Method for cutting crisp material substrate

A technology for brittle material substrates and cutting methods, applied in glass cutting devices, welding/welding/cutting items, stone processing equipment, etc., can solve problems affecting product yield and damage to glass substrates, so as to improve product yield and guarantee The effect of cut quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be described in further detail below in conjunction with the accompanying drawings.

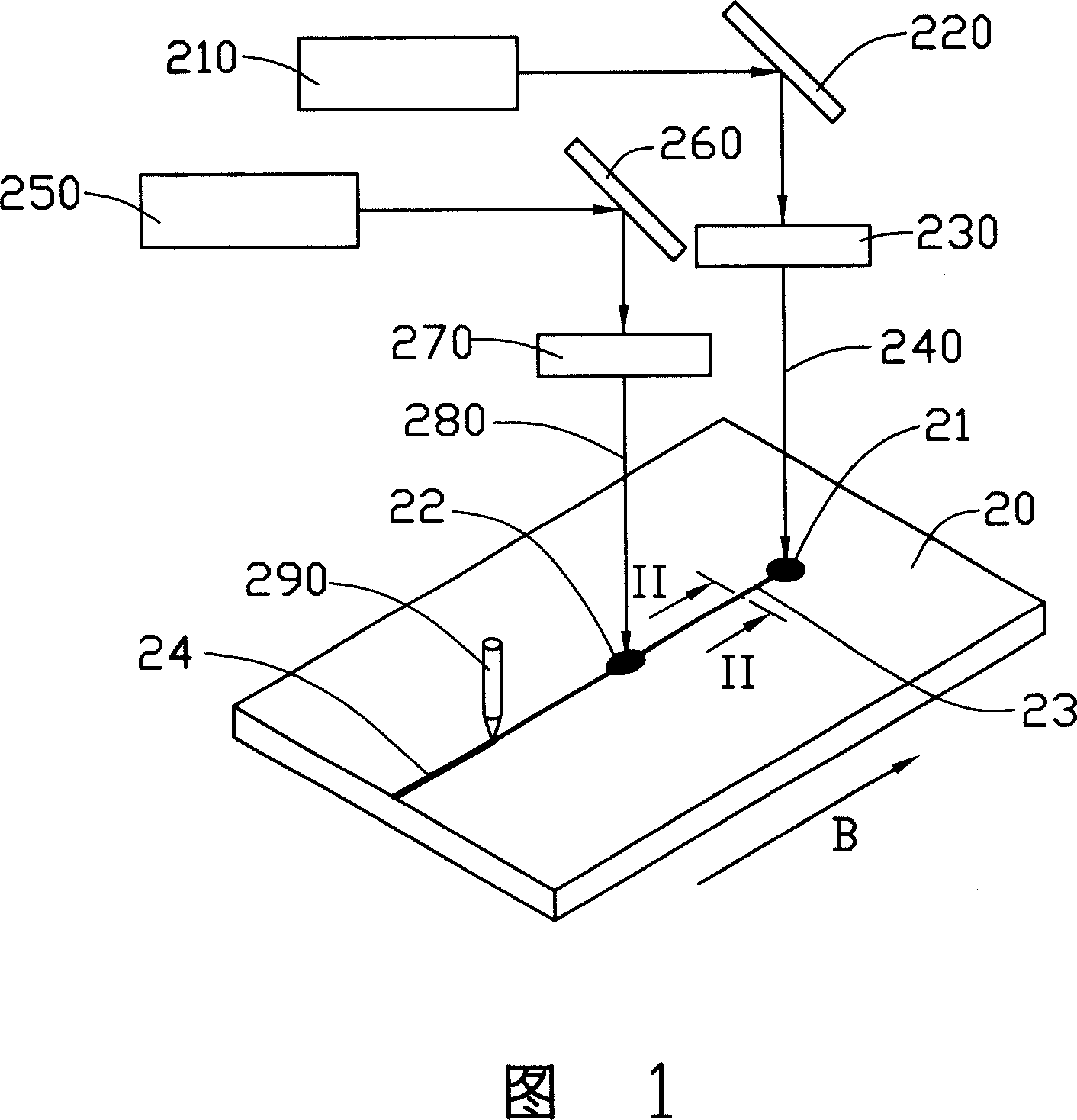

[0016] Please refer to FIG. 1, the method for cutting a brittle material substrate provided by an embodiment of the present invention includes the following steps:

[0017] (1) A brittle material substrate 20 is provided, and the brittle material substrate 20 may be a glass substrate, a ceramic substrate, a quartz substrate, a silicon wafer (Silicon Wafer) and the like.

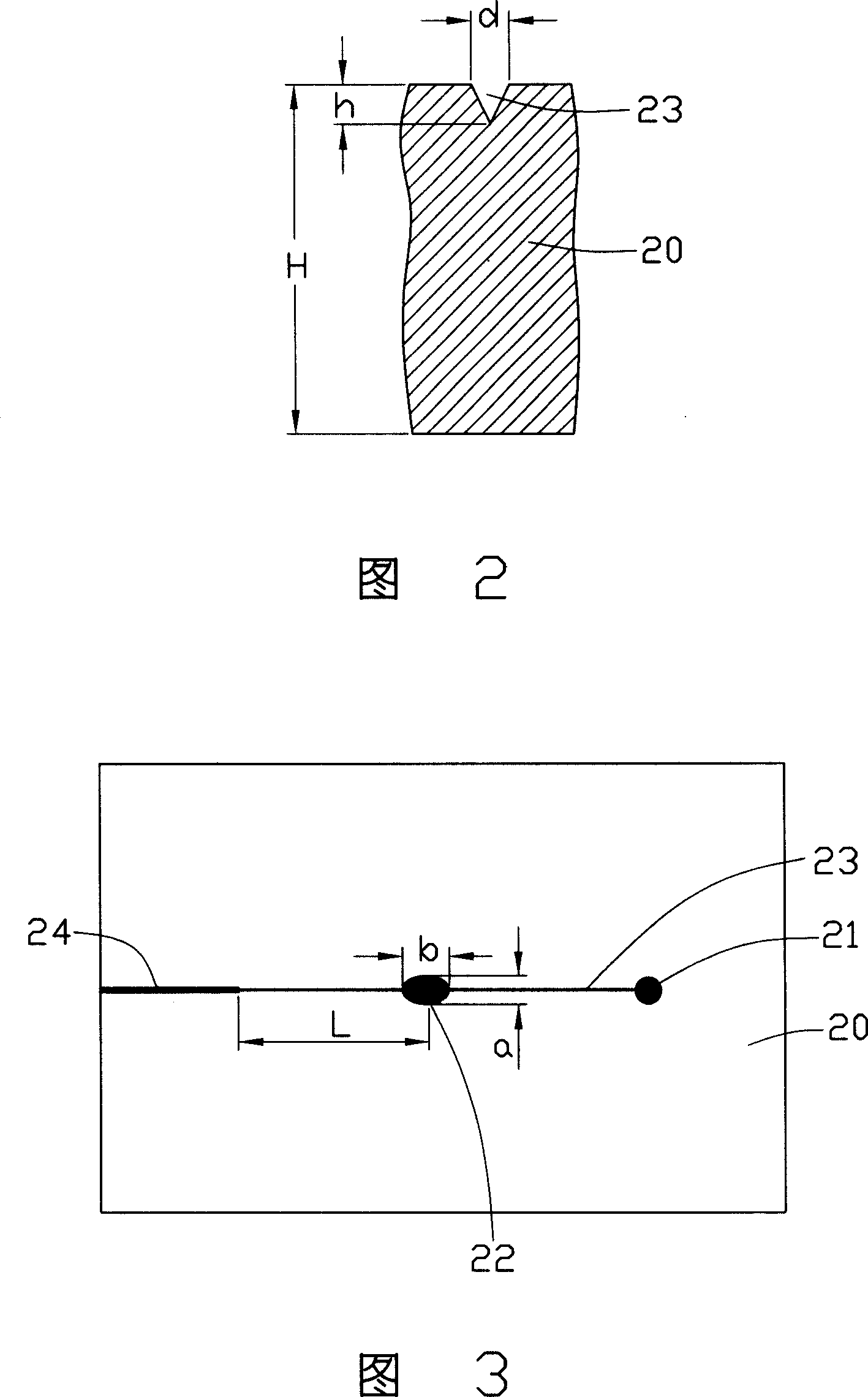

[0018] (2) Using the first laser beam 240 generated by the solid-state laser 210 to form a pre-cut line (Pre-crack) 23 on the surface of the brittle material substrate 20 . The specific steps are as follows:

[0019] The brittle material substrate 20 to be processed is placed on the carrier platform (not shown); the first laser beam 240 generated by the solid-state laser 210 is guided to the first focusing lens group 230 after passing through the first reflector 220, the first The focusing...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com