Axial fast flow gas laser device

A technology of gas laser and axial fast flow, which is applied to gas laser parts, lasers, laser parts, etc., can solve the problems of volume increase and space utilization reduction, and achieve the effect of small temperature difference change

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments. The following description will help those skilled in the art better understand other advantages, objectives and features of the present invention.

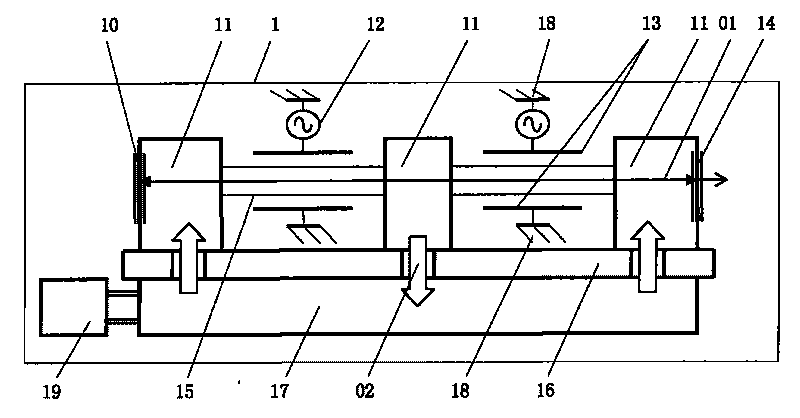

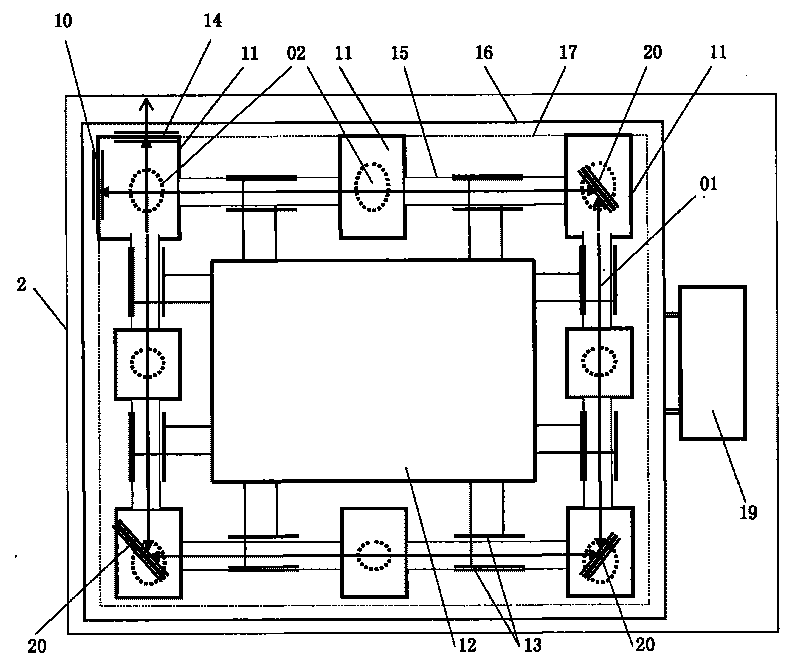

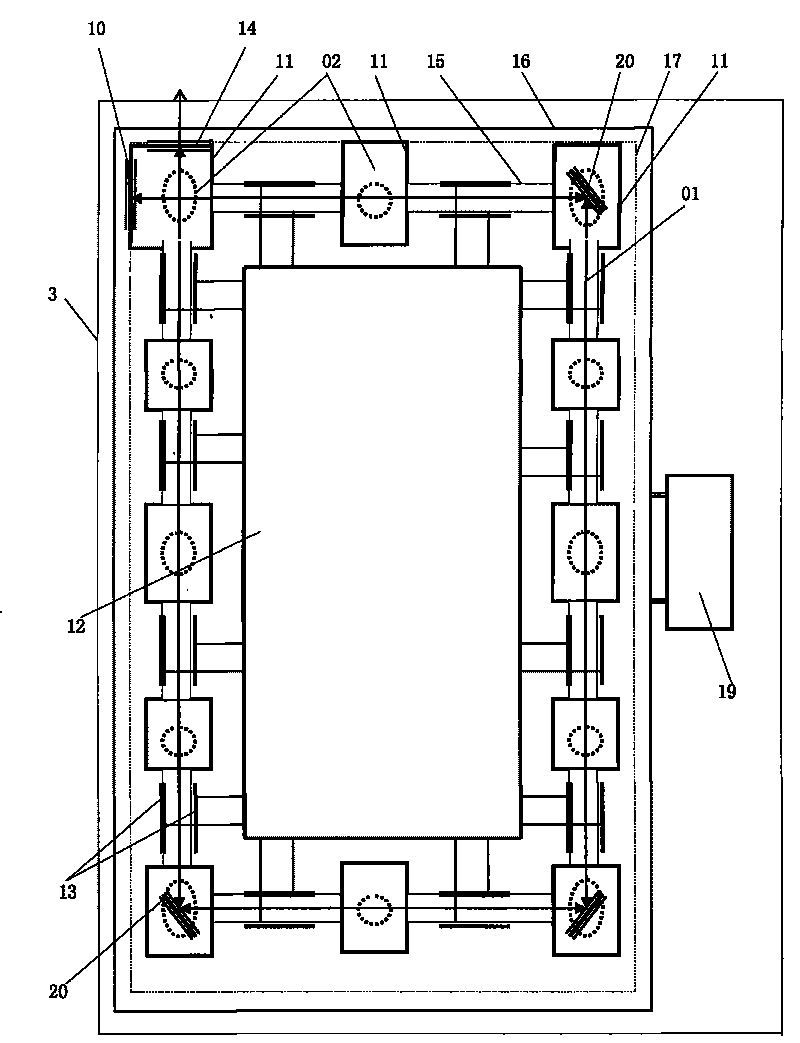

[0030] At first introduce the first embodiment of the device of the present invention, refer to figure 1 . figure 1 An axial fast flow gas laser device 1 is shown, which is used to output laser beams. The device 1 mainly includes: a resonant cavity, a gas circulation cooler 17, a flat plate 16, a discharge electrode 13, a radio frequency power supply 12 and a gas pump 19, The resonant cavity further includes: a front mirror 14 , a rear mirror 10 , a discharge tube 15 and an optical path support 11 .

[0031] figure 1 As shown in the axial fast flow gas laser device 1, the optical path support 11 is fixed at both ends of the discharge tube 15 to connect the optical path 01 and the gas path 02, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com