Patents

Literature

53results about How to "Little change in temperature difference" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Snake breeding method

The invention discloses a snake breeding method. The method comprises the first step of selecting and building a breeding base, the second step of breeding snakes outside and conducting quarantine, wherein the healthy snakes are cleaned, made to have a medicated bath and placed into an open breeding place, the third step of feeding the snakes with food and bait, wherein the snakes are fed every 10-12 days, the fourth step of conducting overwintering and oversummering management, wherein cold water is sprayed onto the open breeding place and fresh water is injected into water troughs every day in summer, the food supply quantity to the snakes is increased before the hibernation period of the snakes comes, and during the hibernation period of the snakes, at least four 100-W incandescent lamps are arranged in an underground activity region, the fifth step of conducting sanitation and safety management, wherein gaps between cobblestones are filled with fermentation beds, and the sixth step of conducting breeding, wherein isolated snake rooms are arranged in the open breeding place and pregnant female snakes are individually placed in the snake rooms. By means of the method, the advantages of a traditional open breeding method and the advantages of a snake room breeding method are combined, the suitable temperature and good ventilation of the living environment of the snakes are both guaranteed, and excrement of the snakes does not need cleaning.

Owner:徐州博创建设发展集团有限公司

Metal surface cleaning anti-scaling agent containing compound acid

InactiveCN103074635ALittle change in temperature differenceEasy to implementActive agentSurface cleaning

The invention belongs to the technical field of chemical cleaning of metal surfaces, and particularly relates to a metal surface cleaning anti-scaling agent containing compound acid. The agent comprises two or more components in parts by weight as follows: 70-98 parts of sulfamic acid, 0.05-20 parts of glycolic acid, 0.05-20 parts of tartaric acid, 0.05-20 parts of lactic acid, 0.05-20 parts of gluconic acid, 0.05-20 parts of salicylic acid, 1.5-1.8 parts of a sulfamic acid corrosion inhibitor and 0.2-0.45 part of a surfactant. The agent utilizes sulfamic acid as the main pickling potion, the material status is solid, therefore the transportation is convenient, the cost is low, the pickling temperature is low, the implementation is facilitated, and time, labor and energy are saved. During water washing after pickling, the temperature difference born by a water wall can be reduced greatly under the condition of insufficient heat source capacity, and the protection of the water wall is facilitated. The agent is further provided with characteristics of simple postprocessing, low cleaning cost, and the like, can be applied to chemical surface cleaning of various metal materials such as carbon steel, stainless steel, alloy steel and the like, and can be widely applied to chemical cleaning of various large-capacity boilers and heat exchangers.

Owner:LIAONING ELECTRIC POWER COMPANY LIMITED POWER SCI RES INSTION +3

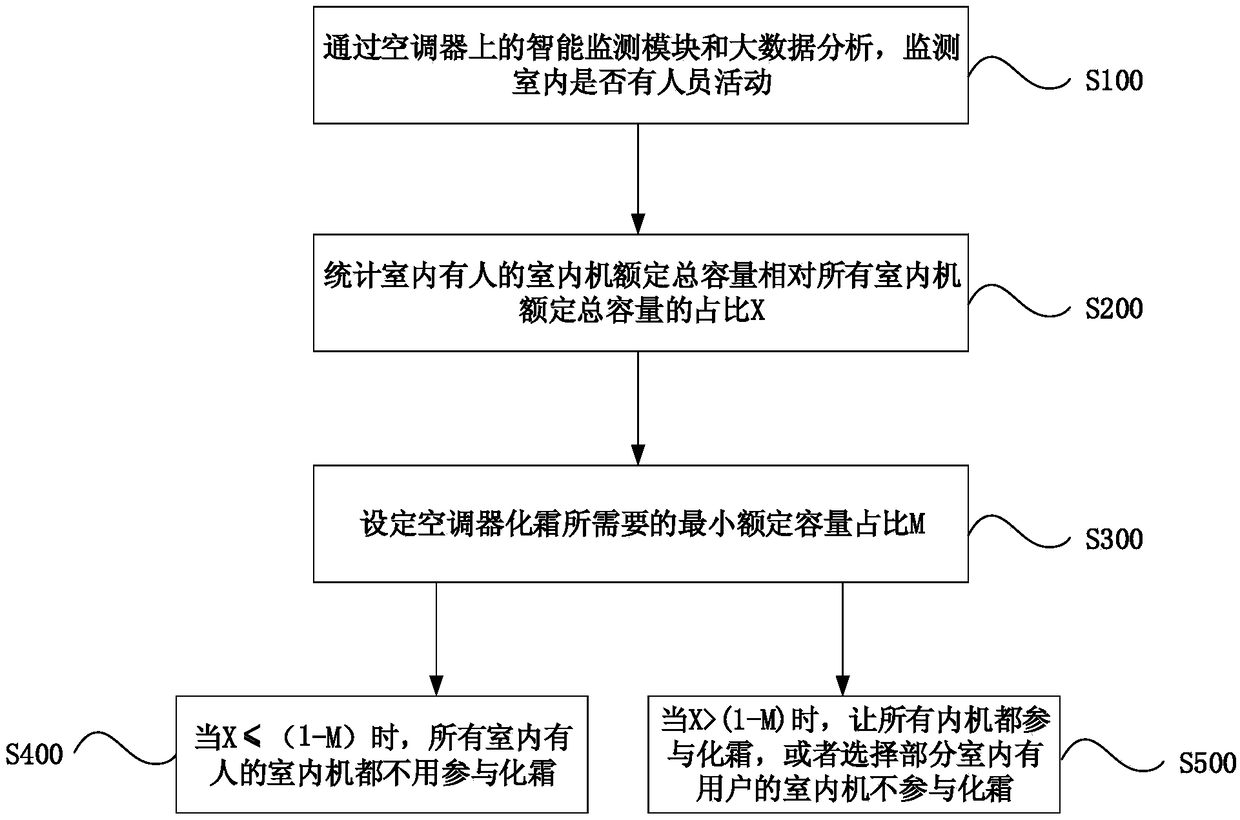

Air conditioner defrosting method and air conditioner

InactiveCN109458698ALittle change in temperature differenceAffect temperatureMechanical apparatusLighting and heating apparatusEngineeringDefrosting

The invention discloses an air conditioner defrosting method and an air conditioner, and relates to the field of air conditioners. The air conditioner defrosting method is used for optimizing the defrosting effect of the existing air conditioner. The air conditioner defrosting method includes the following steps that the ratio X of the rated capacity sum of indoor units in manned rooms to the rated total capacity sum of all working indoor units is monitored; and if X is smaller than or equal to N, at least one of all the indoor units in the manned rooms does not participate in defrosting, wherein N is a set value. According to the air conditioner defrosting method in the technical scheme, before defrosting, the indoor units are distinguished into the indoor units in the manned rooms and the indoor units in the unmanned rooms. During defrosting, all or part of indoor units in heating modes in the manned rooms do not participate in defrosting, in other words, at least one of the indoor units in the manned rooms does not participate in defrosting circulation, by means of the arrangement, the situation that the temperatures of the indoor units are affected due to defrosting is avoided,the temperature difference change caused by defrosting is effectively reduced, the comfort of users is improved, and the experience of the indoor users corresponding to the indoor units is better.

Owner:GREE ELECTRIC APPLIANCES INC

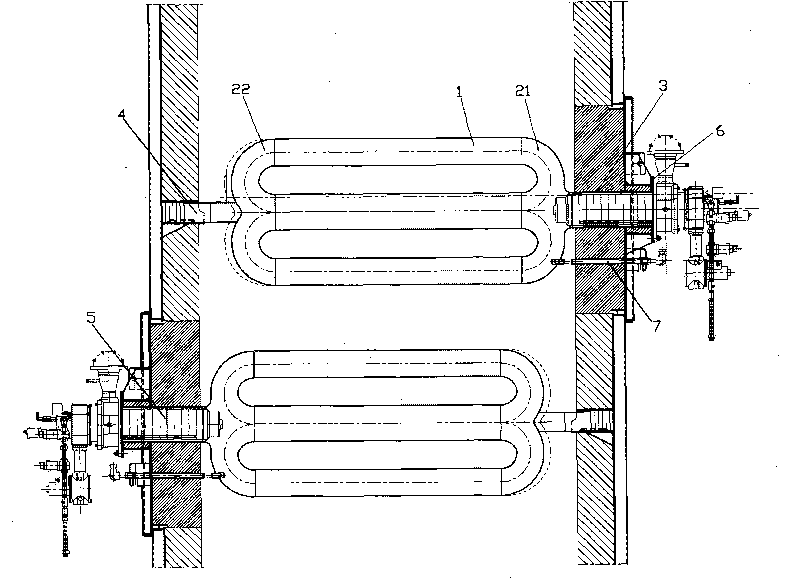

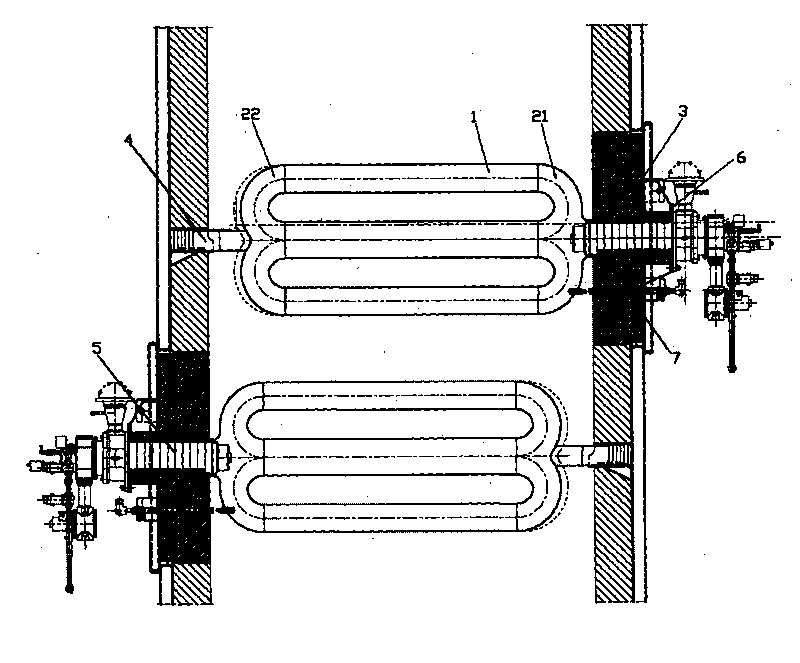

Double-P type radiant tube and manufacture method thereof

ActiveCN101724744ALighten the loadReduce design weightFurnace typesHeat treatment furnacesStraight tubeEngineering

The invention relates to a double-P type radiant tube. The double-P type radiant tube is arranged in a heat treatment furnace and comprises three parallel arrayed straight tubes, and both ends of each straight tube are symmetrically welded with two bent tubes, wherein the middle of one bent tube is provided with an air inlet tube coaxially arranged with the middle straight tube, while the other bent tube is welded with one end of a supporting tube coaxial to the middle straight tube. The manufacture method of the double-P type radiant tube comprises the following steps of: (1) calculating the manufacture size of the double-P type radiant tube; (2) cutting a plate, rolling the plate and welding the plate into the straight tubes; (3) punching and forming a plate into half bent tubes and welding the half bent tubes into the bent tubes; and (4) argon arc welding the manufactured straight tubes and the bent tubes and welding the supporting tube.

Owner:JIANGSU KUSUN SPECIAL STEEL PROD

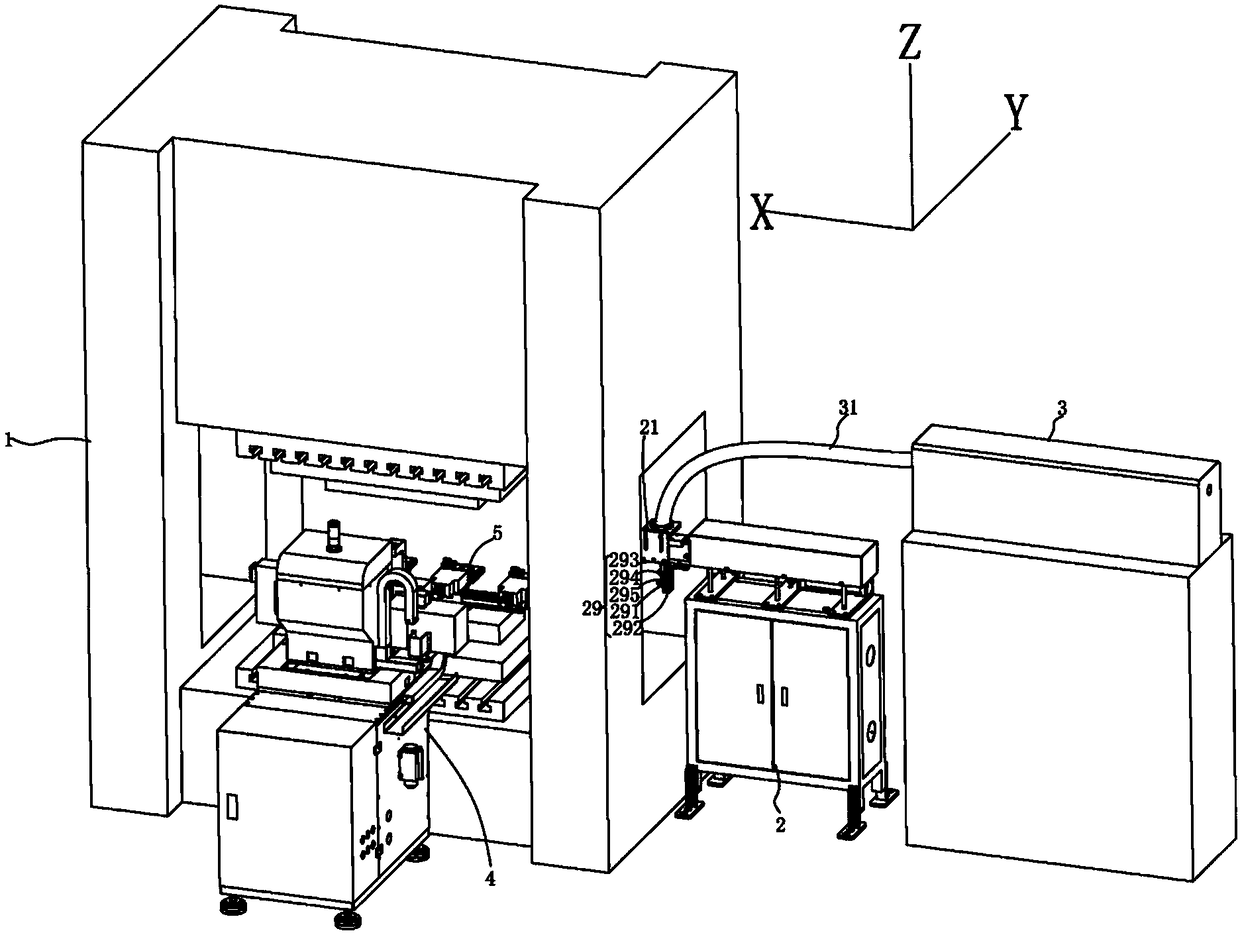

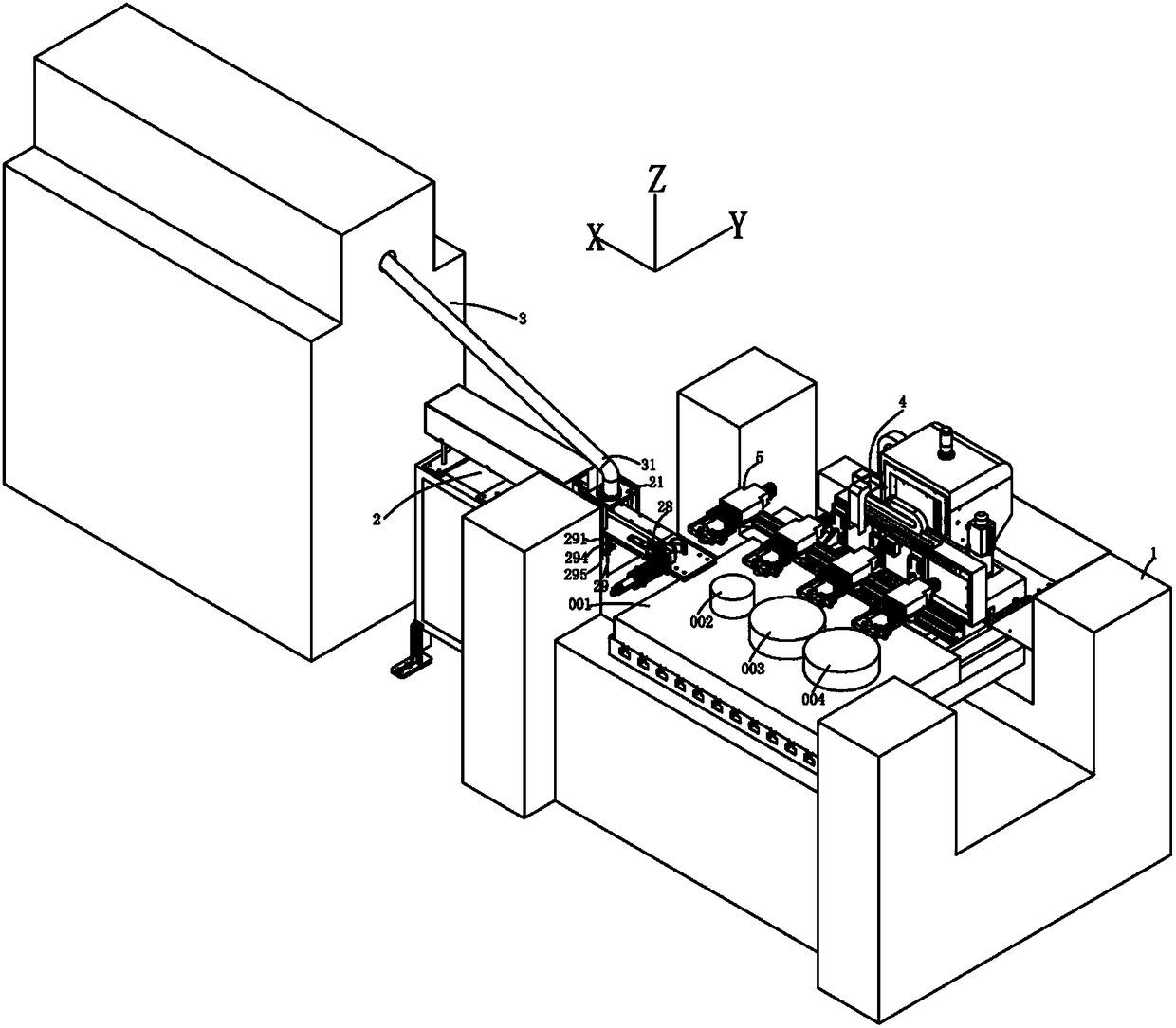

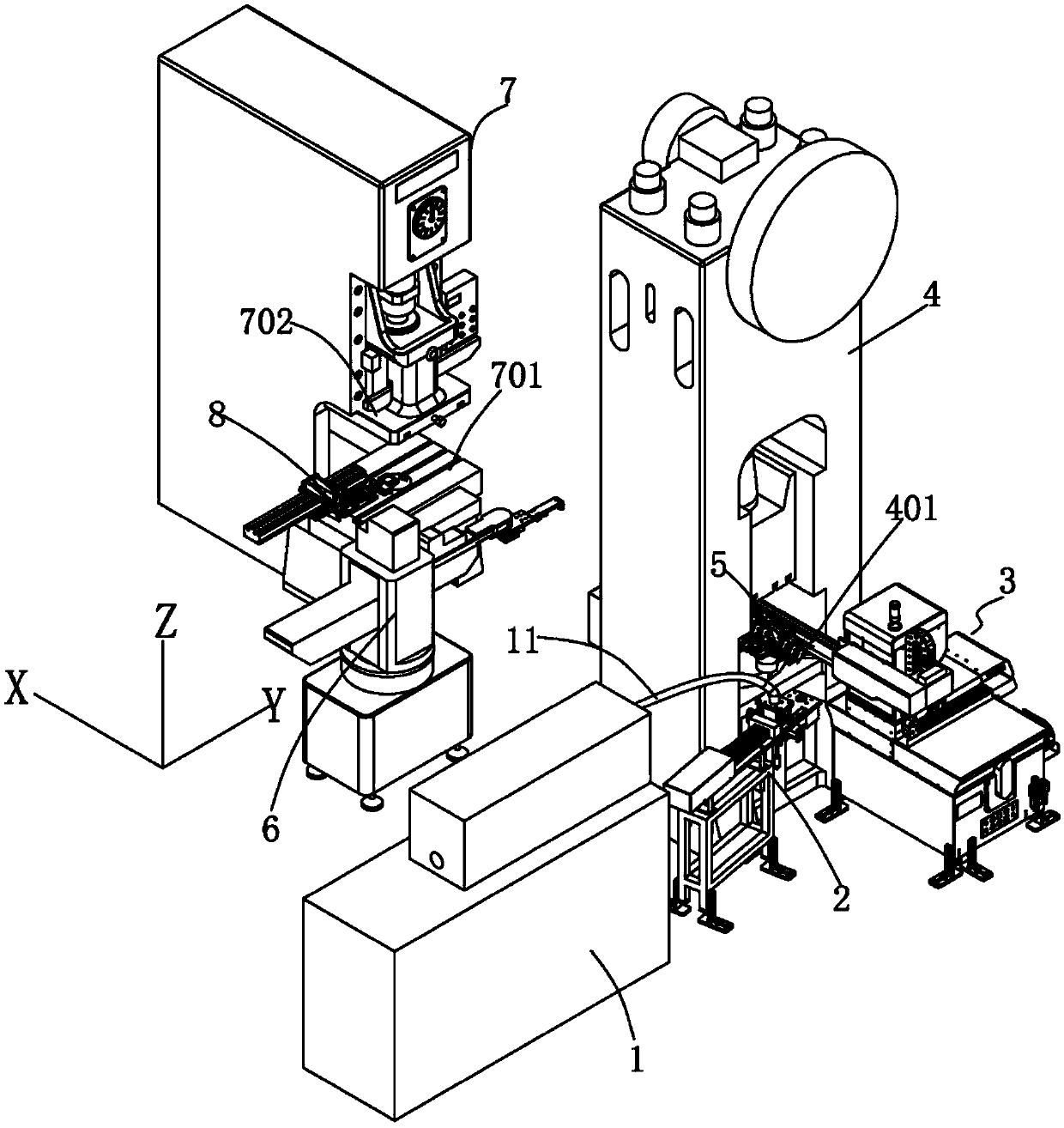

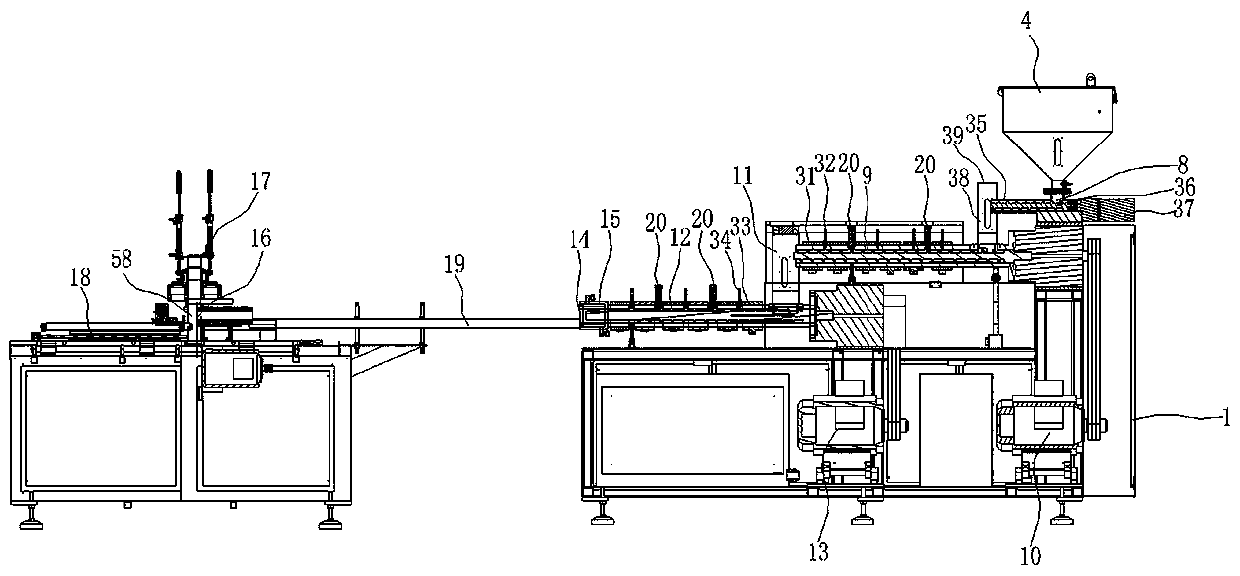

Full-automatic nut forging machine

ActiveCN108555210ATransplanting speed is fastSimple structureNutsPiercing pressesPunchingEngineering

The invention discloses a full-automatic nut forging machine which comprises a forging bed, wherein a cabinet of the forging bed is provided with an upsetting station, a molding station, a punching station and a material receiving station; the forging bed is also provided with an upsetting mold, a shaping mold and a punching mold; the side edge of the cabinet is provided with a material receivingmachine and a heating furnace, a discharge pipe of the heating furnace is connected with a material receiving nozzle of the material receiving machine, the material receiving machine is also in movable butt joint with a material moving mechanism at the front end of the cabinet; the heating furnace is used for heating a nut blank; the discharge pipe is used for overturning the nut blank by 90 degrees; the material receiving machine is used for horizontally pushing the overturned nut blank to the butt joint position with the material moving mechanism; the material moving mechanism is provided with four material clamping components, drives the material clamping components to synchronously move, horizontally transfers the nut blanks / nuts on the butt joint position of the material receiving machine, upsetting station, molding station and punching station to the upsetting station, the molding station, the punching station and the material receiving station, and is matched with the forging bed to complete upsetting, molding, punching and material receiving.

Owner:东莞辉科机器人自动化股份有限公司

Manufacturing technology of hollowed-out peach wood screen

ActiveCN107199614AImprove compactnessLittle change in temperature differenceScreensDecorative surface effectsWaxSaline water

The invention discloses a manufacturing technology of a hollowed-out peach wood screen. The technology is characterized by comprising the steps as follows: (1) material selection is performed as follows: a peach tree with the tree age being 20 years or above is selected as a machining material; (2) board sawing is performed as follows: a peach wood board is 1.8-2 cm thick; (3) heating and boiling in saline water are performed as follows: the board is immersed in water with the sodium chloride concentration ranging from 0.7% to 1% for heating and boiling; (4) high-pressure fumigation is performed as follows: the board is vertically placed on a distillation layer of a pressure cooker, a preservative is added, and high-temperature fumigation is performed; (5) softening in an acid and a base is performed as follows: the board is immersed in a sodium hydroxide solution and a hydrochloric acid solution respectively for soaking treatment; (6) drying is performed as follows: the board is vertically placed in a drying box, and a drying technology is performed; (7) hollowing-out engraving is performed as follows: the hollowed-out screen is engraved; (8) waxing is performed as follows: the screen is coated with wood wax by the aid of a soft brush and is coated repeatedly for 3-4 times. With the technology, the content of moisture in the peach wood board can be reduced, the anti-corrosion and moisture-proof performance can be improved, and the engraving performance and the smoothness of the peach wood board can be improved.

Owner:FUNAN TENGBO ARTS & CRAFTS CO LTD

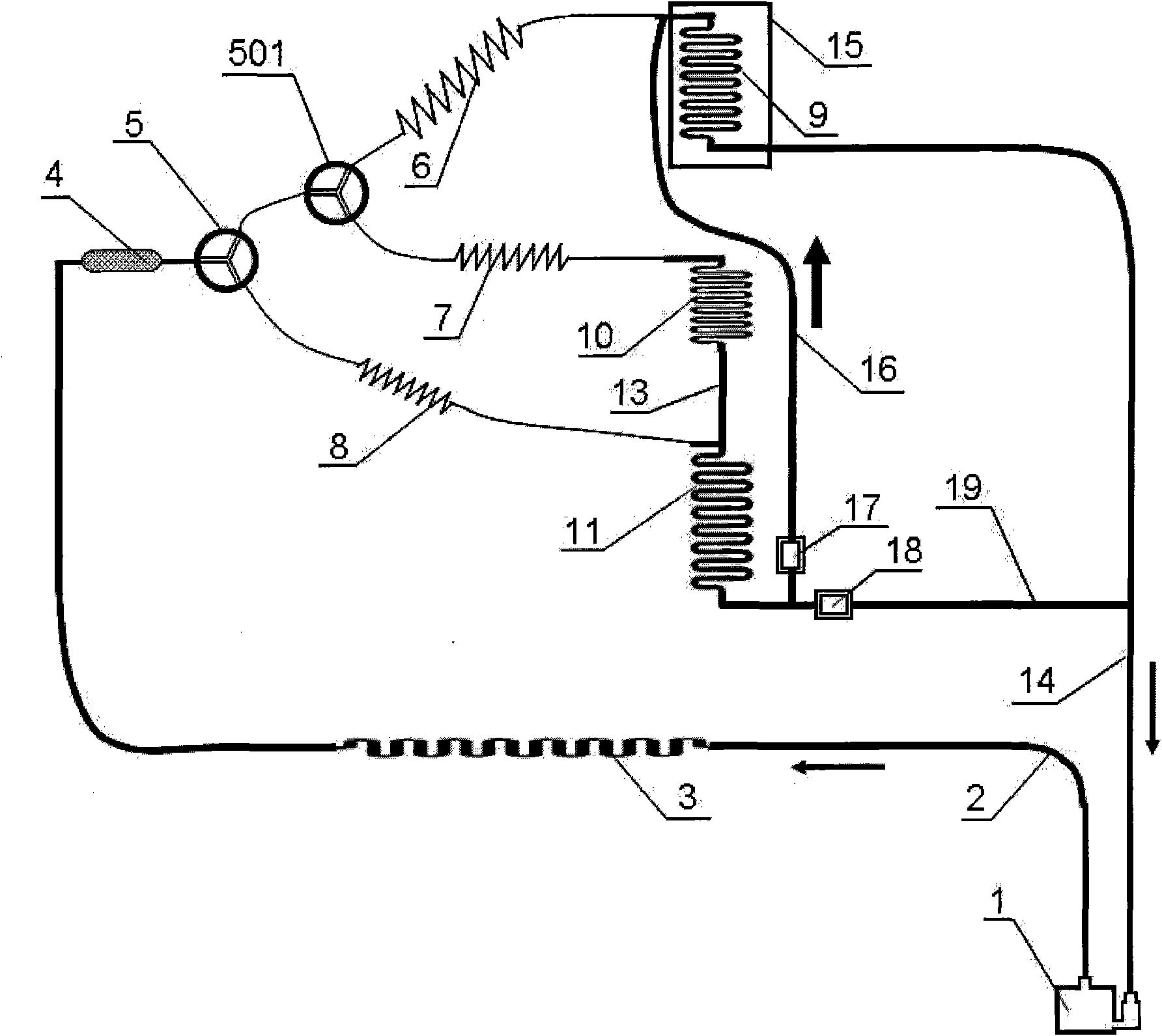

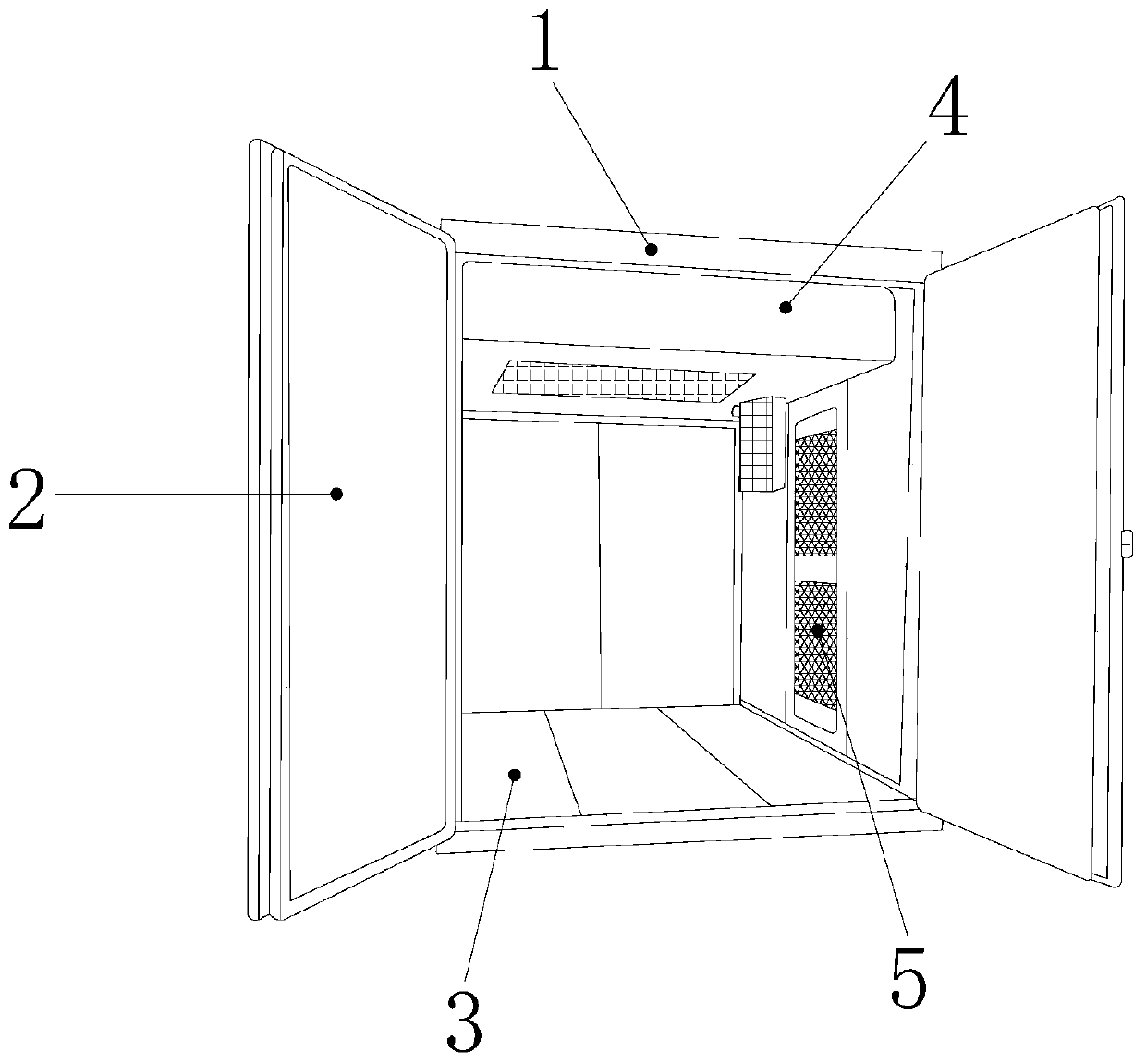

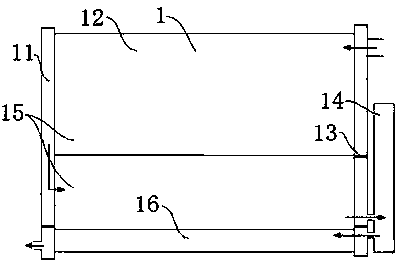

Heat exchange system for multi-refrigerating circuit refrigerator and refrigerator-disinfection cabinet all-in-one machine

InactiveCN101858663AUniform temperatureEasy to keep freshCompression machines with several evaporatorsHeatFrostBusiness efficiency

The invention discloses a heat exchange system for a multi-refrigerating circuit refrigerator and a refrigerator-disinfection cabinet all-in-one machine. The heat exchange system has the main characteristics that: an outlet end of a freezing chamber evaporator is connected with an inlet end of a refrigerating chamber evaporator through a freezing-refrigerating connection tube; the refrigerating chamber evaporator is placed in a anti-freezing fluid box; the outlet end of the freezing chamber evaporator is connected with a muffler through a freezing-return-air connection tube; a normally closed two-way valve is arranged on the freezing-return-air connection tube; the refrigerating chamber evaporator and the freezing chamber evaporator can be connected in parallel with two capillary tubes respectively; and a condenser is arranged at a position close to an inner liner of a disinfection cabinet. The heat exchange system can greatly reduce temperature difference change of a rear wall of an inner liner of a refrigerating chamber, can avoid frost formation in the refrigerating chamber evaporator, and can make the temperature in the refrigerating chamber more uniform, which are beneficial for keeping fruits and vegetables fresh; and the system can realize separate refrigeration of the refrigerating chamber, and can select the capillary tubes with greater flow to improve the energy efficiency ratio of a compressor.

Owner:凌建军

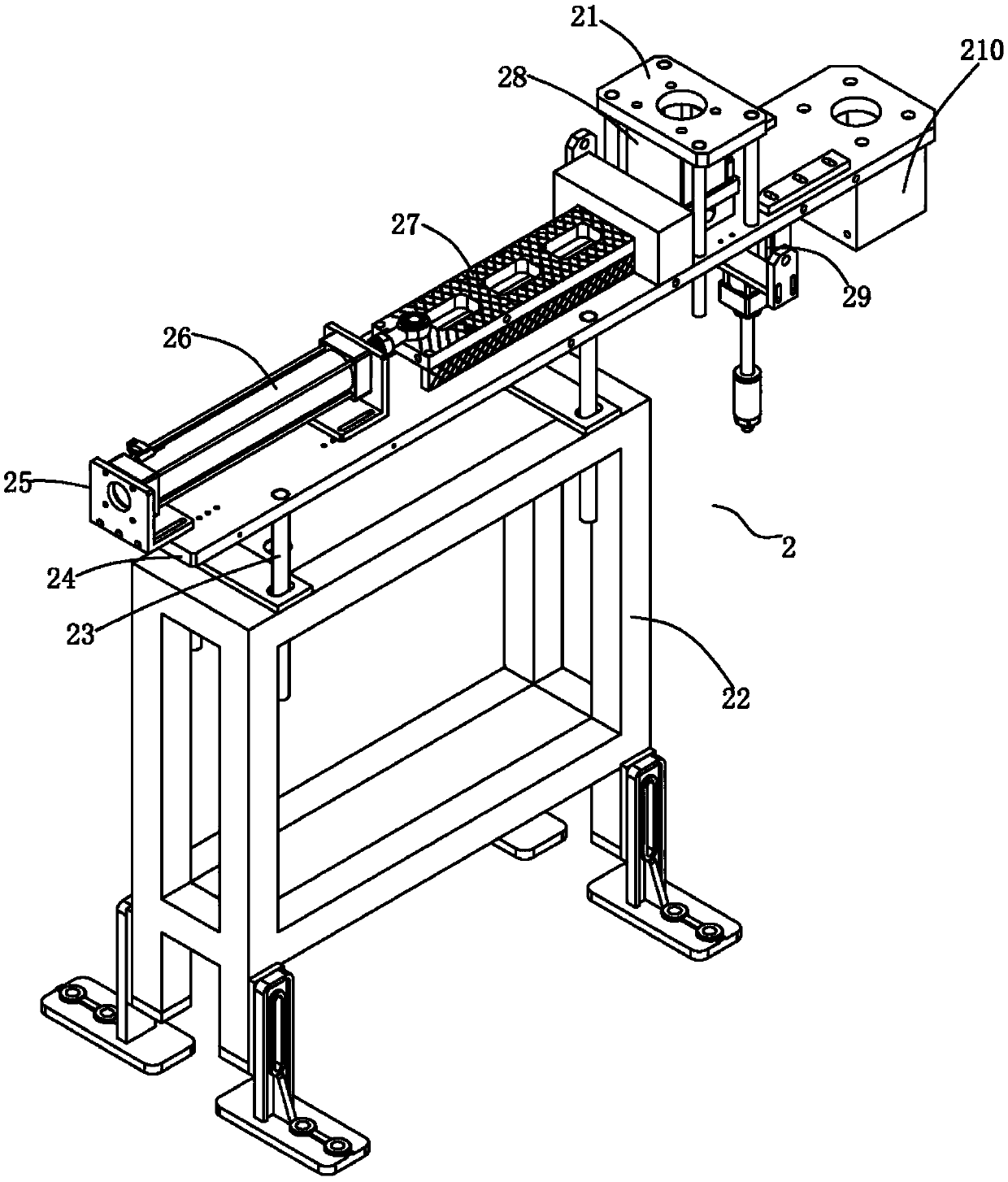

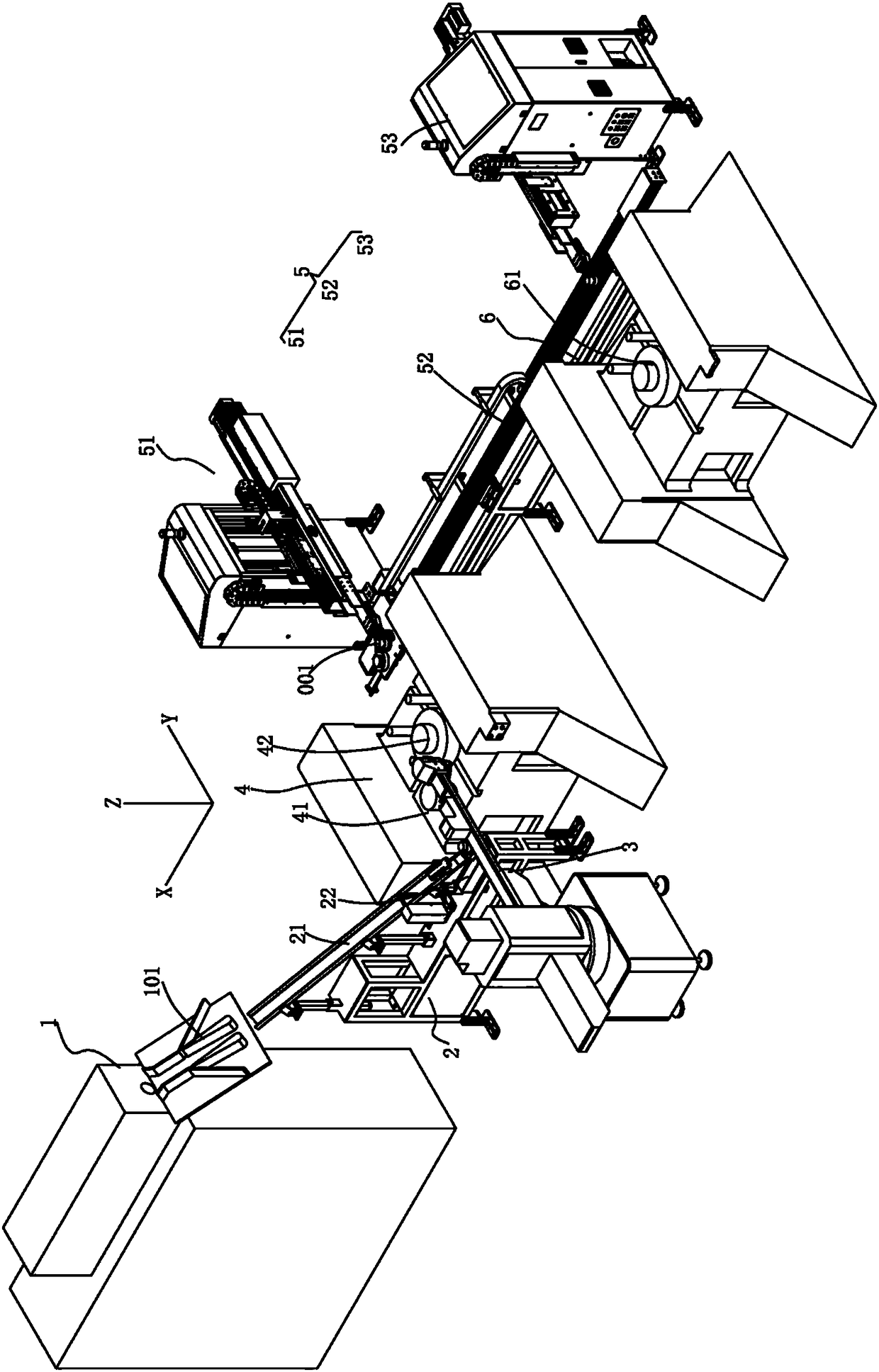

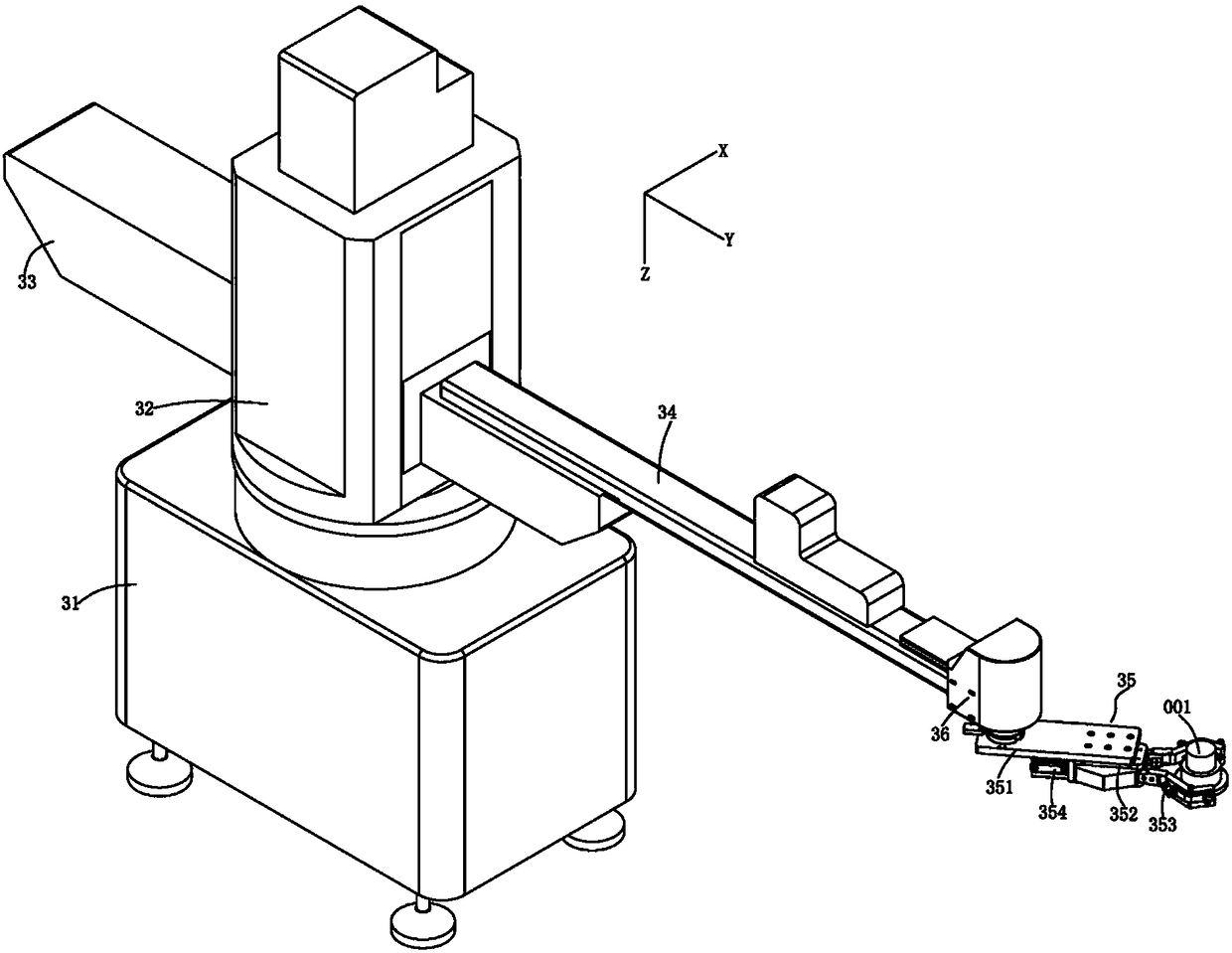

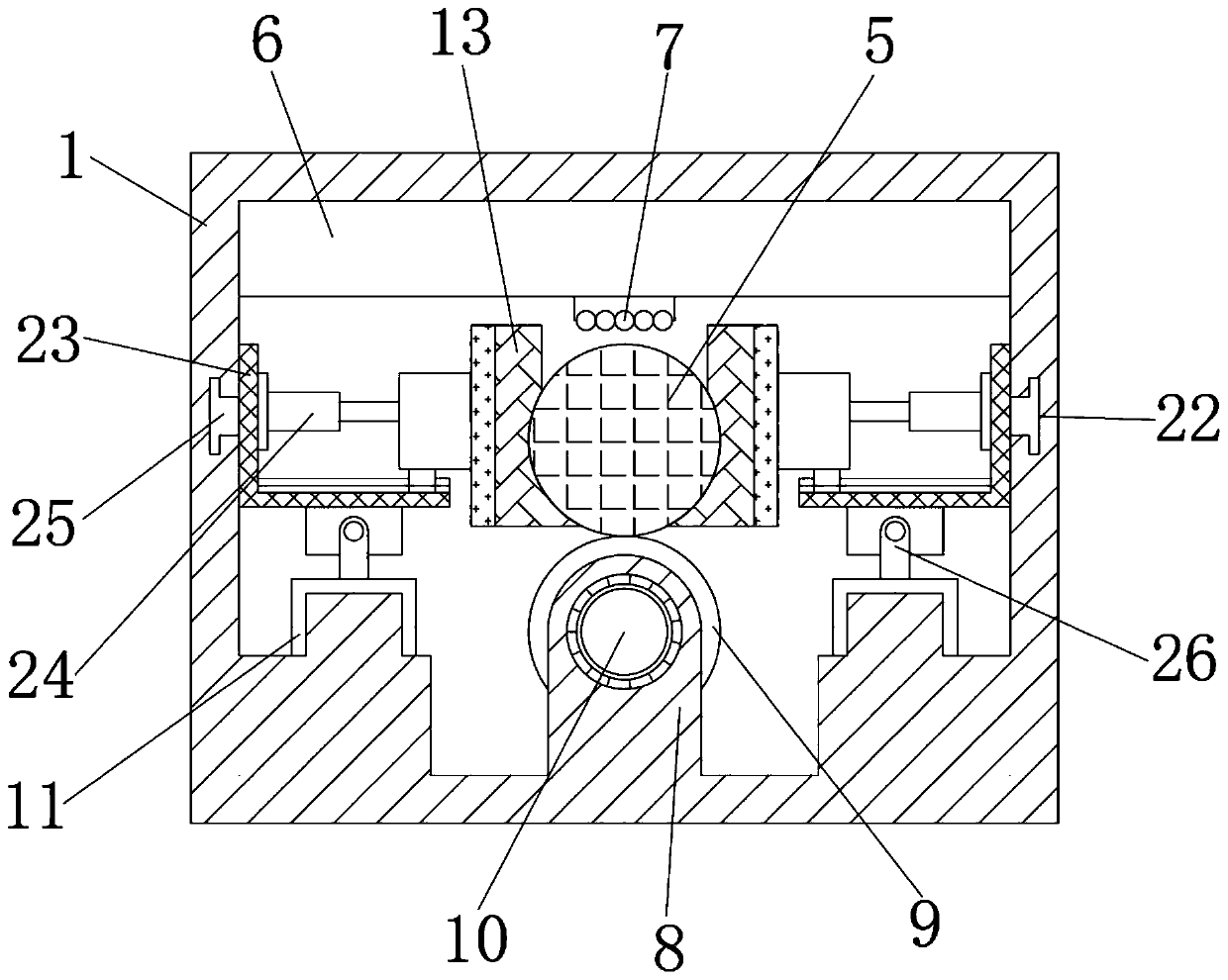

Full-automatic bearing ring forging machining production line

The invention discloses a full-automatic bearing ring forging machining production line. The full-automatic bearing ring forging machining production line comprises a heating furnace, a material pushing machine, a first forging machine, a material moving mechanism, a swirl pendulum material moving mechanism, a second forging machine and a discharging mechanism. The heating furnace is used for heating bearing rings to be forged. The material pushing machine is used for feeding the bearing rings which are blanked to a material receiving nozzle to a position connected with the material moving mechanism in a butting mode. The first forging machine is provided with a forging roughing station, a forming station, a punching station, a forging roughing mold, a forming mold and a punching mold. Thematerial moving mechanism includes four material-taking clamp assemblies, and the material moving mechanism can drive the four material-taking clamp assemblies to move synchronously and can transversely transfer the bearing rings located at the butting position of the material pushing machine and the material moving mechanism, the forging roughing station, the forming station and the punching station to the forging roughing station, the forming station, the punching station, and the butting position of the material moving mechanism and the swirl pendulum material moving mechanism. The swirl pendulum material moving mechanism is used for clamping and transferring the bearing rings which are punched to the second forging machine. The second forging machine is used for machining the bearingrings for secondary forming. The discharging mechanism is used for clamping and discharging the bearing rings which complete the secondary forming to a material receiving box or a next station.

Owner:东莞辉科机器人自动化股份有限公司

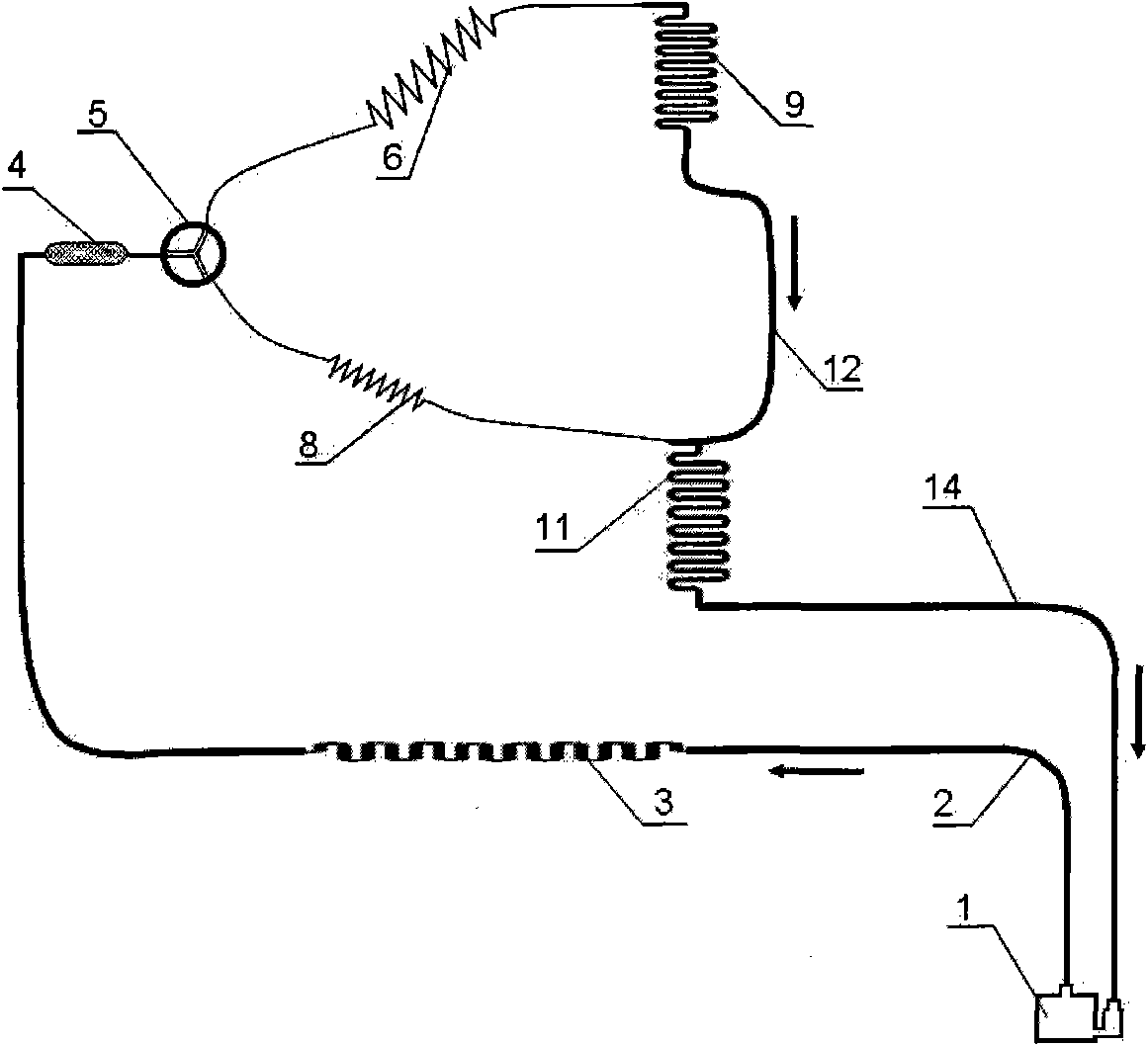

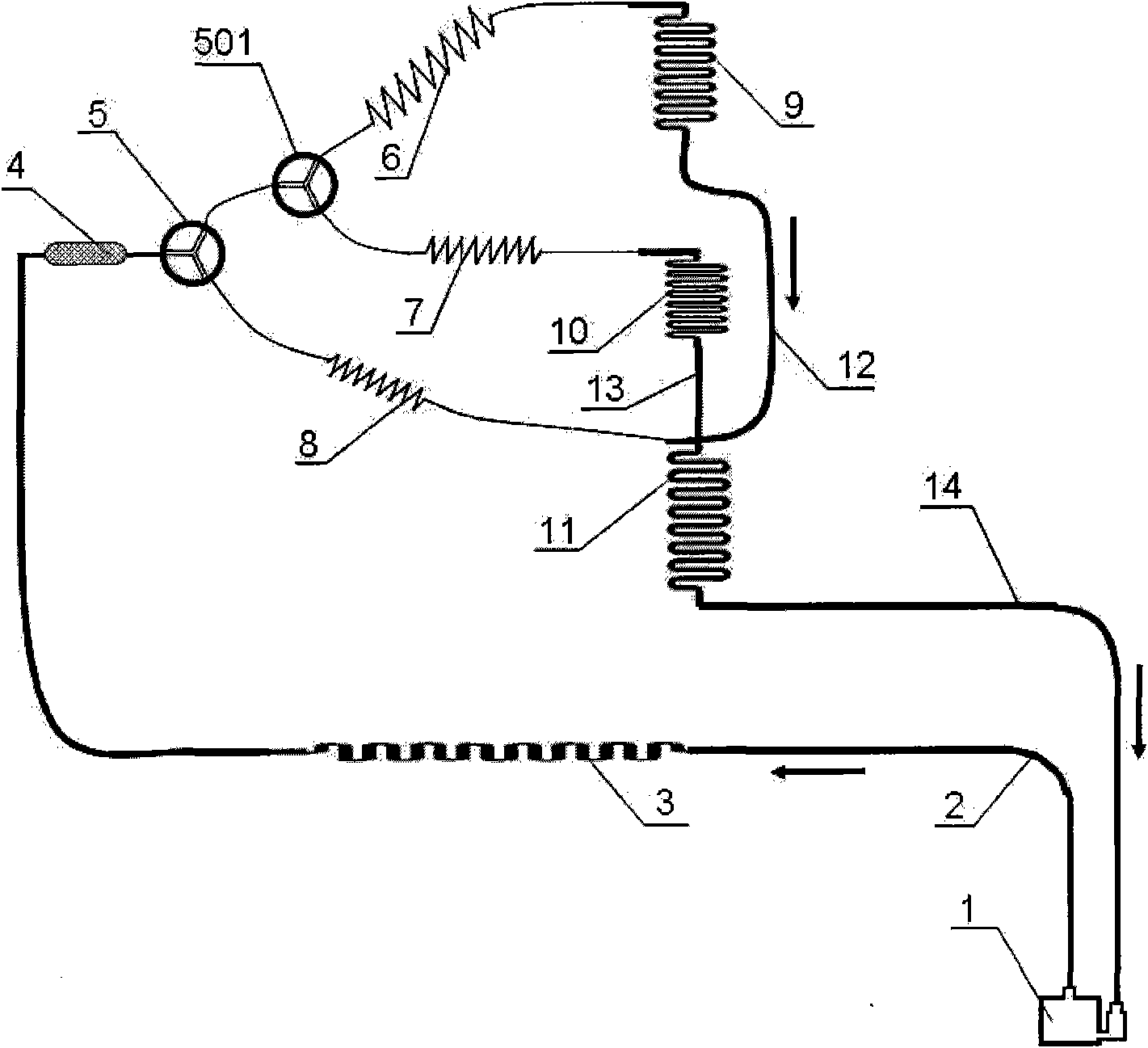

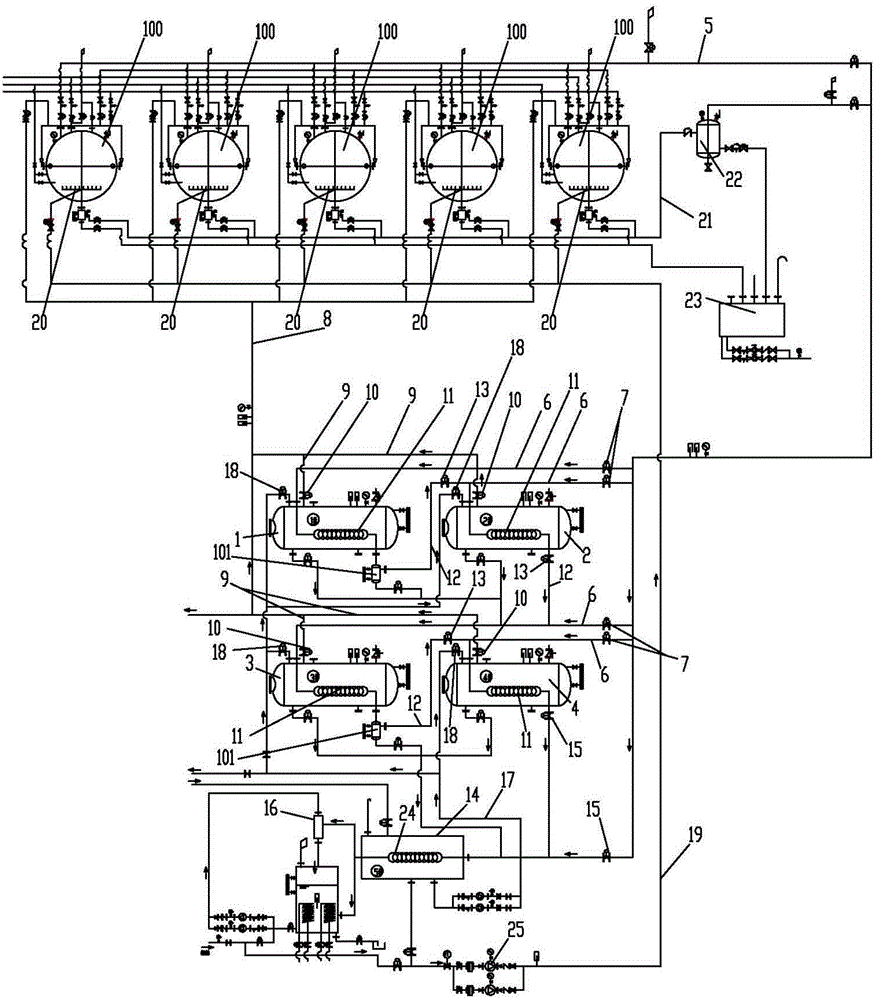

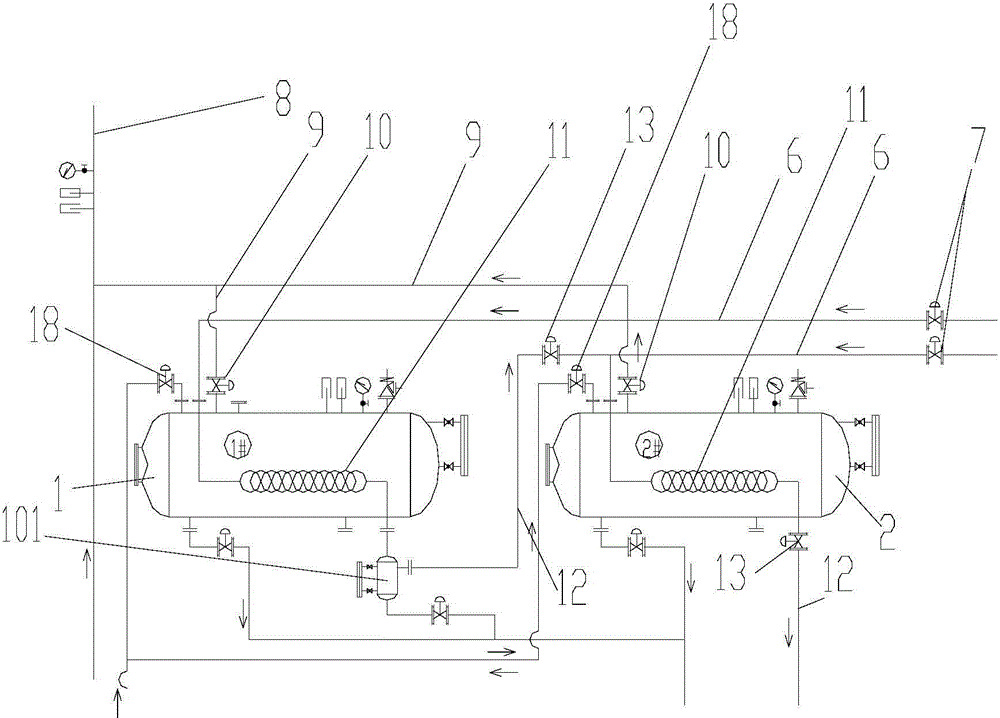

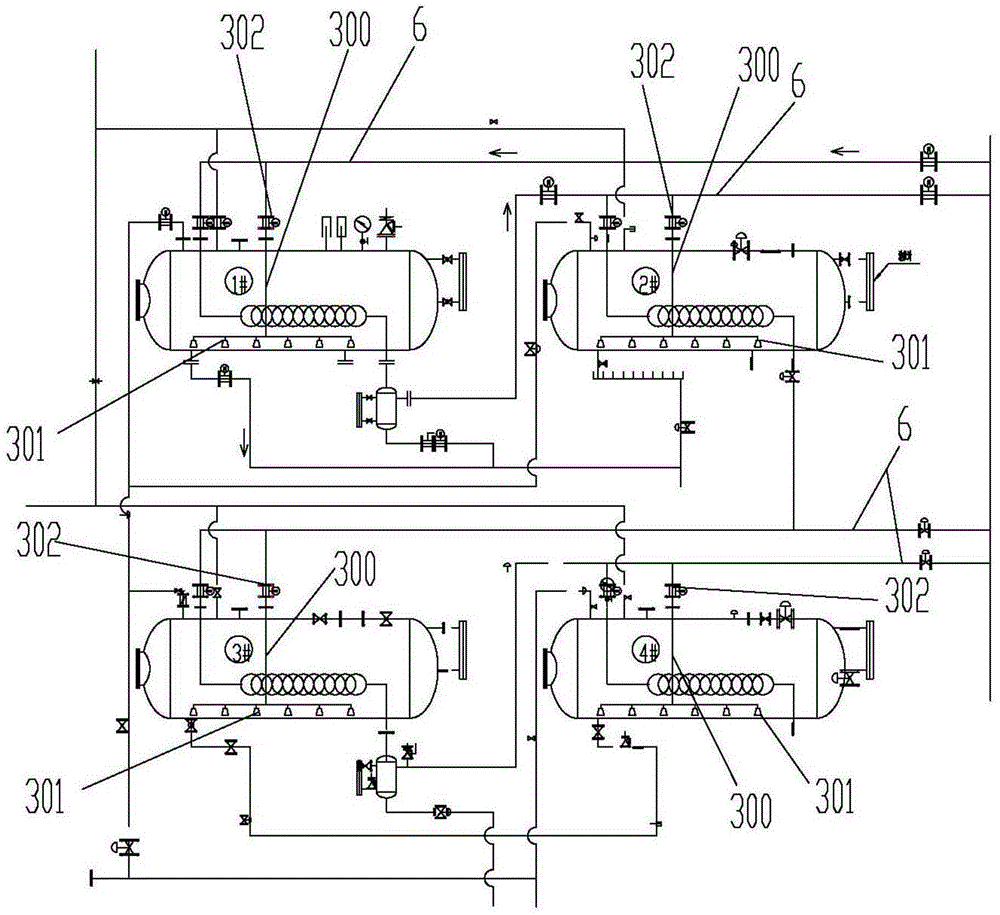

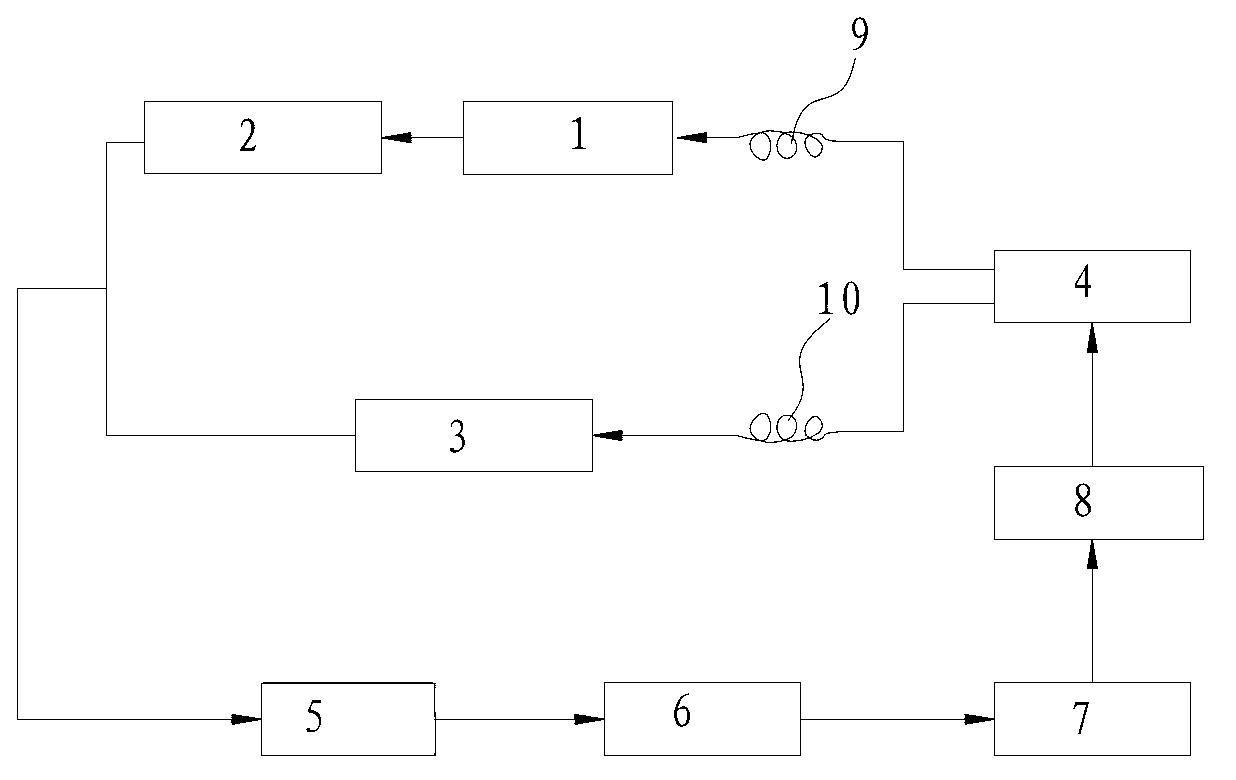

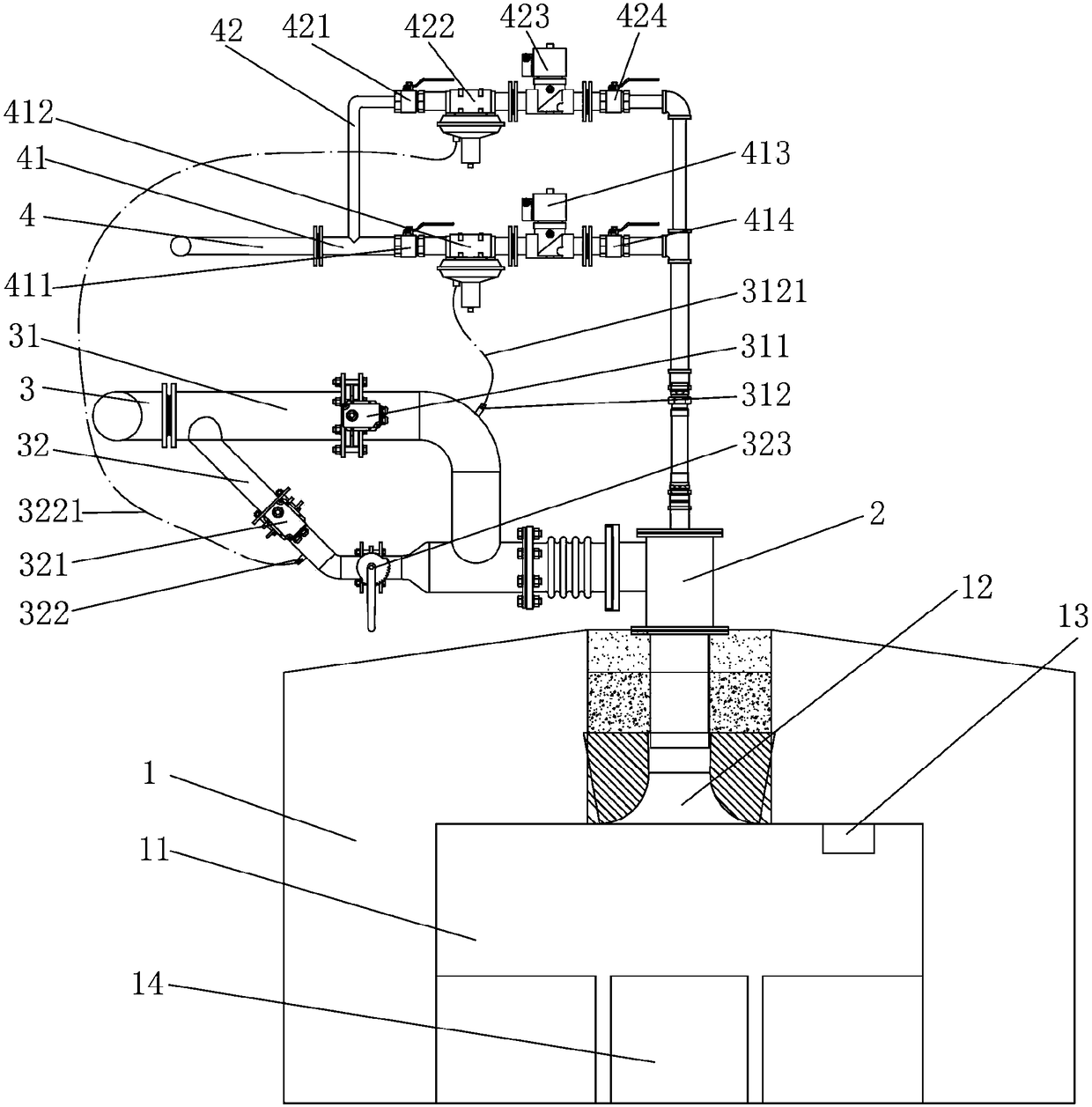

Still kettle quick accumulated residual steam accumulated energy circulating device and method

ActiveCN104589478AQuality improvementLittle change in temperature differenceCeramic shaping apparatusStationary conduit assembliesEngineeringControl valves

The invention discloses a still kettle quick accumulated residual steam accumulated energy circulating device and a still kettle quick accumulated residual steam accumulated energy circulating method. The device comprises an energy accumulating device communicated with a still kettle, wherein the energy accumulating device at least comprises a first energy accumulating container and a second energy accumulating container; steam inlet ends of the first energy accumulating container and the second energy accumulating container are communicated with a steam discharging end of the still kettle through a steam discharging pipeline; steam discharging ends of the first energy accumulating container and the second energy accumulating container are communicated with a steam inlet end of the still kettle through a steam returning pipeline; a steam discharging control valve used for controlling medium flow in the steam discharging pipeline is arranged on the steam discharging pipeline; a steam returning valve used for controlling medium flow in the steam returning pipeline is arranged on the steam returning pipeline. The still kettle quick accumulated residual steam accumulated energy circulating device is an energy accumulating device which takes water (or soft water) as a medium. The principle is that residual steam in a steam discharging still kettle is stored by adopting a high pressure-dividing way to a low pressure-dividing way, and in a boosting process of a steam inlet still kettle, the stored steam is released from the low pressure-dividing way to the high pressure-dividing way to be supplied.

Owner:周刚 +1

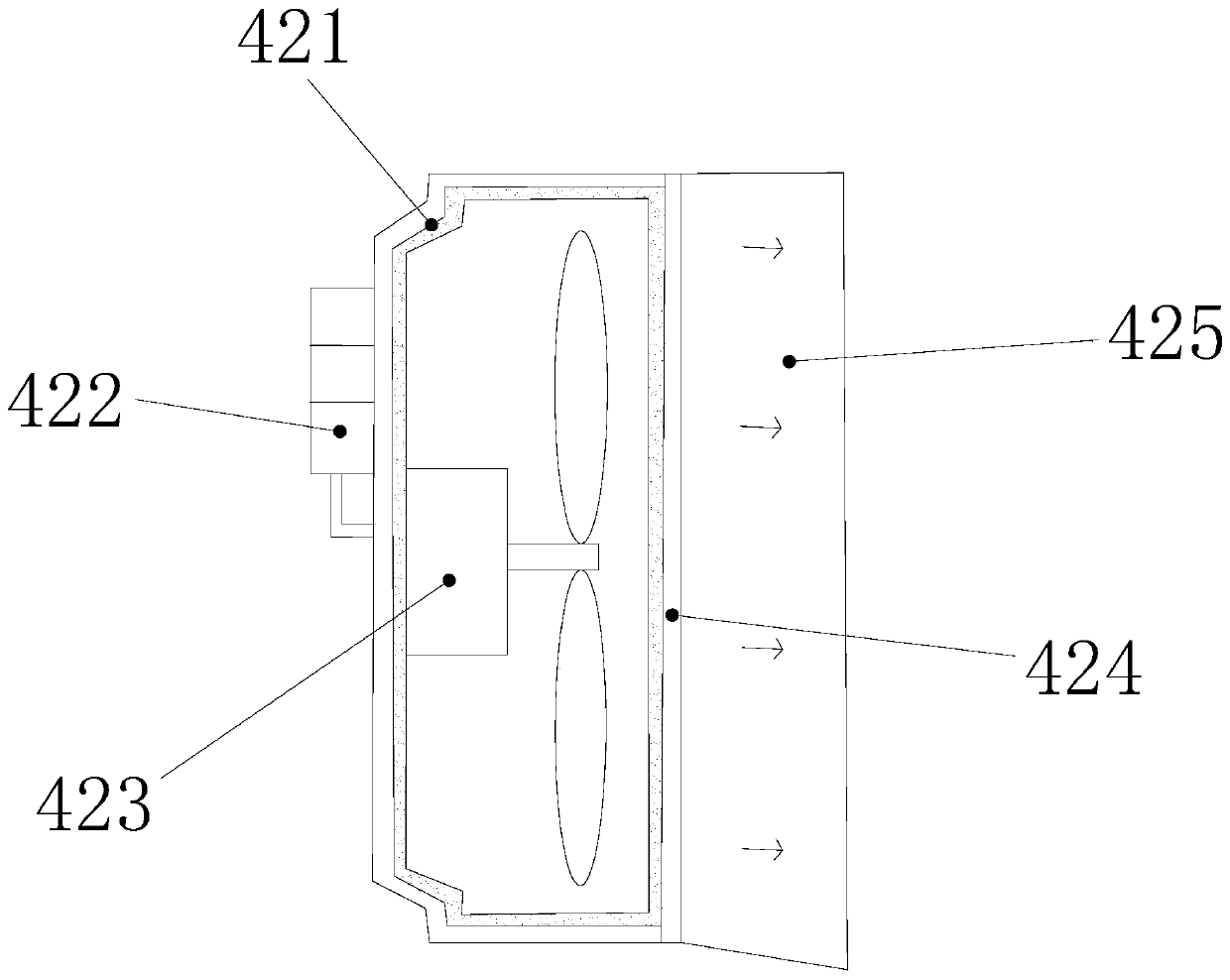

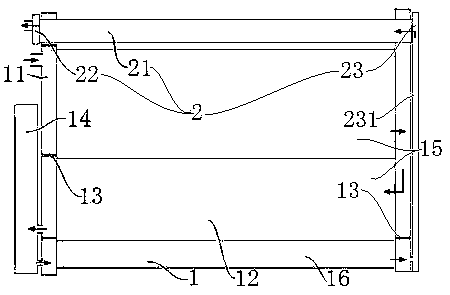

Refrigerator

InactiveCN102997562ALittle change in temperature differenceNot easy to frostLighting and heating apparatusRefrigeration devicesFrostMagnetic valve

The invention discloses a refrigerator. The refrigerator comprises a refrigerator body, a refrigeration evaporator, a first freezing evaporator, a second freezing evaporator and a magnetic valve, wherein the refrigerator body comprises a casing, a refrigeration box inner container and a freezing box inner container, and the refrigeration box inner container and the freezing box inner container are arranged in the casing. The refrigeration evaporator is arranged on a lateral wall of the refrigeration box inner container. The first freezing evaporator is arranged on a lateral wall of the freezing box inner container and communicated with the refrigeration evaporator. The second freezing evaporator is arranged on the lateral wall of the freezing box inner container. The magnetic valve is connected with the refrigeration evaporator and the second freezing evaporator to control a refrigerant to enter the refrigeration evaporator and the second freezing evaporator. When the refrigerator refrigerates, the first freezing evaporator and the second freezing evaporator work alternatively, temperature difference in a freezing chamber is small, frosting is not easily produced in the freezing chamber, and frost layers in the freezing chamber are distributed on four lateral walls of the freezing box inner container in frosting, so that frost are convenient to remove, and energy consumption can be reduced.

Owner:HEFEI MIDEA REFRIGERATOR CO LTD

Anti-bedsore cushion

PendingCN108567532ALittle change in temperature differencePrevent bedsoresDiagnosticsNursing bedsTemperature differenceEngineering

The invention relates to the technical field of medical articles and discloses an anti-bedsore cushion. The anti-bedsore cushion comprises an air cushion bed, wherein the air cushion bed comprises a first air bag, second air bags are fixedly connected to the right side surface of the first air bag, guardrail air pipes are fixedly connected to the tops and the bottoms of the first air bag and the second air bags respectively, and laser boring air holes are formed in opposite surfaces of the two guardrail air pipes and the front sides of the second air bags; the insides of the second air bags are communicated with the guardrail air pipes, and a middle channel pipe is fixedly connected to the top of the left side surface of the one guardrail air pipe. According to the anti-bedsore cushion, airflow ventilates the back of a patient through the middle channel pipe and the laser boring air holes by means of a centrifugal fan, so that skin of the patient is kept dry, a cold-end radiator and ahot-end radiator heat or cool delivered airflow, the environment for recuperation of the patient is regulated, temperature difference change of the environment for recuperation is reduced, and the anti-bedsore effect is achieved.

Owner:JIMEI UNIV

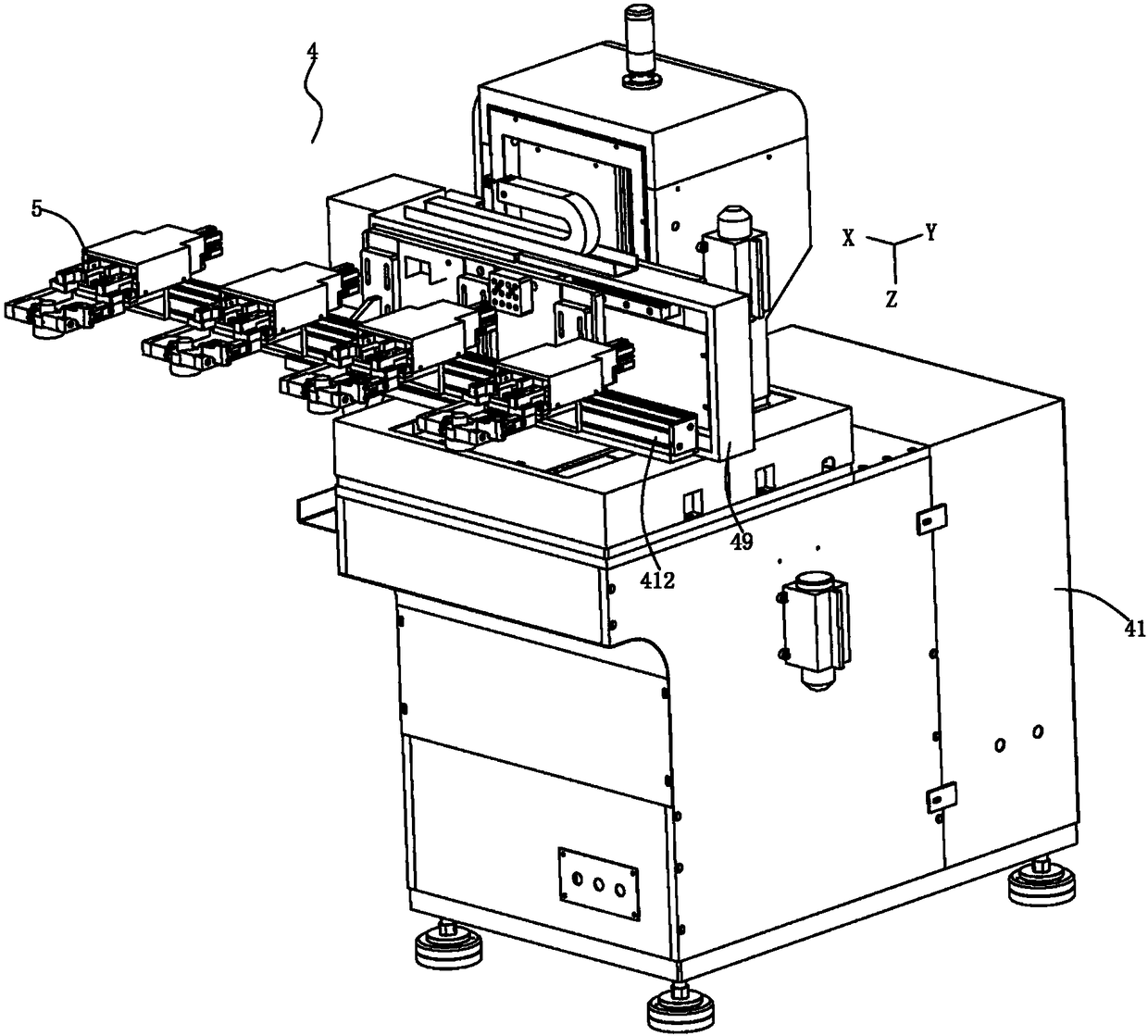

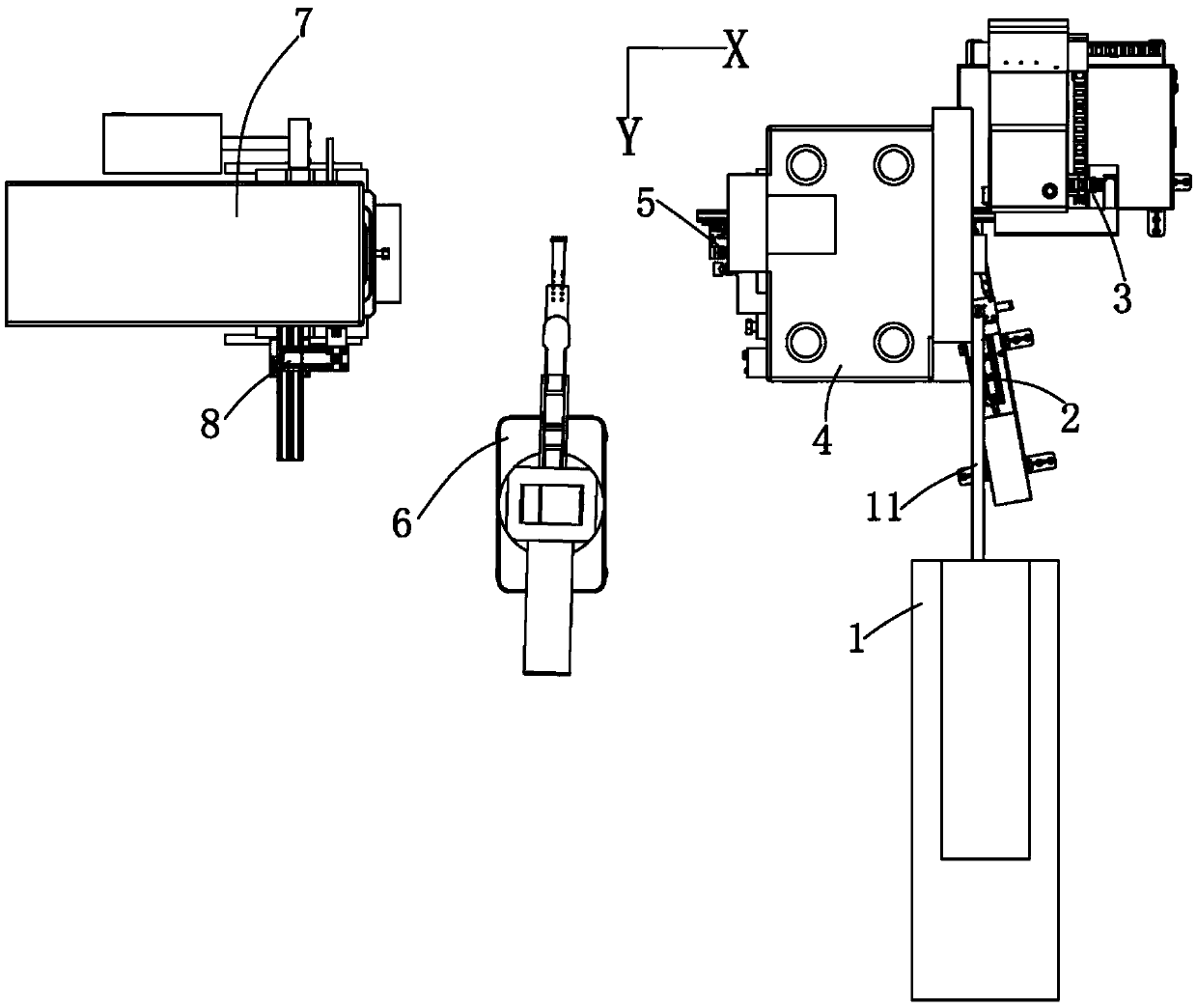

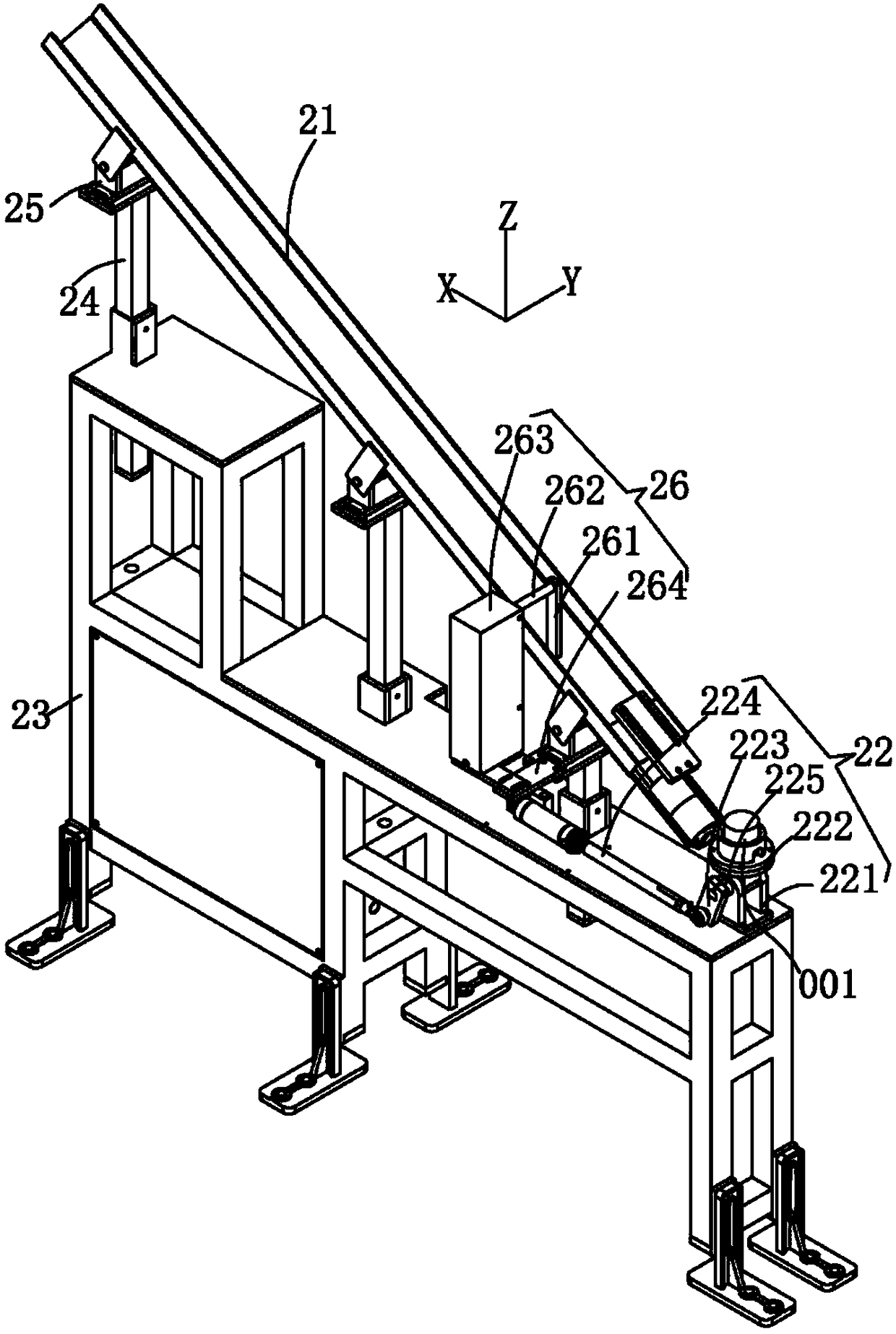

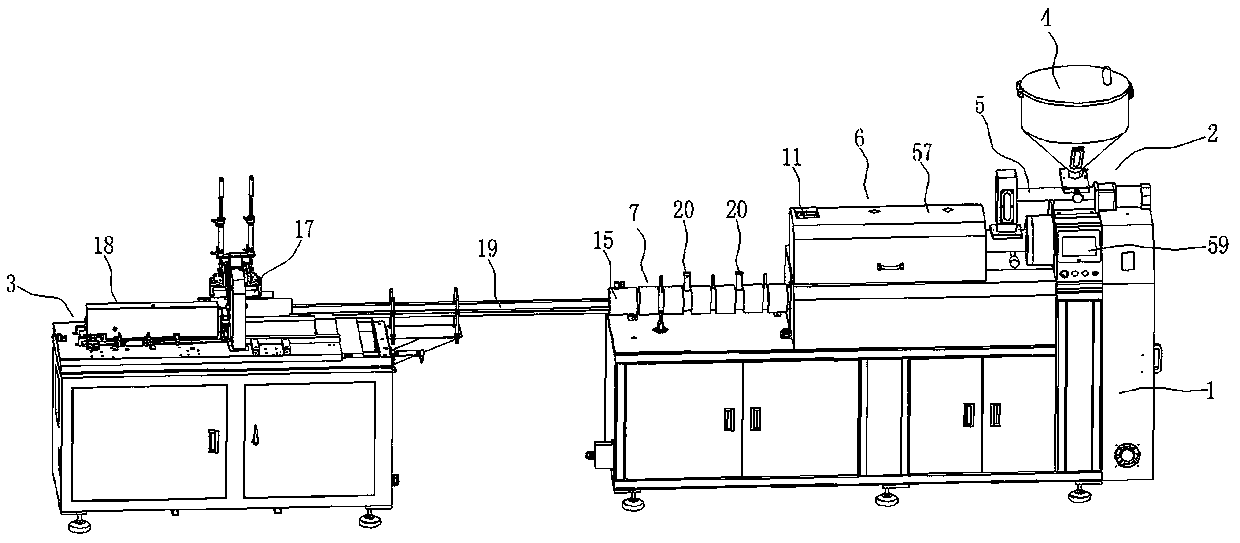

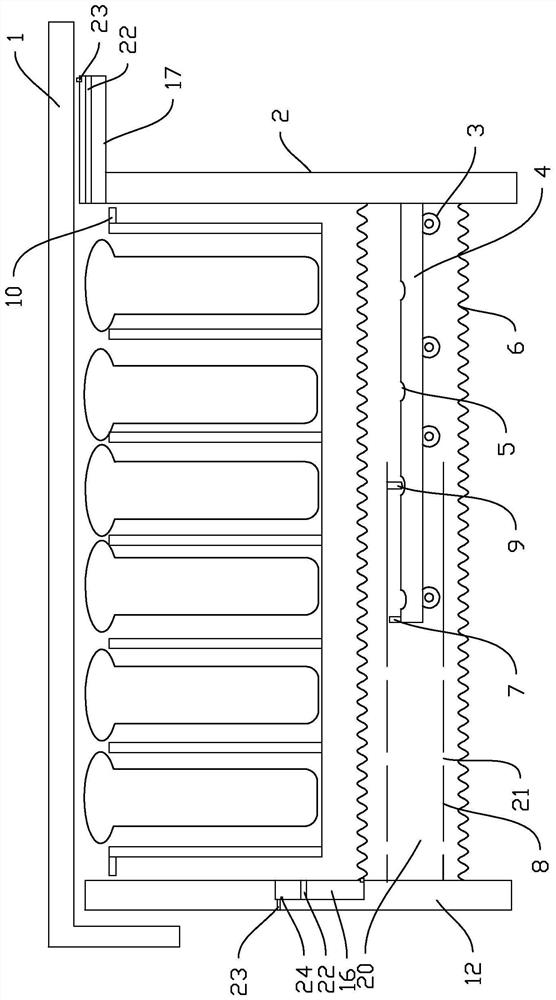

Full-automatic ball cage forging production line

InactiveCN108555218AReasonable layoutEasy to installForging/hammering/pressing machinesForging press detailsProduction linePunch press

The invention discloses a full-automatic ball cage forging production line which comprises a heating furnace, an overturning mechanism, a rotary material moving mechanism and a material moving mechanism, wherein a heating furnace is used for heating a ball cage blank to be molded; the overturning mechanism is used for transferring the ball cage blank to the butt joint position of the overturning mechanism and the rotary material moving mechanism, and overturning the ball cage blank; the rotary material moving mechanism is used for clamping the ball cage blank and transferring the ball cage blank to an upsetting mold of a first punch press and / or clamping the ball cage blank subjected to upsetting on the upsetting mold of the first punch press and transferring the ball cage blank to a molding mold of the first punch press; the material moving mechanism comprises a first transplanting manipulator, a transplanting material conveying assembly and a second transplanting manipulator; the first transplanting manipulator is used for clamping and conveying the ball cage blank on the molding mold of the first punch press to the transplanting material conveying assembly; the transplanting material conveying assembly is used for conveying the ball cage blank subjected to primary molding to the second transplanting manipulator from the first transplanting manipulator; the second transplanting manipulator is used for clamping the ball cage blank subjected to primary molding conveyed by the transplanting material conveying assembly and conveying the ball cage blank to the molding mold ofa second punch press for secondary molding.

Owner:东莞辉科机器人自动化股份有限公司

A direct buried heat preservation and anticorrosion expansion joint

InactiveCN102278562AAvoid erosionExtended service lifePipeline expansion-compensationThermal insulationEngineeringExpansion joint

The invention relates to a direct burial type heat-preservation antiseptic expansion joint which comprises an end tube, a siphunculus, a working bellows, an antiseptic bellows, a pressure-bearing shielding can, a first protective cover, a second protective cover and a guide shielding can, wherein the working bellows is sleeved on the left side of the siphunculus, the two ends of the working bellows are respectively fixed on an internal guide plate and a middle end plate by virtue of working adapters, and the internal guide plate is fixed on the left end of the siphunculus; the pressure-bearing shielding can is sleeved outside the working bellows, the left end of the pressure-bearing shielding can is fixedly connected with the end tube, and the middle of the pressure-bearing shielding is fixedly connected with the middle end plate; the first protective cover is sleeved outside the pressure-bearing shielding can, the left end of the first protective cover is fixedly connected with the end tube, and the right end of the first protective cover is fixedly connected with the pressure-bearing shielding can; the guide shielding can is sleeved on the right side of the outer siphunculus, the left end of the guide shielding can is fixedly connected with the siphunculus, and the antiseptic bellows is sleeved outside the guide shielding can; and the second protective cover is sleeved outside the antiseptic bellows, the two ends of the antiseptic bellows are respectively fixedly connected with the right ends of the first protective cover and second protective cover, and the left end of the second protective cover is sleeved on the right end of the first protective cover. The expansion joint provided by the invention has the advantages of good tightness, long service life and high thermal efficiency.

Owner:QINGHUANGDAO NORTH METAL HOSE

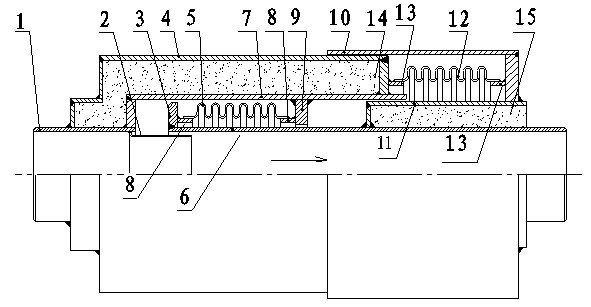

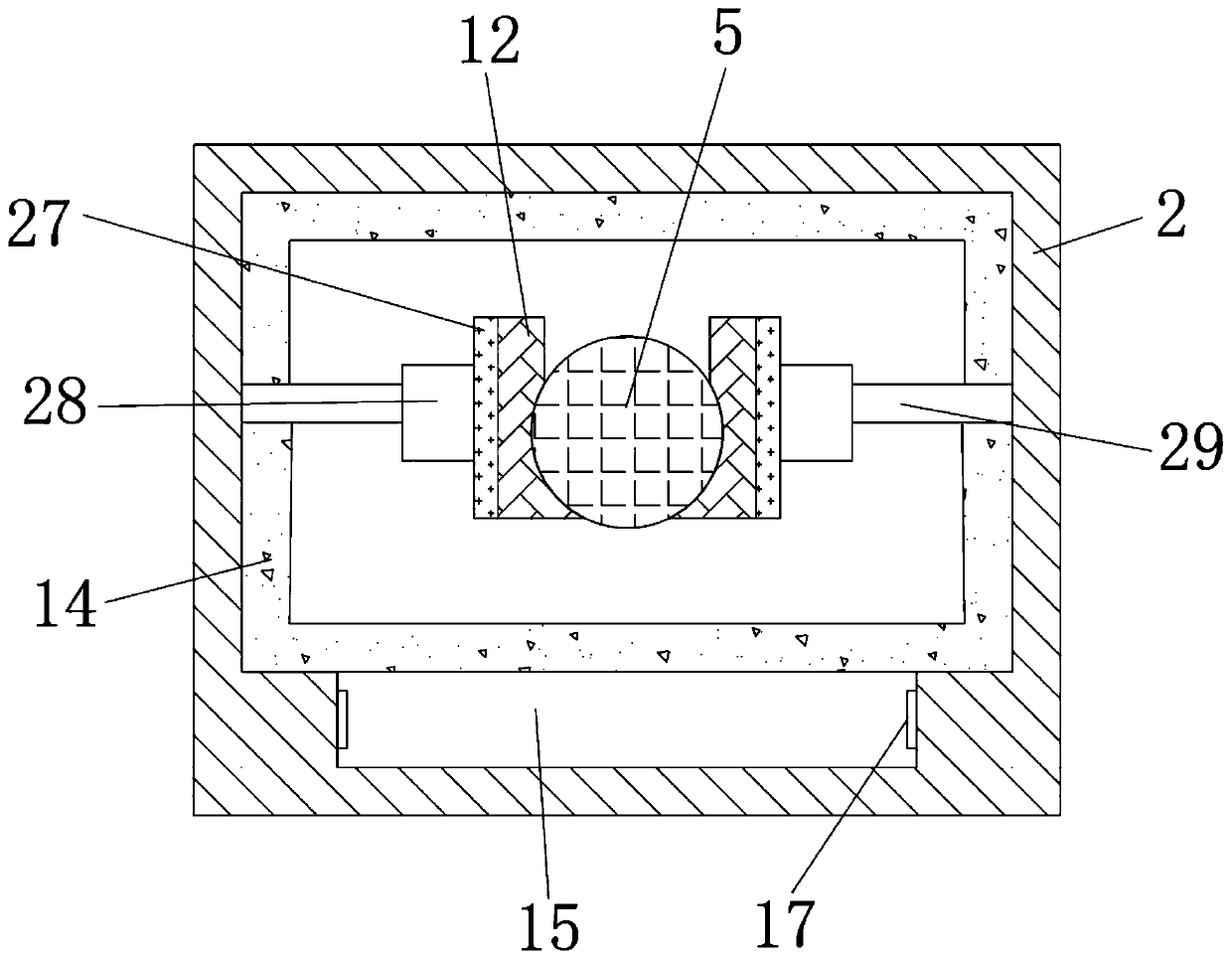

Temperature difference-controlling and condensation-proof inverter station box

InactiveCN110071430AGood anti-condensation performanceIncrease temperatureSubstation/switching arrangement cooling/ventilationDrying gas arrangementsCold airDesiccant

The invention discloses a temperature difference-controlling and condensation-proof inverter station box. The structure thereof comprises a box body, a box door, an installation room, a condensation-proof device and a venting port, wherein edges of both sides of the front and rear ends of the box body are hinged to the box door through hinges. The temperature difference-controlling and condensation-proof inverter station box provided by the invention inductively operate automatically by providing an automatic air supply mechanism and cooperating with the temperature sensor thereon, the cold air is heated by the air heating mechanism and then discharged from the air guiding mechanism into the box body to realize a small temperature difference between the inside and outside of the box, and the temperature inside the box is always maintained at a suitable temperature, thereby avoiding the condensation phenomenon and preventing accidents. In the function of a regenerative desiccant in thedrying box, the temperature difference-controlling and condensation-proof inverter station box provided by the invention realizes the function of drying the humidity in the air, and effectively reduces the humidity of the air inside the inverter station box to further prevent the condensation in the inverter station box, thereby greatly improving the safe operation level of the inverter station equipment and ensuring safe and reliable operation of the power grid.

Owner:沈晖

Thinning transplanting method of Eucommia ulmoides greenhouse seedlings

The invention discloses a thinning transplanting method of Eucommia ulmoides greenhouse seedlings. The method comprises the following steps of: exercising seedlings, selecting seedlings, preparing nutrition soil, selecting a nutrition pot, transplanting the seedlings after being thinned into the nutrition pot, putting the nutrition pot into the greenhouse at a shady spot where no sunshine radiates directly, keeping the temperature within 23-27 DEG C and the relative moisture of 65-80%, slowing the seedlings, and putting the nutrition pot into a greenhouse with sufficient sunshine and the temperature ranges from 18-26 DEG C and the relative moisture is 70-85% so as to cultivate the seedlings. With the adoption of the method, the large amplitude temperature change if the seedling is transplanted into a large field directly is reduced, a normal growing temperature and a good growing environment are ensured, the seedling slowing time is shortened, sufficient soil nutrition supply is provided, and thus the survival rate is increased.

Owner:山东贝隆杜仲生物工程有限公司

Heat treatment device for ultra-long aluminum alloy extruded profile

ActiveCN111334654ARealize intermittent heat dissipationReduce defectsFurnace typesHeat treatment furnacesElectric machineHeating furnace

The invention relates to the technical field of heat treatment of aluminum alloy extruded profiles, in particular to a heat treatment device for an ultra-long aluminum alloy extruded profile. The heattreatment device comprises a heat treatment device body, the heat treatment device body is composed of a heating furnace, a heat preservation box, a water cooling box and an ultra-long profile, the heating furnace, the heat preservation box and the water cooling box are linearly distributed from left to right, a heating host is arranged at the upper end of the inner cavity of the heating furnace.The heat treatment device has the beneficial effects that through matching of the heating furnace, the heat preservation box, an air cooing section and the water cooling box which are linearly distributed, thus the interrupted heat dissipation of the ultra-long profile is achieved, the temperature difference change of adjacent positions is greatly lowered, and the profile defects caused by temperature difference stress are reduced; and a first limiting block and a second limiting block which are symmetrically distributed front and back are arranged, thus the position of the profile is limited, a motor-driven rotating roller is utilized to drive the profile to rotate slowly, so that the profile is evenly heated and dissipated, and the quality of heat treatment is greatly improved.

Owner:佛山市铝鸿金属制品有限公司

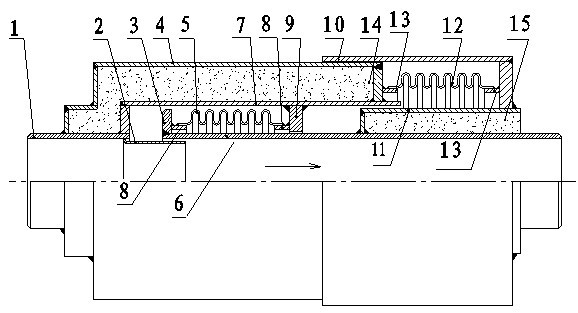

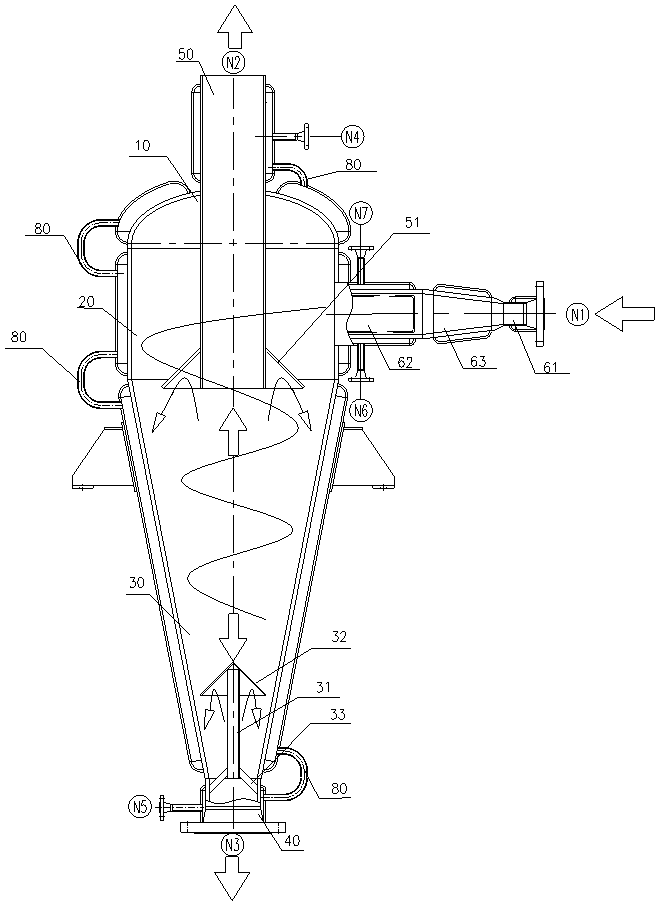

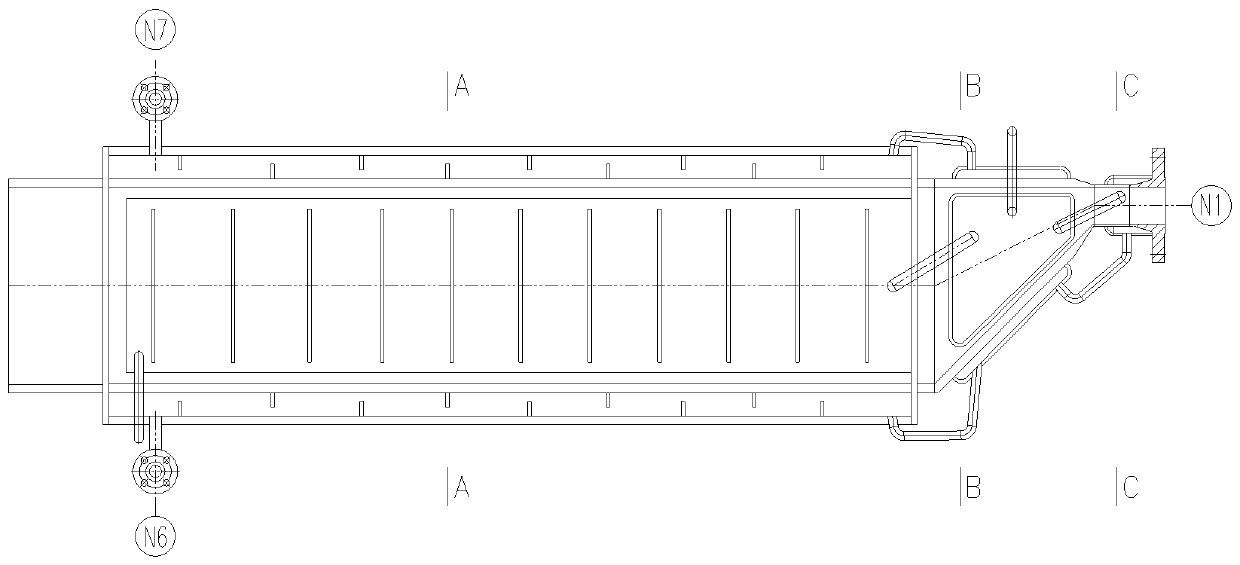

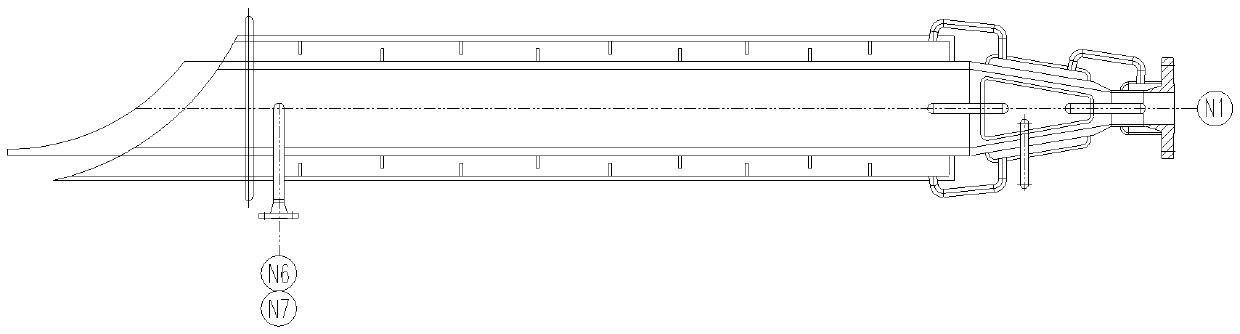

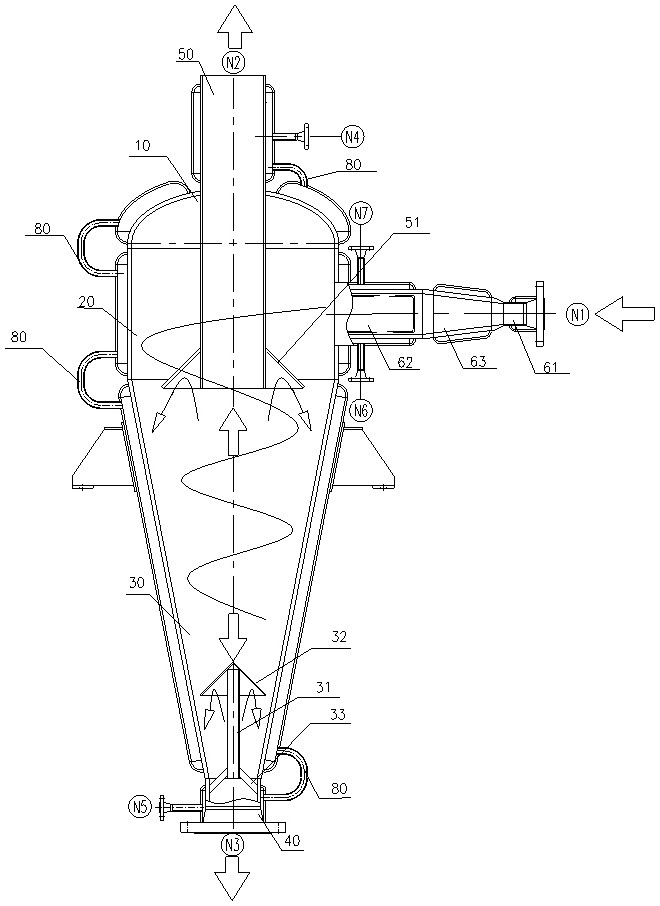

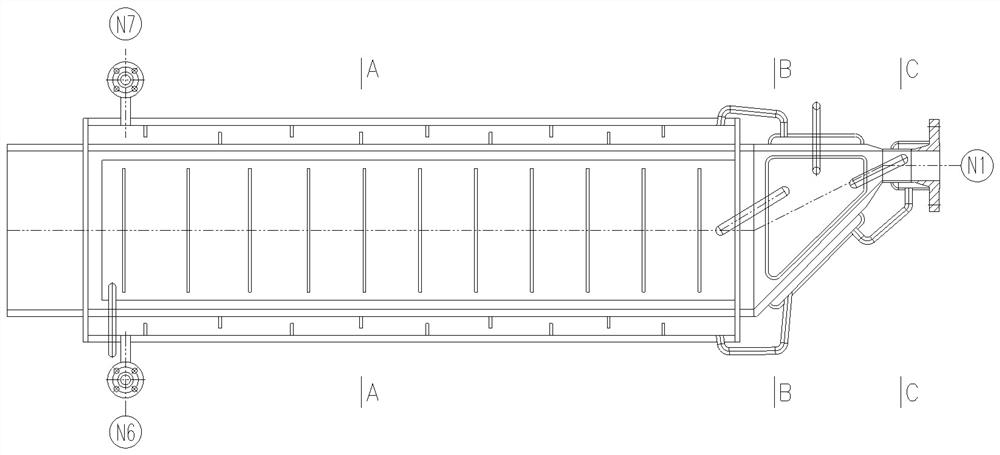

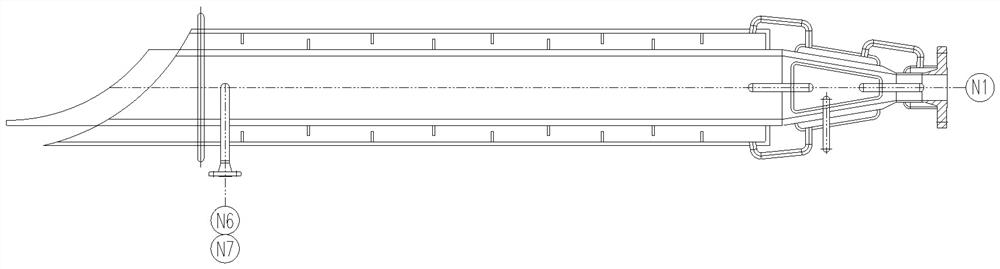

High-freezing-point medium gas-liquid separator with labyrinth-type gas inlet pipe heat-preserving device

ActiveCN109603316AImprove liquiditySolve the stickinessDispersed particle separationCycloneVapor–liquid separator

The invention relates to the technical field of gas-liquid separation devices in chemical engineering equipment, specifically to a high-freezing-point medium gas-liquid separator with a labyrinth-typegas inlet pipe heat-preserving device. The high-freezing-point medium gas-liquid separator successively comprises an elliptical seal head, a cyclone drum body and a cyclone cone body from top to bottom, wherein the elliptical seal head, the cyclone drum body, the cyclone cone body, a liquid discharging pipe and an exhaust pipe located at the exterior of the elliptical seal head are respectively sleeved by a heat-preserving sleeve to form heat-preserving cavities; a connecting circular pipe is arranged between adjacent heat-preserving cavities; a tangential gas inlet pipeline is arranged at one side of the drum body of the cyclone drum body and comprises a gas inlet circular pipe, a cone pipe and a rectangular pipe; four side surfaces of the cone pipe are respectively provided with a conepipe heat-preserving chamber; and four side surfaces of the rectangular pipe are respectively provided with a rectangular pipe heat-preserving chamber. According to the invention, heat-conductive oilenters from the heat-conductive oil inlet of a gas inlet pipe, respectively passes through the heat-preserving chambers located on four side surfaces of the cone pipe, the circular pipe heat-preserving chamber and the heat-preserving chambers located on four side surfaces of the rectangular pipe, and finally flows out from the heat-conductive oil outlet of the gas inlet pipe.

Owner:EAST CHINA ENG SCI & TECH

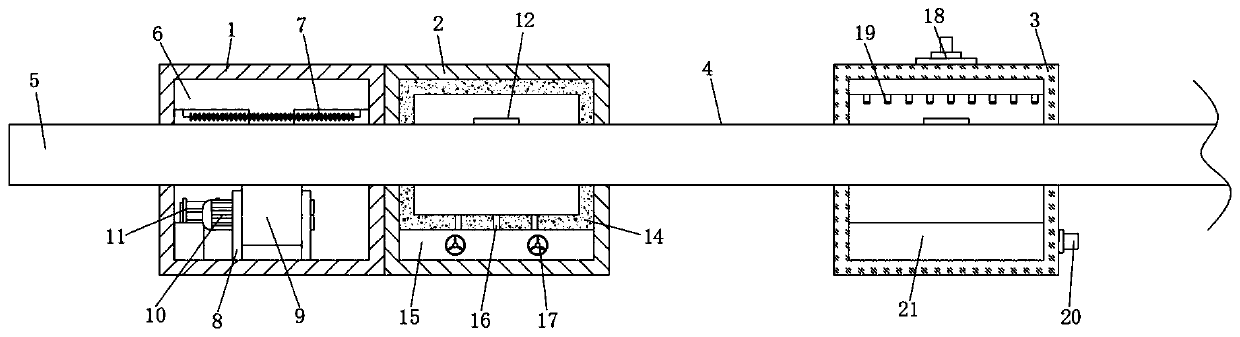

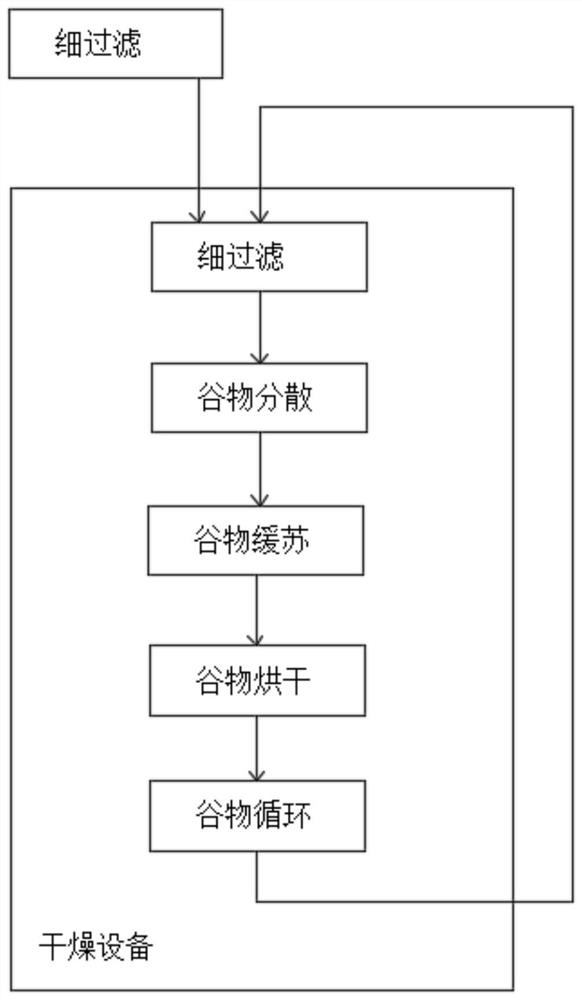

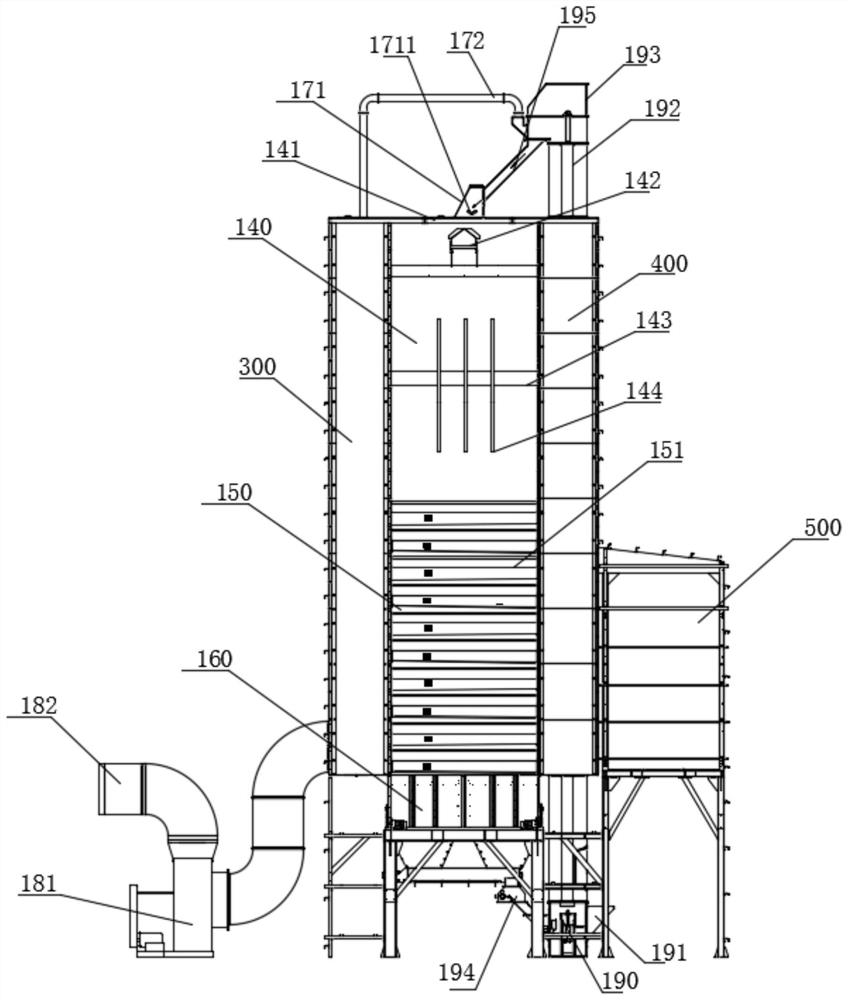

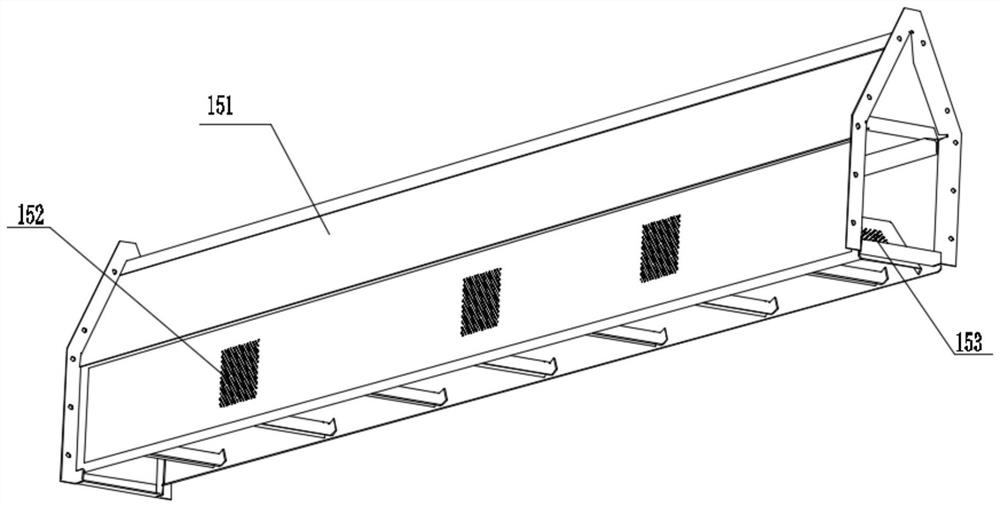

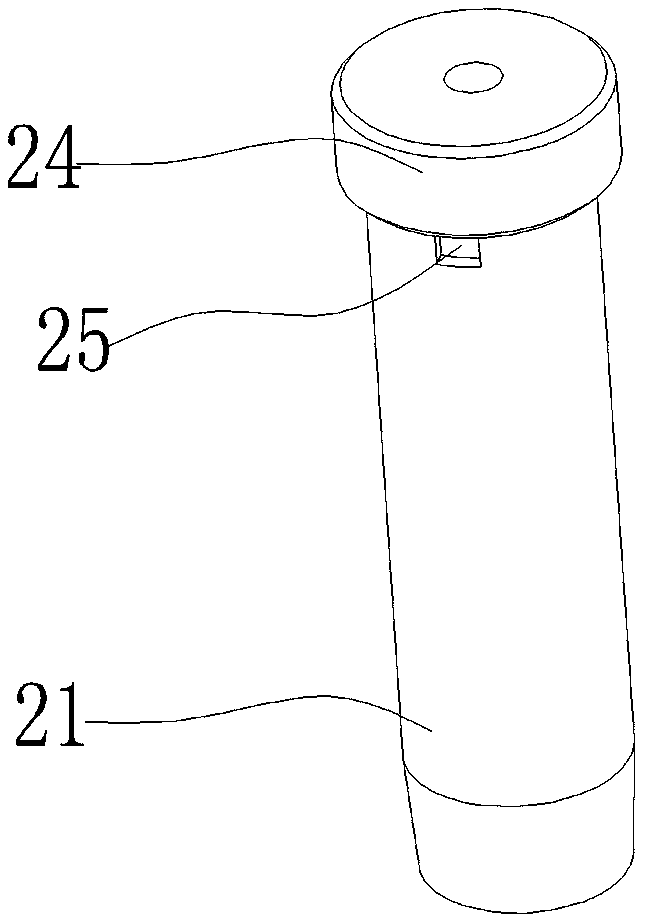

Grain drying process and drying equipment

InactiveCN111700110ALittle change in temperature differenceReduce scorchingDrying gas arrangementsSeed preservation by dryingMetallurgyAir heating

The invention discloses a grain drying process and drying equipment. The process comprises the steps of carrying out primary filtration, fine filtration, grain dispersion, grain tempering, grain drying, grain circulation and grain storage; the drying equipment comprises a drying machine, wherein a supporting base is fixedly installed at the lower end of the drying machine; the drying machine is divided into a tempering homogenizing section, a drying section and a discharging section from top to bottom, and the tempering homogenizing section and the drying section are consistent in height; whengrains are dried, the processes of windless tempering treatment, hot air heating and final tempering discharging are adopted, so that the temperature difference change of the grains is small, and thequality and value of the grains are improved; the height ratio of the tempering homogenizing section to the drying section is set to be 1: 1, so that the overall height of the drying machine can be greatly reduced, and therefore the produced finished product is reduced, and on the premise of ensuring the drying speed, the drying quality is improved.

Owner:安徽麦稻之星机械科技有限公司

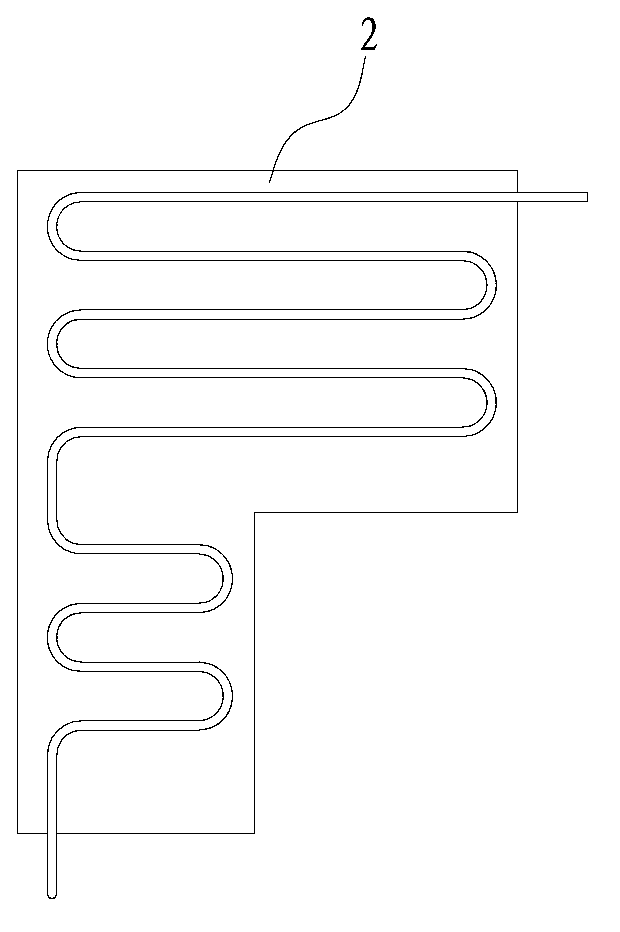

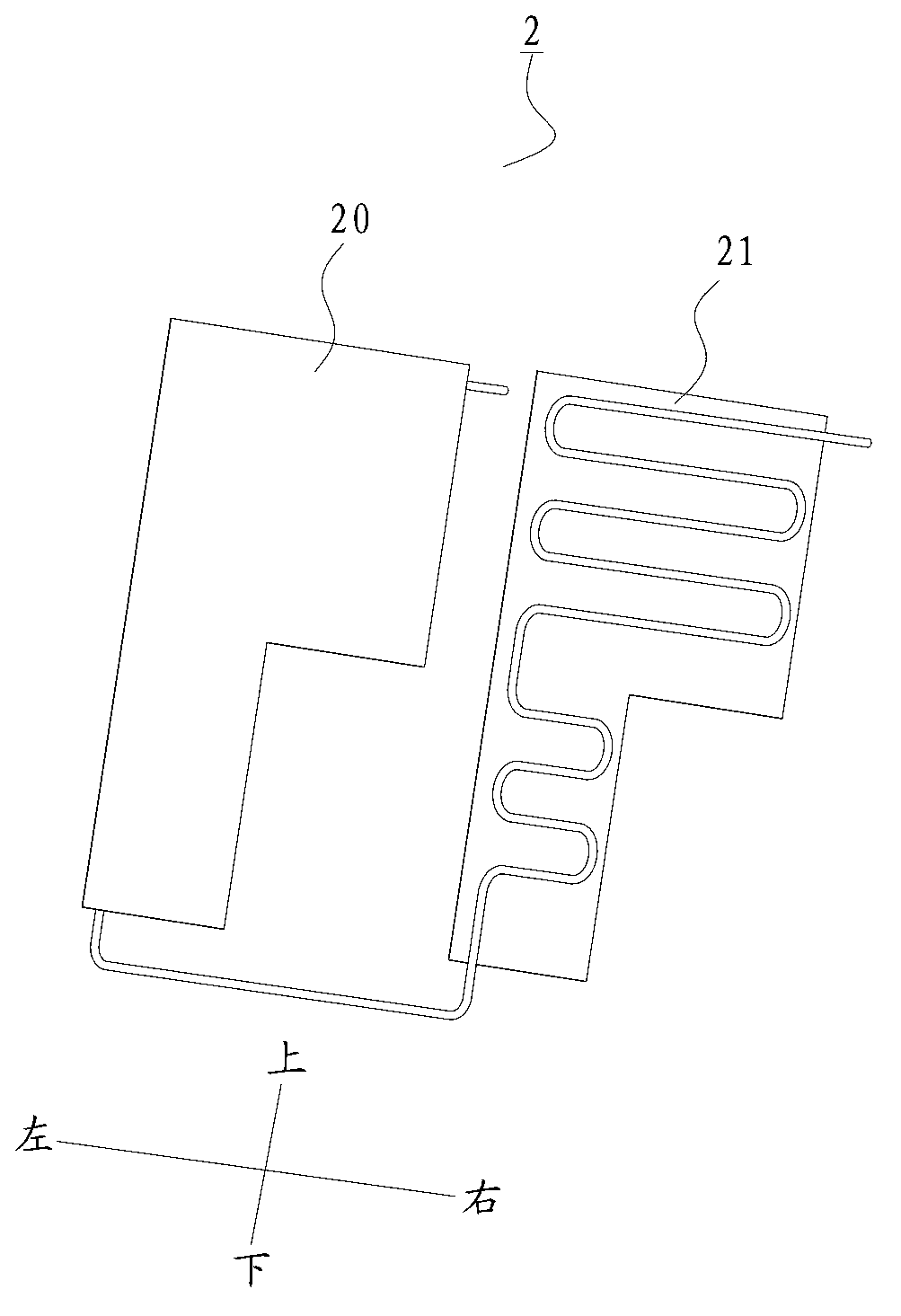

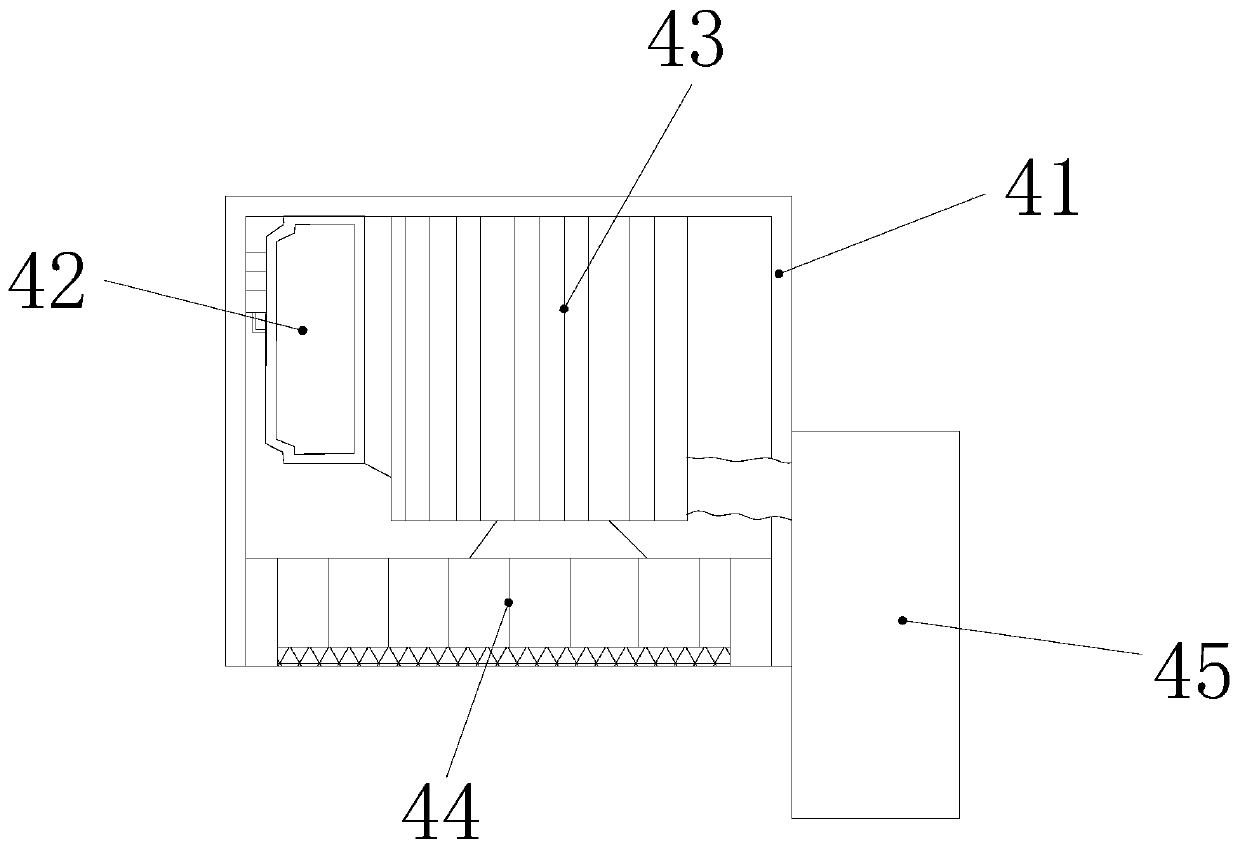

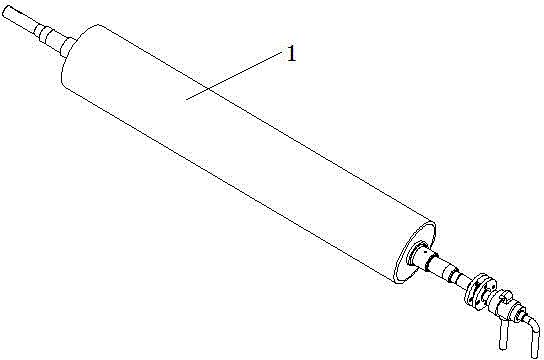

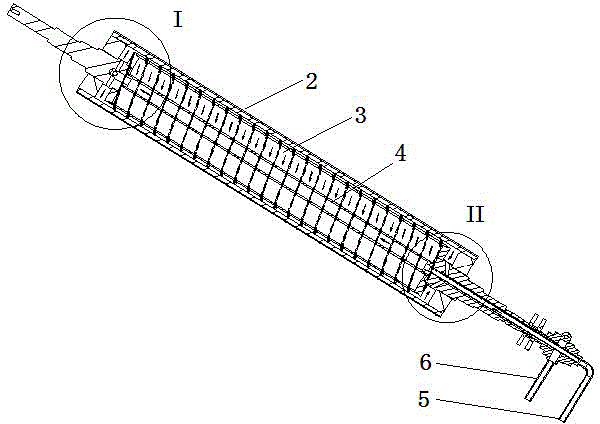

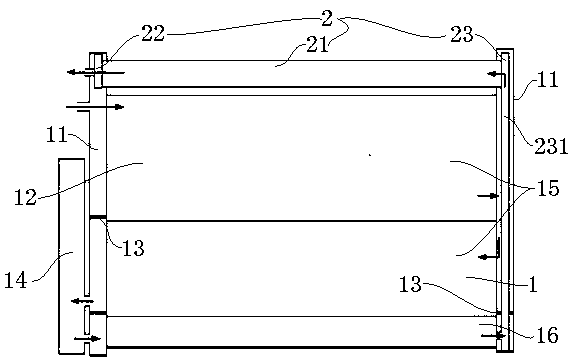

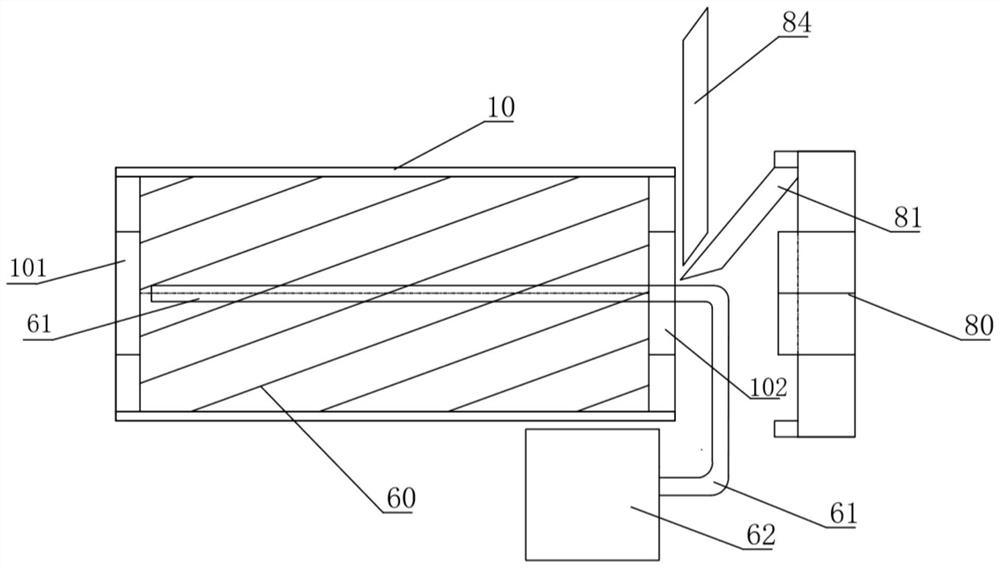

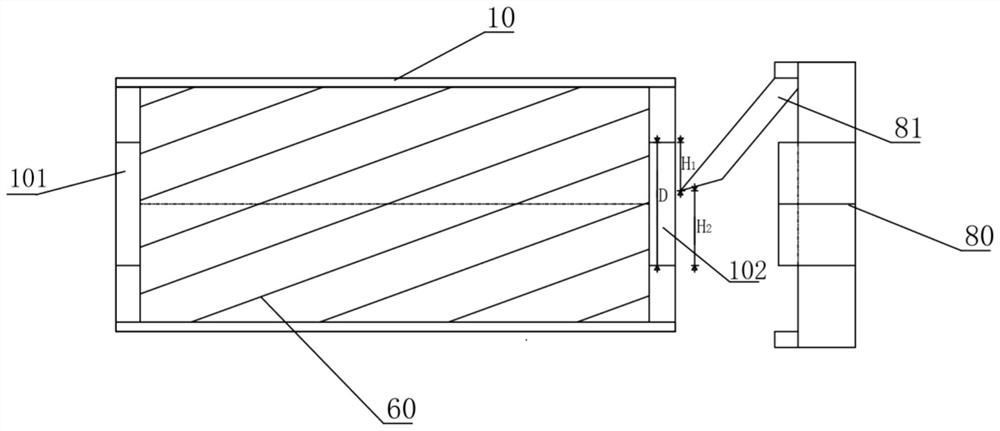

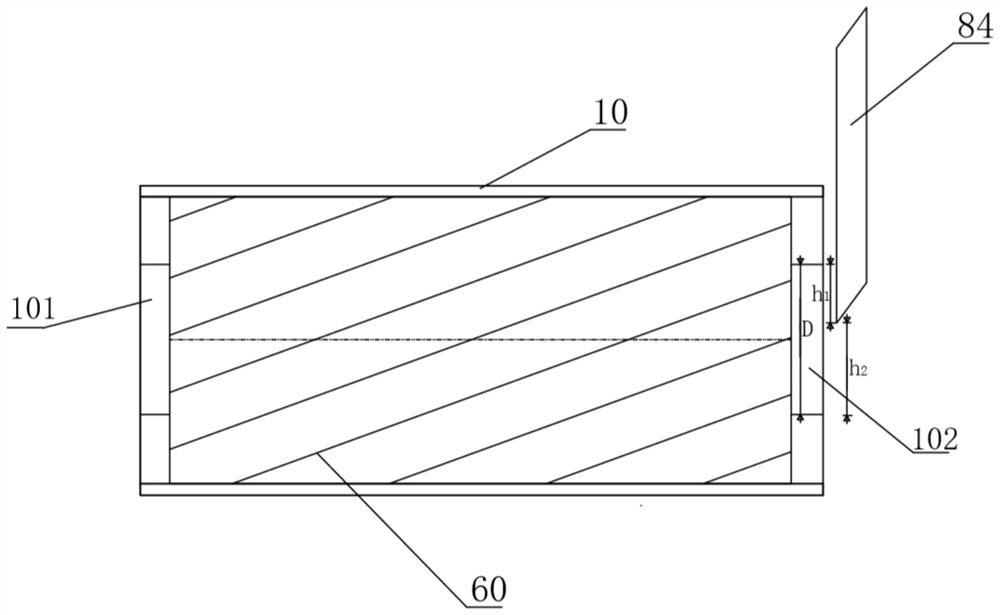

Coating roller of roller coater

InactiveCN103949371AUniform temperatureLittle change in temperature differenceLiquid surface applicatorsCoatingsEngineeringScrew thread

The invention discloses a coating roller of a roller coater. The coating roller comprises a roller body, wherein the roller body comprises a roller shell and a roller core; the roller shell sleeves the roller core; a central channel is formed in the center of the roller core in a penetration manner; a multi-helix thread is arranged on the outer surface of the roller core; the outer surface of the roller core is matched with the inner surface of the roller shell to form a multi-helical channel; a guide-in pipe and an output pipe are arranged at one end of the roller body and are concentric pipes; an input channel is arranged in the guide-in pipe; an output channel is formed between the guide-in pipe and the output pipe; the input channel is communicated with the central channel; the output channel is communicated with the multi-helical channel; a connection head is arranged at the other end of the roller body and is communicated with the central channel and the multi-helical channel. By virtue of heat conduction of the coating roller of the roller coater, the surface of the roller shell is heated at uniform temperature, the temperature difference change of all parts is small, the roller coating quality of the roller coater is greatly improved, a heating medium is clung to the surface of the roller shell for heat transfer, the heat conduction speed is high, the heat loss is low, and the cost is lowered.

Owner:博可机械(上海)有限公司

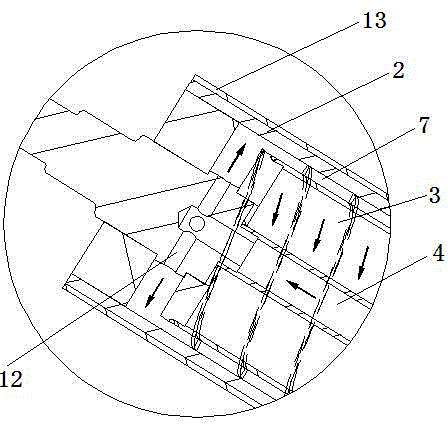

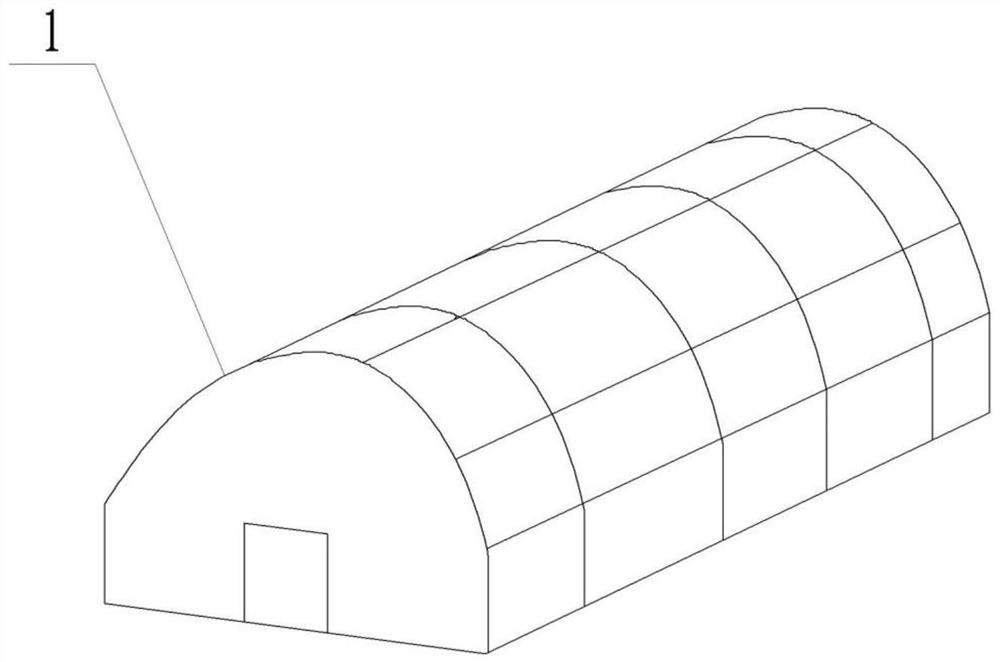

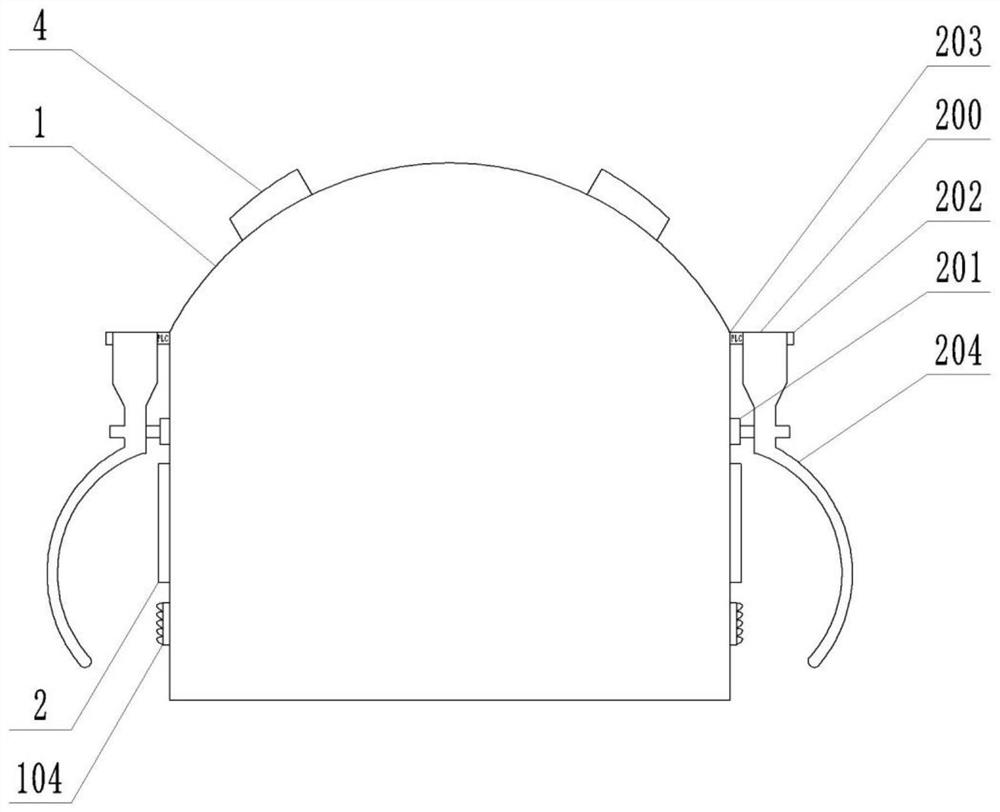

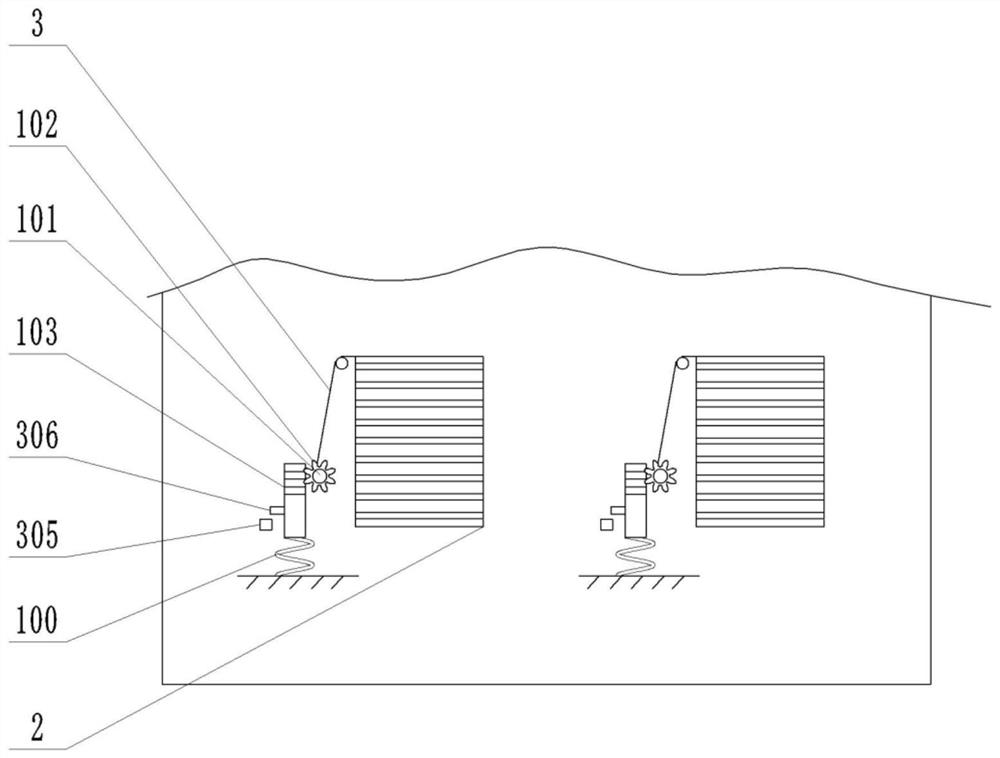

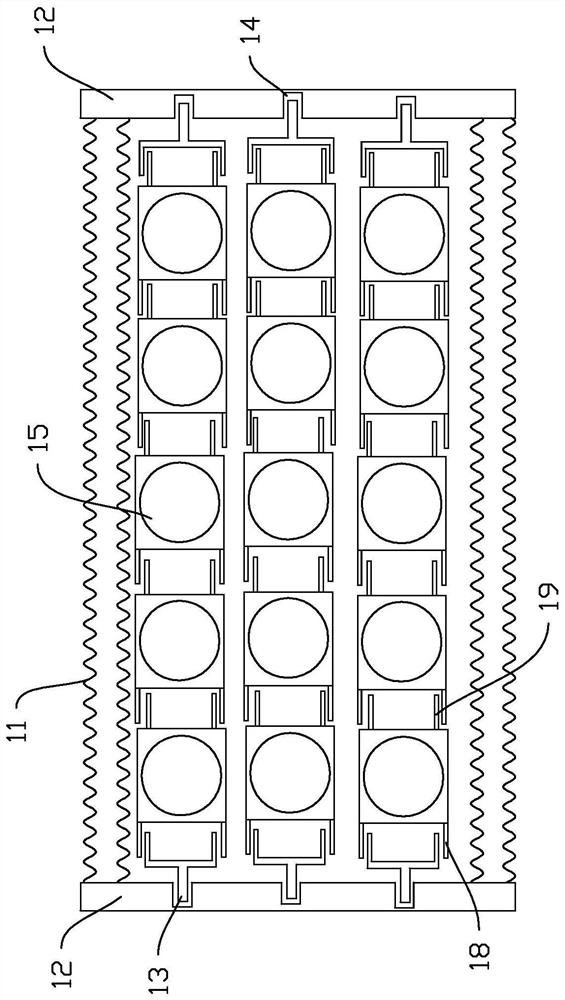

Intelligent greenhouse planting device

InactiveCN112753437ALittle change in temperature differenceGrowth impactClimate change adaptationCleaning using toolsHydraulic cylinderGreenhouse

The invention belongs to the field of greenhouses, and discloses an intelligent greenhouse planting device. The intelligent greenhouse planting device comprises a greenhouse and a window opening and closing device, wherein the greenhouse is provided with shutters used for ventilation in the greenhouse; and the window opening and closing device comprises memory metals, rotating shafts and gears. The intelligent greenhouse planting device further comprises rain and snow prevention mechanisms, wherein the rain and snow prevention mechanisms comprise inflation bottles, hydraulic cylinders, rain and snow sensors and programmable logic controllers (PLC) which are arranged on the outer side wall of the greenhouse; air bags matched with the shutters are connected to bottle openings of the inflation bottles in a sealed mode; compressed air is arranged in the inflation bottles; valves are arranged on the inflation bottles; piston rods of the hydraulic cylinders are movably arranged in the inflation bottles and matched with the valves; bottle plugs are arranged at the upper ends of the piston rods; vertical rods with the diameter being smaller than the diameters of the bottle plugs are arranged at the lower ends of the piston rods; and through holes are formed in the piston rods. According to the scheme, the rain and snow prevention mechanisms are arranged, so that the greenhouse can be continuously ventilated in rainy and snowy days, and rain and snow cannot enter the greenhouse.

Owner:吴跃

A manufacturing process of peach wood hollow screen

ActiveCN107199614BMoisture-proof and anti-corrosionImprove densification performanceScreensDecorative surface effectsManufacturing technologyDistillation

The invention discloses a manufacturing technology of a hollowed-out peach wood screen. The technology is characterized by comprising the steps as follows: (1) material selection is performed as follows: a peach tree with the tree age being 20 years or above is selected as a machining material; (2) board sawing is performed as follows: a peach wood board is 1.8-2 cm thick; (3) heating and boiling in saline water are performed as follows: the board is immersed in water with the sodium chloride concentration ranging from 0.7% to 1% for heating and boiling; (4) high-pressure fumigation is performed as follows: the board is vertically placed on a distillation layer of a pressure cooker, a preservative is added, and high-temperature fumigation is performed; (5) softening in an acid and a base is performed as follows: the board is immersed in a sodium hydroxide solution and a hydrochloric acid solution respectively for soaking treatment; (6) drying is performed as follows: the board is vertically placed in a drying box, and a drying technology is performed; (7) hollowing-out engraving is performed as follows: the hollowed-out screen is engraved; (8) waxing is performed as follows: the screen is coated with wood wax by the aid of a soft brush and is coated repeatedly for 3-4 times. With the technology, the content of moisture in the peach wood board can be reduced, the anti-corrosion and moisture-proof performance can be improved, and the engraving performance and the smoothness of the peach wood board can be improved.

Owner:FUNAN TENGBO ARTS & CRAFTS CO LTD

Vehicle supercooling extension condenser

InactiveCN107560241AIncrease subcoolingImprove cooling effectEvaporators/condensersAutomotive engineeringEngineering

The invention relates to a vehicle supercooling extension condenser. The vehicle supercooling extension condenser comprises a condenser body; and the condenser body comprises a condensation section, astored liquid drying tank and a supercooling section serially connected in sequence. The vehicle supercooling extension condenser further comprises a supercooling extension flow communicating with anoutlet of the supercooling section; and the supercooling extension flow is arranged on a windward surface of the condenser body. The vehicle supercooling extension condenser guarantees the heat exchange efficiency of the condenser under the condition of reducing the windward area of the supercooling section.

Owner:CHONGQING CHANGAN AUTOMOBILE CO LTD

A kind of breeding method of snake

The invention discloses a snake breeding method. The method comprises the first step of selecting and building a breeding base, the second step of breeding snakes outside and conducting quarantine, wherein the healthy snakes are cleaned, made to have a medicated bath and placed into an open breeding place, the third step of feeding the snakes with food and bait, wherein the snakes are fed every 10-12 days, the fourth step of conducting overwintering and oversummering management, wherein cold water is sprayed onto the open breeding place and fresh water is injected into water troughs every day in summer, the food supply quantity to the snakes is increased before the hibernation period of the snakes comes, and during the hibernation period of the snakes, at least four 100-W incandescent lamps are arranged in an underground activity region, the fifth step of conducting sanitation and safety management, wherein gaps between cobblestones are filled with fermentation beds, and the sixth step of conducting breeding, wherein isolated snake rooms are arranged in the open breeding place and pregnant female snakes are individually placed in the snake rooms. By means of the method, the advantages of a traditional open breeding method and the advantages of a snake room breeding method are combined, the suitable temperature and good ventilation of the living environment of the snakes are both guaranteed, and excrement of the snakes does not need cleaning.

Owner:徐州博创建设发展集团有限公司

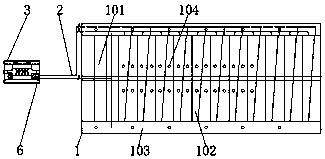

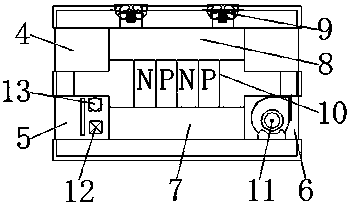

Full-automatic carbon rod extrusion molding machine

PendingCN110181853AReduce contentEffectively ventMetal working apparatusShaping pressMolding machinePulp and paper industry

The invention discloses a full-automatic carbon rod extrusion molding machine. The full-automatic carbon rod extrusion molding machine comprises a machine frame and a main control device arranged on the machine frame and used for controlling the operation of all workpieces, wherein the machine frame is divided into an extrusion area and a cutting area, a material cylinder for containing raw materials, a feeding mechanism, a first-stage screw rod mechanism and a second-state screw mechanism are sequentially arranged in the extrusion area, a cutting mechanism, a carbon rod positioning mechanismand a carbon rod length fixing mechanism are arranged in the cutting area, a carbon rod channel is arranged between the carbon rod positioning mechanism and a carbon rod outlet of a second screw stirrer, and steam discharging devices are correspondingly arranged on a first screw stirrer and the second screw stirrer. According to the full-automatic carbon rod extrusion molding machine, automatic production can be realized, workers can control the start and stop of all the workpieces through the main control device so that a single worker can simultaneously control multiple equipment, the production efficiency is improved, and the production labor cost is reduced; and the two independent screw mechanisms are adopted to separate plasticizing and forming, the first-stage screw mechanism is responsible for plasticizing, and the second-stage screw mechanism is responsible for forming and extruding.

Owner:宁波市奥特曼自动化设备有限公司

Stepping combustion furnace

InactiveCN108344297AHeating evenlyLittle change in temperature differenceCharge composition/stateFurnace typesAir volumeTemperature sense

The invention relates to a stepping combustion furnace. The stepping combustion furnace comprises a furnace body, wherein a nozzle is formed in the top of a furnace chamber of the furnace body, a temperature sensing device is arranged on the inner wall of the furnace chamber of the furnace body, the flaming end of the nozzle extends into the nozzle, the upper end of the nozzle is respectively connected with a combustion-supporting air pipe and a gas pipe, high and low-flame combustion-supporting air pipes of which both ends communicate with each other are formed in the combustion-supporting air pipe, a high-flame analog quantity actuator and a high-flame air volume sampling head are arranged on the high-flame combustion-supporting air pipe, a low-flame analog quantity actuator and a small-flame air volume sampling head are arranged on the low-flame combustion-supporting air pipe, high and low-flame gas pipes of which both ends communicate with each other are formed on the gas pipe, a high-flame proportional valve and a high-flame electromagnetic valve are arranged on the high-flame gas pipe, a low-flame proportional valve and a low-flame electromagnetic valve are arranged on the low-flame gas pipe, the high-flame proportional valve and the low-flame proportional valve communicate with the high-flame air volume sampling head and the small-flame air volume sampling head respectively by virtue of high and low-flame sampling pipes, and the high and low-flame analog quantity actuators and the high and low-flame electromagnetic valves are respectively connected with the temperature sensing device. Black strips cannot be generated on a pipe body, so that the heating is uniform; the pipe body is prevented from being oxidized, so that the gas consumption is reduced.

Owner:CHANGSHUSMLESS STEEL TUBE

Gas-liquid separator for high freezing point medium with labyrinth inlet pipe insulation device

ActiveCN109603316BImprove liquidityImprove insulation effectDispersed particle separationVapor–liquid separatorThermal insulation

The invention relates to the technical field of gas-liquid separation equipment in chemical plants, in particular to a high-freezing-point medium gas-liquid separator with a labyrinth-type intake pipe heat preservation device. It includes an elliptical head, a cyclone cylinder and a cyclone cone from top to bottom; the ellipse head, cyclone cylinder, cyclone cone, liquid discharge pipe and exhaust pipe located outside the ellipse head are all equipped with insulation cover, forming a thermal insulation cavity, and connecting round pipes are provided between adjacent thermal insulation cavities; a tangential air intake pipe is provided on one side of the cyclone cylinder, and the tangential air intake pipe includes an air intake pipe, Tapered pipe and rectangular pipe, the four sides of the tapered pipe are respectively provided with a tapered pipe insulation chamber, and the four sides of the rectangular pipe are respectively provided with a rectangular pipe insulation chamber; the heat transfer oil enters from the heat transfer oil inlet of the intake pipe, passes The insulation cavities on the four sides of the tapered tube, the circular tube insulation cavity and the four sides of the rectangular tube flow out from the heat transfer oil outlet of the intake pipe at last.

Owner:EAST CHINA ENG SCI & TECH

Drum-type tea processing equipment

InactiveCN114304314ALarge speed control rangeWide applicabilityPre-extraction tea treatmentCoil arrangementsInsulation layerEngineering

The drum-type tea processing equipment comprises a drum, the outer wall face of the drum is sequentially wrapped with a heat insulation layer and a heat preservation layer from inside to outside, and a stepped intermittent electromagnetic induction heating system used for intermittently heating the drum is further installed on the outer side face of the heat preservation layer on the outer wall face of the drum. 6-8 leaf guide plates are mounted on the inner wall surface of the roller at equal intervals, and the leaf guide plates continuously extend to the discharge port of the roller from the feed port of the roller; the guide vane plate is of a spiral structure; the stepped intermittent electromagnetic induction heating system comprises N groups of electromagnetic heating coils and an isolation bracket for winding the electromagnetic heating coils; and a gap with the spacing width of 10-15cm is arranged between two adjacent groups of electromagnetic heating coils and is used as a low-temperature buffer zone. The stepped intermittent electromagnetic induction heating system can stably control the temperature in the roller to be 250-280 DEG C; by adopting the technical scheme, the energy consumption is reduced, and the tea processing quality is improved.

Owner:宁波市姚江源机械有限公司

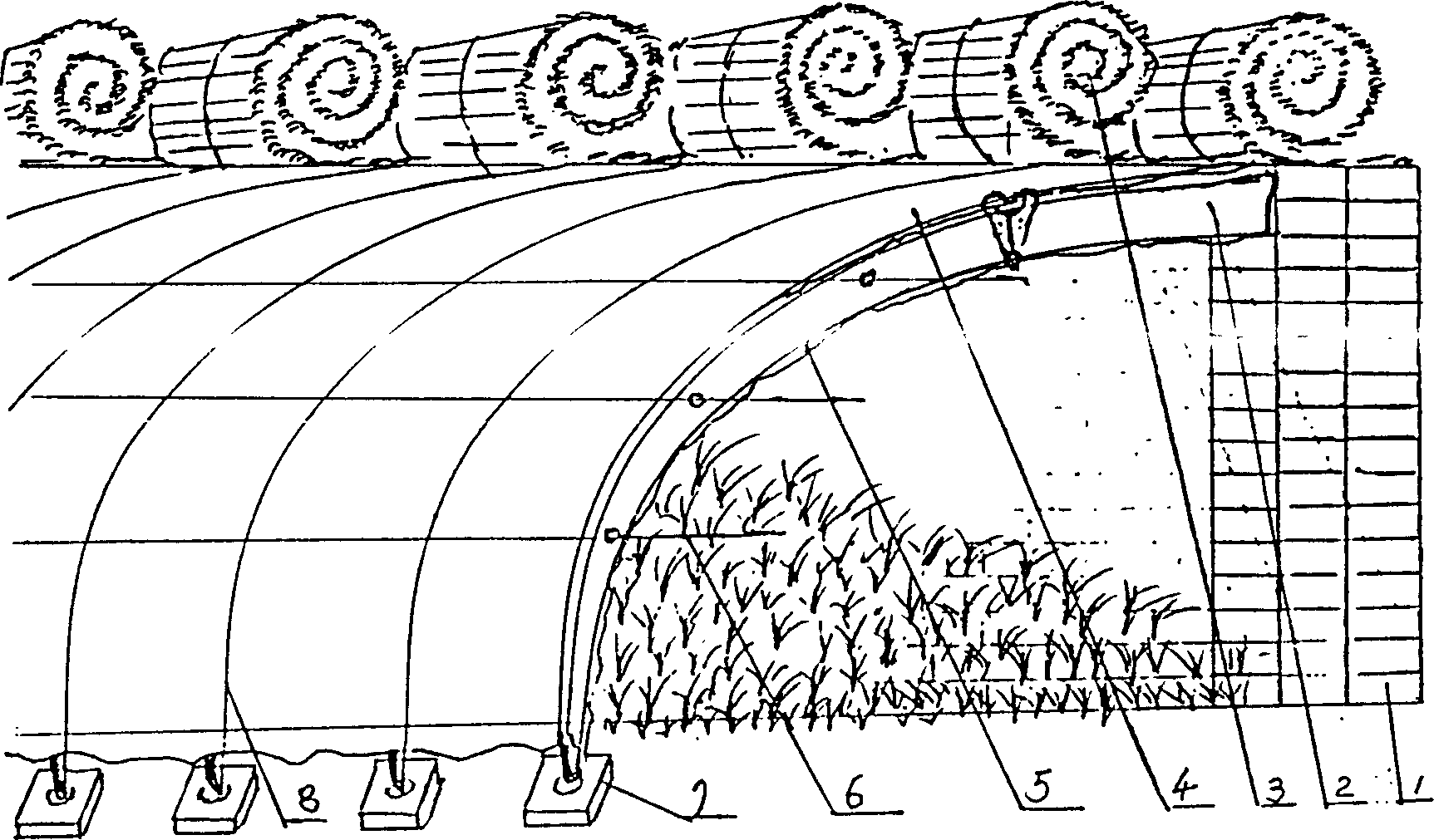

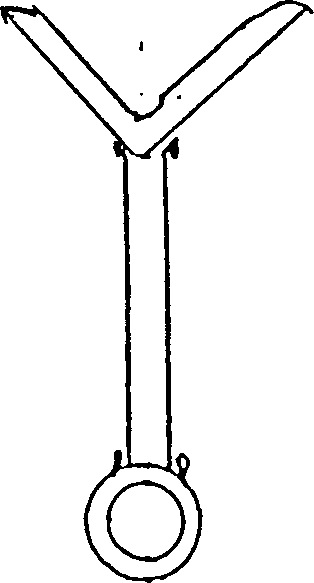

Dual-layer warming shed

InactiveCN1123282CSimple structureEasy to useClimate change adaptationGreenhouse cultivationStructural engineeringEngineering

A dual-layer hot shed for planting plant in the winter structurally features that its semi-arched frame has longitudinal slots on its external arch surface and longitudinal convex strips on its internal concove surface, the thick rods are laid on columms with concove tops, the thin rods are inserted in concave holes on ground shoes, and two layers of insulating film are respectively fixed to said longitudinal slots and convex strips. Its advantages are simple structure, easy installation and long service life.

Owner:RES INST OF METAL CORROSION & PROTECTION CHINESE ACAD SCI

Adjustable Width Freezer Storage Containers

ActiveCN112478402BLittle change in temperature differenceLarge specific heat capacityDomestic cooling apparatusLighting and heating apparatusAlcoholClinical tests

The invention discloses a freezer storage container with adjustable width, which includes a box body, at least one freezer compartment and a box cover. The box body has two oppositely arranged first side walls, and two The telescopic wall and the bottom layer with telescopic function are connected to form a first cavity, the telescopic wall and the bottom layer are filled with absolute alcohol, and at least one second cavity and at least one third cavity are arranged in the first side wall Body, the second cavity is used to receive the absolute alcohol of the telescopic wall, and the third cavity is used to receive the absolute alcohol of the bottom layer; the freezer is placed in the first cavity; the lid is used to cover box. The present invention connects the two first side walls through the telescopic wall and the bottom layer with the telescopic function, so that the distance between the two first side walls can be adjusted, and then the space in which the first cavity can place the freezer compartment and the number of freezer compartments can be adjusted. , to match the needs of different clinical trials.

Owner:NANFANG HOSPITAL OF SOUTHERN MEDICAL UNIV

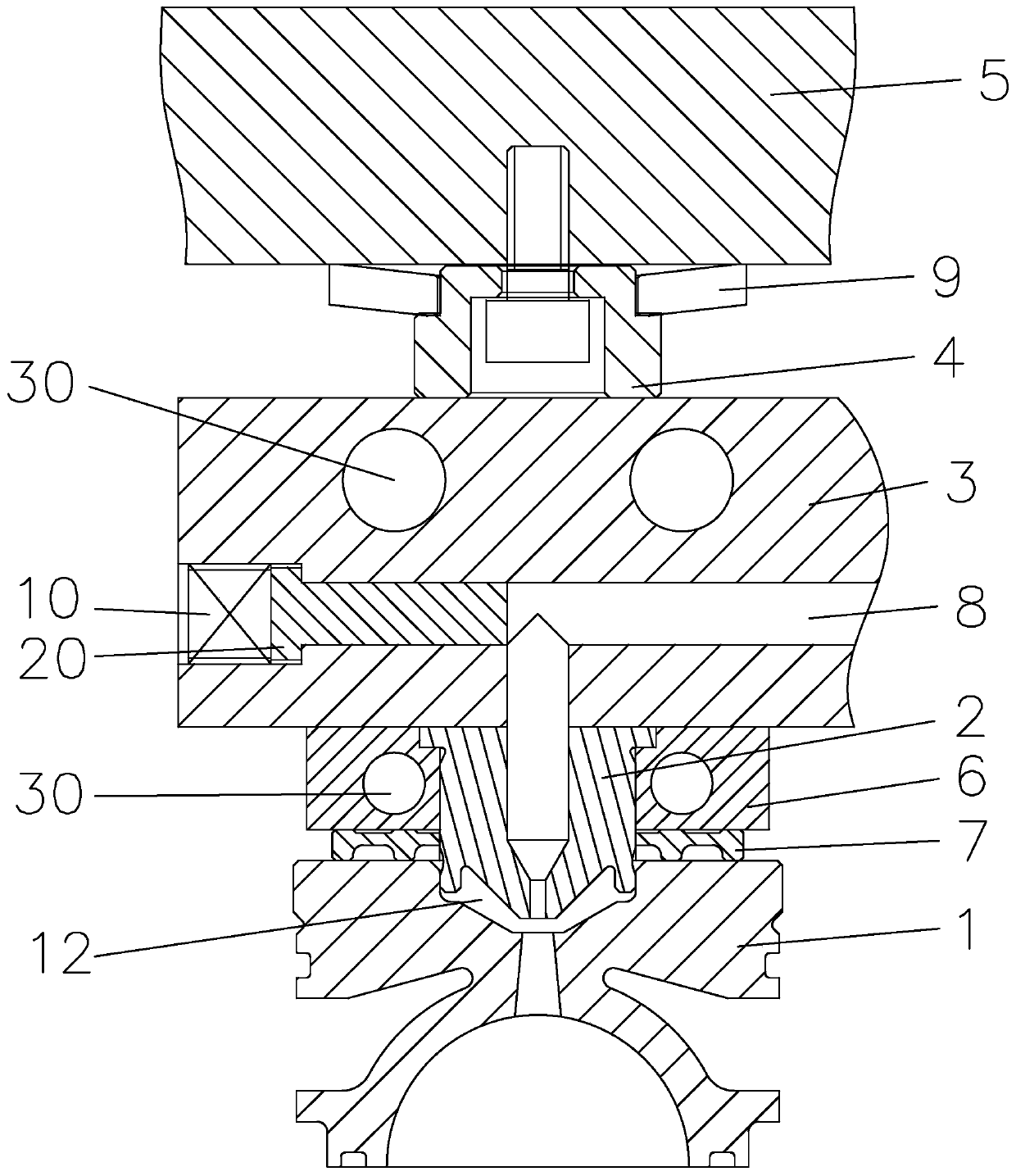

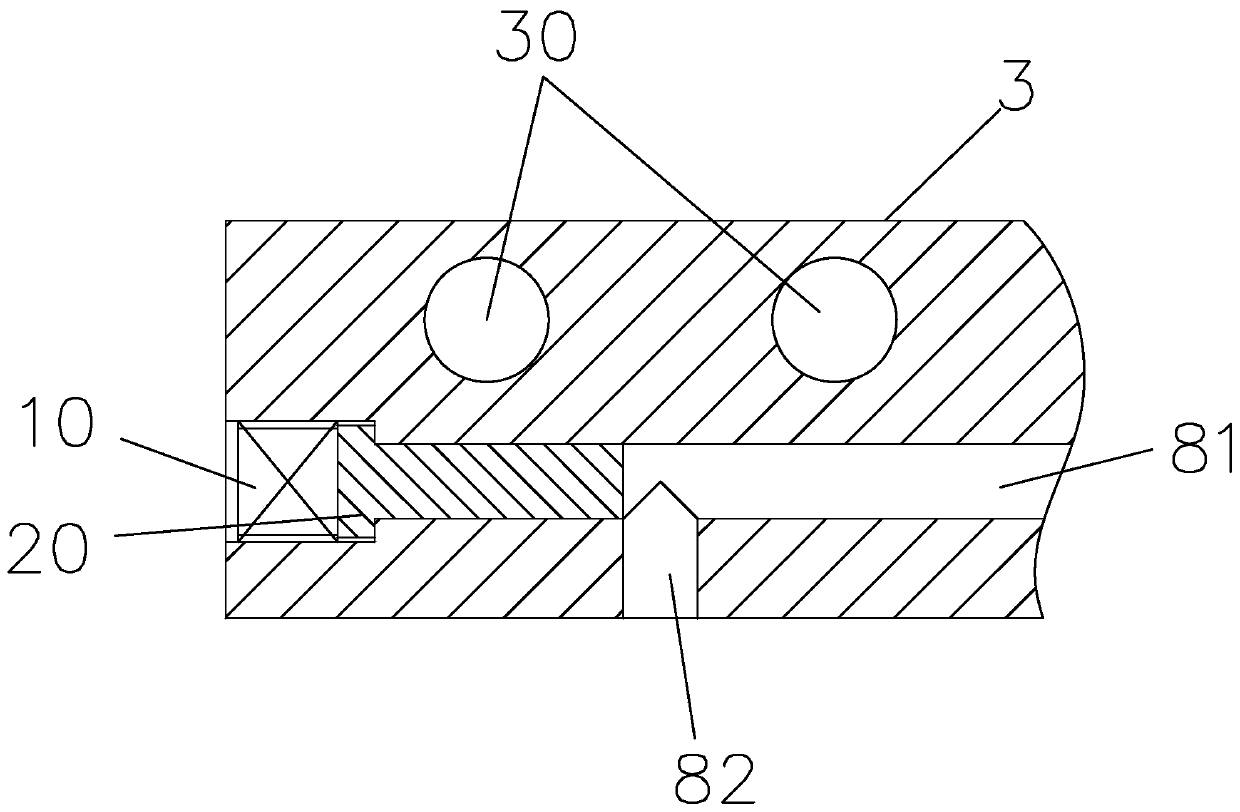

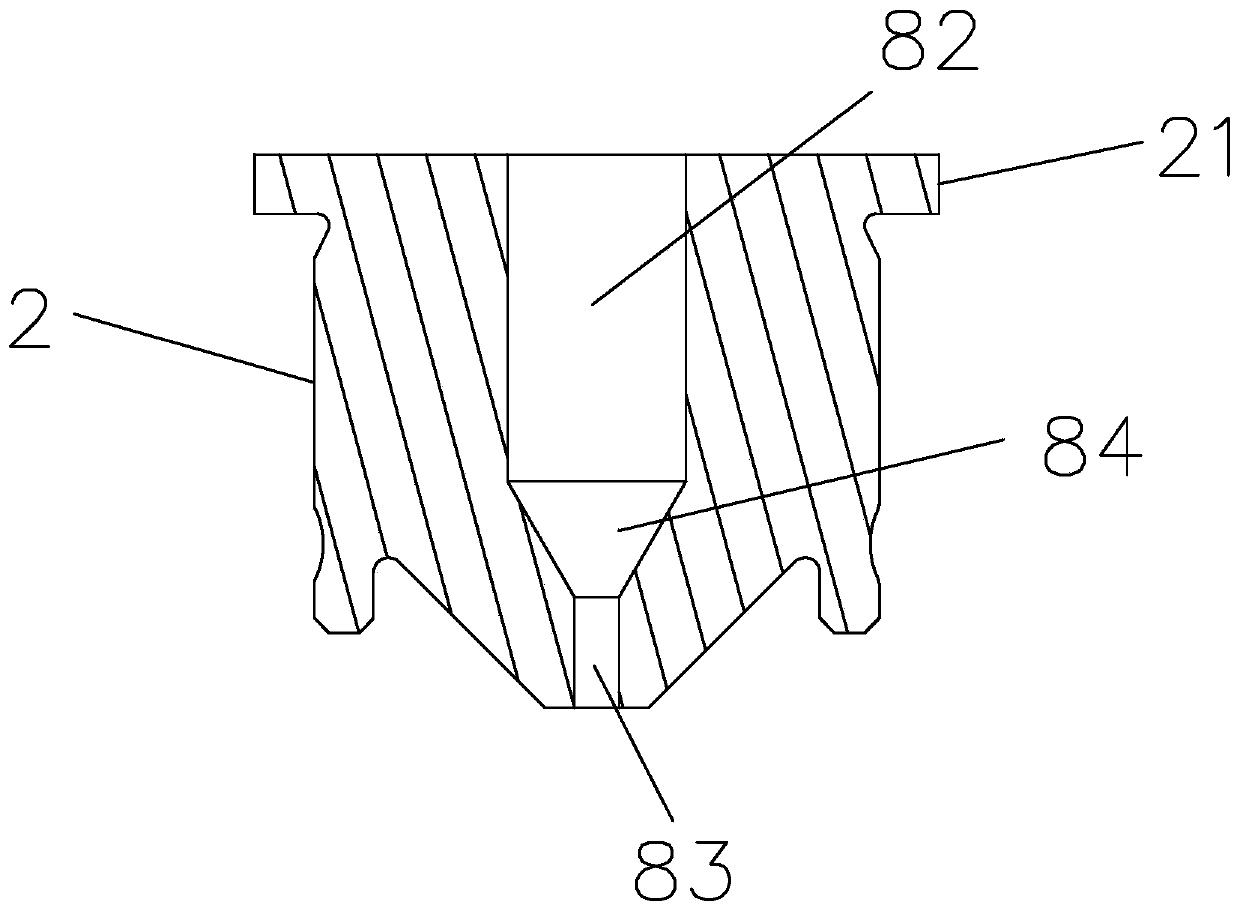

Open type hot runner injection mold device

PendingCN110126211APrecise temperature controlLittle change in temperature differenceHot runnerEngineering

The invention discloses an open type hot runner injection mold device. The open type hot runner injection mold device comprises a mold cavity, an injection nozzle, a hot runner plate, a supporting ring and a back plate which are installed from bottom to top in sequence; the hot runner plate and the injection nozzle are internally provided with a hot runner, and the hot runner sequentially penetrates through the hot runner plate and the injection nozzle to communicate with the interior of the mold cavity; the outer side of the injection nozzle is provided with a heating plate and a heat insulation gasket, and the heating plate and the heat insulation gasket are connected to the outer wall of the injection nozzle in a sleeving mode; the mold cavity is separated from the heating plate throughthe heat insulation gasket; the outer side of the supporting ring is sleeved with a spring gasket; and one end of the spring gasket is connected with the supporting ring, and the other end of the spring gasket is connected with the back plate. According to the open type hot runner injection mold device, the hot runner plate and the heating plate are both provided with heating pipes, thus, the temperature of the hot runner is controlled more precisely, the temperature difference change of plastic is small, meanwhile, the hole diameter of the injection nozzle is increased, the length is decreased, the viscosity of the plastic is improved, and the problem that a bottle blank becomes white and is subjected to wire drawing is effectively solved.

Owner:GUANG DONG XING LIAN PRECISE MACHINERY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com