Dual-layer warming shed

A double-layer thermal insulation and thermal insulation film technology is applied in the field of plant cultivation, which can solve the problems of increasing the load, reducing the service life and increasing the load of the scaffolding in the greenhouse, and achieves the advantages of convenient installation and use, improved service life and reduced labor intensity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

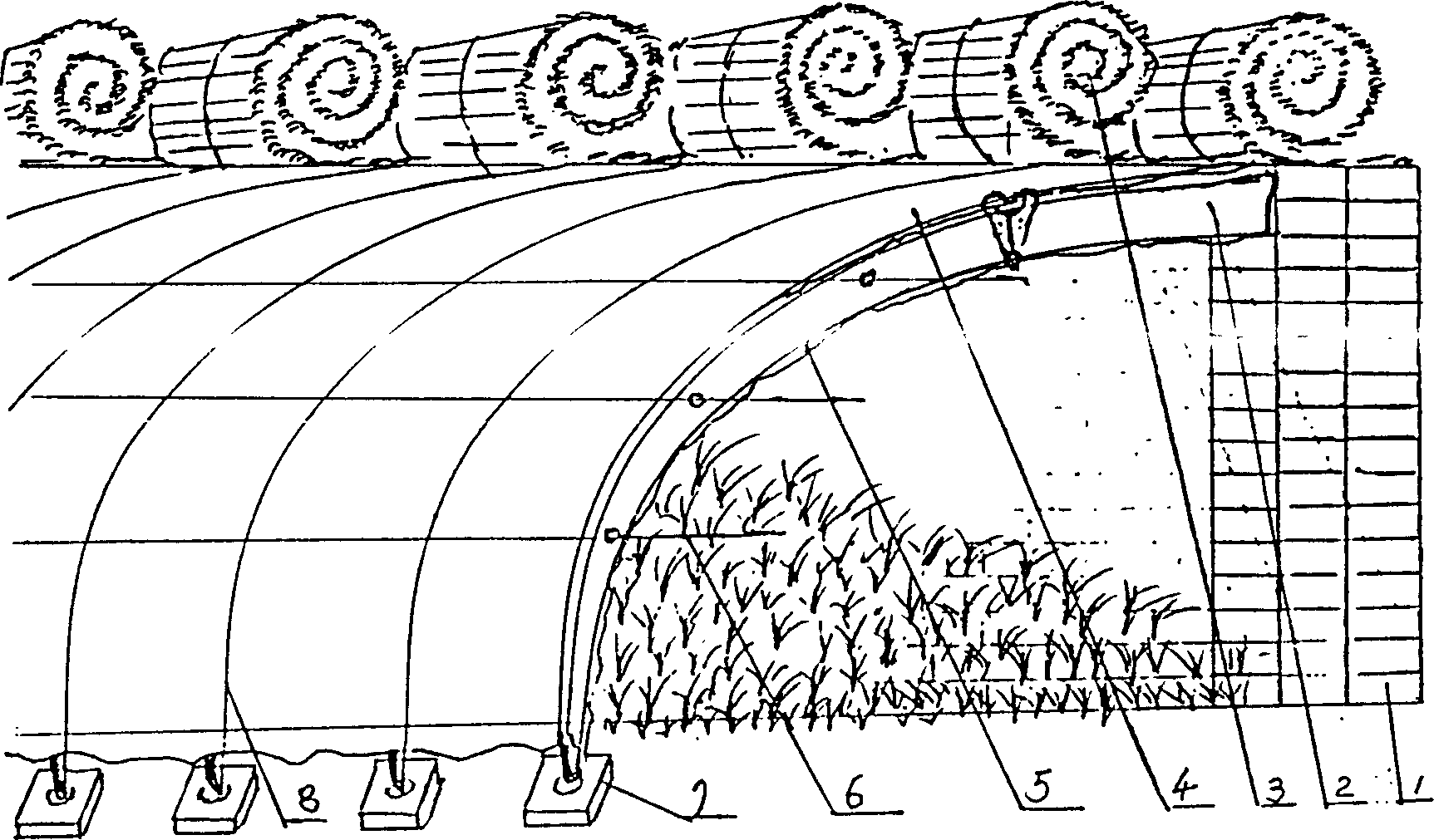

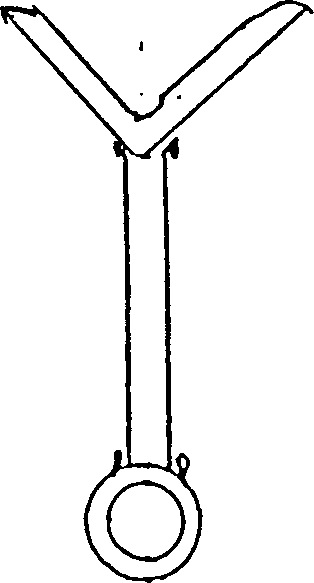

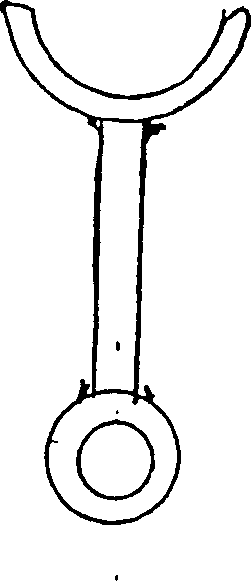

[0010] The pillar (1) of the present invention is equivalent to a facade column, and its lower root is buried firmly in the soil. The end is inserted into the middle hole of the ground shoe, so that the semi-arched scaffolding (2) is fixed. The pillar (1) can be made into a long wall type, and can also be made into a vertical pillar type. The arrangement spacing of the semi-arched scaffolding (2) that is respectively supported by the pillar (1) and inserted into the ground shoe (7) at both ends should be selected at 1 ~3 meters. When the greenhouse is installed, the height of the junction of the butt end of the scaffolding (2) and the pillar (1) is 2 to 3 meters, and the scaffolding (2) is a slope transition arc to the ground shoe (7). After the spacing of the scaffolding is positioned, start to pave the upper and lower thermal insulation films (4, 5). After the upper thermal insulation film (4) is paved on the scaffold (2), press belts (8) or pull wires (also can adopt metal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com