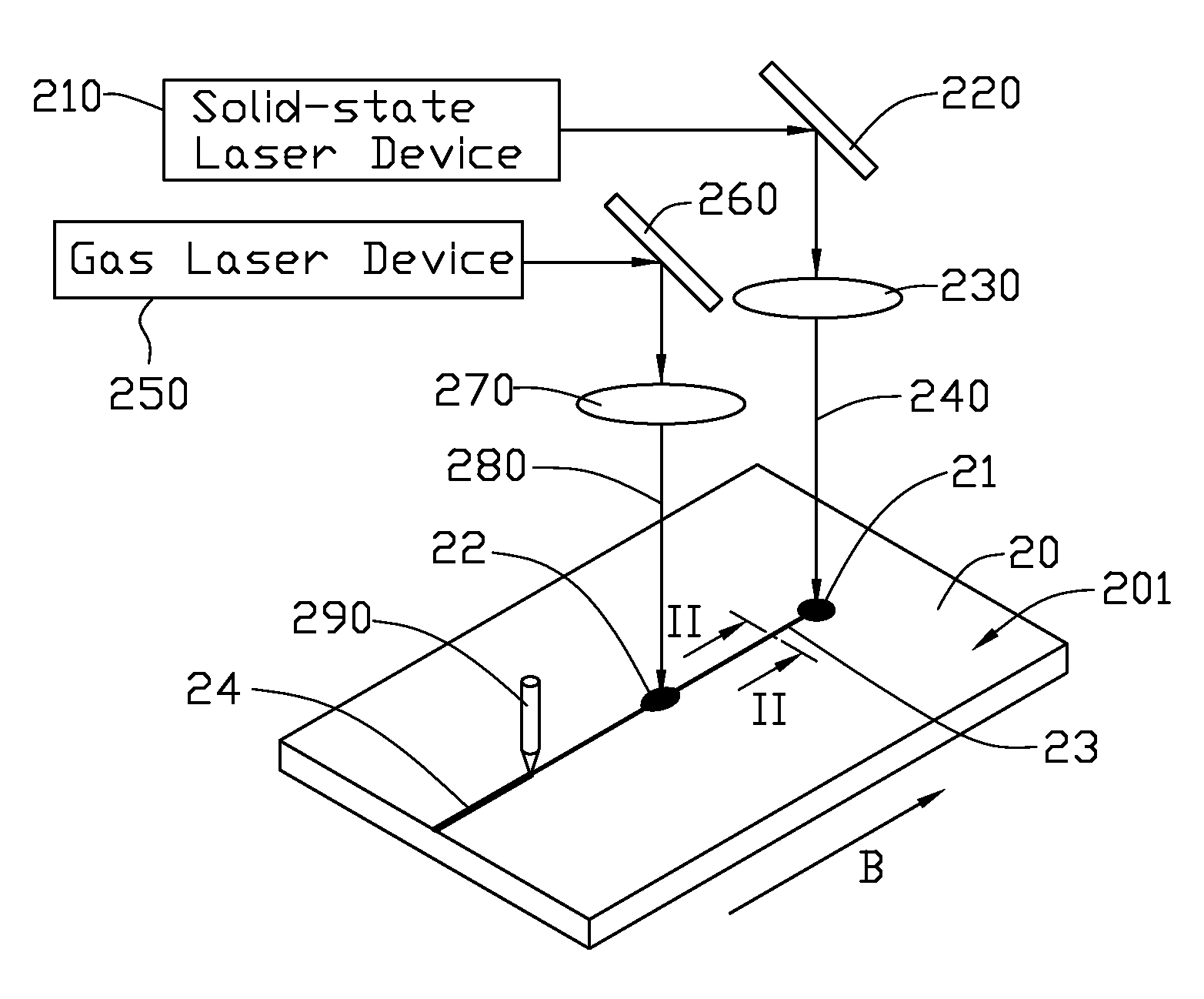

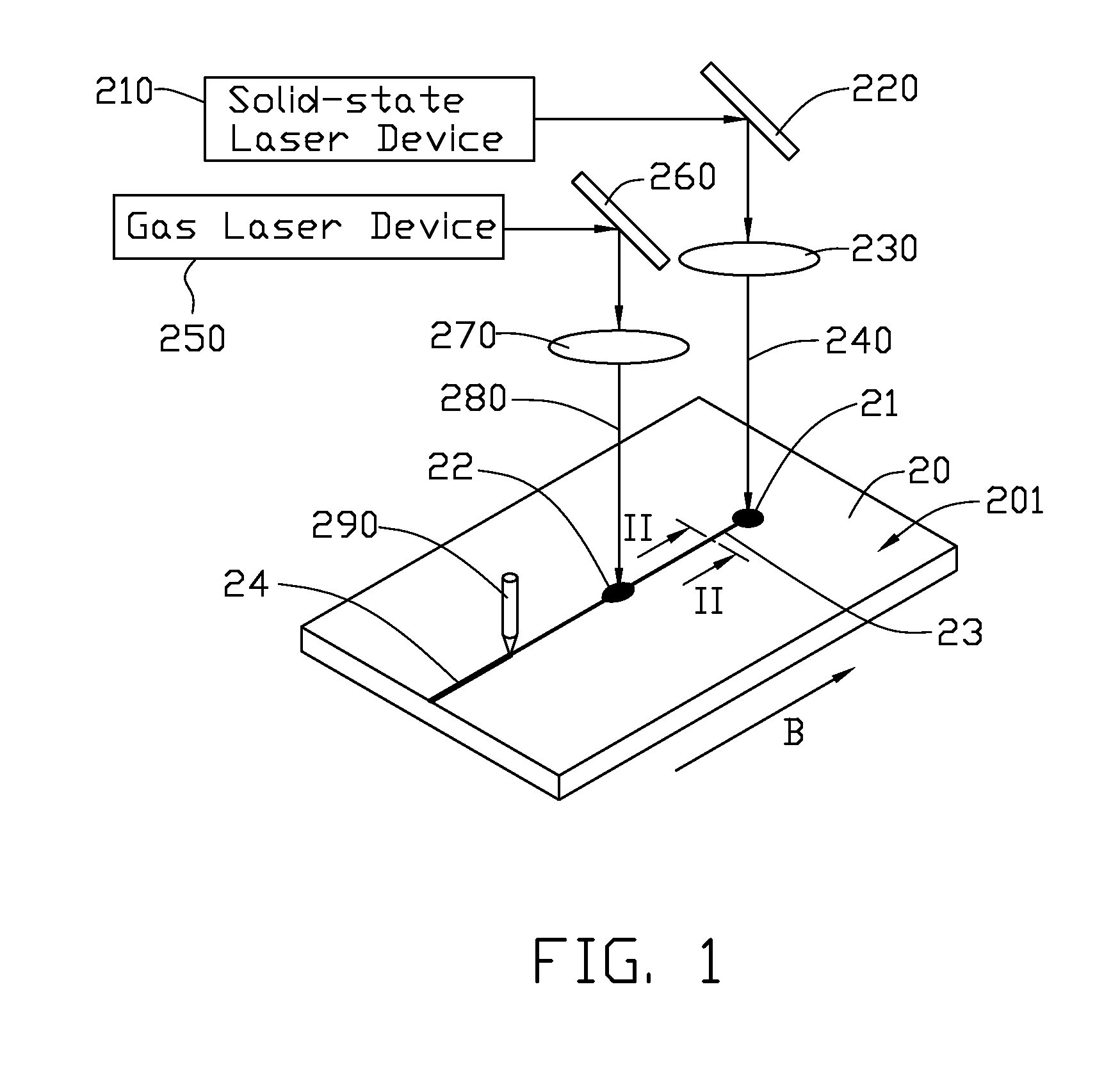

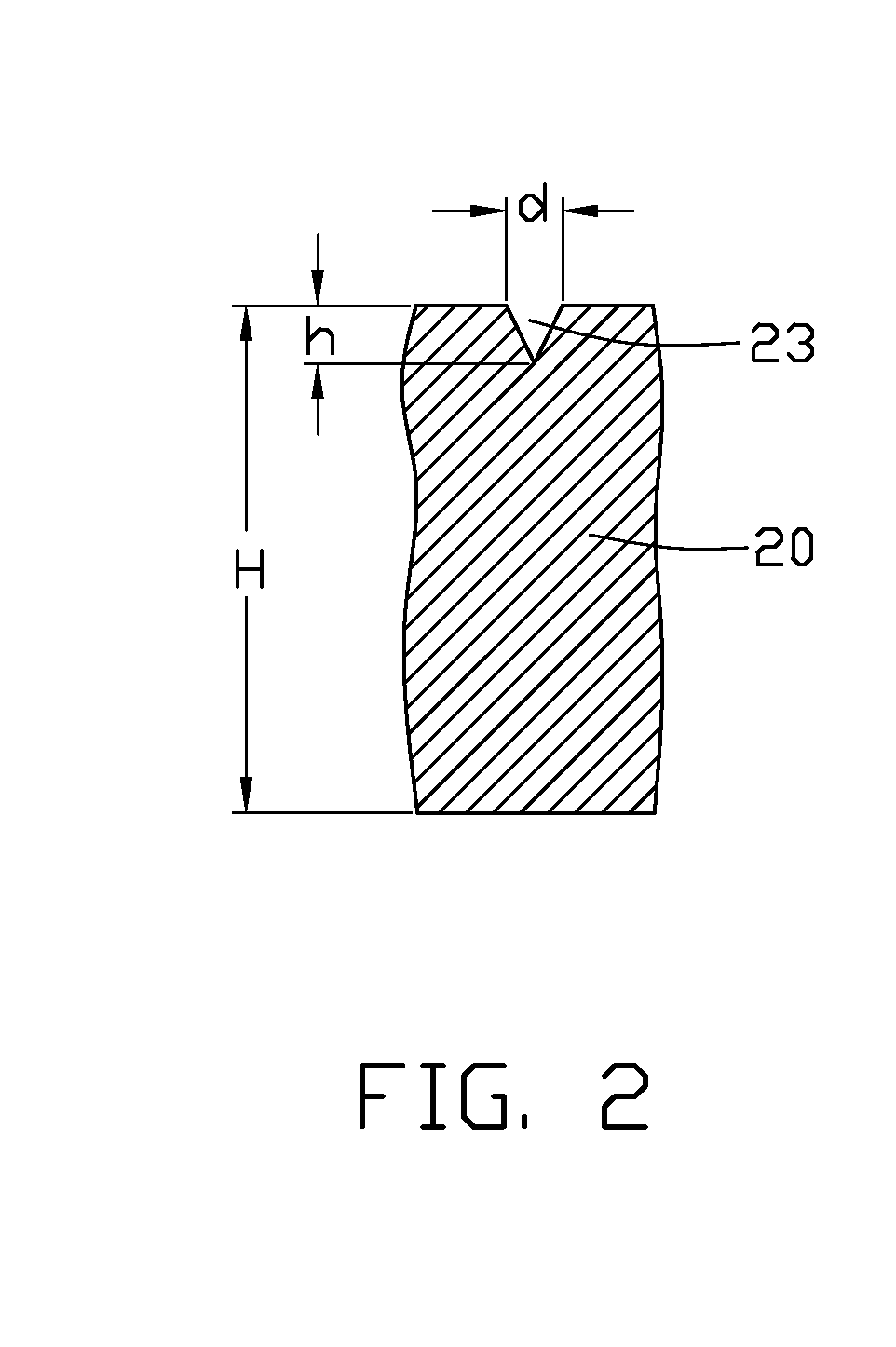

A method for processing a brittle substrate includes first providing a brittle substrate having a substrate surface. Then applying a first laser beam onto the brittle substrate surface to form a pre-cut groove in the brittle substrate, the first laser beam being generated by a solid-state laser device. A second laser beam is then applied onto the brittle substrate surface along the precut groove to heat the brittle substrate, the second laser beam being generated by a gas laser device. Finally, a coolant is applied onto the brittle substrate along the pre-cut groove so as to cause formation of a through crack in the brittle substrate. The first laser beam can be generated by a solid-state laser device, the first laser beam should be of narrow diameter and high energy density, so the first laser beam can form a pre-cut groove rapidly and accurately without generation of micro-cracks, in addition, the pre-cut groove should have a better uniformity and linearity.

Owner:FOXSEMICON INTEGRATED TECHNOLOGY (SHANGHAI) INC +1

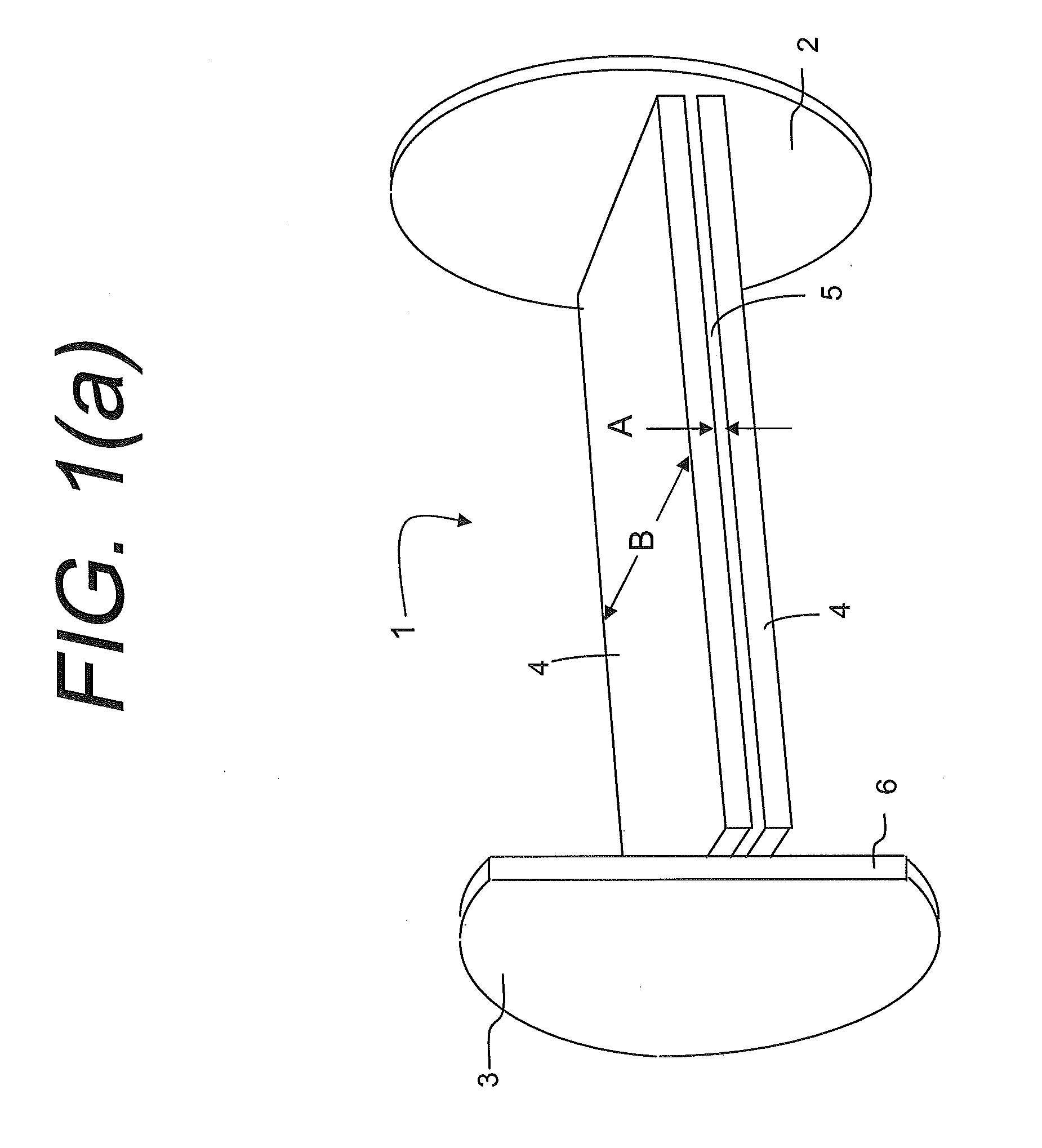

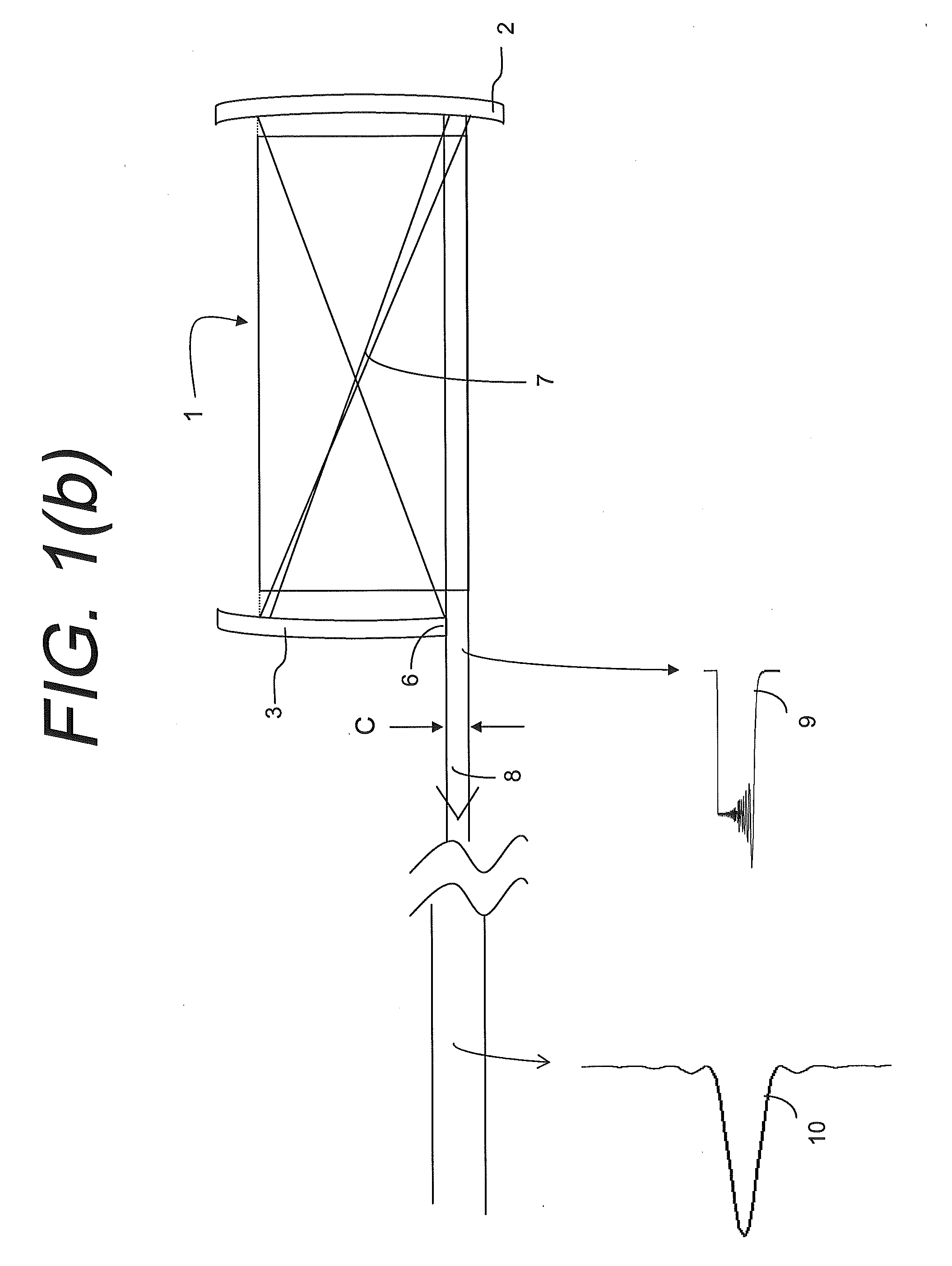

Method for processing brittle substrates without micro-cracks

InactiveUS20080035617A1Improve uniformityImprove linearityFine working devicesGlass severing apparatusSolid-state laser deviceHigh energy

A method for processing a brittle substrate includes first providing a brittle substrate having a substrate surface. Then applying a first laser beam onto the brittle substrate surface to form a pre-cut groove in the brittle substrate, the first laser beam being generated by a solid-state laser device. A second laser beam is then applied onto the brittle substrate surface along the precut groove to heat the brittle substrate, the second laser beam being generated by a gas laser device. Finally, a coolant is applied onto the brittle substrate along the pre-cut groove so as to cause formation of a through crack in the brittle substrate. The first laser beam can be generated by a solid-state laser device, the first laser beam should be of narrow diameter and high energy density, so the first laser beam can form a pre-cut groove rapidly and accurately without generation of micro-cracks, in addition, the pre-cut groove should have a better uniformity and linearity.

Owner:FOXSEMICON INTEGRATED TECH INC

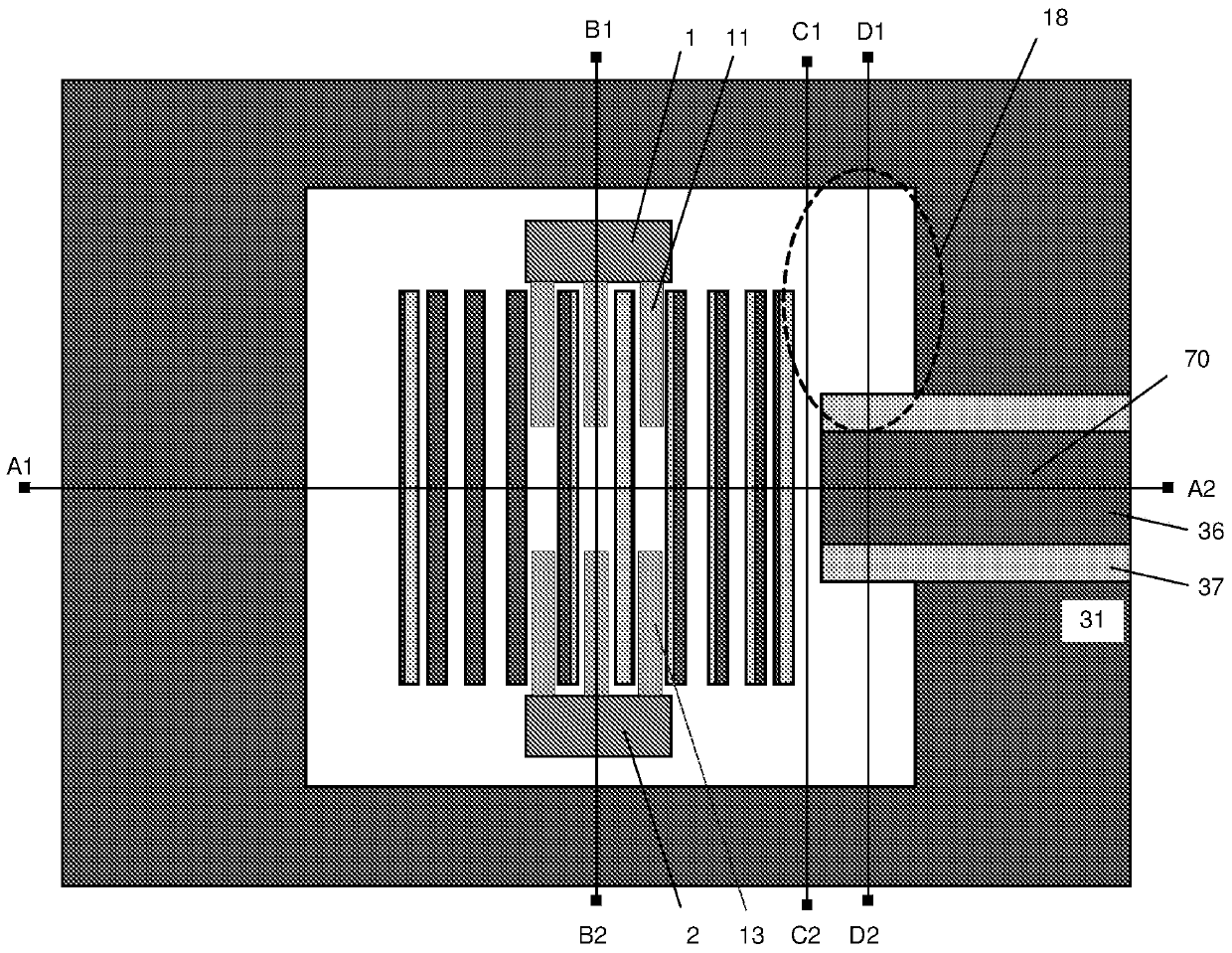

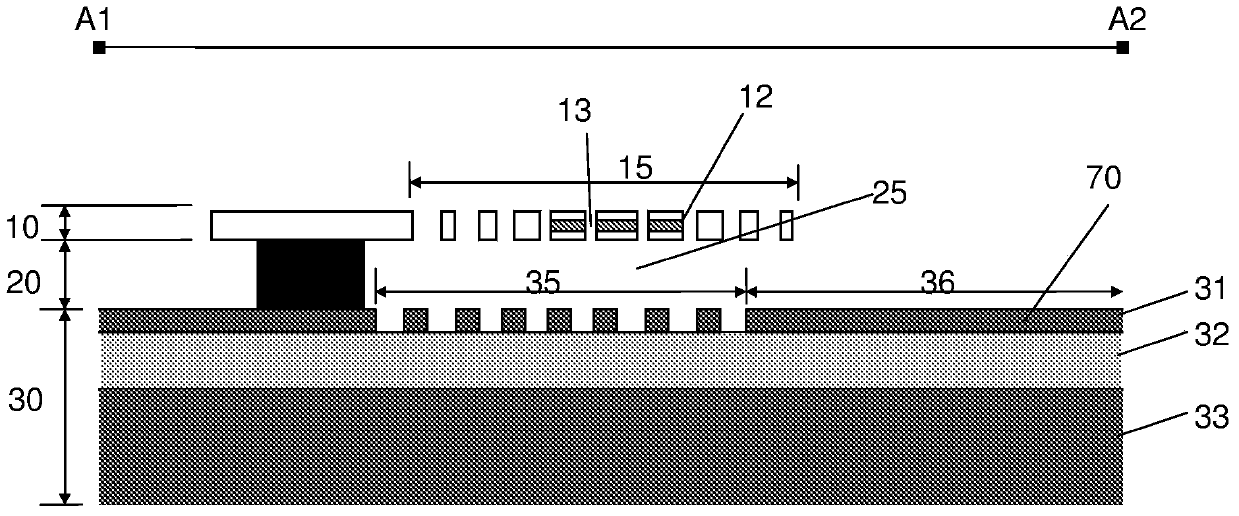

Injection locking type or MOPA type of gas laser device

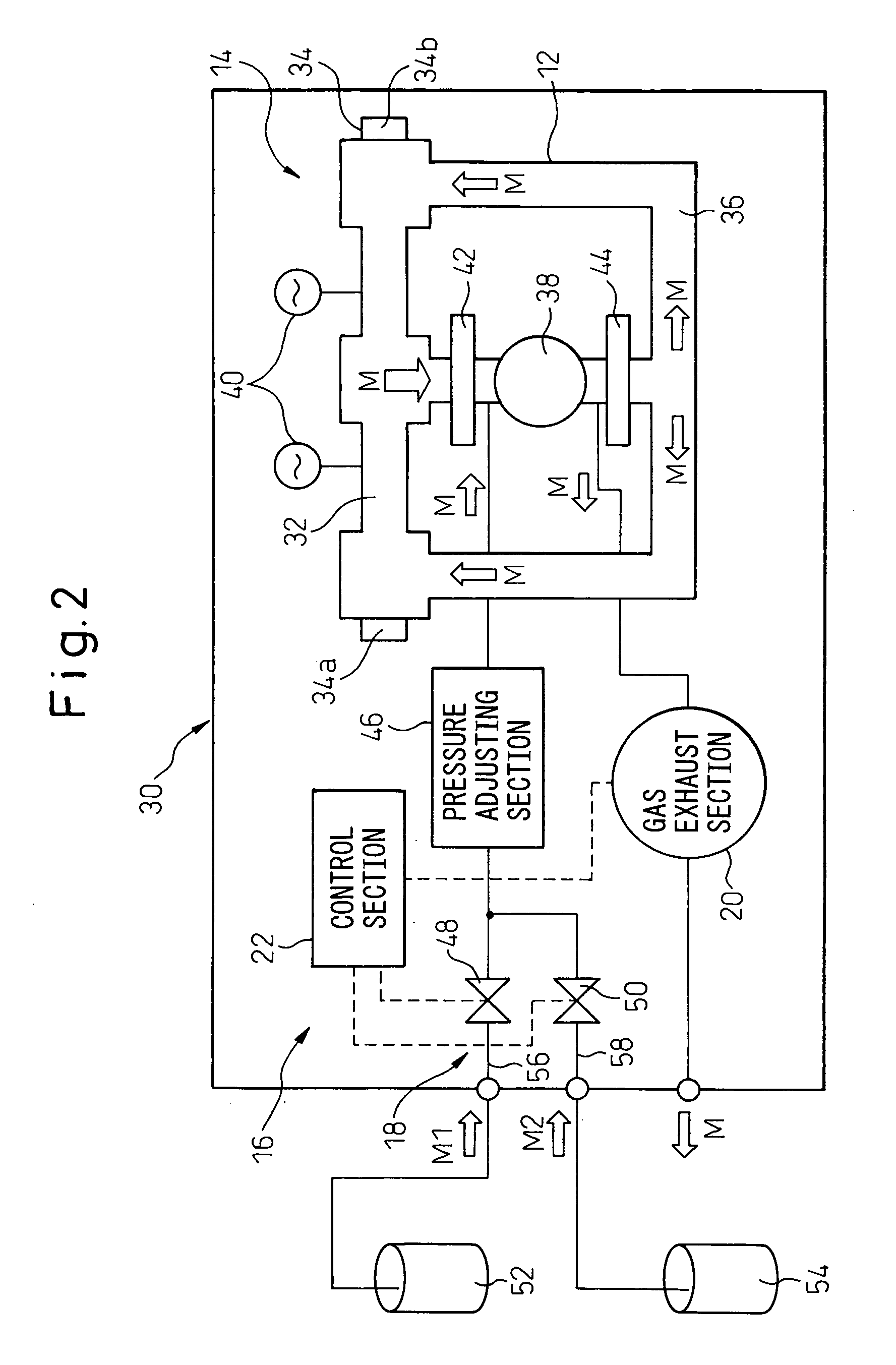

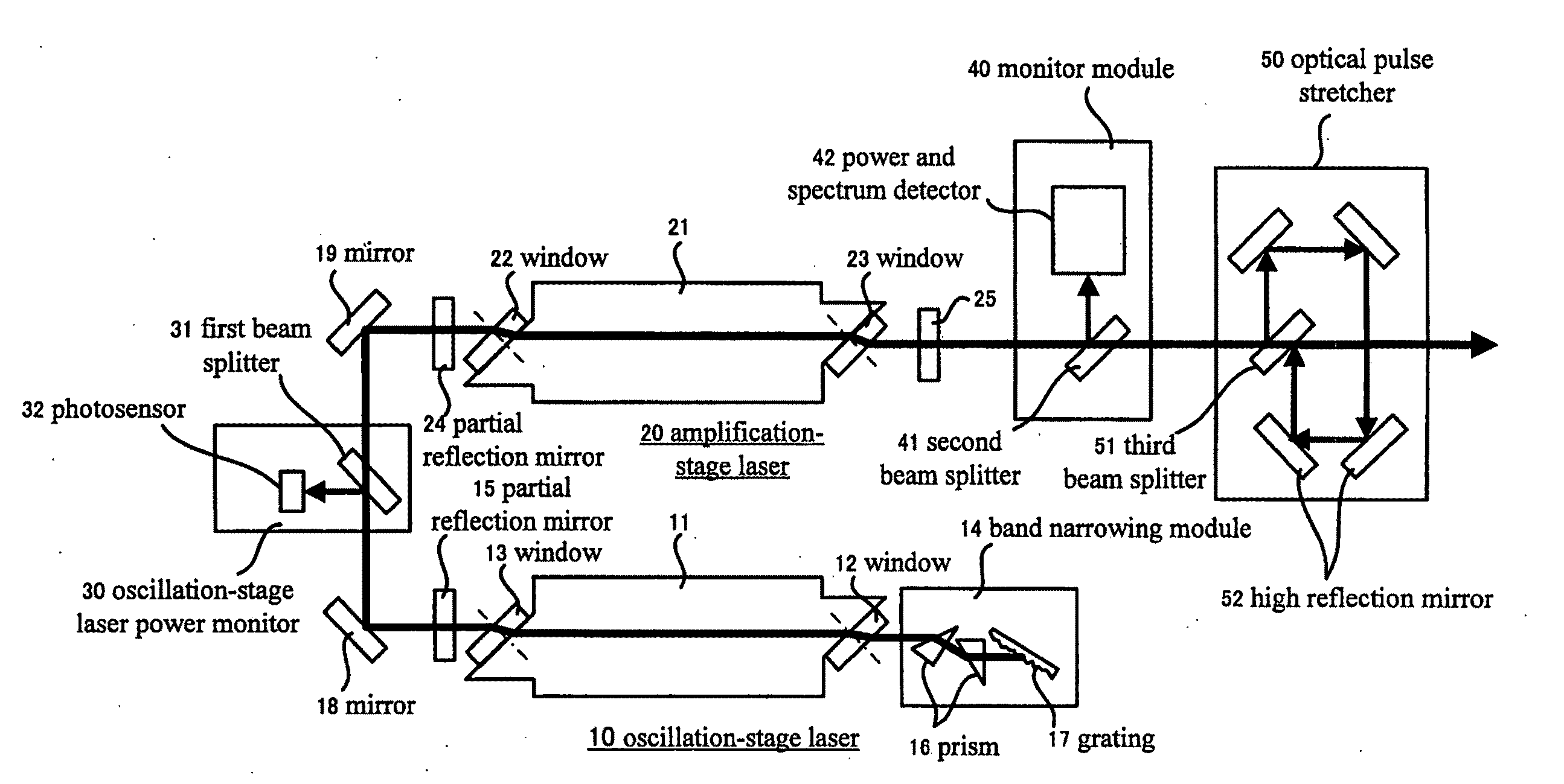

InactiveUS6973111B2Reduced installation areaReduce the possibilityPhotomechanical apparatusOptical resonator shape and constructionInjection lockedAudio power amplifier

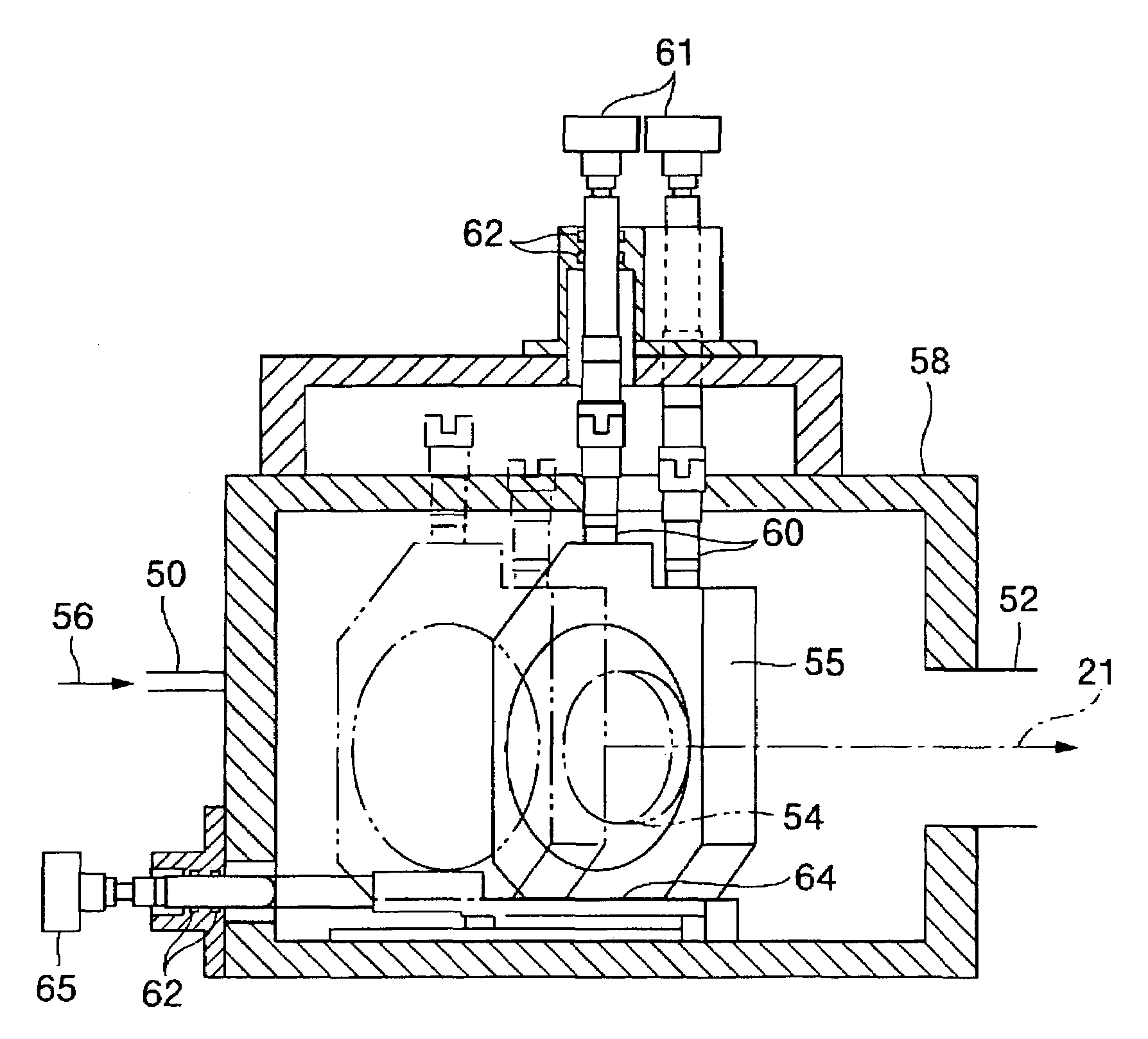

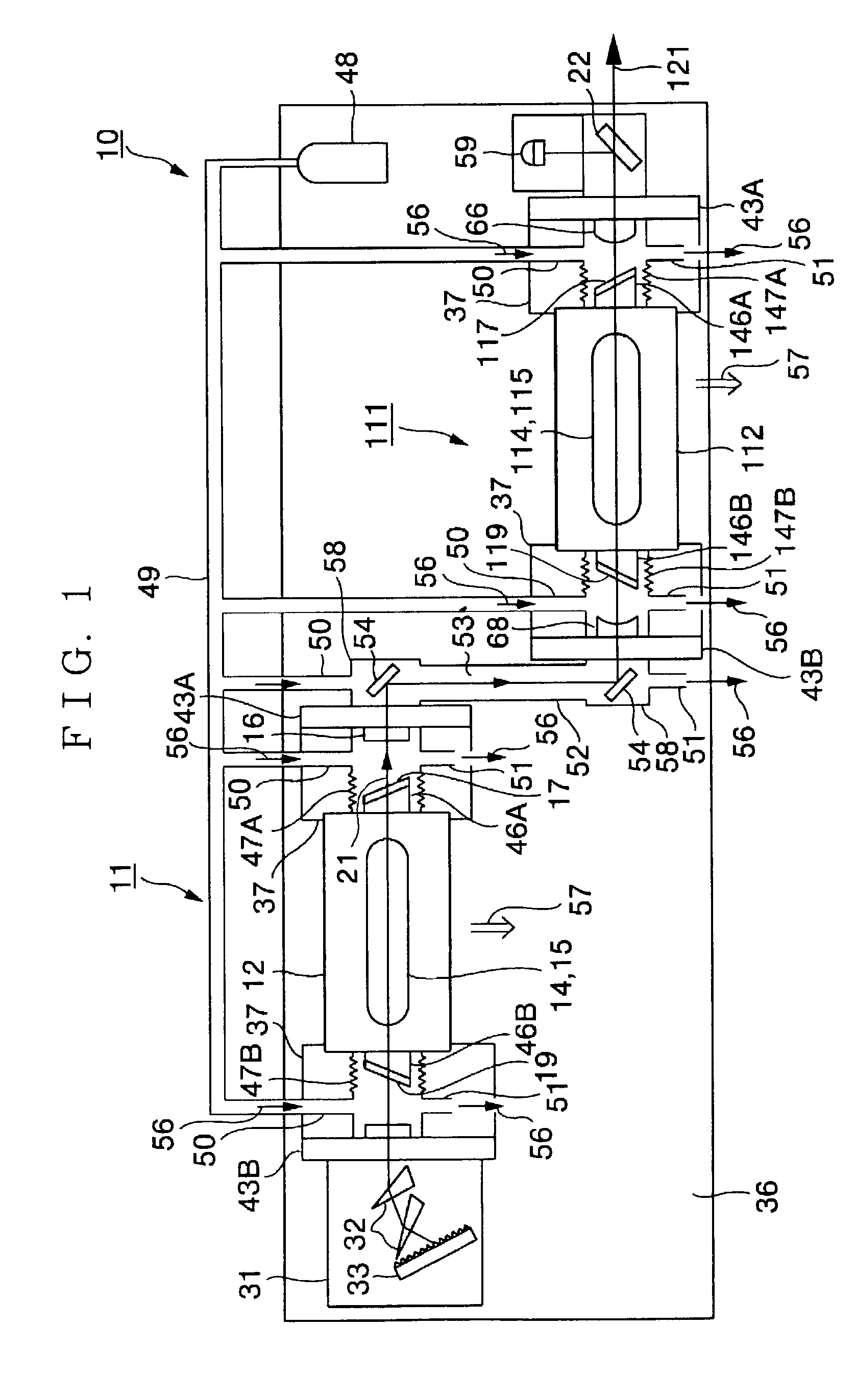

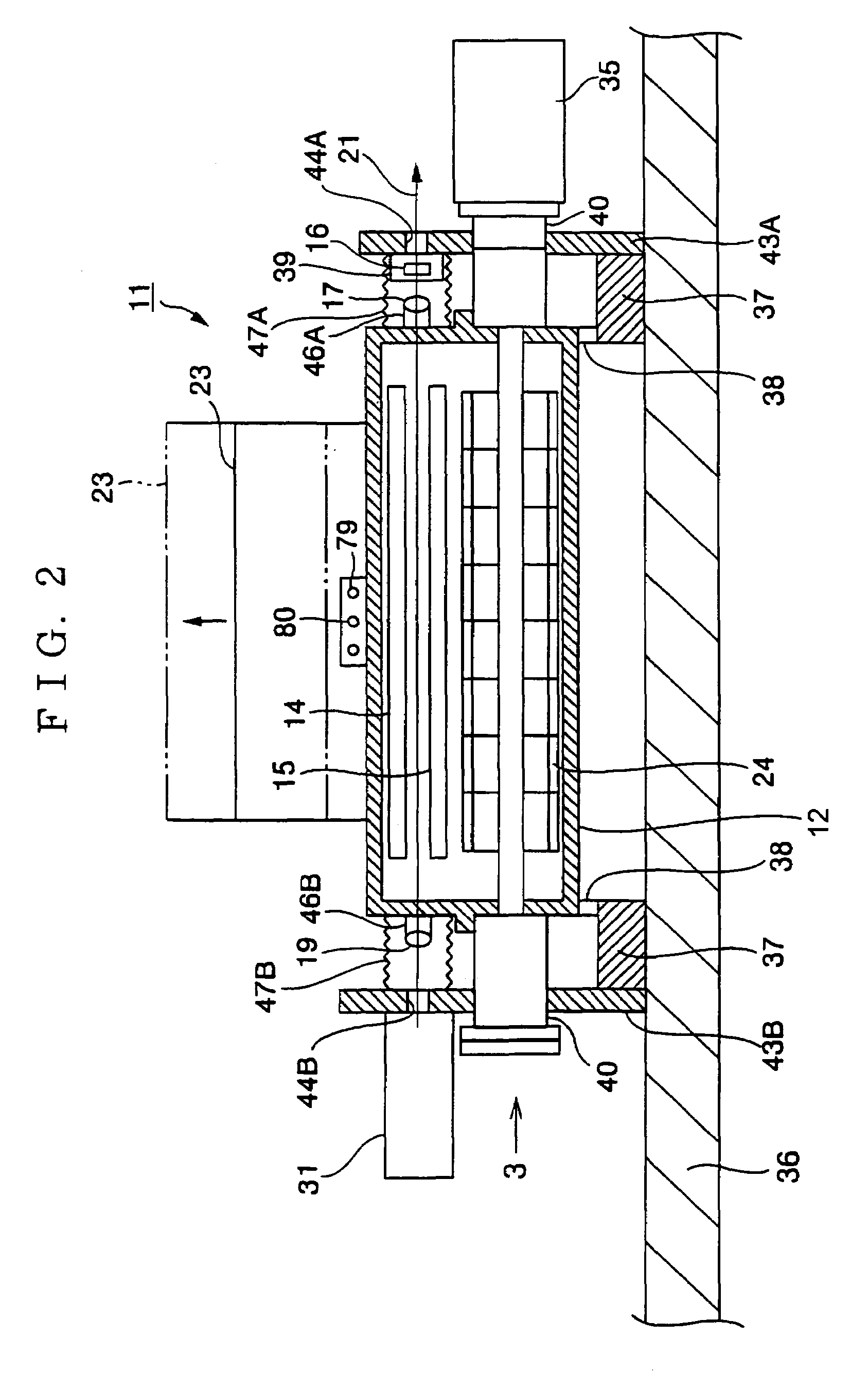

An injection locking type or MOPA type of gas laser device which requires only a small installation area and allows easy maintenance. For this purpose, the laser device includes a seed laser unit (11) for exciting a laser gas inside a laser chamber (12) and oscillating seed laser light (21) and an amplifier (111) for exciting a laser gas inside an amplifying chamber (112) and amplifying pulse energy of the seed laser light (21), and allows the laser chamber (12) and the amplifying chamber (112) to be evacuated to the same side with respect to an optical axis of the seed laser light (21).

Owner:GIGAPHOTON

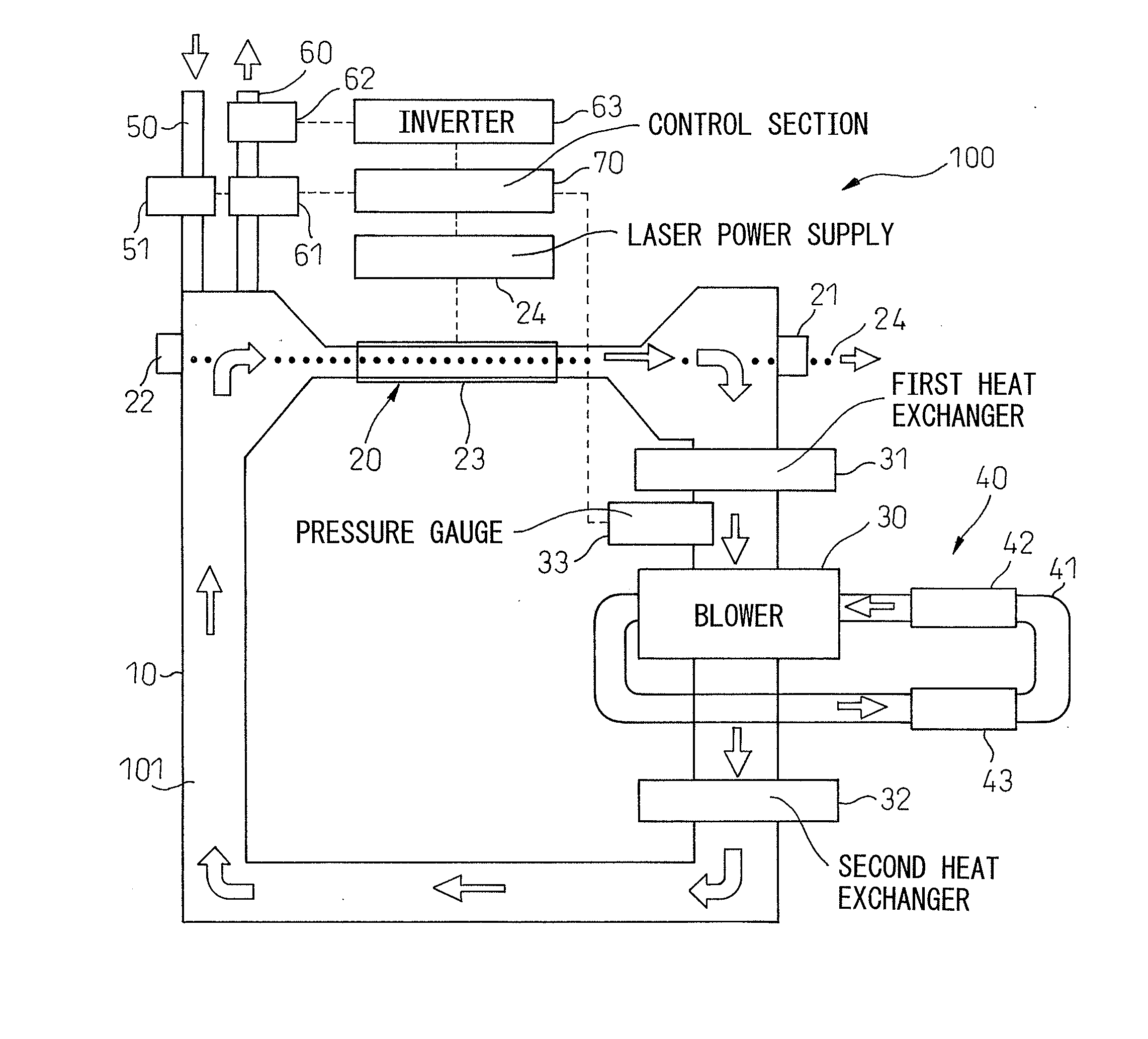

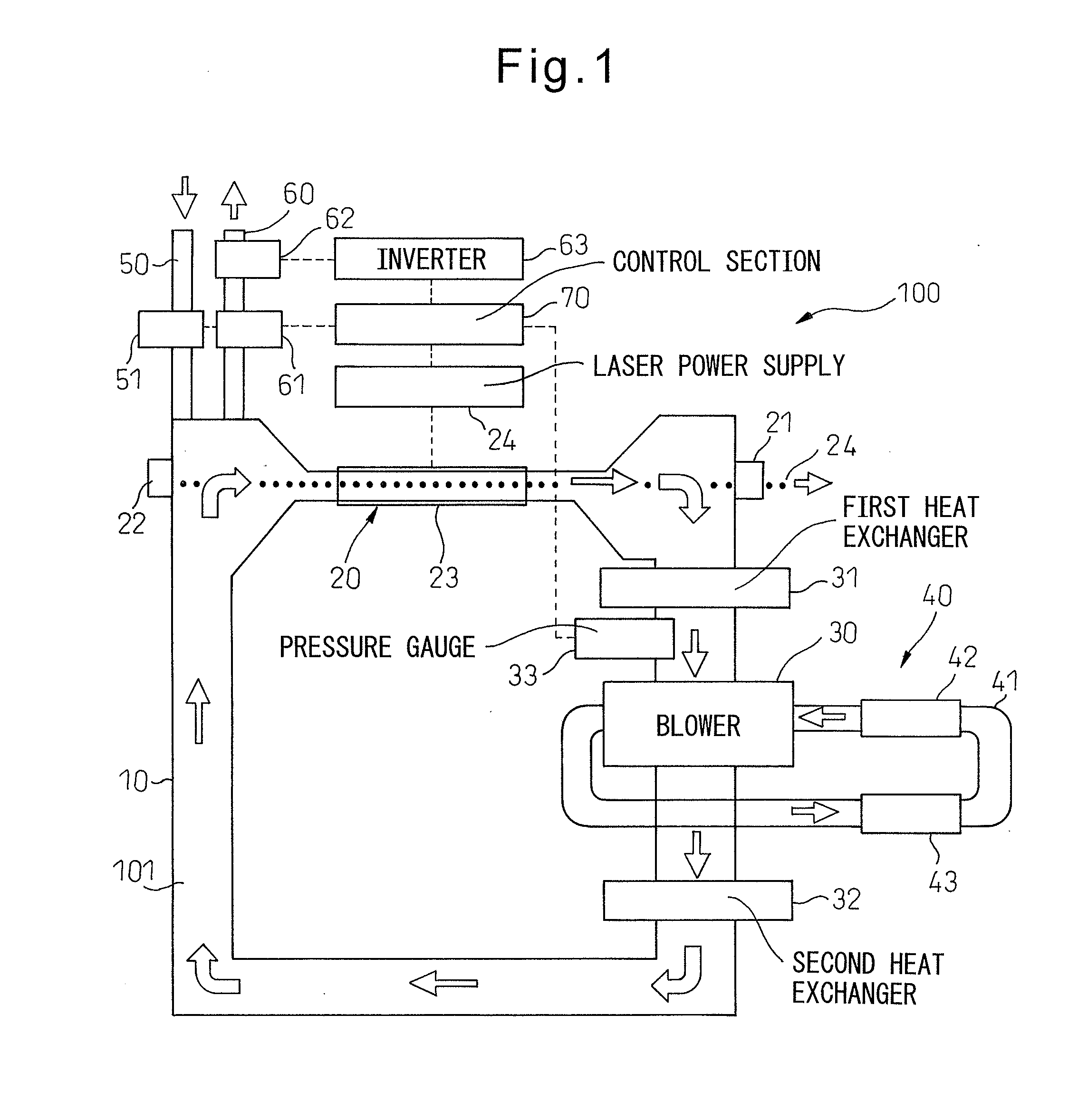

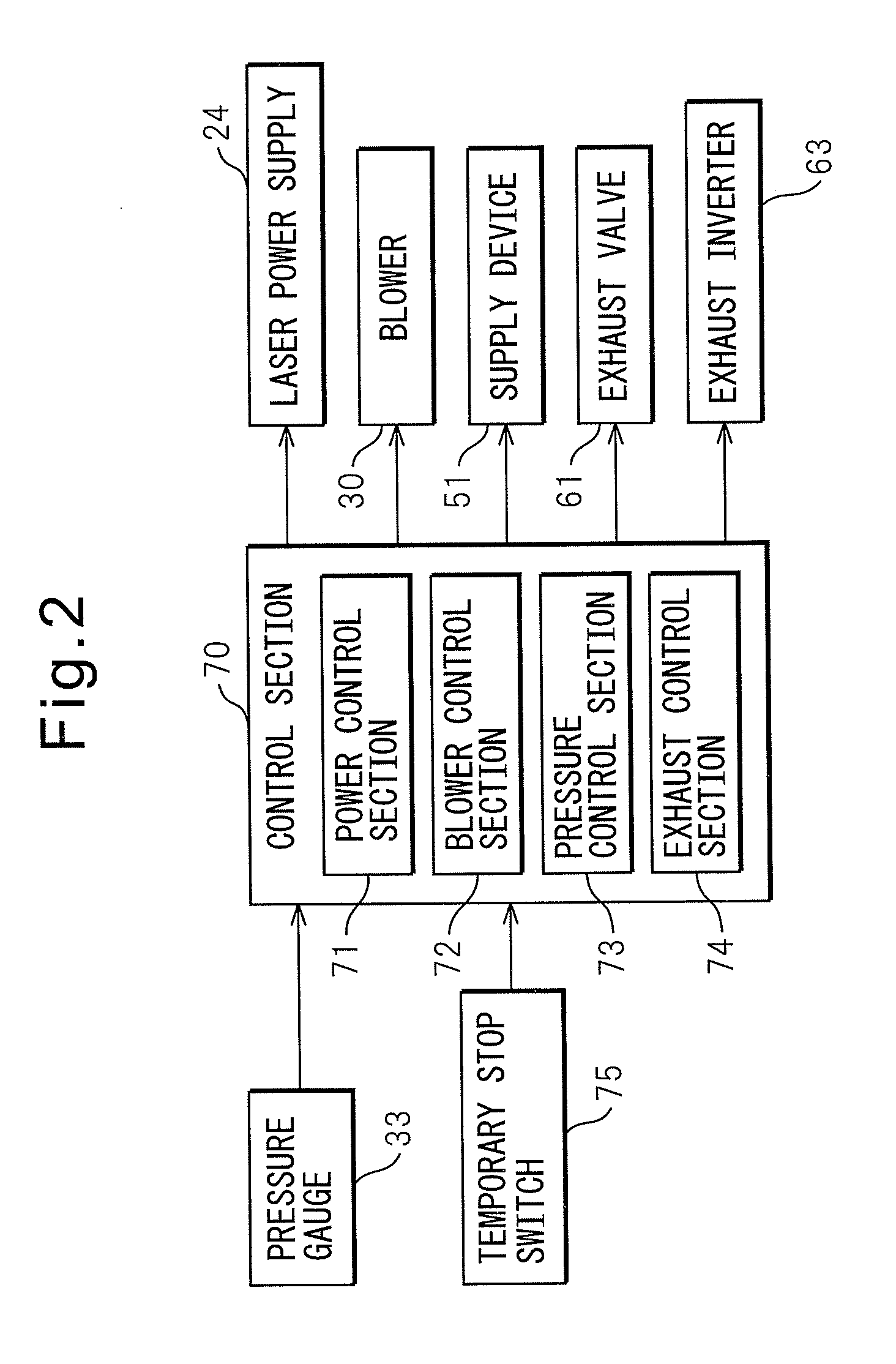

Gas laser device

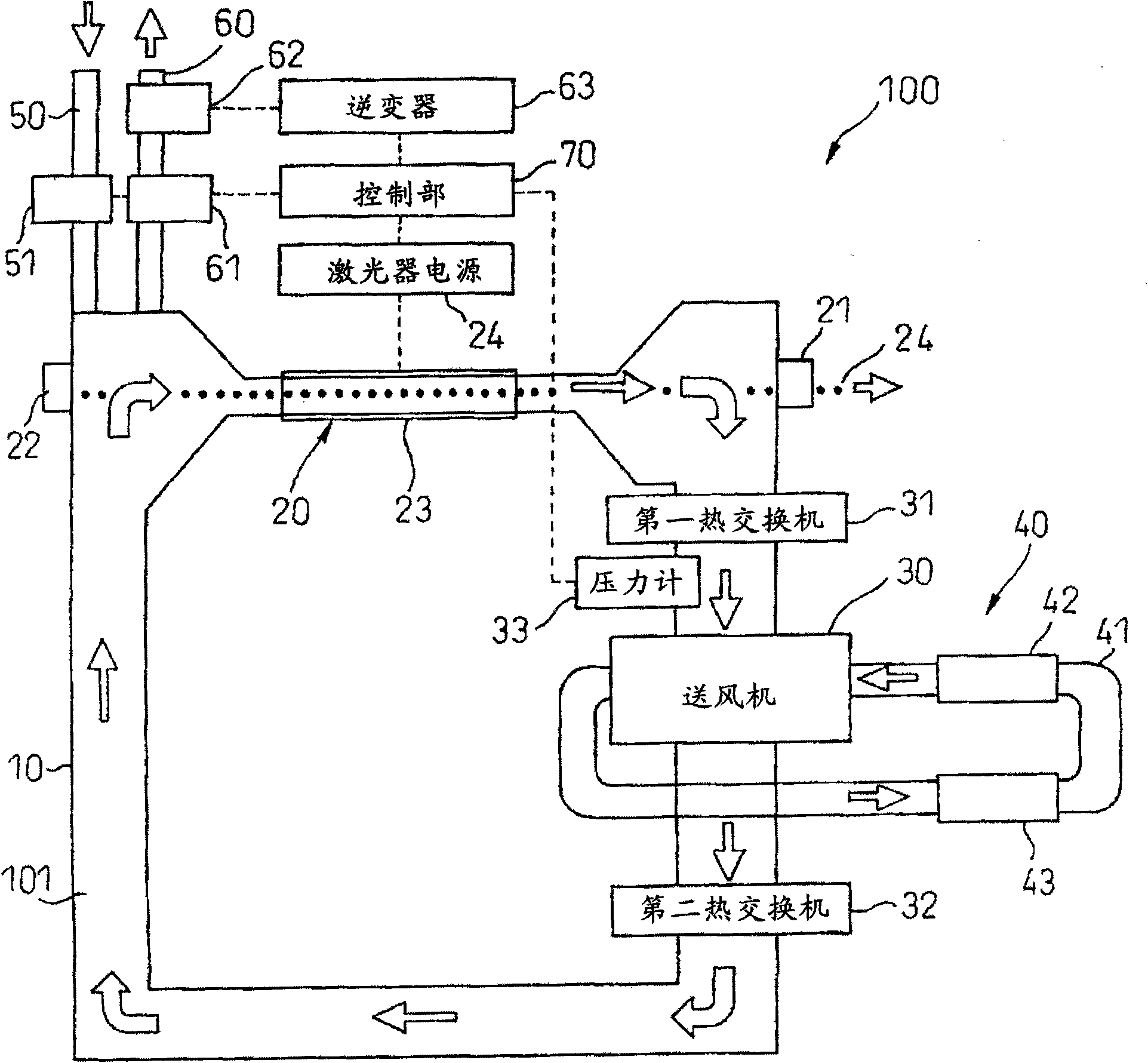

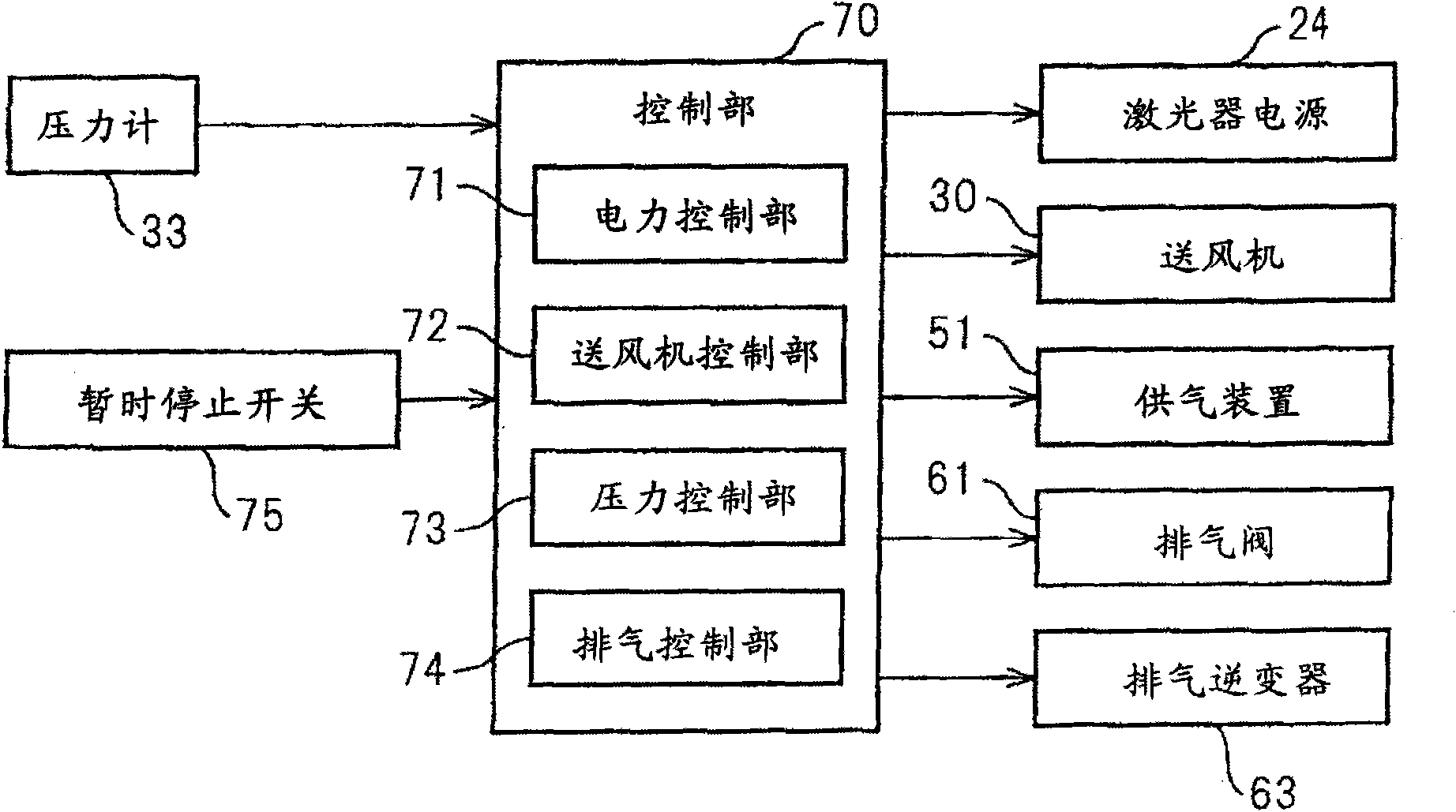

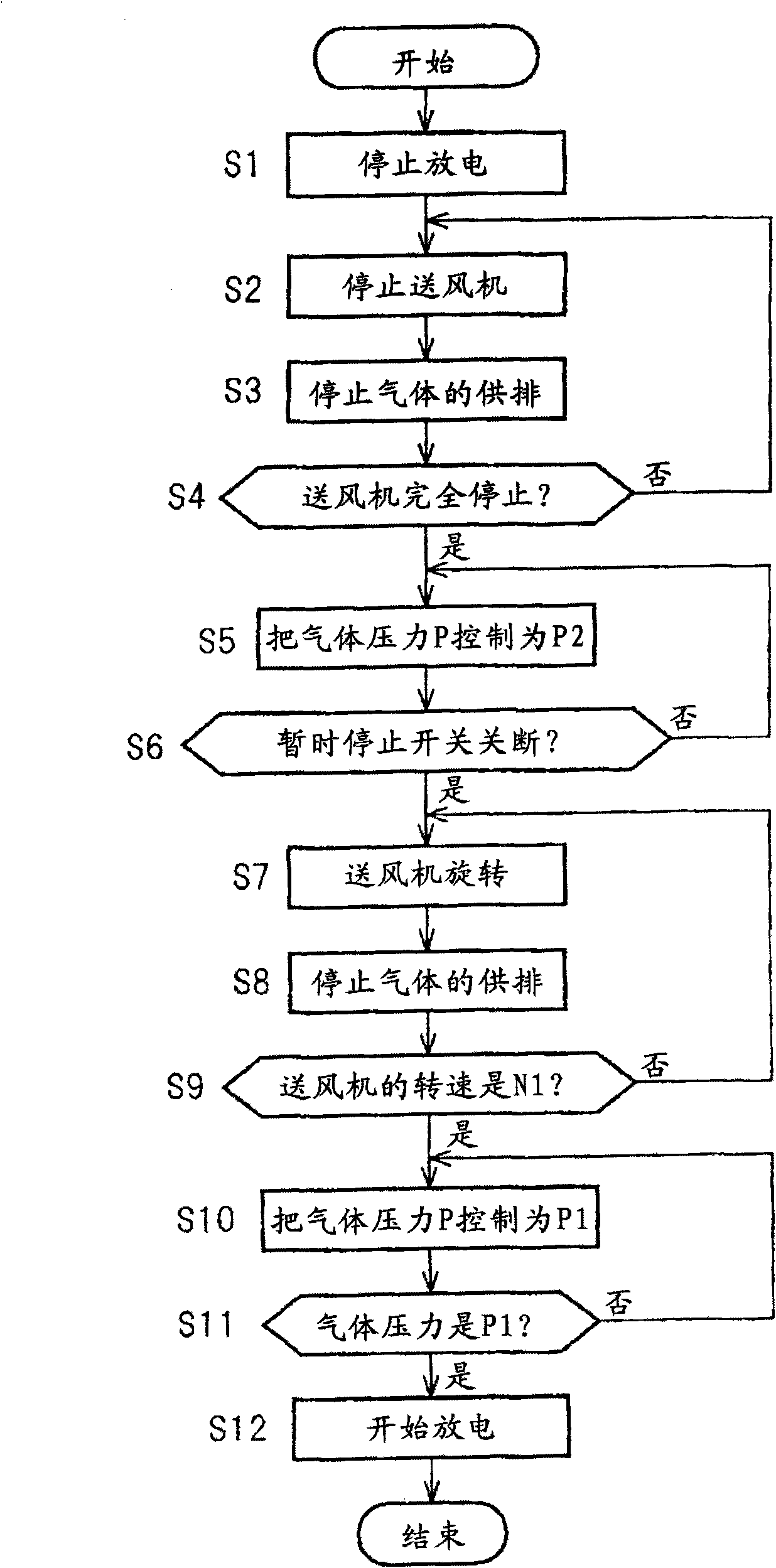

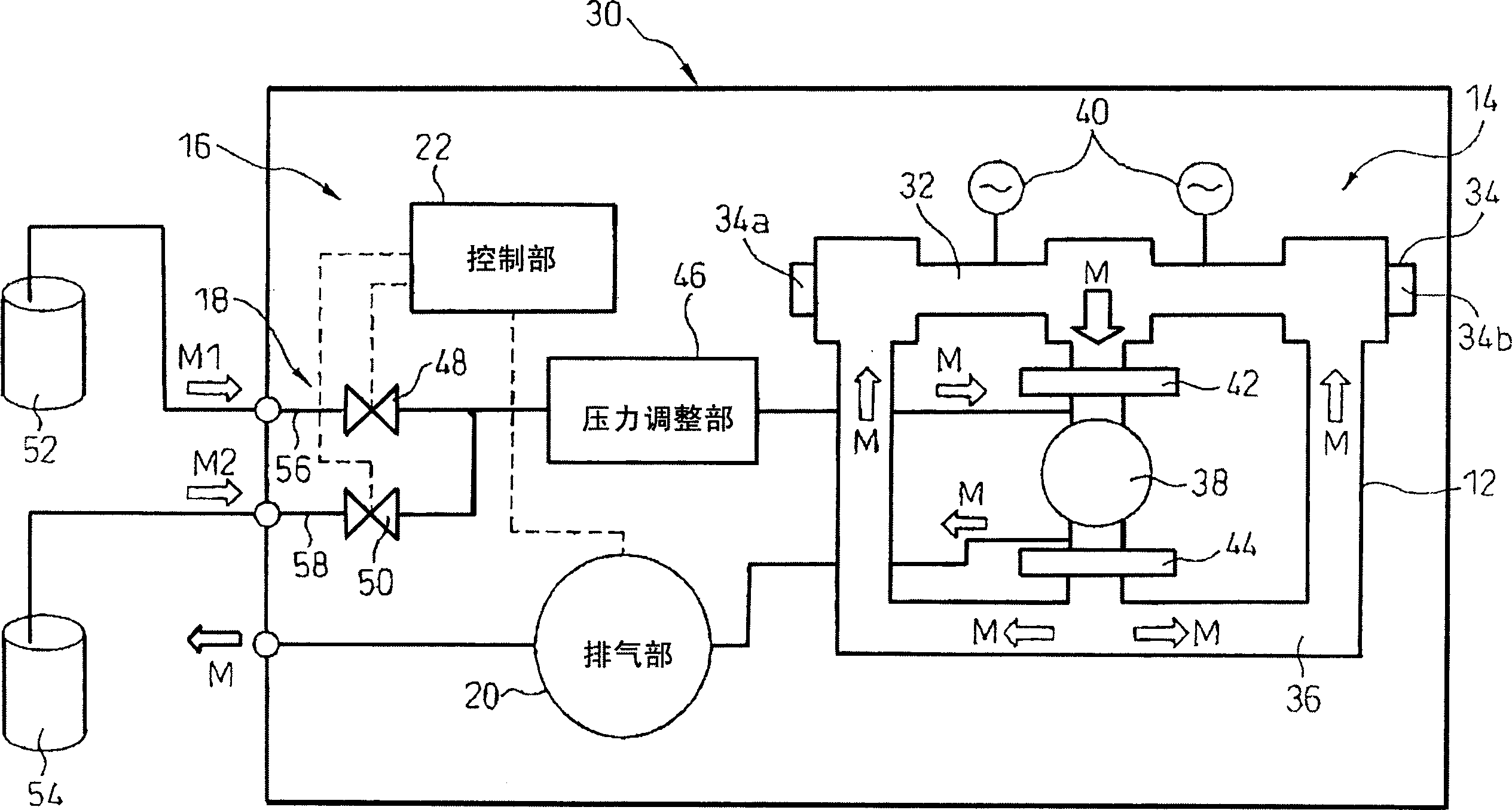

A gas laser device including a blower circulating a laser gas along a gas passage; a pressure detection section detecting a gas pressure of the laser gas in the gas passage; a gas supply and exhaust section supplying the laser gas to the gas passage and exhausting the laser gas from the gas passage; an instruction section instructing a temporary stop of a laser oscillation by a laser oscillator; and a control section controlling the blower and the gas supply and exhaust section in response to an instruction from the instruction section. The control section, before the instruction section instructs the temporary stop, controls the blower to rotate at a predetermined rotation number and controls the gas supply and exhaust section so that the gas pressure detected by the pressure detection section is a first target gas pressure and, once the instruction section instructs the temporary stop, controls the blower so as to reduce the rotation number of the blower or stop the rotation of the blower and controls the gas supply and exhaust section so that the gas pressure detected by the pressure detection section is a second target gas pressure corresponding to the first target gas pressure during the rotation of the blower.

Owner:FANUC LTD

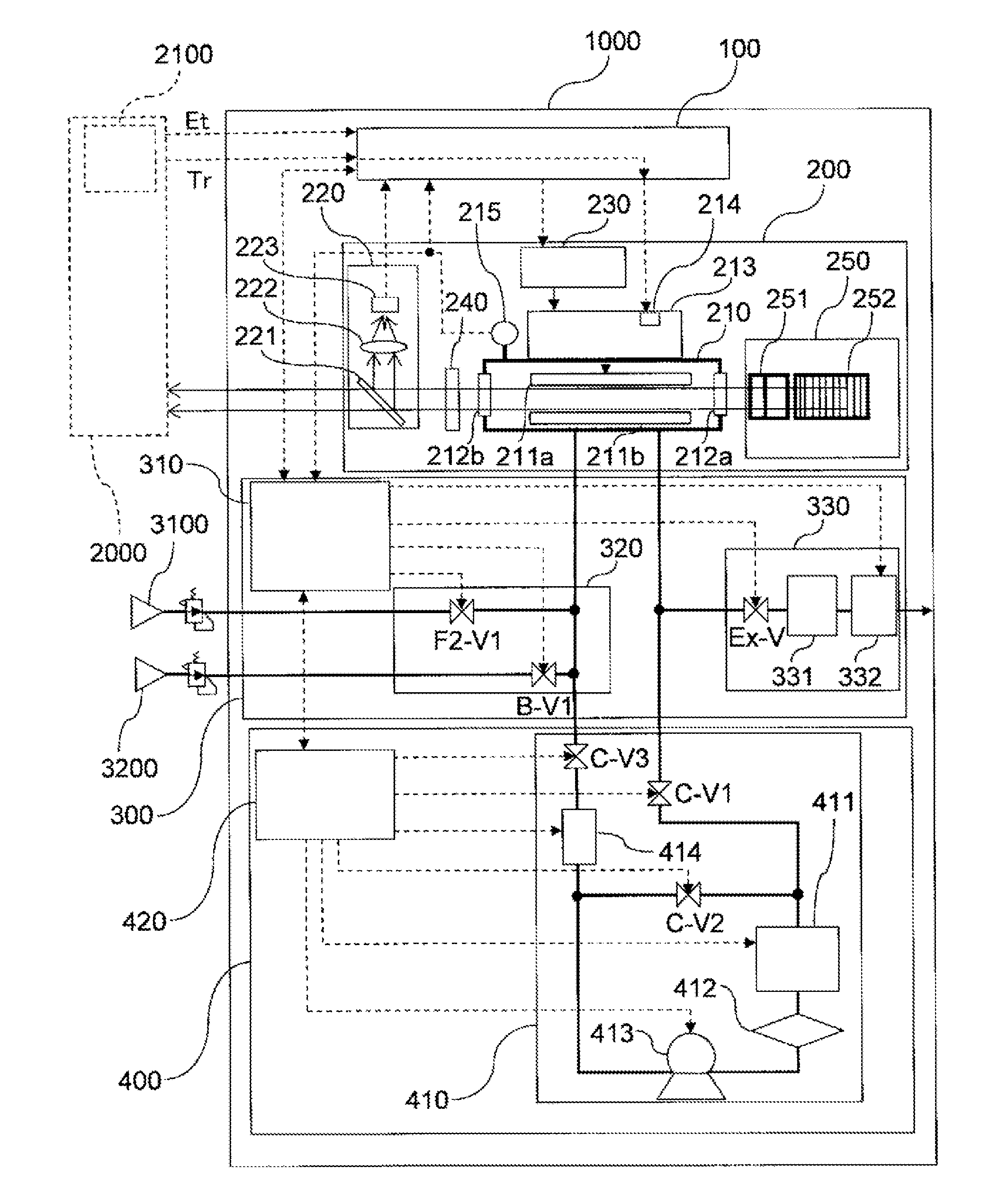

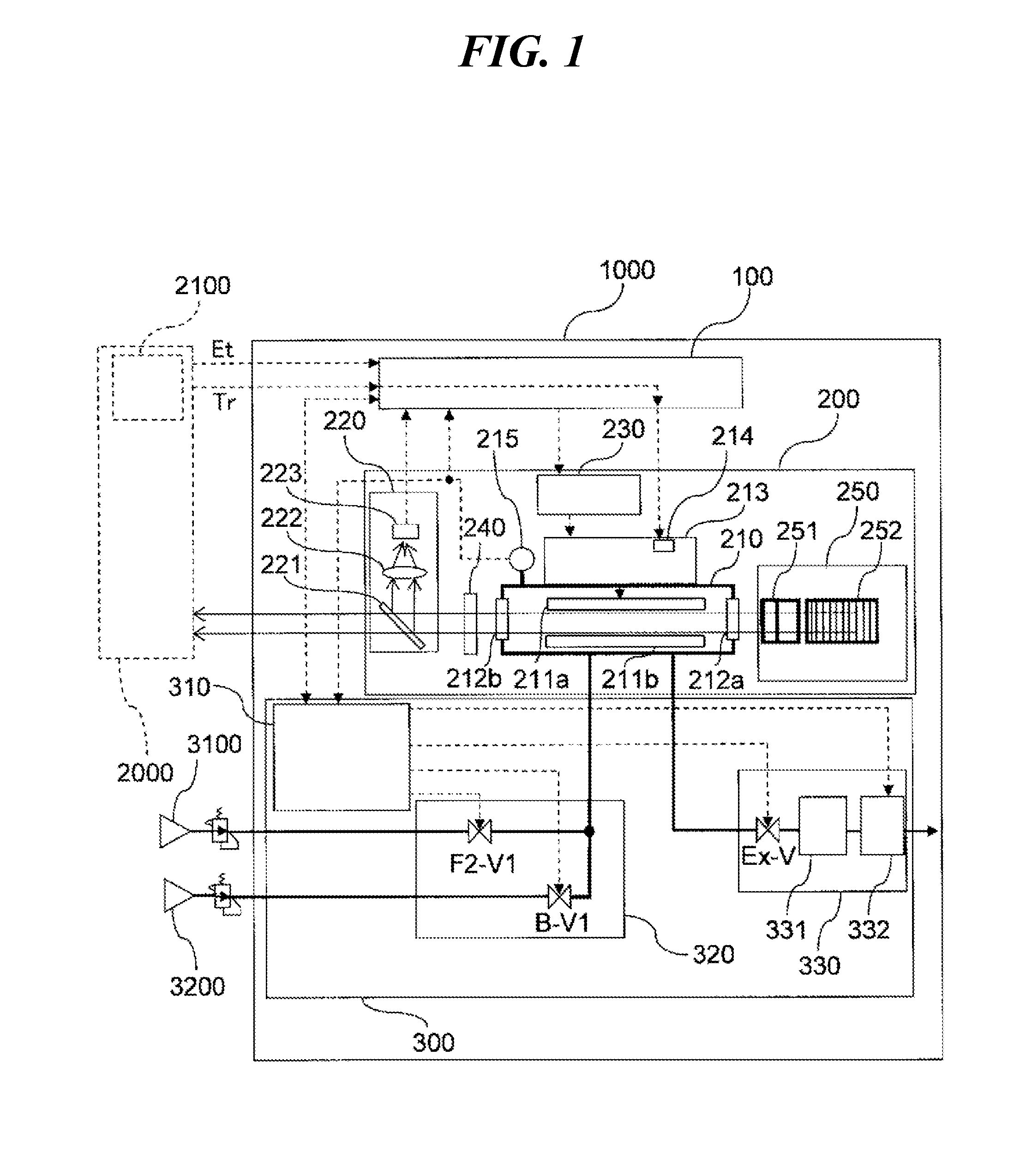

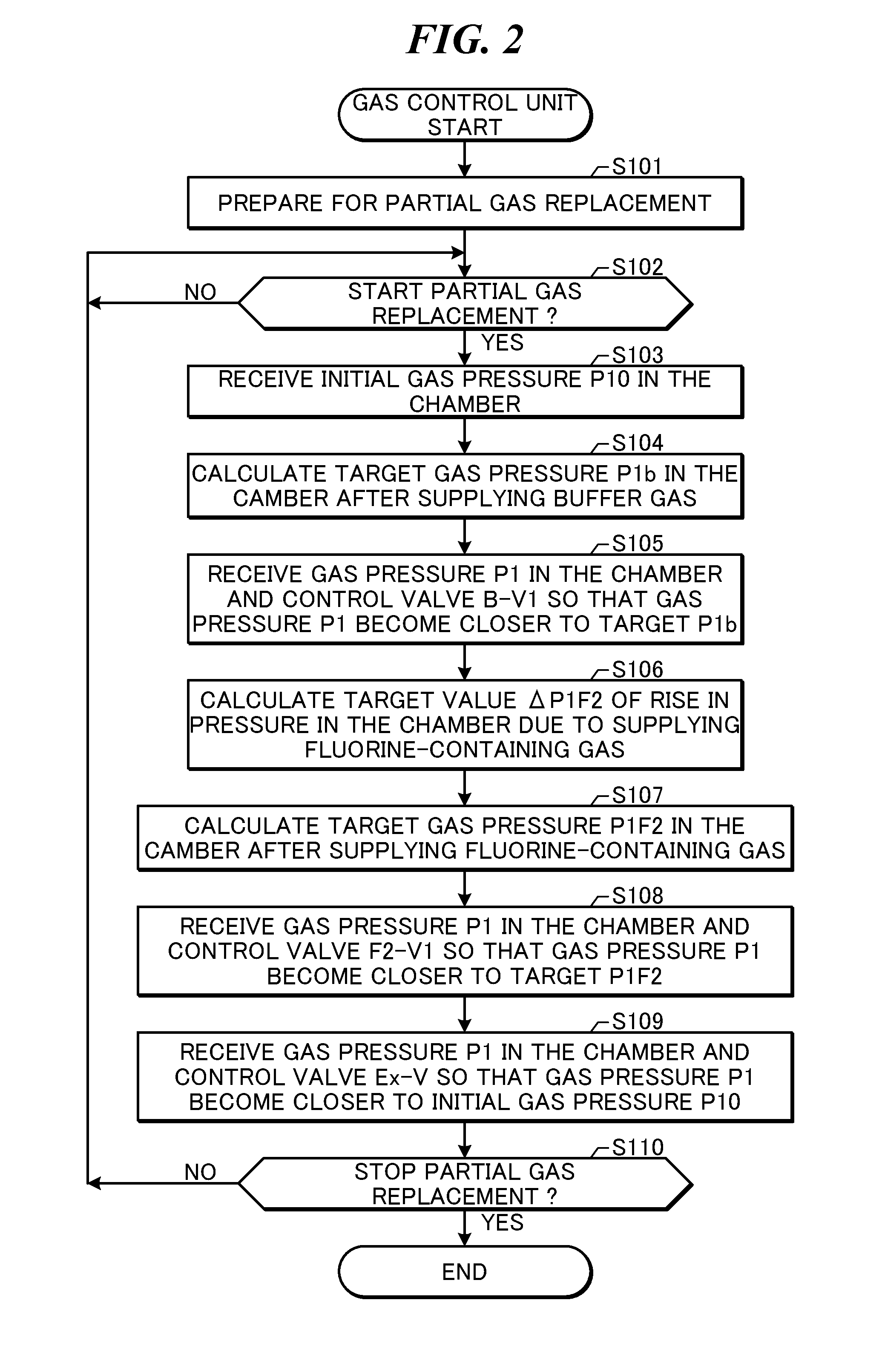

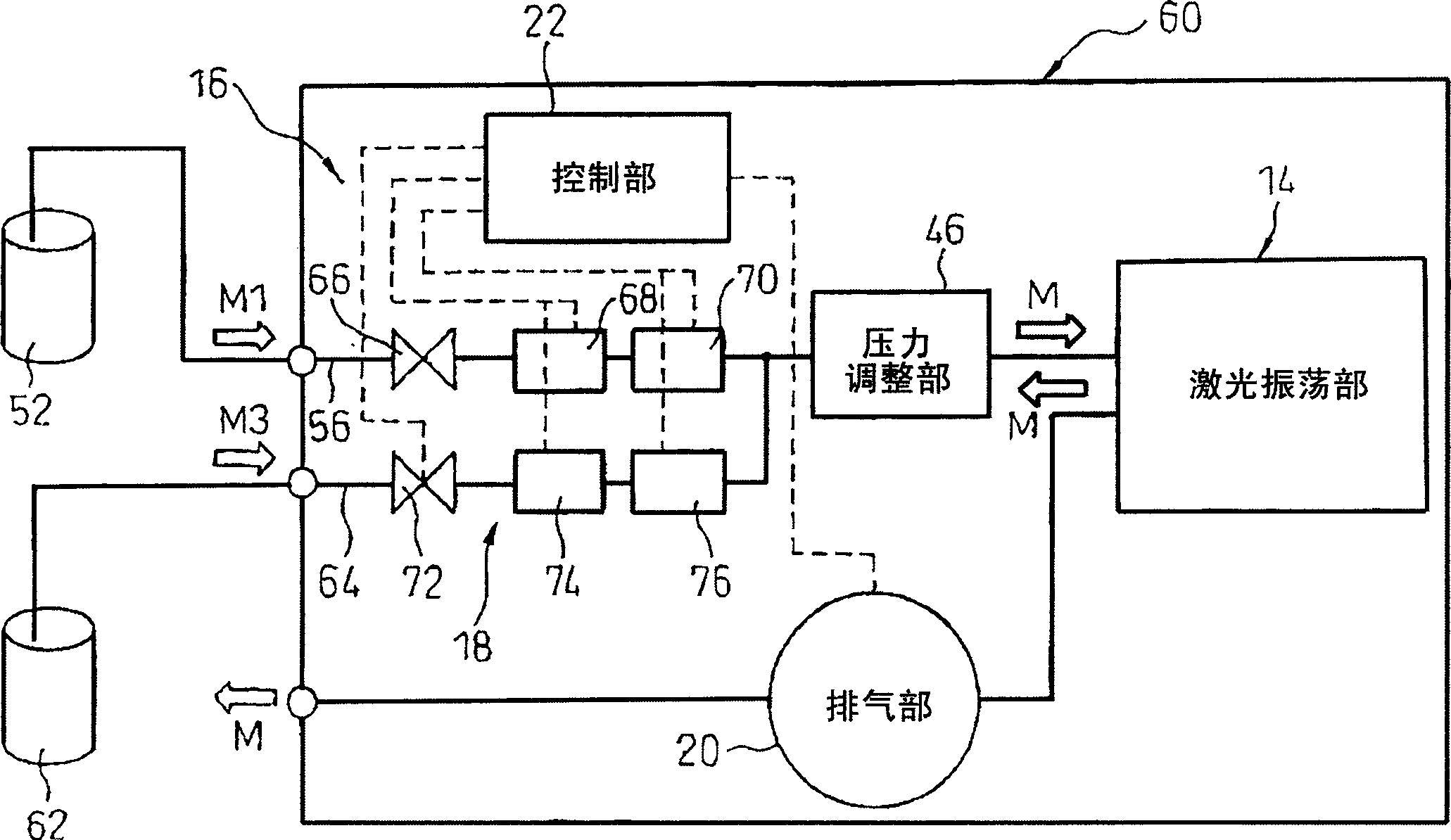

Gas laser apparatus

A gas laser apparatus may include: a laser chamber connected through a first control valve to a first laser gas supply source that supplies a first laser gas containing a halogen gas and connected through a second control valve to a second laser gas supply source that supplies a second laser gas having a lower halogen gas concentration than the first laser gas; a purification column that removes at least a part of the halogen gas and a halogen compound from at least a part of a gas exhausted from the laser chamber; a booster pump, connected through a third control valve to the laser chamber, which raises a pressure of a gas having passed through the purification column to a gas pressure that is higher than an operating gas pressure of the laser chamber; and a controller that calculates, on a basis of a first amount of a gas supplied from the booster pump through the third control valve to the laser chamber, a second amount of the first laser gas that is to be supplied to the laser chamber and controls the first control valve on a basis of a result of the calculation of the second amount.

Owner:GIGAPHOTON

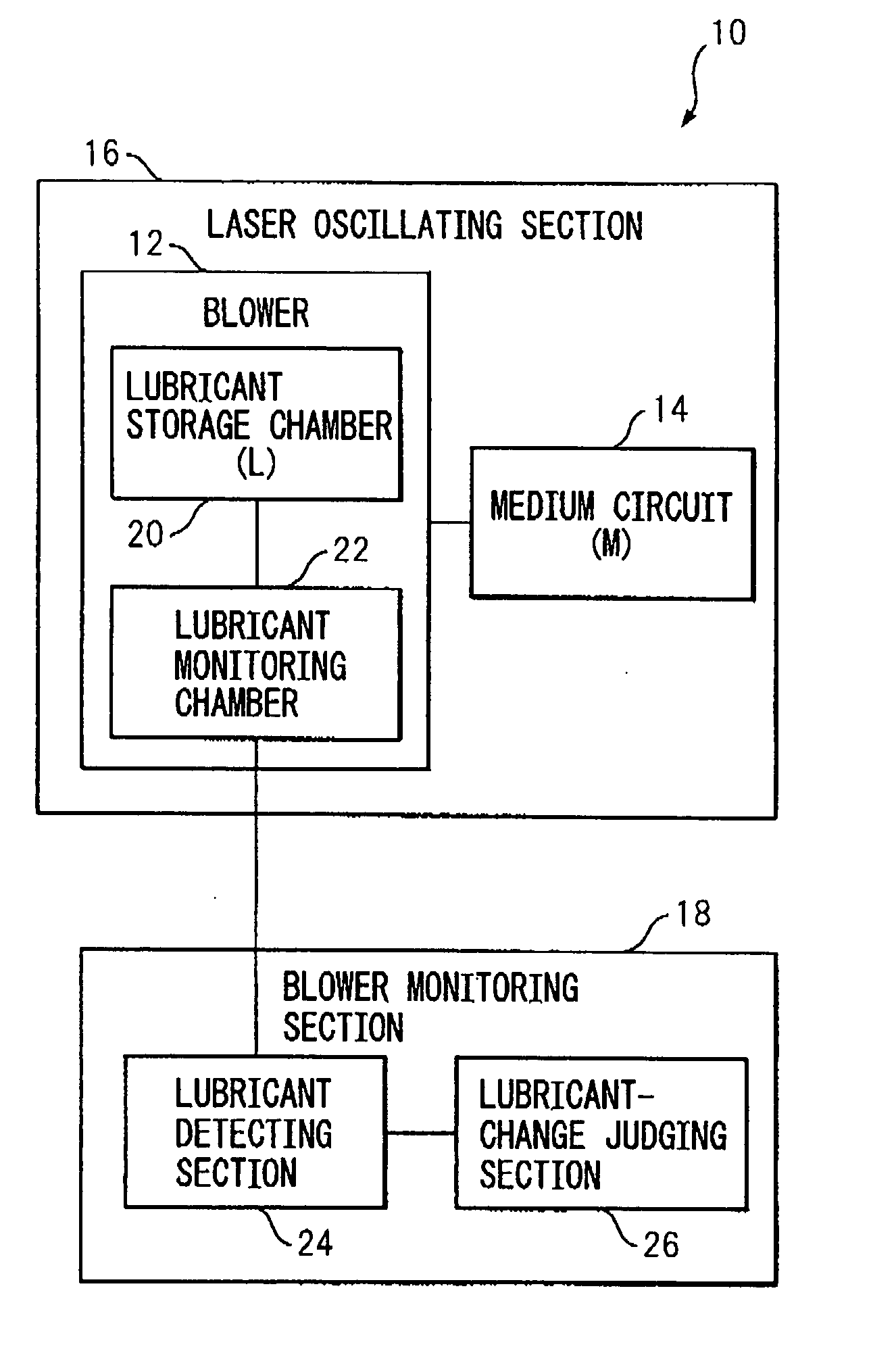

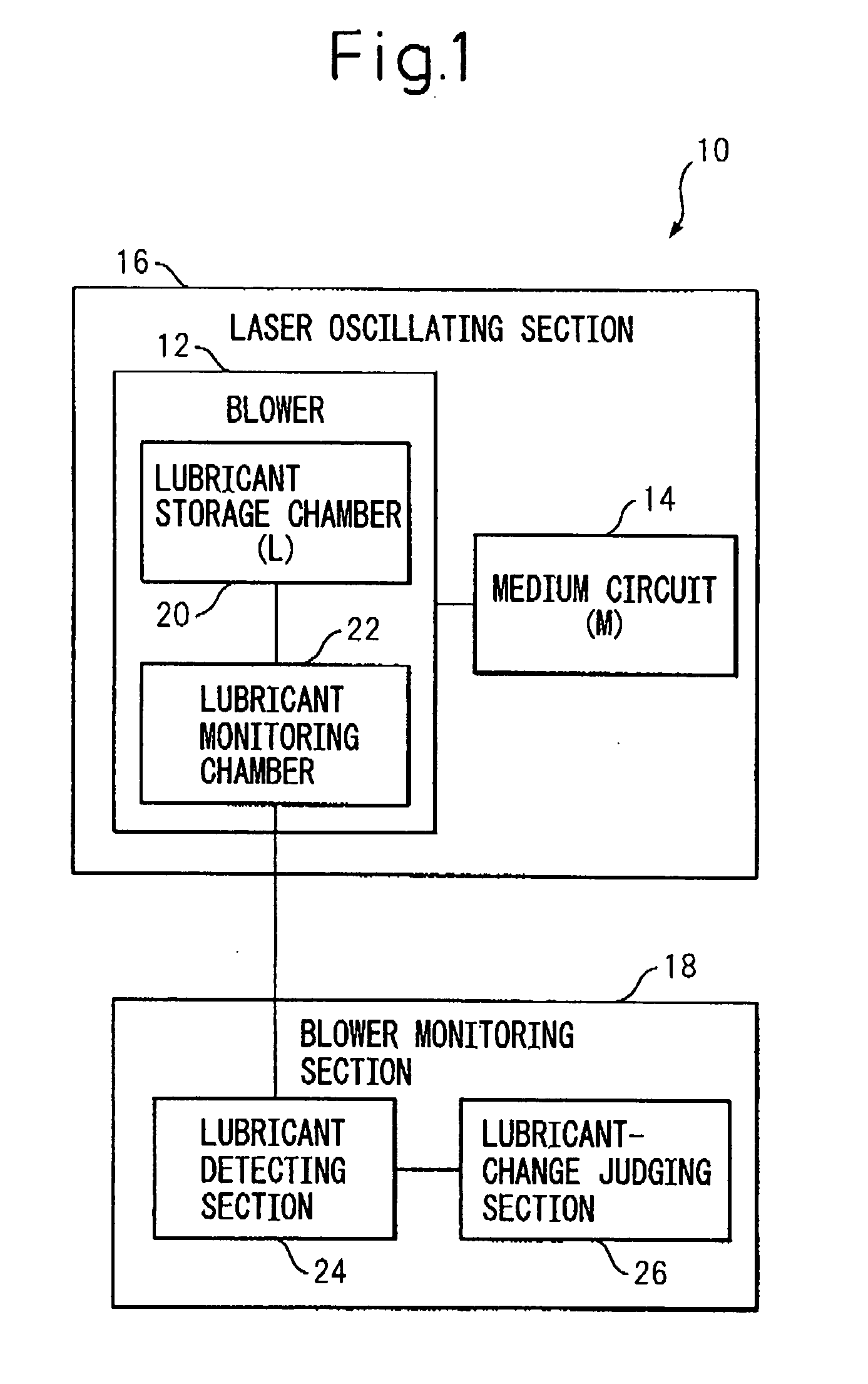

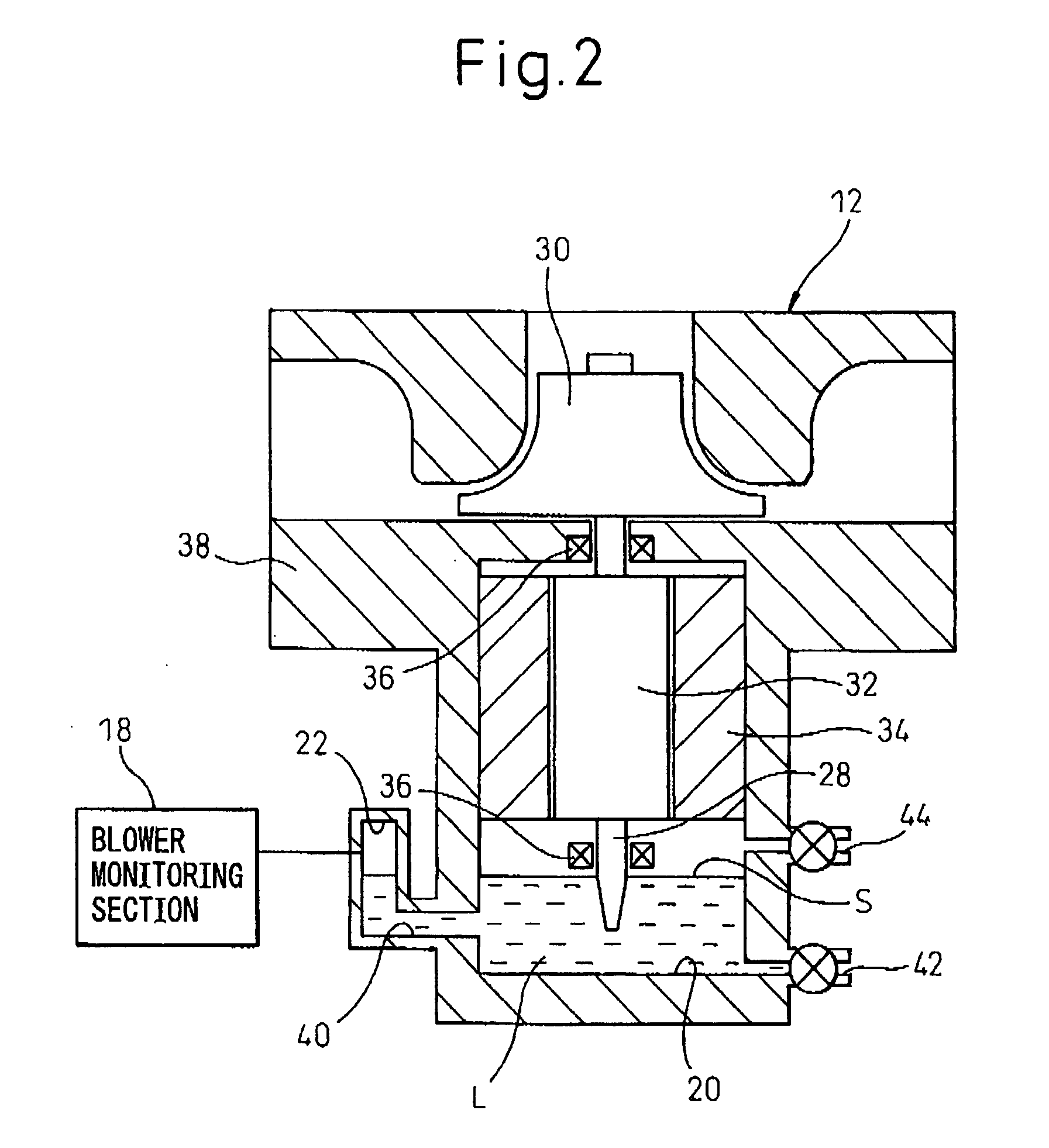

Gas laser apparatus, and method and device for monitoring blower

InactiveUS20080056325A1Reduce the burden onEliminate riskActive medium materialPump controlInternal pressureGas laser device

A gas laser apparatus including a laser oscillating section including a blower forcibly circulating a medium gas in a medium circuit, and a blower monitoring section monitoring a maintenance state of the blower. The blower includes a lubricant storage chamber storing a lubricant, and a lubricant monitoring chamber connected to the lubricant storage chamber to ensure fluidic communication therebetween at a position lower than an oil level of a lubricant having a predetermined appropriate volume and stored in the lubricant storage chamber. The blower monitoring section includes a lubricant detecting section detecting that a lubricant stored in the lubricant storage chamber of the blower flows into the lubricant monitoring chamber and at least a part of the lubricant is present in the lubricant monitoring chamber, as a result of internal-pressure change in the lubricant storage chamber, and a lubricant-change judging section monitoring whether the lubricant detecting section detects a presence of the lubricant in the lubricant monitoring chamber, before the laser oscillating section is activated, and judging that, when the lubricant detecting section does not detect the presence, the lubricant stored in the lubricant storage chamber is in a state immediately after a lubricant change.

Owner:FANUC LTD

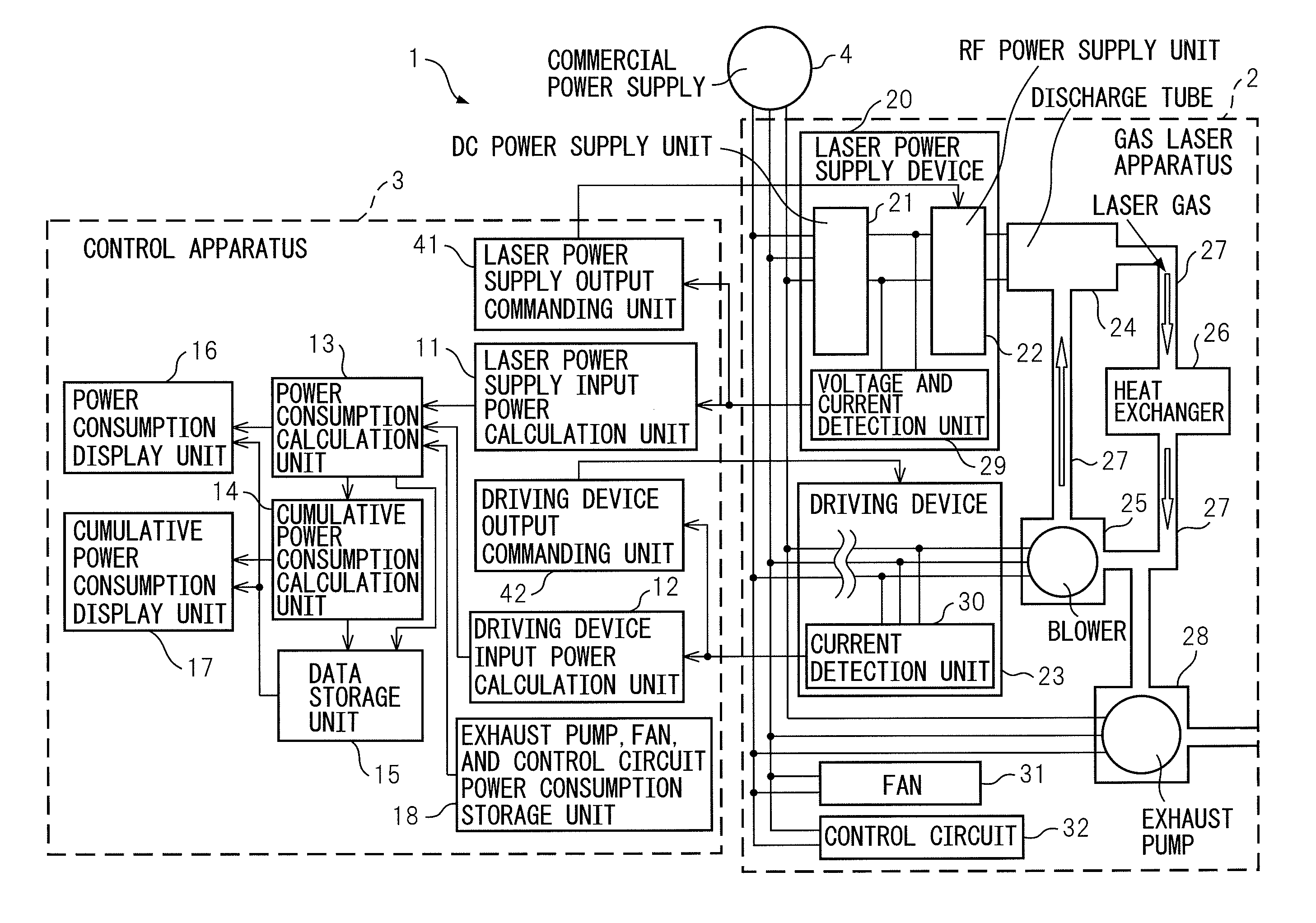

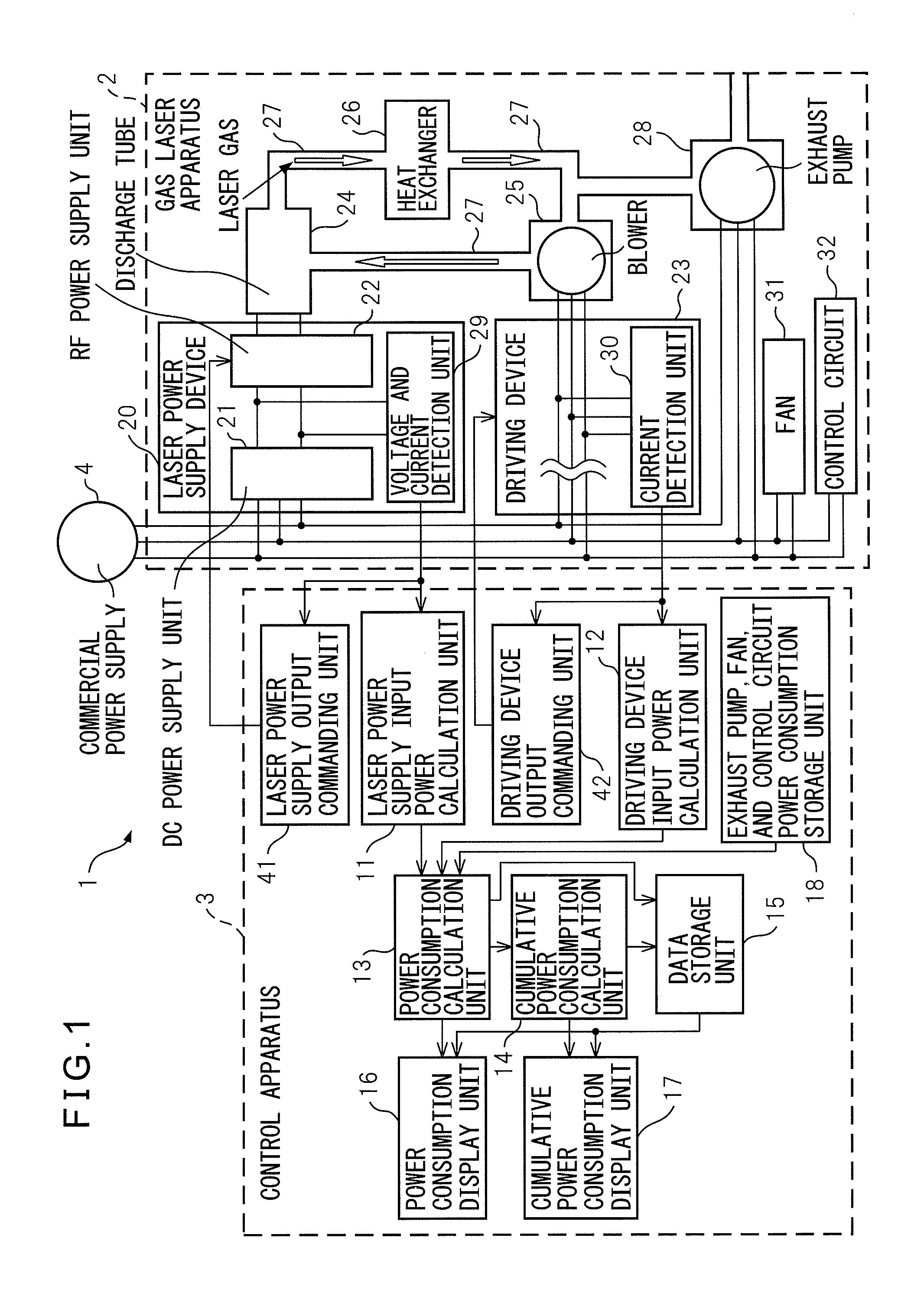

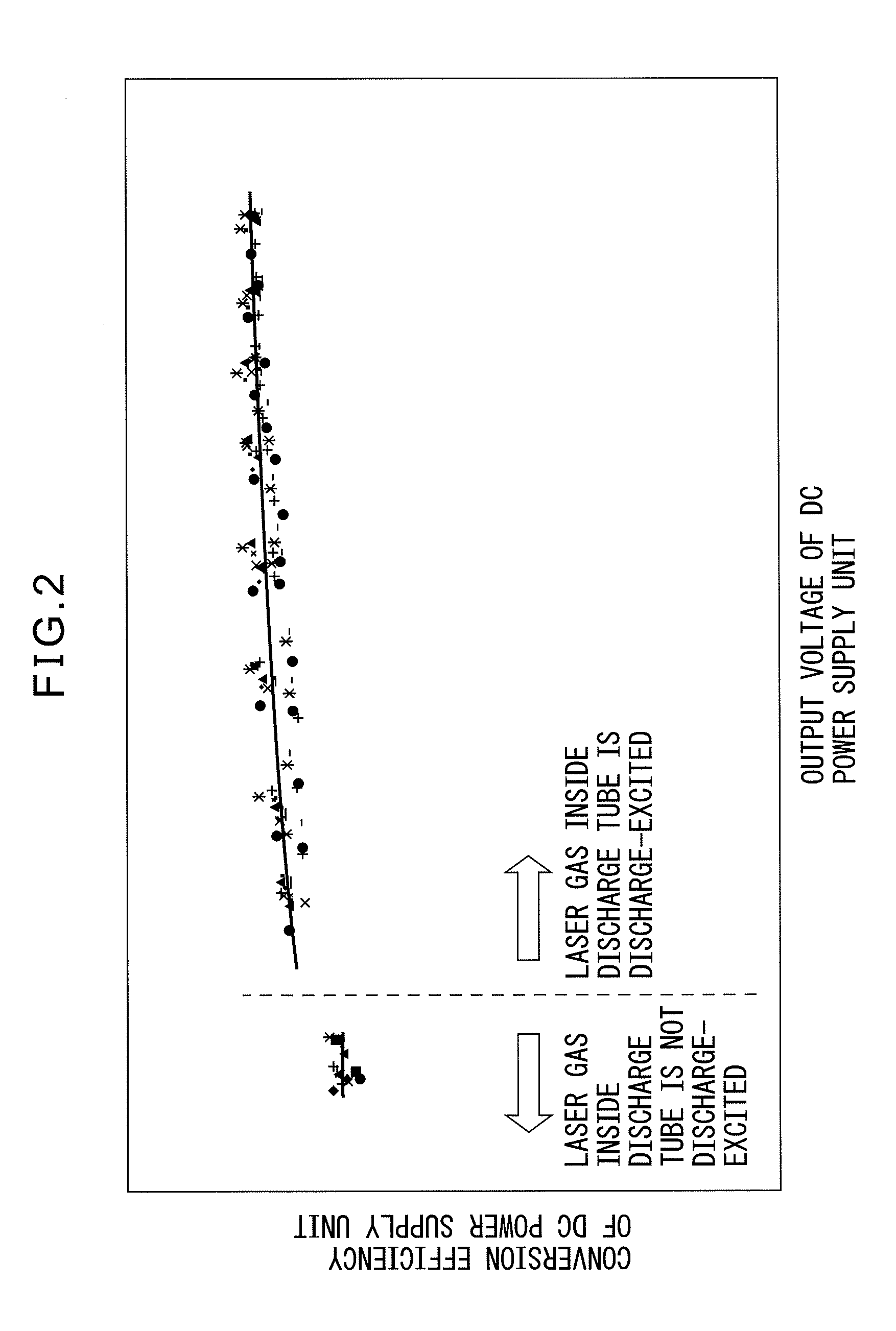

Gas laser apparatus equipped with power calculation unit

ActiveUS20130039377A1Simple and accurate measurementConsuming operationActive medium materialLaser monitoring arrangementsGas laser deviceEngineering

Disclosed is a gas laser apparatus having: a first estimation unit which calculates an estimate of input power to the laser power supply device by using the output current value and output voltage value of the DC power supply unit and also using the efficiency of conversion from input power to output power by the DC power supply unit; a second estimation unit which calculates an estimate of input power to the driving device by using the output current value of the driving device; and a power calculation unit which calculates the power consumption value of the gas laser apparatus, based on the estimate of the input power to the laser power supply device and the estimate of the input power to the driving device.

Owner:FANUC LTD

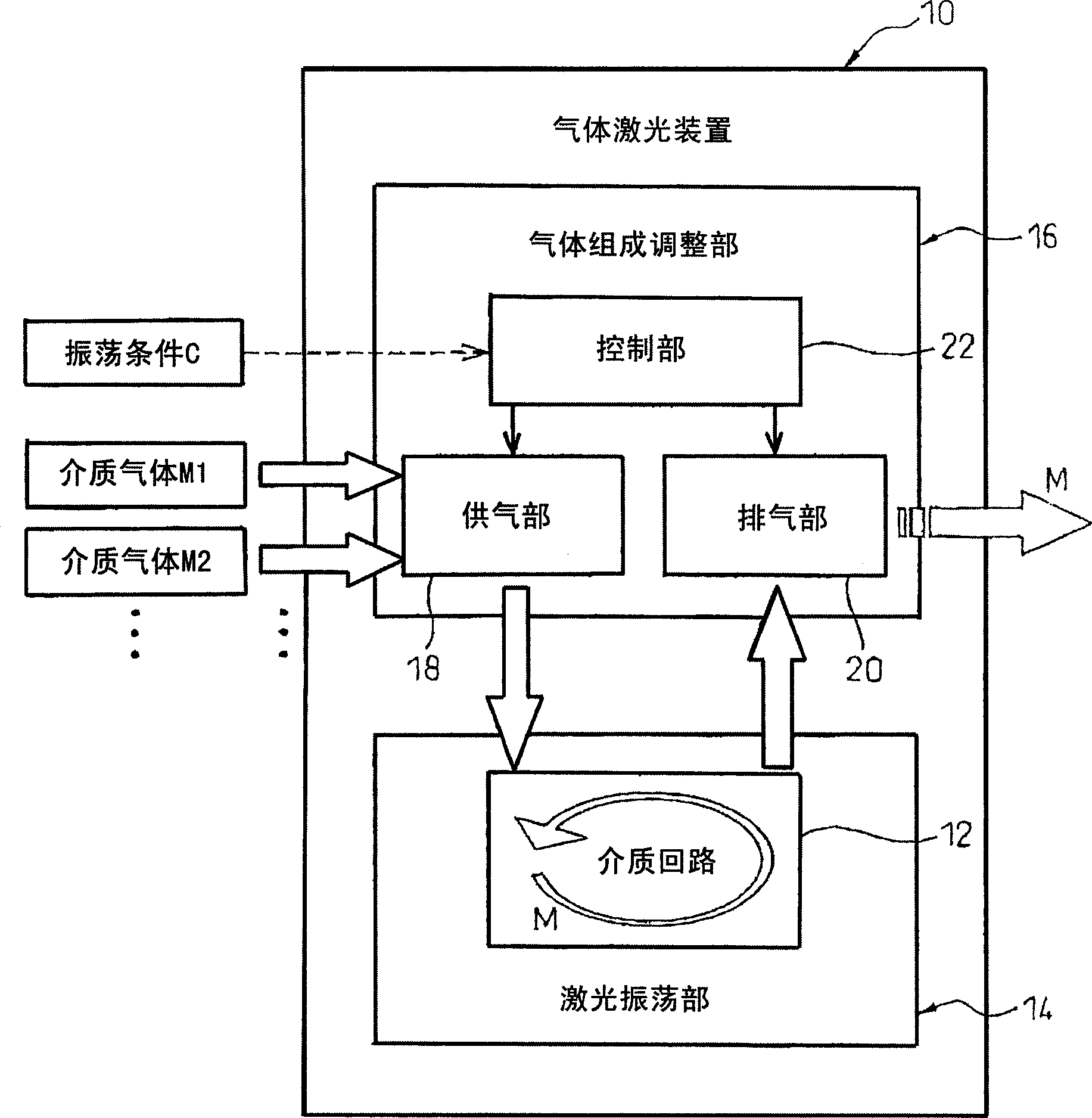

Gas laser apparatus

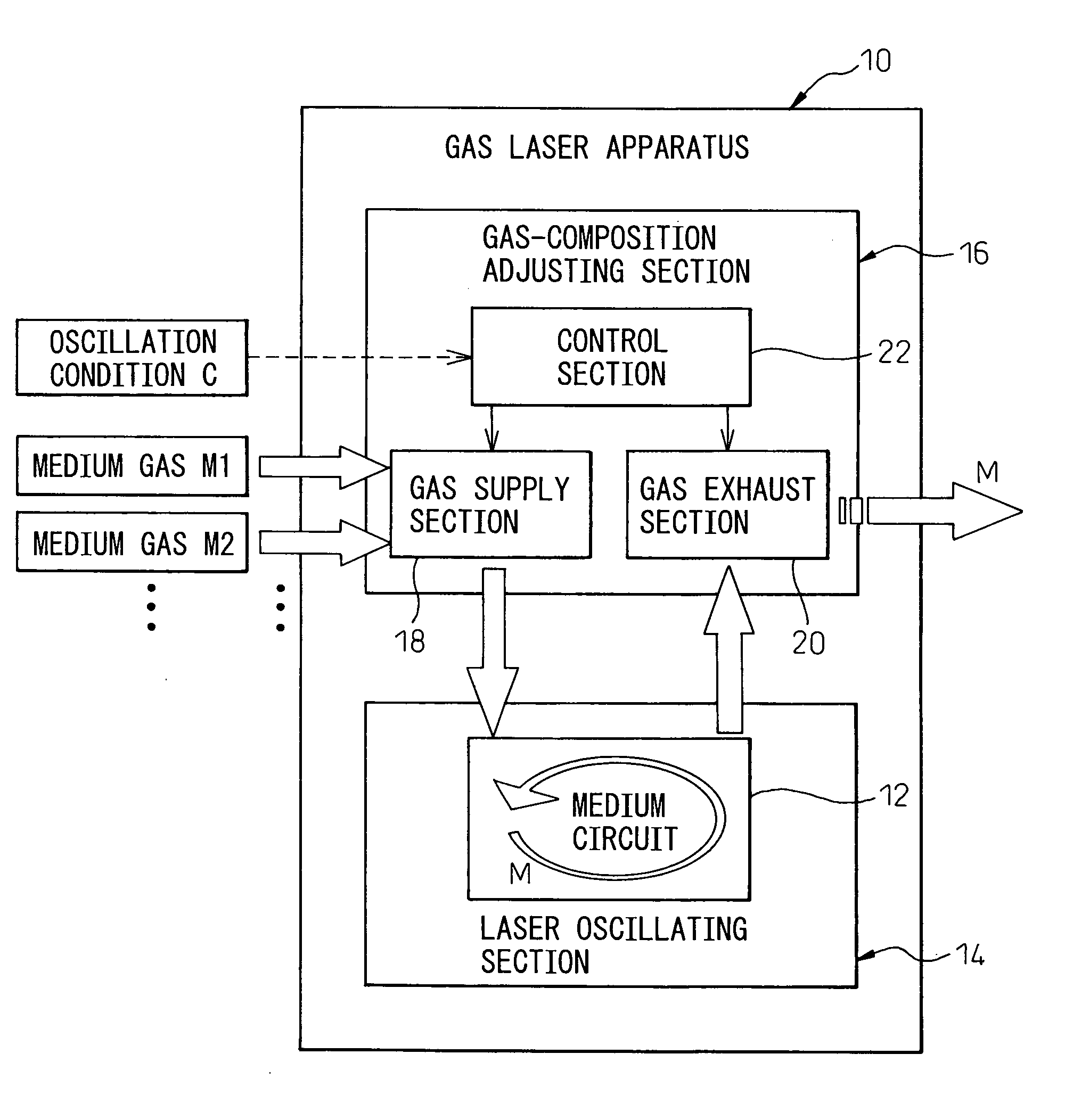

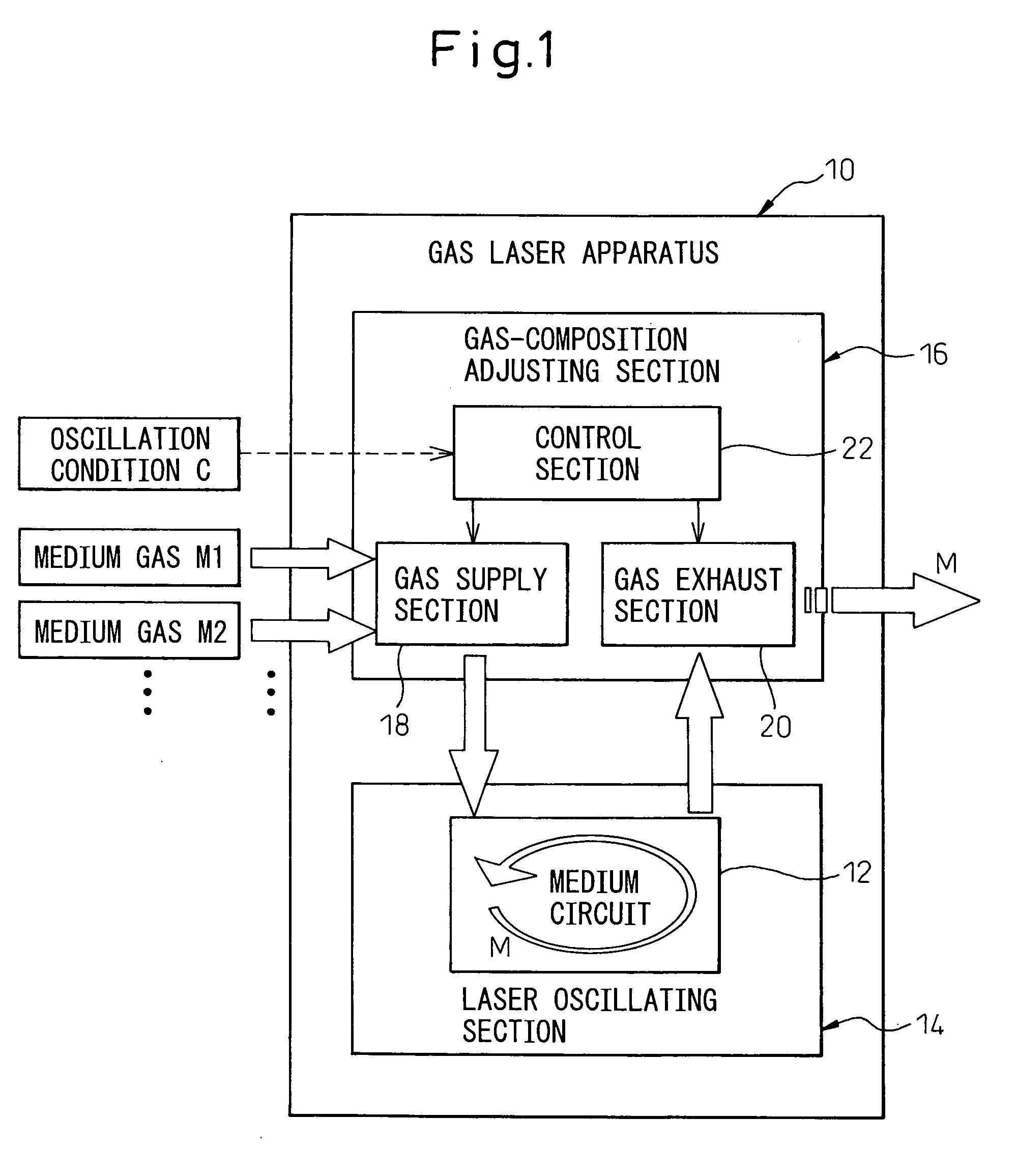

A gas laser apparatus including a laser oscillating section including a medium circuit allowing a medium gas to flow therethrough under pressure, and a gas-composition adjusting section for adjusting the composition of the medium gas flowing through the medium circuit of the laser oscillating section. The gas-composition adjusting section comprising a gas supply section for supplying several types of medium gases having different compositions to the medium circuit of the laser oscillating section with a flow rate of each of the medium gases being adjustable; a gas exhaust section for exhausting the medium gas from the medium circuit of the laser oscillating section; and a control section for controlling the gas supply section and the gas exhaust section, to adjust the composition of the medium gas flowing through the medium circuit, in accordance with an oscillation condition including at least one of an attribute of an object matter acted on by a laser beam oscillated by the laser oscillating section and the accuracy of action of the laser beam.

Owner:FANUC LTD

Optical element for gas laser and gas laser apparatus using the same

ActiveUS20100054297A1Reduce surface roughnessAvoid surface damageOptical resonator shape and constructionActive medium materialExit planeGas laser device

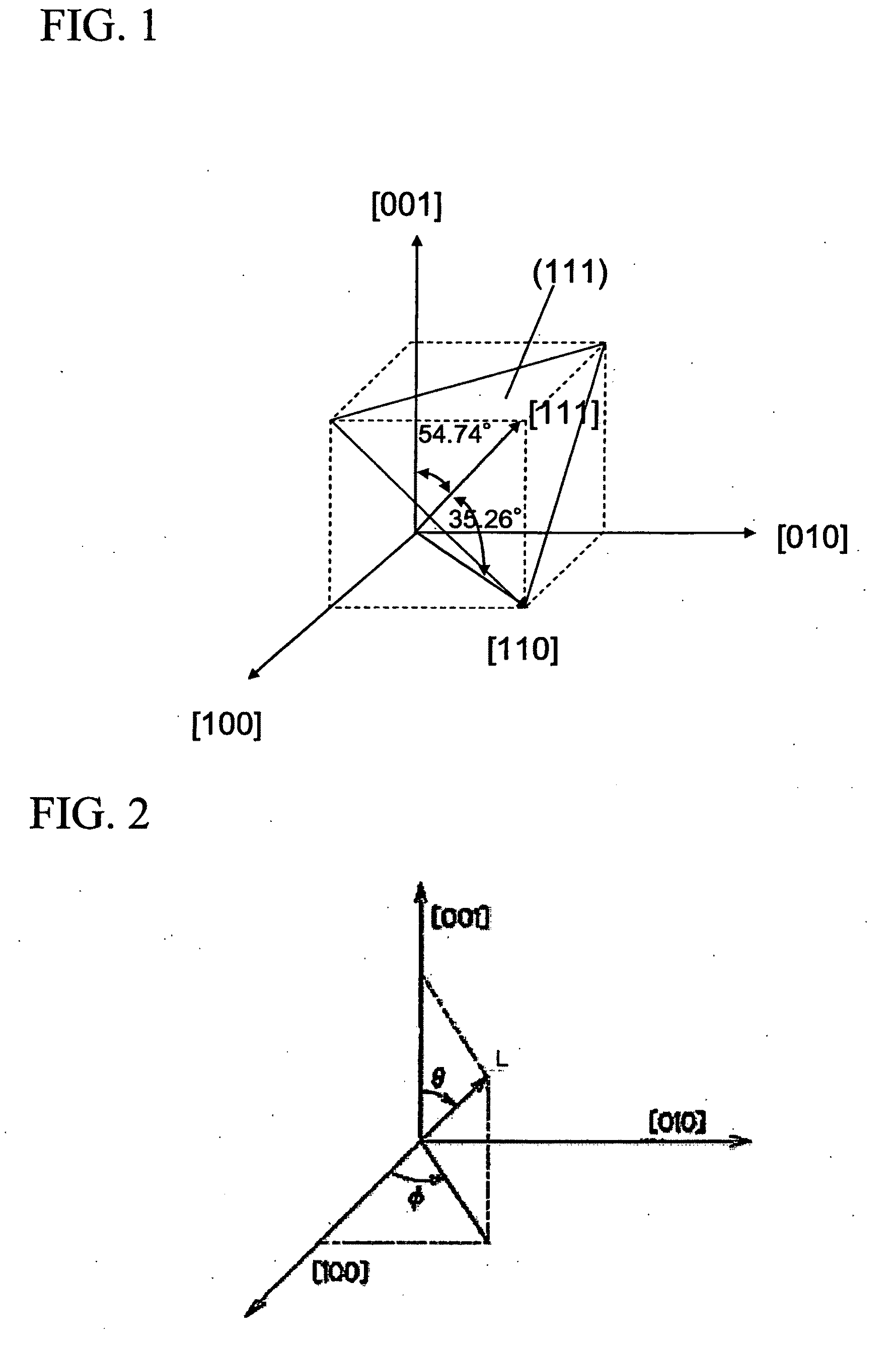

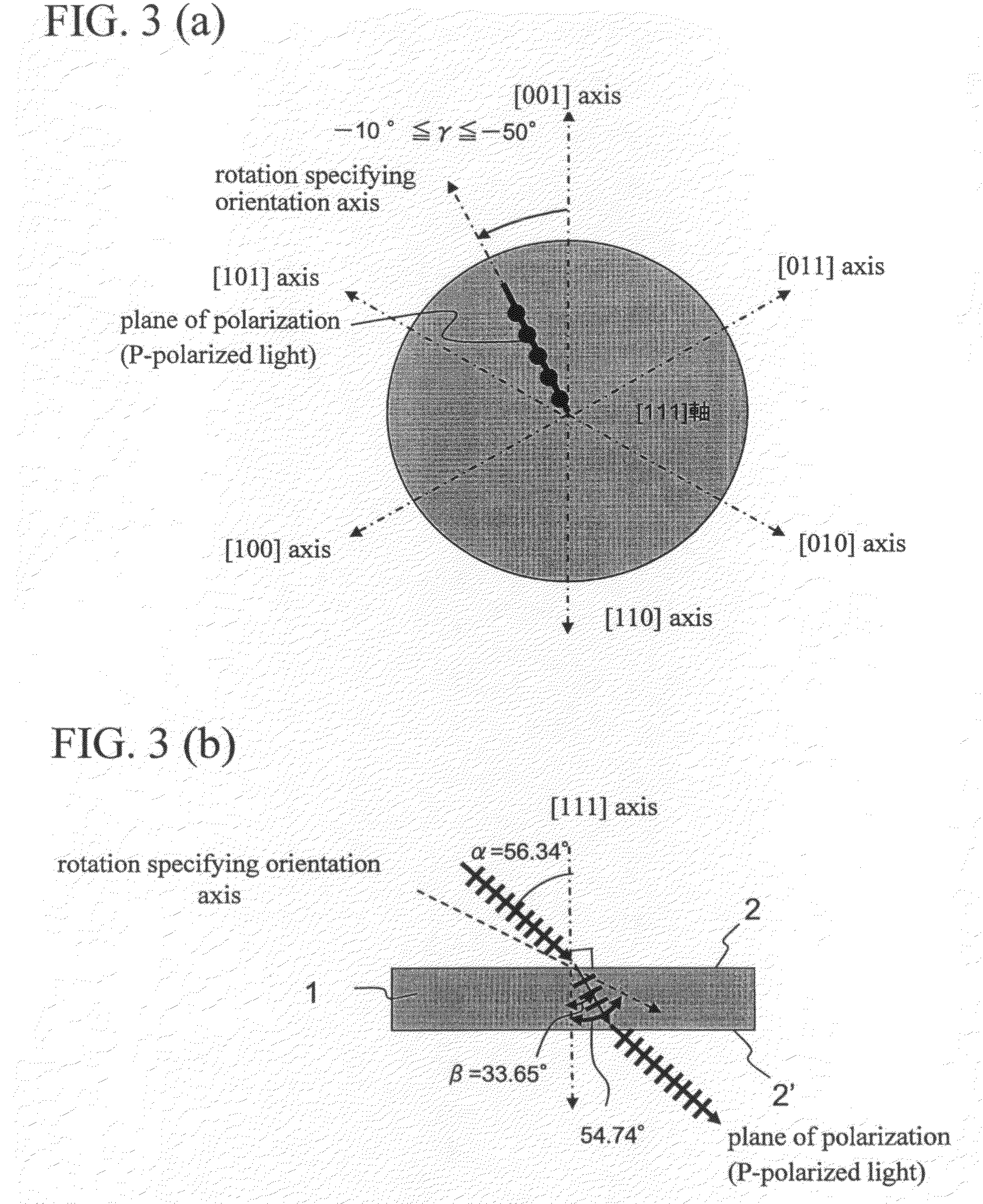

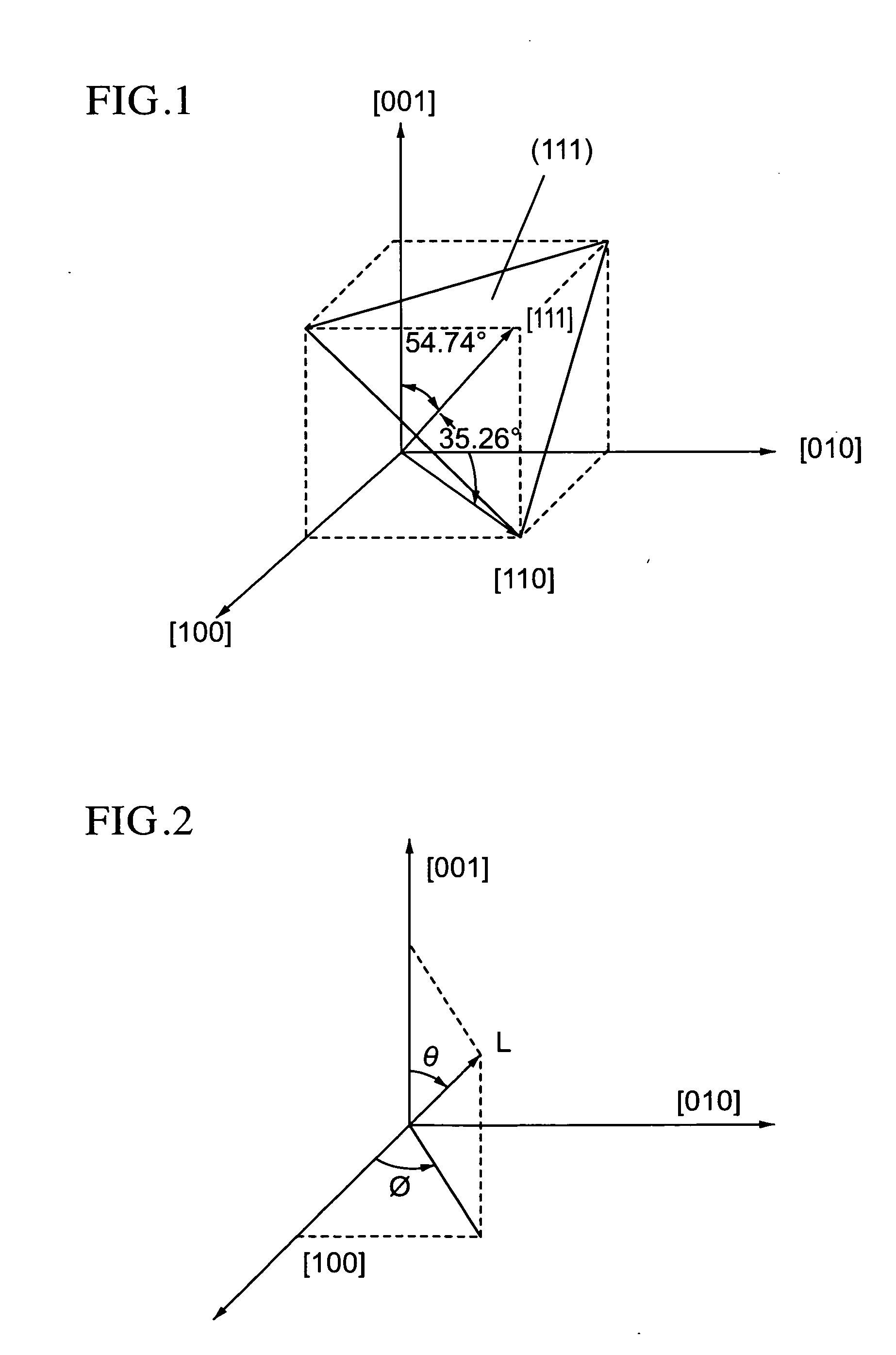

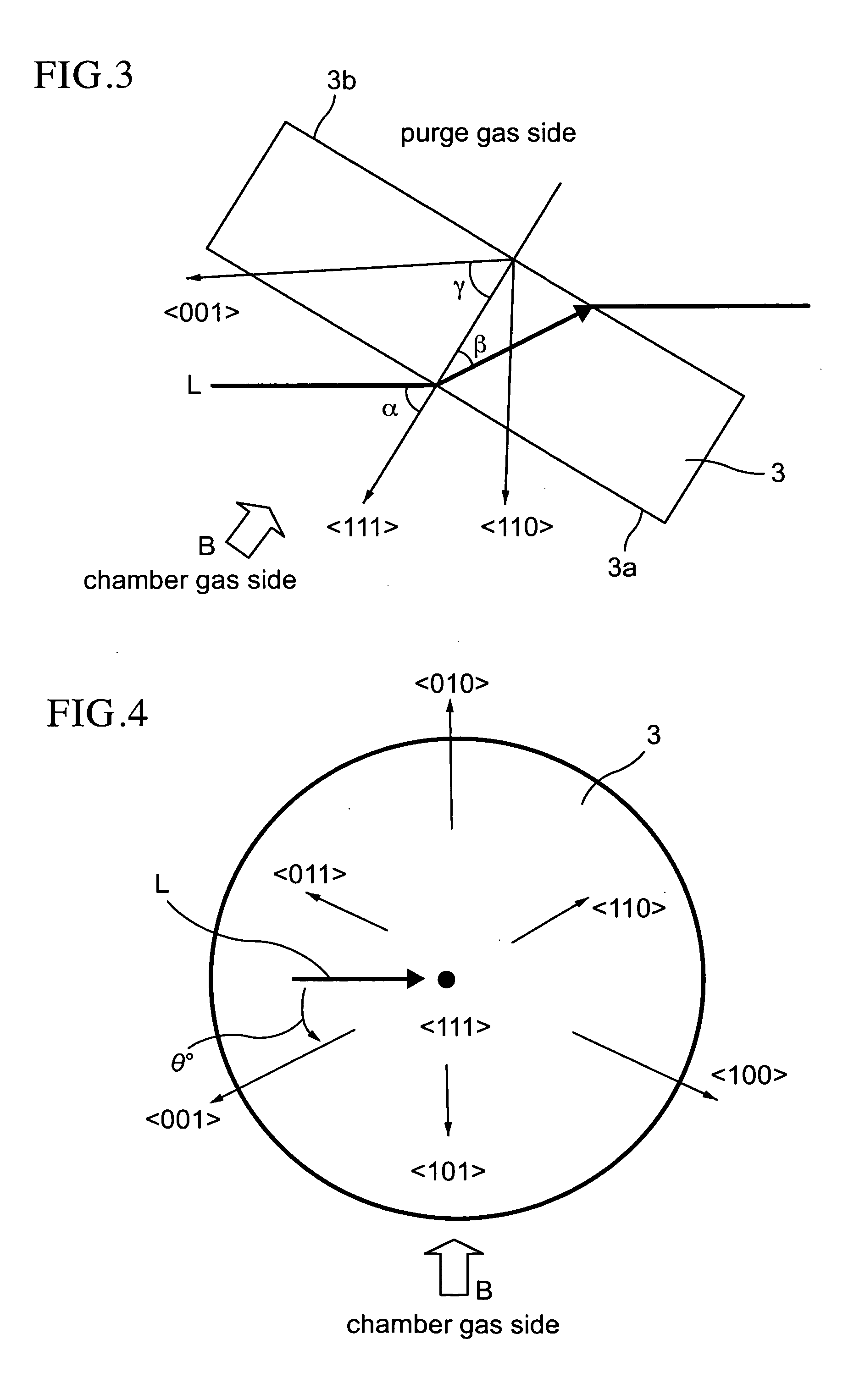

At least either of the light entering plane or the light exiting plane is parallel to the (111) crystal face of the CaF2 crystal and the laser beam entering from the entering plane passes through the plane located between the [111] axis and the first azimuth axis in the locus of rotation of the [001] axis around the [111] axis and including the [111] axis and the first azimuth axis, the plane located between the [111] axis and the second azimuth axis in the locus of rotation of the [010] axis around the [111] axis and including the [111] axis and the second azimuth axis or the plane located between the [111] axis and the third azimuth axis in the locus of rotation of the [100] axis around the [111] axis and including the [111] axis and the third azimuth axis and exits from the exiting plane.

Owner:GIGAPHOTON

Laser device and laser system

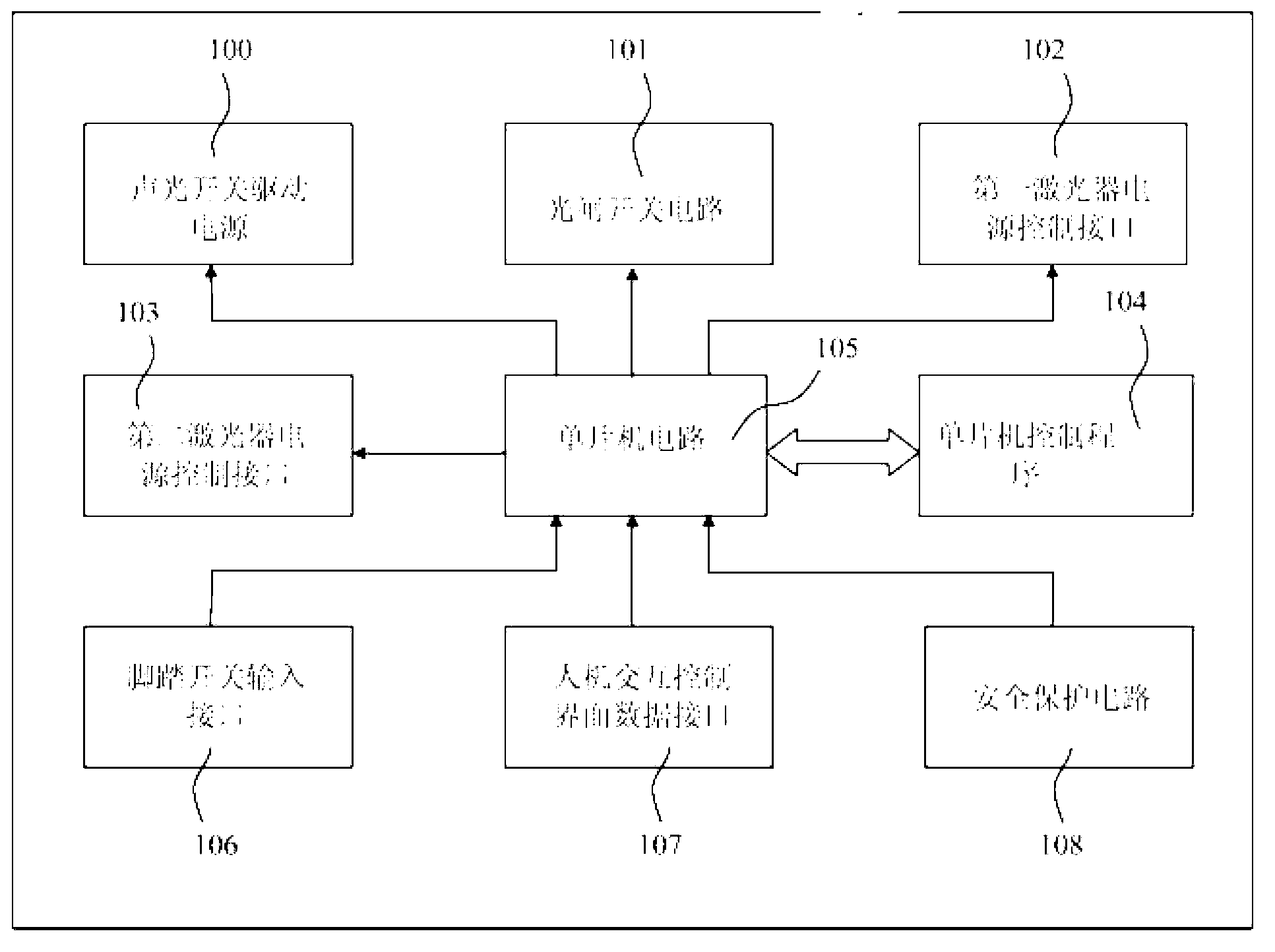

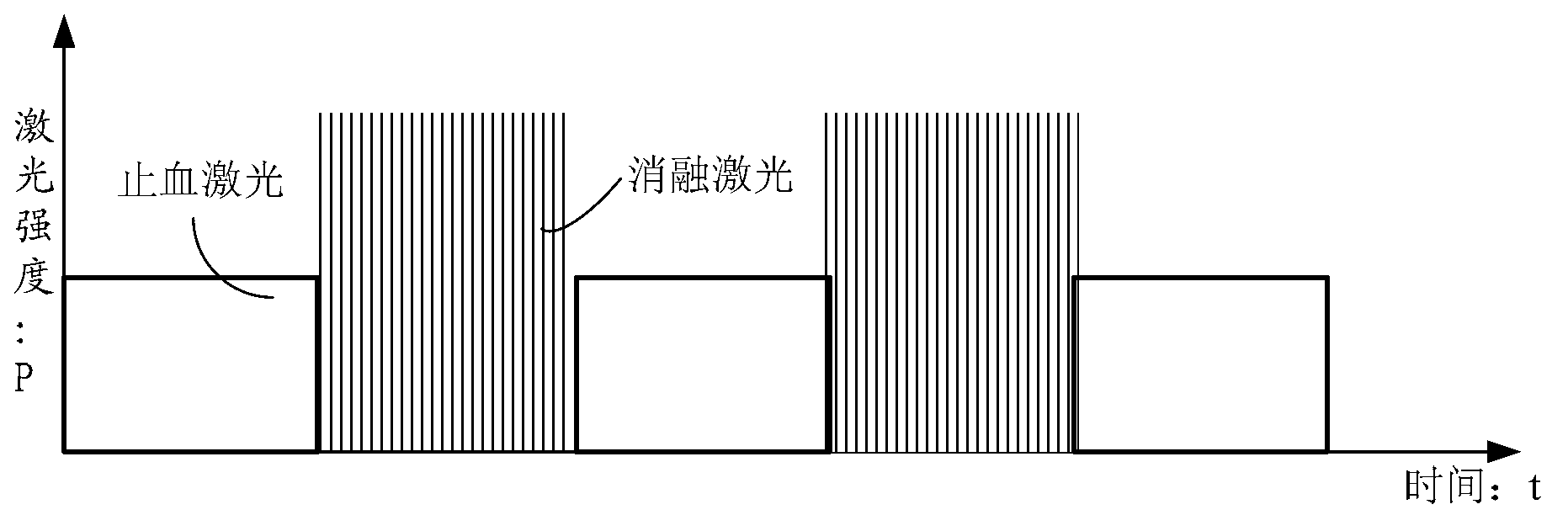

The invention provides a laser device and a laser system. The laser device comprises a laser assembly, a controller and a light combiner assembly, wherein the laser assembly comprises a plurality of lasers, and each laser is used for outputting at least one kind of laser light with a set wavelength; the controller is connected with each laser and used for controlling each laser to output laser light with a corresponding wavelength; and the light combiner assembly is used for collimating the laser light output by each laser with an optical path. The laser device provided by the technical scheme is provided with a plurality of lasers, so that the laser light with multiple wavelengths can be output to meet the requirements of operation in cutting or hemostasis. When the laser light is really output, hemostasis and cutting can be sequentially, reversely or simultaneously carried out. In the three modes, the controller is needed to control the corresponding laser to output corresponding laser light at desired time.

Owner:CAPITAL UNIVERSITY OF MEDICAL SCIENCES

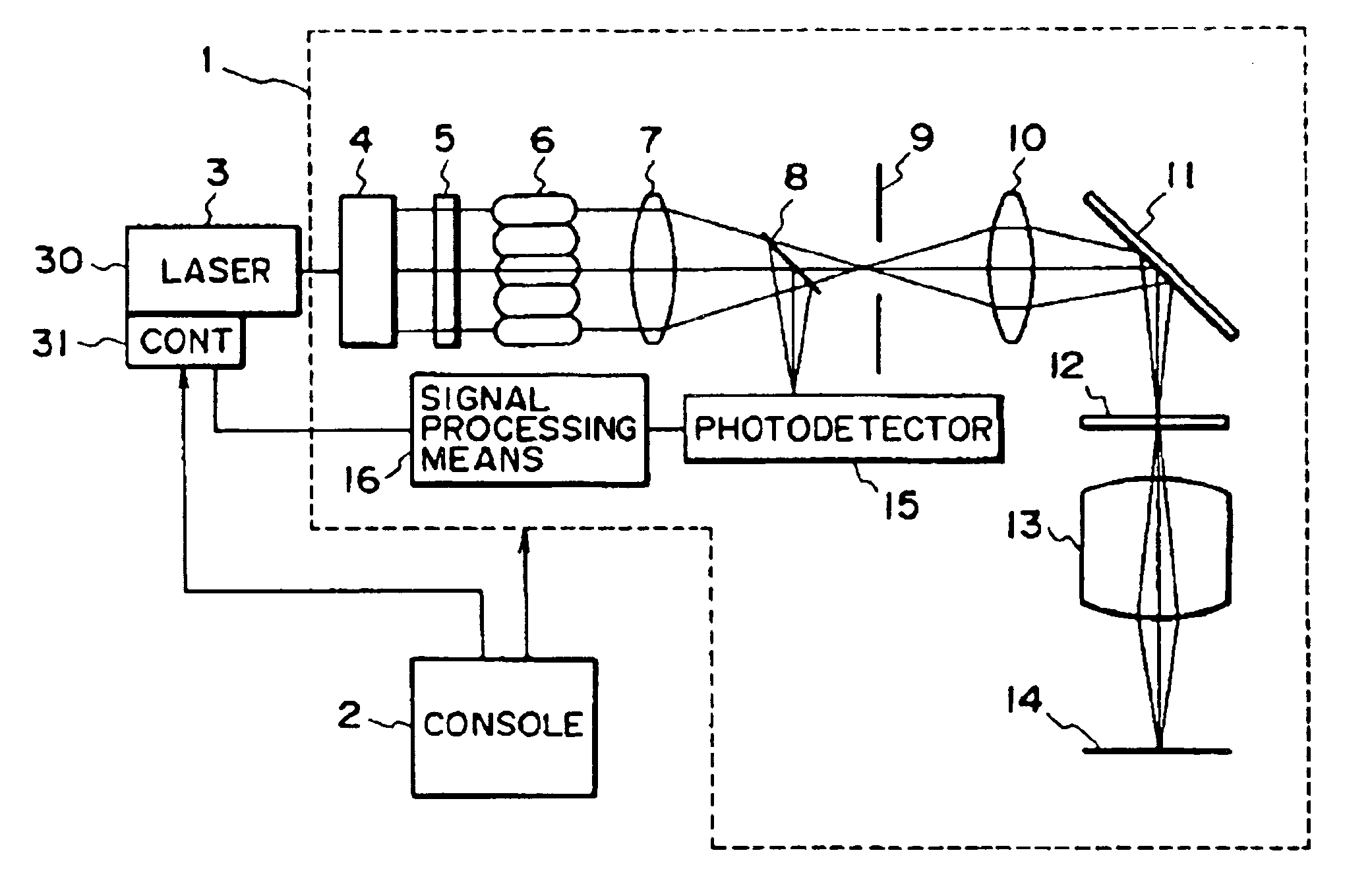

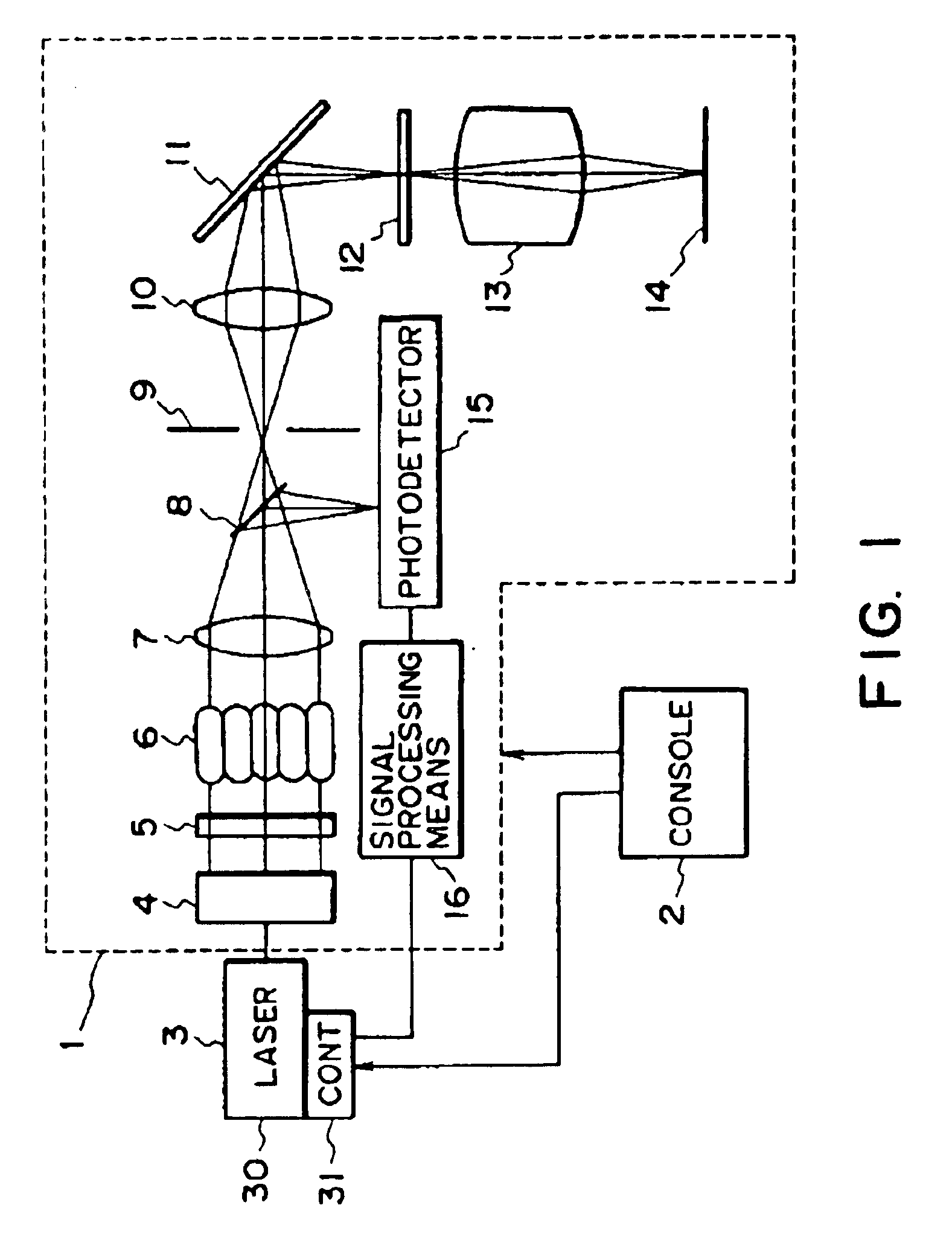

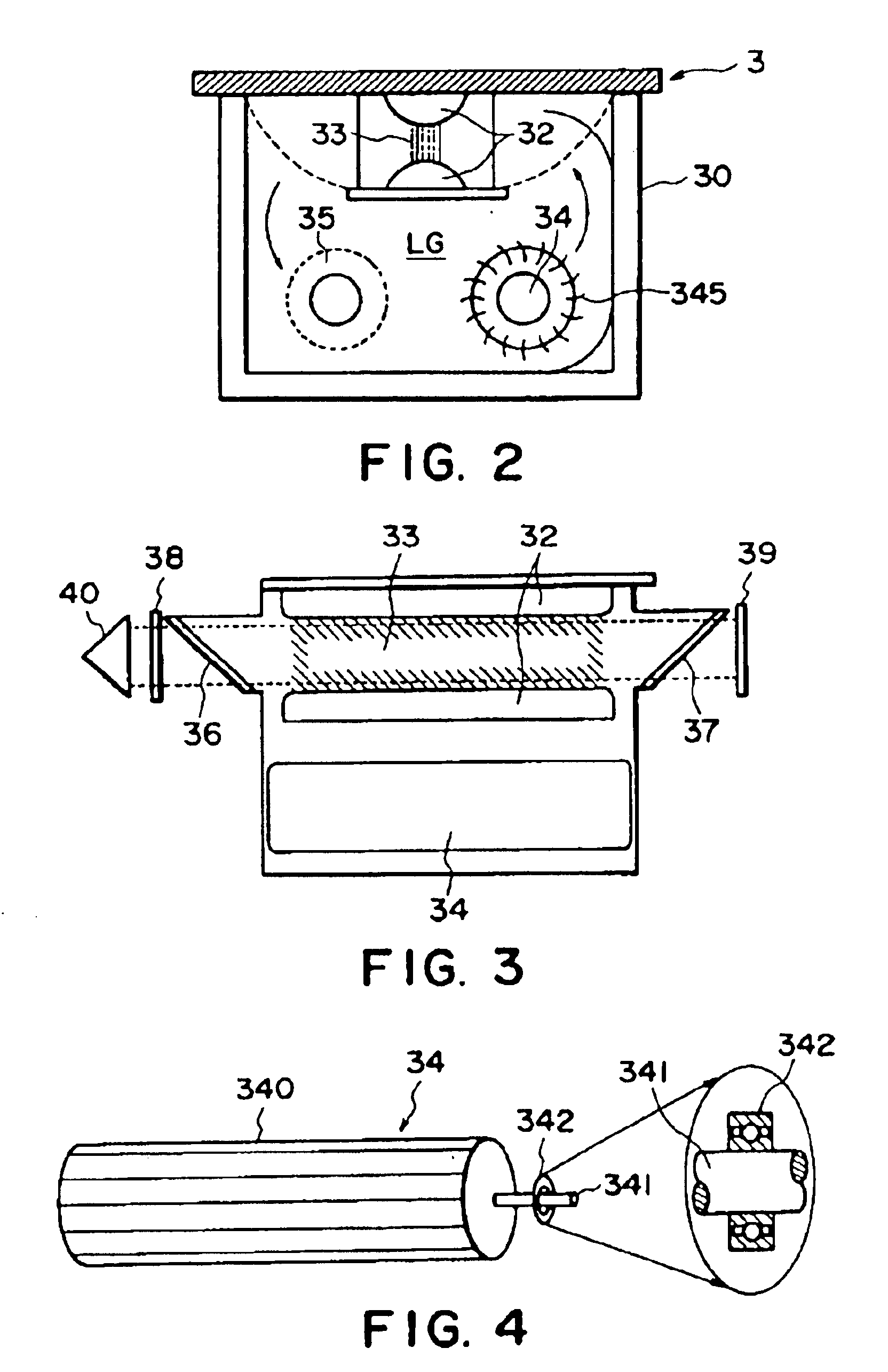

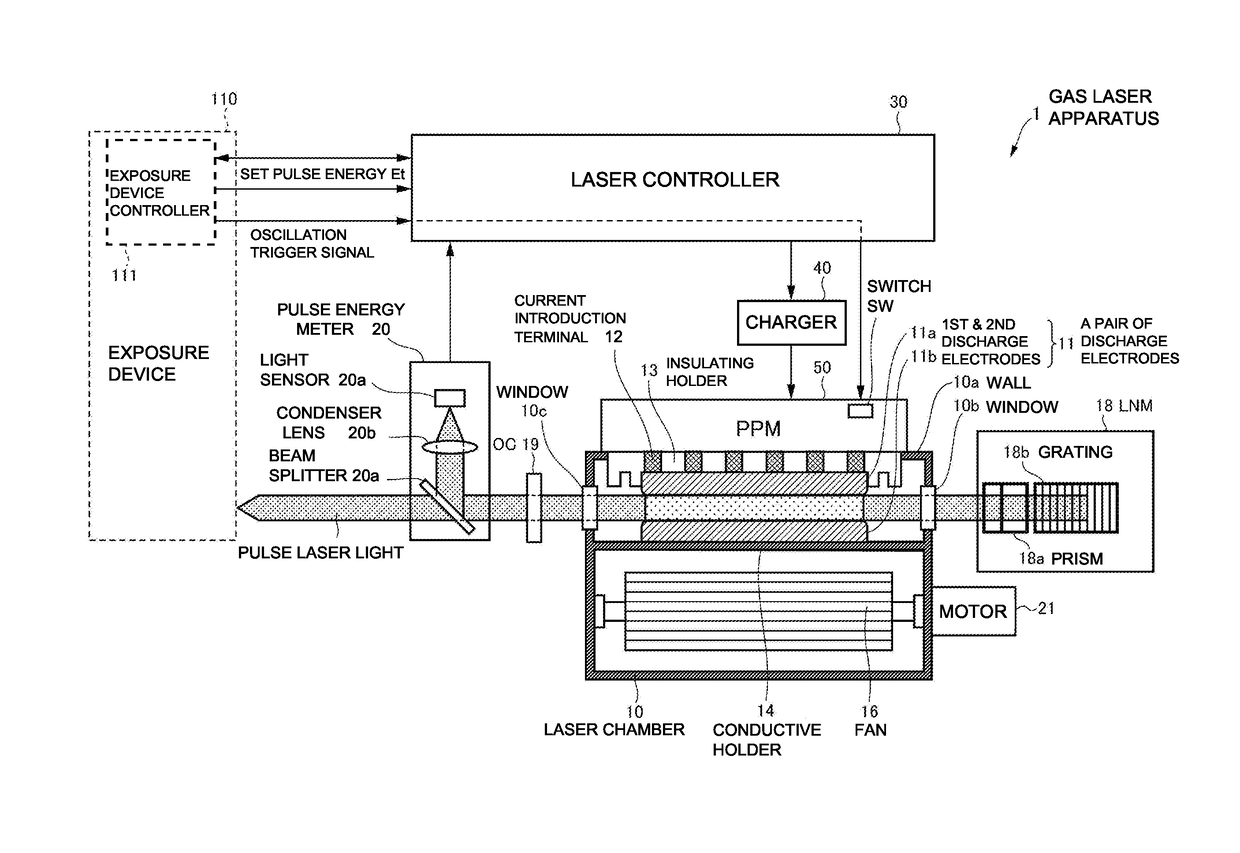

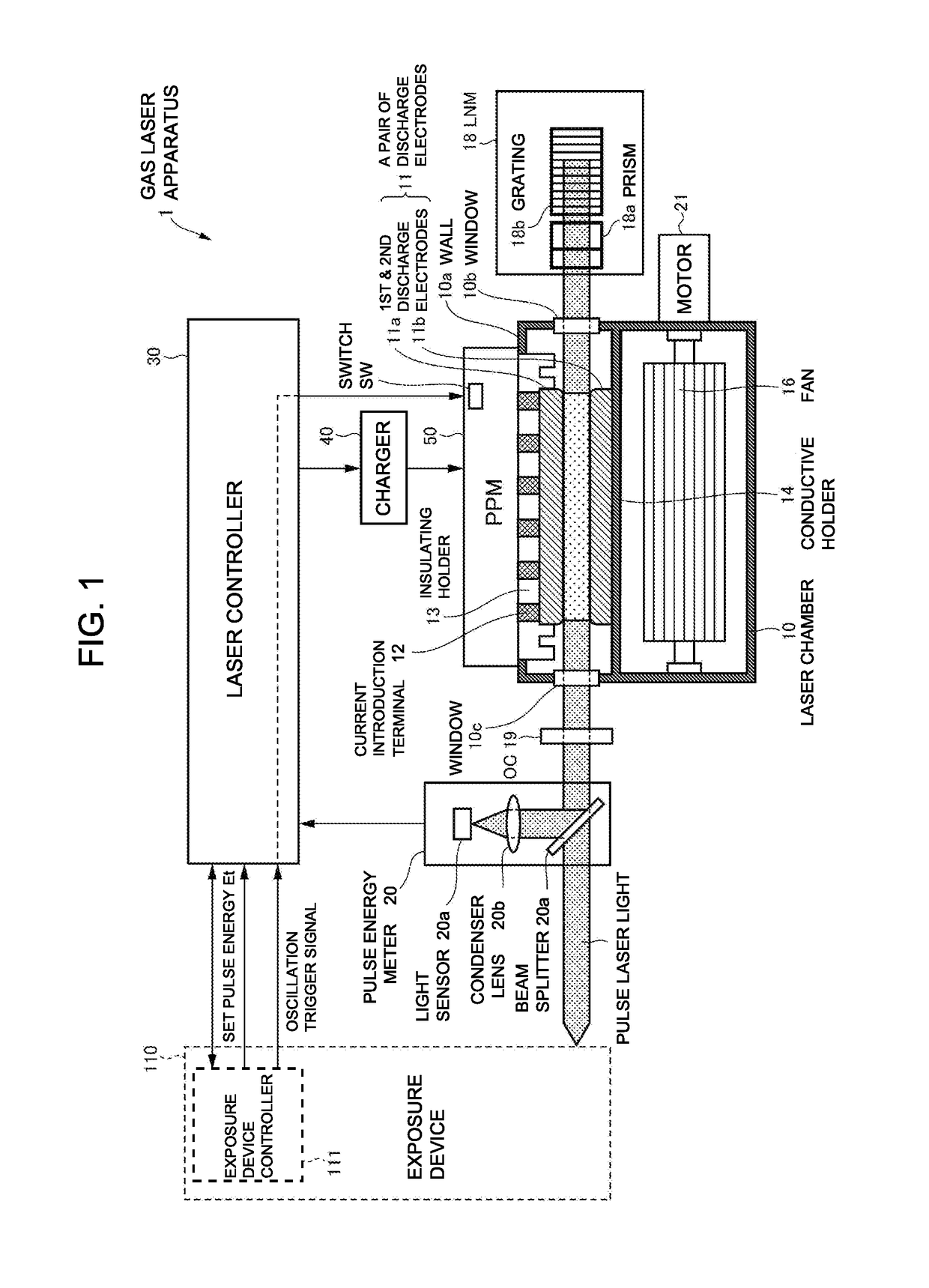

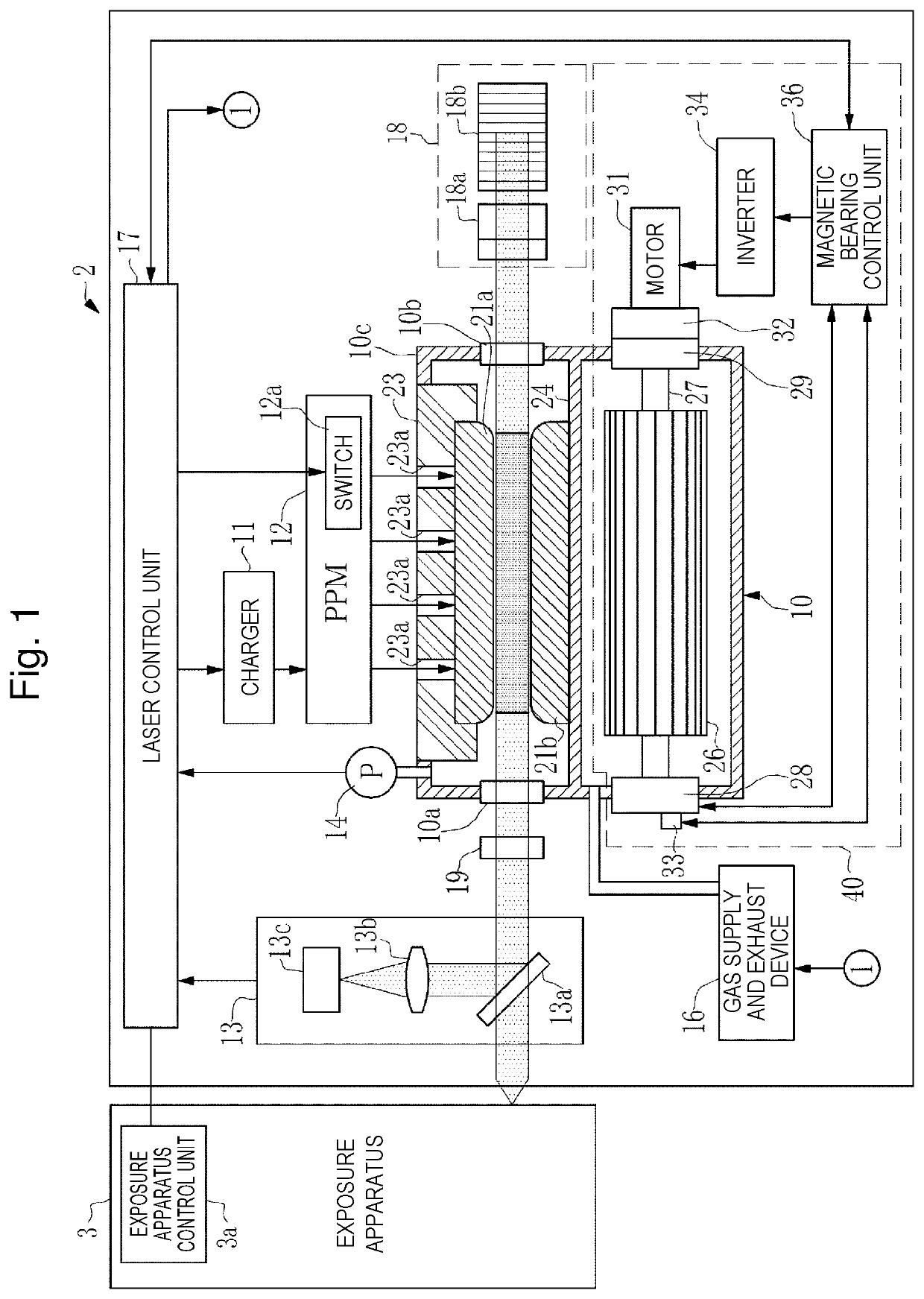

Gas laser device and exposure apparatus using the same

InactiveUS7031364B2Long life-timeIncrease powerSemiconductor/solid-state device manufacturingActive medium materialGas laser deviceGas passing

In a gas laser device, a laser gas sealingly stored in a chamber is excited using a discharging electrode that is electrically discharged. Laser light produced by the electrical discharging is totally reflected by a total reflection mirror. An output window partially reflects the laser light and outputs a portion of the laser light reflected between the total reflection mirror and the output window. A blower circulates the laser gas within the chamber so that the laser gas passing an electrical discharging region of the discharging electrode is circulated in the chamber and is returned to the electrical discharging region of the discharging electrode. The blower is operated according to the state of electrical discharging from the discharging electrode. The blower operation includes operating rotation of the blower in a stand-by state in which no laser gas is excited by the electrical discharging from said discharging electrode so that no laser light is emitted but the gas laser device is in a condition to output the laser light, and operating rotation of the blower in an in-operation state in which the laser gas is excited by the electrical discharging from said discharge electrode and laser light is outputted.

Owner:CANON KK

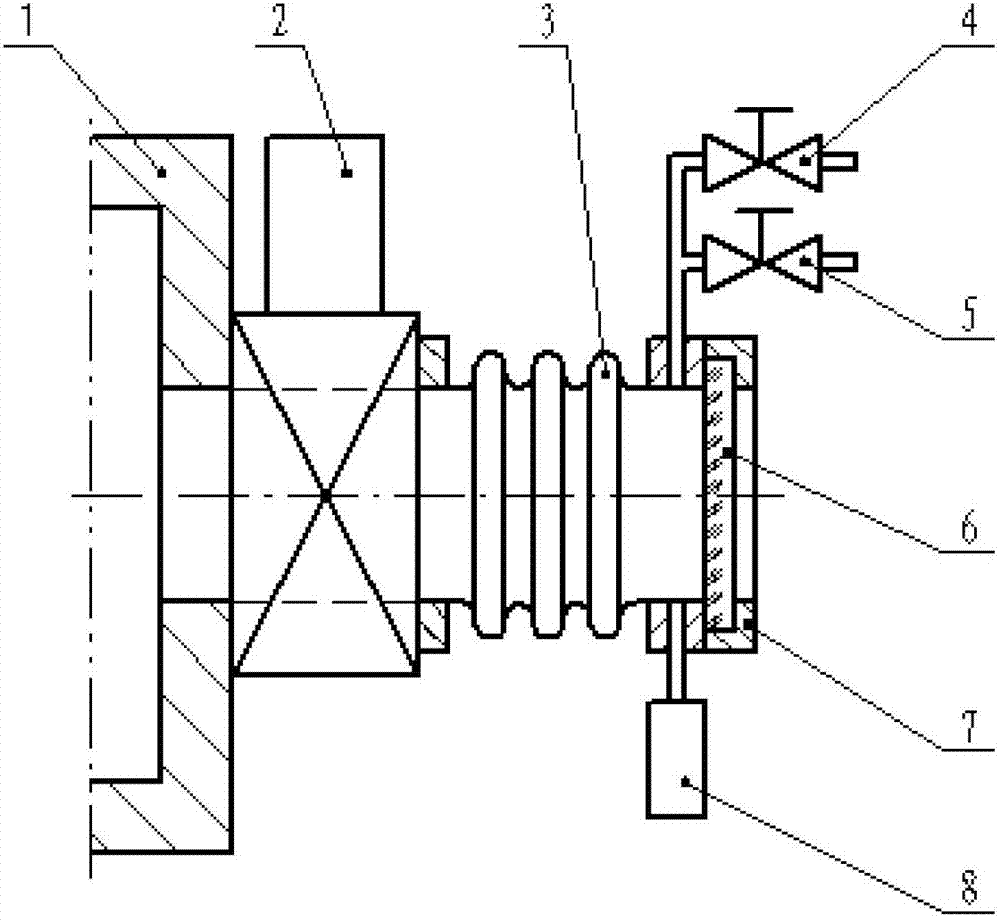

Device for fast and low-loss replacement of laser output mirror

InactiveCN102780145AReduce replacement timeReduce wasteGas laser constructional detailsGas laser deviceMirror mount

The invention discloses a device for fast and low-loss replacement of a laser output mirror, relating to the field of high-power gas laser devices. The device comprises a cavity valve, an output mirror mounting flexible pipe seat, a first pipeline, a second pipeline and a pressure sensor, wherein the cavity valve is hermetically mounted on a working cavity of the laser device, the aperture of a channel of the cavity valve is not less than the clear aperture on the working cavity of the laser device, and a channel hole and a light through hole are coaxially mounted; a flange at one end of the output mirror mounting flexible pipe seat is hermetically and coaxially mounted on the cavity valve, and a flange at the other end is hermetically connected with the laser output mirror through a lens gland bush of the laser device; holes communicated with the outside are formed in the flanges of the output mirror mounting flexible pipe seat, and the first pipeline, the second pipeline and the pressure sensor are respectively hermetically connected with the holes formed in the flanges of the output mirror mounting flexible pipe seat; and pipe valves are respectively mounted on the first pipeline and the second pipeline. The device disclosed by the invention can greatly shorten the replacement time of the laser output mirror and realize very small waste of working gas of the laser device.

Owner:CHANGCHUN INST OF OPTICS FINE MECHANICS & PHYSICS CHINESE ACAD OF SCI

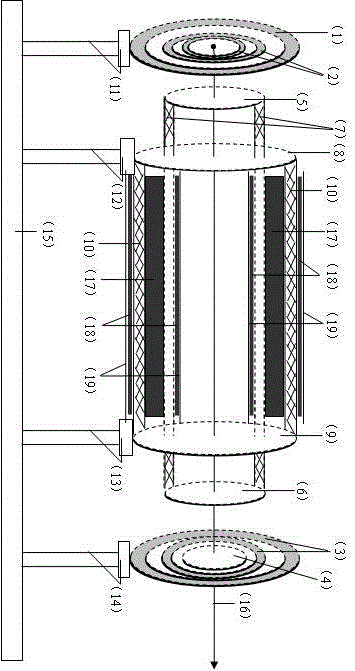

Fabrication method for combined cylindrical discharge high-power gas laser and combined cylindrical discharge high-power gas laser device

The invention relates to a fabrication method for a combined cylindrical discharge high-power gas laser and a combined cylindrical discharge high-power gas laser device, and belongs to the field of optics and optical engineering. The method is characterized in that an inner cylinder and an outer cylinder that are coaxial are placed on a symmetric axis of the device in an embedded manner, and a radio-frequency power supply discharges to excite the combined cylinder to obtain high-power hollow annular carbon dioxide laser beams or carbon dioxide laser beams. A four-mirror stable resonator is adopted, so that high-power laser output can be achieved under a condition of a short laser cavity. The higher-power hollow annular carbon dioxide laser or the carbon dioxide laser can be used for laser processing, material processing and other aspects, and the lower-power hollow annular carbon dioxide laser or the carbon dioxide laser can be used for laser cosmetology, laser surface processing and the like. The hollow annular laser beams can be focused into a hollow beam with a smaller dark space, and can be used for optical spanners, optical tweezers, optical conduits and the like. The device has the advantages that the device is compact in structure and high in output power, and the beams are convenient to transform.

Owner:XIHUA UNIV

Gas Laser Device

ActiveUS20090110016A1Easy constructionLow costOptical resonator shape and constructionActive medium materialGas laser deviceLight beam

A gas laser device is presented that produces a near diffraction limited round beam exiting the discharge vessel. Through the use of a simple focusing system, additional waveguide strip and a spatial filter in conjunction with the new asymmetric hybrid planar waveguide resonator, a round diffraction limited beam can be produced exiting the discharge vessel. Furthermore, a second and very similar design is presented that allows for spatial filtering to take place directly outside of the discharge vessel, thereby enabling filtering of the beam to be an added option.

Owner:LUXINAR LTD

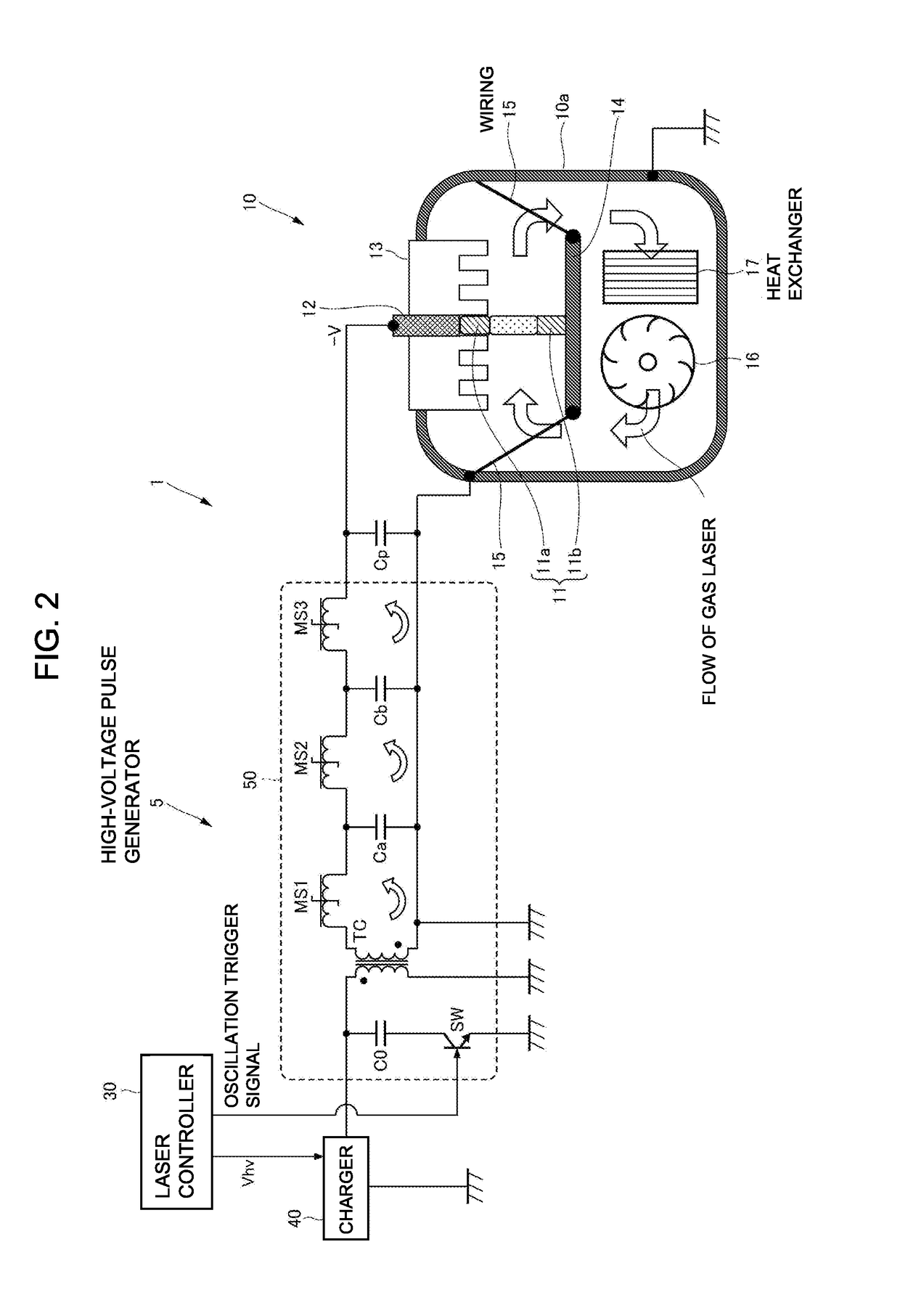

High-voltage pulse generator and gas laser apparatus

A high-voltage pulse generator may include a number “n” (n is a natural number of not less than 2) of primary electric circuits connected in parallel to one another on the primary side of a pulse transformer, and a secondary electric circuit of the pulse transformer, which is connected to a pair of discharge electrodes disposed in a laser chamber of a gas laser apparatus. The “n” primary electric circuits may include a number “n” of primary coils connected in parallel to one another, a number “n” of capacitors respectively connected in parallel to the “n” primary coils, and a number “n” of switches respectively connected in series to the “n” capacitors. The “n” primary electric circuits may be connected to a number “n” of chargers for charging the “n” capacitors, respectively. The secondary electric circuit may include a number “n” of secondary coils connected in series to one another, and a number “n” of diodes each connected to opposite ends of each of the “n” secondary coils, to prevent a reverse current flowing from the pair of discharge electrodes toward the secondary coils.

Owner:NAT UNIV CORP NAGAOKA UNIV TECH +1

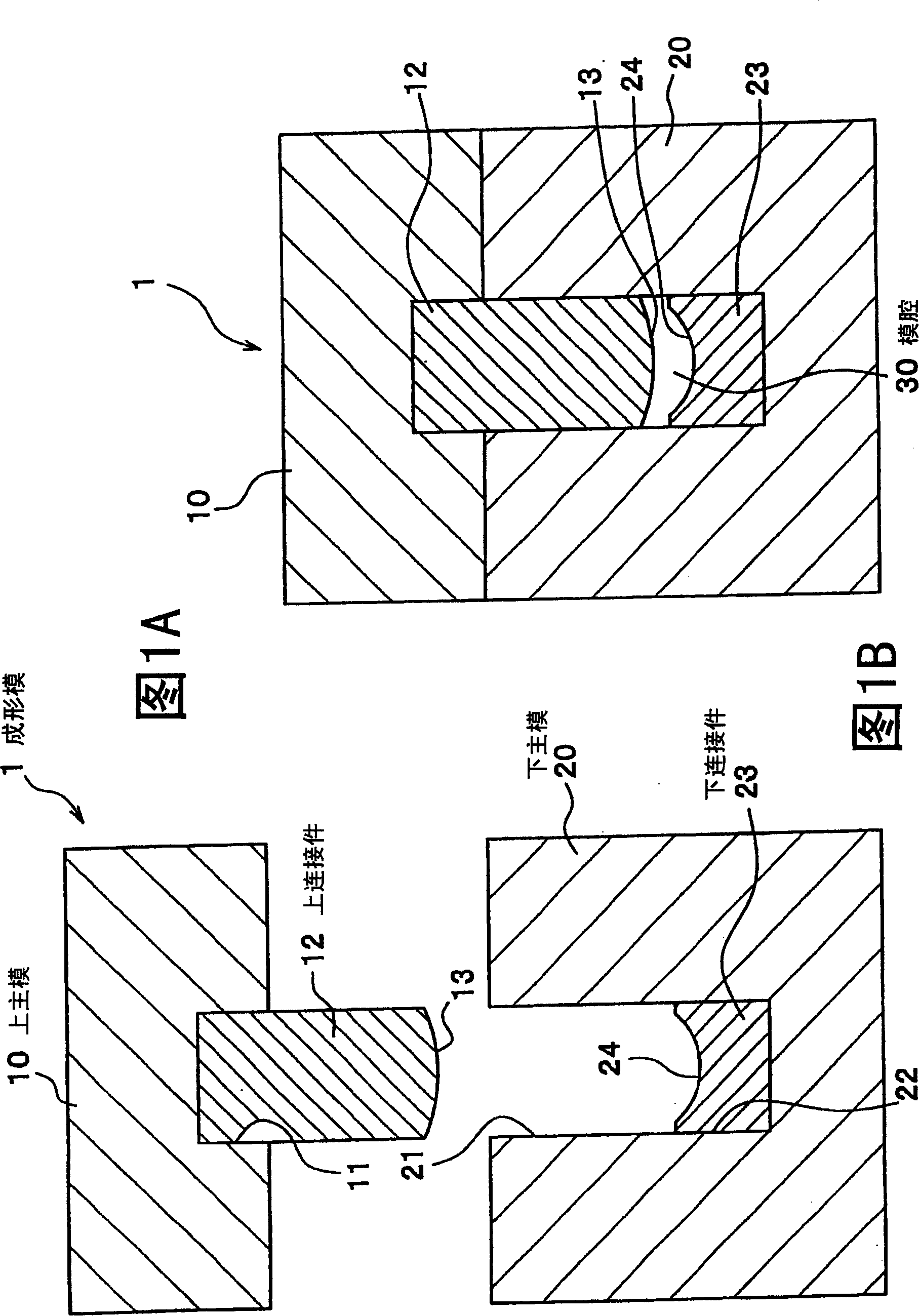

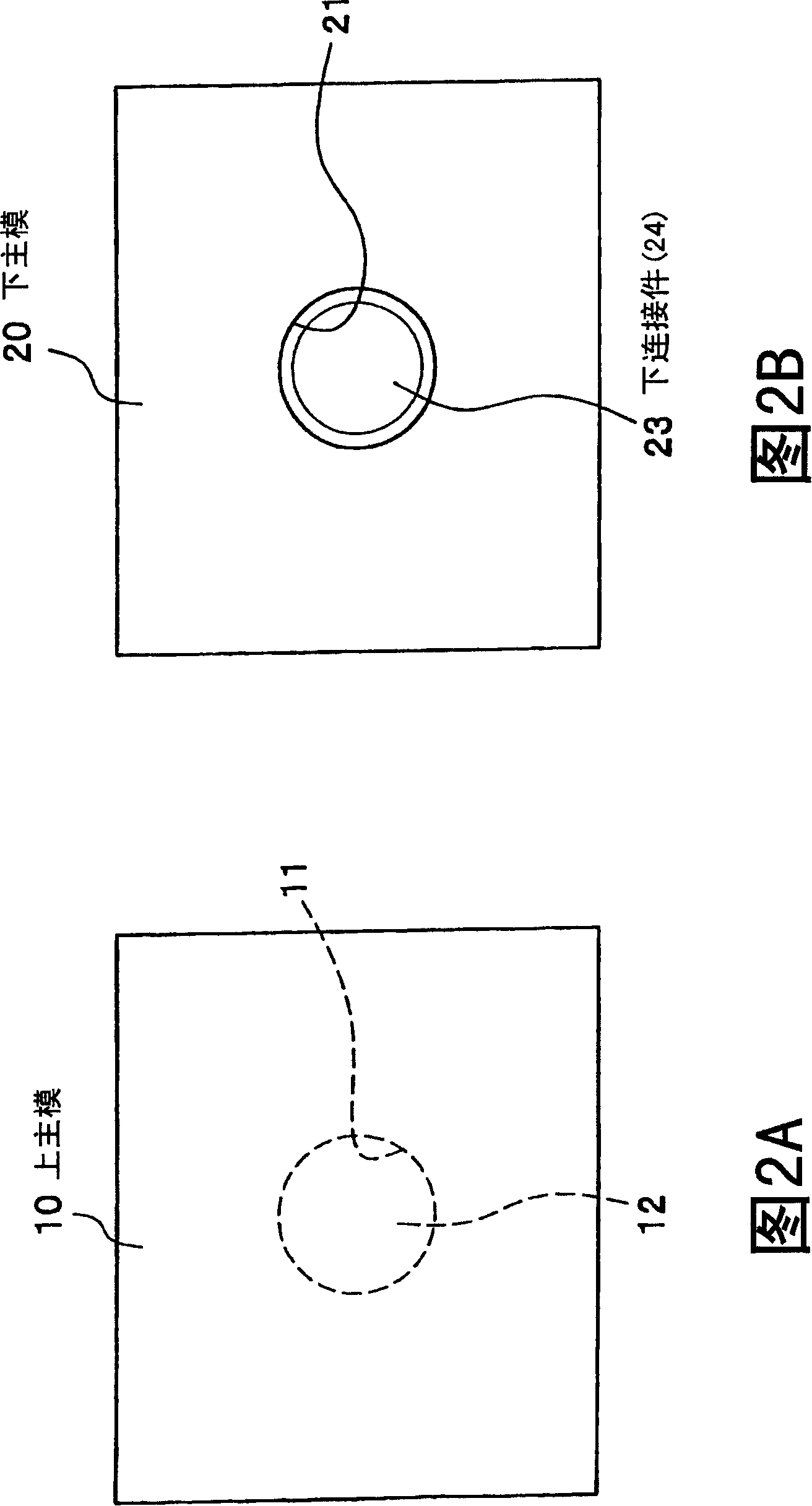

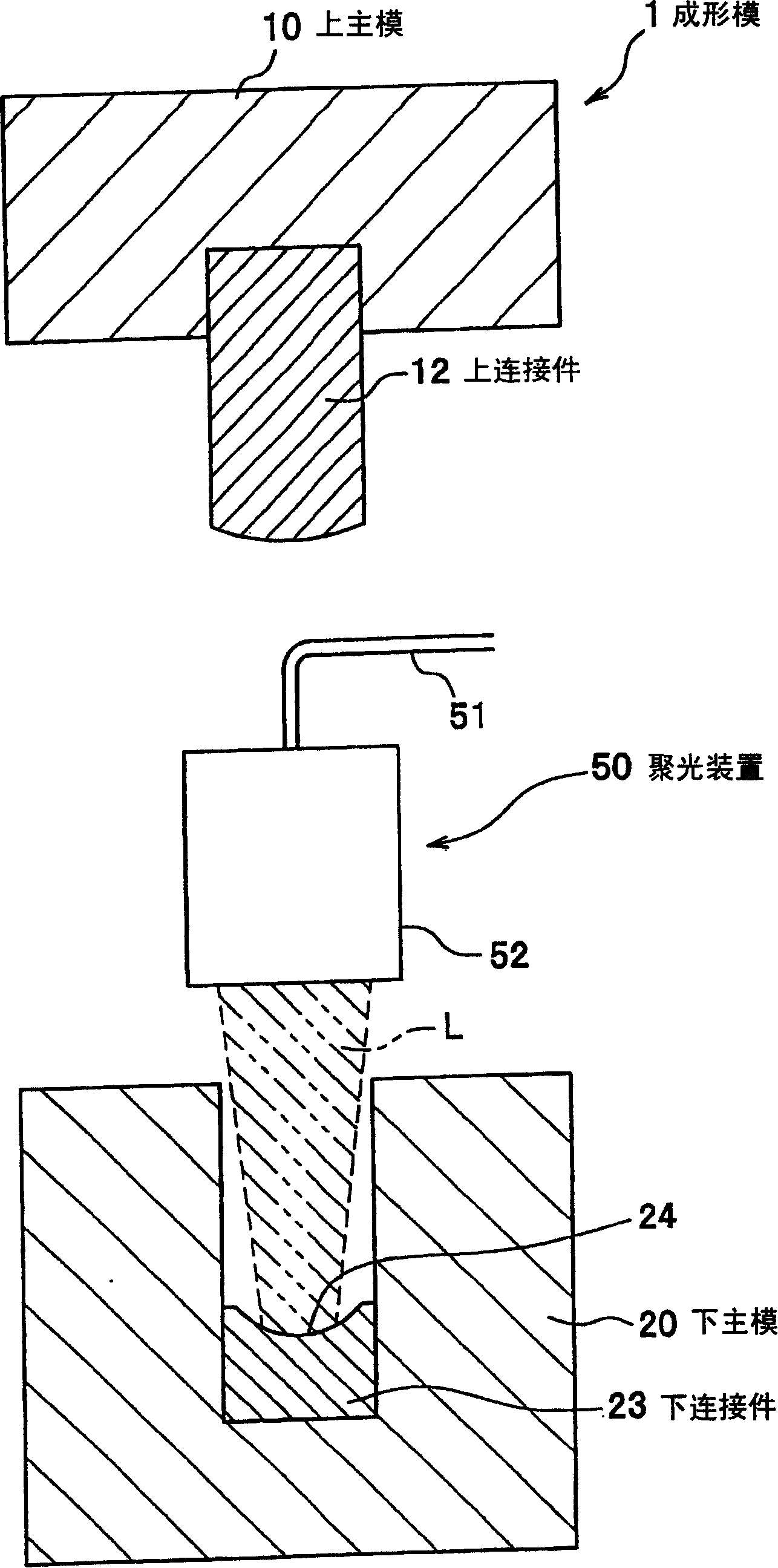

Method for shaping plastics material

InactiveCN101161441AImprove heating efficiencyPrevent oxidation of highly heated surfacesOptical articlesPolyesterAcrylic resin

Owner:FUJIFILM CORP

Discharge-pumped gas laser device

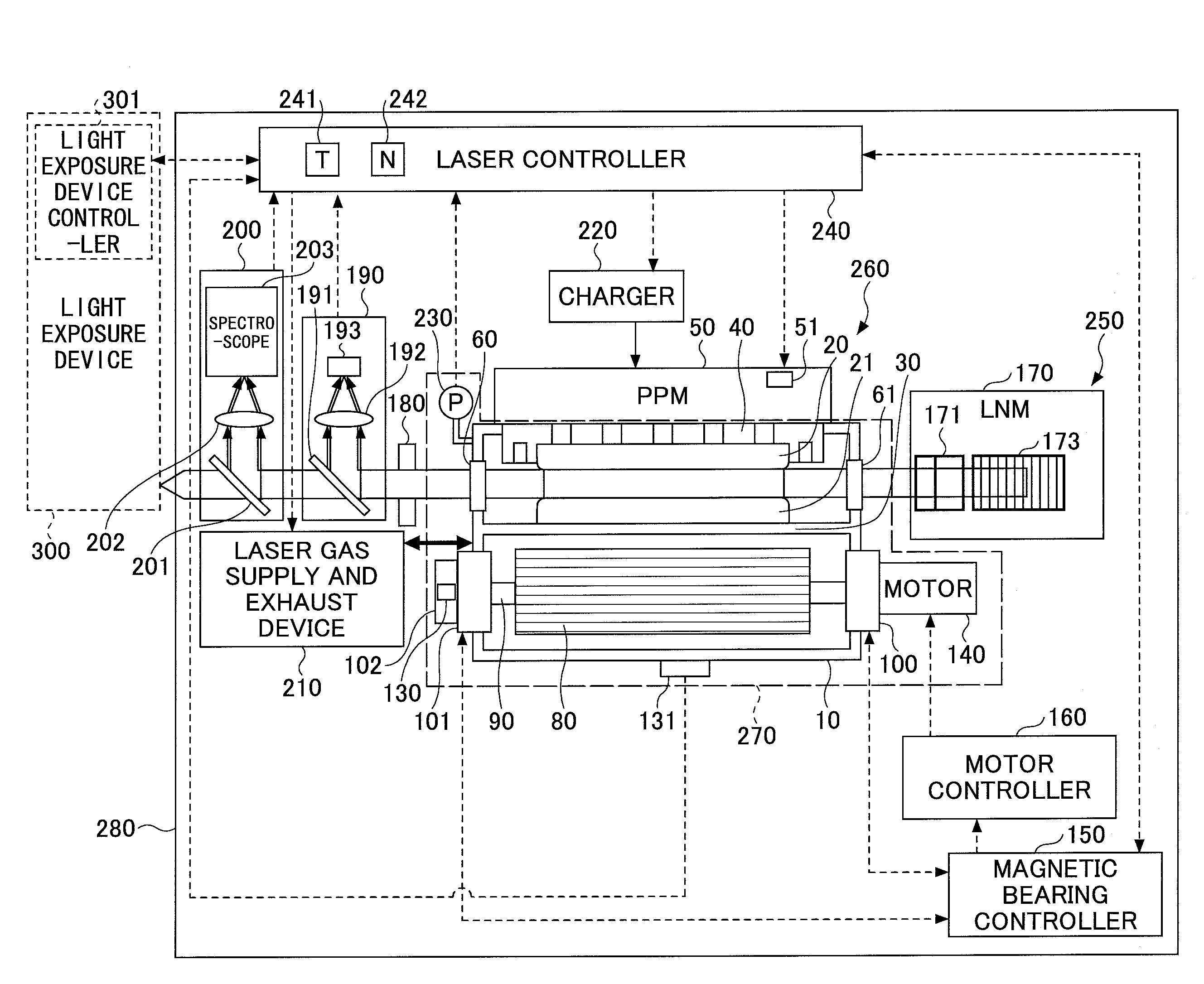

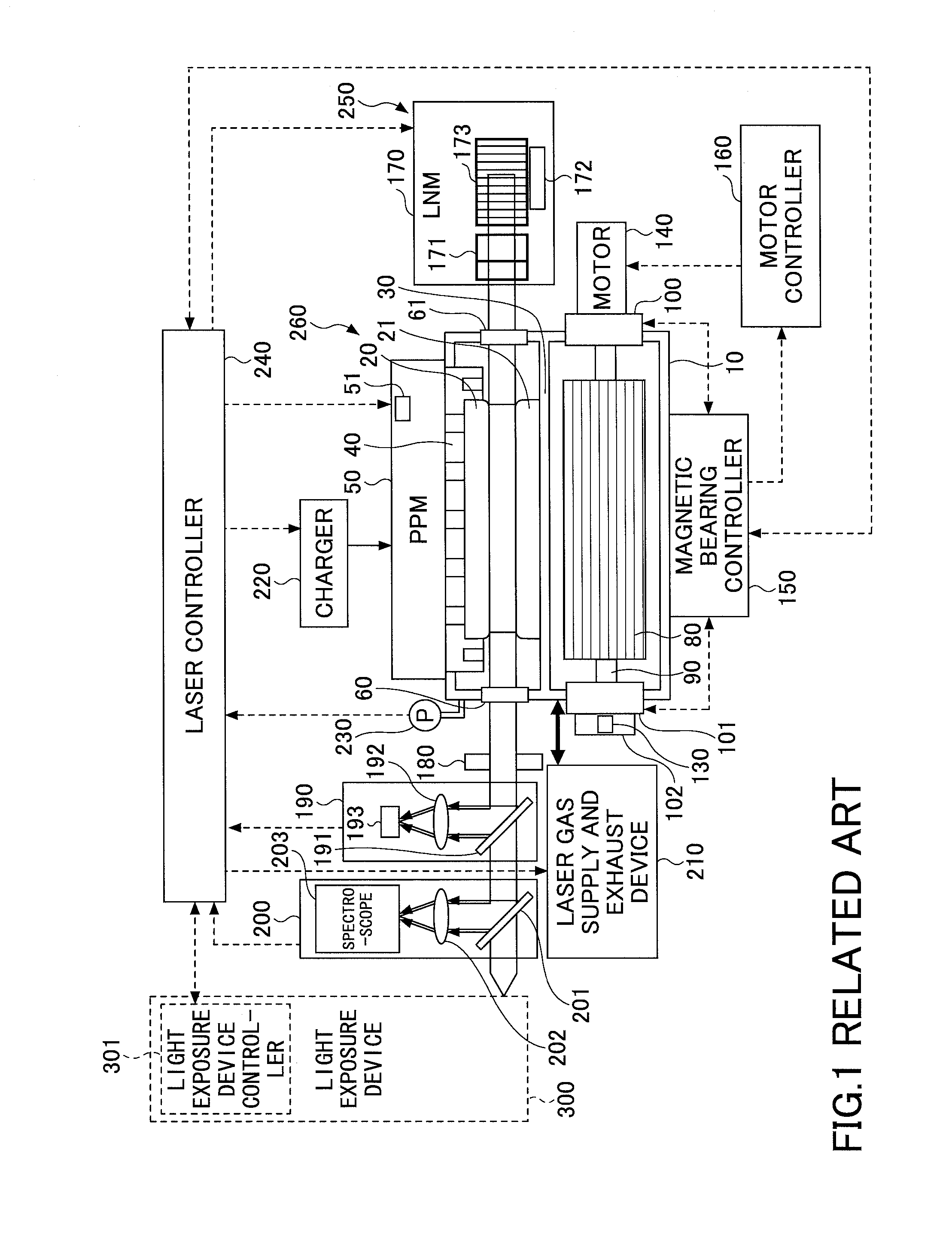

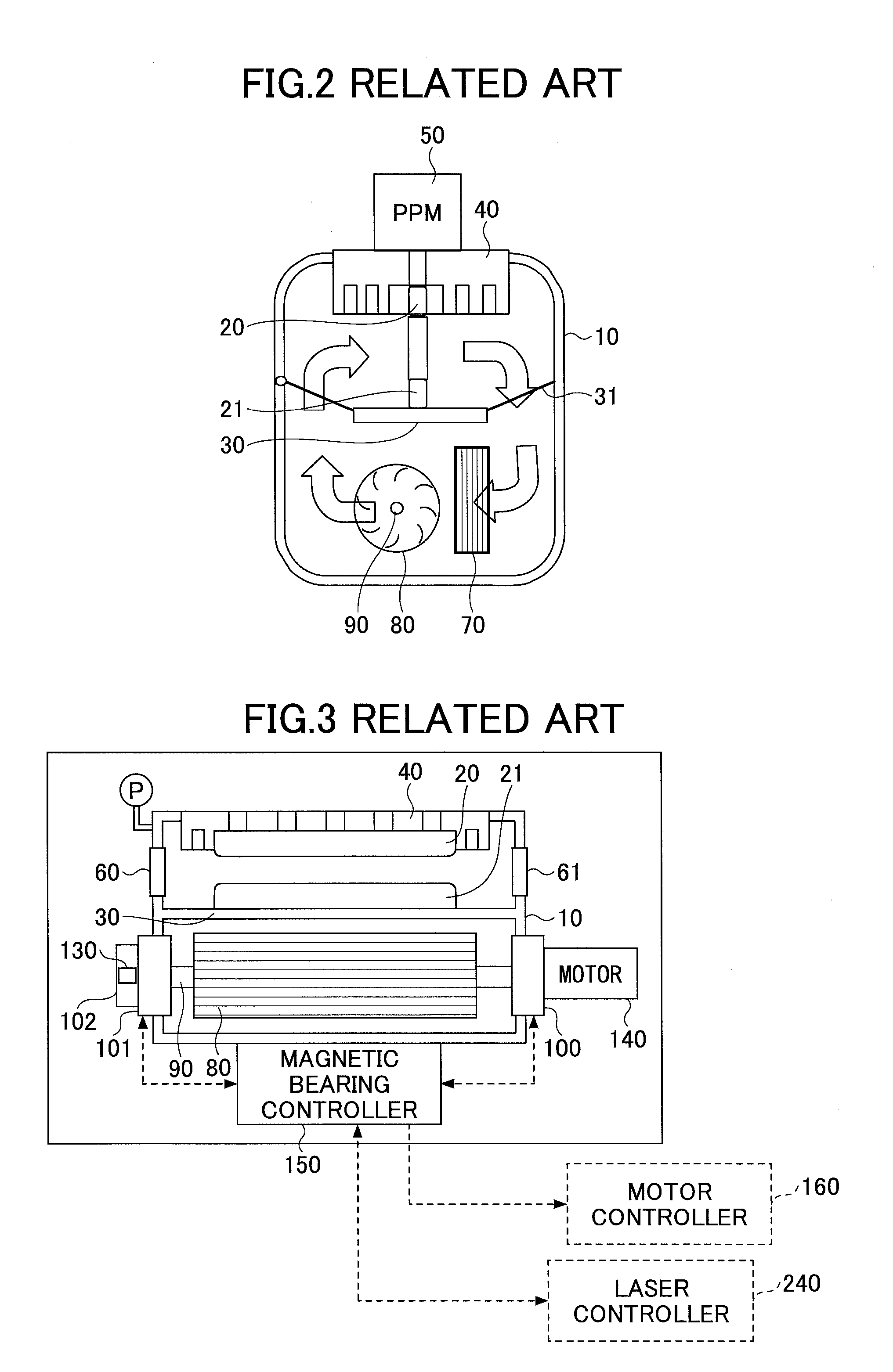

ActiveUS20140105238A1Laser constructional detailsActive medium materialMagnetic bearingGas laser device

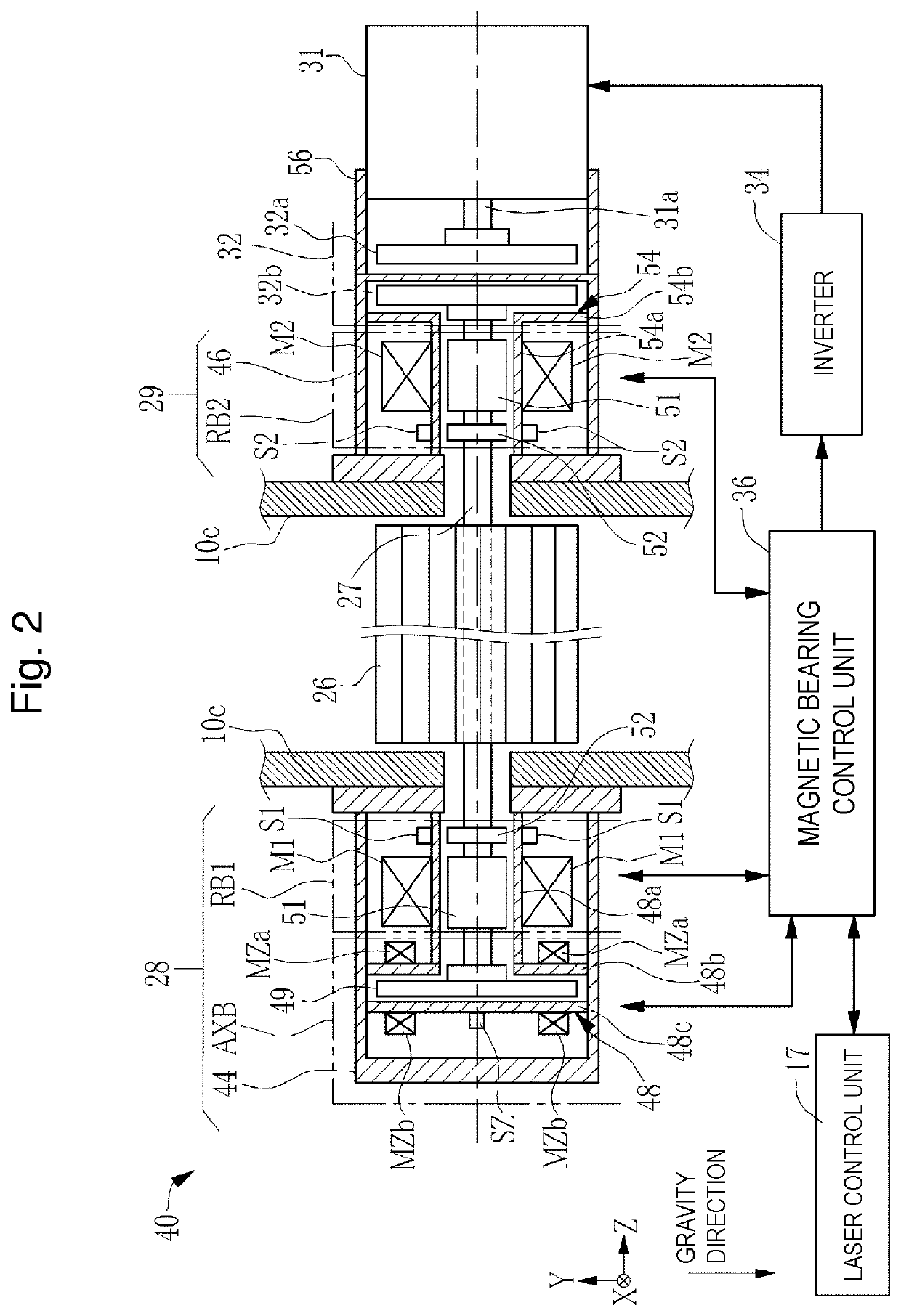

A discharge-pumped gas laser device may include a laser chamber, a pair of discharge electrodes provided in the laser chamber, a fan with a magnetic bearing being provided in the laser chamber and configured to be capable of circulating a gas in the laser chamber, a housing configured to contain the laser chamber, and a magnetic bearing controller connected to the magnetic bearing electrically, being capable of controlling the magnetic bearing, and provided in the housing separately from the laser chamber.

Owner:GIGAPHOTON

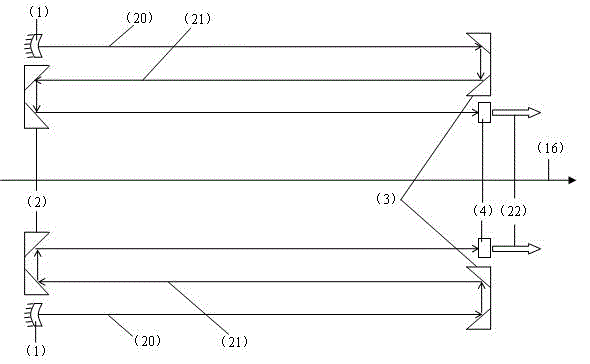

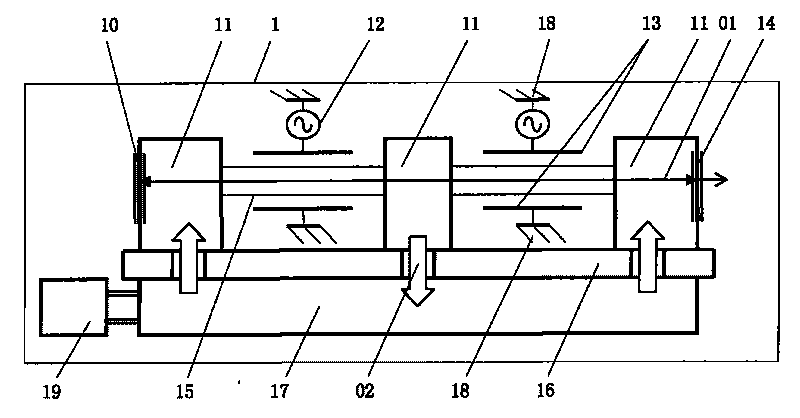

Axial fast flow gas laser device

InactiveCN101752780ALittle change in temperature differenceOptical resonator shape and constructionActive medium materialResonant cavityGas laser device

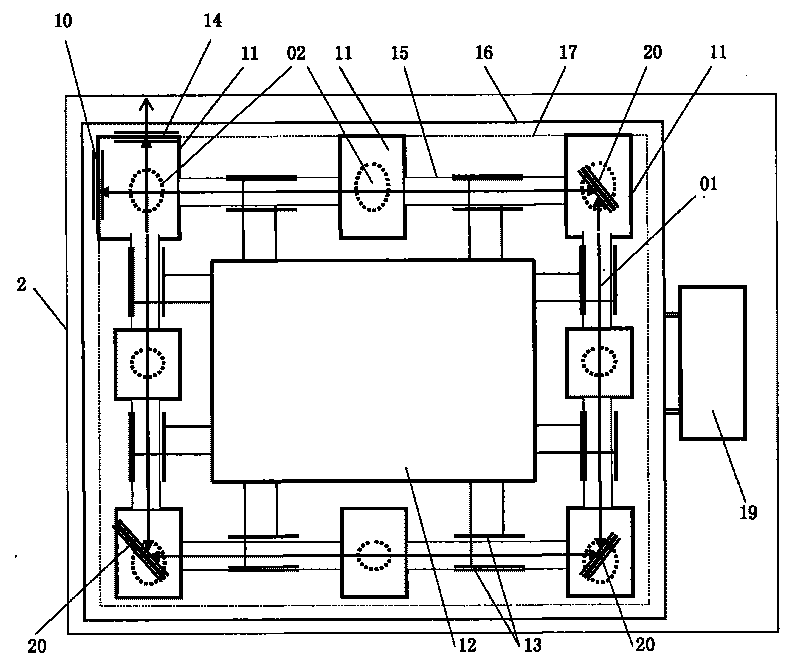

The invention discloses an axial fast flow gas laser device, which comprises a resonant cavity, a gas circulation cooler, a surface plate, discharge electrodes, a radio frequency power supply and a gas pump, wherein the resonant cavity comprises a front reflecting mirror, a catadioptric mirror, a rear reflecting mirror, discharge tubes and a light path bracket; the light path bracket is connected with a plurality of discharge tubes to be arrayed into a rectangle light path; the catadioptric mirror is arranged at the corner of the light path; the front and rear reflecting mirrors are arranged at both ends of the light path; the discharge electrodes are arranged on the discharge tubes; the discharge electrodes are connected to the radio frequency power supply; the gas of the discharge tubes is excited by the radio frequency under the excitation of the radio frequency power supply to form a plasma to generate the glow discharge phenomenon to be incident upon one photon of the plasma of the gas generating the laser; the plasma can generate two photons to emit. The photons oscillate back and forth on the light path between the front and rear reflecting mirrors to generate the laser; the light path bracket is arranged on the surface plate; the gas circulation cooler is arranged at the back of the surface plate; and after generating the laser, the gas is cooled and recycled in the gas circulation cooler under the action of the gas pump.

Owner:刘娟明

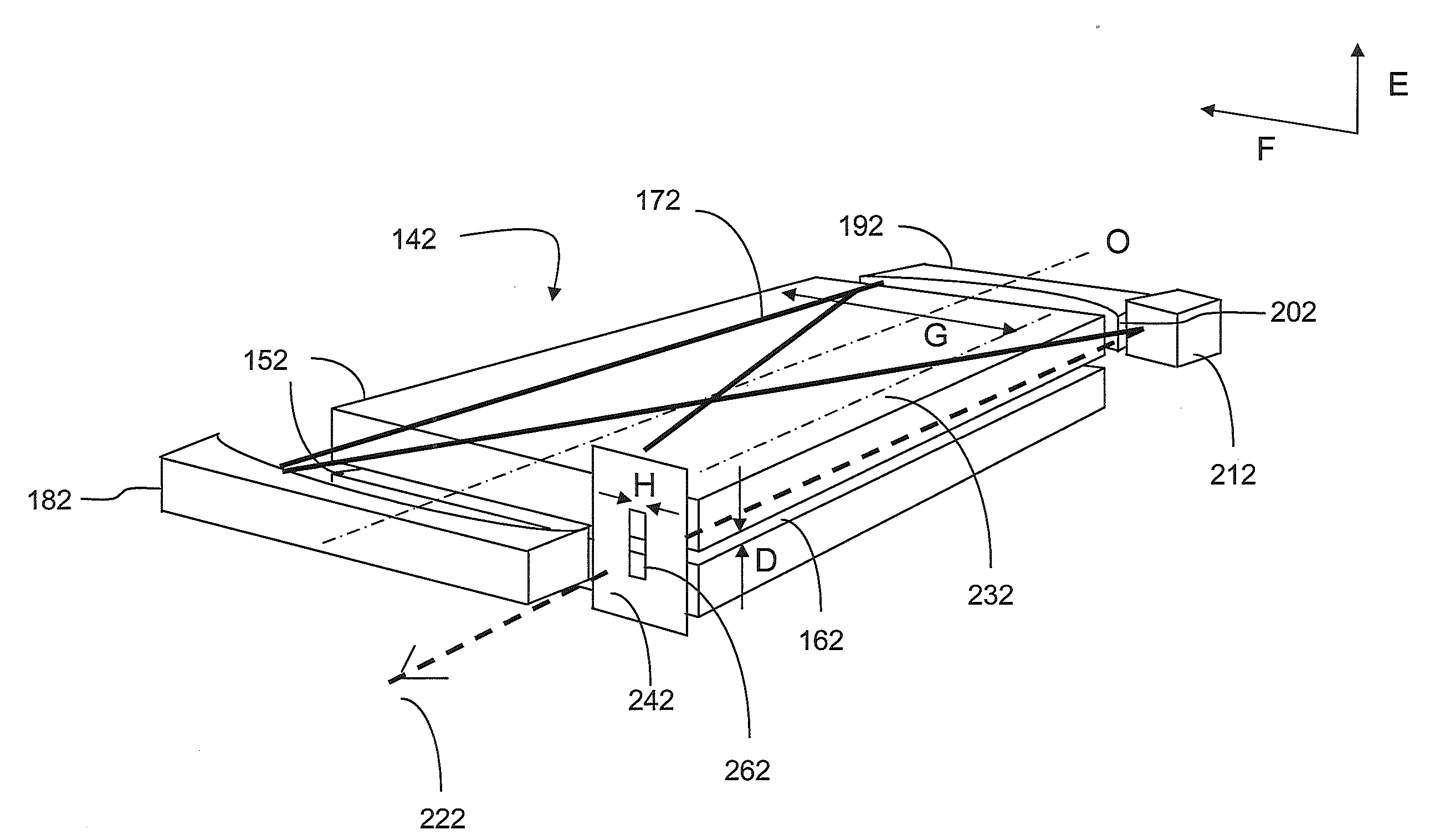

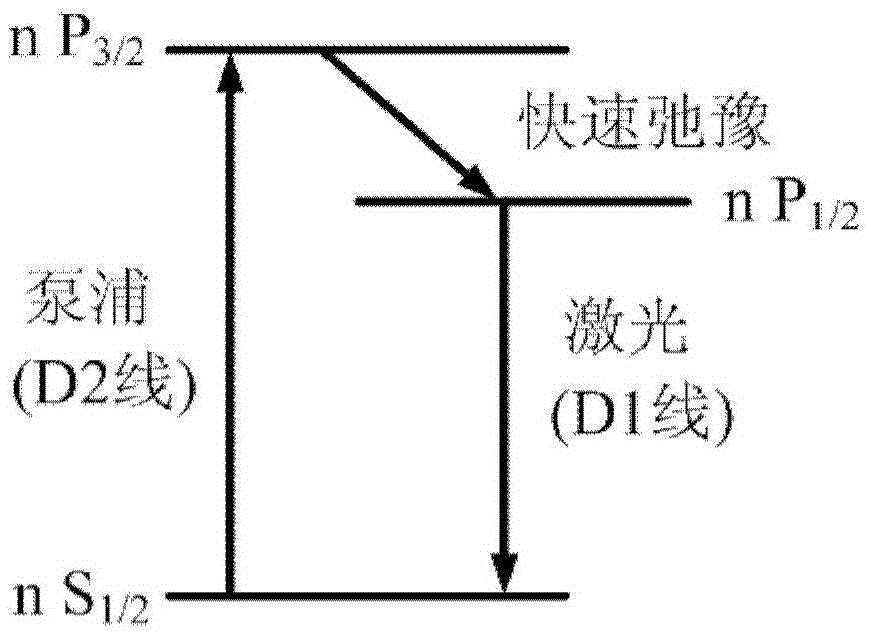

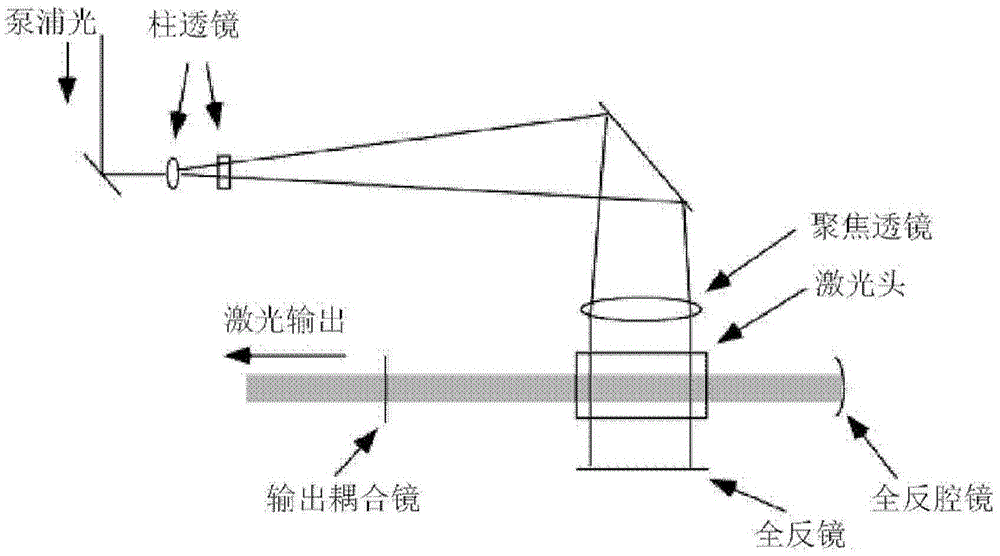

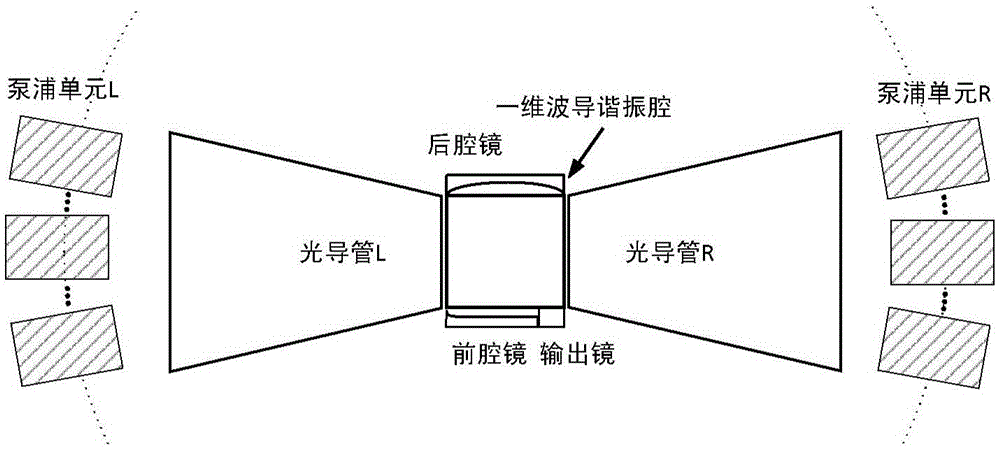

Side face pumping slab waveguide DPAL laser device

ActiveCN105552698AReduces the possibility of contaminating the laser output windowAvoid uneven distributionLaser detailsWaveguideCarbon particle

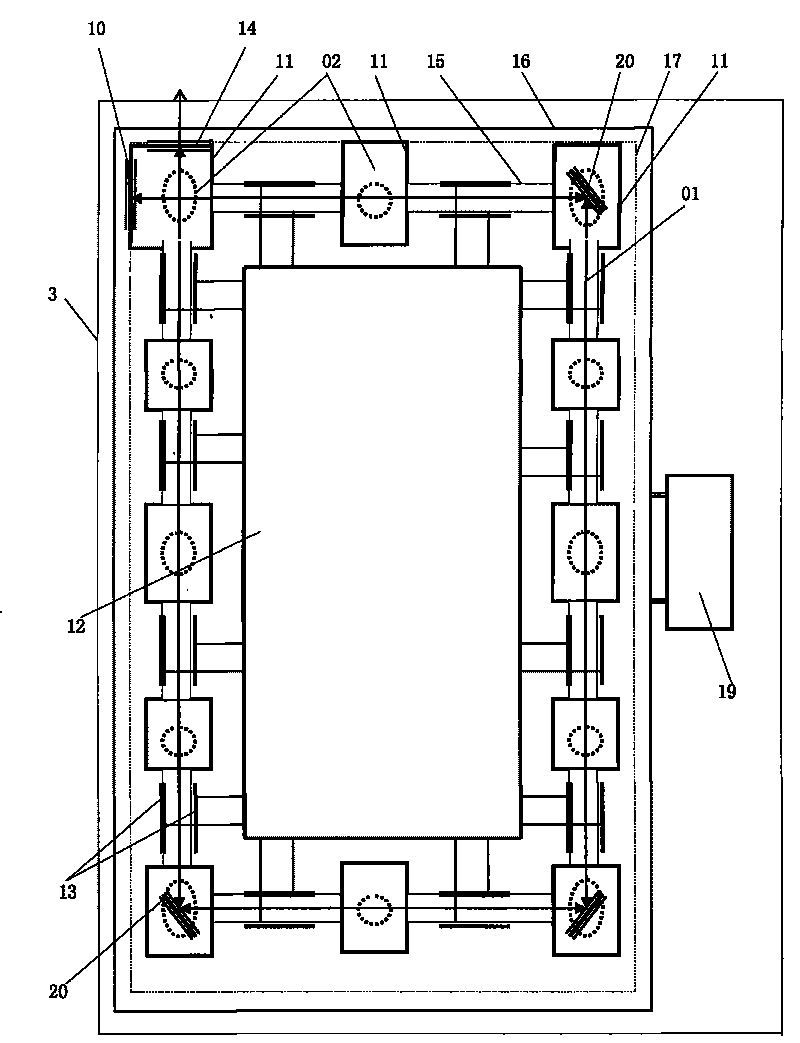

A side face pumping slab waveguide DPAL laser device comprises an LD pumping module L, an LD pumping module R, a light guide pipe L, a light guide pipe R and a one-dimensional waveguide resonance cavity. The LD pumping module L and the LD pumping module R are symmetrically placed about the one-dimensional waveguide resonance cavity. The light guide pipe L and the light guide pipe R are symmetrically placed about the one-dimensional waveguide resonance cavity. All semiconductor laser devices of the LD pumping module L are placed on a spherical face in a stack array or linear array mode and point to a pumping window, wherein the pumping window, in the direction of the LD pumping module L, of the one-dimensional waveguide cavity serves as the center of the spherical face. All semiconductor laser devices of the LD pumping module R are placed on a spherical face in a stack array or linear array mode and point to a pumping window, wherein the pumping window, in the direction of the LD pumping module R, of the one-dimensional waveguide cavity serves as the center of the spherical face. the double-edge side face pumping mode is adopted for the laser device, and therefore the possibility that carbon-particle-polluted lasers generated after high-power-density pumping light and alkane type mixed gas react are output out of window pieces is greatly lowered; the light beam shaping process is simplified, and the problem that pumping light is not uniformly distributed is avoided; the modularized thought is adopted, and the laser device is suitable for various optical pump gas laser devices.

Owner:INST OF ELECTRONICS CHINESE ACAD OF SCI

Gas laser device

A gas laser device including a blower circulating a laser gas along a gas passage; a pressure detection section detecting a gas pressure of the laser gas in the gas passage; a gas supply and exhaust section supplying the laser gas to the gas passage and exhausting the laser gas from the gas passage; an instruction section instructing a temporary stop of a laser oscillation by a laser oscillator; and a control section controlling the blower and the gas supply and exhaust section in response to an instruction from the instruction section. The control section, once the instruction section instructs the temporary stop, controls the blower to reduce the rotation of the blower or stop the rotation of the blower and controls the gas supply and exhaust section so that the gas pressure detected is a second target gas pressure corresponding to a first target gas pressure during the rotation of the blower.

Owner:FANUC LTD

Laser device

InactiveCN103636084AModulation speedReduce power consumptionLaser detailsSemiconductor laser structural detailsIn planeCMOS

The present invention provides a light source for light circuits on a silicon platform. A vertical laser cavity is formed by a gain region arranged between a first mirror structure and a second mirror structure, both acting as mirrors, by forming a grating region including an active material in a silicon layer in a semiconductor structure or wafer structure. A waveguide for receiving light from the region of the mirrors is formed within or to be connected to the region of the mirrors, and functions as an output coupler for the VCL. Thereby, vertical lasing modes are coupled to lateral in-plane modes of the in-plane waveguide formed in the silicon layer, and light can be provided to e.g. photonic circuits on a SOI or CMOS substrate in the silicon.

Owner:DANMARKS TEKNISKE UNIV

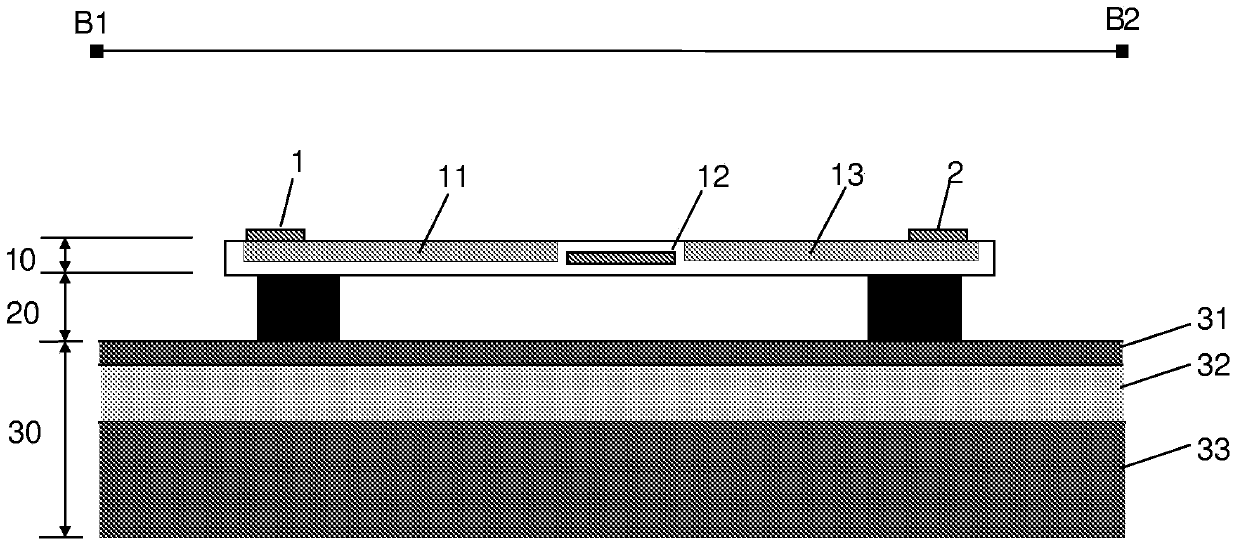

Method and system for processing immersed workpiece by double laser light

ActiveCN105728954AReduce the development of microstructural defects to microcracksReduce the effects of local overheatingWelding/soldering/cutting articlesLaser beam welding apparatusLaser processingGas laser device

The invention discloses a method and a system for processing an immersed workpiece by double laser light. The method includes focusing the laser light A with the wavelength of 1064 nm on the surfaces of the workpiece in water and locally softening the heated workpiece; focusing the laser light B with the wavelength of 10640 nm on the water above the workpiece; breaking through the water by the aid of the laser light B to generate impact waves, enabling the impact waves to act on locally softened regions of the surfaces of the workpiece and removing softened materials so as to groove and process the workpiece. A focus point of the laser light A and a focus point of the laser light B are distanced from each other by hundreds of micrometers. Solid for generating the laser light A and the laser light B and a laser head of a CO2 gas laser device of the system are positioned above a water tank, the center line of laser beams A is a plumb line, the center line of laser beams B intersects with the laser beams A at the focus point of the laser light A on the upper surface of the workpiece, and an intersection angle of the center line of the laser beams B and the laser beams A is 10-30 degrees. The height of a worktable can be adjusted. The thicknesses of water layers on the surfaces of the workpiece are 1-3 millimeters. Compared with laser melt cutting processing, the system and the method have the advantages that the heating temperature of the laser light A is lower than melting points of the materials, accordingly, influence of local overheating can be reduced, and the quality of machined finished products can be guaranteed.

Owner:GUILIN UNIV OF ELECTRONIC TECH

Method of preparing anti-wearing and anti-corrosion coating on surface of ejection roller table of continuous casting machine

ActiveCN106854761AHigh hardnessImprove wear resistanceMetallic material coating processesAlcoholGas laser device

The invention discloses a method of preparing an anti-wearing and anti-corrosion coating on the surface of an ejection roller table of a continuous casting machine. The method comprises the steps of: (1) pretreatment on the surface of the ejection roller table of the continuous casting machine: at room temperature, derusting and deoiling the surface of the ejection roller table of the continuous casting machine and cleaning the surface of the ejection roller table with alcohol; (2) design and preparation of alloy powder: selecting nickel-based alloy powder having good anti-wearing and anti-corrosion performance; and (3) preparation of a laser cladding layer: directly feeding alloy powder into a weld pool in a gravitational synchronic delivery manner with a DL-HL-T5000 type CO2 gas laser device to perform laser cladding to the surface of the ejection roller table of the continuous casting machine, powder thickness after cladding being 1.0-1.5 mm. The ejection roller table of the continuous casting machine is improved in anti-wearing and anti-corrosion performances by more than six times than a new product in the same type, while the cost is only about 50% of the new product.

Owner:SHENYANG DALU LASER TECH

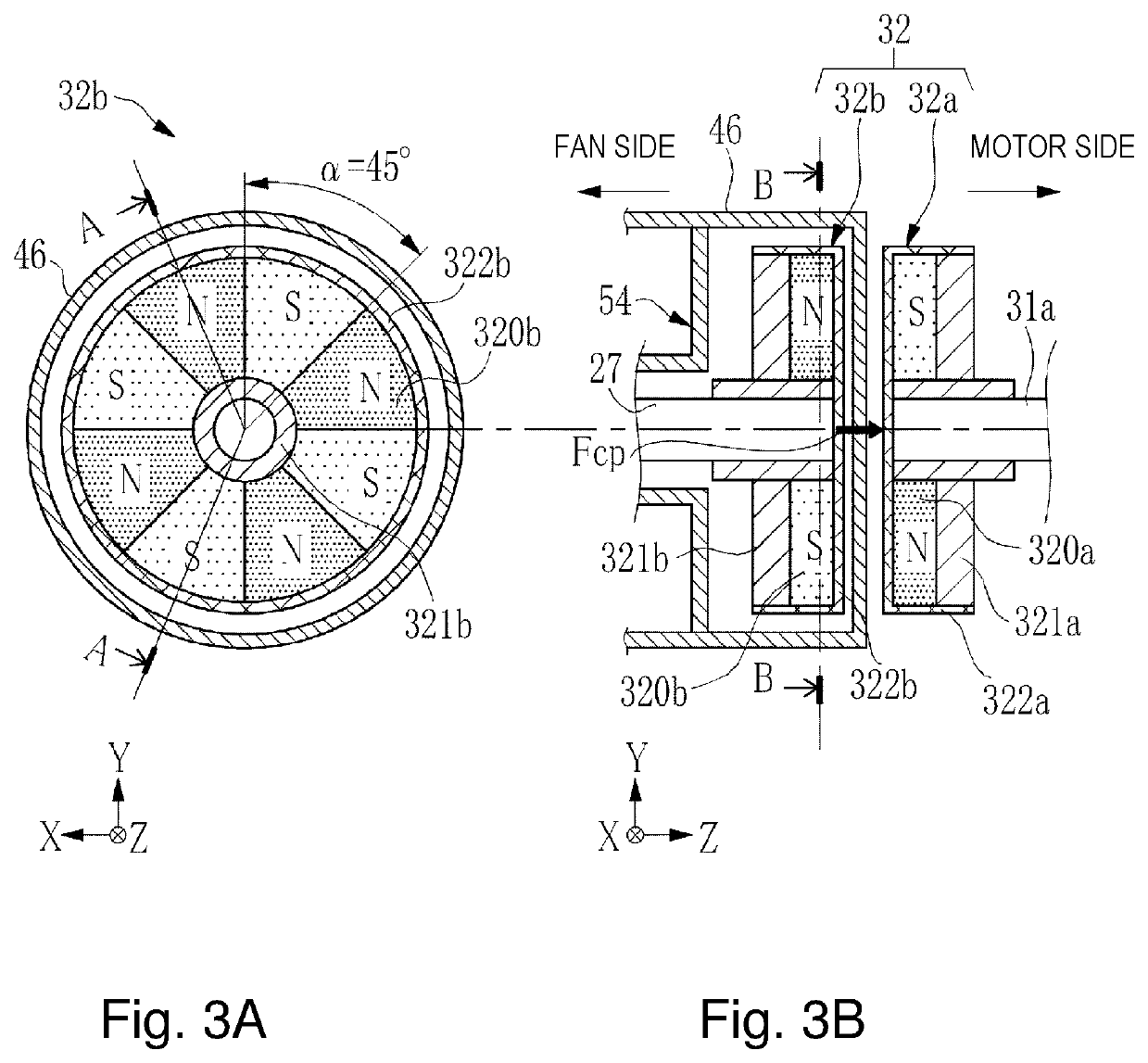

Gas laser apparatus and magnetic bearing control method

A gas laser apparatus includes: a magnetic bearing including an electromagnet capable of controlling a magnetic force, and configured to rotatably support a rotary shaft of a fan in a magnetically levitated state by the magnetic force, the fan being configured to supply a laser gas; an electromagnet control unit configured to control the magnetic force of the electromagnet based on displacement of a levitated position of the rotary shaft and adjust the levitated position; a motor configured to generate torque for rotating the fan; a magnetic coupling configured to couple the rotary shaft and a drive shaft of a motor with a magnetic attractive force and transmit the torque of the motor to the rotary shaft; an attractive force estimating sensor configured to detect a parameter that enables an attractive force of the magnetic coupling to be estimated; an attractive force measuring unit configured to measure the attractive force of the magnetic coupling based on the detected parameter; and a correction unit configured to correct the magnetic force of the electromagnet according to a variation in the attractive force measured by the attractive force measuring unit.

Owner:GIGAPHOTON

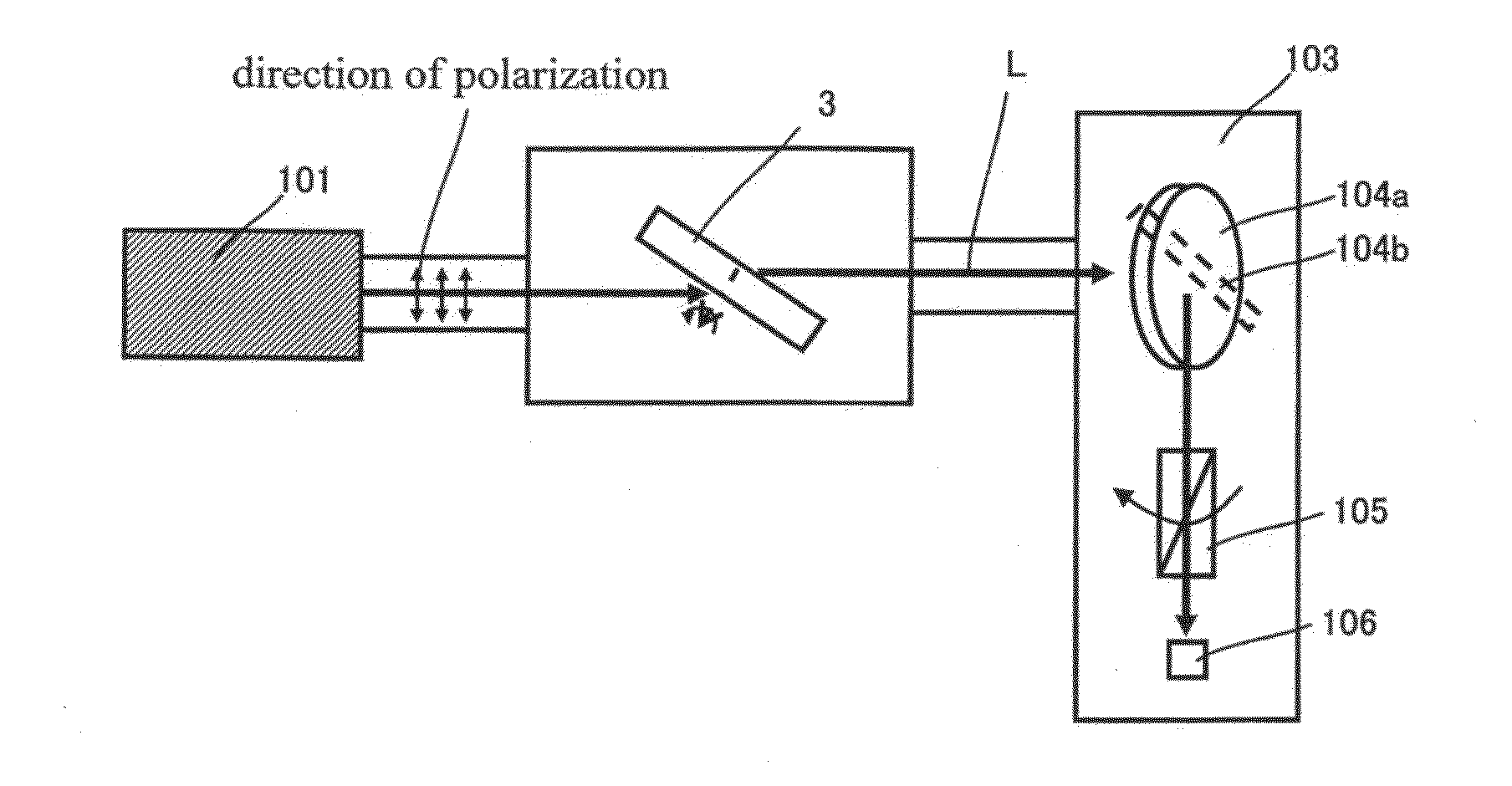

Polarization purity control device and gas laser apparatus provided with the same

ActiveUS20100128747A1Avoid damagePrevent degradationActive medium materialOptical devices for laserGas laser deviceOptoelectronics

A degree of polarization control device includes:a calcium fluoride crystal substrate for transmitting a laser beam;a polarization monitor for measuring the degree of polarization of a laser beam transmitted through the calcium fluoride crystal substrate; anda controller for controlling the rotation angle of the calcium fluoride crystal substrate according to the degree of polarization measured by the polarization monitor;the calcium fluoride crystal substrate being formed by a flat plate having a laser beam entering surface and a laser beam exiting surface running in parallel with the (111) crystal face, the Brewster angle being selected for the incident angle, the rotation angle around the [111] axis operating as a central axis being controlled by the controller.

Owner:GIGAPHOTON

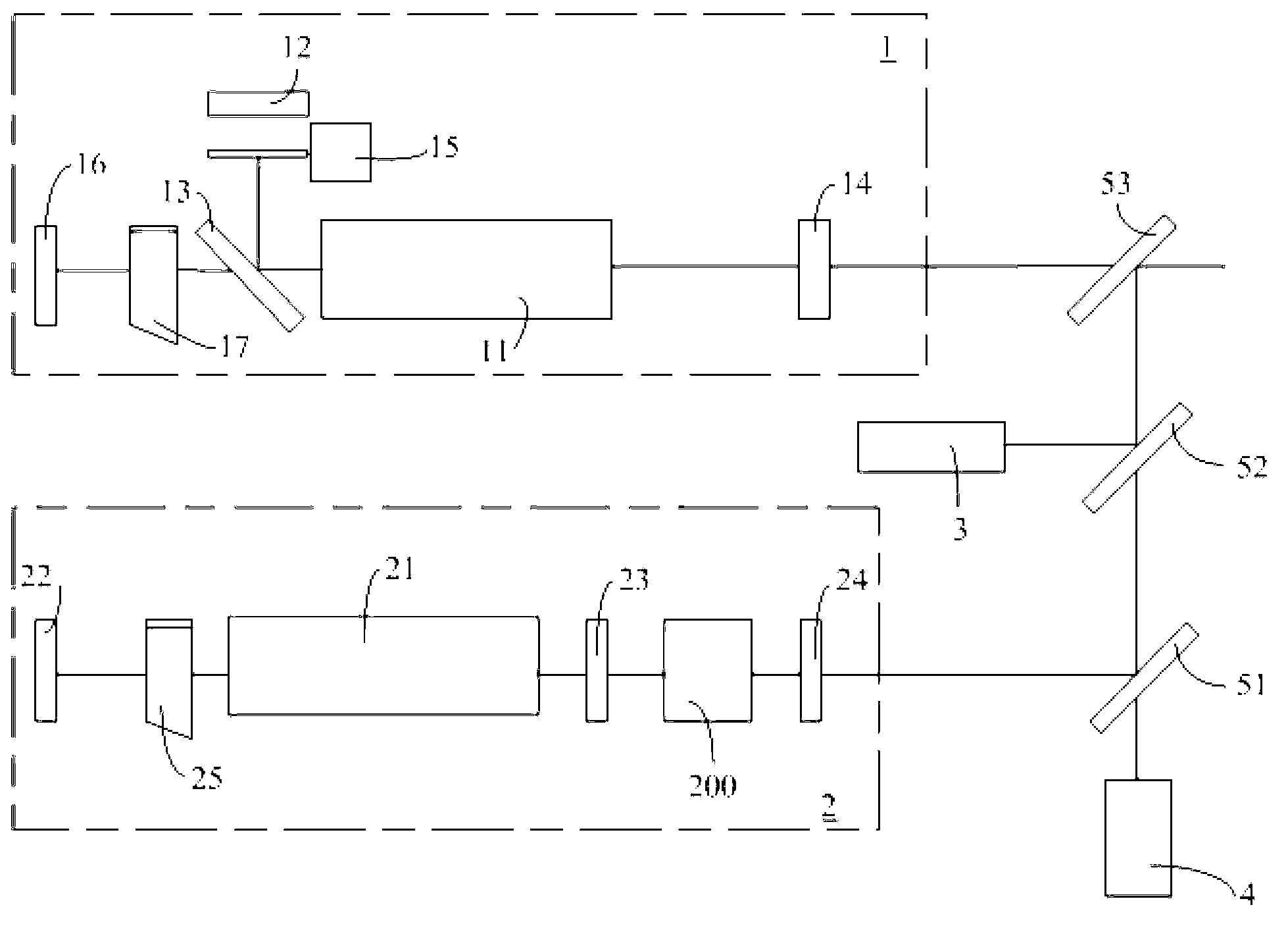

Laser device and laser system using same

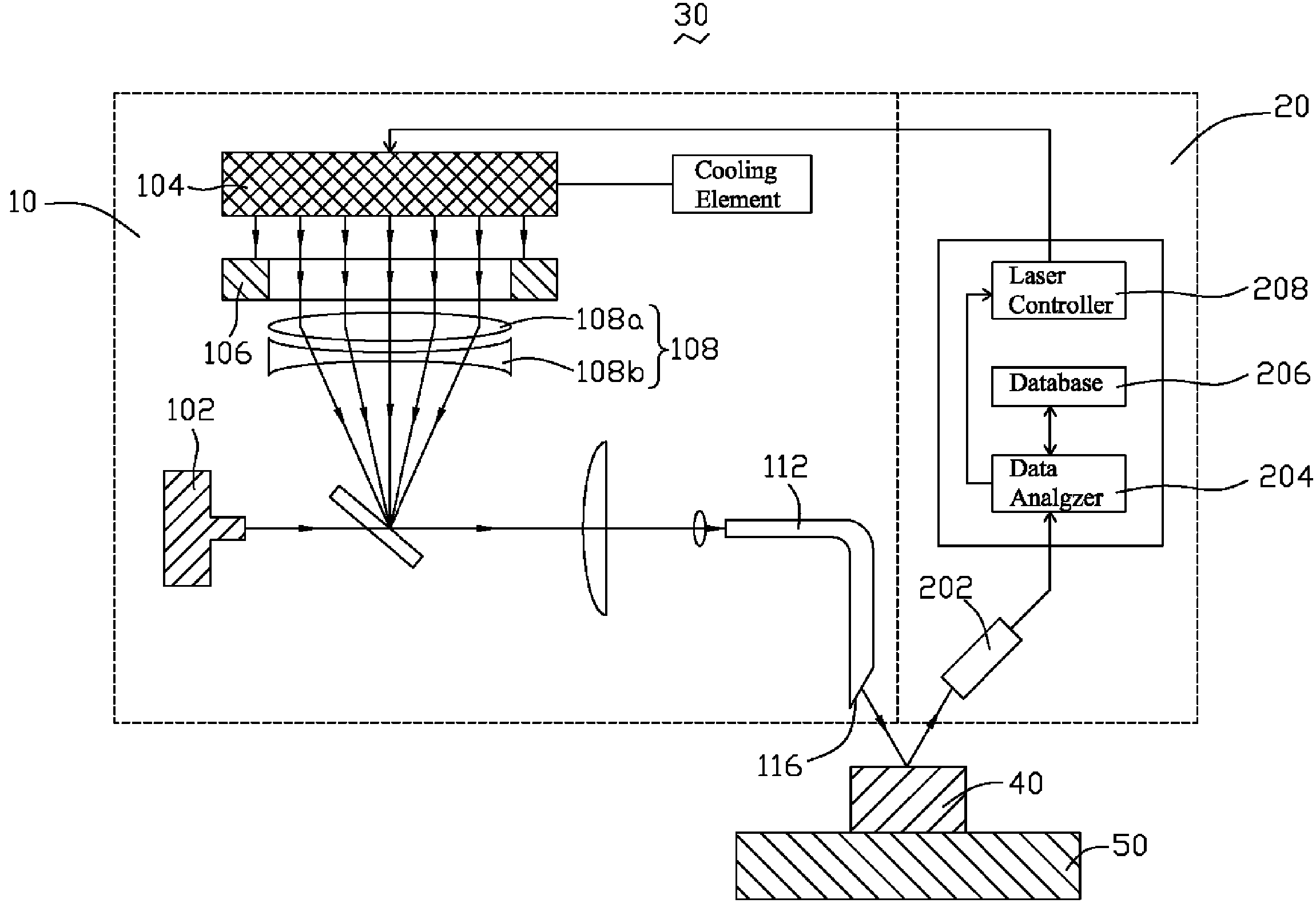

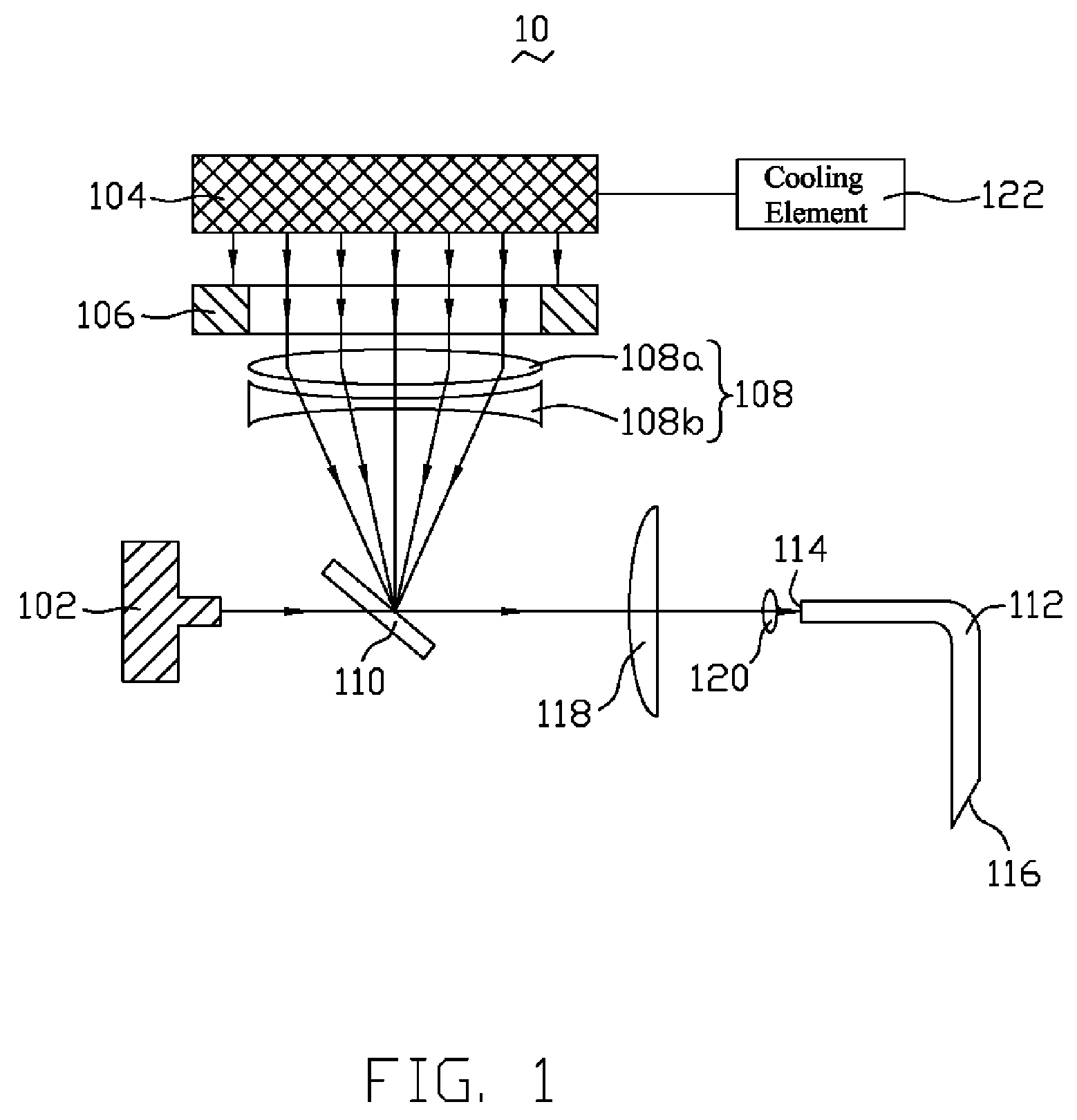

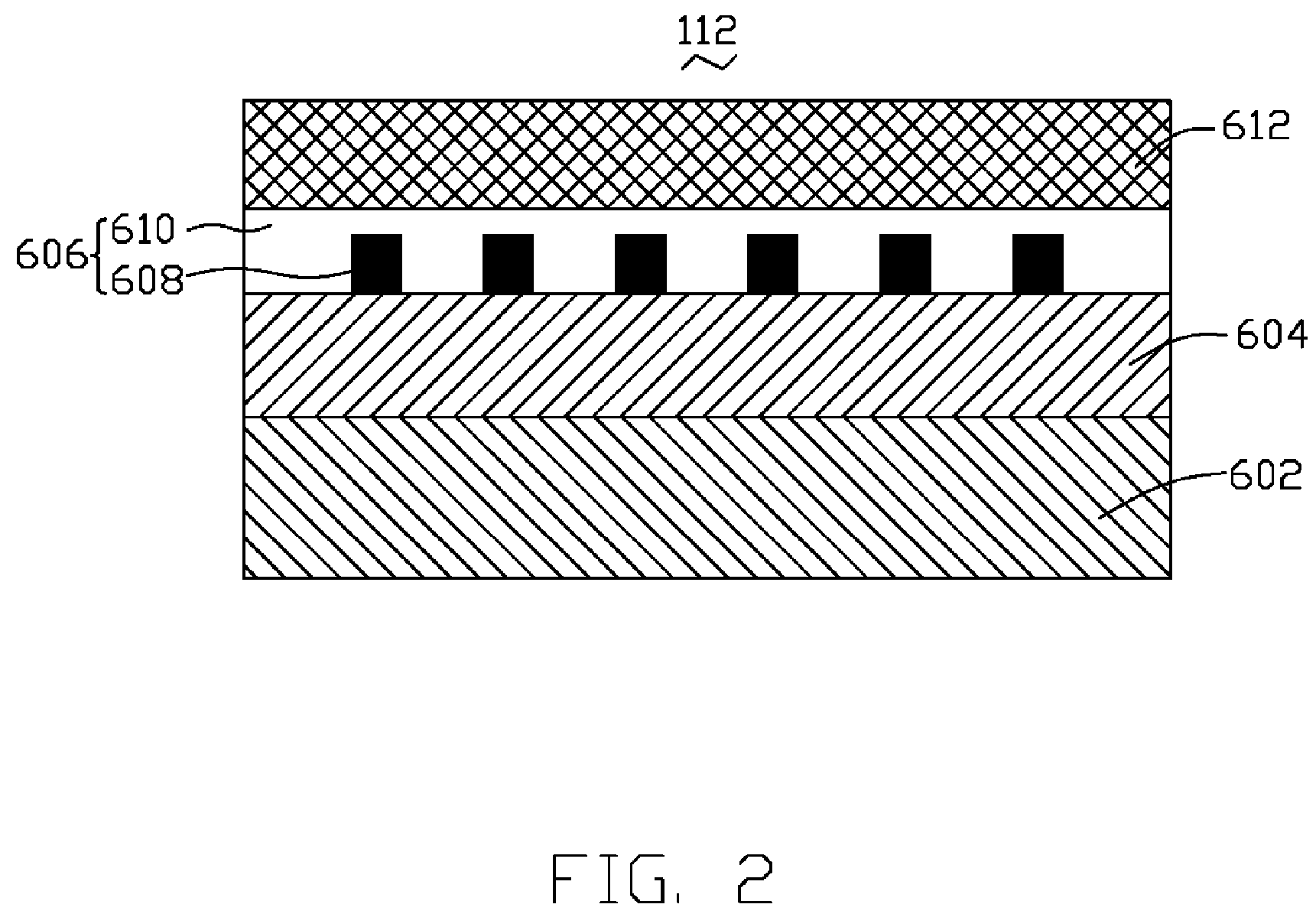

A laser device (10) includes a first laser source (102) for emitting laser beams with a first wavelength, a second laser source (104) for emitting laser beams with a second wavelength, a dichromic beamsplitter (110), and a flexible light waveguide (112). The dichromic beamsplitter is configured for transmitting laser beams emitted from the first laser source and changing a transmission direction of the laser beams emitted from the second laser source. The flexible light waveguide transmits the laser beams from the dichromic beamsplitter, and the flexible light waveguide has a light-input end (114) and a light-output end (116). The light-input end receives the laser beams from the dichromic beamsplitter, and the light-output outputs the laser beams to a workpiece. A laser system (30) using the same is also provided.

Owner:HON HAI PRECISION IND CO LTD

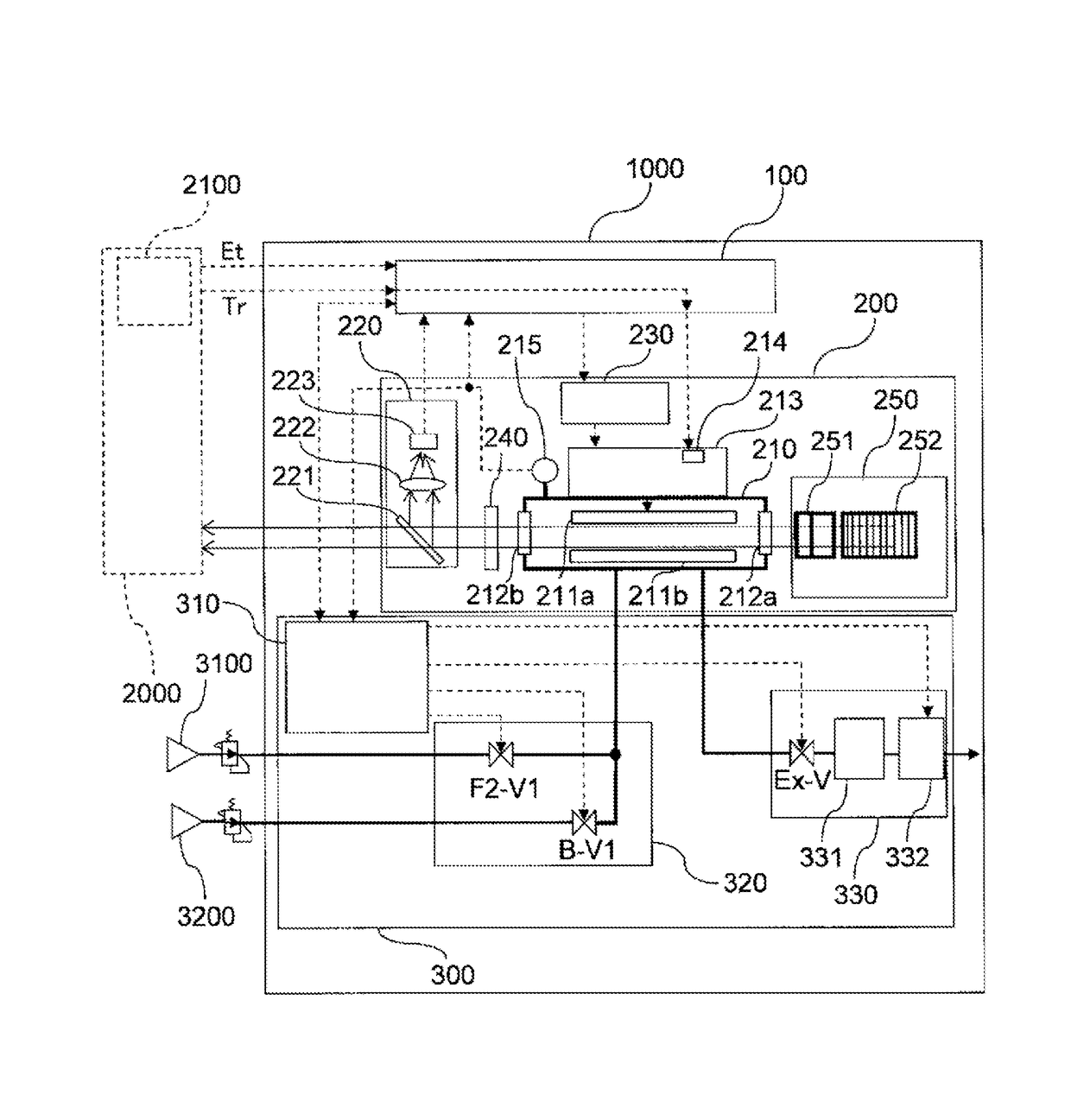

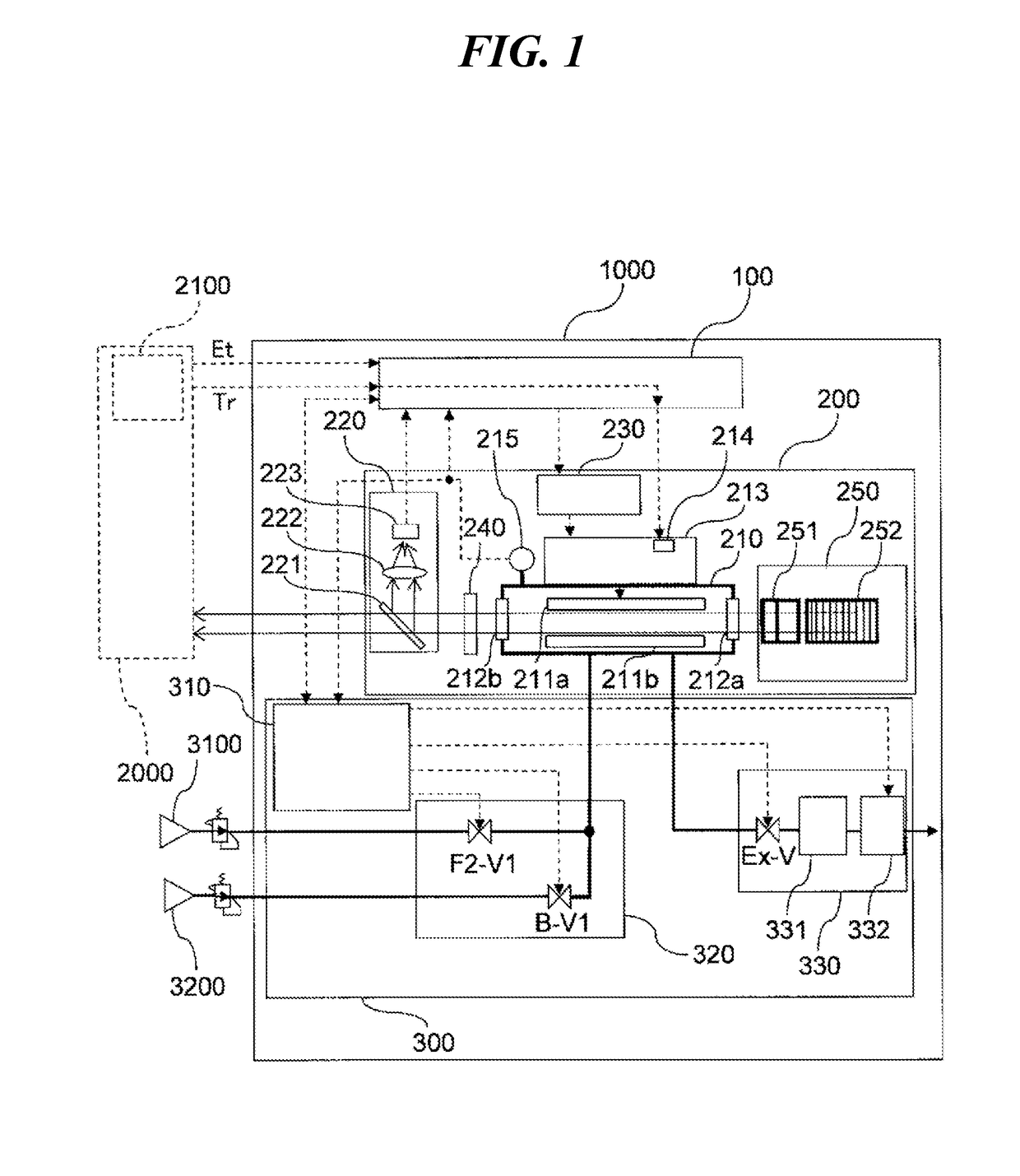

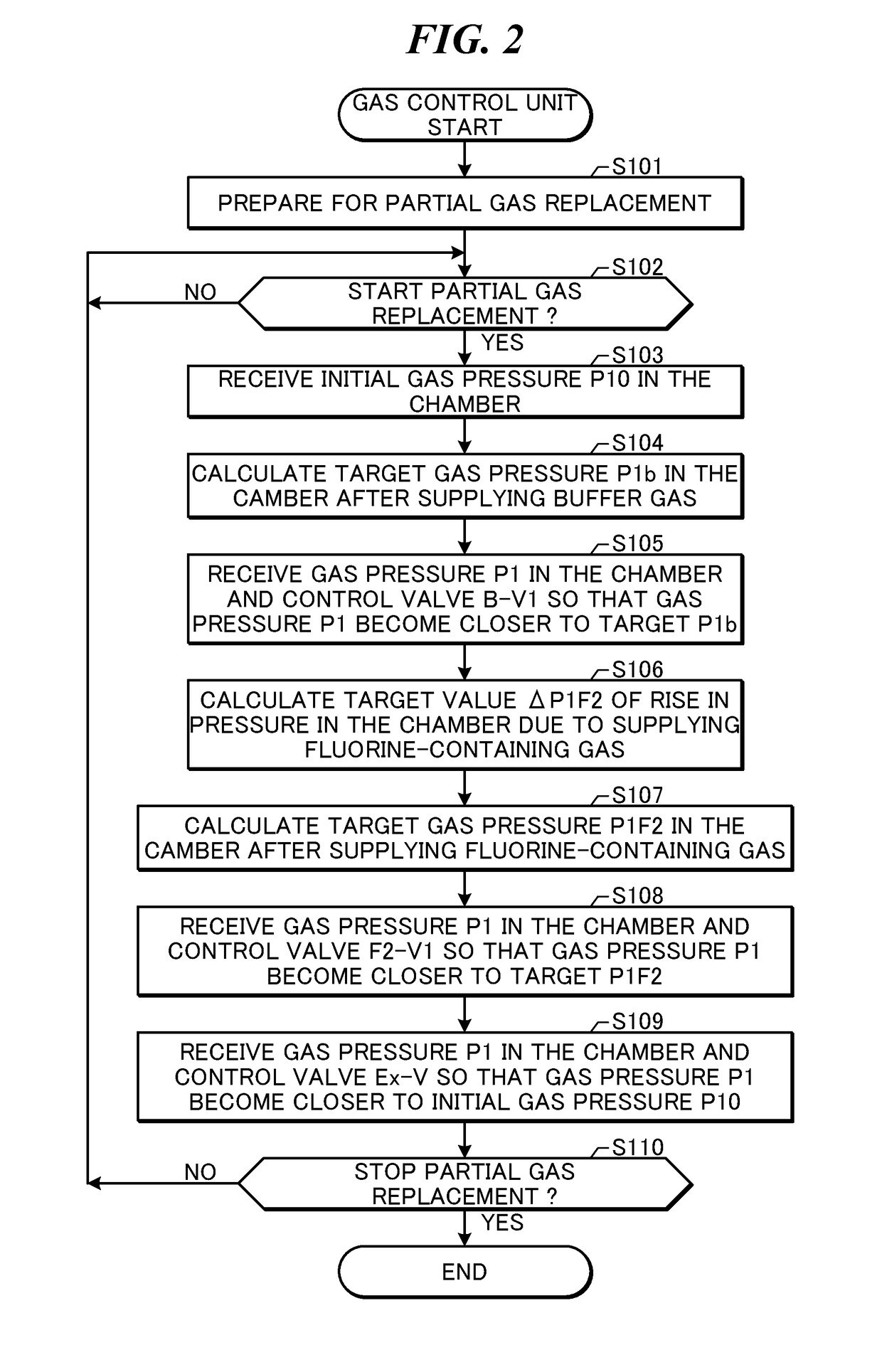

Gas laser apparatus

A gas laser apparatus may include: a laser chamber connected through a first control valve to a first laser gas supply source that supplies a first laser gas containing a halogen gas and connected through a second control valve to a second laser gas supply source that supplies a second laser gas having a lower halogen gas concentration than the first laser gas; a purification column that removes at least a part of the halogen gas and a halogen compound from at least a part of a gas exhausted from the laser chamber; a booster pump, connected through a third control valve to the laser chamber, which raises a pressure of a gas having passed through the purification column to a gas pressure that is higher than an operating gas pressure of the laser chamber; and a controller that calculates, on a basis of a first amount of a gas supplied from the booster pump through the third control valve to the laser chamber, a second amount of the first laser gas that is to be supplied to the laser chamber and controls the first control valve on a basis of a result of the calculation of the second amount.

Owner:GIGAPHOTON

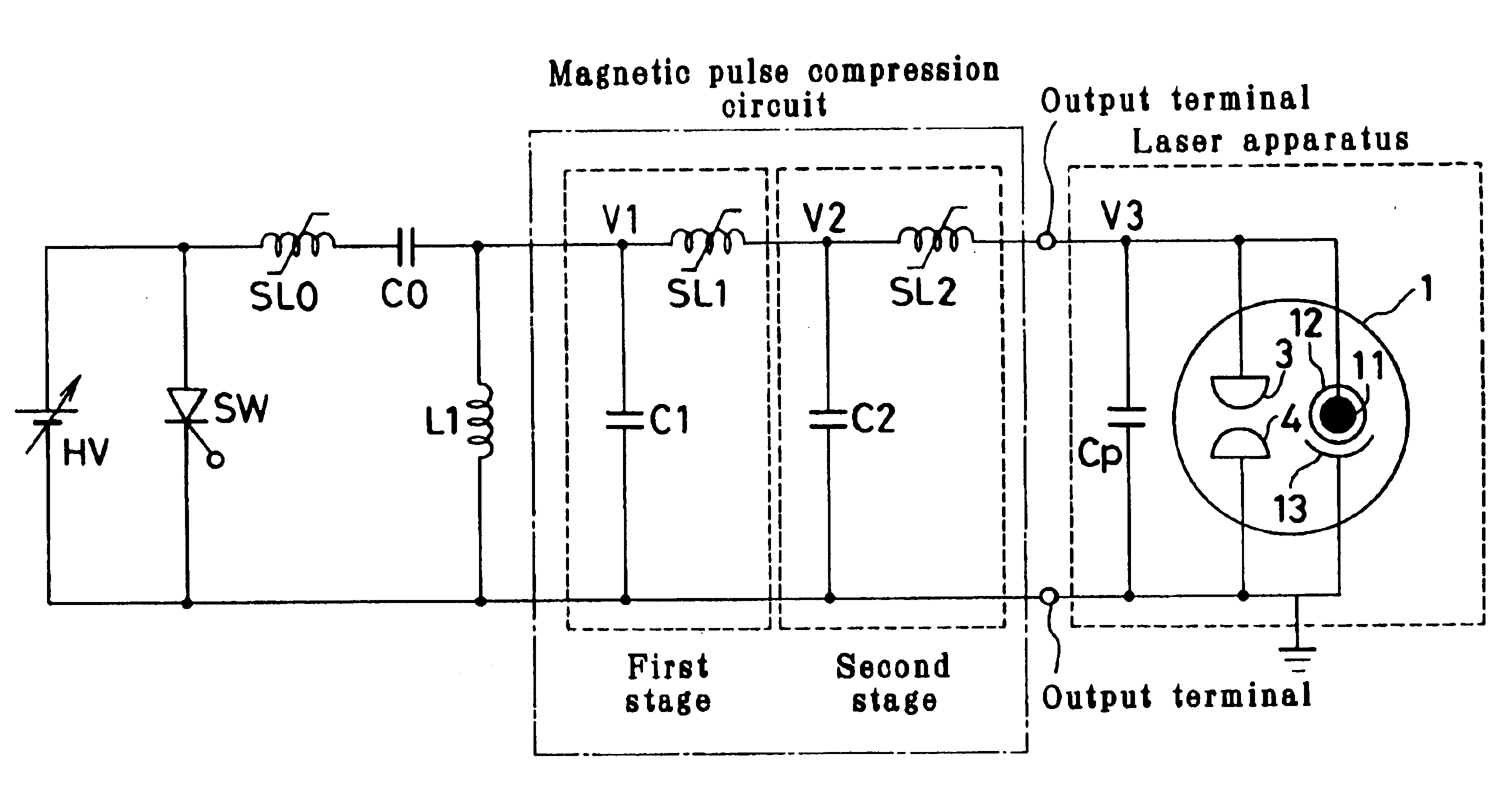

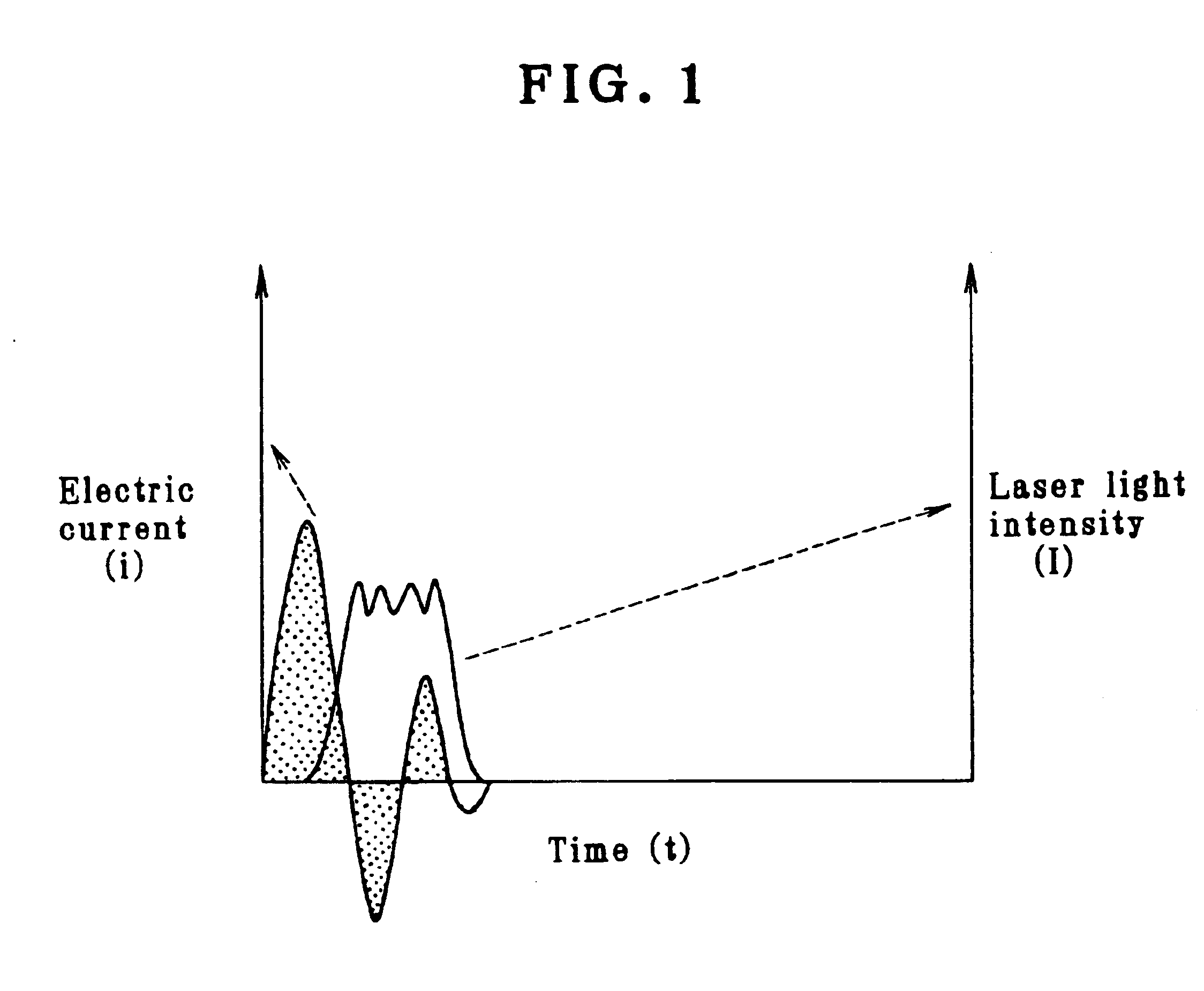

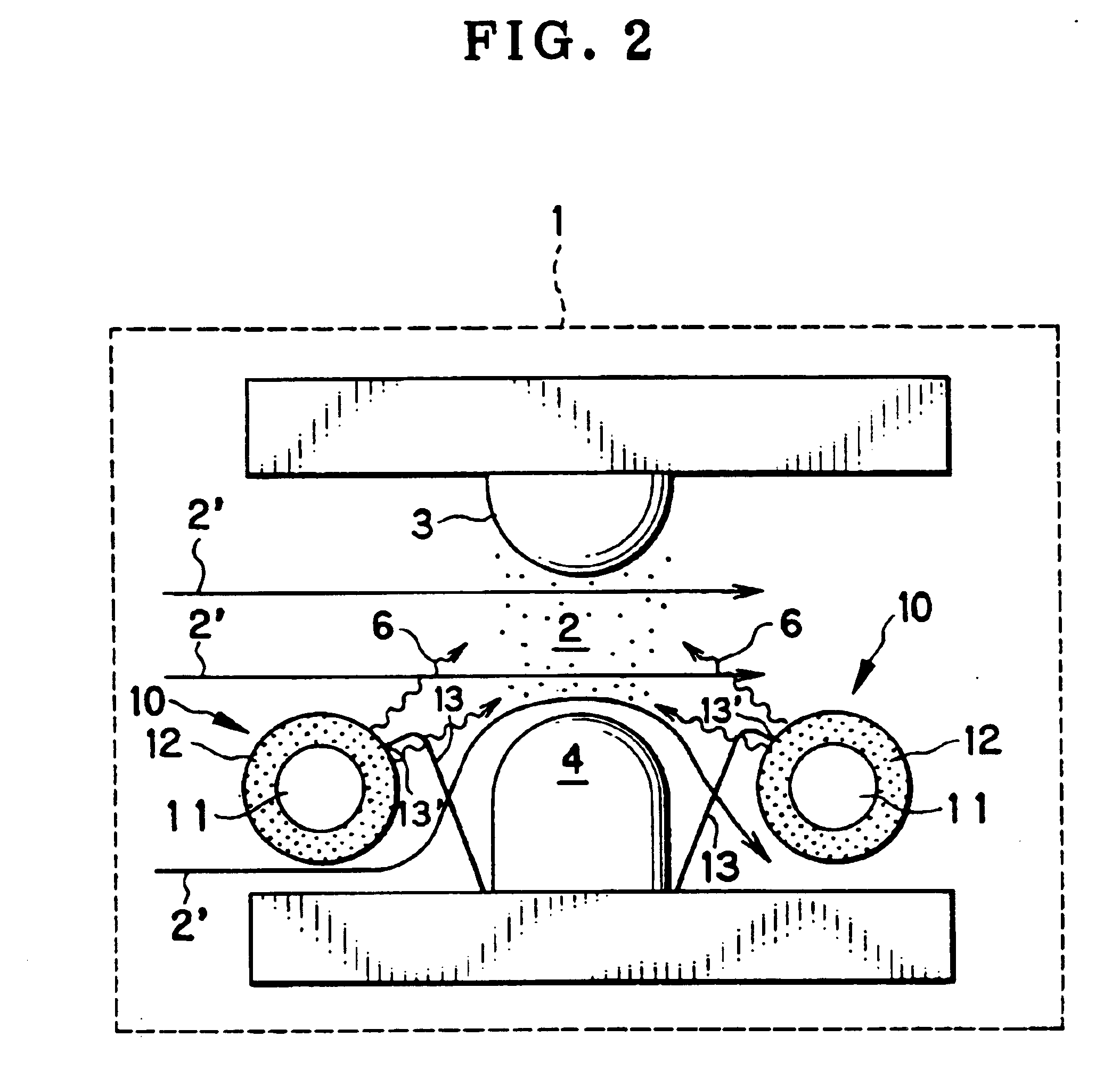

Gas laser apparatus emitting ultraviolet radiation

InactiveUS6847670B1Extend oscillation pulse widthLaser constructional detailsActive medium materialGas laser deviceUltraviolet radiation

The oscillation pulse width is extended in a gas laser apparatus emitting ultraviolet radiation by a high-repetition rate oscillating operation. The gas laser apparatus has a pair of laser discharge electrodes connected to the output terminals of a magnetic pulse compression circuit and disposed in a laser chamber. The pulse width is extended by determining circuit constants so that the period of the oscillating current flowing between the discharge electrodes is shortened and, at the same time, the peak value of the current is increased, whereby the laser gas is continuously excited even during at least one half-cycle subsequent to the first half-cycle of the oscillating current to sustain the laser oscillating operation.

Owner:USHIO DENKI KK

Gas laser apparatus

A gas laser apparatus including a laser oscillating section including a medium circuit allowing a medium gas to flow therethrough under pressure, and a gas-composition adjusting section for adjusting the composition of the medium gas flowing through the medium circuit of the laser oscillating section. The gas-composition adjusting section comprising a gas supply section for supplying several types of medium gases having different compositions to the medium circuit of the laser oscillating section with a flow rate of each of the medium gases being adjustable; a gas exhaust section for exhausting the medium gas from the medium circuit of the laser oscillating section; and a control section for controlling the gas supply section and the gas exhaust section, to adjust the composition of the medium gas flowing through the medium circuit, in accordance with an oscillation condition including at least one of an attribute of an object matter acted on by a laser beam oscillated by the laser oscillating section and the accuracy of action of the laser beam.

Owner:FANUC LTD

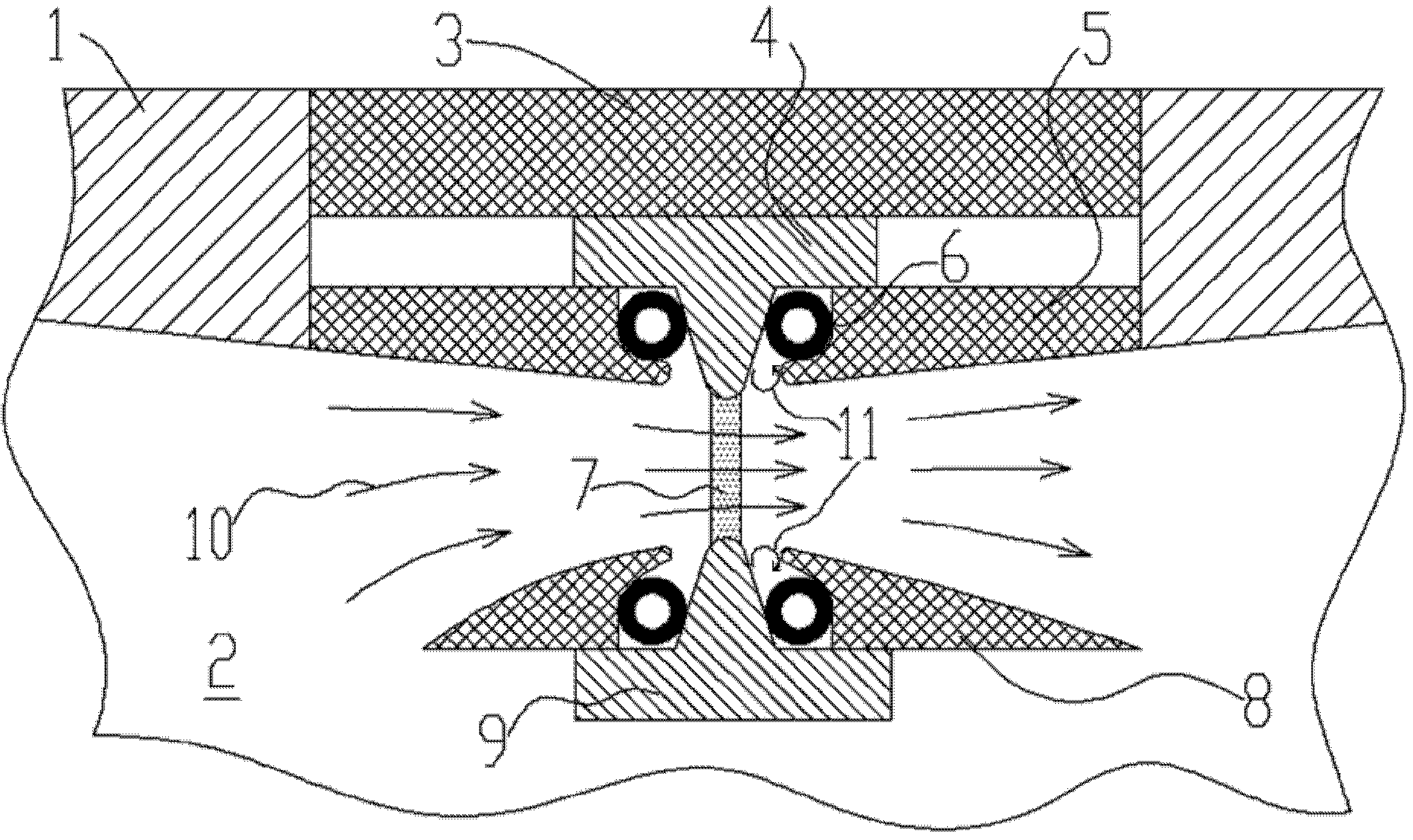

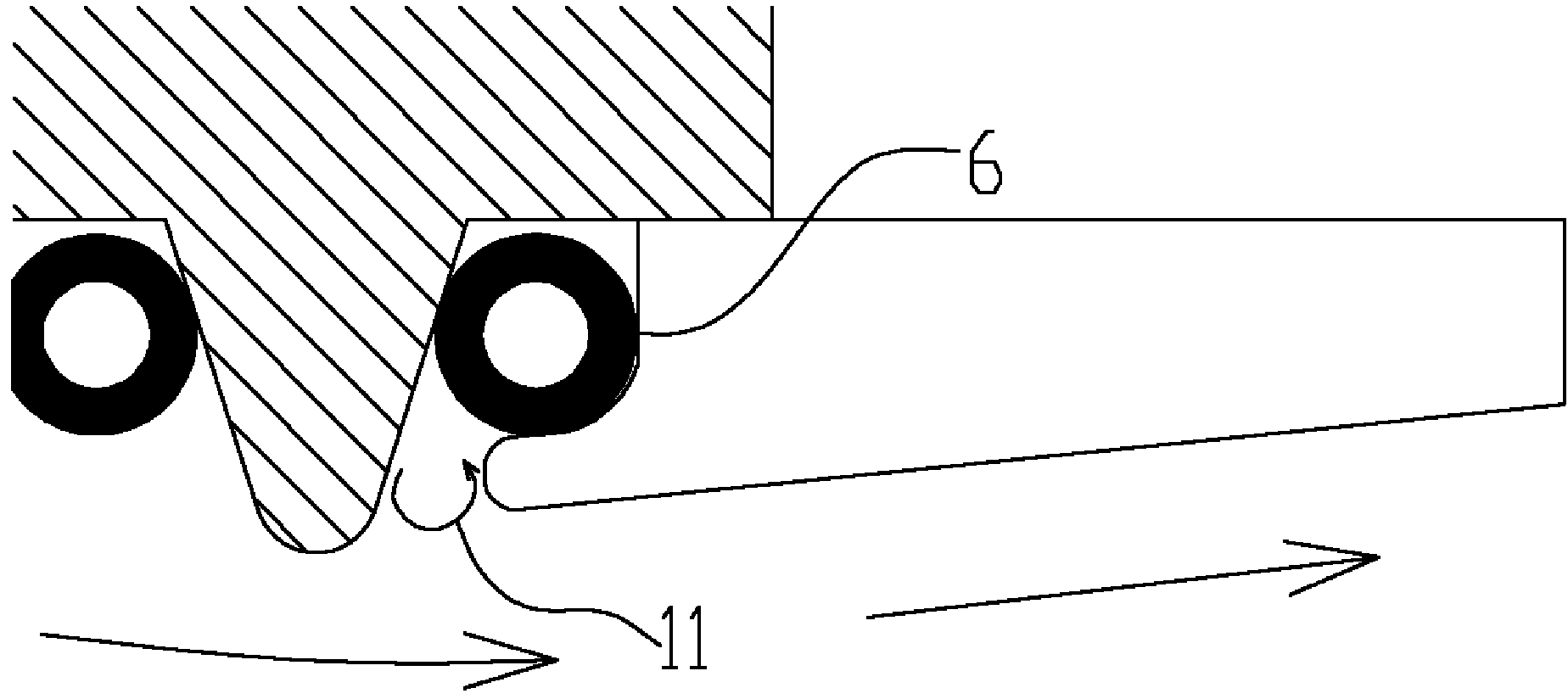

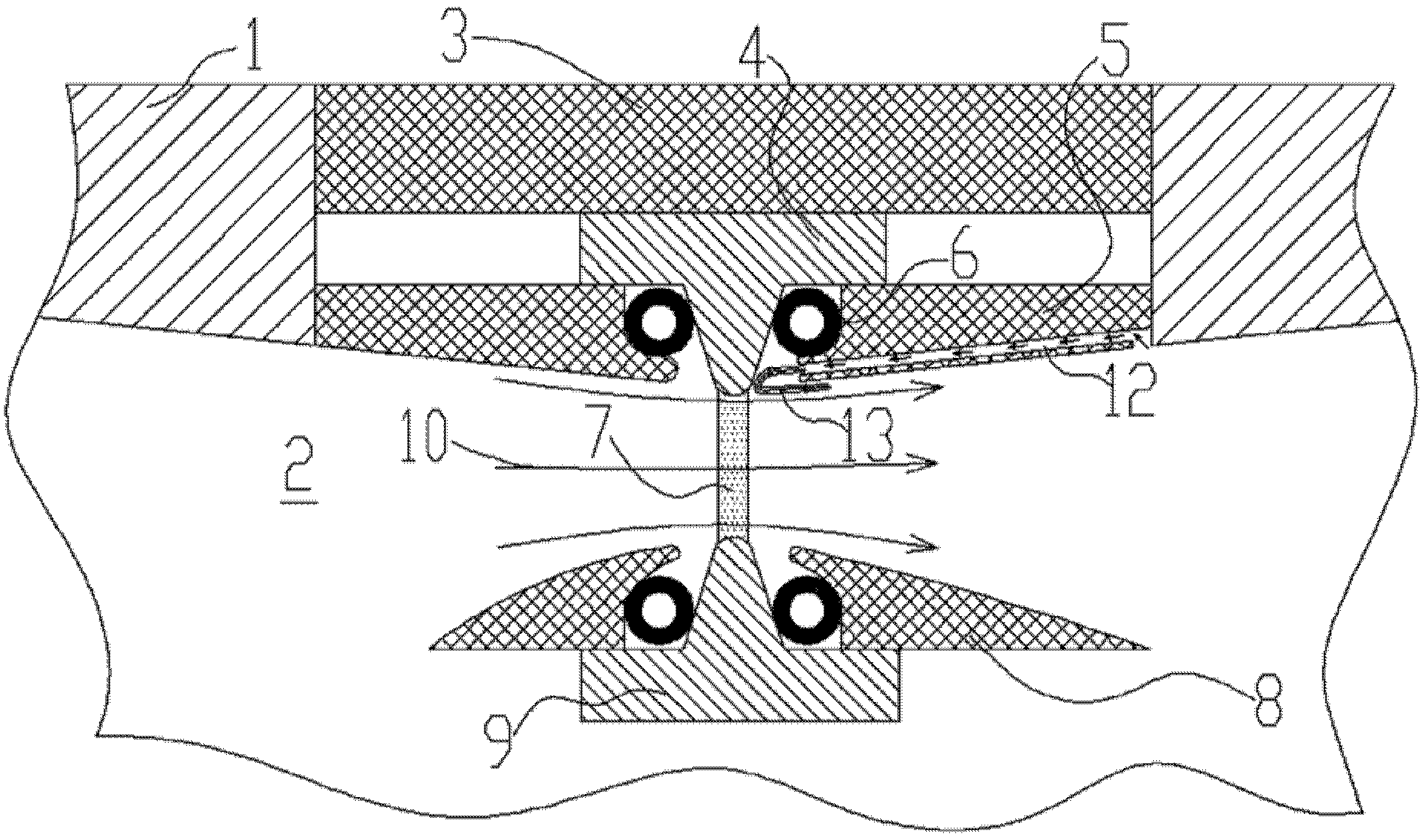

Discharging chamber with micro-channel structure and gas laser device

ActiveCN102842840AAvoid it happening againReduce bit arc phenomenonActive medium materialGas laser constructional detailsGas laser deviceEngineering

The invention discloses a discharging chamber with a micro-channel structure and a gas laser device. The discharging chamber is internally provided with a discharging electrode and a draught fan; and the draught fan drives gas in the discharging chamber to flow through the discharging electrode, so as to form a main gas flow. Flow guide plates are arranged at the two sides of the discharging electrode and a micro-channel is arranged on each flow guide plate; and an outlet of the micro-channel faces to a gap between each flow guide plate and the discharging electrode. The discharging chamber further comprises a pre-ionizing device and is supported among the flow guide plates and the discharging electrode. According to the discharging chamber with the micro-channel structure and the gas laser device, the micro-channel structure is formed in the discharging chamber of an excimer laser device, thereby preventing the generation of a vortex air flow, reducing an arc phenomenon generated on the side face of the discharging electrode, increasing the discharging stability, improving the laser energy and prolonging the service life of a pre-ionizing electrode.

Owner:RAINBOW SOURCE LASER RSLASER

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com